Page 1

1

User Manual S200 Open

Update April 2018

S200 Open

User Manual

Page 2

2

User Manual S200 Open

Update April 2018

AQUALABO

Registered office:

AQUALABO - 90 rue du Professeur Paul MILLIEZ - 94500 CHAMPIGNY SUR MARNE –

FRANCE

PLC with capital of 1,492,900 Euros – SIRET (Business registration number) 499 665 230

00011- RCS (Trade & Corporate Register) Créteil – NAF (Business subsector ID number)

2651B - Intra-Community VAT: FR 91 499665230

www.aqualabo.fr Hotline: +33 (0)5.62.75.95.70

E-mail: info@aqualabo.fr

Website: www.aqualabo.fr

Subject to technical amendments. Errors and omissions excepted.

Page 3

3

User Manual S200 Open

Update April 2018

Contents

1 General information ................................................................................................................. 7

1.1 General overview .............................................................................................................. 7

1.2 Notes in bold print ............................................................................................................. 7

1.3 Warranty ........................................................................................................................... 7

1.4 Electrical connection ......................................................................................................... 8

1.5 Safety Instructions ............................................................................................................. 8

1.6 Damage due to transport ................................................................................................... 8

2 Technical data ......................................................................................................................... 9

2.1 General overview .............................................................................................................. 9

2.2 Variable measurements .................................................................................................. 10

3 Description ............................................................................................................................ 11

4 Operation .............................................................................................................................. 12

4.1 Controls .......................................................................................................................... 12

4.2 Display ............................................................................................................................ 13

4.2.1 Graphic symbol ......................................................................................................... 13

4.2.2 General menu: .......................................................................................................... 14

4.2.3 Example of access to a sub-menu, selection of "Temperature Compensation” menu15

5 Installation ............................................................................................................................. 17

5.1 Assignment of terminals .................................................................................................. 17

5.1.1 Assignment of pins .................................................................................................... 17

6 Access and display ................................................................................................................ 19

6.1 How to use menus .......................................................................................................... 19

6.1.1 Codes ....................................................................................................................... 19

6.2 LCD display adjustments ................................................................................................. 19

6.2.1 Contrast adjustment .................................................................................................. 19

6.2.2 Adjusting the backlight .............................................................................................. 20

6.3 Display - Loss of communication ..................................................................................... 20

7 Use of measurements provided by a Modbus RS485 sensor ................................................ 21

7.1 OPTOD digital optical sensor for measuring dissolved oxygen ........................................ 21

7.1.1 Reminder of connection to the terminal: .................................................................... 21

7.1.2 Setting / configuring of displayed measurements ...................................................... 21

7.1.3 Sensor information .................................................................................................... 23

Page 4

4

User Manual S200 Open

Update April 2018

7.1.4 Oxygen measurement configuration .......................................................................... 24

7.1.5 Calibration methods .................................................................................................. 25

7.1.6 One-point calibration sequence ................................................................................. 26

7.1.7 Two-point calibration ................................................................................................. 26

7.1.8 Calibration of zero point – detailed procedure ........................................................... 27

7.1.9 Calibration of the final point - detailed procedure ...................................................... 28

7.1.10 Error calibration – message .................................................................................... 29

7.2 Digital sensor for measuring nephelometric turbidity ....................................................... 30

7.2.1 General information about the turbidity probe ........................................................... 30

7.2.2 Setting / configuring of displayed measurements ...................................................... 31

7.2.3 Sensor information .................................................................................................... 33

7.2.4 Configuration of the nephelometric turbidity measurement ........................................ 33

7.2.5 Method for calibrating nephelometric turbidity ........................................................... 34

8 Controller adjustments .......................................................................................................... 37

8.1 Allocation of controller values .......................................................................................... 37

8.2 Controller action direction ................................................................................................ 37

8.3 Assignment of controller output ....................................................................................... 37

8.4 Pulse frequency .............................................................................................................. 38

8.5 Checking the pulse frequency ......................................................................................... 38

8.6 Minimum pulse ................................................................................................................ 39

8.7 Controller parameter settings .......................................................................................... 39

8.7.1 Standard point adjustment ........................................................................................ 40

8.7.2 Proportional band (P band) ....................................................................................... 40

8.7.3 Integral action time (integral gain) ............................................................................. 40

8.7.4 Hysteresis ................................................................................................................. 40

8.7.5 Max./min. limit value ................................................................................................. 41

8.7.6 Alarm period ............................................................................................................. 41

8.7.7 Dosage monitoring .................................................................................................... 41

8.8 Manual operating mode ................................................................................................... 41

8.8.1 Manual controller mode ............................................................................................. 41

8.8.2 Automatic controller mode ........................................................................................ 42

8.9 Date and time .................................................................................................................. 42

8.10 Analog outputs .............................................................................................................. 42

Page 5

5

User Manual S200 Open

Update April 2018

8.10.1 Assignment of measured values ............................................................................. 43

8.10.2 Definition of current active range ............................................................................. 43

8.10.3 Setting the range ..................................................................................................... 43

8.11 Power on delay ............................................................................................................. 44

8.12 Service menu ................................................................................................................ 44

8.12.1 Device data ............................................................................................................. 44

8.12.2 Analog inputs .......................................................................................................... 44

8.12.3 Measurement from a digital sensor ......................................................................... 44

8.12.4 Deleting data / return to factory settings .................................................................. 45

8.13 Languages .................................................................................................................... 45

9 Initial commissioning ............................................................................................................. 46

9.1 Checking the hardware installation .................................................................................. 46

9.2 Basic settings of the equipment ....................................................................................... 46

10 Maintenance and servicing .................................................................................................. 47

10.1 General overview .......................................................................................................... 47

10.2 Cleaning and calibration of probes ................................................................................ 47

11 Alarm messages.................................................................................................................. 48

11.1 List of error messages ................................................................................................... 48

12 MODBUS RTU .................................................................................................................... 49

12.1 Shielding ....................................................................................................................... 49

12.2 Communication parameters .......................................................................................... 49

12.3 MODBUS functions used .............................................................................................. 49

12.4 MODBUS S200 registry list ........................................................................................... 50

13 Sensor - Actuator bus (MODBUS RTU) ............................................................................... 51

13.1 Shielding ....................................................................................................................... 51

13.2 Communication parameters .......................................................................................... 51

14 Appendix ............................................................................................................................. 52

14.1 What to do in the event of a power failure ..................................................................... 52

14.2 Battery .......................................................................................................................... 52

15 Spare parts and wear parts ................................................................................................. 53

15.1 Wear parts .................................................................................................................... 53

16 Electrical connection ........................................................................................................... 54

16.1 Assignment of terminals ................................................................................................ 54

Page 6

6

User Manual S200 Open

Update April 2018

17 Hotline-Aftersales Service contact details ............................................................................ 56

Page 7

7

User Manual S200 Open

Update April 2018

1 General information

1.1 General overview

This technical manual contains instructions for installing, commissioning, maintaining and

repairing the S200 Open measurement and monitoring device.

Please follow the safety instructions and notes in bold print at all times!

1.2 Notes in bold print

Titles in bold print, alerts and warnings have the following meaning, in this technical

manual:

Important:

This alert is used in the event of non-compliance with functional or operating

instructions, or when the recommended procedures or misinterpretation of these

instructions may cause an accident or injury.

Warning:

This entry is used in the event of non-compliance with functional or operating

instructions, or when the recommended procedures or misinterpretation of these

instructions may damage the equipment.

Note:

This section is used to highlight key points.

1.3 Warranty

The manufacturer shall ensure the operational safety and reliability of the system when, and

only when, the following conditions have been met:

- Installation, connection, adjustment, maintenance and repairs are carried out exclusively

by qualified and authorized expert staff.

- Only original spare parts are used for repairs.

- The measuring and monitoring device shall be used in accordance with the information

and instructions set out in this manual.

Warning:

The warranty shall not apply if the device is not used as intended.

Note:

Wear parts are not under warranty (see table at end of manual).

Page 8

8

User Manual S200 Open

Update April 2018

1.4 Electrical connection

Warning:

Only use the power supply specified on the nameplate to run the S200 measurement and

monitoring device!

The device is delivered to run, by default, on a 230V/50Hz or 110V/50Hz power supply.

1.5 Safety Instructions

S200 Open measuring and monitoring devices are manufactured and tested according to

standards DIN EN 61010-1 / VDE 0411-1. This device left the factory in good condition. In

order to maintain this condition, and to ensure the safety during use, the user must comply

with the information and warnings given in this manual. If it is suspected that operating in total

safety is no longer possible, we recommend that you turn off the device and disable it to

prevent any accidental operation.

Follow these instructions:

- if the system shows visible signs of deterioration

- if the system is apparently no longer operational

- after an extended period of storage under poor conditions.

