BST106-N59[B] Shovel Loader Weigher

www.zemicusa.info

Operation Manual V5.0

Changsha Supmeter Technological Co.,Ltd.

Preface

High-Frequency Sampling Multi-filtering Algorithm

Acceleration Compensation High Accuracy&Stablity

www.zemicusa.info

Thank you very much for your purchase!

This manual covers safety precautions, brief introduction, technical specifications, operation interface,

installation&connection, function&operation, fault treatment, working specification and so on. In order to

make the product running at its best, please read this manual in advance, and reserve it for the future

reading.

The continuous technology update, performance perfection and quality improvement may lead to

some differences between this manual and the physical product, please understand.

Without our authorization, the contents of this manual are not allowed to be copied and reproduced.

Main Features:

ARM CPU system with higher arithmetic speed.

Dust-proof stainless Steel shell suitable for dust atmosphere.

EMC design with high anti-jamming capability, suitable for industrial environment.

The DC24V power input circuit of weighing indicator has reverse polarity protection function.

640×480 dots TFT color display screen for English/Chinese character display.

The display information of Bucket Lifting/Declining state, Single-bucket-loading-weight,

Totalized Loading Weight, Positive/Negative Deviation Value, Alarm state, Date/Time and other

auxiliary data are used for adjusting if Single-bucket-loading-weight is valid and the loading

process should be stopped.

Menu&Shortcut mode operation with key tone.

Number, English Alphabet, Simplified/Complex Chinese can be inputted.

The information of User Name, Car.No., Goods No., and Operator No. can be inputted.

Upper/Lower Limit of Single-bucket-loading-weight, Totalized Loading Weight and Date/Time can be set.

Operating Time, Single-bucket-loading-weight, Totalized Loading Weight and Alarm Information can be

recorded automatically.

Using 2 oil pressure sensors for getting higher weighing accuracy than using 1 oil pressure

sensor.

24-bit High-precision and high-speed ∑-△ A/D conversion module with 1,000,000 internal code

used and max. sampling frequency 400Hz.

High sampling frequency, multiple digital filter and acceleration compensation algorithm for

ensuring high weighing accuracy in the lifting process of the bucket.

1000 Loading Records can be saved, queried and printed, and each record can contain 50pcs

Single-bucket-loading-weight value.

1000 Reload Records can be saved and open for reloading.

Auto-locking, Key-locking, Key-unlocking, Digital Setting&Calibration and I/O Testing

functions available.

1

Contents

www.zemicusa.info

1. SAFETY PRECAUTIONS .............................................................................................................. 4

2. BRIEF INTRODUCTION ............................................................................................................... 5

2.1 OPERATING PRINCIPLE .......................................................................................................................... 5

2.2 SYSTEM CONFIGURATION ...................................................................................................................... 5

2.3 APPLICABLE SHOVEL LOADERS............................................................................................................. 5

3. TECHNICAL SPECIFICATIONS ................................................................................................. 6

3.1 TECHNICAL SPECIFICATION OF WEIGHING INDICATOR .......................................................................... 6

3.2 TECHNICAL SPECIFICATION OF OIL PRESSURE SENSOR ......................................................................... 7

3.3 TECHNICAL SPECIFICATION OF POSITION SENSOR ................................................................................. 8

3.4 SYSTEM ACCURACY .............................................................................................................................. 8

4. OPERATION INTERFACE ........................................................................................................... 8

4.1 MAIN DISPLAY INTERFACE .................................................................................................................... 8

4.2 KEYPAD DIAGRAM ................................................................ .............................................................. 11

4.3 KEYPAD OPERATION............................................................................................................................ 11

4.3.1 Menu Operation & Parameter Setting Operation .......................................................................11

4.3.2 Operation for System Calibration .............................................................................................. 12

4.3.3 Operation in Loading Process ................................................................................................... 12

5. INSTALLATION&CONNECTION ............................................................................................. 13

5.1 INSTALLATION ..................................................................................................................................... 13

5.1.1 Structure of Shovel Loader ........................................................................................................ 13

5.1.2 Installation of Weighing Indicator ............................................................................................. 14

5.1.3 Installation of Position Sensor ................................................................................................... 15

5.1.4 Installation of Oil Pressure Sensor ............................................................................................ 16

5.1.5 Cable Laying ............................................................................................................................. 17

5.2 TERMINAL ........................................................................................................................................... 17

2

5.3 CONNECTION....................................................................................................................................... 18

www.zemicusa.info

5.3.1 Oil Pressure Sensor Connector (LC-DN/LC-UP) ...................................................................... 18

5.3.2 Position Sensor Connector (POSITION) ................................................................................... 18

5.3.3 Power Supply Connector (POWER) ......................................................................................... 19

6. SYSTEM ADJUSTMENT&CALIBRATION PROCEDURE ................................................... 20

7. FUNCTION&OPERATION ......................................................................................................... 21

7.1 MAIN MENU ........................................................................................................................................ 21

7.2 PARAMETER SETTING .......................................................................................................................... 23

7.2.1Weighing Parameters .................................................................................................................. 23

7.2.2 Calibration Parameters .............................................................................................................. 24

7.2.3 Setpoint Parameters ................................................................................................................... 24

7.2.4 Alarm Parameters ...................................................................................................................... 25

7.2.5 Communication Parameters ....................................................................................................... 26

7.2.6 Display Parameters ................................ ................................................................ .................... 26

7.3 SYSTEM CALIBRATION ........................................................................................................................ 27

7.3.1 Zero Calibration【Zero】 ......................................................................................................... 27

7.3.2 Zero Compensation【Z.cmp】 ................................................................................................. 28

7.3.3 Span Calibration【Cal】 ........................................................................................................... 29

7.3.4 Span Compensation【S.cmp】 ................................................................................................. 30

7.3.5 Loading Test .............................................................................................................................. 31

8. FAULT TREATMENT .................................................................................................................. 32

9. WORKING SPECIFICATION ..................................................................................................... 33

9.1 BRIEF DESCRIPTION ............................................................................................................................ 33

9.2 DETAILED DESCRIPTION ...................................................................................................................... 34

APPENDIX A. PRINT FORMATS .................................................................................................. 36

APPENDIX B. REGISTER TABLE OF HOST-SLAVE MODBUS[ASCII] ................................ 37

3

1. Safety Precautions

www.zemicusa.info

Lithium Battery Installation

A Lithium battery should be equipped in the weighing indicator. If it is not allowed to be

transported together with the product because of embargo, please make a purchase

according to the model offered by us and install it by yourself.

Prohibit using the product under dangerous environment

Prohibit using the product under the dangerous environment with combustible gas and

explosive dust. If you have this need, please use our explosion-proof products.

Avoid using the product under overheated environment

Make sure that the weighing indicator works under the environment with allowed temperature

range to get good performance and long working life.

Please keep the product away from direct sunlight.

Installation & Power Supply of Weighing Indicator

Weld the mounting bracket of the weighing indicator firmly on the metal frame of the shovel

loader driving cab. The installation position should be convenient for operation.

The power switch of the weighing indicator should be turned off and ensure that the power

cables are not charged before DC24V power connection to avoid short circuit fault.

Please make sure that the power supply is correct before power-on.

Installation of Oil Pressure Sensor

Strictly follow the ‘Safety Precaution’ described in ‘5.1.4 Installation of Oil Pressure Sensor’.

