Sur-Gard MLR2000 Installation Manual

Sur-Gard MLR2000

Virtual Network Receiver

Installation

WARNING: This manual contains information on limitations regarding

product use and function and information on the limitations as to

liability of the manufacturer. The entire manual should be carefully read.

Manual

version 1.5

FCC Compliance Statement

CAUTION: Changes or modifications not expressly approved by Digital Security Controls could void

your authority to use this equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

Re-orient the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/television technician for help.

The user may find the following booklet prepared by the FCC useful: “How to Identify and Resolve

Radio/Television Interference Problems”. This booklet is available from the U.S. Government Printing Office, Washington D.C. 20402, Stock # 004-000-00345-4.

IMPORTANT INFORMATION

This equipment complies with Part 68 of the FCC Rules. On the side of this equipment is a label that

contains, among other information, the FCC registration number and ringer equivalence number

(REN) for this equipment. If requested, this number must be provided to the Telephone Company.

FCC Registration Number: 1VDCAN-25404-AL-N

REN: 0.2B

USOC Jack: RJ11C

Telephone Connection Requirements

A plug and jack used to connect this equipment to the premises wiring and telephone network must

comply with the applicable FCC Part 68 rules and requirements adopted by the ACTA. A compliant

telephone cord and modular plug is provided with this product. It is designed to be connected to a

compatible modular jack that is also compliant. See installation instructions for details.

Ringer Equivalence Number (REN) The REN is used to determine the number of devices that may

be connected to a telephone line. Excessive RENs on a telephone line may result in the devices not

ringing in response to an incoming call. In most but not all areas, the sum of RENs should not exceed

five (5.0). To be certain of the number of devices that may be connected to a line, as determined by the

total RENs, contact the local Telephone Company. For products approved after July 23, 2001, the

REN for this product is part of the product identifier that has the format

US: AAAEQ##TXXXX. The digits represented by ## are the REN without a decimal point (e.g., 03

is a REN of 0.3). For earlier products, the REN is separately shown on the label.

Incidence of Harm If this equipment Sur-Gard MLR2000 causes harm to the telephone network, the

telephone company will notify you in advance that temporary discontinuance of service may be

required. But if advance notice is not practical, the Telephone Company will notify the customer as

soon as possible. Also, you will be advised of your right to file a complaint with the FCC if you

believe it is necessary.

Changes in Telephone Company Equipment or Facilities The Telephone Company may make

changes in its facilities, equipment, operations or procedures that could affect the operation of the

equipment. If this happens the Telephone Company will provide advance notice in order for you to

make necessary modifications to maintain uninterrupted service.

Equipment Maintenance Facility If trouble is experienced with this equipment Sur-Gard

MLR2000, for repair or warranty information, please contact the facility indicated below. If the

equipment is causing harm to the telephone network, the Telephone Company may request that you

disconnect the equipment until the problem is solved. This equipment is of a type that is not intended

to be repaired by the end user.

Simplex Time Recorder Co. 100 Simplex Drive, Westminster MA 01441-0001 USA, Tel: (978) 7312500

Additional Information Connection to party line service is subject to state tariffs. Contact the state

public utility commission, public service commission or corporation commission for information.

If your home has specially wired alarm equipment connected to the telephone line, ensure the installation of this equipment Sur-Gard MLR2000 does not disable your alarm equipment. If you have questions about what will disable alarm equipment, consult your telephone company or a qualified

installer.

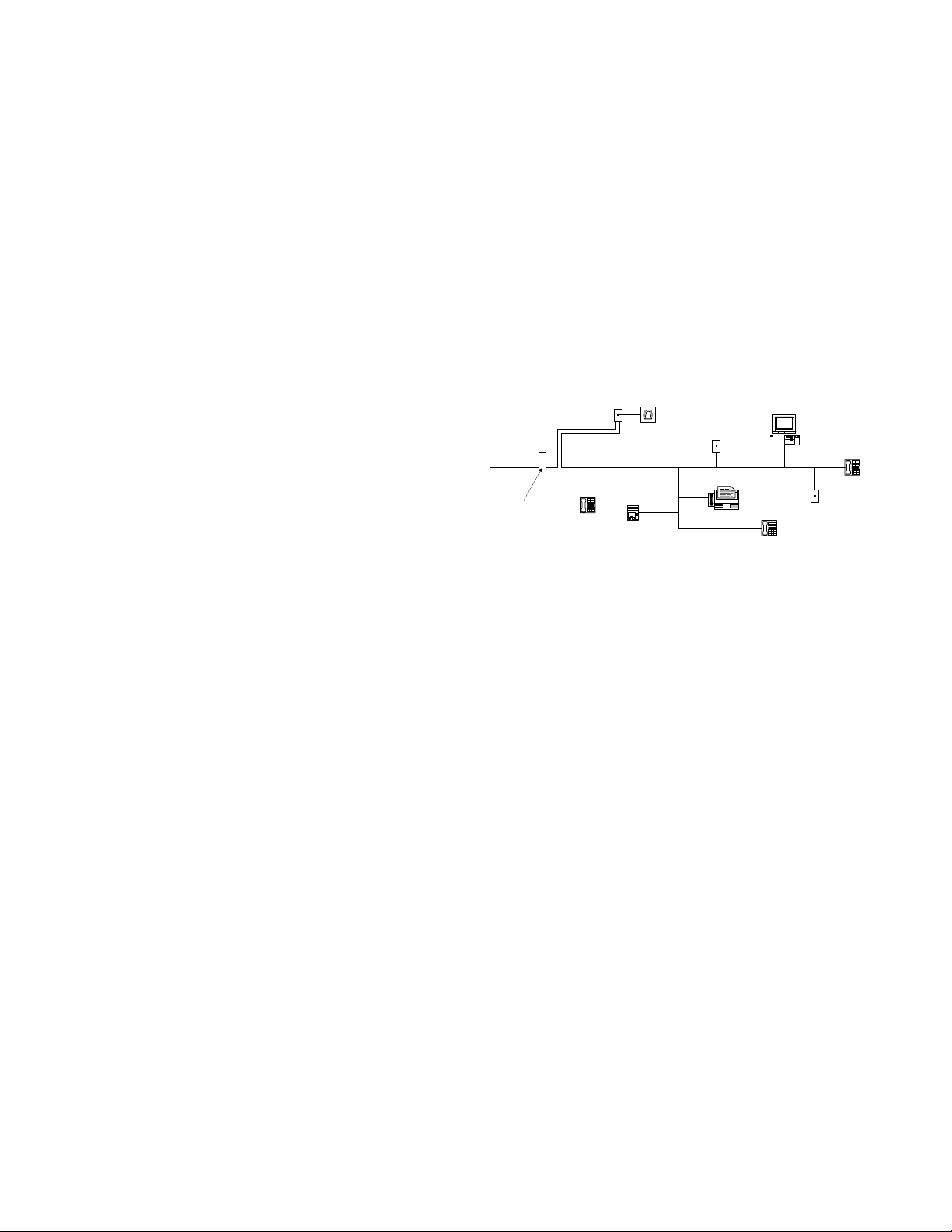

Network

Service

Provider's

Facilities

Telephone

Network

Demarcation

Point

Customer Premises Equipment and Wiring

RJ-31X

Jack

Alarm Dialing

Equipment

Line

Telephone

Answering

System

Unused

RJ-11 Jack

Fax Machine

Telephone

Computer

Unused

RJ-11 Jack

Telephon

Industry Canada Statement

IC: 160A-MLR2000

NOTICE: This equipment meets the applicable Industry Canada Terminal Equipment

Technical Specifications. This is confirmed by the registration number. The abbreviation,

IC, before the registration number signifies that registration was performed based on a

Declaration of Conformity indicating that Industry Canada technical specifications were

met. It does not imply that Industry Canada approved the equipment.

NOTICE: The Ringer Equivalence Number (REN) for this terminal is 01. The REN

assigned to each terminal equipment provides an indication of the maximum number of

terminals allowed to be connected to a telephone interface. The termination on an interface may consist of any combination of devices subject only to the requirement that the

sum of the Ringer Equivalence Numbers of all the devices does not exceed five.

