BST106-F19 Weighing Controller

For: Dynamic Axle Weigher

Operation Manual V7.2

Changsha Supmeter Technological Co.,Ltd.

1

Preface

Thank you very much for your purchase!

This manual covers safety precaution, technical specification, operation interface, installation&

connection, function&operation and so on. In order to make the product running at its best, please read this

manual in advance, and reserve it for the future reading.

The techno log y upd ate , funct io n enha nce me nt and qua lit y impr ove ment ma y lea d to so me di fference s

between this manual and the physical product, please understand.

Without our autho rization, the contents of this manual are not allowed to be copied and reproduced.

Main Features:

Suitable for Dynamic Axle Weigher (Max. axle count 99 and max. speed 10km/h).

EMC design with high anti-jamming capability, suitable for industrial environment.

6+10 green VFD digital tubes for for English character and digit display.

Optional English keypad, Simplified Chinese keypad and Complex Chinese keypad.

Menu&Shortcut mode operation with key tone.

24-bit High-precision and high-speed ∑-△A/D conversion module with 1/1,000,000 internal

resolution and sampling frequency 400Hz.

Special anti-vibration digital filtering algorithm for ensuring the weighing stability and accuracy

when there is str ong vibration on the load receptor, and the rapid response capability when the

weight signal changes.

Max. Con nection Quanti ty: 8 Loadcells (350Ω).

Auto Zero Initial Calibration after Power-on, Auto Zero Tracking, Zero Fine Adjustment, Zero

Calibration and Load Calibration functions available.

Optional Data Calibration function.

Auto-locking, Key-locking, Key-unlocking, Digital Setting&Calibration and I/O Testing

functions available.

1 Optional and definable analog signal output [AO: 4~20mA].

3 Normally open switch inputs [DI] and 5 normally open relay switch outputs [DO].

2 Optional communication ports for linking to Host IPC/PLC, LED Remote Display, Serial

Printer and Wireless Module.

The present axle weighing record can be printed automatically and manually.

The historical axle weighing records can be queried and printed.

With the multitasking mode, the weighing&control process will not be interrupted by parameter

setting and the other operations.

Model Panel-mounting: F19

Model Explosion-proof:F19EX

2

Contents

1. SAFETY PRECAUTION .................................................................................................................4

2. TECHNI CAL SPE CIFI CATION ....................................................................................................5

3. OPERATION INTERFACE ............................................................................................................7

3.1 MODEL PANEL-MOUNTING OPERATION INTERFACE ............................................................................... 7

3.2 MODEL EXPLOSION-PROOF OPERATION INTERFACE .............................................................................. 8

3.3 KEYPAD OPERATION.............................................................................................................................. 9

3.4 STATE INDICATION ............................................................................................................................... 10

3.5 ALARM SIGN ........................................................................................................................................11

4. INSTALLATION&CONNECTION ..............................................................................................12

4.1 INSTALLATION ..................................................................................................................................... 12

4.1.1 Model Panel-mounting Installation ........................................................................................... 12

4.1.2 Model Explosion-proof Installation ........................................................................................... 13

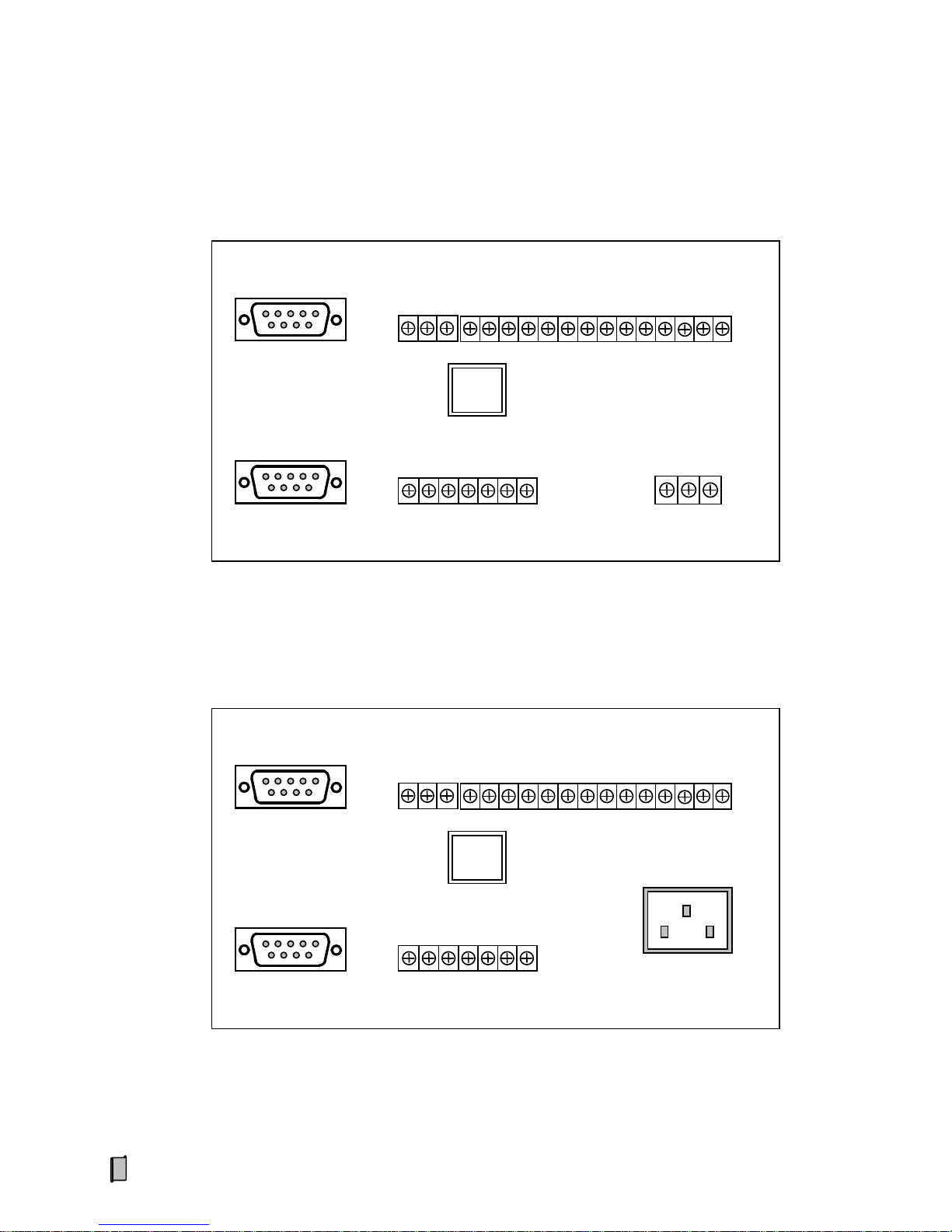

4.2 TERMINAL ........................................................................................................................................... 14

