SUPREME SUP18-A240V12, SUP20-A240V12, SUP23-A240V12, SUP25-A240V12, SUP20-A240V20 Installation Instructions And Homeowner's Manual

...

Models

Caution

: Do not tamper with

ADVANTAGE

(ECM MOTOR)

:

SUPXX-A240V12

SUPXX-A240V20

INSTALLER / SERVICE TECHNICIAN:

USE THE INFORMATION IN THIS MANUAL FOR THE INSTALLATION AND

SERVICING OF THE FURNACE AND KEEP THE DOCUMENT NEAR THE UNIT

FOR FUTURE REFERENCE.

HOMEOWNER:

PLEASE KEEP THIS MANUAL NEAR THE FURNACE FOR FUTURE

REFERENCE.

Printed in Canada

Printed on 100% recycled paper

the unit or its controls. Call a

2015-03-25

qualified service technician.

Manufactured by:

Industries Dettson inc.

3400 Industrial Boulevard

Sherbrooke, Quebec - Canada

J1L 1V8

X40233 Rev. A

TABLE OF CONTENT

1- SAFETY .......................................................... 3

1.1- DANGER, WARNING AND CAUTION ................. 3

1.2- IMPORTANT INFORMATION .............................. 3

1.3- DANGER OF FREEZING ..................................... 3

2- INSTALLATION .............................................. 3

2.1- POSITIONING THE FURNACE ............................ 4

2.2- CLEARANCES TO COMBUSTIBLE MATERIAL 4

2.2.1- Heating unit ................................................................. 4

2.2.2- Supply air ducts .......................................................... 4

2.3- CONFIGURATIONS.............................................. 4

2.3.1- Upflow installation ...................................................... 4

2.3.2- Downflow installation ................................................. 4

2.3.3- Horizontal installation ................................................ 4

2.4- ELECTRICAL SYSTEM ........................................ 4

2.4.1- Conversion from two to one supply wires for model

over 27kW ................................................................................... 5

2.5- INSTALLATION OF THE THERMOSTAT ........... 5

2.5.1- Anticipator adjustment (if required) on thermostat

equipped with heat anticipator adjustment ............................. 6

2.5.2- Ducts and filters .......................................................... 6

2.6- SUPPLY AIR ADJUSTMENTS ............................. 6

2.6.1- HEAT KW/CFM adjustment ........................................ 6

2.6.2- AC/HP size ................................................................... 7

2.6.3- System type ................................................................. 7

2.6.4- AC/HP CFM adjust ...................................................... 7

2.6.5- ON/OFF delay .............................................................. 7

2.6.6- Continuous fan ............................................................ 7

2.6.7- Low-voltage circuit ..................................................... 7

2.6.8- Basic furnace configuration....................................... 7

2.7- INSTALLATION OF ACCESSORIES................... 8

2.7.1- Humidifier and humidistat connection ...................... 8

2.1.1. Electronic Air Cleaner (EAC) connections ............... 8

2.7.2- Dehumidify capability with standard humidistat

connection ................................................................................. 8

2.7.3- Use of a heat pump ..................................................... 8

3- OPERATION ................................................... 8

3.1- START-UP ............................................................ 8

3.2- USE OF MANUAL FURNACE CONTROLS ........ 8

3.3- OPERATING SEQUENCE .................................... 9

3.3.1- Continuous fan ............................................................ 9

3.3.2- Cooling mode – single stage ..................................... 9

3.3.3- Cooling mode – two stage.......................................... 9

3.3.4- Cooling mode – dehumidification ............................. 9

3.3.5- Electric heat heating mode – 1 stage ........................ 9

3.3.6- Electric heat heating mode – 2 stage ......................... 9

3.3.7- Heat pump heating mode – single stage ................... 9

3.3.8- Heat pump heating mode – two stage ....................... 9

3.4- AIRFLOW VERIFICATION................................... 9

3.4.1- Supply Air Temperature Rise Test ........................... 10

3.4.2- High limit verification ................................................ 10