Install the oil pressure sensors and plate type three-way joints firmly, and seal them as

prescribed to avoid oil leaking.

Installation of Position Sensor

Install the position sensor according to required position and angle, and adjust Detecting

Distance to 3~5mm.

Cable Laying

Oil pressure sensor signal calble and position sensor signal cable should be laid in flexible

pipe for protection, and fix them with nylon strip.

Try to keep signal calbles away from the place with high temperature and possible extrusion,

and reserve enough bending length to avoid being pulled apart.

Environmental Protection

Before the Lithium battery equipped in the weighing indicator being discarded, please

insulate its positive or negative pole, do not put it into fire.

Although the weighing indicator is made of the lead-free components, after used in the

industrial environments, it’s possible to be polluted. So, while being discarded as worthless,

the weighing indicator should be processed lawfully as leady industrial waste for environment

protection.

Other Notes

The installation, wiring and maintenance should be operated by the engineers with the

relevant professional knowledge and safety operation ability. Although being not described in

this manual, the relevant safety operating procedures and standards should be followed.

4

2. Brief Introduction

www.zemicusa.info

2.1 Operating Principle

Shovel Loader Weigher is a dynamic weighing and auto-totalizing equipment installed on shovel

loader without changing the original structure of shovel loader.

When the lift-arm of Shovel Loader is lift to a certain height, the position sensor will trigger the

weighing process, and the weighing indicator will collect the oil pressure signals from lower and

upper oil chambers of arm-lifting oil cylinder. After signal processing and compensation,

Single-bucket-loading-weight will be got and totalized to Totalized Loading Weight automatically,

and the Deviation Value between Totalized Loading Weight and Setpoint, alarm messages will be

displayed. The operator can judge if the present Single-bucket-loading-weight is valid according to

the alarm messages, and confirm the loading weight of last bucket according to Negative Deviation

Value for avoiding overloading. After Totalized Loading Weight reached setpoint, the operator should

stop loading process, save and print Loading Record.

2.2 System Configuration

1 Weighing Indicator with Thermal Printer.

2 Oil Pressure Sensors [0~25MPa].

2 Plate Type Three-way Joints.

1 Position Sensor [Detecting Distance: 5~8mm].

1 Mounting Fitting.

2.3 Applicable Shovel Loaders

Suitable for shovel loader with loading capacity 1~12t:

LiuGong ZL Series.

XiaGong XG Series.

LongKing ZL/LG Series.

XuGong ZL/LW Series.

JinGong ZL/ JGM Series.

LinGong LG Series.

ChengGong ZL/CG Series.

CAT Series……

5

3. Technical Specifications

www.zemicusa.info

3.1 Technical Specification of Weighing Indicator

Product Executing Standard

CMC GB/T7724-2008《Electronic Weighing Meter》PRC National Standard.

OMIL R76: 2006《Non-automatic Weighing Instruments》International Recommendation.

Weighing Accuracy

Accuracy Grade: III .

Number of Nerification Intervals: n=3000.

Error Distribution Coefficient: P=0.5.

Power Supply

Operating Voltage: DC24V±20%.

Max. Power: 10W.

Display

640×480 dots TFT color display screen for English, Simplified/Complex Chinese character

display.

Kaypad

20 keys for Menu&Shortcut mode operation with key tone.

Optional English keypad, Simplified Chinese keypad and Complex Chinese keypad.

Number, English Alphabet, Simplified/Complex Chinese can be inputted.

Auto-locking, Key-locking, Key-unlocking, Digital Setting&Calibration and I/O Testing functions

available.

Weighing Range: 100~12,000kg.

Display Division: 1kg, 5kg, 10kg, 50kg.

Oil Pressure Sensor Input Interface (LD-UP/LD-DN)

2 Oil Pressure signal inputs.

Signal Input Range: 4~20mA.

Excitation Voltage Output: DC12V.

Weighing Signal Sampling Circuit

24-bit ∑-△ADC with 1,000,000 internal code used.

Max. Sampling Frequency: 400Hz.

Zero Drift: ±0.1μV/℃ RTI (Relative to Input).

Gain Drift: ±5ppm/℃.

Non-linearity: 0.005%FS.

6

Position Sensor Input Interface (POSITION)

www.zemicusa.info

1 Switch signal Input.

Excitation Voltage Output: DC12V.

Print Port (PRINTER)

RS232.

Digital Communication Interface (COM1)

RS232。

Connectable: IPC/PLC and Wireless Module.

Report Print

1000 Loading Records can be saved, queried and printed, and each record can contain 50pcs

Single-bucket-loading-weight value.

Outline Dimension

168 × 213 × 50 mm (W×H×D).

Cut Dimension

Model Horizontal Panel-mounting: 153 × 77 mm (W×H).

Model Vertical Panel-mounting: 77 × 153 mm (W×H).

Weight Approx. 2.0kg.

Temperature and Humidity

Service Temperature: -20℃ to +40℃.

Storage Temperature: -30℃ to +60℃.

Relative Humidity: Max. 85%RH.

Protection Level: IP65.

3.2 Technical Specification of Oil Pressure Sensor

Supply Voltage: DC9~36V.

Capacity: 0~25MPa or 0~40Mpa.

Output Signal: 4~20mA.

Long term stability 1year @ +25℃: ±0.3%FS.

Overpressure: 100MPa.

Burstpressure: 200MPa.

Connector: M12×1mm.

Operating Temperature: -40℃~+125℃.

Protection Level: IP67 with connector installed.

Approvals: CE/EMC.

7

3.3 Technical Specification of Position Sensor

GOODS: 00

OP.: 01

SET: 60.00t

[6]

[7]

[2]

CARNO: 00000

Left[9]/Right[10]

[11]

[5]

4.500 t

[1]

[3]

[4]

[12]

LOAD [LOCK] 05-20-2009 23:59:45

OK

12

+1.200t

61.200t

USER:

ADD

[8]

[13]

www.zemicusa.info

HALL Type Proximity Switches

Operating Voltage: DC5~24V.

Detecting Distance: 5~8mm.

Response Frequency: 5KHz.

Quiescent Current:Max. 2mA.

Thread Size: M8×1mm.

Service Temperature: -25℃~+70℃.

Protection Level: IP67.

Standard Detecting Target: Magnet.

3.4 System Accuracy

Accuracy of Single-Bucket -Weight: 0.5%~1.0%FS.

Accuracy of Totalized Loading Weight: ±1.0% (OIML Y(b) Accuracy Grade).