4.2.1 Model DC24V Terminal ............................................................................................................ 14

4.2.2 Model AC85~264V/AC220V T ermin al ..................................................................................... 14

4.3 DO/DI FUNCTION DEFINITION ............................................................................................................ 18

4.4 DO/DI CONNECTION FOR TYPLE APPLICATION ................................................................................... 19

5. OPERATION PROCEDURE ........................................................................................................20

6. FUNCTION&OPERATION ..........................................................................................................21

6.1 MAIN DISPLAY INTERFACE .................................................................................................................. 21

6.1.1 Gross/Net Weight, Axle No. / Axle Count, Axle Weight / Total Axle Weight [TOT] ................ 21

6.1.2 Gross/Net Weight, AO Output Value [Ao] ................................................................................ 22

6.2 MAIN MENU ........................................................................................................................................ 23

6.3 F1-SET PARAMETER SETTING ............................................................................................................. 25

6.3.1 Weighing Parameters (SCAL) ................................................................................................... 25

6.3.2 Calibration Parameters ( CALP)................................................................................................. 27

6.3.3 Setpoint Parameters (SEtP) ....................................................................................................... 29

6.3.4 Communication Parameters (SErP) ........................................................................................... 31

6.3.5 Display Parameters (dISP) ........................................................................................................ 33

6.3.6 Time Parameter (tIEE) ............................................................................................................... 33

6.3.7 A Sample of Parameter Setting .................................................................................................. 34

3

6.4 F2-CAL SYSTEM CALIBRATION .......................................................................................................... 35

6.4.1 Zero Calibration (ZEro) ............................................................................................................. 35

6.4.2 Data Calibration (dAtA) ............................................................................................................ 36

6.4.3 Load Calibration (LoAd) ........................................................................................................... 38

6.5 F3-REC RECORD QUERY .................................................................................................................... 39

6.6 F4-CLN DATA CLEARING ................................................................................................................... 40

6.7 F5-LOC KEY-LOCKER ......................................................................................................................... 41

6.7.1 Key-unlocking (oP En) ............................................................................................................... 41

6.7.2 Key-locking (Locc) ................................................................................................................... 41

6.7.3 Password Set (PASS) ................................................................................................................. 42

APPENDIX A. PRINT FORMATS ...................................................................................................43

APPENDIX B. REG ISTER TABLE OF HOST-SLAVE MODBUS[ASCII/RTU] ........................44

APPENDIX C. DATA FRAME FORMA T OF CONTINUOUS SENDING [ASCII] ....................47

4

1. Safety Precaution

Lithium Battery I nstallation

A Lithium batter y should be equipped in th e product. If it is not allowed to be transported

together with the product because of embargo, please make a purchase according to the

model offered by us and install it by yourself.

Application environment

Make sure that this product w orks under the environment where is accord with th e technical

specifications. Do not open the shell before power-off.

Avoid using the product under overheated environment

Make sure that the produc t works under the environment with allowed tem perature r ange to

get good performance and long working life.

Please keep the produc t awa y from dir ect sunli ght. If it is installed in a cabinet, pleas e install

cooling fans on the top of the cabinet.

Controller Grounding Protection

The product, as a low-voltage equipment, should be kept away from the high-voltage

equipments.

For avoiding bodily injury from electric shock accident and keeping the product separate from

strong interference, the metal shell of the product should be grounded directly and the ground

resistance should be less than 4Ω.

Scale Frame Grounding Protection

For avoiding bodily injury from electric shock accident and keeping the loadcells separate

from strong interference, the scale frame should be connected with the electronic scale

grounding net and the ground resistance should be less than 4Ω.

Cable Laying

Weighing signal, analog sig nal a nd c om munication signal cables should be laid in pipes, and

do not lay them together with power cables.

Power Supply

Please make sure that the inputted voltage is correct before power-on.

If the voltage fluctuation ex ceeds the allowed range, please use a power stabilizer to get a

stable voltage supply.

Environmental Protection

Before the Lithium battery equipped in the product being discarded, please insulate its

positive or negative pole, do not put it into fire.

Although the product is made of the lead-free components, after used in the industrial

environments, it’s possible to be polluted. So, while being discarded as worthless, the product

should be processed lawfully as leady industrial waste for environment protection.

Other Notes

The installation, wiring and maintenance should be operated by the engineers with the

relevant professional knowledge and safety operation ability. Although being not described in

this manual, the relevant safety operating procedures and standards should be followed.

5

2. Technical Specification

Executing Standard

CMC GB/T 7724-2008《Electronic Weigh ing Meter》PRC National Standard.

OMIL R76: 2006《Non-automatic Weighing Instruments》International Recommendation.

Accuracy Grade: III .

Number of Verification Intervals: 5,000.

Static Weighing Accuracy: 0.2‰.

Display

6+10 Green VFD digital tubes for for English character and digit display.

Weight Display Range: -99,999~+999,999.

Scale Capacity: Setting Range 1~999,999.

Scale Division: Op tional 1, 2, 5, 10, 20, 50, 100, 200, 500.

Display Resolution: 1/100,000.

Weight Unit: Optional kg, t, g, none.

Decimal Point: Optional 0, 0.0, 0.00, 0.000, 0.0000.

Display Refreshing Time: Se t ting Range 0. 01~1.00s.

Kaypad

Optional 8-key English keypad, Simplified Chinese keypad and Complex Chinese keypad.

Menu&Shortcut mode operation with key tone.

Loadcell Interface

Excitation Voltage/Max. Curre nt : DC10V/250mA [8-350Ω loadcells].

Signal Input Range: 0~25mV.

Output Sensitivity of Loadcell: 1.0~2.5mV/V.

24-bit ∑-△ADC with internal resolution 1/1,000,000.

Sampling Frequency: 400Hz.

Special anti-vibration digital filtering algorithm.

Zero Drift: ±0.1μV/℃ RTI (Relative to Input).

Gain Drift: ±5ppm/℃.

Non-linearity: 0.005%FS.

Switch&Analog S ignal Interface

3 Normally Open Switch Inputs [DI].

5 Nor mally Open Relay Switch Outputs [DO]: AC250V/DC24V, 1A.

1 Optional&Definable Analog Signal Output [AO]: 4~20mA, Non-linearity: 0.05%FS.

Digital Communication Interf a c e

COM1: Fixed configuration RS232&RS485. Free to use one of them.

COM2: Optional RS232/RS485/RS422/Profibus-DP/Ethernet modules.