4- MAINTENANCE ............................................ 10

4.1- AIR FILTER ........................................................ 10

4.2- MOTOR LUBRICATION ..................................... 10

5- FURNACE INFORMATION ........................... 11

Table 1: Sequence of operation ......................................... 12

Table 2: Technical specifications ........................................ 13

Table 3: Electric furnace SUP, ECM ½ HP motor, air flow

tables .................................................................................. 14

Table 4: Electric furnace SUP, ECM 1.0 HP motor, air flow

tables .................................................................................. 15

Table 5: Parts list, S

TABLES

UPREME

Advantage ECM .................... 19

FIGURES

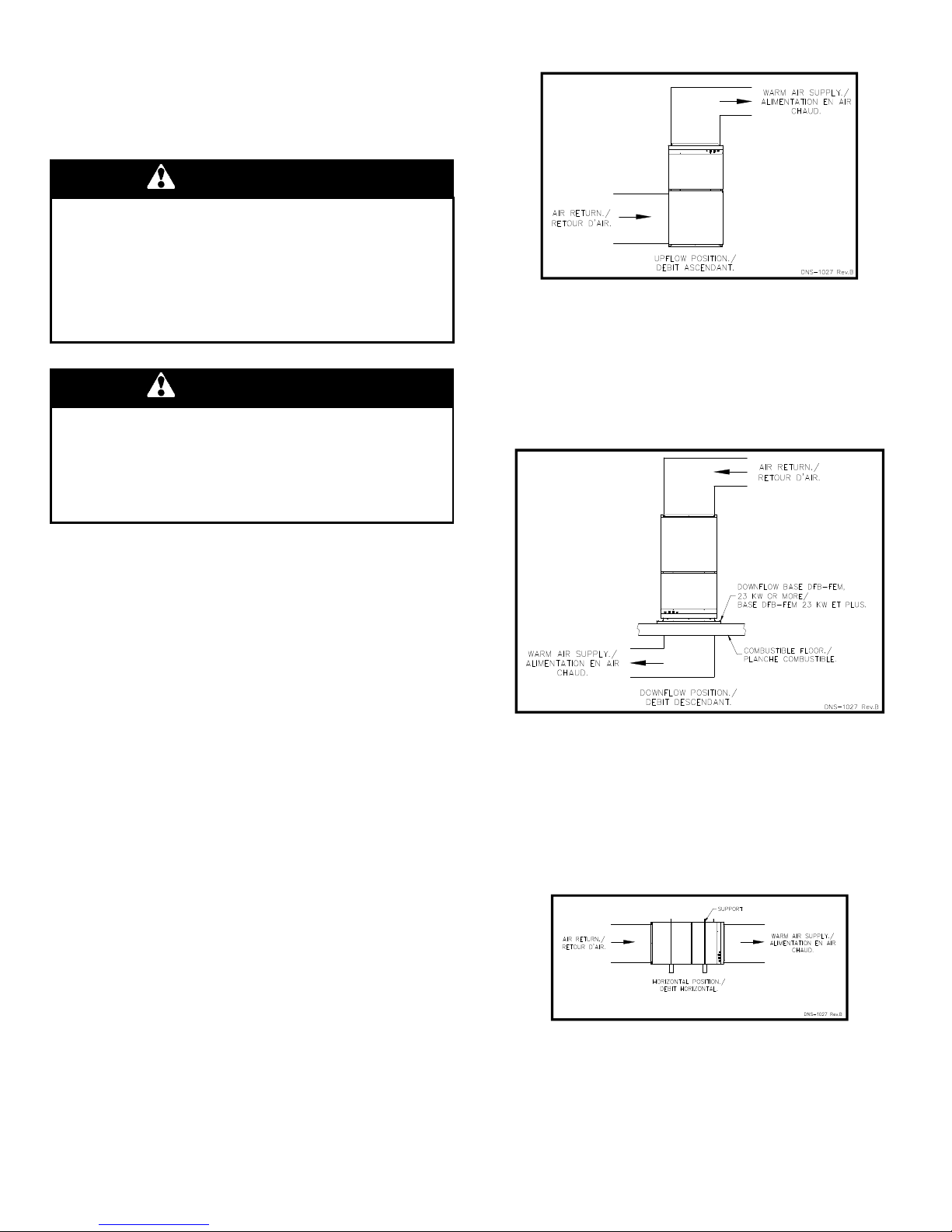

Figure 1: Upflow installation .................................................. 4