Table of Contents

Section 1 - Introduction ............................................. 1

1.1 CPM2000 ................................................................ 1

1.2 DRL2000 ................................................................. 1

1.3 Power and Supervision............................................. 1

1.4 CPM2000 Outputs/ Inputs ....................................... 1

1.5 System Overview...................................................... 2

1.6 Virtual Receiver Architecture .................................... 2

1.7 Number of Line Cards Supported............................. 2

1.8 Redundancy............................................................. 2

1.9 Approvals ................................................................ 2

1.10 Virtual Connectivity ................................................. 2

1.11 Internal 10B2 Ethernet............................................. 2

Section 2 - Quick Start ............................................... 3

2.1 Receiver Setup and Operation.................................. 3

2.2 Bench Testing .......................................................... 9

Section 3 - Installation............................................. 10

3.1 Dimensions............................................................ 10

3.2 Definity DNIS ......................................................... 10

3.3 Mounting the Receiver........................................... 10

3.4 Printer Connections ............................................... 10

3.5 Computer Connections.......................................... 10

3.6 Telephone Line Connections .................................. 10

3.7 Grounding............................................................. 10

3.8 Power Supply......................................................... 10

3.9 Battery Charging Current....................................... 10

3.10 Removing and Installing System Components ........ 10

3.11 To Install a Line Card Module ................................. 10

Section 4 - DRL2000 Digital Receiver Line Card .... 11

4.1 General Information............................................... 11

4.2 DRL2000 Features.................................................. 11

4.3 Installation............................................................. 11

4.4 DRL2000 Controls.................................................. 11

Section 5 - DRL2000 Operating Mode ..................... 12

5.1 DRL2000 Standby Mode ........................................ 12

5.2 DRL2000 Cold Start-up.......................................... 12

5.3 Communications in Progress.................................. 12

Section 6 - Advanced Programming ...................... 13

6.1 Profile Introduction ................................................ 13

6.2 A.H.S. (Automatic Handshake Selection) ................ 14

6.3 Dynamic Options: [30] - [FF]............................... 17

Section 7 - DRL2000 Communication Formats ....... 24

7.1 Common Formats.................................................. 24

7.2 Sur-Gard DTMF Formats......................................... 24

7.3 Acron Format......................................................... 24

7.4 Ademco Contact ID................................................24

7.5 Ademco Express .....................................................26

7.6 Ademco Super Fast (High Speed Format) ................26

7.7 FBI Super Fast Format.............................................26

7.8 ITI Format...............................................................26

7.9 ITI Sensor Library ....................................................26

7.10 Modem II, Modem IIE, Modem IIIa² and

BFSK Formats .........................................................27

7.11 SIA FSK ..................................................................27

7.12 Silent Knight FSK1, FSK2 ........................................27

7.13 Silent Knight FSK2 Protocol ....................................27

7.14 Sescoa Super Speed ...............................................28

7.15 DRL2000 Predefined Library Decoding and Event

Codes Table27

Section 8 - CPM2000 Central Processing Module... 30

8.1 General Information ...............................................30

8.2 Features .................................................................30

8.3 CPM2000 Controls.................................................30

Section 9 - CPM2000 Wiring Diagram ..................... 31

9.1 Loss of Socket/Automation.....................................31

9.2 CPM Redundancy...................................................31

9.3 CPM Restoral .........................................................31

Section 10 - MLR2000 Computer Interface............. 32

10.1 Virtual connectivity.................................................32

10.2 Automation Mode..................................................32

10.3 TCP/IP Ports............................................................32

10.4 Client Side Connects ..............................................32

10.5 Stream Packet Structure .........................................32

10.6 Status Addressing...................................................32

10.7 Overview of Communication ..................................32

10.8 Console spcifies which SG Automation to

Supervise................................................................33

Section 11 - PSU2000 Power supply Module .......... 36

Section 12 - Automation Protocols ......................... 37

12.1 Data Byte protocol..................................................37

12.2 Acknowledgment of the Signal ..............................37

Section 13 - Detailed Description of Computers ... 38

13.1 COM Responses .....................................................38

13.2 Automation Absent...............................................38

Appendix A - DRL2000 Communication Formats...........39

Appendix B - Decimal - HEX - Binary Conversion Chart.40

Appendix C - ASCII Character Chart ..............................41

Appendix D - Printer Words: Options [60-6F]................42

Appendix E - Panels Compatibility List ..........................44

WARNING Please Read Carefully

Note to Installers

This warning contains vital information. As the only individual in contact with system users, it is your

responsibility to bring each item in this warning to the attention of the users of this system.

System Failures

This system has been carefully designed to be as effective as possible. There are circumstances, however,

involving fire, burglary, or other types of emergencies where it may not provide protection. Any alarm

system of any type may be compromised deliberately or may fail to operate as expected for a variety of

reasons. Some but not all of these reasons may be:

■ Inadequate Installation

A security system must be installed properly in order to provide adequate protection. Every installation

should be evaluated by a security professional to ensure that all access points and areas are covered. Locks

and latches on windows and doors must be secure and operate as intended. Windows, doors, walls, ceilings and other building materials must be of sufficient strength and construction to provide the level of

protection expected. A reevaluation must be done during and after any construction activity. An evaluation by the fire and/or police department is highly recommended if this service is available.

■ Criminal Knowledge

This system contains security features which were known to be effective at the time of manufacture. It is

possible for persons with criminal intent to develop techniques which reduce the effectiveness of these

features. It is important that a security system be reviewed periodically to ensure that its features remain

effective and that it be updated or replaced if it is found that it does not provide the protection expected.

■ Access by Intruders

Intruders may enter through an unprotected access point, circumvent a sensing device, evade detection by

moving through an area of insufficient coverage, disconnect a warning device, or interfere with or prevent

the proper operation of the system.

■ Power Failure

Control units, intrusion detectors, smoke detectors and many other security devices require an adequate

power supply for proper operation. If a device operates from batteries, it is possible for the batteries to

fail. Even if the batteries have not failed, they must be charged, in good condition and installed correctly.

If a device operates only by AC power, any interruption, however brief, will render that device inoperative

while it does not have power. Power interruptions of any length are often accompanied by voltage fluctuations which may damage electronic equipment such as a security system. After a power interruption has

occurred, immediately conduct a complete system test to ensure that the system operates as intended.

■ Failure of Replaceable Batteries

This system’s wireless transmitters have been designed to provide several years of battery life under normal conditions. The expected battery life is a function of the device environment, usage and type. Ambient conditions such as high humidity, high or low temperatures, or large temperature fluctuations may

reduce the expected battery life. While each transmitting device has a low battery monitor which identifies when the batteries need to be replaced, this monitor may fail to operate as expected. Regular testing

and maintenance will keep the system in good operating condition.

■ Compromise of Radio Frequency (Wireless) Devices

Signals may not reach the receiver under all circumstances which could include metal objects placed on or

near the radio path or deliberate jamming or other inadvertent radio signal interference.

■ System Users

A user may not be able to operate a panic or emergency switch possibly due to permanent or temporary

physical disability, inability to reach the device in time, or unfamiliarity with the correct operation. It is

important that all system users be trained in the correct operation of the alarm system and that they know

how to respond when the system indicates an alarm.

■ Smoke Detectors

Smoke detectors that are a part of this system may not properly alert occupants of a fire for a number of

reasons, some of which follow. The smoke detectors may have been improperly installed or positioned.

Smoke may not be able to reach the smoke detectors, such as when the fire is in a chimney, walls or roofs,

or on the other side of closed doors. Smoke detectors may not detect smoke from fires on another level of

the residence or building.

Every fire is different in the amount of smoke produced and the rate of burning. Smoke detectors cannot

sense all types of fires equally well. Smoke detectors may not provide timely warning of fires caused by

carelessness or safety hazards such as smoking in bed, violent explosions, escaping gas, improper storage

of flammable materials, overloaded electrical circuits, children playing with matches or arson.

Even if the smoke detector operates as intended, there may be circumstances when there is insufficient

warning to allow all occupants to escape in time to avoid injury or death.

■ Motion Detectors

Motion detectors can only detect motion within the designated areas as shown in their respective installation instructions. They cannot discriminate between intruders and intended occupants. Motion detectors

do not provide volumetric area protection. They have multiple beams of detection and motion can only be

detected in unobstructed areas covered by these beams. They cannot detect motion which occurs behind

walls, ceilings, floor, closed doors, glass partitions, glass doors or windows. Any type of tampering

whether intentional or unintentional such as masking, painting, or spraying of any material on the lenses,

mirrors, windows or any other part of the detection system will impair its proper operation.

Passive infrared motion detectors operate by sensing changes in temperature. However their effectiveness

can be reduced when the ambient temperature rises near or above body temperature or if there are intentional or unintentional sources of heat in or near the detection area. Some of these heat sources could be

heaters, radiators, stoves, barbeques, fireplaces, sunlight, steam vents, lighting and so on.

■ Warning Devices

Warning devices such as sirens, bells, horns, or strobes may not warn people or waken someone sleeping

if there is an intervening wall or door. If warning devices are located on a different level of the residence

or premise, then it is less likely that the occupants will be alerted or awakened. Audible warning devices

may be interfered with by other noise sources such as stereos, radios, televisions, air conditioners or other

appliances, or passing traffic. Audible warning devices, however loud, may not be heard by a hearingimpaired person.

■ Telephone Lines

If telephone lines are used to transmit alarms, they may be out of service or busy for certain periods of

time. Also an intruder may cut the telephone line or defeat its operation by more sophisticated means

which may be difficult to detect.

■ Insufficient Time

There may be circumstances when the system will operate as intended, yet the occupants will not be protected from the emergency due to their inability to respond to the warnings in a timely manner. If the system is monitored, the response may not occur in time to protect the occupants or their belongings.

■ Component Failure

Although every effort has been made to make this system as reliable as possible, the system may fail to

function as intended due to the failure of a component.

■ Inadequate Testing

Most problems that would prevent an alarm system from operating as intended can be found by regular

testing and maintenance. The complete system should be tested weekly and immediately after a break-in,

an attempted break-in, a fire, a storm, an earthquake, an accident, or any kind of construction activity

inside or outside the premises. The testing should include all sensing devices, keypads, consoles, alarm

indicating devices and any other operational devices that are part of the system.

■ Security and Insurance

Regardless of its capabilities, an alarm system is not a substitute for property or life insurance. An alarm

system also is not a substitute for property owners, renters, or other occupants to act prudently to prevent

or minimize the harmful effects of an emergency situation.

Limited Warranty

Digital Security Controls warrants the original purchaser that for a period of twelve months from the date

of purchase, the product shall be free of defects in materials and workmanship under normal use. During

the warranty period, Digital Security Controls shall, at its option, repair or replace any defective product

upon return of the product to its factory, at no charge for labour and materials. Any replacement and/or

repaired parts are warranted for the remainder of the original warranty or ninety (90) days, whichever is

longer. The original purchaser must promptly notify Digital Security Controls in writing that there is

defect in material or workmanship, such written notice to be received in all events prior to expiration of

the warranty period.

as a user license under the terms of the software license agreement included with the product. The

Customer assumes all responsibility for the proper selection, installation, operation and maintenance of any products purchased from DSC. Custom products are only warranted to the extent that

they do not function upon delivery. In such cases, DSC can replace or credit at its option.

International Warranty

The warranty for international customers is the same as for any customer within Canada and the United

States, with the exception that Digital Security Controls shall not be responsible for any customs fees,

taxes, or VAT that may be due.

Warranty Procedure

To obtain service under this warranty, please return the item(s) in question to the point of purchase. All

authorized distributors and dealers have a warranty program. Anyone returning goods to Digital Security

Controls must first obtain an authorization number. Digital Security Controls will not accept any shipment

whatsoever for which prior authorization has not been obtained.