Connectable: Host IPC/PLC, LED Remote Display, Serial Printer and Wireless Module.

6

Report Print

The present axle weighing record can be printed automatically and manually.

The historical axle weighing records can be queried and printed.

Operating Specification

Optional Operating Voltage

Operating Voltage 1: DC24V±20%.

Operating Voltage 2: AC85~264V, 50/60Hz.

Operating Voltage 3: AC220V±15%, 50/60Hz.

Free to configure one of them.

Max. Power Consumption: 10W.

Outline Size

Model Panel-mounting: 164×82×188mm [W×H×D].

Model Explosion-proof: 340×390×205mm [W×H×D].

Panel Cut-out Size

Model Panel-mounting: 153×77mm [W×H].

Operating Temperature: -25℃ to +40℃.

Storage T emperature: -30℃ to +60℃.

Relative Humidity: Max. 85%RH.

Application Environment of Model Explosion-proof

Explosion gas environment: Zone 1&2.

Classes of explosion gas mixture: IIA, IIB.

Temperature grades of explosion gas mixture: T1~T6.

Ex-mark: Ex d IIB T6 Gb.

Protection Level

Front Panel of Model Panel-mounting: IP65.

Model Explosion-proof: IP65.

Weight

Model Panel-mounting: Approx. 1.6kg.

Model Explosion-proof: Approx. 19.2kg.

7

3. Operation Interface

3.1 Model Panel-mounting Operation Interface

F1

±

→C←

CAL

→0←

ZERO

∧

→T←

TARE

∨

∑

ENT

G/N

>

MENU

SET

<

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

8

3.2 Model Explosion-proof Operation Interface

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

F1

±

G/N

►

MENU

SET

◄

∑

ENT

→T←

TARE

▼

→0←

ZERO

▲

→C←

CAL

9

3.3 Keypad Operation

If there is not any keypad operation in one minute and it’s not in the processes of ‘F2 Calibration’ & ‘F6 Factory

Adj.’, the controller will return to ‘Main Display Interface’ automatically.

*: Keep the key pressed for 2 seconds.

Menu Operation

Key Name Description

【MENU】 Enter Main Menu / Exit.

【ENT】 Enter / Save / Alarm Acknowledge.

【◄】

Cursor shifts left.

【►】 Cursor shifts right.

【▲】

Display the previous interface or option.

Digit input: +1.

【▼】

Display the next interface or option.

Digit input: -1.

Quick Operation

【

】

*

Key-locking.

Key-unlocking.

【SET】 Setpoint parameters setting.

【G/N】 Gross Weight / Net Weight display switch.

【→C←】

【CAL】

*

Load Calibration.

【→0←】

【ZERO】

*

[-ZEro-]: Zero Calibration with Power-down Protection and Clearing Tare Weight.

[≡ZEro≡]: Zero Fine Adjustment without Power-down Protection and without Clearing

T are Weight.

The controller will switch to Gross Weight display.

【→T←】

【TARE】

*

[≡tArE≡]: Manual Tare without Power-down Protection.

[-PStr-]: Preset Tare Weight with Power-down Protection.

[-rStr-]: Clear Tare Weight wit h Power-down Protection.

The controller will switch to Net Weight display.

【

】* Record Query.

【】

*

Clear Screen:

C lear the display value of Axle Count and Total Axle Weight.

Cear Alarm.

Cancel the present axle weighing process.

【

】* Time display and setting.

【

±

】 ‘+’/‘-’ switch.

【】

Main Display Interface: Print Present Axle Weighing Record.

R ecord Query State: Print Historical Axle Weighing Record.

【∑】

Stop Axle Weighing Process & Print: After the present axle has been weighed, the axle

weighing process will end and the Axle Weighing Record will be printed.

10

3.4 State Indication

Sign Description

[GROSS] Gross Weight display.

[NET] Net Weight display.

[LOCK]

ON: Key-locked.

OFF: Key-unlocked.

[◣◢]

Weight is stable: Weight Variance per [107] ‘Stablity Judging Time’ is in [106] ‘Stablity

Judging Range’.

[→0←]

The present Gross Weight or Net Weight display value is in ‘Display Value Auto-Zero

Range.

[kg/t/g] Weight unit.

[ NUM] Axle No. or Axle Count display.

[TOT] Total Axle Weight display.

[SET] Parameter setting state.

[RUN]

ON: Axle W eighing state.

OFF: Waiting or Calibrating state.

[ZERO] Net Weight value ≤ Non-load Zero Range [Min. Valid Axle Weight].

[NZ] It’s allowed to do Zero Fine Adjustment.

[FILL] Weigh t value is increasing [An axle is entering the weighing platform].

[COMP] Permit to do axle identification by DI switch.

[DISC] Weight value is reducing [An axle is exiting from the weighing platform].

[HH] Total Axle Weight Upper Limit Alarm.

[HI] Axle Weight Upper Limit Alarm .

11

3.5 Alarm Sign

Sign Alarm Cause Solution

Err1 RAM Failure. Replace the chip RAM.

Err2.1

Err2.2

EEPROM Failure. Replace the chip EEPROM.

Err3

Signal Reversed.

Not connected.

Connect the loadcel l correctly.

Err4 ADC Failure. Replace the ADC module.

oV-Ad Over ADC Range.

Weigh ing signal exceeds A/D conversion range.

1. Check if the loadcell is connected.

2. Check if the capacity of loadcell is too small.

3. Check if the loading weight is too big.

oL Overload Alarm.

Gross Wei ght > (Scale Capacity + 9 × Scale Division).

1. Check if the loadcell is connected.

2. Check if the capacity of loadcell is too small.

3. Check if the loading weight is too big.

oV-tr

Not meet the condition of

Maunal Tare.

When Gross Weight is at the state with negative value display,

overload alarm or dynamic variation, ‘Manual Tare’ will be

invalid.

oV-nZ

Over

‘Zero Fine Adjusting

Range’.

Refer to parameter [1 23] ‘Zero Fine Adjusting Range’.

HEAt

Preheating Time Countdown

[min.sec].

Refer to parameter [128] ‘Auto Zero Initial Calibration after

Power-on’, [129] ‘Auto Zero Initial Calibrating Time’ and

[130] ‘Auto Zero Initial Calibrating Range’.

Wait for the preheating time over or press any key to exit.

oV-Zr

Over ‘

Auto Zero Initial

Calibrating Range’.

Prt-undEF Print port is not defined. Refer to ‘Communication Parameters’.