4. Operation Interface

4.1 Main Display Interface

8

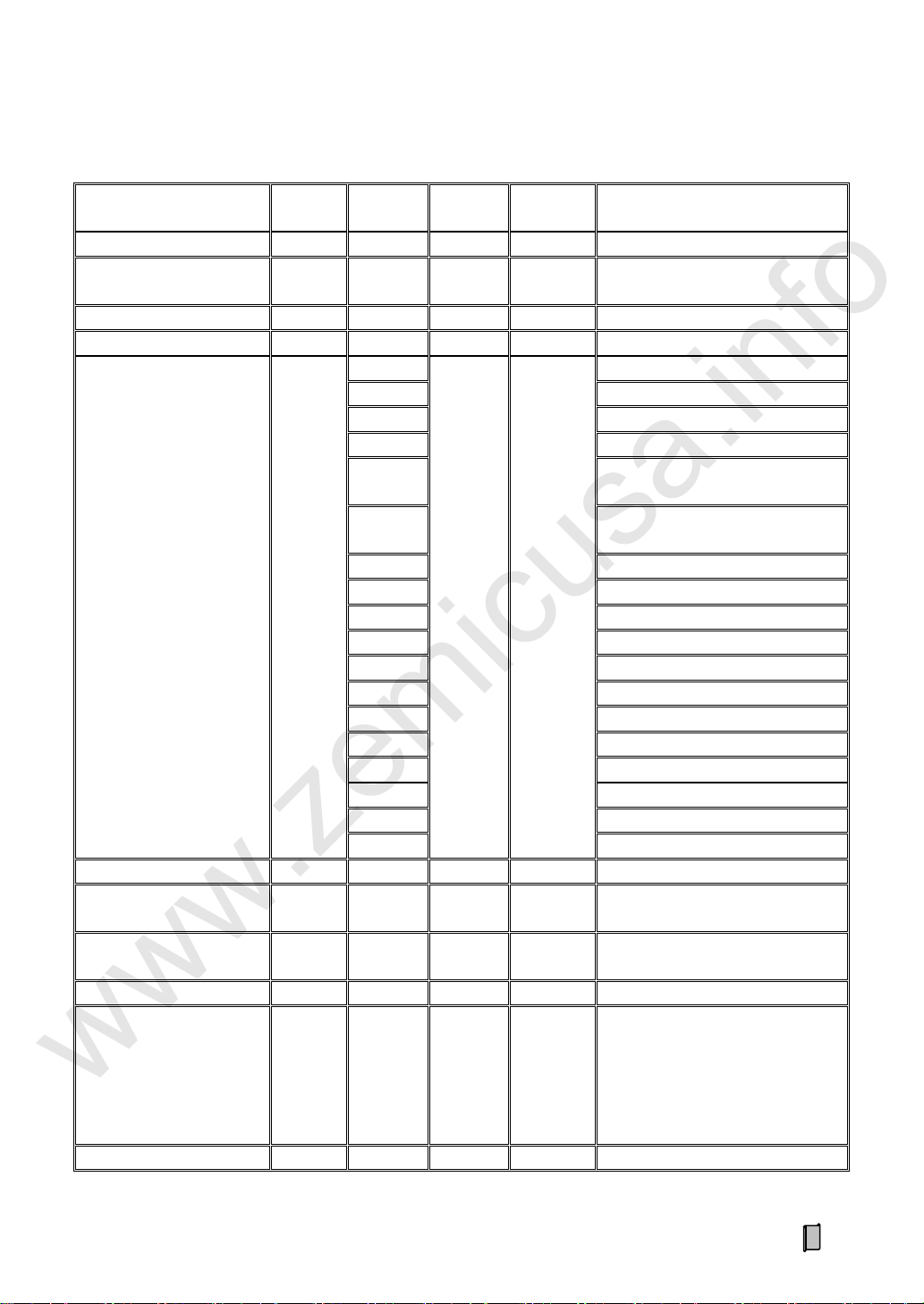

No.

Sign

Description

[1]

Working State

LOAD: Loading state.

DEDUCT: Deducting state with flashing yellow background.

PAUSE: Pause state with flashing red background.

[LOCK]: Keypad is locked.

[903] Date Format Hour : Minute : Second

[2]

CARNO

Car No.

[3]

GOODS

Goods Name.

[4]

OP.

Operator Name.

[5]

SET

Setpoint Value.

[6]

Blue ▲

The bucket of shovel loader is below the position sensor.

Blue ▼

The bucket of shovel loader is above the position sensor.

Red ■

Pause State.

[7]

OK

Weighing Normal.

STALL

The operator has released the accelerator of shovel loader in weighing process:

Acceleration Value < [400] Stall Alarm Point.

LOW

Lower Limit Alarm of Single-bucket-loading-weight:

Loading Weight < [401] Load Lower Limit.

HIGH

Upper Limit Alarm of Single-bucket-loading-weight:

Loading Weight > [402] Load Upper Limit.

UND-T

Undertime Alarm: Weighing Time < [403] Min. Weighing Time.

OV-T

Overtime Alarm: Weighing Time > [404] Max. Weighing Time.

[8]

USUER

User Name.

[9]

Bucket Count

The display area of „Bucket Count‟ will change to red background if the key【Void】

is pressed for „Cancel Totalizing‟ or „Cancel Deducting‟.

[10]

Deviation Value

Deviation Value = Totalized Loading Weight-Setpoint Value.

[11]

Totalized

Loading Weight

“Last Bucket” Prompt: The display area of „Totalized Loading Weight‟ will change

to red background if „Negative Deviation Value<3t‟, it means that the next bucket

may be the last one, the operator should determine the loading weight of the next

bucket according to the actual Negative Deviation Value.

[12]

Single-bucketloading-weight

The display area of „Single-bucket-loading-weight‟ will change to flashing red

background while alarming.

[13]

TOT

The present Single-bucket-loading-weight has been totalized to Totalized Loading

Weight.

NO TOT

The present Single-bucket-loading-weight has not been totalized to Totalized

Loading Weight because of alarming.

After totalizing, the present Single-bucket-loading-weight can be deducted from

Totalized Loading Weight via the key【Void】.

Refer to parameter [406] „Totalizing/Deducting Permission While Alarming‟.

DED

The present Single-bucket-loading-weight has been deducted from Totalized Loading

Weight.

NO DED

The present Single-bucket-loading-weight has not been deducted from Totalized

Loading Weight because of alarming.

After deducting, the present Single-bucket-loading-weight can be totalized to

Totalized Loading Weight again via the key【Void】.

Refer to parameter [406] „Totalizing/Deducting Permission While Alarming‟.

www.zemicusa.info

9

Press key【Display】to switch the following display interfaces:

AD1: XXXXX

AD2: XXXXX

AD: XXXXX

NET: 0.000t

T2: 0.000s

T3: 0.000s

ACC: 0.0000

T1: 0.000s

V3: 0.000

A0: 0.0000

LR: 1.000

V1: 0.000

Z.CMP: 0

SPAN: 1000

S.CMP: 0

ZERO: 10000

R-AD1: XXXXX

R-AD2: XXXXX

R-AD: XXXXX

R-NET: 0.000t

1. Display Interface A for Testing Oil Pressure Sensor

R-NET: Real-time Weight Value.

R-AD1: Oil Pressure Signal Real-time AD Value from Lower Oil Chamber.

R-AD2: Oil Pressure Signal Real-time AD Value from Upper Oil Chamber.

R-AD: Real-time AD Value = [R-AD1]-[R-AD2].

2. Display Interface B for Testing Oil Pressure Sensor

NET: Single-Bucket-Loading-Weight without Acceleration Compensation.

AD1: Oil Pressure Signal Average AD Value from Lower Oil Chamber in Weighing

Process.

AD2: Oil Pressure Signal Average AD Value from Upper Oil Chamber in Weighing

Process.

AD: AD Value at Weighing Segment = AD1-AD2.

3. Display Interface A for Testing Position Sensor

T1: Time spent by Upper Magnet Block passing by Proximity Switch [s].

T2: Time spent by Proximity Switch running between two Magnet Blocks [s].

T3: Time spent by Lower Magnet Block passing by Proximity Switch [s].