1.6 Damage due to transport

We carefully pack the S200 Open measuring and monitoring devices for transport. Please

check that the content of the delivery is complete and in good condition. Any damage due to

transport must be reported immediately (carrier).

The device must never be exposed to temperatures outside the range of -20 to +70°C

(transport and intermediate storage).

Subject to technical amendments. Subject to changing the assembly of components.

Page 9

9

User Manual S200 Open

Update April 2018

2 Technical data

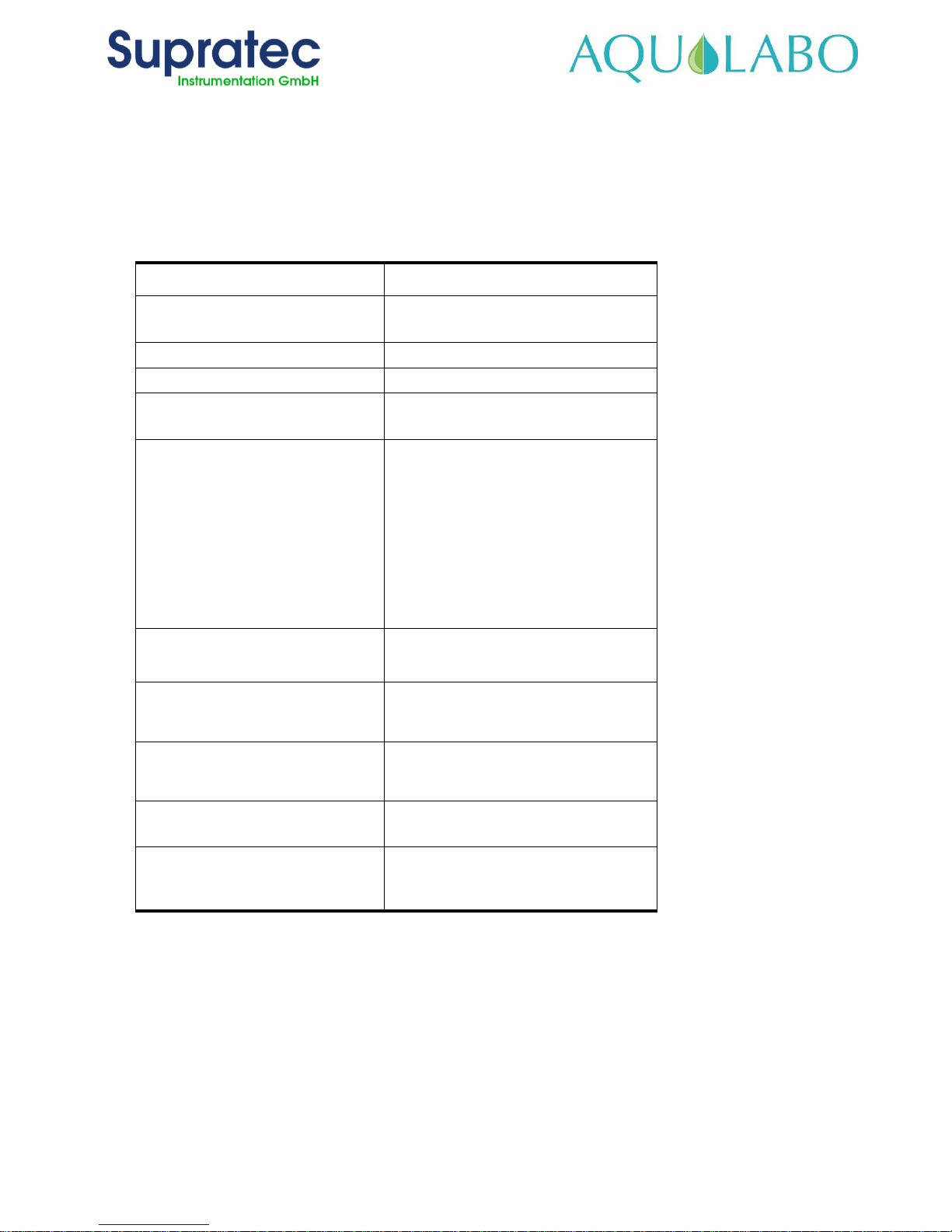

2.1 General overview

Article

Adjustment ranges

Power supply unit

230 V/AC ± 10 % (50/60Hz)

117 V/AC ± 10 % (50/60Hz)

Power consumption

16 VA

Level of protection

IP 65

Fuse (device)

80 mAT (230V)

160 mAT (117V)

Electrical properties of the

contact relay

Max. direct current/max. startup current

Rated voltage/max. switching

voltage

Max AC switching capability

to direct current

6A/16A

250VAC, 24VDC

6A

6A

Operating temperature

-20° to 50°C

Permissible storage temperature

-20°C to +65°C

Permissible humidity

Max. 90% to +40°C (noncondensing)

Device dimensions

166 x 161 x 73.5 mm (l x h x d)

Weight

Approx. 1.1 kg

Warning:

Unit fuse of 16A max.

Page 10

10

User Manual S200 Open

Update April 2018

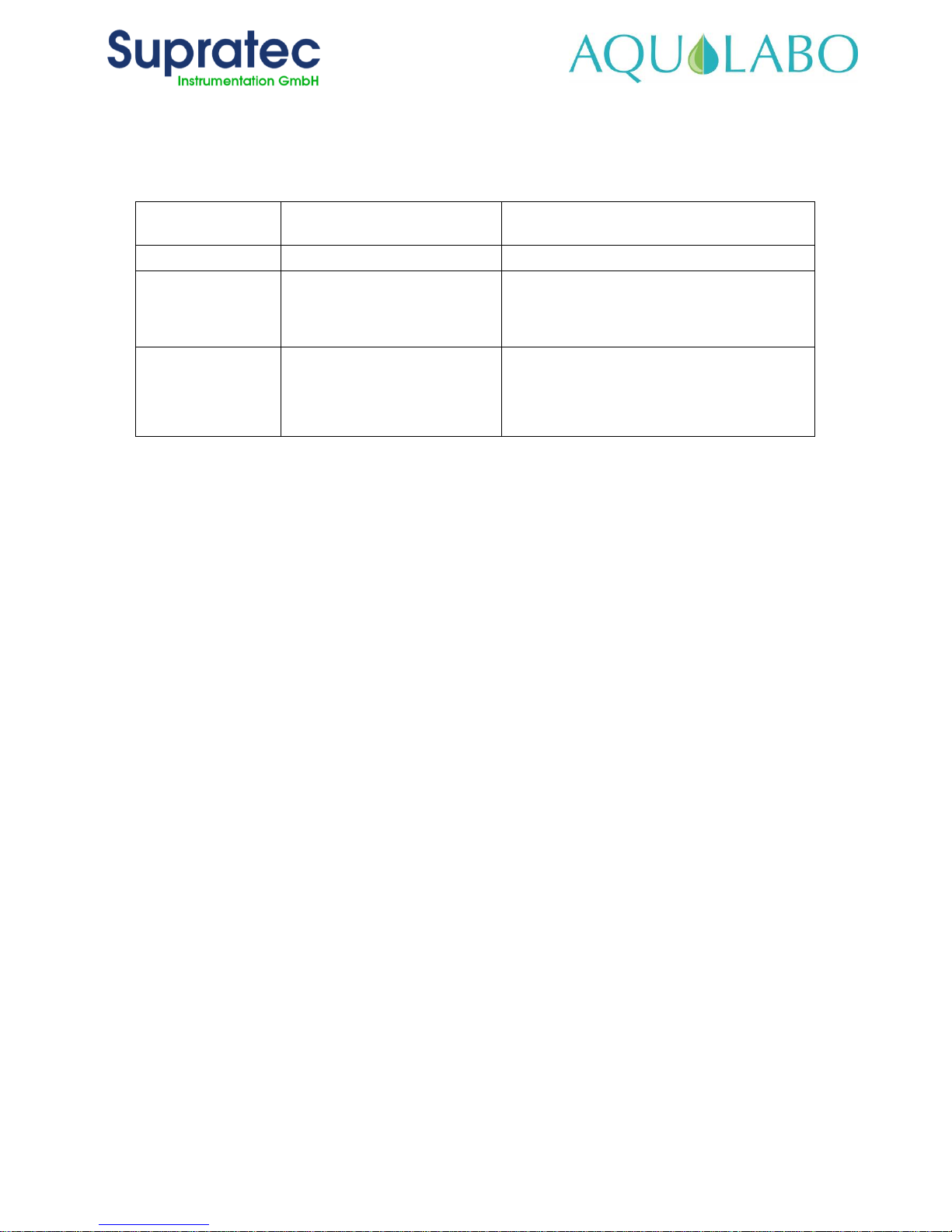

2.2 Variable measurements

Measured

variable

Measuring and

monitoring tools

Resolution

Input current:

0/4 to 20 mA

Charge of 0.01 mA / 50 Ω

Oxygen

0.00 mg/l to 20.00 mg/l

0% to 200%

ModBus digital sensor:

0.1 mg/l and 1%.

