BST100-B11/B21 Weighing Controller

www.zemicusa.info

For: Ration Belt Weighfeeder

Operation Manual V3.6

Changsha Supmeter Technological Co.,Ltd.

Preface

Model Panel-mounting: B11

Model Wall-mounting: B21

www.zemicusa.info

Thank you very much for your purchase!

This manual covers safety precautions, technical specifications, operation interface, installation&

connection, function&operation and so on. In order to make the product running at its best, please read this

manual in advance, and reserve it for the future reading.

The technology update, function enhancement and quality improvement may lead to some differences

between this manual and the physical product, please understand.

Without our authorization, the contents of this manual are not allowed to be copied and reproduced.

Main Features:

Suitable for Ration Belt Weighfeeder with Ration Flow Feeding & Ration Weight Batch Control.

EMC design with high anti-jamming capability, suitable for industrial environment.

16-bit LED display screen for English character and digit display.

Menu&Shortcut mode operation with key tone.

Optional English keypad, Simplified Chinese keypad and Complex Chinese keypad.

High-precision ∑-△ A/D conversion technology and broad-range speed pulse input circuit.

Max. Connection Quantity: 8 Loadcells (350Ω).

Auto-locking, Key-locking, Key-unlocking, Digital Setting&Calibration and I/O Testing

functions available.

Auto Zero Tracking, Speed Calibration and Belt Length Calibration functions available.

One optional „Flow Setpoint‟ analog signal input [AI: 4~20mA].

Max.3 definable „Flow/Control Current /…‟ analog signal outputs [AO: 4~20mA].

Quick and steady PID for ration feeding control available.

3 Definable normally open switch inputs [DI] and 4 definable normally open relay or transistor

switch outputs [DO].

The feeder and belt weigher can be started and stopped by DI&DO signals.

1 „Totalized Weight High-speed Pulse‟ output [PO].

2 Optional communication ports for linking to IPC/PLC, remote display&operation terminal,

serial printer and wireless module.

Support industry configuration software, e.g. iFix.

Weight Records per shift/day/month of a year can be queried and printed.

With the multitasking mode, the weighing&control process will not be interrupted by parameter

setting and the other operations.

1

Contents

www.zemicusa.info

1. SAFETY PRECAUTIONS .............................................................................................................. 5

2. TECHNICAL SPECIFICATIONS ................................................................................................. 6

3. OPERATION INTERFACE ........................................................................................................... 8

3.1 MODEL PANEL-MOUNTING OPERATION INTERFACE ............................................................................... 8

3.2 MODEL WALL-MOUNTING OPERATION INTERFACE ................................................................................ 9

3.3 STATE INDICATION ............................................................................................................................... 10

3.4 KEYPAD OPERATION.............................................................................................................................11

3.4.1 Menu Operation ..........................................................................................................................11

3.4.2 Quick Operation .........................................................................................................................11

4. INSTALLATION&CONNECTION ............................................................................................. 12

4.1 INSTALLATION ..................................................................................................................................... 12

4.1.1 Model Panel-mounting Installation ........................................................................................... 12

4.1.2 Model Wall-mounting Installation ............................................................................................. 13

4.2 TERMINAL ........................................................................................................................................... 14

4.2.1 Model Panel-mounting Terminal ............................................................................................... 14

4.2.2 Model Wall-mounting Terminal ................................................................................................ 14

4.3 CONNECTION....................................................................................................................................... 15

4.3.1 Loadcell & Speed Sensor Connector (SENSOR) ................................................................ ...... 15

4.3.1.1 Loadcell Connection (SENSOR/LOADCELL) ............................................................. 15

4.3.1.2 Speed Sensor Connection (SENSOR/SPEED) .............................................................. 16

4.3.1.2.1 Photoelectric Encoder Connection ·································································· 16

4.3.1.2.2 Proximity Switch Connection ········································································· 16

4.3.1.2.3 Speed Generator Connection ··········································································· 17

4.3.2 4~20mA Analog Output/Input & Totalized Weight Pulse Connector (AO/AI/PO) ................... 17

4.3.2.1 4~20mA Analog Output Connection (AO) .................................................................... 18

4.3.2.2 4~20mA Analog Input Connection (AI) ........................................................................ 18

4.3.2.3 Totalization Weight Pulse Output Connection (PO)....................................................... 18

4.3.3 Switch Output/Input Connector (DO/DI) .................................................................................. 19