ACC: Acceleration Value at Weighing Segment [dm/s2].

4. Display Interface B for Testing Position Sensor

V1: Average Speed of Upper Magnet Block passing by Proximity Switch [m/s].

V3: Average Speed of Lower Magnet Block passing by Proximity Switch [m/s].

A0: [208] IdleAcc.Value (Acceleration Value at Idle Speed) [dm/s2].

LR: [205] Run Length Ratio.

5. Calibration Parameters display Interface

ZERO: [200] Zero Value.

Z.CMP: [201] Zero Compensation Coefficient.

SPAN: [202] Span Coefficient.

S.CMP: [203] Span Compensation Coefficient.

www.zemicusa.info

10

4.2 Keypad Diagram

Key Name

Description

【Menu】

Enter Main Menu / Exit.

【Ent】

Enter/Save.

【◄】

Cursor shifts left.

Backspace.

【►】

Cursor shifts right.

【▲】

Cursor shifts up.

Display the previous option.

【▼】

Cursor shifts down.

Display the next option.

【Set】

Setpoint Parameters Setting.

【No.】

Input Car Number.

【0~9】

Number Input.

【A-Z】

English Alphabet Input.

【Print】

Input Method [Number/English/Chinese] Switch.

www.zemicusa.info

4.3 Keypad Operation

If there is not any keypad operation in one minute and it‟s not in the processes of „F2 Calibration‟ & „F7 Factory

Adj.‟, the weighing indicator will return to „Main Display Interface‟ automatically.

4.3.1 Menu Operation & Parameter Setting Operation

11

4.3.2 Operation for System Calibration

No.

Key Name

Description

1

【Disp】

Display Interface Switch.

2

【Lock】

Key-locking .

Key-unlocking.

3

【Deduct】

Deduct the next Single-bucket-loading-weight from Totalized

Loading Weight.

4

【Zero】

Zero Calibration with unloading and idle speed.

5

【Cal】

Span Calibration with loading and idle speed.

6

【Mode】

Unused.

7

【Z.cmp】

Zero Compensation with unloading and accelerating.

8

【S.cmp】

Span Compensation with loading and accelerating.

9

【Rec】

Query/Print Loading Records.

Reload: Find and open record from the buffering database of

„Reloading Records‟ for reloading.

0

【Cls】

Clear Screen without Saving Present Loading Record.

Key Name

Description

【Load】

Enter Loading state (Display blue sign „▲‟).

It‟s necessary to let the bucket of shovel loader stay at the lowest position

before pressing【Load】.

【Finish】

[Save]: Save&Print Loading Record and Clear Screen after Loading

process finished.

[Buffer]: Save Loading Record into the buffering database of

„Reloading Records‟ and Clear Screen.

[Cls]: Clear Screen without saving Loading Record.

[Exit].

【Pause】

Enter Pause state (Display red sign „■‟).

【Void】

Cancel Totalizing: After totalizing, the present

Single-bucket-loading-weight can be deducted from Totalized

Loading Weight via this key.

Cancel Deducting: After deducting, the present

Single-bucket-loading-weight can be totalized to Totalized Loading

Weight again via this key.

【Print】

Print Loading Records.

【On/Off】

Press it to turn the power on.

Keep it pressed for 2 seconds to turn the power off.

www.zemicusa.info

4.3.3 Operation in Loading Process

12

5. Installation&Connection

2

3

4 1 5

www.zemicusa.info

5.1 Installation

5.1.1 Structure of Shovel Loader

1: Bucket; 2: Lift-arm; 3: Arm-lifting Oil Cylinder; 4: Oil Connecting Port of Upper Oil Chamber;

5: Oil Connecting Port of Lower Oil Chamber.

Related Operation Terms:

Arm-up: Lift the lift-arm so that the bucket rises.

Arm-down: Put the lift-arm down so that the bucket goes down to the lowest position.

Bucket-up: Flip the bucket upward to the limit position.

Bucket-down: Flip the bucket downward.

Discharge: Flip the bucket downward for discharging materials.

Shovel: Shovel materials into the bucket.

13

5.1.2 Installation of Weighing Indicator

Weld the mounting bracket of the weighing indicator firmly

on the metal frame of the shovel loader driving cab. The

installation position should be convenient for operation.

Suggestion: Install the weighing indicator in the driving cab of

shovel loader and on the side the door will not be opened

frequently.

1 2 3

4

www.zemicusa.info

1: Fastening Nut for Lateral Rotation; 3: Fastening Nut for Vertical Rotation; 4: Printer

14

5.1.3 Installation of Position Sensor

7

2

1

9

10

11

12 5 3

4 6 8

www.zemicusa.info

Position sensor includes two modules:

Proximity Switch module: Main Mounting Plate with a chute for length adjustment,

Sub-mounting Plate with a chute for angle adjustment and Proximity Switch [Detecting Distance:

5~8mm].

Magnet Module: Thread Pole, Weld-nut, Tight-nut, Nylon Block, Upper Magnet Block and Lower

Magnet Block.

1: Lift-arm Seat; 2: Lift-arm; 3: Main Mounting Plate;4: Sub-mounting Plate; 5: Weld-nut;

6: Thread Pole; 7: Upper Magnet Block; 8: Nylon Block; 9: Lower Magnet Block; 10: Proximity Switch;

11: Fastening Nut for Length Ajustment; 12: Fastening Nut for Angle Ajustment.

Detecting Distance Adjustment:

Method 1: Adjust the distance between the

inductive surface of proximity switch and

magnet block to 5mm.

Method 2: Adjust the distance between the

inductive surface of proximity switch and

Nylon Block to 8mm.

Suggestion: Install the position sensor on the

lift-arm seat and lift-arm which are at the same side

that the weighing indicator installed on.

15

5.1.4 Installation of Oil Pressure Sensor

1. Intallation Position

The upper oil connecting port and lower oil connecting port of

arm-lifting oil cylinder are the installation positions of oil

pressure sensors.

Suggestion: Install the oil pressure sensors on the arm-lifting

oil cylinder which is at the same side that the weighing

indicator installed on.

2. Safety Precaution

Using a stable and strong base to support the bucket of the

loader for avoiding accidental injury.

In the process of dismounting and mounting, the shovel loader

should be kept at flameout state.

Put a bucket under the oil connecting ports that will be

dismounted for oil collecting.

If the shovel loader has worked for a long time, the oil

temperature in the bucket-lifting cylinder will be very high.

Please let the shovel loader at flameout state for some time

before dismouting to avoide scalding.

Before dismounting the oil connecting port of the upper oil

chamber, let the bucket-lifting action bar stay at the position of

„LIFT‟ for making the upper oil chamber connect with main oil

tank and relief pressure.

Before dismounting the oil connecting port of the lower oil

chamber, let the bucket-lifting action bar stay at the position of

„FALL‟ for making the lower oil chamber connect with main

oil tank and relief pressure.

When somebody stays in driving cab, do not stay under the

shovel loader for avoiding accidental injury.

3. Installation

Wrap some sealing ribbons on the screw of oil pressure sensor

avoid oil leakage, and install it on the three-way joint firmly.

Fix the three-way joint [thickness: 19mm/21mm] and the oil

tube connector on the arm-lifting oil cylinder by the

lengthened screw rods which is about 20mm longer than

original screw rods.

4. Check Oil Passage

Start shovel loader, and lift the lift-arm and bucket with

accelerating for several times.

