Page 1

GESELLSCHAFT F Ü R U M W E LTUND V E R FA H R E N S T E C H N I K M B H

Supratec

AERATION TECHNOLOGY

®

P E R M O X O M 1 2 0

O v a l M e m b r a n e Tu b e D i f f u s e r

w i t h s t a i n l e s s s t e e l b o d y

for fine bubble or coarse bubble diffusion of liquids

von-Drais-Straße 7

D-55469 Simmern / Hunsrück

tel.: +49 6761 / 9 65 09-00

fax: +49 6761 / 9 65 09-01

e-mail: info@oxyflex.de

internet: www.oxyflex.de

Supratec

Gesellschaft für Umweltund Verfahrenstechnik mbH

Page 2

von-Drais-Straße 7 • D-55469 Simmern • tel.: +49 6761 / 9 65 09-00 • fax: +49 6761 / 9 65 09-01 • info@oxyflex.de

Supratec

Gesellschaft für Umweltund Verfahrenstechnik mbH

®

PERMOX OM120

Oval membrane tube diffuser

® ®

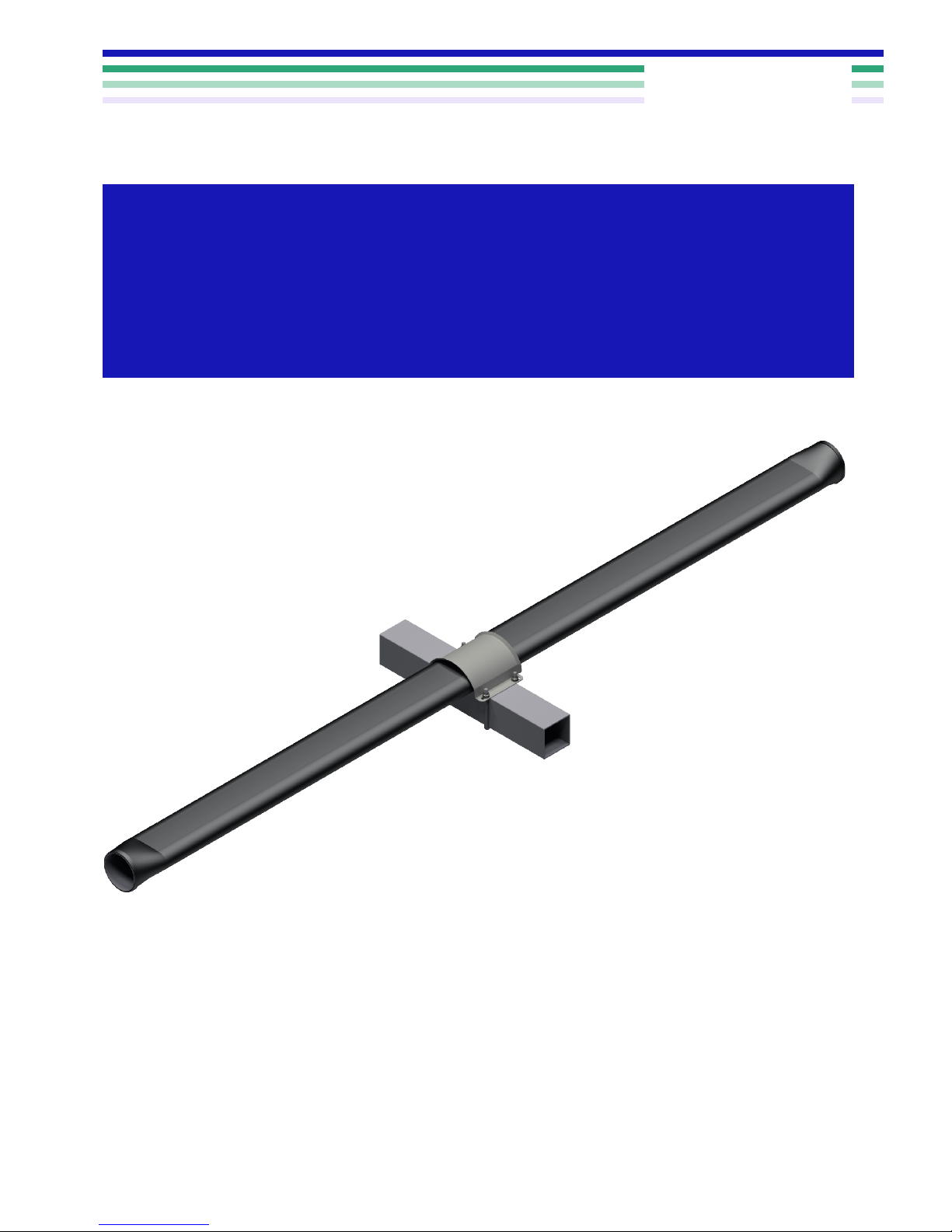

The PERMOX OM120 oval membrane tube diffuser is an improvement of old PERMOX OM

with new width of 120 mm, instead of former width of only 90 mm.