Conditions to Void Warranty

This warranty applies only to defects in parts and workmanship relating to normal use. It does not cover:

• damage incurred in shipping or handling;

• damage caused by disaster such as fire, flood, wind, earthquake or lightning;

• damage due to causes beyond the control of Digital Security Controls such as excessive voltage,

mechanical shock or water damage;

• damage caused by unauthorized attachment, alterations, modifications or foreign objects;

• damage caused by peripherals (unless such peripherals were supplied by Digital Security Controls);

• defects caused by failure to provide a suitable installation environment for the products;

• damage caused by use of the products for purposes other than those for which it was designed;

• damage from improper maintenance;

• damage arising out of any other abuse, mishandling or improper application of the products.

Items Not Covered by Warranty

In addition to the items which void the Warranty, the following items shall not be covered by Warranty: (i)

freight cost to the repair centre; (ii) products which are not identified with DSC's product label and lot

number or serial number; (iii) products disassembled or repaired in such a manner as to adversely affect

performance or prevent adequate inspection or testing to verify any warranty claim. Access cards or tags

returned for replacement under warranty will be credited or replaced at DSC's option. Products not covered by this warranty, or otherwise out of warranty due to age, misuse, or damage shall be evaluated, and

a repair estimate shall be provided. No repair work will be performed until a valid purchase order is

received from the Customer and a Return Merchandise Authorisation number (RMA) is issued by DSC's

Customer Service.

Digital Security Controls’s liability for failure to repair the product under this warranty after a reasonable

number of attempts will be limited to a replacement of the product, as the exclusive remedy for breach of

warranty. Under no circumstances shall Digital Security Controls be liable for any special, incidental, or

consequential damages based upon breach of warranty, breach of contract, negligence, strict liability, or

any other legal theory. Such damages include, but are not limited to, loss of profits, loss of the product or

any associated equipment, cost of capital, cost of substitute or replacement equipment, facilities or services, down time, purchaser’s time, the claims of third parties, including customers, and injury to prop-

The laws of some jurisdictions limit or do not allow the disclaimer of consequential damages.

erty.

If the laws of such a jurisdiction apply to any claim by or against DSC, the limitations and disclaimers contained here shall be to the greatest extent permitted by law. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so that the above may not

apply to you.

Disclaimer of Warranties

This warranty contains the entire warranty and shall be in lieu of any and all other warranties,

whether expressed or implied (including all implied warranties of merchantability or fitness for a particular purpose) And of all other obligations or liabilities on the part of Digital Security Controls Digital Security Controls neither assumes responsibility for, nor authorizes any other person purporting to

act on its behalf to modify or to change this warranty, nor to assume for it any other warranty or liability concerning this product.

This disclaimer of warranties and limited warranty are governed by the laws of the province of Ontario,

Canada.

WARNING: Digital Security Controls recommends that the entire system be completely tested on a

regular basis. However, despite frequent testing, and due to, but not limited to, criminal tampering

or electrical disruption, it is possible for this product to fail to perform as expected.

Installer’s Lockout

Any products returned to DSC which have the Installer’s Lockout option enabled and exhibit no other

problems will be subject to a service charge.

Out of Warranty Repairs

Digital Security Controls will at its option repair or replace out-of-warranty products which are returned

to its factory according to the following conditions. Anyone returning goods to Digital Security Controls

must first obtain an authorization number. Digital Security Controls will not accept any shipment whatsoever for which prior authorization has not been obtained.

Products which Digital Security Controls determines to be repairable will be repaired and returned. A set

fee which Digital Security Controls has predetermined and which may be revised from time to time, will

be charged for each unit repaired.

Products which Digital Security Controls determines not to be repairable will be replaced by the nearest

equivalent product available at that time. The current market price of the replacement product will be

charged for each replacement unit.

There is absolutely no warranty on software and all software products are sold

Section 1 - Introduction

The MLR2000 is a Multi-Line, Multi-Format Digital Receiver for

commercial fire and burglary. The basic unit consists of 60 individual line-cards (DRL2000) connected to a dual redundant central resource, router and protocol converter (CPM2000). The

MLR2000 includes many features, especially high bandwidth

internal buses and high bandwidth external connections to

allow traditional network philosophies to be observed for the

first time on a central station receiver. The MLR2000 can

decode a variety of popular and widely used communication

formats. Refer to Appendix A, DRL2000 Communication Formats for a list of the available communication protocols.

The MLR2000's real-time clock and calendar 'stamps' all information received with the time and date, and all information

may be printed or forwarded to a computer. To ensure security,

adjustment of the clock, calendar and other programming is

protected by password codes.

1.1 CPM2000

The CPM2000 Central Processing Module oversees operation of the receivers. Along with its built-in keypad and

LCD message screen, the CPM2000 features TCP/IP, two

parallel printers, one serial printer and two serial computer

interface capability.

1.2 DRL2000

Each DRL2000 module can monitor two telephone lines.

The line card module is equipped with a 256-event nonvolatile memory buffer to record events and corresponding telephone numbers. Caller Source capability is built-in

and telephone numbers can be printed out, sent to automation and stored in memory. Events and information

stored in memory can be printed at any time. Each line

card also features flash EPROM uploads through the

Debug port for software upgrades or options programming.

1.3 Power and Supervision

1.3.1 Power

The MLR2000 power supplies inputs are 120 Vac at 10A,

60 Hz. Each AC power supply supplies a nominal 28 Vdc

+/-5% power. The receiver is equipped with 24V

rechargeable stand-by battery connections at 160 Ahr.

and an automatic battery charger. Provision is made for an

internal battery pack for temporary use. User supplied

batteries may be used externally but must be fused and

connected to 10-32 lugs supplied via a stud termination.

Full power operation is .5 Amps per line and 1 Amp per

CPM at 28 Vdc nominal. All elements have extensive

power down capabilities and are implemented in CMOS

logic.

1.3.2 Supervision

The stand-by battery voltage and connections are supervised. The Line Cards are also continuously supervised to

ensure uninterrupted communication with the CPM2000.

Any trouble conditions are reported on the LCD screens

and sent to the printer and the computer.

The DRL2000 Line Card Module also verifies communications with the CPM2000. In the event of a malfunction,

the operator will be advised with a visual indication and

the Line Cards will continue to function. Each line card will

continue to receive information.

The printer is supervised for off-line, paper out and other

trouble conditions. The communication link to the computer through the RS232 ports is monitored by the supervisory 'heartbeat' test transmissions.

1.3.3 Compatibility

Central station automation software packages such as:

• MAS • DICE • SIMS II • GENESYS • S.I.S. • IBS

•MicroKey

support the MLR2000 Sur-Gard interface.

Refer to automation software specifications for compatibility.

NOTES: Automation connections are considered

supplementary per UL864 Listing. Compatibility

with the automation software in a system used at a

central station is intended to be handled under a

separate UL1981 software and/or site certification

evaluation.

1.4 CPM2000 Outputs/ Inputs

• The CPM2000 features four switched-negative

(PGMOUT1 is activated when automation fails) outputs,

two relay outputs and four inputs.

1.5 System Overview

• Patented Caller Identification (Call Display) capability

• Patent Pending DNIS Identification

• nonvolatile RAM on each DRL2000 line card module for

programming and event buffer.

• Fast Ethernet communication between line-cards and

CPM

• Flash download for software upgrades

• Up to 64 different options set (profiles per line)

• Patented virtual configurations

• 3/1, 4/2 formats with or without parity, 4/1 without parity at 10, 14, 20, or 40 baud

• 4/1, 4/2, 4/3, and 4/3 DTMF formats

• Optional* formats: 3-2, 4/1, 4/2 extended

• ACRON DTMF format

• Contact ID (DTMF) format

• Adcor 20 baud

• Super fast or high speed DTMF format, with or without

parity

• DTMF 4/1 express format (optional)

• DTMF 4/2 express format

• FBI super fast format with or without parity

• Radionics Modem II, Modem IIE, Modem IIIa2 and BFSK

formats

• SIA format: 110 and 300 baud, tone and data acknowledgement

• SK FSK0, FSK1, FSK2

• Any handshake frequencies by increment of 100 Hz

from 100 Hz to 2300 HZ, Dual Tone, SIA FSK, Modem II

and ITI selected by configuration commands

• Up to 8 different handshakes per profile.

• Large, easy to read 2-line, 16-characters-per-line, LCD

(Liquid Crystal Display) screen

• All modules function individually to help ensure uninterrupted operation during hardware or software upgrades

• Inputs on CPM2000 for UPS supervisory

• 255 lines maximum per receiver

• 256-event memory buffer on each individual line card

•Real-time clock

• CPM2000 features 32-bit micro-controller

• Two parallel printer port; three serial RS232 ports and

one 10 BaseT connection.

• Programmable serial ports configuration

• Programmable System Functions: Computer and printer

• Fast transmission of multiple alarms to the computer

and printer to ensure operator's quick response

*All formats noted as optional are selected using configuration commands.

1

• Continuous verification of the computer-receiver links

with the 'heartbeat' function

• Switched-negative outputs on CPM2000 (special applications)

• AC-lost detection and stand-by battery supervision

• Low battery detection and automatic low battery disconnect to prevent deep-discharge damage to battery

• Operator Acknowledge

• Telephone Line Supervision

1.6 Virtual Receiver Architecture

The most novel feature of the DRL2000 is the ability to

use Telco information delivered as a DNIS (dialed number

identification service) to allow the Sur-Gard expert format

identification system to option on the fly each received call

to eliminate dedicated line pool hardware. Instead the

DNIS allows call up options which set up virtual line pools

to identify security formats and extend account numbers.

Standard dialed number identification is supported up to

10 digits.

Each dialed number should be assigned to a virtual

receiver. Each dialed number would have formerly been a

line pool on conventional line-cards.

1.7 Number of Line Cards Supported

The system will support a maximum of 255 line-cards concurrently connected. Optional hubs will be required for

backplane connectivity in installations beyond 5 shelves.