4.3.3.1 Relay Switch Output (DO) to Load Connection ............................................................ 20

2

4.3.3.2 Transistor Switch Output (DO) to Load Connection ..................................................... 20

www.zemicusa.info

4.3.3.3 Relay Switch Output (DO) to PLC Connection ............................................................. 21

4.3.3.4 Transistor Switch Output (DO) to PLC Connection ...................................................... 22

4.3.3.5 Switch Input (DI) to Switch/PLC Connection ............................................................... 23

4.3.4 Digital Communication Port Connection (COM1/2)................................................................. 24

4.3.4.1 Model Panel-mounting Communication Port ................................................................ 24

4.3.4.2 Model Wall-mounting Communication Port .................................................................. 24

4.3.4.3 RS232 to IPC/PLC Host-slave&Point-to-point Network ............................................... 25

4.3.4.4 RS232 to Printer, Remote Display&Operation Terminal Point-to-point Network ......... 25

4.3.4.5 RS485/CANBUS/Profibus-DP to IPC/PLC Host-slave Data-bus Network ................... 26

4.3.4.6 RS485 to Remote Display&Operation Terminal Point-to-point Network ..................... 26

4.3.4.7 RS422 to IPC/PLC Host-slave Data-bus Network ......................................................... 27

4.3.4.8 Ethernet Host-slave Network ......................................................................................... 27

4.3.5 Power Supply Connector (POWER) ......................................................................................... 28

4.3.6 Ground Protection ..................................................................................................................... 28

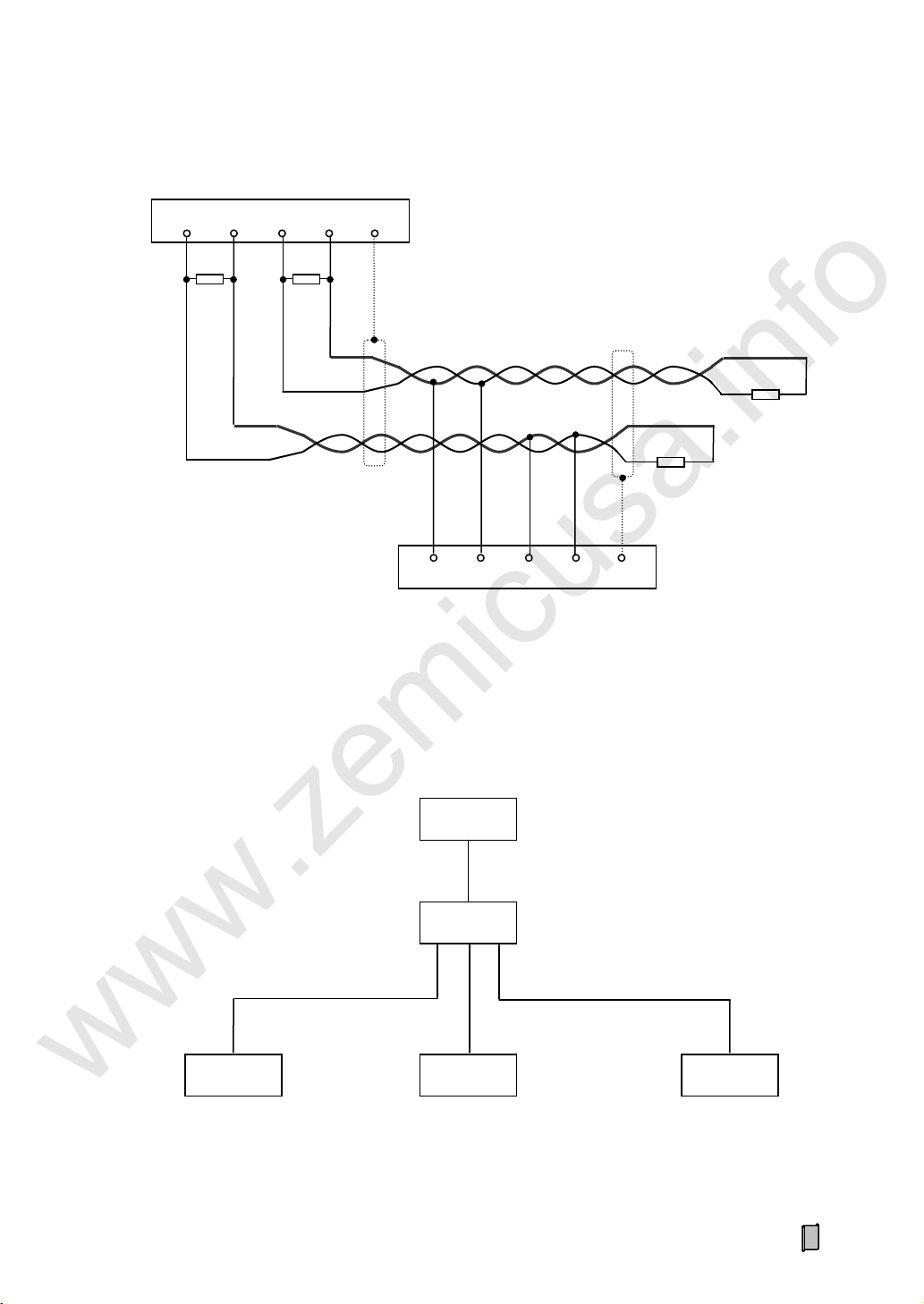

5. OPERATION PROCEDURE ....................................................................................................... 29