®

PERMOX OM120 oval membrane tube diffuser consists of a solid, strong stainless steel body

(AISI 316).

This special design of the oval membrane tube diffuser results in a flat membrane area, active

only to the top, similar to most efficient plate diffusers. Even for different specific air loads, the

entire flat active membrane surface works always evenly. A higher efficiency and significantly

longer operation time is resulting by this special shape compared to normal tube diffusers The .

®

oval membrane tube diffuser OM provides the advantages similar to a modern PERMOX 120

plate diffuser with regard to limited pressure increase and increase efficiency.

The diffuser membrane is secured to the body by two stainless steel 1-ear clips. The high-quality

membranes are available in EPDM (ethylene propylene diene rubber).

®

The PERMOX OM120 is available in two sizes:

®

- PERMOX OM120 - 1.5 with an active flat membrane surface of 0.18 m²

®

- PERMOX OM120 - 2.0 with an active flat membrane surface of 0.24 m²

®

The PERMOX OM120 oval membrane tube diffuser is a fine bubble aeration element for

efficient aeration, which is mainly used for the oxygen supply of biological waste water treatment

plants.

®

The PERMOX OM120 oval membrane tube diffuser is characterized by the following superior

features:

Ø higher efficiency compared to standard tube diffusers

Ø high operational reliability by limited pressure increase

Ø significantly extended operation time, also due to stainless-steel-body

Ø special diffuser design, optimized for liftable grids (no buoyancy)

Ø available in different lengths

Ø insusceptible to fouling

®

The membranes are perforated individually. The PERMOX OM120 oval membrane tube diffuser

3

is able to cover a very broad operating range of up to 20 m /h per meter.

N

®

The PERMOX OM120 oval membrane tube diffuser can be operated in intermittent mode.

As an alternative to fine-bubble aeration diffuser, the membrane can also be manufactured for a

coarse-bubble version.

®

The oval membrane tube diffuser type PERMOX OM has been used successfully in Germany

and worldwide in communal and industrial waste water treatment plants for many years. It is also

suitable for aerating liquids of all kinds were stainless steel bodies are suitable. We will be

pleased to send you our current list of references on request.

(as of date August 2018)

Page 3

Supratec

Gesellschaft für Umweltund Verfahrenstechnik mbH

von-Drais-Straße 7 • D-55469 Simmern • tel.: +49 6761 / 9 65 09-00 • fax: +49 6761 / 9 65 09-01 • info@oxyflex.de