1.8 Redundancy

The MLR2000 has a main power supply module for side A

and for side B, and an optional stand-by power supply per

rack. Additional 10B2 Ethernet is available as a backup B

side. This and the ability to mount an optional second

CPM2000 controller will allow for seamless system redundancy in maximum configuration. In practical terms this

means that any line card may fail and not affect system

performance ; and with redundant CPM's the B unit will

take up where the A unit failed with a loss of no more

than 30 seconds. External networking components would

necessarily be duplicated to take full advantage of this

configuration.

1.9 Approvals

1.9.1 Industry Approvals

The MLR2000 in redundant configuration is listed under

the following UL standards:

• UL 864 Control Units for Fire-Protective Signaling Systems

• UL 1610 Central Station Burglar Alarm Units

This equipment should be installed in accordance

with the requirements of NFPA72, NFPA70 and

UL827.

1.9.2 System Connectivity

The system may have two identical CPMs both connected

to internal resources. Internal connections are A and B

side 28 V power and A and B side 10B2 Ethernet. Additional internal connections are power monitoring services

on the primary rack. External connections are two parallel

printer and three serial ports. The serial ports are intended

primarily for debug applications but may be used for fallback automation outputs (optional). The primary automation connection is via 10BT Ethernet connection. Again if

redundant CPM's are used the external network components must be duplicated to allow for full redundancy.

1.9.3 Automation Mode

In automation mode it is expected that the primary connection is via TCP/IP networking on the 10BT Ethernet

connection. A menu on the CPM2000 will prompt the

user for the IP address setup and port setup. Once the

configuration management port is set up, all other

options and setups may be done via a Telnet session or

the Sur-Gard Console.

1.9.4 UL Manual Mode

For UL manual mode, each event will activate the internal

buzzer to be acknowledged manually. Each event will be

sent automatically to all connected printers.

NOTE: For central station applications the signaling

performance of each dact shall be manually tracked.

Failure to receive a signal from a dact over a 24-hour

period shall be handled as a trouble signal.

1.10 Virtual Connectivity

Each receiver has one IP address and a number of associated ports. Internal socket programming uses specific

ports for expected tasks. The MLR2000 is the listener.

1.10.1 Configuration Management - Sur-Gard Configuration Port 1024

A tool is provided for NT 4 + or Windows 9x/2000/XP

environments which provides graphical style menu for

configuration management. Additional features are storage of virtual receiver setups, formats conversion table

and configuration wizards.

1.10.2 Status Addressing

Line card status will be reported via physical addressing.

This will be assigned by shelf and slot number. All device

status information is in Sur-Gard format. The reporting of

status on this port, automation output and printer will

relate to physical addressing.

1.10.3 Automation input/output (Port 1025, 1026)

Traditional automation communication will be provided

via a minimum of two ports. The primary port is Sur-Gard

standard output and provides Sur-Gard standard automation output.

Optional secondary automation communication will be

provided to map to proprietary types. It is expected that

named virtual receiver types will be mapped to this output. In addition two way automation commands may be

supported on this port.

1.11 Internal 10B2 Ethernet

Internal Ethernet is not standard TCP/IP instead it has allocated proprietary type per Internet standards. Full physical

10B2 requirements are met allowing approved segment

interconnects to be used including hubs, optical transceivers and wan interconnects (wan interconnects preclude

trap and capture commands).

2

Section 2 - Quick Start

2.1 Receiver Setup and Operation

2.1.1 Unpacking

Carefully unpack the receiver and inspect for shipping

damage. If there is any apparent damage, notify the carrier immediately.

2.1.2 Ethernet Connections

NOTES: Be sure to be properly grounded.

• Take a 50 ohm coaxial cable and connect one end to the

BNC connector (ETHERNET A) of the CPM2000. The

other end of the coaxial cable should be connected to

the BNC connector (ENET A IN) of the backplane.

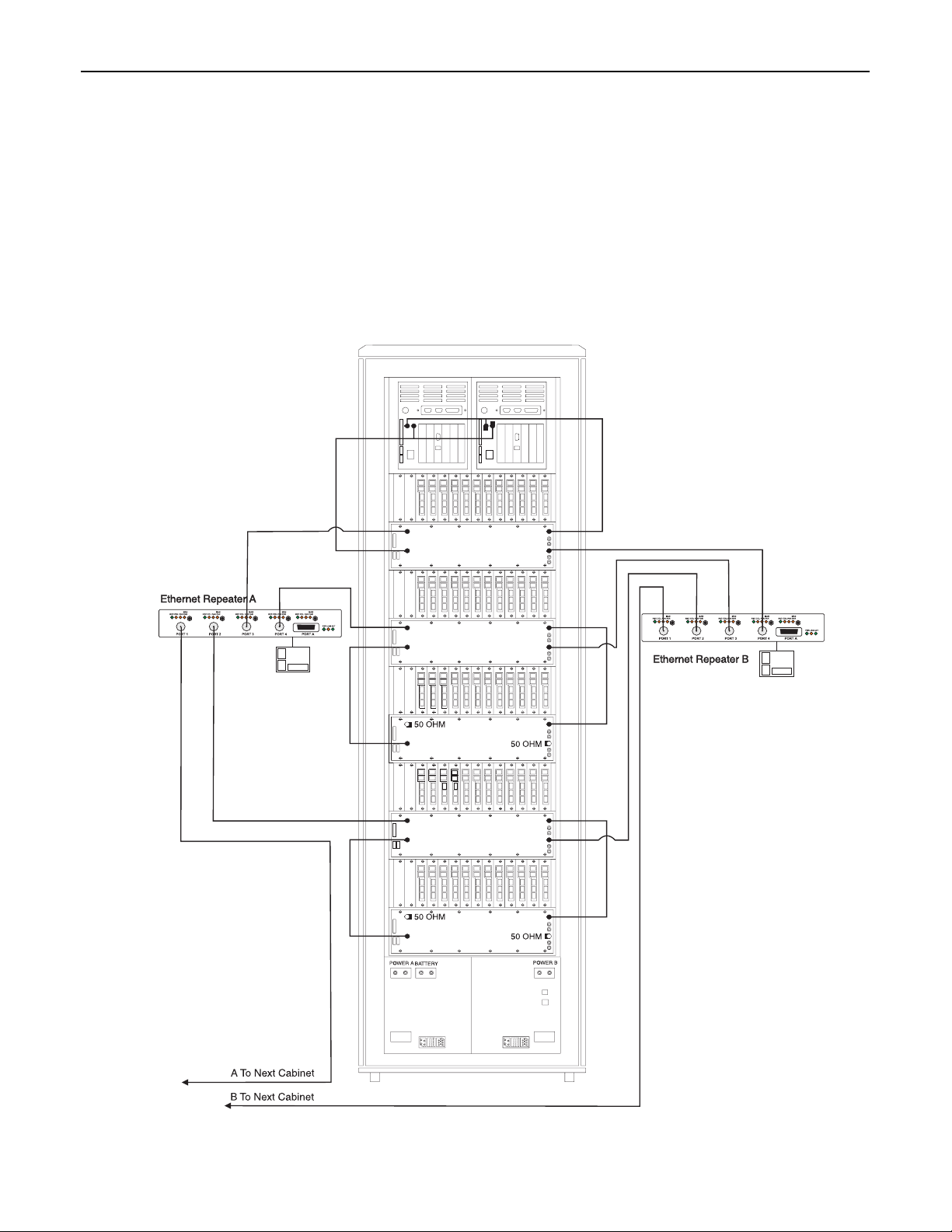

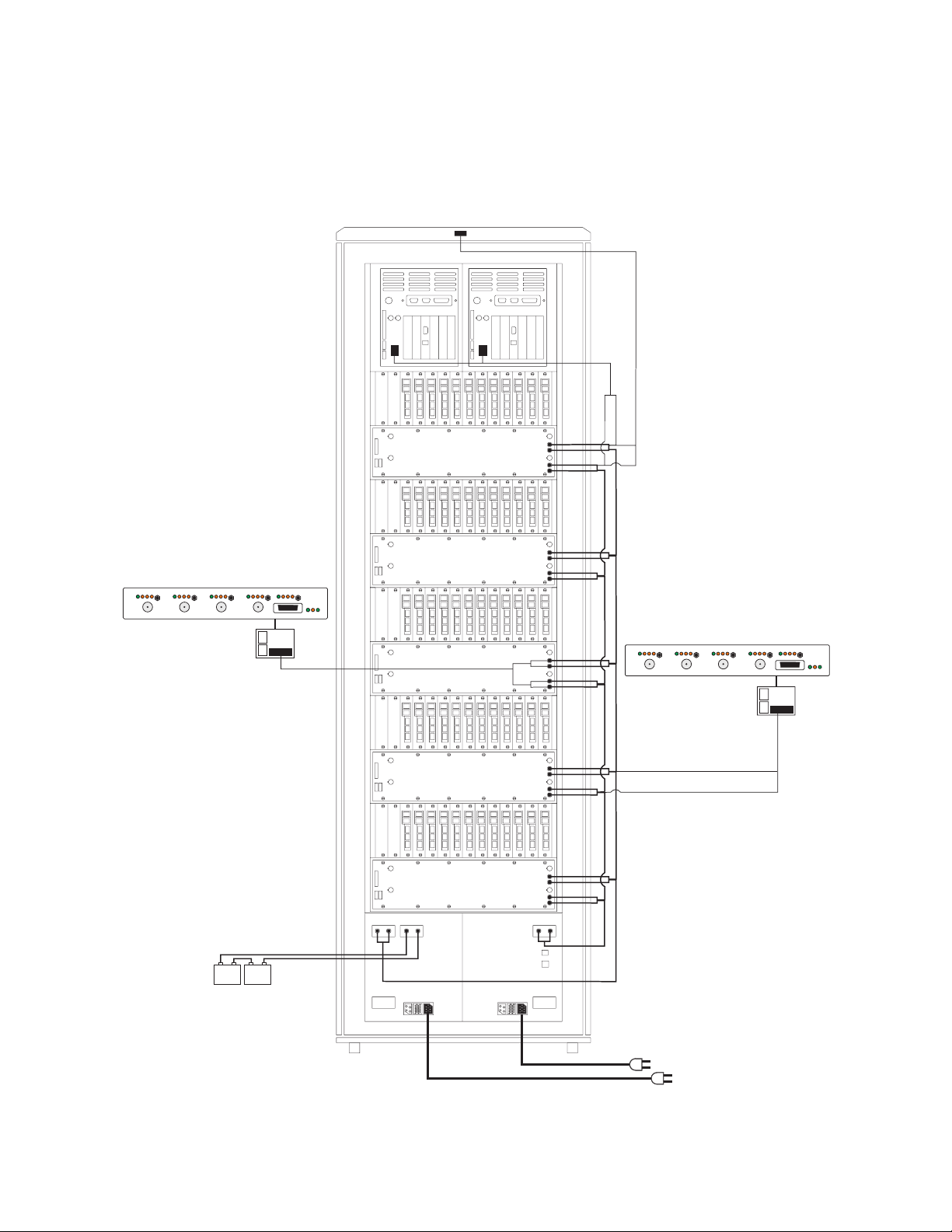

Figure 1, 60 Line Cards Configuration

• Take a 50-ohm coaxial cable and connect one end to

the BNC connector (ETHERNET B) of the CPM2000. The

other end of the coaxial cable should be connected to

the BNC connector (ENET B IN) of the backplane.