6. FUNCTION&OPERATION ......................................................................................................... 30

6.1 MAIN DISPLAY INTERFACE .................................................................................................................. 30

6.1.1 Totalized Weight, Belt Speed & Flow ....................................................................................... 30

6.1.2 Totalized Weight, Flow Setpoint & Flow .................................................................................. 30

6.1.3 Flow & Control Current ............................................................................................................ 31

6.1.4 Totalized Weight, Load Setpoint & Load .................................................................................. 31

6.1.5 Alarm Items ............................................................................................................................... 32

6.1.6 Other Display Interface ............................................................................................................. 33

6.2 MAIN MENU ...................................................................................................................................... 34

6.3 F1-SET SETTING ................................................................................................................................. 36

6.3.1 Basic Scale Parameters (SCAL) ................................................................................................ 36

6.3.2 Extra Scale Parameters (SCAL1) .............................................................................................. 37

6.3.3 Basic Control Parameters (CtrL) ............................................................................................... 38

6.3.4 Extra Control Parameters (CtrL1) ............................................................................................. 39

6.3.5 Flow Parameters (Flou) ............................................................................................................. 40

6.3.6 Speed Parameters (SPEd) .......................................................................................................... 41

6.3.7 Load Parameters (LoAd) ........................................................................................................... 42

3

6.3.8 Weight Record Parameters (SAVE) ........................................................................................... 42

www.zemicusa.info

6.3.9 Communication Parameters (SErP) ........................................................................................... 43

6.3.10 I/O Parameters (-Io-) ............................................................................................................... 44

6.3.11 Display Parameters (dISP) ....................................................................................................... 46

6.3.12 Date/Time Parameters (tIEE) .................................................................................................. 46

6.3.13 A Sample of Parameter Setting ................................................................................................ 47

6.4 F2-CAL SYSTEM CALIBRATION .......................................................................................................... 48

6.4.1 Zero Calibration (ZEro) ............................................................................................................. 48

6.4.2 Dynamic Span Calibration (LoAd) ............................................................................................ 49

6.4.3 Static Span Calibration with Chain Weight (CHAn) ................................................................. 51

6.4.4 Static Span Calibration with Hanging Weight (HAng) .............................................................. 53

6.4.5 Segmenting Span Correction (SEgC) ........................................................................................ 55

6.4.6 Speed Calibration (SPEd) .......................................................................................................... 57

6.4.7 Belt Length Calibration (LEnS) ................................................................................................ 58

6.5 F3-REC WEIGHT RECORD FOR QUERYING&PRINTING ....................................................................... 59

6.6 F4-CLN DATA CLEARING .................................................................................................................... 61

6.7 F5-SAF SECURITY .............................................................................................................................. 62

6.7.1 Auto-locking (ALoc) ................................................................................................................. 62

6.7.2 Key-locking (Locc) ................................................................................................................... 62

6.7.3 Key-unlocking (oPEn) ............................................................................................................... 63

6.7.4 Password Set (PASS) ................................................................................................................. 64

6.7.5 RAM Reset (dEFU) ................................................................................................................... 65

6.8 F6-FAC FACTORY ADJUSTMENT ......................................................................................................... 65

6.8.1 AO Zero Adjustment (AoxE) ..................................................................................................... 65

6.8.2 AO Full Range Adjustment (AoxF) ........................................................................................... 66

6.8.3 AI Zero Adjustment (AI1E) ....................................................................................................... 66

6.8.4 AI Full Range Adjustment (AI1F) ............................................................................................. 67

6.9 F7-INF PRODUCT INFORMATION ......................................................................................................... 67

7. RATION FLOW AUTO-FEEDING SYSTEM ............................................................................ 68

APPENDIX A. PRINT FORMATS .................................................................................................. 69

APPENDIX B. COMMUNICATION PROTOCOLS ..................................................................... 70

4

1. Safety Precautions

www.zemicusa.info

Lithium Battery Installation

A Lithium battery should be equipped in the product. If it is not allowed to be transported

together with the product because of embargo, please make a purchase according to the

model offered by us and install it by yourself.