®

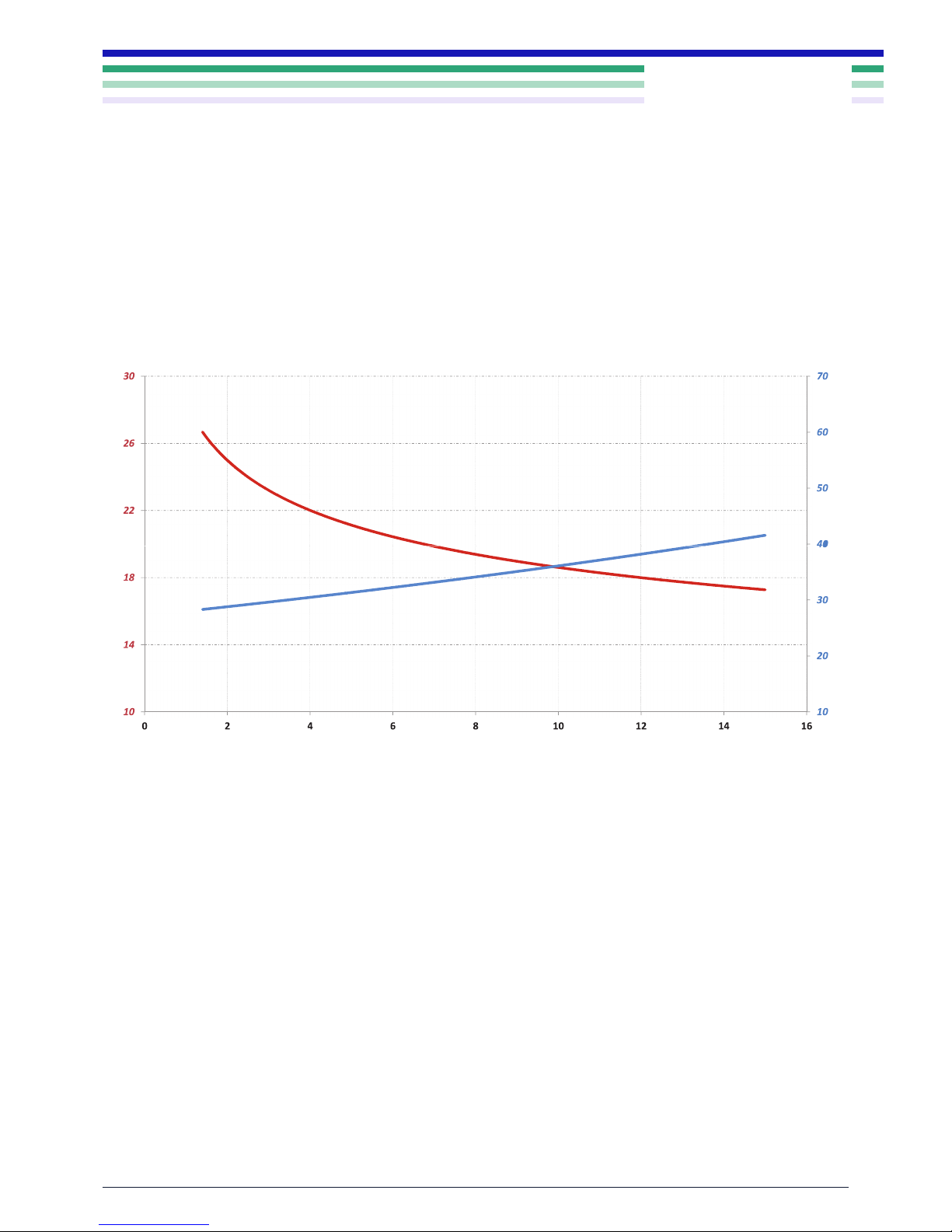

With the fine-bubble design of PERMOX OM120 oval membrane tube diffuser, specific oxygen

3

transfer rates in pure water of more than 25 g O /(m x m ) can be achieved with an extensive

2 N ET

layout and correct water depth.

The following diagram shows the example of a result of an oxygen transfer test. The values were

measured in a rectangular tank with a water depth of 4.0 m, a diffuser blow-in depth of

3.8 m and coverage of 20%.

The values cannot be transferred to other plants. The results that are shown here depend on

several influencing factors, such as the tank shape, blow-in depth, coverage or a separate

recirculation due to additional mixers.

Supratec will be pleased to prepare a technical data sheet for each individual application for you

on request.

AIR-PULSING: mixing without a mixer

The option of the intermittent operating mode means that in a combined tank with alternating

®

nitrification and denitrification phases and for a sufficient coverage by PERMOX OM120 oval

membrane tube diffusers, the use of a mixer will not be necessary ("Air-Pulsing" process).

Any sedimentation of the activated sludge during the denitrification phase is prevented by shortterm aeration intervals. The required aeration intervals are individually adapted to the respective

plant with regard to its specific conditions such as the sludge index of the waste water. The

aeration time is limited to some minutes and the process is repeated approximately every 10 to

20 minutes depending on the plant type.

1

The diagram cannot be used in order to derive warranty claims of any kind.

specific standard oxygen transfer SSOTR

[gO / ( x m )]

2 ET

m

3

N

pressure loss of diffuser

[hPa]

®

specific airload of PERMOX OM120 oval-membrane-tube-diffuser

3

[m /h per m diffuser length]

N

specific standard oxygen transfer SSOTR and pressure loss of

® 1

PERMOX OM120 oval-membrane-tube-diffuser

pressure loss

specific standard

oxygen transfer SSOTR

(as of date August 2018)

Page 4

Supratec

Gesellschaft für Umweltund Verfahrenstechnik mbH

von-Drais-Straße 7 • D-55469 Simmern • tel.: +49 6761 / 9 65 09-00 • fax: +49 6761 / 9 65 09-01 • info@oxyflex.de

Installation

®

The PERMOX OM120 oval membrane tube diffuser is suitable for installation on rectangular

stainless steel pipes by using U-bolts (M8). U-bolts are available for rectangular pipe dimension

100 mm x 100 mm or 80 mm x 80 mm as standard (other sizes on request).