Turbidity

0.00 to 50.00 NTU

0.0 to 200.0 NTU

0 to 1,000 NTU

0 to 4,000 NTU

ModBus digital sensor from

0.01 to 1 NTU.

Page 11

11

User Manual S200 Open

Update April 2018

3 Description

The S200 Open measuring and monitoring device is easy to use.

Equipment:

• Backlit display

• Cursor-controlled operation with only 5 keys

• Browser menu in plain text

• Up to 6 different settings simultaneously (depending on the type of code)

• Password protected access

• Ease of integration into process technology via the existing Modbus RTU

• Connection for digital probes, including power supply

• 2 digital outputs for controlling frequency metering pumps

• 3 relay outputs

• 2 digital inputs, switching input or frequency input

• 2 electrically insulated ModBus RTU interfaces

• 2 electrically insulated 0/4 - 20mA outputs

• Up to 4 adjustable individual PI controls (depending on the type of code)

• Retroactive control via an additional 0/4-20 mA analog input

• Real-time clock with backup battery

• Additional housing for sensors

Page 12

12

User Manual S200 Open

Update April 2018

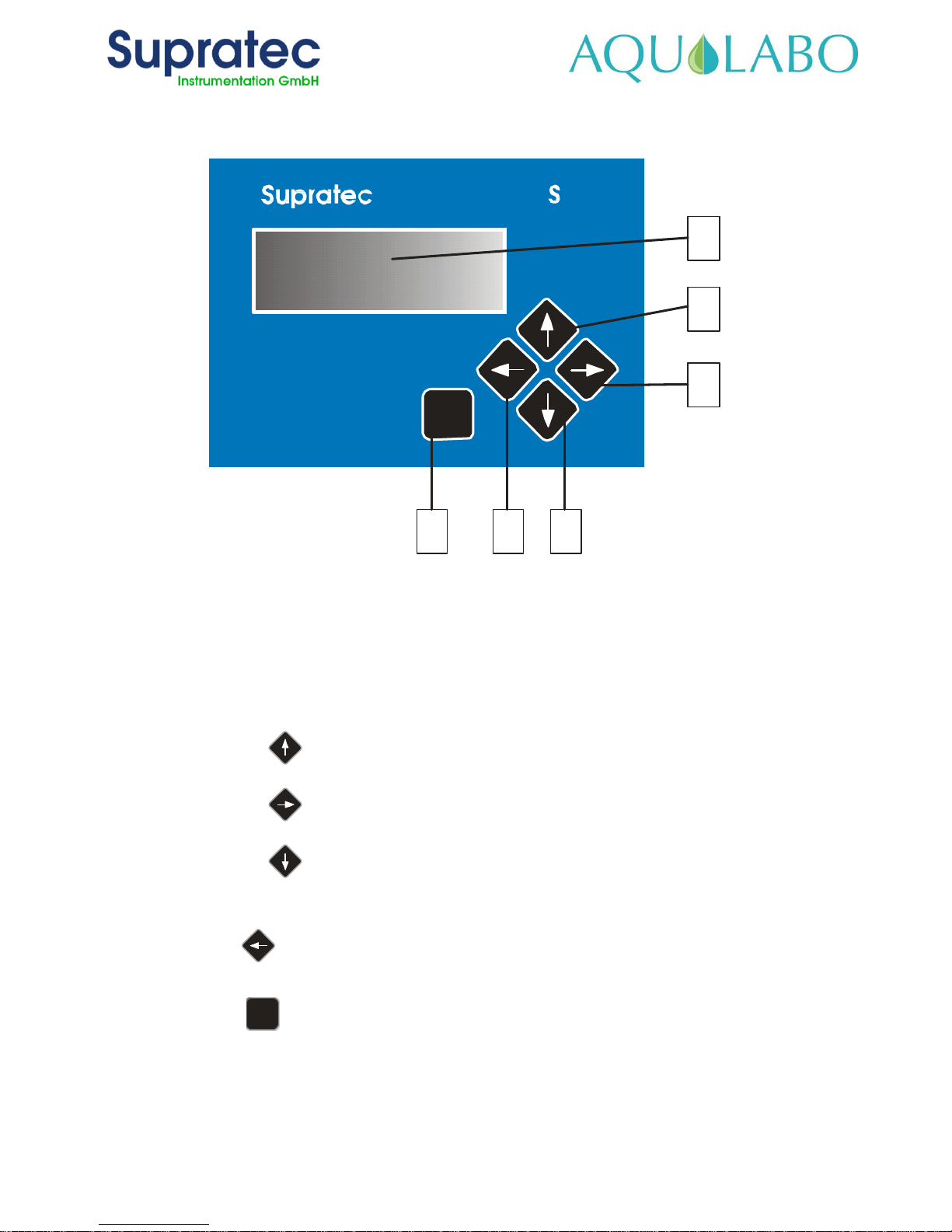

4 Operation

4.1 Controls

(1) Display Backlit LCD screen with 4 lines of 20 characters each

(2) Key Cursor control/Numerical value increase

(3) Key Choice confirmation/Function change

(4) Key Cursor control/Numerical value decrease Choice of operating menu

(5) Key Value backup/Return to level 1 menu

(6) Key Cancel input without saving/Return to the home screen.

6

1

5 4

3

2

200

ESC

Page 13

13

User Manual S200 Open

Update April 2018

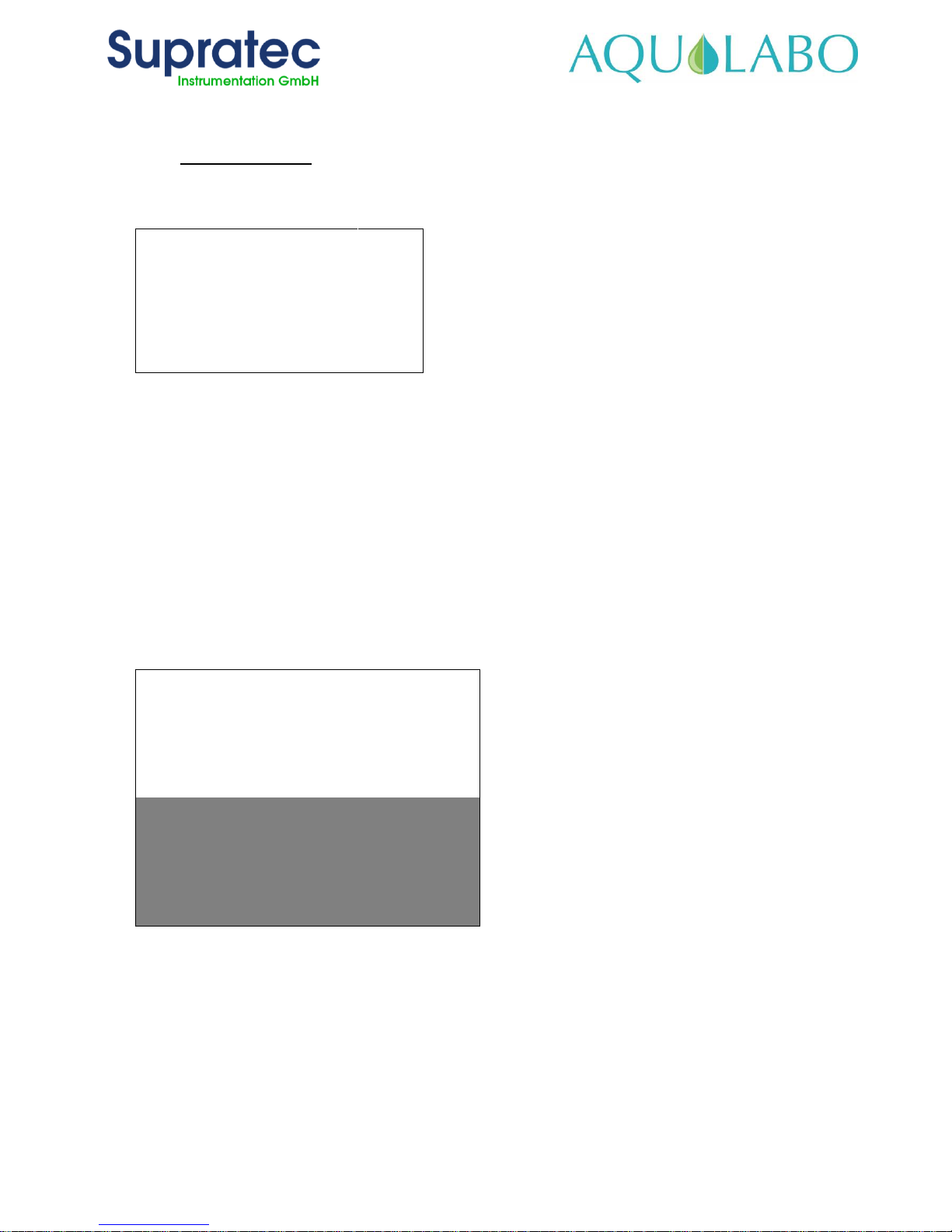

4.2 Display

4.2.1 Graphic symbol

4.2.1.1 Main screen for visualization of measurements and related units:

02

7.89

mg/l

pH

7.82

pH

°C

29.3

°C

↓

Man→

Note:

The example display may differ depending on the device's configuration.