Prohibit using the product under dangerous environment

Prohibit using the product under the dangerous environment with combustible gas and

explosive dust. If you have this need, please use our explosion-proof products.

Avoid using the product under overheated environment

Make sure that the product works under the environment with allowed temperature range to

get good performance and long working life.

Please keep the product away from direct sunlight. If it is installed in a cabinet, please install

cooling fans on the top of the cabinet.

Controller Grounding Protection

The product, as a low-voltage equipment, should be kept away from the high-voltage

equipments.

For avoiding bodily injury from electric shock accident and keeping the product separate from

strong interference, the metal shell of the product should be grounded directly and the ground

resistance should be less than 4Ω.

Scale Frame Grounding Protection

For avoiding bodily injury from electric shock accident and keeping the loadcells and speed

sensor separate from strong interference, the scale frame should be connected with the

electronic scale grounding net and the ground resistance should be less than 4Ω.

Cable Laying

Weighing signal, speed signal, analog signal and communication signal cables should be laid

in pipes, and do not lay them together with power cables.

Power Supply

Please use line isolation transformer to keep the power supply of the product separate from

the other driving power supply. If the voltage fluctuation exceeds the allowed range of the

product, please use a voltage-stabilized power supplier.

Environmental Protection

Before the Lithium battery equipped in the product being discarded, please insulate its

positive or negative pole, do not put it into fire.

Although the product is made of the lead-free components, after used in the industrial

environments, it’s possible to be polluted. So, while being discarded as worthless, the product

should be processed lawfully as leady industrial waste for environment protection.

Other Notes

The installation, wiring and maintenance should be operated by the engineers with the

relevant professional knowledge and safety operation ability. Although being not described in

this manual, the relevant safety operating procedures and standards should be followed.