Check if there is the phenomenon of oil leakage at the oil

connecting ports.

www.zemicusa.info

16

5.1.5 Cable Laying

4

5

1

3 2 3 4 1 2 2

1

POWER

POSITION

LC-DN

LC-UP

9

34681

COM1

ON

OFF

4

5

1

3

2

www.zemicusa.info

Oil pressure sensor signal calble and position sensor signal cable should be laid in flexible pipe for

protection, and fix them with nylon strip.

Try to keep signal calbles away from the place with high temperature and possible extrusion, and

reserve their bending length enough to avoid being pulled apart.

5.2 Terminal

17

5.3 Connection

No.

Pin

Description

1

SIG-

4~20mA Weighing Signal Input -.

2

SIG+

4~20mA Weighing Signal Input +.

3

EXC-

Excitation Voltage Output - for Oil Pressure Sensor .

4

EXC+

Excitation Voltage Output + for Oil Pressure Sensor (DC12V).

5

SHD

Shield.

No.

Pin

Description

1

VS+

Excitation Voltage Output + for Oil Pressure Sensor ( DC12V).

2

SIN-A

Position Sensor A Signal Input.

3

SIN-B

Position Sensor B Signal Input.

Unused.

4

VS-

Excitation Voltage Output - for Oil Pressure Sensor.

5

SHD

Shield.

POSITION

3 4 1 2 4 5 1 3 2

LC-DN/LC-UP

www.zemicusa.info

5.3.1 Oil Pressure Sensor Connector (LC-DN/LC-UP)

Oil Pressure Sensor is definable via parameter [106] „Loadcell Channel‟ with default value „2: LC-DN-UP‟:

LC-DN: Connect the oil pressure sensor on the lower oil chamber of arm-lifting oil cylinder.

LC-UP: Connect the oil pressure sensor on the upper oil chamber of arm-lifting oil cylinder.

5.3.2 Position Sensor Connector (POSITION)

18

5.3.3 Power Supply Connector (POWER)

No.

Pin

Wire Color

Description

Voltage

1

GND

Black

DC Input -

DC24V±20%

2

+24V

Red

DC Input +

Note: Reverse polarity protection function available.

2

1

POWER

www.zemicusa.info

The power switch of the weighing indicator should be turned off and ensure that the power cables are not

charged before DC24V power connection to avoid short circuit fault.

Find the DC24V terminal with relative stable voltage in the driving cab, then connect the terminal „+24V‟of

the weighing indicator to the FUSE, and connect „GND‟ to the metal frame of the driving cab.

Please make sure that the power supply is correct before power-on.

19

6. System Adjustment&Calibration Procedure

Power on

Zero Calibration

Loading Opertaion

Loading Test

Zero Compensation

Span Calibration

Span Compensation

Oil Pressure Sensor Testing

and Parameters Setting

Position Sensor Testing

and Parameters Setting

www.zemicusa.info

20

7. Function&Operation

Main Menu

Second Menu

Description

1: SET

[Para. Setting]

1 Weighing

Weighing parameters setting.

2 Calibration

Calibration parameters setting.

3 Setpoint

Setpoint parameters setting.

4 Alarm

Alarm parameters setting.

5 Communcation

Communication parameters setting.

6 Display

Display and operation interface parameters setting.

2: CAL

[System

Calibration]

1 Zero Cal. [Unload&Idle]

Zero Calibration.

Lift the lift-arm and bucket of shovel loader with unloading

and idle speed for correcting Zero Value, Run Length Ratio

or IdleAcc.Value (Acceleration Value at Idle Speed).

2 Zero Comp. [Unload&ACC]

Zero Compensation.

Lift the lift-arm and bucket shovel loader with unloading and

accelerating for correcting Zero Compensation Coefficient.

3 Span Cal. [Load&Idle]

Span Calibration.

Lift the lift-arm and bucket shovel loader with loading and

idle speed for correcting Span Coefficient.

4 Span Comp. [Load&ACC]

Span Compensation.

Lift the lift-arm and bucket shovel loader with loading and

accelerating for correcting Span Compensation Coefficient.

3: REC

[Record Query]

1 Loading Records

Query Loading Records.

2 Reloading Records

Query Reloading Records.

Find and open record from the buffering database of

„Reloading Records‟ for reloading.

3 Operation Records

Query Operation Records.

4: CLR

[Data Clearing]

1 Clear Screen

Clear Screen with Saving Loading Record.

2 Clear Loading Rec.

Clear Loading Records.

3 Clear Reloading Rec.

Clear Reloading Records.

4 Clear Operation Rec.

Clear Operation Records.

www.zemicusa.info

7.1 Main Menu

21

Main Menu

Second Menu

Description

5: LOC

[Key-locker]

1 Key-unlocking

Unlocking keypad.

2 Key-locking

Locking keypad.

3 Password Set

Exfactory Passwords:

Operator Password: 000000.

Administrator Password: 000001.

6: TIME

[Time Setting]

1 Date

[903] Date Format.

2 Time

Hour: Minute: Second.

3 Week

Monday ~ Sunday.

7: FAC

[Factory Adj.]

1 Hardware Test

AD Value of Weighing Signal Linearity Test and Position

Signal Test.

2 Simplified Chinese

Download Simplified Chinese.

3 Complex Chinese

Download Complex Chinese.

4 Para. Backup

Parameter Backup.

5 Para. Recovery

Parameter Recovery.

6 Reset Defaults

Reset to factory defaults.

8: INF

[Product Info.]

1 Version No.

Only for query.

2 Serial No.

Only for query.

3 Exfactory Date

Only for query.

4 Auth. Code

Authorization Code.

Only for query.

www.zemicusa.info

22

7.2 Parameter Setting

No.

Range

Default

Description

Set

100

0~1

1

Load Weight Unit

Display Unit of Loading Weight.

0: kg

1: t

Note: Internal Scale Unit is kg.

101

0~1

1

TOT Weight Unit

Display Unit of Totalized Loading Weight.

0: kg

1: t

102

0~3

3

Ton-Decimal

0: o; 1: o.o; 2: o.oo; 3: o.ooo

103

1~50

10

Display Division

1, 2, 5, 10, 20, 50

If the Weight Variance without Decimal Point is less

than Display Division value, the display value will not

change. 104

0~200

50

Zero Range [kg]

105

0~5

5

ADC Frequency [Hz]

ADC Sampling Frequency.

0: 5; 1: 10; 2: 50; 3: 100; 4: 200; 5: 400

106

0~3

2

[*]

Loadcell Channel

0: LC-DN [Connect „LC-DN‟ to the oil pressure

sensor on the lower oil chamber of arm-lifting oil

cylinder; „LC-UP‟ is unused]

1: LC-UP [Connect „LC-UP‟ to the oil pressure

sensor on the lower oil chamber of arm-lifting oil

cylinder; „LC-DN‟ is unused]

2: LC-DN-UP [Connect „LC-DN‟ to the oil pressure

sensor on the lower oil chamber of arm-lifting oil

cylinder and connect „LC-UP‟ to the oil pressure

sensor on the upper oil chamber ]

3: LC-UP-DN [Connect „LC-UP‟ to the oil pressure

sensor on the lower oil chamber of arm-lifting oil

cylinder and connect „LC-DN‟ to the oil pressure

sensor on the upper oil chamber ]

www.zemicusa.info

7.2.1Weighing Parameters

* „Reset Defaults‟ operation has no effect on this parameter.