• Make sure that there are 50 ohm BNC terminators on

the other end of the T Connectors of the CPM2000

labelled ETHERNET A AND B.

• Make sure that there are 50 ohm BNC terminators connected on the BNC terminals marked ENET A OUT and

ENET B OUT of the backplane. (This should be already

done.)

3

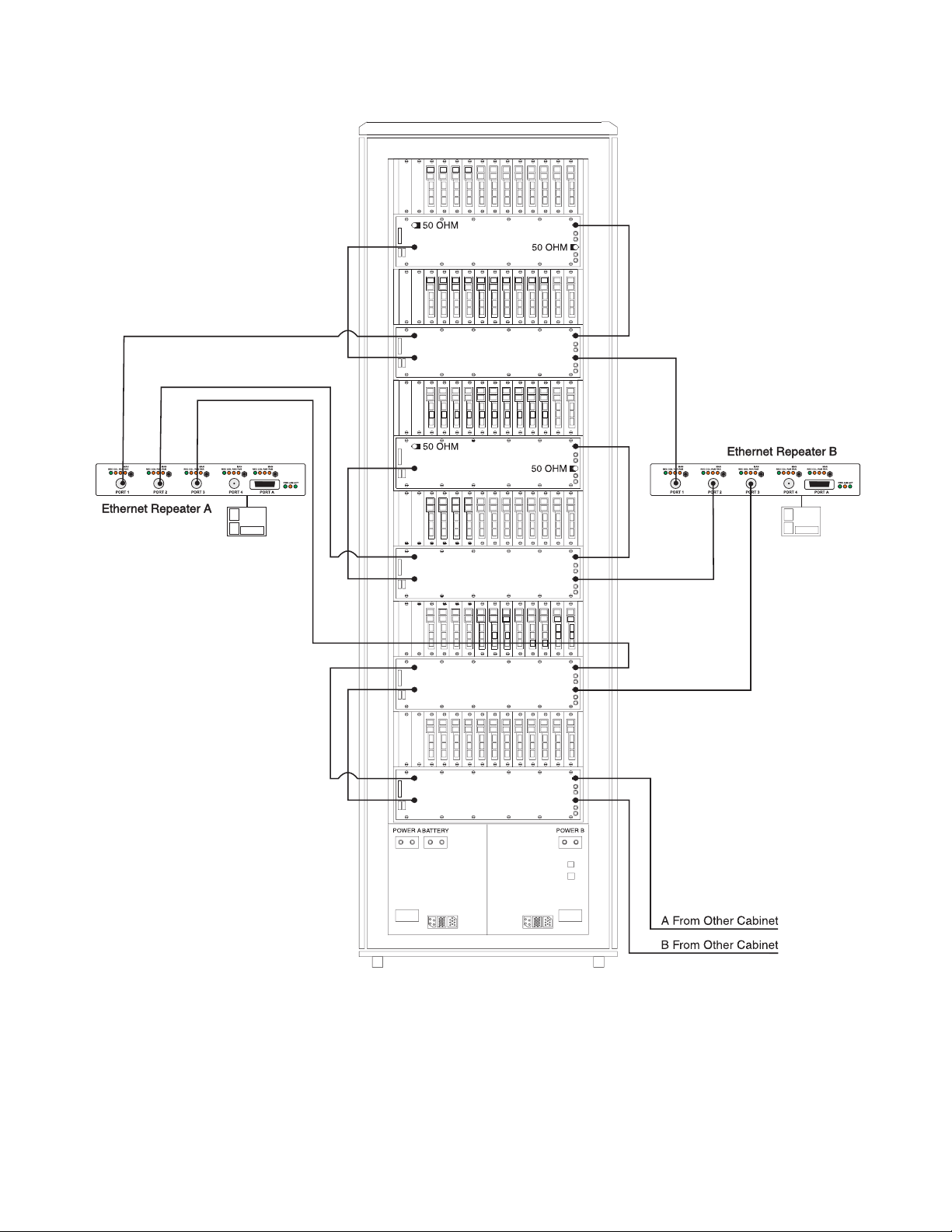

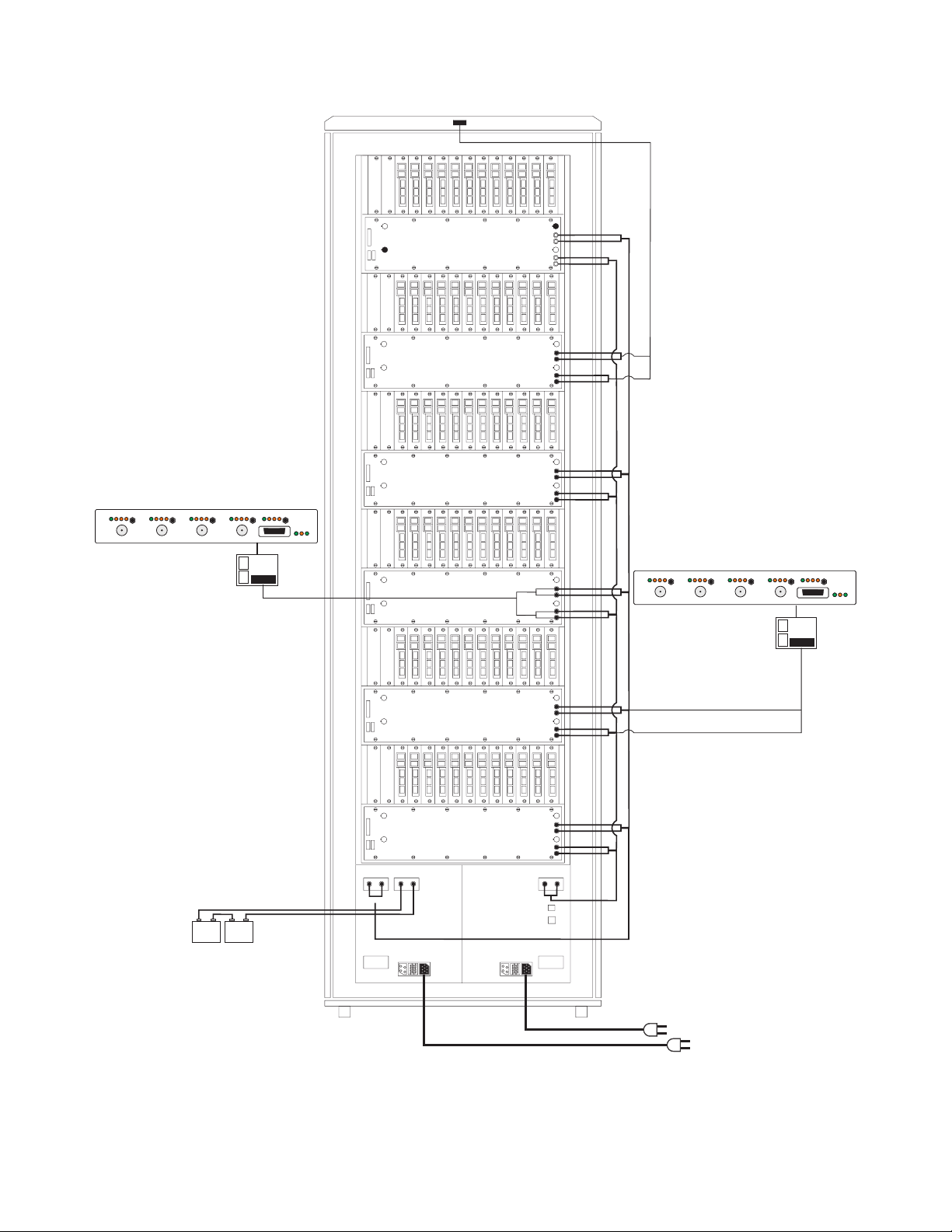

Figure 2, 72 Line Cards Configuration (Expansion cabinet)