Membrane: EPDM

Oval tube body: stainless steel (AISI316)

Clamp saddle: stainless steel (AISI316)

U-bolts: stainless steel (AISI316)

Seals: EPDM

flat active diffuser surface

(as of date August 2018)

Page 5

Supratec

Gesellschaft für Umweltund Verfahrenstechnik mbH

von-Drais-Straße 7 • D-55469 Simmern • tel.: +49 6761 / 9 65 09-00 • fax: +49 6761 / 9 65 09-01 • info@oxyflex.de

INSTALLATION INSTRUCTIONS

Dimensions

Storage

The diffusers shall be stored in their packing inside a dry and aerated building. DIN 7716 has to

be considered.

Preparation

®

Before installation of the oval membrane tube diffusers PERMOX OM120, it has to be checked

that the piping system is clean inside. Cuttings, sludge or other dirt have to be removed, as

those will be transported into the diffusers as soon as blowers are set into operation and causing

serious damage to the diffuser membranes.

Levelling

®

Oval membrane tube diffusers PERMOX OM120 can be installed on square pipes with

dimensions 80 mm x 80 mm or 100 mm x 100 mm (different sizes on request). The piping

system has to be levelled to maximum ± 10 mm.

Installation on rectangular pipe

®

Oval membrane tube diffusers PERMOX OM120 must be mounted horizontally and rightangled

on rectangular stainless steel distribution pipes with bore holes Ø 30 mm at the top. The

®

distance between the oval membrane tube diffusers PERMOX OM120 on the distribution pipe

(connection bore hole axis) should be at least 200 mm, recommended 250 mm – 500 mm and

must not exceed 1,000 mm (differences possible on request). A self-sticking round EPDM flat

gasket (50/30 mm x 3 mm) is positioned around the bore hole of the distribution pipe. The

surfaces of the rectangular pipe must be clean, dry and straight.

®

The air socket outer-Ø = 28 mm at the bottom side of oval membrane tube diffuser PERMOX

OM120 is inserted from above into the bore hole Ø = 30 mm of the rectangular distribution pipe.

The gasket must sit clean and undamaged between the diffuser and the pipe.

The fixing clamp saddle will be put from the top to the oval-membrane-tube-diffuser

®

PERMOX Om120. By using 2 pieces of U-bolts M8 around the rectangular pipe, the clampsaddle, resp. the diffuser will be fixed.

The fixing has to be done by symmetrically tightening with self-locking nuts M8 to ensure a

firmly, horizontally and right-angled mounting. The threads of the U-bolts must be lubricated

beforehand to avoid seizing. Starting torque is 4 Nm and has to be increased until clamp saddle

is drawn down to the rectangular distribution pipe and the diffuser is safely tightened.

120

mm

®

PERMOX OM120 - 1.5 1660 mm

®

PERMOX Om120 - 2.0 2210 mm

(as of date August 2018)

Page 6

Supratec

Gesellschaft für Umweltund Verfahrenstechnik mbH

von-Drais-Straße 7 • D-55469 Simmern • tel.: +49 6761 / 9 65 09-00 • fax: +49 6761 / 9 65 09-01 • info@oxyflex.de

OPERATING INSTRUCTIONS

Functional check and leak test

®

After the oval membrane tube diffusers PERMOX OM120 have been installed, a function check

and leak test must be performed. In order to do this, the tank has to be filled up to a level of

approx. 10 cm above the top edge of the diffuser with clean water.

To check the function visually, the diffusers should be loaded with the specified amount of air

(see load table on last page).

After ensuring that all diffusers are working well, the air flow can be reduced (min. specific load

in table on last page) in order to make it easier to perform the leak test. Rising large bubbles

indicate leaks (e.g. due to gaskets that have been dislodged). Those must be remedied.

The successfully performed functional check and leak test must be documented.

The water level has to be raised to at least 100 cm above the top edge of the diffuser as quickly

as possible.

Important: the air flow shall not be stopped between these afore noted tests and following

diffuser run-in!

Diffuser run-in

The compressed air must not be turned off between the functional check, resp. leak test and the

®

run-in of the diffusers. Oval membrane tube diffusers PERMOX OM120 with EPDM membrane

must be operated continuously for at least 60 hours with the specified specific load (see run-in of

diffusers on last page) before performing a conclusive oxygen transfer test.

Bubble pattern test

The bubble pattern shall be assessed first after the above-described run-in of the diffusers has

been completed. For this purpose the diffusers have to be operated from the maximum down to

the minimum specific load (see load table at last page).

The evenness of the aeration (bubble pattern test) has to be checked when the tank is filled to a

level of at least. 100 cm of water above the diffuser top edge.

Checking the evenness of the aeration is only possible at a water temperature of above 10°C.