Figure 2: Downflow installation .............................................. 4

Figure 3: Horizontal installation ............................................. 4

Figure 4 : Conversion from two to one supply wires ............. 5

Figure 5: 1-stage thermostat, electric heating only ............... 5

Figure 6: 2-stage thermostat, electric heating only ............... 5

Figure 7: 1 stage thermostat, electric heat and cooling

application .............................................................................. 5

Figure 8: 2-stage heating & 1-stage air conditioning & heat

pump thermostat .................................................................... 6

Figure 9: 2-stage heating & 2-stage air conditioning & heat

pump thermostat + dehumidification mode ........................... 6

Figure 10 : Fan Control Board ............................................... 6

Figure 11 : Standard humidistat connections ........................ 8

Figure 12 : Thermostat connections ...................................... 8

Figure 12 : Electronic air cleaner connections ...................... 8

Figure 10 : Advantage furnace controls................................. 9

Figure 15 : Furnace dimensions .......................................... 16

Figure 16 : Electrical diagram S

Figure 17: Parts list, S

UPREME

UPREME

Advantage ECM.................. 18

Advantage ECM ... 17

2

1- SAFETY

1.1- DANGER, WARNING AND CAUTION

The words DANGER, WARNING and CAUTION are used to

identify the levels of seriousness of certain hazards. It is

important that you understand their meaning. You will notice

these words in the manual as follows:

DANGER

Immediate hazards which WILL result in death or serious

bodily and/or material damage.

WARNING

Hazards or unsafe practices which CAN result in death or

serious bodily and /or material damage.

CAUTION

Hazards or unsafe practices which CAN result in minor

bodily and /or material damage.

d. Never block or otherwise obstruct the filter and/or

return air openings;

e. Ask the technician installing your furnace to show and

explain to you the following items:

i. The main disconnect switch or circuit breaker;

ii. The air filter and how to change it (check monthly

and clean or replace if necessary);

f. Before calling for service, be sure to have the

information of section 5 of your manual close by in

order to be able to provide the contractor with the

required information, such as the model and serial

numbers of the furnace.

IMPORTANT:

All local and national code requirements

governing the installation of central electric heating equipment,

wiring and the flue connection MUST be followed. Some of the

codes that may apply are:

ANSI/NFPA 70: National Electrical Code

CSA C22.1 or CSA C22.10: Canadian Electrical Code

Only the latest issues of these codes may be used, and are

available from either:

The National Fire Protection Agency

1 Batterymarch Park

Quincy, MA 02269

1.2- IMPORTANT INFORMATION

WARNING

Non-observance of the safety regulations outlined in this

manual will potentially lead to consequences resulting in

death, serious bodily injury and/or property damage.

WARNING

Installation and repairs performed by unqualified persons

can result in hazards to them and to others. Installations

must conform to local codes or, in the absence of such

codes, to codes of the country having jurisdiction.

The information contained in this manual is intended for

use by a qualified technician, familiar with safety

procedures and who is equipped with the proper tools and

test instruments.

Failure to carefully read and follow all instructions in this

manual can result in death, bodily injury and/or property

damage.

a. It is the homeowner’s responsibility to engage a

qualified technician for the installation and subsequent

servicing of this furnace;

b. Do not use this furnace if any part of it was under water.

Call a qualified service technician immediately to

assess the damage and to replace all critical parts that

were in contact with water;

c. Do not store gasoline or any other flammable

substances, such as paper or carton near the furnace;

or

The Canadian Standards Association

178 Rexdale Blvd.

Rexdale, Ontario M9W 1R3

1.3- DANGER OF FREEZING

CAUTION

If your furnace is shut down during the cold weather

season, water pipes may freeze, burst and cause serious

water damage. Turn off the water supply and bleed the

pipes.