4

2.1.3 Power Cable Connections

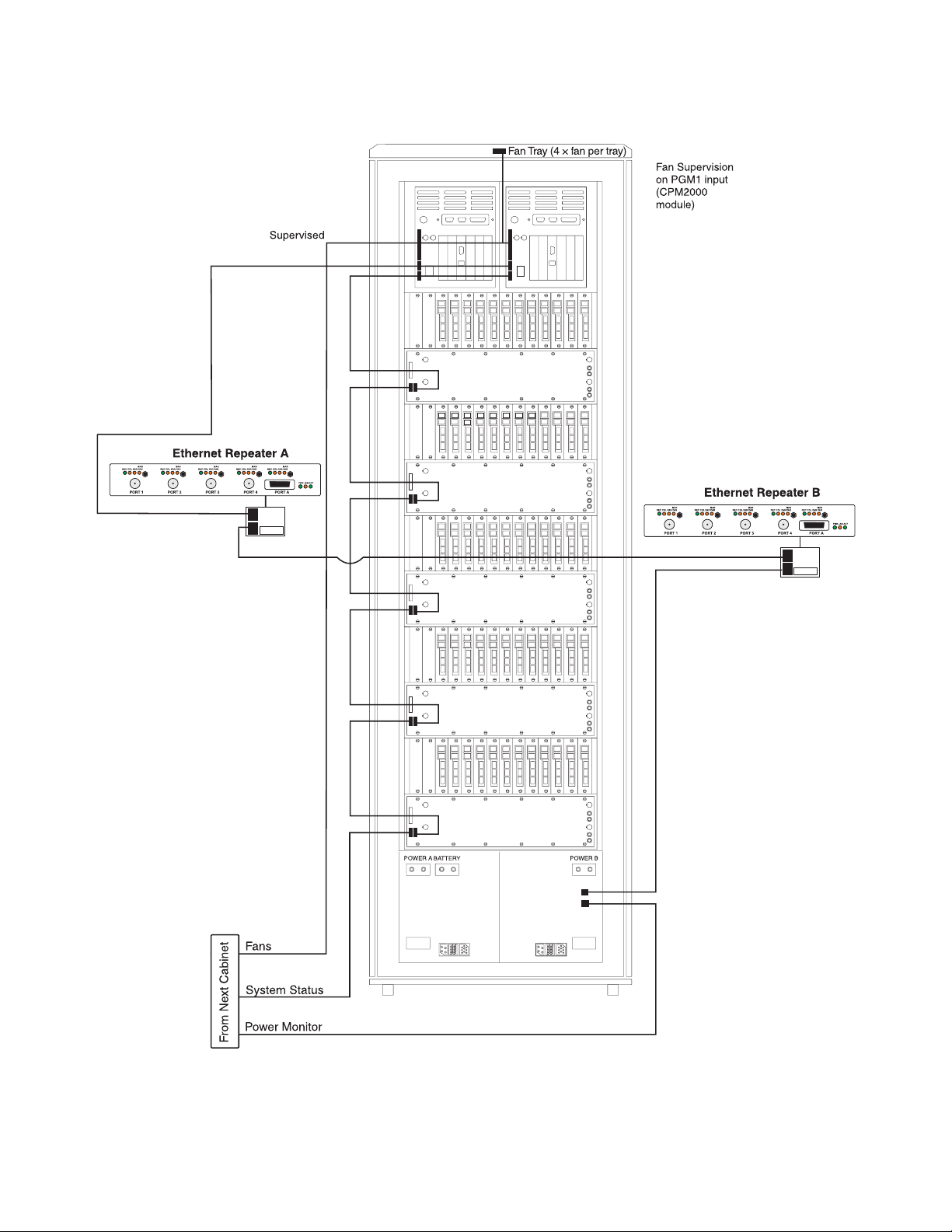

Ethernet Repeater B

Ethernet Repeater A

• Take the power cable for the CPM2000 and connect the

labelled wire to the designated terminal on the backplane. Take the other end of the power cable and connect it to the power connector on the CPM2000.

Figure 3, 60 Line Cards Configuration

Fan Tray

• Take the power cables (10 gage) and connect one end

to the power terminals of the backplane marked PWRGND (black cable) and +28 V

other end of the power cables and connect to a 28 V

DC A (red cable). Take the

DC

power supply (make sure power is OFF).

REC COL PA RP AR

PORT 1

Ethernet Repeater A

MAN

MAN

PORT 2

REC COL PA RP AR

MAN

PORT 3

REC COL PA RP AR

NOTE: Battery wiring

should be run in conduit

and batteries should be

housed in a separate UL

Listed enclosure.

Recommended batteries:

2x12V / 140-190Ah

4 hours backup batteries

used in conjunction with

power generator.

Model:INTERSTATE SG8D.

+-+

WARNING: To reduce the

risk of electric shock, this

product is provided with a

grounding type power

supply cord. Connect

product to a grounded

receptacle.

REC COL PA RP AR

MAN

PORT 4

-

MAN

REC COL PA RP AR

PWR JAM ACT

PORT A

Non Power

Limited Circuit

POWER A

BATTERY

--

++

POWER B

120V/60Hz/10A

Ethernet Repeater B

MAN

POR T 1

REC COL PA RP AR

MAN

PORT 2

REC COL PA RP AR

NOTE: AC supply cords

shall be run in conduit

or be provided with

equivalent mechanical

protection.

REC COL PA RP AR

PORT 3

MAN

MAN

MAN

REC COL PA RP AR

REC CO LP AR PAR

PORT A

PWR JAM ACT

PORT 4

5

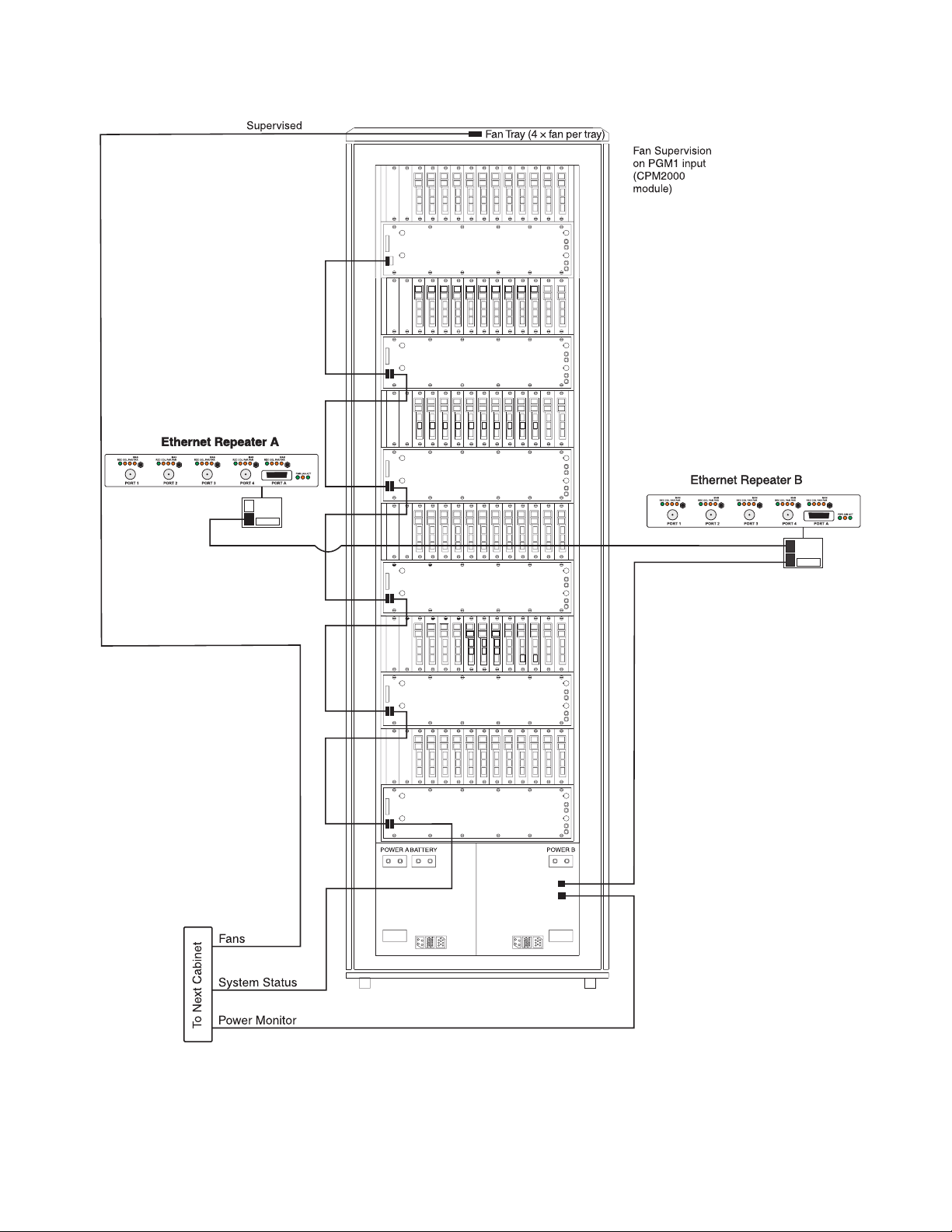

Figure 4, 72 Line Cards Configuration (Expansion Cabinet)

Ethernet Repeater B

Ethernet Repeater A

Ethernet Repeater A

MAN

MAN

MAN

MAN

PORT 4

REC COL PAR PAR

PORT A

MAN

PWR JAM ACT

REC COL PAR PAR

PORT 1

REC COL PAR PAR

PORT 2

REC COL PAR PAR

PORT 3

REC COL PAR PAR

Fan Tray

Ethernet Repeater B

MAN

REC COL PAR PAR

PORT 2

MAN

REC COL PAR PAR

PORT 1

REC COL PAR PAR

PORT 3

MAN

MAN

PORT 4

REC COL PAR PAR

PORT A

MAN

PWR JAM AC T

REC COL PAR PAR

NOTE: Battery wiring

should be run in conduit

and batteries should be

housed in a separate UL

Listed enclosure.

Recommended batteries:

2x12V / 140-190Ah

4 hours backup batteries

used in conjunction with

power generator.

Model:INTERSTATE SG8D.

Non Power

Limited Circuit

+-+

-

WARNING: To reduce the

risk of electric shock, this

product is provided with a

grounding type power

supply cord. Connect

product to a grounded

receptacle.

POWER A

BATTERY

--

++

POWER B

120V/60Hz/10A

NOTE: AC supply

cords shall be run in

conduit or be

provided with

equivalent

mechanical

protection.

6

2.1.4 Signaling/Supervisory Connections

Figure 5, 60 Line Cards Configuration

7

Figure 6, 72 Line Cards Configuration (Expansion Cabinet)

8

2.2 Bench Testing

It is suggested that the receiver be tested before actual

installation; becoming familiar with the connections and

setup of the unit on the work bench will make final installation more straightforward.