23

7.2.2 Calibration Parameters

No.

Range

Default

Description

Set

200

0~130000

10000

Zero Value [AD Value]

Zero Value at Idle Speed.

201

0~999999

10000

Zero Comp.Coeff.

Zero Compensation Coefficient at Accelerated Speed.

202

1~999999

1000

Span Coefficient

Span Coefficient at Idle Speed.

203

0~999999

0

Span Comp.Coeff.

Span Compensation Coefficient at Accelerated Speed.

204

5.0~100.0

10.0

Mag.Block Length [mm]

Length of Upper/Lower Magnet Block on Position

Sensor.

205

0.001~9.999

1.000

Run Length Ratio [LR]

Running Length Ratio LR=L1/L3.

L1: The actual running length of Upper Magnet Block

passing by Proximity Switch.

L3: The actual running length of Lower Magnet Block

passing by Proximity Switch.

206

0~250

100

Min. Switch Time [ms]

Min. Valid Time spent by Upper Magnet Block passing

by Proximity Switch.

Min. Valid Time spent by Lower Magnet Block passing

by Proximity Switch.

207

0~1000

500

Max. Comp.Weight [kg]

Max. Compensation Weight.

208

-0.0500

~+0.0500

0.0000

IdleAcc.Value A0 [dm/s2]

Acceleration Value at Idle Speed.

Key【Print】: „+‟/„-‟ switch.

No.

Range

Default

Description

Set

300

8 Characters

0

Car No.

301

8 Characters

01

Goods 302

8 Characters

01

Operator

303

20 Characters

01

User Name

304

0~99999

60000

Setpoint [kg]

www.zemicusa.info

* „Reset Defaults‟ operation has no effect on Calibration Parameters.

7.2.3 Setpoint Parameters

24

7.2.4 Alarm Parameters

No.

Range

Default

Description

Set

400

-0.0500

~+0.0500

-0.0050

Stall AlarmPoint [dm/s2]

If „Acceleration Value < Stall Alarm Point‟, the

weighing indicator will display the alarm message

„STALL‟.

Key【Print】: „+‟/„-‟ switch.

401

0~99999

5000

Load Lower Limit [kg]

Lower Limit of Single-bucket-loading-weight.

If „Loading Weight < Load Lower Limit‟, the weighing

indicator will display the alarm message „LOW‟.

402

0~99999

10000

Load Upper Limit [kg]

Upper Limit of Single-bucket-loading-weight.

If „Loading Weight > Load Upper Limit‟, the weighing

indicator will display the alarm message „HIGH‟.

403

0.000~99.999

0.100

Min. Weigh Time [s]

Min. Weighing Time.

If „Weighing Time < Min. Weighing Time‟, the

weighing indicator will display undertime alarm

message „UND-T‟.

404

0.000~99.999

10.000

Max. Weigh Time [s]

Max. Weighing Time.

If „Weighing Time > Max. Weighing Time‟, the

weighing indicator will display overtime alarm message

„OV-T‟.

405

0~1

1

Alarm Sound

0: OFF

1: ON

406

0~1

0

TOT/DEDwithAlarm

Totalizing/Deducting Permission While Alarming.

0: OFF

1: ON

www.zemicusa.info

25

7.2.5 Communication Parameters

No.

Range

Default

Description

Set

800

0~99

01

Comm. Address

Communication Address.

801

802

0~5

5

3

COM1/COM2 Baud Rate

0: 1200bps; 1: 2400bps; 2: 4800bps

3: 9600bps; 4: 19200bps; 5 :115200bps

803

804

0~2

0

0

COM1/COM2 ParityCheck

0: None; 1: Even; 2: Odd

805

806

0~4

0

2

COM1/COM2 Comm. Mode

Communication Mode.

0: Host-slave ASC [Modbus ASCII]

1: Continuous ASC [Continuous Sending ASCII]

2: Print [A]

3: Print [B]

4: Print [C]

No.

Range

Default

Description

Set

900

0~2

0

Language

0: S-Chinese [Simplified Chinese]

1: C-Chinese [Complex Chinese]

2. English

901

0.1~2.0

0.5

Disp.RefreshTime [s]

Display Refreshing Time.

902

0~1

0

Auto-Locking

0: OFF

1: ON [ If there is not any keypad operation in one

minute and it‟s not in the processes of „F2 Calibration‟

& „F7 Factory Adj.‟, the weighing indicator will lock

the keypad and return to „Main Display Interface‟

automatically ]

903

0~2

0

Date Format

0: YYYY. MM. DD [Year. Month. Day]

1: MM. DD. YYYY [Month. Day. Year]

2: DD. MM. YYYY [Day. Month. Year]

www.zemicusa.info

7.2.6 Display Parameters

26

7.3 System Calibration

New LR: 1.000

Old A0: 0.0000

New A0: 0.0000

Old LR: 1.000

0.000 t

1 Zero Calibration [Unload&Idle-speed]

▲

OK

OldZero

15000

NewZero

0

【Start】

www.zemicusa.info

7.3.1 Zero Calibration【Zero】

Make sure the bucket of shovel loader is empty.

BUCKET-UP: Flip the bucket upward to the limit position.

ARM-DOWN: Put the lift-arm down so that the bucket goes down to the lowest position.

Press key【Load】to display the blue sign „▲‟.

Press key【Zero】to display interface „Zero Calibration‟:

Lift the lift-arm and bucket with idle speed.

After the proximity switch passed by the weighing segment, display:

Blue sign „▼‟.

New Zero Value.

New Run Length Ratio.

New IdleAcc.Value A0 [Acceleration Value at Idle Speed, dm/s2].

Message „Save‟.

Message „Error‟: The detection result exceeds allowed range, and it‟s not allowed to be

saved.

Press key【Load】to display dialogue box „Save A0 or LR?‟.

Press key【◄】/【►】to select the button „Save A0‟, then prsee key【Enter】for saving new

Zero Value and IdleAcc.Value A0, and keep Run Length Ratio unchanged.

Select the button „Save LR‟, then prsee key【Enter】for saving new Zero Value and Run

Length Ratio and reset IdleAcc.Value to zero.

Suggestion: Please select „Save LR‟ at the first time of „Zero Calibration‟, after this, please

select „Save A0‟.

【Menu】: Exit without saving.

Repeat the above steps, if the variation of detection results are in the allowable range, Zero

Calibration process will be completed.

27

7.3.2 Zero Compensation【Z.cmp】

AD: XXXXX

ACC: 0.0000

R-AD: XXXXX

C.ER: 0

0.000 t

2 Zero Compensation [Unload&ACC-speed]

▲

OK

OldComp

0

NewComp

0

【Start】

www.zemicusa.info

Make sure the bucket of shovel loader is empty.

BUCKET-UP: Flip the bucket upward to the limit position.

ARM-DOWN: Put the lift-arm down so that the bucket goes down to the lowest position.

Press key【Load】to display the blue sign „▲‟.

Press key【Z.cmp】to display interface „Zero Compensation‟:

Lift the lift-arm and bucket with the usual accelerator in actual operation and keep the

accelerator stable.

After the proximity switch passed by the weighing segment, display:

Blue sign „▼‟.

New Zero Compensation Coefficient.