12

4. Installation&Connection

4.1 Installation

4.1.1 Model Panel-mounting Installation

Outline Size

W×H×D[mm]

Front Panel Size

W×H[mm]

Box Body Size

W×H[mm]

Panel Cut-out Size

W×H[mm]

164×82×188 164×82 152×76 153×77

Installation Mode

153

77

Panel Cut-out Size

Outline Size Front Panel Size

188

82

164

(76)

(152)

13

4.1.2 Model Explosion-proof Installation

Outline Size

W×H×D[mm]

Mounting Size

W×H[mm]

Mounting Hole Size

[mm]

340×390×205 288×230 Ф11

14

4.2 Terminal

4.2.1 Model DC24V Terminal

4.2.2 Model AC85~264V/ AC220V Terminal

ETHERNET

POWER

N

L

E

LOADCELL

SIG-

SIG+

EXC-

SEN-

EXC+

SEN+

SHD

DO/DI

DO1+

DO1-

DO2+

DO2-

DO3+

DO3-

DO4+

DO4-

DO5+

DO5-

COM

DI1

DI2

DI3

AO

AO+

AO-

SHD

COM1

COM2

ETHERNET

LOADCELL

SIG-

SIG+

EXC-

SEN-

EXC+

SEN+

SHD

DO/DI

DO1+

DO1-

DO2+

DO2-

DO3+

DO3-

DO4+

DO4-

DO5+

DO5-

COM

DI1

DI2

DI3

AO

AO+

AO-

SHD

COM1

COM2

POWER

DC-

DC+

PG

15

No. Pin Description

LOADCELL Loadcell Port

Connection Mo de 6-Wire 4-Wire

Internal Dip Switch DIP1 DIP1→【6-WIRE】

DIP1→【4-WIRE】

[Default Set]

1 SIG- Weighing Signal [mV] Input -. Weighing Signal [mV] Input -.

2 SIG+ Weighing Signal [mV]Input +. Weighing Signal [mV] Input +.

3 EXC- Excitation Voltage -. Excitation Voltage -.

4 SEN- Feedback Voltage -.

5 EXC+ Excitation Voltage + [DC10V]. Excitation V ol tage + [DC10V].

6 SEN+ Feedback Voltage +.

7 SHD Shield Ground. Shield Ground.

POWER Power Input Port

DC24V DC24V[±20%] Power Input

1 DC- DC Input -.

2 DC+ DC Input +.

3 PG P rotective Ground.

AC AC85~264V or AC22 0V[±15%] Power Input

1 N Null Wire.

2 E Protective Ground.

3 L Live Wire.

The metal shell should be grounded directly to avoid electric shock.

16

No. Pin Description

COM1

RS232/RS 485 Digital Communication Port

[Free to use one of them]

DB9 Socket RS232 RS485

1 B- Data -.

2 A+ Data +.

3

4

5 GND Signal Ground / Shield Ground. Shield Ground.

6 TXD Transmit Data.

7 RXD Receive Data.

8

9 +5V +5V/100mA Output. +5V/100mA Output.

No. Pin Description

COM2

RS232/RS485/RS422/Profibus-DP/Ethernet Digital Communication Port

[It's optional to configure one of them]

DB9 Socket RS232 RS485 RS422 Profibus-DP

1 B- TXD-

2 RXD A+ TXD+

3 TXD RXD+ DP- [B-]

4 RXD-

5 GND GND GND GND

6

7

8 DP+ [A+]

9

RJ45[DCE] Socket

Ethernet

[T568B Wiring Mode]

1 RXD+ Orange-white

2 RXD- Orange

3 TXD+ Green-white

4 Unused Blue

5 Unused Blue-white

6 TXD- Green

7 Unused Brown-white

8 Unused Brown

17

No. Pin Description

AO Anal o g Output Port [Definable]

1 AO+ 4~20mA Output +.

2 AO- 4~20mA Output -.

3 SHD Shield Ground.

DO/DI Relay Sw itch Signal Output / Switch Signal Input Port

DO Relay Switch Signal Output [Definable]

1 DO1+

Normally Open Contact Output 1 [+/-].

2 DO13 DO2+

Normally Open Contact Output 2 [+/-].

4 DO25 DO3+

Normally Open Contact Output 3 [+/-].

6 DO37 DO4+

Normally Open Contact Output 4 [+/-].

8 DO49 DO5+

Normally Open Contact Output 5 [+/-].

10 DO5-

DI Sw itch Signal Input

11 COM DI Common Terminal [GND].

12 DI1 Switch Signal Input 1.

13 DI2 Switch Signal Input 2.

14 DI3 Switch Signal Input 3.

Contact Capacity of Relay Switch: AC250V/DC24V, 1A.

18

4.3 DO/DI Function Definition

Note: Whether to do Axle Identification by switch DI1 or not is decided by the parameter “[205] dI1.Id”.

No. Pin Sign al Name Description

1 DO1+

RUN Axle Weighing State.

2 DO13 DO2+

FINI Axle Weighing Process Finished.

4 DO25 DO3+

HH Total Axle Weight Upper Limit Alarm.

6 DO37 DO4+

HI Axle Weight Upper Limit Alarm.

8 DO49 DO5+

ZERO Non-load Zero Range.

10 DO511 COM COM DI Common Terminal [GND].

12 DI1 AXLE_ID

Axle Identification.

ON: There is an axle entering t he weighing platform.

13 DI2 TARE

Manual Tare.

OFF→ON→OFF.

14 DI3

【∑】

Axle Wei ghing State: Stop Axle Weighing Pro cess & Print

(After the present axle has been weighed, the weighing

process will end and the Axle Weighing Record will be

printed).

OFF→ON→OFF.

【】

Waiting State: Print the present Axle Weighing Record.

OFF→ON→OFF.

19

4.4 DO/DI Connection for Typle Application

Weighing Platform

V≤10km/h

A1~A99

A1 A2

…

An

Summing Box

Optional Axle Identification DI Switch

COM

DI1

DI2

DI3

Push Button

Switch

DI Common Terminal

Axle Identification AXLE_ID

Maunal Tare TARE

Stop Axle Weighing Pro ces s / Print

Axle Weighing State

RUN

Axle Weighing Process Finished

FINI

Total Axle Weight Upper Limit

HH

Axle Weight Upper Limit

HI

Non-load Zero Range

ZERO

AC220V or DC24V

DO1+

DO1-

DO2+

DO2-

DO3+

DO3-

DO4+

DO4 -

DO5+

DO5-

DO [Realy]

DI

20

5. Operation Procedure

Connection & Power on

Zero Calibration

Other Settings

Key-locking

Scale Setting

Auto Zero Tracking Range &

Zero Fine Adjusting Range Setting

Setpoint Setting

[Data Calibration]

Load Calibration

21

6. Function&Operation

6.1 Main Display Interface

【▲】【 ▼】: Display interface switch.