The displayed graphic symbols indicate which keys are available to operate the device.

↓ This indicates that you can switch to the operating level using the appropriate key.

→ This indicates that the command function switches from manual to automatic by

pressing the key.

4.2.1.2 Visualization:

↕→

Calibration

Temp. Compens./

Controller setting

Manual mode

Time / date

Basic settings

Service

Enter the code

Grey area area of the menu not visible on the 4-line screen.

Note:

Grey area of the menu not visible on the 4-line screen.

↕ Indicates that the cursor can be moved up or down using the cursor keys.

→ The additional arrow on the right indicates that a sub-menu or input of numeric values can

be selected.

Page 14

14

User Manual S200 Open

Update April 2018

Note:

In the instructions for use, the following line appears above the menu window, as

follows:

/Service/LCD Display/

This line enables users to easily find this menu item in the device.

/Service/LCD Display/: This means that the selected sub-menu is "Service”.

/Service/LCD Display/: This means that an additional sub-menu has been selected.

4.2.2 General menu:

From the main screen (real-time display of measurements), the DOWN arrow gives access to

the General menu. The list of items accessible from the General menu is as follows:

↕→

Calibration

Temp. Compens./

Controller setting

Manual mode

Time / date

Basic settings

Service

Page 15

15

User Manual S200 Open

Update April 2018

4.2.3 Example of access to a sub-menu, selection of "Temperature Compensation ”

menu

Calibration

↕→

Temp. Compens./

Controller setting

Manual mode

…

Use the key to select the "temperature compensation” sub-menu.

↕→

Temp. Compens./

Manual Comp.

Default temp.

25.0°C

Use the key to switch the temperature compensation mode from automatic to

manual. If the temperature is compensated automatically, Pt100 / Pt1000 is used.

↕→

Temp. Compens./

Automat. Comp.

Default temp.

25.0°C

Use the … key to select the settings input.

Page 16

16

User Manual S200 Open

Update April 2018

Temp. Compens./

Automat. Comp.

Default temp.

←

25.0 ↕°C

↕ A flashing arrow indicates you are in input mode. Use the arrow keys - up or down - to

change the numeric value.

← This indicates that the cursor key - left arrow - is used to complete the input and the

value is saved.

Note:

The information entered can be canceled at any time by pressing the key.

The old value is retained.

ESC

Page 17

17

User Manual S200 Open

Update April 2018

5 Installation

5.1 Assignment of terminals

Option SD 1.Eing 1.dig Eing 2.dig Eing Rel. 1 Rel. 2 Rel. 3

10 11 12 13 1 2 20 21 22 23 24 25 80 81 82 83 84 85 L N PE

90 91 92 93 94 95 96 97 4 5 6 7 30 31 32 33 70 71 72 73 PE PE PE PE

2.RS485 1.RS485 2.Eing 3Eing Analog.Ausg Digit.Ausg.

Eing. = input Ausg. = output

5.1.1 Assignment of pins

Function

Terminals

Description

Power supply voltage

L/N/PE

230 V/AC ± 10 % (50/60 Hz)

PE distribution block

PE, PE, PE, PE

PE distributor

Digital input 1

20+21+22

Digital input 21/22 (contact

without potential)

Electronic contact, 12V power supply

voltage

20/-22

Digital input 2

23+24+25

Digital input 24/25 (contact

without potential)

Electronic contact, 12V power supply

voltage

+23/-25

Analog output 1

0 / 4-20 mA max. load 500Ω

30+31

-30/+31

Analog output 2

0 / 4-20 mA max. load 500Ω

32+33

-32/+33

Digital output 1

Max. load 200 mA / 30V

70+71

Digital output for electronic monitoring

Dosing pumps

Digital output 2

Max. load 200 mA / 30V

72+73

Digital output for electronic monitoring

Dosing pumps

Switching from output relay 1

80+81

Potential-free contact

Switching from output relay 2

82+83

Potential-free contact

Switching from output relay 3

84+85

Potential-free contact

Page 18

18

User Manual S200 Open

Update April 2018

Union

Terminals

Description

Modbus RS485 interface for

connecting digital probes

12VDC power supply voltage

90+91+92+93+94

90 = 0 V, 91 = +12 V,

92 = B, communication

93 = A, communication

Modbus RS485 interface

for communication with

the

95+96+97

95 = B

96 = A

Page 19

19

User Manual S200 Open

Update April 2018

6 Access and display

6.1 How to use menus

All settings are accessible via a menu. Changing a defined value (for example).

Note:

This manual includes all available menu items. Depending on the selected code (see

the specific “Codes” paragraph), all menu items cannot be displayed, and/or, all menu

items cannot be selected.

6.1.1 Codes

There are 3 access levels to provide access using codes that protect the device from

unauthorized operation.

A) Code A - 00: all entries are locked, except codes B, C and D

B) Code B - 15: user code

C) Code C - 55: maintenance code

D) Code D - NN: code for factory service

6.2 LCD display adjustments

6.2.1 Contrast adjustment

From the general menu, SERVICE sub-menu then, display setting:

■■■■■■□□□□□□□□□□

↕→

Contrast. adjust.

■■■■■■■■■■□□□□□□

Backlight

The contrast level of the LCD display can be adjusted.

Note:

It may not be possible to adjust the contrast too high or too low.

Please adjust the contrast as follows:

Press the key in, keep it in while pressing to increase contrast.

ESC

ESC

Page 20

20

User Manual S200 Open

Update April 2018

To decrease contrast, press the key while pressing

at the same time.

This function may need to be adjusted after a factory reset.

6.2.2 Adjusting the backlight

The intensity of the backlight can be changed using the "backlight” menu.

Note:

Backlight intensity: it should be as bright as required. A backlight that is too bright

reduces the useful life of the display.

6.3 Display - Loss of communication

If communication with a Modbus RS485 digital sensor is lost, the parameter display, e.g. oxygen

in mg/L for an OPTOD sensor, will flash until communication is restored.

Page 21

21

User Manual S200 Open

Update April 2018

Assignment of terminals

Color of wires

Operation

Union

Black

Ground

Terminal 90

Red

DC 12V +

Terminal 91

Green

RS485 - (B)

Terminal 92

White

RS485 + (A)

Terminal 93

7 Use of measurements provided by a Modbus RS485 sensor

7.1 OPTOD digital optical sensor for measuring dissolved oxygen

MODBUS RTU

TERMINAL .RS485

90 91 92 93 94

7.1.1 Reminder of connection to the terminal:

7.1.2 Setting / configuring of displayed measurements

The operator has access to the range of parameters from a digital

sensor such as the OPTOD from the BASIC SETTINGS submenu.

Calibration

Temp.

Compens./

Controller

setting

Manual mode

Time / date

↕→

Basic

settings

Service

Page 22

22

User Manual S200 Open

Update April 2018

↕→

Correct. PT

Controller param.

Switch-on delay

Analog output

Digi. Input 2

↕→

Select parameters

Language

Bus address

The SELECT PARAMETERS leads to the list of active parameters from 1 to 6. These are the 6

usable display areas on the screen.

↕→

Parameter 1

Parameter 2

…

Selecting one of the six parameters leads to a list of choices:

- No measurement

- Temperature measurement

- Turbidity measurement

- Oxygen digital sensor

- MES-Turb. measurement

- pH digital sensor.

In this case, the temperature or oxygen will be selected as these 2 parameters are delivered by

the OPTOD sensor.

Parameter 1

↕→

Oxygen dig. sensor

Note that these two parameters can be viewed simultaneously by configuring parameters 1 and

2.

Parameter 2

↕→

Temp. measurement

Page 23

23

User Manual S200 Open

Update April 2018

The main screen then displays:

02

7.89

mg/l

°C

140.00

°C

↓

Man→

The temperature value from OPTOD is displayed after activating the TEMP COMPENS. menu.

Default temp.

25.0°C

Choose sensor

↕→

Oxygen

The main screen then displays:

02

7.89

mg/l

°C

23.10

°C

↓

Man→

7.1.3 Sensor information

The operator has access to information on the connected sensor from the main SERVICE menu.