If the heater is left unattended during the cold weather season,

take the following precautions:

a. Close the main water valve in the house and purge the

pipes if possible. Open all the faucets in the house;

b. Ask someone to frequently check the house during the cold

weather season to make sure that there is sufficient heat to

prevent the pipes from freezing. Tell this person to call an

emergency number if required.

2- INSTALLATION

This furnace is a true multi-position unit, in that it will function in

an upflow, downflow or horizontal configuration to the left or the

right. Only a few modifications are required during installation

to change from one position to another. The unit is shipped in

the upflow configuration and instructions as to how to change to

the other positions are included in this manual.

3

The unit requires a 120/240 - 208 VAC power supply to the

control panel, thermostat hook-up as shown on the wiring

diagram.

2.1- POSITIONING THE FURNACE

WARNING

Fire and explosion hazard.

The furnace must be installed in a level position, never

where it will slope toward the front.

Do not store or use gasoline or any other flammable

substances near the furnace.

Non-observance of these instructions will potentially result

in death, bodily injury and/or property damage.

CAUTION

This furnace is not watertight and is not designed for

outdoor installation. It must be installed in such a manner

as to protect its electrical components from water. Outdoor

installation will lead to a hazardous electrical condition and

to premature failure of the equipment.

Figure 1: Upflow installation

2.3.2- Downflow installation

The return duct may be installed to the back, on the left side, on

the right side or under the unit. The supply duct shall be installed

on the top of the unit.

When the furnace is installed in the downflow position on a

combustible floor. The downflow base DFB-SUP can be used.

Refer to Figure 2 and the installation instructions provided with

the base.

Figure 2: Downflow installation

If the furnace is installed in a basement or on a dirt floor, in a

crawl space for example, it is recommended to install the unit on

a cement base 2.5 cm to 5.0 cm (1’’ to 2’’) thick.

In addition, the heater should also be located close to the center

of the air distribution system.

2.2- CLEARANCES TO COMBUSTIBLE MATERIAL

2.2.1- Heating unit

The furnace is approved for zero clearance to combustible

material regardless of the heating capacity.

2.2.2- Supply air ducts

Ducts can be installed with a zero clearance to combustible

material.

2.3- CONFIGURATIONS

This furnace requires suitable ductwork.

2.3.1- Upflow installation

The return duct may be installed to the back, to the bottom, on

the left side, or on the right side of the unit. The supply duct shall

be installed on the top of the unit. Care should be taken not to

damage the wires inside while cutting the opening. Install the

filter rack supplied with the unit according to the instructions

provided with it. It is also recommended to install the blower

door before handling or moving the unit. Refer to Figure 1 for

additional details.

2.3.3- Horizontal installation

The return duct may be installed to the back, on the left side, on

the right side or under the unit. The supply duct shall be installed

on the top of the unit.

When the furnace is installed in the horizontal position, either

suspended or on a combustible floor with a choice of right or left

discharge, the clearances from combustible material must be

adhered to. Refer to Figure 3 for additional details.

Figure 3: Horizontal installation

2.4- ELECTRICAL SYSTEM

The S

UPREME

furnace is completely pre-wired and all field wiring

must be connected to the terminal blocks on the unit. It requires

a 120/240 - 208 volt.

4

WARNING

Risk of fire.

The conductor sizing must conform to the last edition of the

local or national codes.

Failure to follow this rule can result in death, bodily injury

and/or property damage.

Power supply to the unit can be done using copper or aluminum

wires. The wire size must be decided in accordance to the unit

power consumption, the over current protection type and

capacity, the wire type and length, and the environment where

the unit is installed. If an aluminum wire is used, other

precautions must be taken to insure the conformity of the

installation. In all cases, all the factors affecting the wire gauge

must be considered and the installation codes followed.

The exterior of the unit must have an uninterrupted ground to

minimize the risk of bodily harm. A ground terminal is supplied

with the control box for that purpose. A connector is supplied on

the ground terminal to ground an added accessory.

In the event that wires inside the unit require replacement, these

must be copper wires only with same temperature rating and

sizes as originals.