6.1.1 Gross/Net W eight, Axle No. / Ax le Count, Axle Weight / Total Axle Weigh t [TOT]

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

In the Axle Weighing process, display:

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

Axle Count [E00~E99] & Total Axle Weight.

T otal Axle W eig ht will be kept displaying till the next axle weighing

process started.

After the axle weighin g process, display:

Axle No. [A01~A99] & Axle Weight.

After Axle 99 has been weighed, the weighing process will end.

22

6.1.2 Gross/Net Weight, AO Output Value [Ao]

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

AO: 4.00~20.00mA.

23

6.2 Main Menu

Main Menu Second Menu

Sign Function Sign Description

F1-SEt

Parameter

Setting

-SCAL- Scale parameters setting.

-CALP- Calibration parameter setting.

-SEtP- Setpoint parameters setting.

-SErP- Communication parameters setting.

-dISP- Display and oper ation interface parameters setti ng.

-tIEE- Time parameters setting.

F2-CAL

System

Calibration

-ZEro-

Zero Calibration without loading on the weigher to correct Zero

Value.

-dAtA-

Data Calibration: Input the specification parameter values of loadcell

[Total Capacity and Output Sensitivity] according to the actual

configuration

of the weighing system to correct Span Coefficient. If

there is no access to get the specificat ion parameter values for Data

Calibration, then it’s necessary to do Load Calibration.

-LoAd-

Load Calibration: After doing Data Calibration, if there are

conditions for Load Caliration, do Load Caliration with loading

standard weight on the weigher to correct Span Coefficient further for

higher weighing accuracy.

F3-rEC

Record

Query

Record Query.

F4-CLn

Data

Clearing

--CLS-

Clear Screen:

C lear the display value of Axle Count and Total Axle Weight.

C ancel the present axle weighing process.

--CLr- Clear Records: Clear all of the axle weighing records.

F5-Loc Key-locker

-oPEn- Key-unlocking.

-Locc- Key-locking.

-PASS-

Password Set.

Exfactory Passwords:

Operator Passwor d: 000000.

Administrator Pas s word: 000001.

24

Main Menu Second Menu

Sign Function Sign Description

F6-FAC

Factory

Adjustment

Special for manufactur er.

-SPAn-

Exfactory Span Adjustment: Use standard weighing test equipment to

adjust the weighing signal interfa ce for normalizing Span Coefficien t

to 1.

-AdtS- AD Value of Weighing Signal Linearity Test.

-AoZF- AO Zero/Full Adjustment.

-AotS- AO Linearity Test.

-dIdo- DI/DO Input&Output Te st.

-dEFU- RAM Reset : Reset to factory defaults.

-dStS- Display/DO Reliability Test.

F7-InF

Product

Information

Only for query.

--VEr- Vers ion No.

--Sn-- Serial No.

-dAtE- Exfactory Date.

-AutH- Authorization Code.

F8-Aud Audit Trail

Only for query.

-Cntr- Operation A udit Trail Counter [0~999999].

-oPtr-

Operation T ra il.

nonE: No Operation.

SCAL: Scale Setting.

CLr: Clear Records.

dEFU: RAM Reset.

25

6.3 F1-SET Parameter Setting

6.3.1 We ighing Parameters (SCAL)

No. Sign Range Default Description Set

100 UnIt 0~3 2

Weight Unit

0: None

1: kg

2: t

3: g

101 dot 0~4 ooo.oo

Decimal Point

0: ooooo

1: oooo.o

2: ooo.oo

3: oo.ooo

4: o.oooo

102 SCALE 1~999999 2000

Scale Capacity

Max. loading weight of the load receptor.

Scale Capacity≤ (Loadcell Capacity × Loadcell

Quantity) – Load Receptor Weight.

When ‘Weight value = Scale Capacity’, AO of

weight signal will output current 20mA.

103 dIV 1~500 1

Scale Division

1, 2, 5, 10, 20, 50, 100, 200, 500

104 ZEro

-20000~

+999999

0

[*]

Zero Value

Only for query.

105 SPAn >0

1.0000

[*]

Span Coefficient

Max. display value: 99.9999.

Only for query.

106 Stb.r 0~500 1

Stablity Judging Range [Division]

Set value = 0: No ‘Stablity Judging’.

Set value > 0: Weight Variance per [107] ‘Stablity

Judging Time’ being in [106] ‘

Stablity Judging

Range’ means ‘Weight is stable’.

107 Stb.t 0.5~5.0 1.0 Stablity Judging Time [s]

[*]: ‘RAM Reset’ operation has no effect on the parameter.

26

No. Sign Range Default Description Set

108 FrE 400 400

Sampling Frequency [Hz]

400

109 FILt 0~9 5

Anti-Vibration Digital Filter

Digit Cutoff Frequency

0 None

1

80Hz

2

56Hz

3

40Hz

4

28Hz

5

20Hz

6

14Hz

7

10Hz

8

7Hz

9

5Hz

110 StAb 2~20 10

Sample Number for Axle Weight Stablity

Judgement

27

6.3.2 Calibration Parameters (CALP)

No. Sign Range Default Description Set

120 AZt.P 0~1 0

Auto Zero Tracking Permission

0: oFF

1: on (Only when weight is stable, Auto Zero

Tracking will be allowed. Refer to Parameter

[106]/[107])

121 AZt.t 1~10 1

Auto Zero Tracking Time T [s]

T = Set value × [107] Stablity Judging Time.

122 AZt.r 0.1~50.0 0.2

Auto Zero Tracking Range [Division]

Zero Tracking Rate = [122] / [121].

Suggestion: Zero Tracking Rate ≤ 0.5[Division/s].

123 nEAr.Z 0~50000 50

Zero Fine Adjusting Range

If Gross Weight variation caused by

Zero Value

changing is within this range, ‘

Zero Fine

Adjustment’ will be valid.

Suggestion: Set value ≤ (Scale Capacity × 4%).

124 LoAd 1~999999 10000

Calibrating Weight

Loading Weight for Span Calibration.

125 totL 1~999999

12000

[*]

Total Capacity of Loadcells

To tal Capacity of Loadcells = Loadcell Capacity ×

Loadcell Number.

Only for query.

126 SEnS

0.5000

~5.0000

2.0000

[*]

Output Sensitivity of Loadc e ll [mV/V]

Only for query.

127 Ao.Er -2.00~+2.00 0.00

AO Offset Value [mA]

Try to change ‘AO Offset Val ue’ for making the AO

current display valu e of the AO receiving terminal

the same as that of the controller.