Manual mode

Time / date

Basic settings

↕→

Service

Display setting

Device data

Analog inputs

↕→

Oxygen dig. sensor

Page 24

24

User Manual S200 Open

Update April 2018

Pressing the right arrow on the OX. DIGITAL SENSOR line gives access to the following information:

• Sensor serial number

• Software version

• Hardware version

• Instant measurements of all available parameters for the sensor in question. In the case of the

OPTOD sensor: temperature, oxygen as a saturation %, oxygen in mg/L, and oxygen in ppm.

7.1.4 Oxygen measurement configuration

The dissolved oxygen content expressed in mg/L, for a given solution, depends on the temperature of the

liquid, salinity and atmospheric pressure if that solution is in contact with the atmosphere.

In terms of temperature, the OPTOD sensor generally uses its own temperature measurement.

The sensor does not have this information for the other two parameters: salinity and atmospheric pressure.

They must therefore be provided by the S200 Open device.

The BASIC ADJUSTMENT submenu, from the main menu, provides access to the oxygen digital sensor

configuration.

Correct. PT

↕→

Oxygen dig. sensor

Controller param.

Switch-on delay

The first line MEASURE. VALUE on this screen lets you select units for the dissolved oxygen parameter

by choosing the unit: %saturation, mg/L or ppm

Oxygen dig. sensor

↕→

Measval in ppm

Temp. measurement

23.27°C

The operator may activate/deactivate the oxygen measurement compensation parameters on the lower

levels of the same screen.

The choices are therefore repeated:

• EXT.TEMP.COMPENS.: definite temperature value to apply an external temperature

compensation; 25.0 °C by default,

• AIR PRESS. COMPENS.: helps adjust the external compensation value for atmospheric pressure

( hPa)

• SALINITY COMP.: known salinity value for the solution studied in g/kg

Page 25

25

User Manual S200 Open

Update April 2018

For example, in the case of atmospheric pressure configuration, the screen displays the following:

↕→

Air pressure comp.

Switched off

Air pressure

←

1013↕hPa

The second line represents compensation activation/deactivation: OFF / ON.

By accessing the fourth line, the operator can adjust the pressure value (icon ↕: using the Up or Down

arrows).

7.1.5 Calibration methods

The S200 Open offers two calibration methods, as a saturation %, for the oxygen probe:

• Calibration of the final value (calibration at one point – 100%)

This method allows the probe to be calibrated quickly. It is a standard method.

• Two-point calibration (0 and 100%)

This two-point method calibrates the zero point and the probe slope. This is a more complex

and exact method because a “zero-point solution” is also required.

Select the different calibration methods using the menu: CALIBRATION

↑→

Calibr. oxygen

↑→

2-point Calibr.

Reading 100.1 %

Calibr. 0.0 %

Calibr. 100.0 %

Use the right arrow to select the method.

↕→

1-point calibr.

Reading 100.1 %

Calibr. 100.0 %

Page 26

26

User Manual S200 Open

Update April 2018

7.1.6 One-point calibration sequence

The one-point calibration of the OPTOD sensor is performed by positioning the pre-cleaned sensor in the

air above the water surface to create steam-saturated air conditions (100% oxygen saturation).

1-point calibr.

Reading 100.1 %

↑→

Calibr. 100.0 %

When the cursor is located on the CALIBR. 100.0 % line, the right arrow is used to start the calibration

sequence.

1-point calibr.

Reading 100.1 %

→←

Calibr. 100.0↕%

Pressing the right and left arrows simultaneously will start the measurement sequence.

1-point calibr.

Reading 99.9□%

↕→

Calibr. 100.0↕%

A square symbol □ flashes on and off during the measurement sequence.

After this sequence, the down arrow allows you to view the updated slope value.

Calibr. 100.0↕%

Slope

↕

-0.93 %

7.1.7 Two-point calibration

A sodium sulfite solution (concentration < 2 % by weight) is used as the zero point calibration

solution for the two-point calibration sequence. The general condition of the sensor must be

checked before starting the sequence.

Page 27

27

User Manual S200 Open

Update April 2018

Note:

The oxygen probe must be checked periodically (depending on the proportion of

impurities present). It is important to rinse the probe and pellet before each check.

Organic deposits on the active pellet, such as mud or biofilm, may result in measurement

errors. These deposits can be removed by carefully using hot soapy water and a sponge.

Never use an abrasive cleaner.

7.1.8 Calibration of zero point – detailed procedure

The sodium sulfite solution must be ready for calibration.

1. Remove the probe from the original liquid medium, rinse it and check for any deposit of

dirt/contamination as described, where applicable.

2. Immerse the probe in a container filled with sodium sulfite solution.

3. Keep stirring slowly to ensure local gas exchange at the OPTOD’s active membrane.

4. Wait until the value is stabilized.

5. Use the or arrow key to select the CALIBR 0.0% line.

2-point Calibr.

Reading 0.1 %

↕→

Calibr. 0.0 %

Calibr. 100.0 %

6. Use the right arrow to start the sequence.

2-point Calibr.

Reading 0.1 %

→ ←

Calibr. 0.0↕%

Calibr. 100.0 %

7. Pressing the right and left arrows simultaneously will start the measurement sequence.

2-point Calibr.

Reading 0.1□%

→←

Calibr. 0.0↕%

Calibr. 100.0 %

Page 28

28

User Manual S200 Open

Update April 2018

A flashing square behind the displayed value indicates that the automatic calibration process

is in progress. This display turns off when zero point calibration is complete.

8. Thoroughly rinse the probe with clear water and wipe the sensor.

7.1.9 Calibration of the final point - detailed procedure

The second point calibration is performed with 100% oxygen saturation. It is carried out by

placing the probe in the air-saturated water, or in the air saturated with steam. In this second

case, the sensor may be placed about 2 cm above the surface of the water.

1. Use the or arrow key to select the CALIBR 100.0% line.

2-point Calibr.

Reading 100.1 %

Calibr. 0.0 %

↕→

Calibr. 100.0 %

2. Use the right arrow to start the sequence.

2-point Calibr.

Reading 100.1 %

Calibr. 0.0 %

→ ←

Calibr. 100.0↕%

3. Pressing the right and left arrows simultaneously will start the measurement sequence.

2-point Calibr.

Reading 0.1□%

Calibr. 0.0 %

↕→

Calibr. 100.0↕%

A flashing square behind the displayed value indicates that the automatic calibration process

is in progress. This display turns off when the calibration is complete.

Once the two-point calibration sequence is complete, pressing the DOWN arrow displays the

coefficients, zero point and slope, calculated by the sensor during both stages.

Page 29

29

User Manual S200 Open

Update April 2018

7.1.10 Error calibration – message

If, however, due to a manipulation error, the calibration sequence led to the creation of erroneous

coefficients, a message to that effect will be repeated on the main screen.

The main screen then displays:

02

1.12

mg/l

°C

23.10

°C

↓

Error

Calibr.

O2

Page 30

30

User Manual S200 Open

Update April 2018

Assignment of terminals

Color of wires

Operation

Connection

Black

Ground

Terminal 90

Red

DC 12V +

Terminal 91

Green

RS485 - (B)

Terminal 92

White

RS485 + (A)

Terminal 93

7.2 Digital sensor for measuring nephelometric turbidity

MODBUS RTU

2.RS485

90 91 92 93 94

7.2.1 General information about the turbidity probe

Turbidity sensors are optical sensors. The sensor measurement

principle is based on the IR light method dispersed at 90° (ISO

7027). The measurement is carried out in the infrared range. This

sensor may age during operation which results in sensor drift.

These influences are offset by calibration.

The sensor is calibrated in the factory, so there is no need to

perform calibration during initial commissioning. The sensor shall

be cleaned at regular intervals, during operation, depending on

the level of contamination of the liquid studied.

Page 31

31

User Manual S200 Open

Update April 2018

7.2.2 Setting / configuring of displayed measurements

The operator has access to the choice of parameters coming from

a digital sensor in the BASIC ADJUSTMENT submenu.

Calibration

Temp. Compens./

Controller setting

Manual mode

Time / date

↕→

Basic settings

Service

Correct. PT

Controller param.

Switch-on delay

Analog output

Digi. Input 2

↕→

Select parameters

Language

Bus address

The SELECT PARAMETERS choice leads to the list of active parameters from 1 to 6. These

are the 6 usable display areas on the screen.

↕→

Parameter 1

Parameter 2

…

Selecting one of the six parameters leads to a list of choices:

- No measurement

- Temperature measurement

- Turbidity measurement

- Oxygen digital sensor

- MES-Turb. measurement

- pH digital sensor.

Page 32

32

User Manual S200 Open

Update April 2018

In this case, temperature or turbidity will be selected as these 2 parameters are delivered by the

sensor.

↕→

Parameter 1

Turbidity meas.

Note that these two parameters can be viewed simultaneously by configuring parameters 1 and

2.

↕→

Parameter 2

Temp. measurement

The main screen then displays:

SS

2.9

NTU

°C

140.00

°C

↓

Man→

The temperature value from the turbidity sensor is displayed after activation in the TEMP.