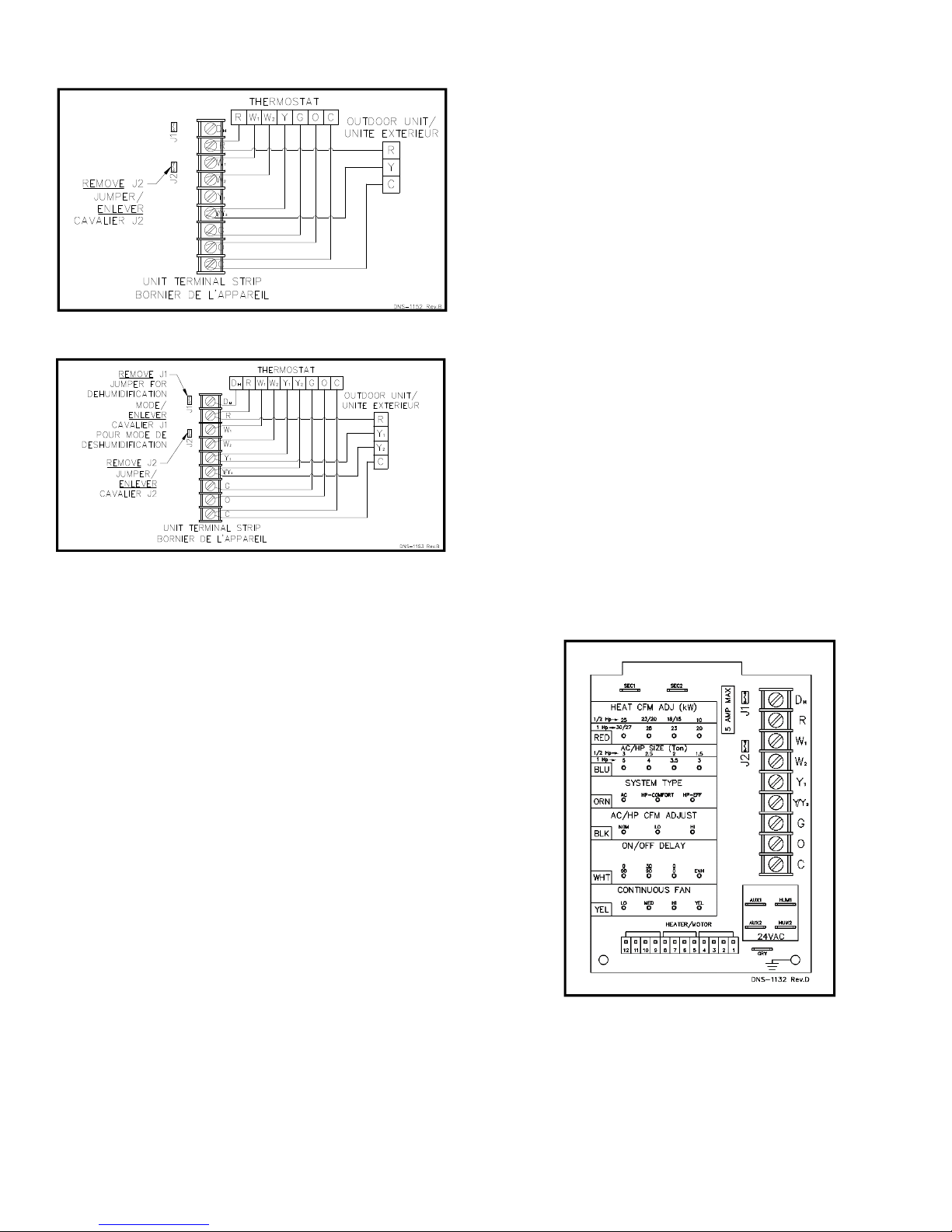

2.5- INSTALLATION OF THE THERMOSTAT

A thermostat must be installed to control the temperature of the

area to be heated. Follow the instructions supplied with the

thermostat. Some thermostats need to connect the C terminal

on the furnace and thermostat. Install the thermostat on an

interior wall in a location where it will not be subject to direct

sunlight, lamps, air diffusers, fireplaces, etc. Seal openings in

walls to avoid air currents that may influence the operation of the

thermostat. Also refer to the wiring diagrams provided with the

heating/air conditioning unit. The connections must be made as

indicated on Figure 5 to Figure 9. Refer to the electrical diagram

(Figure 16

).