If t

he AO current display value of the AO receiving

terminal is smaller than that of the controller

because of signal attenuating, the ‘AO Offset Value’

should be set to positive value.

If the AO current display value of the AO re ceiving

terminal is bigger than that of the controller because

of interference signal superposing, the ‘AO Offset

Value’ should be set to negative value.

【±】: Optional ‘ -’ (negative sign) at the highest bit.

[*]: ‘RAM Reset’ operation has no effect on the parameter.

28

No. Sign Range Default Description Set

128 InI.Z 0~1 0

Auto Zero Initial Calibration after Power-on

0: oFF

1: on [without Power-down Protection]

129 InI.t 0~1800 10 A uto Zero Initial Calibrating Time [s]

130 InI.r 0~50000 50

Auto Zero Initial Calibrating Range

Suggestion: Set value ≤ (Scale Capacity × 20%).

29

6.3.3 Setpoint Parameters (SEtP)

No. Sign Range Default Description Set

200 VALId 1~999999 20

Non-load Zero Range [Min. V alid Axle W eight]

Essential condition of triggering the axle weighing

process: Net Weight > Min. Valid Axle W eight.

Optional condition of triggering axle weighing: DI1

Axle Identification Switch turns on.

201 HoLd.t 5~999 30

Allowable Holding Time of Valid Axle Weight [s]

When holding time of valid axle weight is bigger

than this set value, the axle weighing process will

be invalid.

202 End.tI 5~999 10

Auto-end Time [s]

After the previous axle has been weighed:

After this time delayed, if there is no new axle

enter into the weighing platform, the axle

weighing process will end and the weighing

record will be printed automatically.

In this time, if key【∑】is pressed, the axle

weighing process will end and the weighing

record will be printed automatically.

203 tot.H 1~999999 10000

Total Axle Weight Upper Limit

When ‘Total Axle Wei ght > Set Value’, DO switch

‘Total Axle Weight Upper Limit’ will

turn on

automatically.

204 nEt.H 1~999999 1800

Axle We ight Upper Limit

When ‘Axle Weight > Set Value’, DO switch ‘Axle

Weight Upper Limit’ will turn on autom a tica lly.

205 dI.Id 0~1 0

Axle Identification by Input Switch DI1

0: oFF

1: on

206 do.SL 0~1 0

DO Output Permission

0: oFF

1: on

30

No. Sign Range Default Description Set

207 Ao 0~3 3

AO Signal

0. groS [Gross W eight]

1. nEt [Net Weight]

2. dISP [Displayed Weight]

3.AnEt [Axle Weight]

208 Au.Prt 0~1 1

Auto Print

0: oFF

1: on [It’s necessary to define print port]

Refer to Appendix A.

209 Prt.F 1~2 1

Print Format

1: Format 1

2: Format 2

31

6.3.4 Communication Parameters (SErP)

No. Sign Range Default Description Set

800 Adr 0~99 1 Communication Address

801

802

bPS1

bPS2

0~5

3

3

COM1/COM2 Baud Rate

0:

1200bps

1

:

2400bps

2

:

4800bps

3

:

9600bps

4

:

19200bps

5: 115200bps

803

804

CHC1

CHC2

0~2

0

0

COM1/COM2 Parity Check

0. none [None Check]

1. EVEn

[Even Check]

2. odd

[Odd Check]

805 Con1 0~6 3

COM1 Communication Mode

0. HASC

[Host-slave, Modbus ASCII]

1. Hrtu

[Host-slave, Modbus RTU]

2. Cont

[Continuous Sending ASCII]

3. Prt

[Print]

4. USE1

[User1]

5. USE2

[User2]

6. USE3

[Host-slave, BWT Netherlands]

806 Con2 0~6 2

COM2 Communication Mode

0. HASC [Host-slave, Modbus ASCII]

1. Hrtu

[Host-slave, Modbus RTU]

2. Cont

[Continuous Sending ASCII]

3. dP-C

[Modicon Profibus-DP]

4. dP-S

[Siemens Profibus-DP]

5. Prt

[Print]

6. USE3

[Host-slave, BWT Netherlands]

807 dAtA 0~3 2

Data for Continuous Sending Mode

0. groS [Gross We ight]

1. nEt [Net Weight]

2. dISP

[Displayed Characters]

3. tot [Total Axle W eight]

32

No. Sign Range Default Description Set

808 S.Int 4~400 80

Continuous Sending Interval Number N

Sending Interval T ime: T = N

× 2.5 [ms].

Sending Frequency: F = 1000 / T [Hz].

Examples

Interval Number N Sending Frequency F

4 100Hz

8 50Hz

10 40Hz

40 10Hz

80 5Hz

100 4Hz

400 1Hz

Note

Baud Rate Max. Sending Frequency

1200bps 5Hz

2400bps 10Hz

4800 bps 25Hz

9600 bps 50Hz

19200 bps 100Hz

115200 bps 100Hz

809 dAt.F 0~3 0

Modbus Data F ormat

Reading&Writing Order of 4-Byte Registers:

0: 4321 [HB4 HB3 LB2 LB1]

1: 3412 [HB3 HB4 LB1 LB2]

2: 1234 [LB1 LB2 HB3 HB4]

3: 2143 [LB2 LB1 HB4 HB3]

The HEX byte order of float and long int registers

in the weighing controller is ‘HB4 HB3 LB2 LB1’.

33

6.3.5 Display Parameters (dISP)

No. Sign Range Default Description Set

900 LAng 0~1

0/1

[*]

Printing Language

0. CHn [Chinese]

1. Eng [English]

901 dS.tI 0.01~1.00 0.20 Display Refreshing Time [s]

902 Au.Loc 0~1 0

Auto-Locking

0: oFF

1: on

[ If there is not any keypad operation in

one minute and it’s not in the processes of ‘F2

Calibration’ & ‘F6 Factory Adj.’, the controller will

lock the keypad and return to ‘

Main Display

Interface’ automatically ]

903 dAtE 0~2

0

[*]

Date Format

0: yy. EE. dd [Year. Month. Day]

1: EE. dd. yy [Month. Day. Year]

2: dd. EE. yy [Day. Month. Year]

904 FAn.r 0~1 1

Cooling Fan Running

0. oFF

1. on

[*]: ‘RAM Reset’ operation has no effect on the parameter.

6.3.6 Time Parameter (tIEE)

No. Sign Range Default Description Set

998

Local

Time

HH[Hour]. MM[Mintus]. SS[Second]

[903] Date Format - W[Week]

[W=7: Sunday]

34

6.3.7 A Sample of Parameter Setting

Modify the parameter ‘[102] Scale Capacity’.