COMPENS. menu.

↕→

Default temp.

25.0°C

Choose sensor

Turbidity

The main screen then displays:

SS

2.9

NTU

°C

23.10

°C

↓

Man→

Page 33

33

User Manual S200 Open

Update April 2018

7.2.3 Sensor information

The operator has access to information on the connected sensor from the main SERVICE menu.

Manual mode

Time / date

Basic settings

↕→

Service

Display setting

Device data

Analog inputs

↕→

Turbidity meas.

Pressing the right arrow in the TURBIDITY MEASUREMENT LINE gives access to the following

information:

• Sensor serial number

• Software version

• Hardware version

• Instant measurements of all available parameters for the sensor in question.

7.2.4 Configuration of the nephelometric turbidity measureme nt

The BASIC ADJUSTMENT submenu provides access to the digital nephelometric turbidity

sensor configuration. In this case, the sensor work range is selected from among the four

provided.

Correct. PT

↕→

Turbidity meas.

Controller param.

Switch-on delay

The first RANGE line on this screen is used to select the range of measurement from among the

4 available:

0-50; 0-200; 0-1,000 or 0-4,000 NTU

Turbidity meas.

↕→

Range 0-50 NTU

Temperature

measurement

23.27°C

Page 34

34

User Manual S200 Open

Update April 2018

Note:

After selecting the measurement range and in the event of excess when the S200 Open

device returns to Measurement Mode, the measurement will remain frozen on the screen.

In this case, and if the measurement remains frozen, return to the measurement range

selection menu to choose a wider range.

7.2.5 Method for calibrating nephelometric turbidity

As noted above, the nephelometric turbidity sensor has 4 measurement ranges, with separate

calibration coefficients, all calibrated using the menu: CALIBRATION. The calibration sequence

for the 0-200 NTU range is described below.

Note:

The turbidity probe must be checked periodically (depending on the proportion of

impurities present). It is important to rinse the probe before each check. Organic deposits

on the probe, such as mud or biofilm, may result in measurement errors. These deposits

can be carefully removed using hot soapy water and a soft sponge. Never use an abrasive

cleaner. Limestone deposits can be removed using a dilute hydrochloric acid solution

(max . 5%).

7.2.5.1 Calibration of zero point – detailed procedure

Operating conditions:

The sensor is placed in distilled water for this calibration step. The total absence of bubbles on

the active part of the sensor (optical part) will be checked.

Select CALIBRATION in the general menu:

↑→

Calibr. turbidity

Range 0-200 NTU

Reading 3.1 NTU

↕→

Calibr. 0.0 NTU

Calibr. ..0.0 NTU

Use the right arrow, on the first accessible line, to activate the calibration sequence.

Pressing the right and left arrows simultaneously will start the measurement sequence.

Page 35

35

User Manual S200 Open

Update April 2018

Range 0-200 NTU

Reading 3.1□NTU

↕→

Calibr. 0.0 NTU

Calibr. ..0.0 NTU

A square symbol □ flashes on and off during the calibration sequence.

When the first calibration stage has been completed, remove the distilled water sensor and wipe

it.

7.2.5.2 Calibration of the second point - detailed procedure

Operating conditions:

The second point is calibrated in an aqueous suspension of formazine with constant

stirring.

To calibrate the turbidity sensor, use a reference solution in the median area of the given

measuring range, such as a 100 NTU reference solution for the 0-200 NTU range.

Use the DOWN arrow key to select the second CALIBR. 0.0 NTU line.

Range 0-200 NTU

Reading 100.1 NTU

Calibr. 0.0 NTU

↕→

Calibr. ..0.0 NTU

Use the right arrow to start the sequence.

Range 0-200 NTU

Reading 100.1 NTU

Calibr. 0.0 NTU

↕→

Calibr. ..0.0 NTU

Use the UP arrow to adjust the digital display to the value of the aqueous formazine suspension

used, for example, 100.0 NTU.

Once the suspension is perfectly uniform, pressing the right and left arrows simultaneously will

start the measurement sequence.

Page 36

36

User Manual S200 Open

Update April 2018

Range 0-200 NTU

Reading 100.1 NTU

Calibr. 0.0 NTU

↕→

Calibr. 100.0 NTU

Again, a flashing square behind the displayed value indicates that the automatic calibration

process is in progress. This display turns off when the calibration is complete.

Once the two-point calibration sequence is complete, pressing the DOWN arrow displays the

coefficients, zero point and slope, calculated by the sensor during both stages..

Zero-Point

0.00 NTU

Slope

↑

2.01 %

Page 37

37

User Manual S200 Open

Update April 2018

8 Controller adjustments

8.1 Allocation of controller values

Up to four individual controllers can be assigned to different values.

One or more controllers can be enabled in the BASIC/CONTROL PARAM. ADJUSTMENT

submenu.

The operator then has 4 choices.

↕→

Setting contr.1

Setting contr.2

Setting contr.3

Setting contr.4

An initial choice allows the operator to define the measurement related to this controller.

• Temperature measurement

• Turbidity measurement

• Ox. digital sensor

• MES-Turb. measurement

• pH digital sensor

• No measurement.

8.2 Controller action direction

Controller 1

↕→

No measurement

Working direct.

Reduce

The controller action direction shall be determined using the REDUCE/INCREASE

adjustment. For example, REDUCE indicates that the controller is running when the value is

greater than the pre-determined set point. As a result, the value decreases (lower value).

8.3 Assignment of controller output

The controller output signal may be assigned to various actuators (relay, etc.).

Page 38

38

User Manual S200 Open

Update April 2018

Working direct.

Reduce

Controller output

↕→

Relay 1

The operator may choose: relay 1, relay 2, digital output 1, digital output 2, analog output 1

or analog output 2.

8.4 Pulse frequency

The controller output is switched so as to pulse the frequency by means of the pulse setting. A

0 p/h setting allows the controller to switch for controller pulse intervals. The numerical value

such as 36 p/h indicates that 3,600 pulses/hour are released at 100% of dosage capacity.

Controller output

Relay 1

Pulse frequency

↕→

100* 0 P/h

The right arrow lets you change the pulse numerical value.

Controller output

Relay 1

Pulse frequency

←

100* 0↕P/h

8.5 Checking the pulse frequency

The pulse interval time setting determines the total pulse interval time. A controlled variable of

50% indicates that the pulses and interval time are of equivalent duration when the value is

set to 10 sec., in this case, it would return to 5 seconds.

A controlled variable of 0 % indicates no pulse.

A controlled variable of 100% indicates no interval.

Pulse frequency

100* 36 P/h

Pulse interval

↕→

10s

Page 39

39

User Manual S200 Open

Update April 2018

8.6 Minimum pulse

The "Minimum pulse” setting determines the shortest pulse time for a pulse interval

controller. This is particularly important for the widest actuators, since shorter pulses

cannot be processed.

Note:

The minimum pulse time shall not exceed 25% of the pulse interval time.

Pulse interval

10s

Minimum pulse

0.5s

8.7 Controller parameter settings

Select the CONTROLLER SETTING function in the main menu.

↕→

Temperature contr.

The right arrow gives access to the setting details. The example described below represents the

temperature parameter.

Set point

↕→

0.0°C

P-range

0.0°C

Each item can be changed, right arrow then up or down, to set a numerical value.

Set point

←

1.5°↕C

P-range

0.0°C

Page 40

40

User Manual S200 Open

Update April 2018

Once the quantity is changed, adjusted to the desired value, the left arrow validates and accesses

a controller setting item in the list. The available adjustable items are shown below.

Reset time

↕→

0 sec

Hysteresis

0.0°C

Max. limit val.

↕→

0.0°C

Min. limit val.

0.0°C

Limit Delay

↕→

0 sec

Dosing monit.

0 min.

8.7.1 Standard point adjustment

Value to be defined for the selected measurement, example temperature in °C.

8.7.2 Proportional band (P band)

Note:

When a proportional band of 0.00 is set, the controller operates like an ON/OFF

controller without the proportional action.

The proportional band setting determines the monitoring range of the proportional controller. If

the differential between the adjustment point reaches the size of the proportional band, the control

operates with a controlled variable of 100%.

8.7.3 Integral action time (integral gain)

Note:

When an integral action time of 0 sec. is defined, checking operates like a proportional

monitor, as long as a P band has been determined.

When adjusting the integral action time, the PI check monitoring rate is defined.

8.7.4 Hysteresis

If the controller is used like an ON/OFF controller, the hysteresis parameter can be used to

adjust a default dead band around the set point.

Page 41

41

User Manual S200 Open

Update April 2018

Example:

Set point = 7.0°C

Hysteresis = 0.5°C

The hysteresis range of 0.5 is evenly distributed around the set point. The controller

becomes enabled at 6.75°C and disabled at 7.25°C.