(as of date August 2018)

self-locking nuts

EPDM membrane

clamp saddle

bore hole Ø = 30 mm

U-bolts M8

distribution pipe

oval stainless steel body

washers

flat gasket

Page 7

Supratec

Gesellschaft für Umweltund Verfahrenstechnik mbH

von-Drais-Straße 7 • D-55469 Simmern • tel.: +49 6761 / 9 65 09-00 • fax: +49 6761 / 9 65 09-01 • info@oxyflex.de

Oxygen transfer test

Prior to carrying out an oxygen transfer test as a proof of the efficiency of the oval-membrane-

®

tube-diffusers PERMOX OM120, afore mentioned steps must have been completed.

The oxygen transfer test can be carried out in accordance with the accepted regulations (e.g.

DIN EN 12255-15 2003 or DWA-M 209) using the fresh water or waste water method. Specified

warranty values must be rigorously adhered to. A calibrated and exact measurement of the air

volume is required.

Commissioning

If commissioning is delayed it must be ensured that the diffusers are sufficiently covered by

®

water (at least 100 cm) so that oval-membrane-tube-diffusers PERMOX OM120 are protected

against strong sun, frost and mechanical damage caused by falling objects, for example.

MAINTENANCE INSTRUCTIONS

®

The oval-membrane-tube-diffuser PERMOX OM120 is a low-maintenance system and is

partially self-cleaning due to the different specific air loads during the normal operating cycle.

Especially with an intermittent operation mode, the normal operation cycle can be used for

parallel maintenance as described below. Depending on the operating conditions an additional

appropriate maintenance cycle has to be executed. This maintenance cycle is also used for

removing deposits after longer periods of inactivity and long-term operation with low specific

loads

Maintenance cycle

Any deposits are removed by short-term load-dependent changes of the membrane extension.

This also prevents any accumulation of biological growth.

For PERMOX OM120 we recommend a daily and no less than weekly maintenance loading (see

load table on last page) of approx. 15-30 minutes. Using intermittent operation, the first 10-15

minutes of each aeration cycle are used with the higher maintenance air flow in advance of

standard operation

Monitoring

The bubble pattern and the pressure loss should be checked and documented at regular

intervals under similar operating conditions (such as water level and air quantity). The pressure

loss development in the load-dependent, seasonal comparison makes it possible to evaluate the

condition of the container objectively.

In the event of significant changes of the bubble pattern (e.g. partial massive large bubbles

instead of homogenous fine bubble pattern) and/or increase of pressure loss of the system (for

more than 40 hPa compared to commissioning), Supratec should be consulted immediately.

Particularly in the case of systems that are operated intermittently, there is a risk that damaged

diffusers can allow the ingress of live sludge into the entire pipework system. This will adversely

affect the function and service life of all diffusers.

(as of date August 2018)

Page 8

Supratec

Gesellschaft für Umweltund Verfahrenstechnik mbH

von-Drais-Straße 7 • D-55469 Simmern • tel.: +49 6761 / 9 65 09-00 • fax: +49 6761 / 9 65 09-01 • info@oxyflex.de

(as of date August 2018)

Cleaning

The condition of the diffusers must be checked whenever the tank is empty. Particular attention

must be paid to soiling (deposits, sludge, etc.), which can usually be easily removed from the

membranes. Depending on the type and composition of the soiling, one of the following methods

or a combination of several methods might be required. Testing for compatibility and successful

results must always be carried out first on individual membranes (particularly with alkalis and

acids). We recommend:

- Manually: Cleaning with water and a soft brush is often sufficient for removal of

existing deposits

- Alkaline solutions: Soapy water can usually be used to support manual cleaning.

- Acids: In some cases (e.g. limescale) the membranes must be cleaned by

adding acids to the compressed air (see below).

Acid dosing

In systems in which limescale deposits are expected, we recommend to clean those systems

with diluted acid (85% formic acid for EPDM) at regular intervals. If necessary, diluted acid is

dosed into the compressed air in order to minimise the pressure loss of the membrane and

increase the service life of the diffuser. For this purpose, we offer a mobile acid dosing station.

Please contact Supratec for further information.

Oval-membrane-tube-diffuser

®

PERMOX OM120

EPDM

3

[m /h per meter]

N

Functional check

8

Diffuser run-in prior to the oxygen

transfer test (at least 60 hrs)

12

Bubble pattern

(starting with higher specific load)

3 - 12

3

Minimum specific load (0 m /h/m or ...)

N

1

Nominal operating range

4 - 12

Maximum continous load

15

Maximum short-term specific load /

maintenance load

20

Our QMS is certified in

compliance with DIN EN ISO 9001

Load table

We reserve the right to make technical changes.

For current version please check our website www.oxyflex.de

Loading...

Loading...