Figure 5: 1-stage thermostat, electric heating only

2.4.1- Conversion from two to one supply wires for

model over 27kW

Warning – When using one terminal block on models over

27kW, the installation must be performed with copper wire

ONLY in order to comply with the Canadian electrical code. The

usage of an aluminum or copper wire is acceptable on models

25kW and lower.

Move all wires from the two pole terminal to the three pole

terminal following the corresponding colors as shown in Figure

4.

The breaker and the supply conductors must be sized by adding

the ampacities of the two terminals indicated on the nameplate.

Refer to the electrical diagram Figure 16.

Figure 4 : Conversion from two to one supply wires

Before After

Figure 6: 2-stage thermostat, electric heating only

Figure 7: 1 stage thermostat, electric heat and cooling

application

5

Figure 8: 2-stage heating & 1-stage air conditioning & heat

pump thermostat

Figure 9: 2-stage heating & 2-stage air conditioning & heat

pump thermostat + dehumidification mode

2.5.1- Anticipator adjustment (if required) on thermostat

equipped with heat anticipator adjustment

Some thermostats are equipped with a heat anticipator that must

be adjusted according to the instructions supplied. This is to

ensure that the heating mode is comfortable and economical.

Generally speaking, on a single stage thermostat, a reading of

the current must be taken with an ammeter as follows:

1. Move the anticipator to its highest setting, rendering it

ineffective.

2. Remove the wire from the W1 terminal and connect an

ammeter between the terminal and the wire.

3. Call for heat by raising the set point on the thermostat and

allow the furnace to run for 3 to 4 minutes to reach its peak

output.

4. Once the current has stabilized, a reading should be taken

and the anticipator adjusted to that value. If longer heating

cycles are desired, the anticipator can be set to a higher

value

b. Cover the vertical sections of the supply and return air duct

with soundproofing material;

c. Use baffles in short radius elbows;

d. Use flexible hangers to suspend the ducts.

The S

UPREME

blower compartment. It must be installed on the outside of one

of the three sides or the bottom of the furnace. Once the location

of the installation has been determined, use the four square

knockouts for ease of cutting the opening.

A heat pump or an air conditioner can be added to this furnace,

in either the supply or return air duct. Carefully follow the

instructions provided with these appliances to ensure proper

installation and hook-up to the electric furnace. Refrigerant and

drainage pipes must in no way hinder access to the furnace

panels.

furnace is equipped with a filter frame for the

2.6- SUPPLY AIR ADJUSTMENTS

Fan Control Board taps are used by the installer to configure a

system. The ECM motor uses the selected taps to modify its

operation to a pre-programmed table of airflows (Refer to Table

3 and Table 4). Airflows are based on system size or mode of

operation and those airflows are modified in response to

thermostat inputs.

SUP electric furnace must be configured to operate properly with

system components with which it is installed. To successfully

configure a basic system (see information printed on circuit

board label located next to select pins), move the 6 select wires

to the pins which match the components used. (Refer to Figure

10 below)

Figure 10 : Fan Control Board

2.5.2- Ducts and filters

The ducts must be sized such a way as to accommodate the

specified airflow and the available static pressure. Refer to the

applicable local and/or national installation codes.

Insulate the ducts that lead through non-heated areas. Use

flexible supply and return air connectors to avoid the

transmission of vibration. To make the unit run even quieter, the

installer should:

a. Use two elbows between each outlet and the supply and

return air plenum;

2.6.1- HEAT KW/CFM adjustment

Installer must verify (factory set) the electric heat airflow

adjustment required for kW size heater installed.

The select pins are marked 25, 23/20, 18/15, 10 (for ½ HP ECM

motor unit) and 30/27, 25, 23, 20, (for 1.0 HP ECM motor unit).

6

Loading...

Loading...