The differential is therefore 0.5°C = hysteresis

8.7.5 Max./min. limit value

The threshold setting monitors the maximum deviation of the actual value. When you reach

the predetermined limits, the alarm relay is activated and a related message appears in the

status bar.

The alarm message and display may be delayed for an adjustable time.

8.7.6 Alarm period

Once the predetermined limit values have been reached, the alarm message is delayed until

the scheduled time. If you set the numerical value to 0 sec, the alarm message appears

immediately (without delay).

8.7.7 Dosage monitoring

If dosing is performed with 100% capacity for a longer period than the set dosing time, dosing

will be interrupted and an alarm message will appear. Once the predetermined limits have

been reached, the alarm relay is activated and a related message appears in the status bar.

The alarm message must be confirmed by switching from Automatic to Manual Operating

mode. If you set the numerical value to 0 min, the alarm message appears immediately (without

delay).

8.8 Manual operating mode

Manual mode is switched automatic on the main display screen for measurements by pressing

the right arrow.

8.8.1 Manual controller mode

The manual mode allows you to act on the controller outputs by neutralizing the settings defined

for automatic operation.

Manual mode

↕→

Contr. 1 0%.

Auto switch-off

After 0 min.

The variables managed by the controller can be set in the controller's manual settings. Each

controller can be set separately. The output signal provided for the controller is managed

directly, such as the relay, analog output, etc.

The preset monitoring type for the controller is used for monitoring, pulse frequency or pulse

intervals.

For example, the action of a single, normally open relay is managed in manual mode, by

adjusting to 100% for a period of X minutes when closed.

Page 42

42

User Manual S200 Open

Update April 2018

Manual mode

↕→

Contr. 1 100%.

Auto switch-off

After 1 min.

The adjustable “automatic stop” time indicates a override stop at the scheduled time. The

predetermined variable is then set at 0%.

8.8.2 Automatic controller mode

Automatic mode

Contr. 1 0%.

When the controller is in automatic mode, the current controlled variable.

8.9 Date and time

The date and time settings are available in the main menu to adjust the clock built into the device

in real time.

08:50 25.03.18

↕→

Minutes 49

Hours

Day 25

Each item can be changed to make the adjustment (minutes, hours, days, months, year).

08:50 25.03.18

←

Day 25↕

Month 3

Year 18

8.10 Analog outputs

The S200 measurement and monitoring device enables all measurement values to be

output as standard current signals of 0/4-20mA according to standard DIN IEC 60381-1.

You can adjust the output type at this location. BASIC ADJUSTMENT has to be chosen

from the main menu and then ANALOG OUTPUT.

Page 43

43

User Manual S200 Open

Update April 2018

↕→

Analog. Output 1

Analog. Output 2

8.10.1 Assignment of measured values

Advancing through the menus:

BASIC ANALOG / ANALOG OUTPUT / ANALOG OUTPUT1

If analog output 1 is used to transfer the temperature measurement, the following screen will be

obtained:

↕→

Temp. measurement

Range 4-20mA

0/4mA = 0.00°C

20 mA = 14.00°C

Various parameters can be assigned to analog outputs, such as temperature measurement

and an accessible parameter with a digital sensor.

When the analog output is used as a controller, the "No Measurement” setting must be

selected here.

8.10.2 Definition of current active range

The RANGE line allows you to switch between two current range choices:

• Conventional 4-20 mA

• Extended 0-20mA.

Temp. measurement

↕

→

Range 0-20mA

0/4mA = 0.00°C

20 mA = 14.00°C

8.10.3 Setting the range

Temp. measurement

Range 0-20mA

↕→

0/4mA = 10.00°C

20 mA = 30.00°C

Page 44

44

User Manual S200 Open

Update April 2018

Lines 3 and 4 of this screen determine the values of the parameter, e.g. temperature, associated

with the low and high limits of the output current range.

8.11 Power on delay

This function is accessible in the menu:

BASIC ADJUSTMENT/ SWITCH-ON DELAY

Switch-on delay

Delay time

↕→

3 min.

Device operation can be offset as a result of loss of power. The time adjustment range is from 0

to 60 minutes.

8.12 Service menu

The SERVICE menu is accessible directly in the main menu. It provides key information on the

device, connected digital sensor, and analog inputs.

Display setting

Device data

Analog inputs

Turbidity meas.

Note: Refer to the specific paragraph for the display setting.

8.12.1 Device data

This submenu provides access to three key items for the device:

• Serial number

• Software version

• Hardware version.

8.12.2 Analog inputs

How analog inputs operate can be checked here.

8.12.3 Measurement from a digital sensor

For example, as the device is associated with a digital nephelometric turbidity sensor, this

TURBIDITE MEASUREMENT submenu provides:

• Serial number

Page 45

45

User Manual S200 Open

Update April 2018

• Software version

• Hardware version

• All measurements provided by the given sensor.

8.12.4 Deleting data / return to factory settings

The DELETE DATA menu allows you to restore the factory settings (reset).

Pressing the down and right arrows simultaneously resets the device.

8.13 Languages

The language is chosen in the BASIC SETTING / LANGUAGES sub-menu.

Page 46

46

User Manual S200 Open

Update April 2018

9 Initial commissioning

9.1 Checking the hardware installation

Warning:

Before connecting the power supply to the device, check the supply voltage with respect

to the data plate and compare them.

Check the wiring of the device with respect to the wiring diagram.

9.2 Basic settings of the equipment

Firstly, set the display language for the various menus.

Note that the BASIC SETTING submenu is accessible only after you have entered the Level 3

code, see CODES paragraph.

Refer to the specific paragraphs, using the contents, to define the read and displayed parameters,

as well as the entire configuration of the controller, analog outputs, etc.

Page 47

47

User Manual S200 Open

Update April 2018

10 Maintenance and servicing

10.1 General overview

Be sure to use only a damp cloth to clean the casing. The use of strong, caustic or abrasive

cleaning agents (acid cleaners, etc.) is not recommended!

The S200 measurement and monitoring device is easy to service, but ensure that a qualified

technician checks it and performs maintenance at regular intervals.

Please contact us for any other questions regarding our measurement, monitoring and metering

system.

10.2 Cleaning and calibration of probes

Depending on the water quality, the probes should be cleaned at intervals of 1 to 6 months (or

sooner if required). Calibration is required according to the type of probe.

Warning:

Disable the metering function before removing the probes.

Page 48

48

User Manual S200 Open

Update April 2018

11 Alarm messages

11.1 List of error messages

Alarm message

Cause

Activity

Solution

Limit value of

controller 1

The lower or upper limit value of

controller 1 has been

exceeded/fallen below

Alarm relay switches

Check the

measurement and

monitor

Limit value of

controller 2

The lower or upper limit value of

controller 2 has been

exceeded/fallen below

Alarm relay switches

Check the

measurement and

monitor

Limit value of

controller 3

The lower or upper limit value of

controller 3 has been

exceeded/fallen below

Alarm relay switches

Check the

measurement and

monitor

Limit value of

controller 4

The lower or upper limit value of

controller 4 has been

exceeded/fallen below

Alarm relay switches

Check the

measurement and

monitor

Monitoring the

metering of controller

1

Controller 1 operated

in a control value of 100 % for a

period exceeding the metering

monitoring time.

Controller 1 is switched off and

the alarm relay switched

Check the measuring and

monitoring; confirm the

message by

briefly switching to

manual mode.

Monitoring the

metering of controller

2

Controller 2 operated

in a control value of 100 % for a

period exceeding the metering

monitoring time.

Controller 2 is switched off and

the alarm relay switched

"

Monitoring the

metering of controller

3

Controller 3 operated

in a control value of 100 % for a

period exceeding the metering

monitoring time.

Controller 3 is switched off and

the alarm relay switched

"

Monitoring the

metering of controller

4

Controller 4 operated

in a control value of 100 % for a

period exceeding the metering

monitoring time.

Controller 4 is switched off and

the alarm relay switched

"

Delayed start-up

Turning on the S200 power supply

Start-up of the controller will be

delayed for the set period of time

"

External stop of the

controller

Digital input 1 of terminal 21/22 has

been switched

The controller is stopped

If digital input 1 is not

switched, the controller will

work again

Calibrat. error. O2

An error occurred while calibrating

the oxygen digital sensor

The controller function remains

active, the wrong calibration

value is accepted

Repeat calibration or

replace probe

Calibrat. error. NTU

An error occurred while

calibrating the turbidity digital

sensor

The controller function remains

active, the wrong calibration

value is accepted

Repeat calibration or

replace probe

Page 49

49

User Manual S200 Open

Update April 2018

12 MODBUS RTU

The S200 measurement and control device is equipped with a Modbus RTU interface.

This piece of equipment has an RS 485 interface.

Shielding = Terminal 97

A = + Terminal 96

B = - Terminal 95

12.1 Shielding

The use of shielded cables provides high protection against electromagnetic interference,

especially high frequencies. However, the effectiveness of the shield depends on the careful

installation of the cable.