The following items are required:

• 28 VDC Power supply

• One telephone line

• One or more dialer or digital dialer control panels

2.2.1 Power Up

When the 28 V

will beep for approximately 1-2 minutes during system initialization. The buzzer will deactivate as soon as the

CPM2000 software initializes and is running. The LCD display on the CPM2000 should display 'Primary'. If the Line

Cards do not have telephone lines connected, the

DRL2000 modules will activate 'Line Fault' lights. The telephone line should be connected to the POTS jack at the

back of the DRL SUBRACK. As soon as the line card

detects a phone line, a line restore message will be sent to

the printer and computer output. If the phone line is

removed, a line fault message will be sent to the printer

and computer output.

If there is no computer or printer connected, a trouble

message will be displayed on the CPM2000 LCD and the

'ACK' light will flash. Press the [ACK] button to silence the

CPM2000 buzzer.

The watchdog LED on the line card should flicker as soon

as it is initialized. The Trouble LED will activate if the line

card is not receiving a poll from the CPM2000. As soon as

the line card responds to the polling, the Trouble LED

should deactivate.

2.2.2 Operation with Default Programming

Without any changes to the factory default programming,

the receiver operates as follows:

• Answers incoming calls on the first ring

• Sends 2300 Hz as the first handshake

• Sends 1400 Hz as the second handshake

• Sends dual tone as the third handshake

• Sends SIA FSK tone as the fourth handshake

• Sends ITI , Modem IIE/ IIIa

• Sends Modem II tone as sixth handshake

• Receives all communication formats, except for: 3/2, 4/1

express, 4/2 extended and 4/2 checksum.

• The above formats can be manually selected.

• Signals can be displayed on the debug output computer

as they are received. The signals are then sent to the

parallel printer and computer connected to serial port

COM1 or to the 10BT connector. The default event

codes described in the 'DRL2000 Library Decoding and

Event Codes Table' will be used with the Sur-Gard automation communication protocol to send signals to the

computer, if connected.

• If a computer is not connected, press the [ACK] button

on the CPM2000 module to silence the buzzer.

DC power is applied, the CPM2000 unit

2

tone as fifth handshake

2.2.3 Debug Output

The debug output is another means of accessing the linecard's programmed options and diagnostics features. A

debug cable is required to connect by serial communication from the line card to a standard PC running Windows

9x/2000/XP.

2.2.4 Debug Cable Connectivity

• Connect the RJ45 end of the debug cable to the debug

jack on the front of the line card or to the debug jack of

the paddle board on the back of the sub-rack.

• Connect the female DB-9 connector to the serial port of

a computer (COM1 port - usually DB-9 male, COM2

port - DB-25 female).

2.2.5 Debug Software Setup

• Using WIN95, point and click on the 'START' button.

Access 'Programs' -> 'Accessories' -> 'HyperTerminal'.

Once in the HyperTerminal window, point and click on

'Hypertrm.exe' icon.

• A connection description window should appear. A

prompt should appear on the 'Name' category. Type a

name. Point and click on the 'OK' button.

• A phone number window should appear. Choose the

direct to COM port required for connection and point

and click on 'OK'.

• COMX properties windows should appear. The configuration should be:

• Bits per second: 19200

•Data bits: 8

• Parity: None

• Stop bits: 1

• Flow control: None

• Point and click on the 'OK' button after setting the configuration.

• The HyperTerminal window should appear. Press any

button. The debug menu will be displayed.

2.2.6 Button Commands

A:This button will display the address of the line card. The

address includes the shelf and slot number of the line

card making each line card unique.

D:This button will initiate the download of a file to the

line card.

O:This button will enable the user to dump the current

programmed options of the line card or set an option

to a particular value.

P:Sets the message priority to be displayed. This is useful

for debugging purposes only.

2.2.7 Downloading steps

1. Press the 'D' button to initiate downloading of the

binary file. The Hyper Terminal will display:

Ready to download.

CCCC

2. Point and click at 'Transfer' on the Hyper Terminal

menu and access the 'Send File' category. The 'Send

File' window should appear.

3. Change the protocol to 'X-modem' and place the correct path and file name of the binary file to be downloaded.

4. Point and click on the [Send] button and the downloading status window should appear.

The line card will restart automatically after a successful

download.

2.2.8 Printer output

Printer Examples:

Date Time SS/00 Receiver Type Receiver # Line # Account # Alarm Code Message

Ex. JUN 01 2000 - 08:00:22 - 01/02 -SG - 01 - 061 - 965 - E9 RESTORE

Ex. JUN 01 2000 - 08:00:22 - 01/02 -SG - 01 - 061 - 965 - F9 TROUBLE

Ex. JUN 01 2000 - 08:00:22 - 01/02 -SG - 01 - 061 - 965 - 2 PANIC ALARM

9

Section 3 - Installation

3.1 Dimensions

The MLR2000 is implemented into a 42U * 600 mm *

800 mm cabinet. The cabinet has 7 subracks, each on is

19 inches * 6U high. Housed in the top subrack, the

CPM2000 comes complete with its own 19 inch * 6U

tray. Bellow the CPM2000 tray, the MLRX-2000 expansion

cage provides for up to 12 DRL2000 line cards. Each

DRL2000 line card is 6U * 6HP * 220 mm. Each paddle

board is 3U * 6 HP * 220 mm. The PSU-2000 comes complete in its own 19 inch * 6U high cage.

The main MLR2000 cabinet will hold 2×CPM2000,

5×MRLX-2000, 60×DRL2000, 2×PSU-2000.

The expansion MLR2000 cabinet will hold 6×MRLX-2000,

72×DRL2000, 2×PSU-2000.

3.1.1 Spacing

All units of a receiver must be within 50 ft. (cable length)

of the CPM to provide system timing integrity.

3.2 Definity DNIS

The AT&T Definity G3 DTMF vdn codes have been tested

and are supported by the MLR2000.

3.3 Mounting the Receiver

Install the MLR2000 in a closed 19" rack or cabinet with a

locking rear access door. Cover all unused spaces with

blank metal plates. The LCD screen on the receiver is

designed to be viewed below eye level. A Stand-up Unit

(61.25" tall up to 60 telephone lines, part #90000016)

can be supplied for a complete installation.

NOTE: If 60 telephone lines are not used, cover each

unused location with a blank plate.

3.4 Printer Connections

The following UL Listed printers can be used with the

MLR2000: Sur-Gard CPU-1150 (Panasonic KX-P1150)

DMP SCS-PTR (Okidata Microline 182/184)

Connect the parallel printers to the MLR2000 printer output ports using parallel printer cables.

NOTE: A minimum of two printers are required for

UL Listed applications.

Do not use a printer cable which has only 1 common

ground wire.

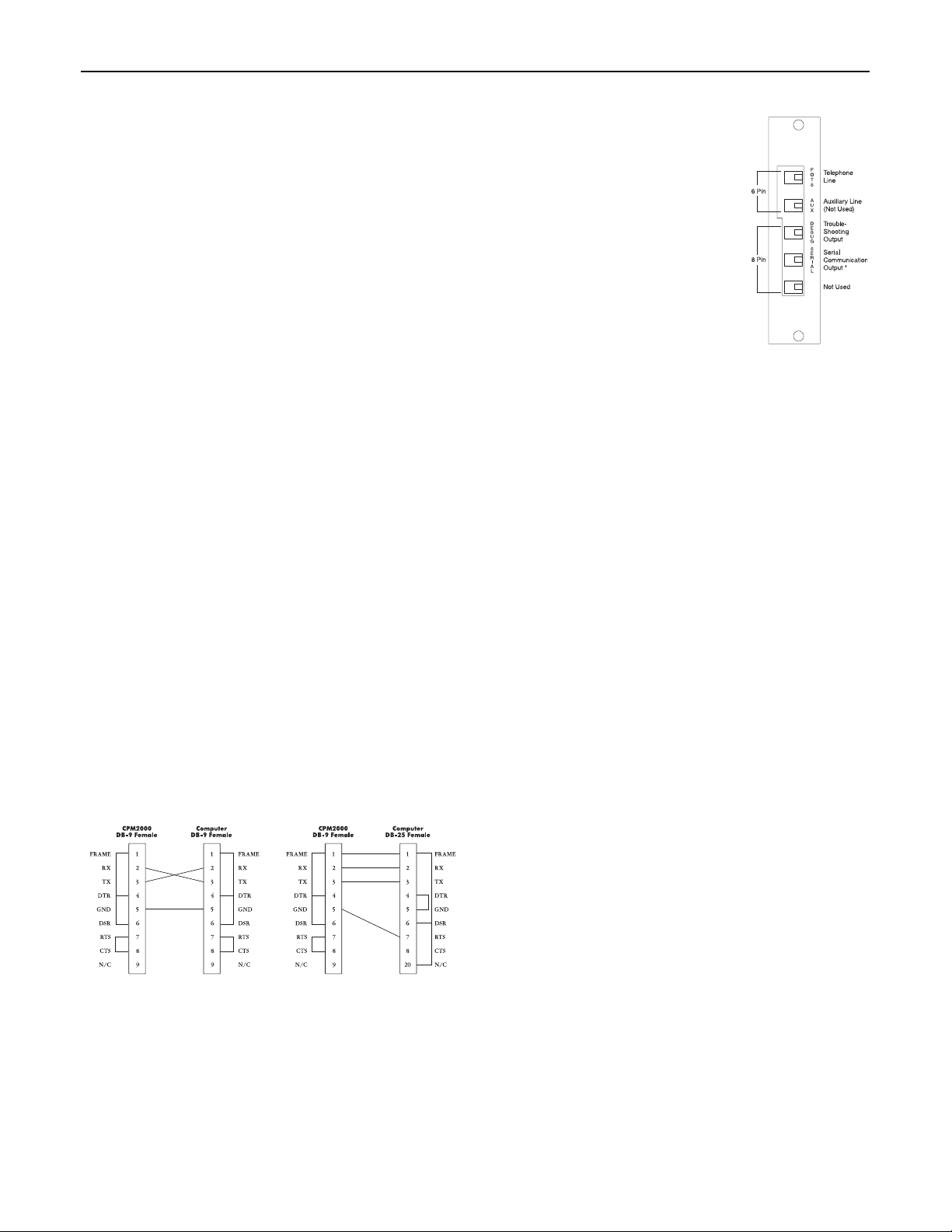

3.5 Computer Connections

Connect the computer to the MLR2000 RS232 port using

a serial cable to COM1.