Compensation Difference [C.ER = New Zero Compensation Coefficient – Old Zero

Compensation Coefficient].

AD: AD Value at Weighing Segment.

ACC: Acceleration Value at Weighing Segment [dm/s2].

R-AD: Real-time AD Value.

Message „Save‟.

Message „Error‟: The detection result exceeds allowed range, and it‟s not allowed to be

saved.

【Enter】: Save; 【Menu】: Exit without saving.

Repeat the above steps, if the variation of detection results are in the allowable range, Zero

Compensation process will be completed.

28

7.3.3 Span Calibration【Cal】

AD: XXXXX

ACC: 0.0000

R-AD: XXXXX

SP.R: 1.00000

0.000 t

3 Span Calibration [Load&Idle-speed]

▲

OK

OldSpan

1000

NewSpan

0

【Start】

www.zemicusa.info

Use truck scale to get the seft-weight [Tare Weight] of the shovel loader.

Load materials into the bucket with 2/3 bucket, and use truck scale to get the gross weight of the

shovel loader and materials in the bucket.

Calculate Calibrating Weight [Calibrating Weight = Net Weight of Materials = Gross Weight –

Tare Weight]

BUCKET-UP: Flip the bucket upward to the limit position.

ARM-DOWN: Put the lift-arm down so that the bucket goes down to the lowest position.

Press key【Load】to display the blue sign „▲‟ .

Press key【Cal】to display interface „Span Calibration‟:

Lift the lift-arm and bucket with idle speed.

After the proximity switch passed by the weighing segment, display:

Blue sign „▼‟.

Weighing Result.

Message „[Enter]: Input Cal. Weight‟.

Press key【Enter】to display interface „Input Calibrating Weight‟.

After inputting the value of Calibrating Weight, press key【Enter】to display:

New Span Coefficient.

Correction Ratio [SP.R = New Span Coefficient / Old New Span Coefficient].

AD: AD Value at Weighing Segment.

ACC: Acceleration Value at Weighing Segment [dm/s2].

R-AD: Real-time AD Value.

Message „Save‟.

Message „Error‟: The detection result exceeds allowed range, and it‟s not allowed to be

saved.

【Enter】: Save; 【Menu】: Exit without saving.

Repeat the above steps, if the variation of detection results are in the allowable range, Span

Calibration process will be completed.

29

7.3.4 Span Compensation【S.cmp】

AD: XXXXX

ACC: 0.0000

R-AD: XXXXX

C.ER: 0

0.000 t

4 Span Compensation [Load&ACC-speed]

▲

OK

OldComp

1000

NewComp

0

【Start】

www.zemicusa.info

Keep Calibrating Weight [the materials weight in the bucket for Span Calibration] unchanged.

BUCKET-UP: Flip the bucket upward to the limit position.

ARM-DOWN: Put the lift-arm down so that the bucket goes down to the lowest position.

Press key【Load】to display the blue sign „▲‟ .

Press key【S.cmp】to display interface „Span Compensation‟:

Lift the lift-arm and bucket with the usual accelerator in actual operation and keep the

accelerator stable.

After the proximity switch passed by the weighing segment, display:

Blue sign „▼‟.

Weighing Result.

Message „[Enter]: Input Cal. Weight‟.

Press key【Enter】to display interface „Input Calibrating Weight‟.

After inputting the value of Calibrating Weight, press key【Enter】to display:

New Span Compensation Coefficient.

Compensation Difference [C.ER = New Span Compensation Coefficient – Old Span

Compensation Coefficient].

AD: AD Value at Weighing Segment.

ACC: Acceleration Value at Weighing Segment [dm/s2].

R-AD: Real-time AD Value.

Message „Save‟.

Message „Error‟: The detection result exceeds allowed range, and it‟s not allowed to be

saved.

【Enter】: Save; 【Menu】: Exit without saving.

Repeat the above steps, if the variation of detection results are in the allowable range, Span

Compensation process will be completed.

30

7.3.5 Loading Test

www.zemicusa.info

Keep Calibrating Weight [the materials weight in the bucket for Span Calibration] unchanged.

BUCKET-UP: Flip the bucket upward to the limit position.

ARM-DOWN: Put the lift-arm down so that the bucket goes down to the lowest position.

Press key【Load】to display the blue sign „▲‟ and entering loading state.

Lift the lift-arm and bucket with the usual accelerator in actual operation and keep the

accelerator stable.

After the proximity switch passed by the weighing segment, display blue sign „▼‟ and record

weighing result.

Repeat the above steps, if the variation of detection results are in the allowable range, the

preliminary Loading Test process is completed.

Do loading test with empty bucket, 1/2 bucket materials and a full bucket of materials, and use

truck scale for checking weighing error.

If these weighing errors are in the allowable range, the last Loading Test process will be

completed.

Press key【Pause】to display the red sign „■‟ and entering pause state.

Press key【Cls】to Clear Screen without Saving Loading Record.

31

8. Fault Treatment

www.zemicusa.info

Power Faults

Check if the power switch turns on.

Check if the power polarity is reversed.

Check if the power voltage is correct.

Check if the fuse in the weighing indicator has blown.

Check if the storage battery of shovel loader works well.

Position Sensor Faults

Check if the signal connection of proximity switch is correct.

Check the tight-nut on nylon block has loosed.

Check the magnet blocks on nylon block has loosed or falled off.

Check the distance between the proximity switch and the magnet block is beyond the

detecting range of 5~8mm.

Check the relevant parameter value are correct.

Check if the proximity switch is damaged.

Oil Pressure Sensor Faults

Check if the signal connection of oil pressure sensor is correct.

Check if there is the phenomenon of oil leakage at the oil connecting ports.

Check the relevant parameter value are correct.

Check if the oil pressure sensor is damaged.

Printer Faults

Check if the signal connection of printer is correct.

Check if the printer is damaged.

Keypad Faults

Check if the keypad connector has loosed or falled off.

Check if the keypad is damaged, and replace it when necessary.

32

9. Working Specification

www.zemicusa.info

9.1 Brief Description

Check oil pressure sensors and position sensor before starting the shovel loader.

Start the shovel loader, then lift the lift-arm and bucket for 5~10 times to preheating the hydraulic

oil.

BUCKET-UP: Flip the bucket upward to the limit position.

ARM-DOWN: Put the lift-arm down so that the bucket goes down to the lowest position.

Turn the power switch of weighing indicator on.

Press key【Zero】for Zero Calibration.

Confirm if there is a need to do System Clibration and loading Test.

After Loading Test, press key【Cls】to Clear Screen without Saving Loading Record.

Press key【Pause】to display the red sign „■‟ and enter pause state, and then let the bucket go

down to the lowest position.

Set Setpoint Parameters.

Press key【Load】to display the blue sign „▲‟ and enter loading state.

After shoveling materials into the bucket, flip the bucket upward to the limit position.

After the shovel loader reached the loading position, lift the lift-arm and bucket with accelerating

for weighing.

Once alarm occurs, press key【Void】to Cancel Totalizing, then lift the lift-arm and bucket for

weighing again.

After weighing finished, flip the bucket downward for discharging materials.

After Totalized Loading Weight reached setpoint, press key【Finish】to save and print Loading

Record, and Clear Screen automatically after Loading process finished.

Before going off work, turn the power switch of weighing indicator off at first, then turn the

power switch of shovel loader off.