The shielding is located near the main ModBus.

12.2 Communication parameters

Transmission speed: 9,600 bps

Data bits: 8

Start-up bits: 1

Shutdown bits: 1

Parity: none

12.3 MODBUS functions used

The following MODBUS functions are used:

• 04 (0x04) Querying registry values - max. reading 40 registers

• 06 (0x06) Single registry writing - writing 1 register.

Page 50

50

User Manual S200 Open

Update April 2018

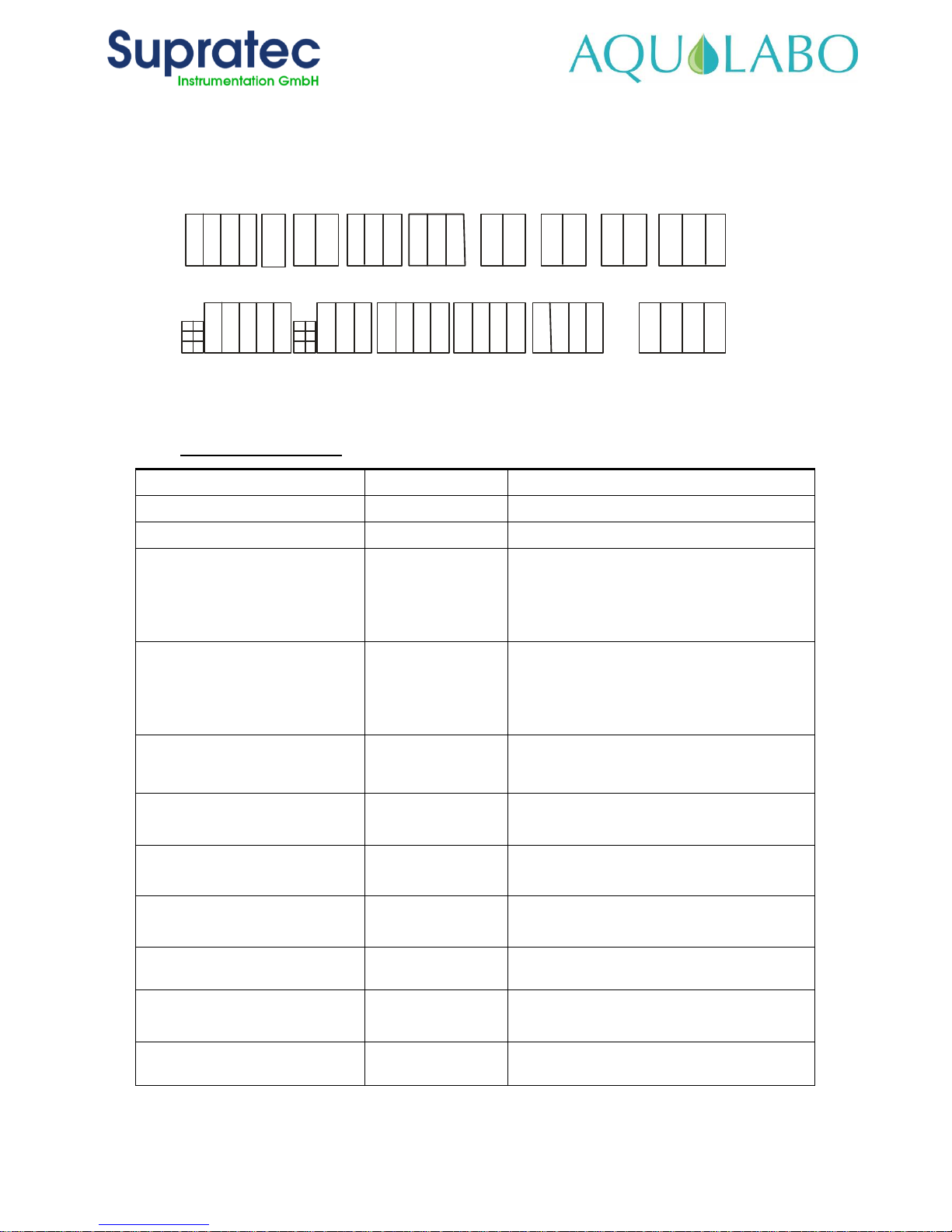

12.4 MODBUS S200 registry list

Registry

Description

Unit

Range of values

Position of

decimal

point

R/W

0

pH measuring value

pH

-200…1,600

xx.xx

R

1

ORP measuring value

mV

-1,500/+1,500

xxxx

R 2 POT Measurement - Measurement

mg/L

0.500

xxx.x

R

3

Temperature value measurement

°C

-3,000…14,000

xxx.xx

R

4

5

Conductivity measurement

µS mS

0 2000

Measurement

range

R

6

Temperature value measurement

Conductivity sensor

°C -3000 14000

xxx.xx

R

7 8

9

Measurement of flowrate water

L/h

0 ±120

xxx R 10

Active chlorine measurement

mg/l

0,500

x.xx

R

11

12

...

...

37

Digital sensor turbidity measurement

°C -3000 14000

xxx.xx

R

38 Turbidity measurement

NTU

0 4000

Measurement

range

R

...

41

O2 digital sensor temperature

measurement

°C -3000 14000

xxx.xx

R

...

43

O2 digital sensor measurement

%

0 2000

xxx.xx

R

Note:

To read register 0 (pH measurement value), select the ModBus 3001 registry. The

address of ModBUS is incremented by +1 at a time.

Page 51

51

User Manual S200 Open

Update April 2018

13 Sensor - Actuator bus (MODBUS RTU)

The S200 measurement and monitoring device is equipped with a sensor - actuator bus. The

Modbus RTU protocol is used.

This piece of equipment has an RS 485 interface.

Shielding = Terminal 94

A = + Terminal 93

B = - Terminal 92

+12V = terminal 91

0V = terminal 90

A max. load of 200mA is allowed for a 12V power supply.

13.1 Shielding

The use of shielded cables provides high protection against electromagnetic interference,

especially high frequencies. However, the effectiveness of the shield depends on the careful

installation of the cable.

The shielding is located near the main ModBus.

13.2 Communication parameters

Transmission speed: 9,600 bps

Data bits: 8

Start-up bits: 1

Shutdown bits: 1

Parity: none

Page 52

52

User Manual S200 Open

Update April 2018

14 Appendix

14.1 What to do in the event of a power failure

If there is a power failure, the unit keeps its last operating state. Once power is restored,

the device continues to operate with all previous settings.

14.2 Battery

The S200 measurement and monitoring device is equipped with a battery so that the internal

clock continues to operate even when there is no power supply. The battery must be replaced

if, for example, the date or time changes abruptly (lithium battery CR 2032)

Fig. 13.2-1: View of the electronic board with the housing lid open

Page 53

53

User Manual S200 Open

Update April 2018

15 Spare parts and wear parts

15.1 Wear parts

Article

Reference

CR 2032 type battery

Page 54

54

User Manual S200 Open

Update April 2018

16 Electrical connection

16.1 Assignment of terminals

No. Post

Function

L

L

Power supply (see nameplate)

Warning: The voltage on the nameplate must be complied with.

N N PE

PE

PE

PE

PE terminal block

PE

PE

PE

PE

PE

PE

1

Measurement input 1, e.g. pH measurement

2

+

4

Measurement input 2, e.g. Redox or 0/4-20 mA measurement

with internal jumper

5 + 6

Pt 100 or Pt 1000 temperature sensor connection

7

+

10

Add-on module connection

Please see the module description for more information about assignment.

11 12

13

20

+ 12V

Digital input 1 - pulse input or switching input

Contact closed = controller shutdown

21 22

21

22

23

+ 12V

Digital input 2 - pulse input or switching input

24 25

24

25

30

Analog output 1 0/4...20 mA (500Ω load)

31

+

32

Analog output 2 0/4...20 mA (500Ω load)

33

+

70

Digital output 1 max. 200mA / 30V

e.g. For monitoring a membrane metering pump

71

72

Digital output 2 max. 200mA / 30V

e.g. For monitoring a membrane metering pump

73

Page 55

55

User Manual S200 Open

Update April 2018

No.

Terminal

Function

80

Relay 1

81

82

Relay 2

83

84

Relay 3

85

90

0 V

+ 12 V

Power supply for bus devices

12V DC 200mA

Sensor - Actuator - Bus

2. RS 485 Interface (Modbus RTU)

91

92

B

93

A

94

95

B

1. RS 485 Interface (Modbus RTU)

96 A 97

Page 56

56

User Manual S200 Open

Update April 2018

17 Hotline-Aftersales Service contact details

AQUALABO

ZA de Bellevue

115 Rue Michel Marion

56850 CAUDAN

FRANCE

Hotline: +33 (0)5.62.75.95.70

Loading...

Loading...