NOTE: Pins 1, 4 and 6 on the receiver side are connected together. Pin 7 and 8 are also shorted

together. Pin 9 is not connected.

3.6 Telephone Line

Connections

Each paddle module has the connections shown here. Connect each

line module output (POTS) to the

telephone line (analog) with 6-pin

modular cables.

NOTE: Use minimum AWG 26

wires for telephone cables.

*NOTE: Connection of an Ademco radio

receiver model 7810RT or 7830R can be

done on the serial port of the paddle

module. The device should be mounted

in the same room as the MLR2000

receiver (within 20 ft.). The connection

shall be run in conduit or equivalent i.e.

providing mechanical protection.

3.7 Grounding

For maximum resistance to static and electrical noise, the

19" rack frame must be connected to earth ground

through the AC utility box.

3.8 Power Supply

Ensure that all electrical connections are made correctly.

After verifying all connections, connect the RED and

BLACK leads to a 24 (2 × 12V batteries in series) VDC

sealed rechargeable battery. Be sure to observe polarity

when connecting the battery. When the battery is connected, test the system under battery power only.

CAUTION: Connecting a positive (+) terminal

to a negative (-) terminal may cause a fire and

possibly serious personal harm.

3.9 Battery Charging Current

The maximum battery charging current is factory set at 5A.

3.10 Removing and Installing System

Components

To remove the Power Supply Modules

The Power Supply charges the battery and provides low

battery voltage disconnect; removing the power supply

module will disconnect the battery and shut down the

entire system. Please make sure there is a second power

supply module installed.

To Remove the CPM2000 Module

Slowly pull the module out of the metal cabinet.

To Remove a Line Card Module

Slowly pull the module out of the sub rack.

3.11 To Install a Line Card Module

Slowly insert the module in the sub rack.

Installation Checklist (Complete Operation)

❑ 19" Rack Mount Cabinet connected to earth ground

❑ SG-PSU2000 Power Supply installed

❑ 6-pin modular cable(s) connected to DRL2000 and tele-

phone line

❑ Parallel Printer Cable connected to MLR2000 Parallel

Printer Port

❑ Parallel Printer power connected

❑ Computer connected to MLR2000 COM1 port using

serial cable

❑ Computer connected to MLR2000 10BT port using

10BT cable

10

Section 4 - DRL2000 Digital Receiver Line Card

The DRL2000 acts as an interface between the digital

alarm transmitter and the CPM2000. Different communication formats can be used to transmit the information.

The main functions of the line-cards are to continuously

monitor the telephone line, receive calls from digital dialers or control panels, and to report alarms to the

CPM2000. In addition, if a Line Card is unable to communicate with the CPM2000, then each Line Card is capable

of functioning independently. Each Line Card can record

256 different alarm messages and 256 Caller-ID telephone

numbers.

4.4 DRL2000 Controls

4.1 General Information

The receiver is capable of processing signals from digital

communicators in variety of formats. The type of signal

(alarm, trouble, restore, cancel and so on) can be printed.

4.2 DRL2000 Features

• Operator selection of communication formats and

handshake priority

• 64 profiles per line card, up to 255 line pools.

• On-Board Ethernet interface.

• Flash Download for software upgrades.

• Records up to 256 messages.

• Records up to 256 Caller-ID phone numbers. This feature helps locate and identify the source of the device in

communication and assists in troubleshooting

• Multiple alarms are forwarded to the computer and

printer through the CPM2000 with minimum delay

• The DRL2000 monitors the telephone line connection,

and line faults will result in reports to the computer and

the printer

• DRL2000 automatically goes into stand-alone mode in

case of CPM2000 failure

• 'Watchdog' timer continually monitors receiver operation

• 'Cold boot' option allows receiver's configuration to be

reset to factory default programming

• DSP processing to reduce data receiving errors, and to

help for weak and noisy signals

• Gain boost available to amplify weak signals

• Serial link for troubleshooting

4.3 Installation

It is recommended that a DRL2000 Cold Start-up be performed when the unit is updated with a new program

version. Refer to Operating Mode Section (DRL2000 Cold

Start-up for information.

After the cold start-up, check the configuration information listed in the Quick Reference Guide to make any

required changes for your particular application.

Each DRL2000 Module has one telephone line.

Momentarily depressing and releasing a button will regis-

ter as a single input or keystroke.

ON LINE: The 'on-line' light will be

ON when the Line Card is on-line in

communication. The 'on-line' light will

be OFF when the Line Card is in Standby Mode. When the line card is on-line

but not in communication, the on-line

LED will FLASH to indicate that the

buffer is full, or that there is a checksum error after download.

LINE FAULT: The 'Line Fault' light will

come ON if the telephone line is disconnected. The 'Line Fault' light will

turn OFF automatically when the telephone line is restored.

TROUBLE: The 'Trouble' light will

come ON when the Line Card is shut

down by an operator's command or

when communication with the

CPM2000 is interrupted. The 'Trouble'

light will be shut OFF when the trouble

condition is corrected.

WATCHDOG: The 'Watchdog' light

will FLASH to indicate that Line Card

operation is being monitored

[ACK] Button: Not used.

[CANCEL] Button: Not used.

HANDSET: Not used.

DEBUG: Connection to a PC for trou-

bleshooting.

[F1] + [F2] Buttons: Press and hold

both buttons simultaneously on power

up for 10 seconds will reset the line

card to factory default.

11

Section 5 - DRL2000 Operating Mode

5.1 DRL2000 Standby Mode

After start-up the Line Card enters the Stand-by Mode

and monitors the telephone line and the CPM2000.

Depending on the system's status, the following conditions will be indicated:

• Line Fault light

• Trouble light: of Line Card communication problem with

CPM2000

5.1.1 Line Fault

The DRL2000 verifies the telephone line voltage. The 'Line

Fault' light will come ON when the voltage drops below

12V.

If the Line Check option is enabled, the following information will be transmitted to the printer and computer:

•Printer:

Jul 17 1998-08: 08: 28-SS/OO-SG-RR-LLL-0000PHONE LINE TROUBLE

• Computer:0RRLLL[#0000¦NLTSSOO][DC4]

A hexadecimal number from 00 to 0B representing the

slot number of the Line Card will be sent for each 'O'

shown above.

A hexadecimal number from 01 to FE representing the

shelf number of the Line Card will be sent for each 'S'

shown above.

If the Line Check option is disabled, the DRL2000 will not

send the report to the printer or computer. Refer to

'DRL2000 Programmable Features' for information on

enabling the Line Check option.

When the line condition returns to normal, the 'Line Fault'

light will be shut OFF.

If the Line Check option is enabled and the telephone line

returns to normal, the following information will be transmitted to the printer and computer:

•Printer:

Jul 17 1998 - 08: 08: 35-SS/OO-SG-RR-LLL-0000PHONE LINE RESTORE

• Computer:0RRLLL[#0000¦NLRSSOO][DC4]

5.1.2 CPM2000 Error

If the DRL2000 cannot detect CPM2000 polling, the trouble light will come on.

If alarm messages cannot be sent to the CPM2000

because of the error, the DRL2000 will start buffering

incoming calls.

Up to 256 alarm messages for the printer and computer

will be retained in the DRL2000 event buffer. When the

event buffer is full, the line card will stop answering the

calls.

When the CPM2000 Error condition is corrected, the

alarm messages in the event buffer will be transmitted to

the CPM2000 with the corresponding time/ date the

alarm have been received.

5.2 DRL2000 Cold Start-up

To perform a Cold Start-up, press the [F1] and [F2] buttons

simultaneously for 10 seconds after a power up.

5.3 Communications in Progress

5.3.1 Data Reception

During data reception, the on-line LED will turn on. The

DRL2000 decodes all information received and stores the

information in its Event Buffer. When a valid signal is

received, the DRL2000 sends a kiss-off signal and transmits the decoded alarm signal to the computer and then

to the printer through the CPM2000.

The DRL2000 will send each message it receives to the

printer for review by the system operator. Two messages

may be sent to the printer to indicate reception problems:

the 'Fault Data' and 'Fault Call'.

5.3.2 Fault Data Message

When this problem is encountered, the following information is transmitted to the printer and the computer:

•Printer:

Jun 25 1998-11:18:07-SS/OO-SG-12-234-0000INVALID REPORT

• Computer: 012234[#0000¦NYNSSOO][DC4]

This output for account code '0000' indicates that data

has been received, but is not valid (for example, there are

unmatched rounds or wrong parity).

5.3.3 Fault Call

When this problem is encountered, the following information is transmitted to the printer and the computer:

•Printer:

Jun 25 1998-11:18:07-SS/OO-SG-12-234-0000COMMUNICATION FAIL

• Computer: 0RRLLL[#0000¦NYCSSOO] [DC4]

This output indicates that a call was received, but no data

was detected. The call may have been a wrong number,

or the calling control panel was unable to connect with

the receiver's handshakes.

5.3.4 Caller ID

When Caller-ID is enabled:

•Printer:

19-Nov-1998 10:40:54 - Nov 19 1998-11:32:25- F3/

00-SG -19-069-123F—

• Computer: 419069 123F0000000000

5.3.5 Calling Name

When Calling name is enabled:

• Computer: u19069 123FSUR-GARD SECURT

•Printer:

19-Nov-1998 10:40:56 - Nov 19 1998-11:32:25-F3/00SG -19-069-123F—SUR-GARD SECURT

12

Loading...

Loading...