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

【MENU】: Exit 【ENT】: Save

M

M

Main Display Interface

【MENU】+【▲】【 ▼】: F1-SEt

【ENT】+【▲】【 ▼】

【ENT】+【▲】【 ▼】

【ENT】

【◄】【 ►】: Moving cursor; 【▲】【 ▼】: Digit input.

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

35

6.4 F2-CAL System Calibration

After doing ‘System Calibration’, Tare Weight value will return to zero automatically.

6.4.1 Zero Calibration (ZEro)

Do Zero Calibration with no loading on the weigher and save the new Zero Value.

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK

HH HI

LO

LL

0

DISC

Main Display Interface

【MENU】+【▲】【 ▼】: F2-CAL

【ENT】+【▲】【 ▼】: -ZEro【

ENT】

M

【MENU】: Exit 【ENT】: Save

M

【▲】【 ▼】:

104: New Zero Value (-20000~+999999).

oLd: O

riginal Zero Value.

Er: Error = New Value - Original Value.

If Zero Val ue exceeds allowed ra nge, [SET] will tu rn off, and it’s not

allowed to save Zero Value.

36

6.4.2 Data Calibration (dAtA)

Input the specification parameter values o f loadcell [Total Capacity and Output Sensitivity] according

to the actual configuration of the weighing system to correct Span Coefficient. If there is no access to get

the specification parameter values for Data Calibration, then it’s necessary to do Load Calibration.

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK

HH HI

LO

LL

0

DISC

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK

HH HI

LO

LL

0

DISC

Main Display Interface

【MENU】+【▲】【 ▼】: F2-CAL

【ENT】+【▲】【 ▼】: -dAtA【

ENT】

M

Input ‘Total Capacity of Loadcells’ [totL]: 1~999999 Weight Unit.

【ENT】

Input ‘Output Sensitivity of Loadcell’ [SEnS]: 0.5000~5.0000mV/V.

【ENT】

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK

HH HI

LO

LL

0

DISC

Input ‘Voltage Ratio’ [VoL.r]: 1.0000~2.0000.

【ENT】

37

Note:

Total Capacity of Loadcells = Lo adcell Capacity × Loadcell Number.

Voltage Ratio = Excitation Voltage on the terminal of controller / Excitation Voltage on the terminal of

loadcells.

The rated excitation voltage for loadcells is DC10V. It’s best to measure the actual voltage value.

4-wire connection: Th e voltage attenuation is big, the voltage on both sides should be measured.

6-wire connection: Th e voltage attenuation is small, Voltage Ratio can be set to 1.0000.

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK

HH HI

LO

LL

0

DISC

【MENU】: Exit 【ENT】: Save

M

【▲】【 ▼】:

105: New Span Coefficient value (Max. Display Value: 99.9999).

oLd: Original Span Coefficient value.

Sr: Span Correction Ratio = New Value / Original Value (Display

Range: 0.00001~9.99999).

38

6.4.3 Load Calibration (LoAd)

After doing Data Calibra tion, if there are conditions for Load Caliration, d o Load Calibration with

loading standard weight on the weigher to correct Span Coefficient further for higher wei ghing accurac y.

The loading weight should be bigger tha n 50% of Scale Capacity value.

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK

HH HI

LO

LL

0

DISC

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

Input ‘Calibrating Weight’: 1~999999 Weight Unit.

Main Display Interface

【MENU】+【▲】【 ▼】: F2-CAL

【ENT】+【▲】【 ▼】: -LoAd【

ENT】

M

【MENU】: Exit 【ENT】: Save

M

【ENT】

【▲】【 ▼】:

105: New Span Coefficient value (Max. Display Value: 99.9999).

oLd: Original Span Coefficient value.

Sr: Span Correction Ratio = New Value / Original Value (Display

Range: 0.00001~9.99999).

Ad: AD Value.

If AD Value ≤ Zero Value, display ‘Err’, [SET] will turn off, and it’s

not allowed to save Span Coefficient.

39

6.5 F3-REC Record Query

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK

HH HI

LO

LL

0

DISC

n: Record No.; [PCS]: Axle Count (1~99).

‘no-rEC’: No record.

Main Display Interface

【MENU】+【▲】【 ▼】:F3-rEC

【ENT】

M

【ENT】

Input Record No.: 1~500.

【▲】【 ▼】: Query the previous/next item of this record.

【◄】【 ►】: Query the previous/next record.

【

PRINT】: Print this record.

【MENU】

M

【▲】【 ▼】

t: Total Axle Weight of A1~An.

Each Axle Weight value of the last record can be queried.

1~9: Axle W eight of A1~A9; A: Total Axle Weight of A10~An.

40

6.6 F4-CLN Data Clearing

Only after Key-unlocking with Administrator Password, it’s allowed to do the operation of ‘Clear Records’.

Main Display Interface

【MENU】+【▲】【 ▼】: F4-CLn

【▲】【 ▼】: --CLS-/--CLr【ENT】

M

【▲】【 ▼】: YES/NO

【MENU】: Exit 【ENT】: Enter

M

CLS: Clear Screen .

CLr: Clear Records.

RUN

NUM

PCS

TOT

SET

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

LL

0

41

6.7 F5-LOC Key -locker

6.7.1 Key-unlocking (oPEn)

6.7.2 Key-locking (Locc)

LL

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

0

M

【ENT】: If inputted password is correct, Key-unlocking

will be valid and [LOCK] will turn off.

Main Display Interface

【MENU】+【▲】【 ▼】: F5-Loc

【ENT】+【▲】【 ▼】: -oPEn【

ENT】

M

LL

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

0

M

【ENT】: I f inputted password is correct, Key-locking

will be valid and [LOCK] will turn on.

Main Display Interface

【MENU】+【▲】【 ▼】: F5-Loc

【ENT】+【▲】【 ▼】: -Locc【

ENT】

M

42

6.7.3 Password Set (PASS)

DEV FALL PACK

LL

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DISC

HH HI

LO

0

LL

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

0

【ENT】

If inputted is Operator Password, this operation interface will be

skipped; if inputted is Administrato r Password, ‘

Administrator Password

[AP]’ or ‘Operator Password [oP]’ can be modified via【▲】【 ▼】.

Main Display Interface

【MENU】+【▲】【 ▼】: F5-Loc

【ENT】+【▲】【 ▼】: -PASS【

ENT】

M

LL

RUN

NUM

PCS

TOT

SET

GROSS

NET

SUM

LOCK

SUPMETER

ZERO NZ SP1 SP2 SP3

FILL COMP DEV FALL PACK DISC

HH HI

LO

0

【MENU】: Exit 【ENT】: Save

M

Input the new Password. Pl eas e r emember it.