33

9.2 Detailed Description

www.zemicusa.info

Checking Before Starting the shovel loader

Check if there is a phenomenon of oil leakage at the oil connecting ports.

Check if the detecting distance of position sensor is in the range of 5~8mm.

Check if there are some iron filings stick on the magnet blocks of position sensor.

Check if the rotation shafts of lift-arm and bucket are with good lubrication to reduce the

friction influence on weighing accuracy.

System Calibration [Zero Calibration&Compensation, Span Calibration&Compensation]

Start the shovel loader, then lift the lift-arm and bucket for 5~10 times to preheating the

hydraulic oil and oil pressure sensors to the temperature in normal working condition.

BUCKET-UP: Flip the bucket upward to the limit position.

ARM-DOWN: Put the lift-arm down so that the bucket goes down to the lowest position.

Turn the power switch of weighing indicator on.

Press key【Zero】to do Zero Calibration with unloading and idle speed for correcting Zero

Value, Run Length Ratio or IdleAcc.Value (Acceleration Value at Idle Speed).

After doing Zero Calibration, keep the bucket at the limit position, and put the lift-arm down

so that the bucket goes down to the lowest position.

Lift the lift-arm and bucket with the usual accelerator in actual operation and keep the

accelerator stable. If the display weight exceeds 30kg, then it‟s need to do System Calibration

again.

It‟s need to do System Calibration again on the following conditions:

After replaced the oil pressure sensors.

After the installation position, angle or detecting distance of the position sensor has been

changed.

The hydraulic system of shovel loader has been changed.

After replaced the bucket of shovel loader.

The weigher has not been used for a long time.

After re-done System Calibration, it‟s need to do Loading Test again.

After Loading Test finished, Press key 【Cls】to Clear Screen without Saving Loading Record.

Working Procedure of Loading

Set Setpoint Parameters.

If the bucket is not on the lowest position when the weighing indicator display the blue sign

„▲‟, please press key【Pause】 to display the red sign „■‟and enter pause state, then let the

bucket go down to the lowest position.

Press key【Load】to display the blue sign „▲‟ and enter loading state.

34

After shoveling materials into the bucket, flip the bucket upward to the limit position. Then

www.zemicusa.info

the magnet blocks on the lift-arm should be under the proximity switch.

After the shovel loader reached the loading position, lift the lift-arm and bucket with the usual

accelerator in actual operation and keep the accelerator stable.

After the proximity switch passed by the weighing segment, display the blue sign „▼‟ and the

present Single-bucket-loading-weight.

If there is no sound-light alarm and the prompt message is „ADD‟, it means that the present

Single-bucket-loading-weight has been added to Totalized Loading Weight automatically and it‟s

allowed to discharge materials from the bucket.

If there is a sound-light alarm and the prompt message is „ADD‟, it means that the present

Single-bucket-loading-weight has been added to Totalized Loading Weight automatically. If you press

key【Void】to Cancel Totalizing, then the prompt message will be „NO ADD‟, then it‟s not allowed

to discharge materials from the bucket, and It‟s need to lift the lift-arm and bucket for weighing again.

If there is a sound-light alarm and the prompt message is „NO ADD‟, it means that the present

Single-bucket-loading-weight has not been added to Totalized Loading Weight and it‟s not allowed to

discharge materials from the bucket. It‟s need to lift the lift-arm for weighing again.

After weighing finished, flip the bucket downward for discharging materials.

After the bucket going down to the lowest position, the weighing indicator will display the

blue sign „▲‟ again, and enter the working process of the next bucket.

“Last Bucket” Prompt: The display area of „Totalized Loading Weight‟ will change to red

background if „Negative Deviation Value<3t‟, it means that the next bucket may be the last

one, the operator should determine the loading weight of the next bucket according to the

actual Negative Deviation Value.

After Totalized Loading Weight reached setpoint, press key 【Finish】to save and print

Loading Record, and Clear Screen automatically after Loading process finished.

When you need to pause, please press key【Pause】to display the red sign ‘■’ .

Before going off work, turn the power switch of weighing indicator off at first, then turn the

power switch of shovel loader off.

Other Attentions

Try to choose a level ground or a ground with the angle less than 15 degrees for weighing and

System Calibration.

Try to avoid weighing in the shovel loader moving process. If you need to do it, the moving

speed should be controlled under 10km/h.

To avoid the water splashing on the weighing indicator when cleaning the shovel loader.

35

Appendix A. Print Formats

NO.:

DATE:

TIME:

OP.:

GOODS:

CARNO:

SET:

TOT:

PCS:

#01:

…

#12:

#200

05-20-2009

23:59:45

01

00

00000010

60.00t

59.90t

12

4.80t

…

2.60

LOADING RECORD

NO.:

DATE:

TIME:

OP.:

GOODS:

CARNO:

SET:

TOT:

PCS:

#200

05-20-2009

23:59:45

01

00

00000010

60.00t

59.90t

12

LOADING RECORD

www.zemicusa.info

Print Format 1 for Single Record

Print Format 2 for Single Record

36

Appendix B. Register Table of Host-Slave MODBUS[ASCII]

Data Name

Type

Address

Attribute

Command

[HEX]

Description

Totalized Loading Weight

Long

40001 R 03

Single-bucket-

loading-weight

Long

40003 R 03

Bucket Count

Long

40005 R 03

Present Record No.

Long

40007 R 03

Alarm State

Long

40009.0

R

03

1: Stall Alarm.

40009.1

40009.2

1: Undertime Alarm.

40009.3

1: Overtime Alarm.

40009.4

1: Upper Limit Alarm of

Single-bucket-loading-weight.

40009.5

1: Lower Limit Alarm of

Single-bucket-loading-weight.

40009.6

40009.7

40009.8

40009.9

40009.10

40009.11

40009.12

40009.13

40009.14

40009.15

……

40009.31

Real-time Weight Value

Long

40011 R 03

Display Unit of Loading

Weight

Short

40013 R 03

Display Unit of Totalized

Loading Weight

Short

40014 R 03

Ton-Decimal

Short

40015 R 03

Bucket State

Short

40016 R 03

0: ▲[Loading].

1: ▲[1].

2: ▲[2].

3: ▲[3].

4-7: ▼.

8: ■[Pause].

Setpoint

Long

40017 R 03

www.zemicusa.info

37

Data Name

Type

Address

Attribute

Command

[HEX]

Description

Historical Record No.

Long

40019 W 10

For Record Query.

Historical Record Data

Packet

12-Short

40021

~40032

R

03

Char 1~8:

1: Second.

2: Minute.

3: Hour.

4: Day.

5: Month.

6: Week.

7: Year.

8: 14H [20D]

Char 9~12: Totalized Loading

Weight [Long]

Char 13~14: Bucket Count [Short]

Char 15~24: Goods [ASCII]

Note: „Char1=2DH‟ means „No

Record‟.

www.zemicusa.info

Record Query: Write the „Record No.‟ for query into the register [40019] at first, then read the whole data packet of the

registers [40021~40032].

38

User’s Memo

www.zemicusa.info

39

www.zemicusa.info

Changsha Supmeter Technological Co.,Ltd.

Address: Building A6, Lugu International Industrial Park,

Changsha, 410205, China

Tel: +86 731 85115100

Fax: +86 731 85158100

Website: www.supmeter.com.cn

E-mail: supmeter@163.com

Loading...

Loading...