【ENT】

43

Appendix A. Print Formats

Format 1

Format 2

WEIGHT

RECORD

NO.:

DATE:

TIME:

AXLES:

A01:

。。。

A09:

EAn:

TOTAL:

001

2009-05-20

23:59:45

12

2.00t

。。。

2.40t

8.80t

30.80t

Record No.

Axle Count

Axle No.1 Weight

。。。

Axle No.9 Weight

Total Weight

of Axle No.10~N

Total Axle W eight

of Axle No.1~N

NO.:

DATE:

TIME:

AXLES:

TOTAL:

001

2009-05-20

23:59:45

12

30.80t

WEIGHT RECORD

44

Appendix B. Register Table of Host-Slave MODBUS[ASCII/RTU]

Data Name Type Address Attribute

Command

[HEX]

Description

Gross Weight Long 40001 R 03

Net Weight

Long

40003 R 03

Running State 1 UnShort

40005.0

R 03

1: Axle W eighing state.

0: Waiting or Calibrating state.

40005.1

40005.2

40005.3

40005.4

40005.5

40005.6

40005.7

40005.8

40005.9

40005.10

40005.11

40005.12 1: Non-load Zero Range.

40005.13

1: Weight Value is stable.

40005.14 1: Overload Alarm.

40005.15 1: Controller Fault.

Running State 2

[Unused]

UnShort

40006.0

R 03

40006.1

40006.2

40006.3

40006.4

40006.5

40006.6

40006.7

40006.8

40006.9

40006.10

40006.11

40006.12

40006.13

40006.14

40006.15

45

Data Name Type Address Attribute

Command

[HEX]

Description

DO State UnShort

40007.0

R 03

1: DO1 ON; 0: DO1 OFF.

40007.1 1: DO2 ON; 0: DO2 OFF.

40007.2 1: DO3 ON; 0: DO3 OFF.

40007.3 1: DO4 ON; 0: DO4 OFF.

40007.4 1: DO5 ON; 0: DO5 OFF.

40007.5

40007.6

40007.7

40007.8

40007.9

40007.10

40007.11

40007.12

40007.13

40007.14

40007.15

Operation UnShort 40008 W 06

0xA500:

Stop Axle Weighing

Process & Print.

0xA501: Unused.

0xA502: Unused.

0xA503: Unused.

0xA504: Unused.

0xA505: Unused.

0xA506: Unused.

0xA507: Unused.

0xA508: Unused.

0xA509: Print.

0xA50A: Clear Screen.

0xA50B: Manual Tare.

0xA50C: A larm A cknow ledge .

0xA50D: Zero Fine Adjustment.

0xA50E: Zero Calibration.

0xA50F: Load Calibration.

Do Span Calibration with the value

of parameter ‘Calibrating Weight’

as loading weight.

0xA510~0xA5FF: Unused.

Calibrating Weight UnLong 40009 R/W 03/10 Parameter No. 124

A1~An Total Axle Weight UnLong 40011 R 03

Axle Count UnLong 40013 R 03

46

Data Name Type Address Attribute

Command

[HEX]

Description

An’s Axle Weight

UnLong

40015 R 03

Non-load Zero Range

[Min. Valid Axle Weight]

UnLong 40017 R/W 03/10

Allowable Holding Time

of Valid Axle Weight

UnShort 40019 R/W 03/06

Auto-end Time UnShort 40020 R/W 03/06

UnShort: Unsigned Short Int; UnLong: Unsigned Long Int; Long: Signed Long Int.

47

Appendix C. Data F rame Format of Continuous Sending [ASCII]

Filed Name

Code

HEX

Description

Example

START [Byte1] = 3D =

Weighing State

[Byte2]

O

4F

Overload

S S 53 Stable

M

4D

Motion

Data Name

[Byte3]

G 47 Gross Weight

N

N

4E

Net Weight

B 42 An’s Axle Weight

T 54

T otal Axle W eig ht of

A1~An

D 44 Displayed Characters

U

55

Unused

Data

[9 Bytes]

Format A:

Weight Data

[Byte4~12]

+/- 2B/2D Sign

+00123.4k

[DEC]

Weight Value

[7 Bytes]

30~39

2EH

0~9

Decimal Point ‘.’

Unit [1 Byte]:

(Space)

k

t

g

20

6B

74

67

Space: None

k: kg

Format B:

Displayed

Characters

[Byte4~12]

d

64

ID Code

d

Point Code

[1 Byte]

00~FF

BIT7=0: Unused

2. dISP

Highest

Bit’s Point:

ON

Point Code

=20H

BIT6=0: Unused

If BIT5=1:

Highest Bit’s Point: ON

If BIT4=1:

Bit5’s Point: ON

If BIT3=1:

Bit4’s Point: ON

If BIT2=1:

Bit3’s Point: ON

If BIT1=1:

Bit2’s Point: ON

If BIT0=1:

Lowest Bit’s Point: ON

Characters

[6 Bytes]

XX XX XX

XX XX XX

ACSII

d

64

ID Code

d

SUM Check [Byte13] 1 Byte XX

SUM=Byte1+Byte2+…

+Byte12

END

[Byte14~15]

<CR>

<LF>

0D

0A

<CR>

<LF>

48

Example 1. Sendin g Weight Data ‘+00123.4kg’

Byte Field Name HEX Note

1 START 3D =

2 Weighing State 53 S

3 Data Name 4E N

4 Sign 2B +

5 Weight Value 30 0

6 Weight Value 30 0

7 Weight Value 31 1

8 Weight Value 32 2

9 Weight Value 33 3

10 Weight Value 2E .

11 Weight Value 34 4

12 Unit 6B k

13 SUM CC SUM=Byte1+Byte2+…+Byte12

14 END 0D <CR>

15 END 0A <LF>

Example 2. Sending

Displayed Characters ‘2. dISP’

Byte Field Name HEX Note

1 START 3D =

2 Weighing State 53 S

3 Data Name 44 D

4 ID Code 64 d

5 Point Code 20

6

Displayed Characters 32 2

7

Displayed Characters 20 Space

8

Displayed Characters 64 d

9 Displayed C haracters 49 I

10

Displayed Characters 53 S

11

Displayed Characters 50 P

12 ID Code 64 d

13 SUM 5E SUM=Byte1+Byte2+…+Byte12

14 END 0D <CR>

15 END 0A <LF>

Changsha Supmeter Technological Co.,Ltd.

Address: Building A6, Lugu International Industrial Park,

Changsha, 410205, China

Tel: +86 731 85115100

Fax: +86 73 1 85158100

Website: www.supmeter.com.cn

E-mail: supmeter@163.com

Loading...

Loading...