5

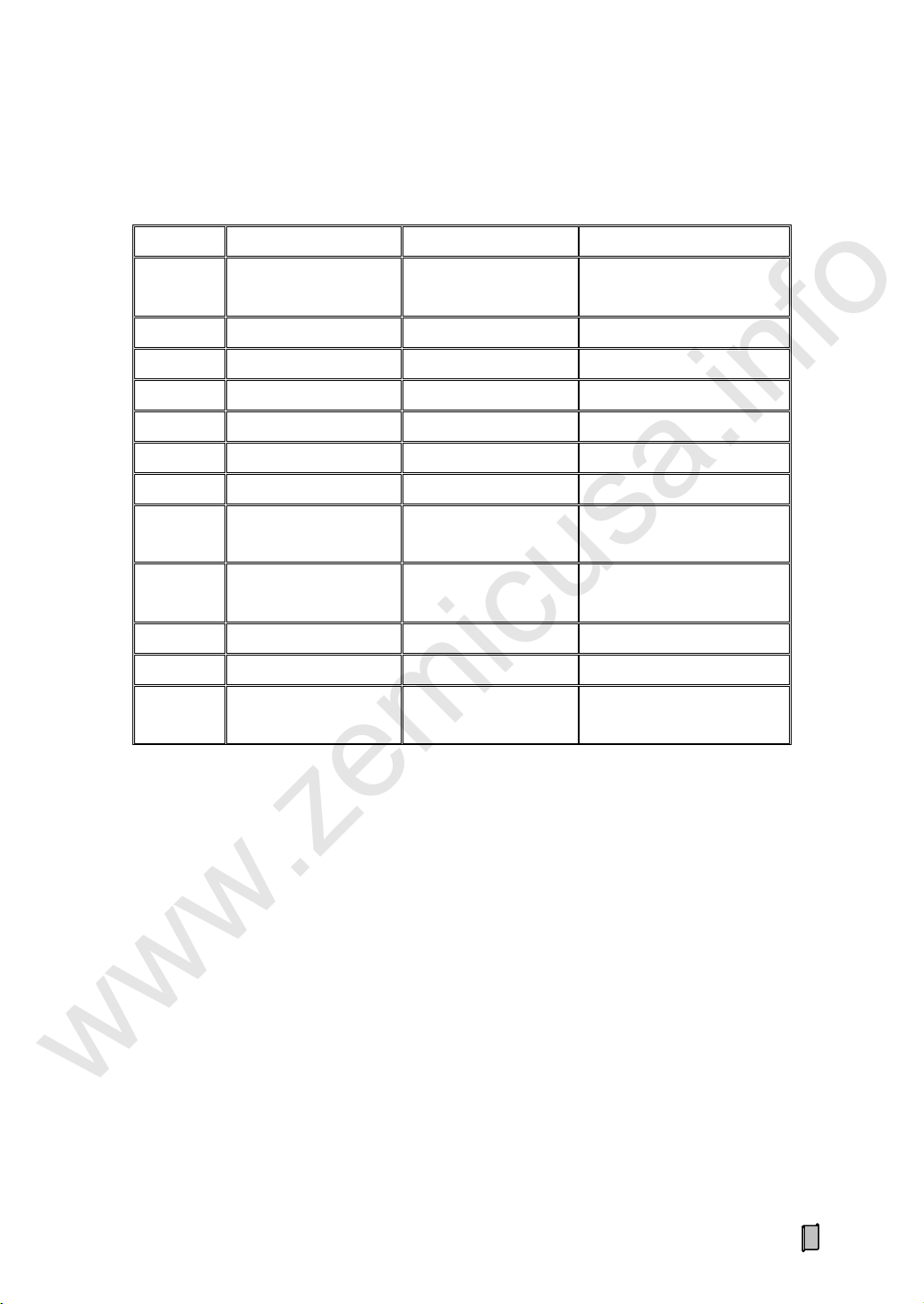

2. Technical Specifications

www.zemicusa.info

Power Supply

Operating Voltage: AC220V±15%.

Operating Frequency: 50/60Hz.

Model Wall-mounting Optional: DC24V±20%.

Max. Power: 15W.

Display

16-bit LED display screen for English character and digit display.

Keypad

6 keys for Menu&Shortcut mode operation with key tone.

Optional English keypad, Simplified Chinese keypad and Complex Chinese keypad.

Auto-locking, Key-locking, Key-unlocking, Digital Setting&Calibration and I/O Testing functions

available.

Loadcell Signal Input Interface (SENSOR/LOADCELL)

1 Weighing Signal Input: 0~25mV.

Excitation Voltage Output: DC10V.

Max. Connection Quantity: 8 Loadcells (350Ω).

Weighing Accuracy

24-bit ∑-△ADC.

Sampling Frequency: 200Hz.

Zero Drift: ±0.1μV/℃ RTI (Relative to Input).

Gain Drift: ±5ppm/℃.

Non-linearity: 0.005%FS.

Speed Sensor Signal Input Interface (SENSOR/SPEED)

1 Speed Pulse Input Signal.

Frequency Range: 0.5~3000Hz.

Output Voltage: DC12V; Max. Current: 100mA.

Analog Signal Output Interface (AO)

Max.3 Definable „Flow/Control Current /…‟ Analog Signal Outputs: 4~20mA (AO3: optional).

Non-linearity: 0.05%FS.

Analog Signal Input Interface (AI)

1 Optional „Flow Setpoint‟ Analog Signal Input: 4~20mA.

Non-linearity: 0.05%FS.

Totalized Weight High-speed Pulse Signal Output Interface (PO)

1 „Totalized Weight High-speed Pulse‟ Output.

Capacity of Contacts: 100mA, DC5~24V.

Weight per Pulse and Pulse Width can be preset.

6

Switch Signal Output Interface (DO)

www.zemicusa.info

4 Definable Normally Open Relay or Transistor Switch Outputs.

Capacity of Relay Switch: AC250V/DC24V, 1A.

Capacity of Transistor Switch: DC24V, 500mA.

Switch Signal Input Interface (DI)

3 Definable Normally Open Switch Inputs.

Digital Communication Interface (COM1/2)

COM1 Optional: RS232/RS485/RS422/Profibus-DP/CANBUS/Ethernet modules.

COM2: RS232.

Connectable: IPC/PLC, Remote Display&Operation Terminal, Serial Printer and Wireless

Module.

Power Supply Output: DC5V, 100mA.

Report Print

Weight Records per shift/day/month of a year can be queried and printed.

Outline Dimension

Model Panel-mounting: 160 × 84 × 188 mm (W×H×D).

Model Wall-mounting: 202 × 305 × 90 mm(W×H×D).

Cut Dimension

Model Panel-mounting: 151 × 76 mm(W×H).

Weight

Model Panel-mounting: Approx. 1.5kg.

Model Wall-mounting: Approx. 3.4kg.

Temperature and Humidity

Service Temperature: -25℃ to +40℃.

Storage Temperature: -30℃ to +60℃.

Relative Humidity: Max. 85%RH.

Protection Level

Model Panel-mounting: IP50.

Model Wall-mounting: IP65.

7

3. Operation Interface

MENU

ESC

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

◄

►

▲

▼

PRINT

ENT

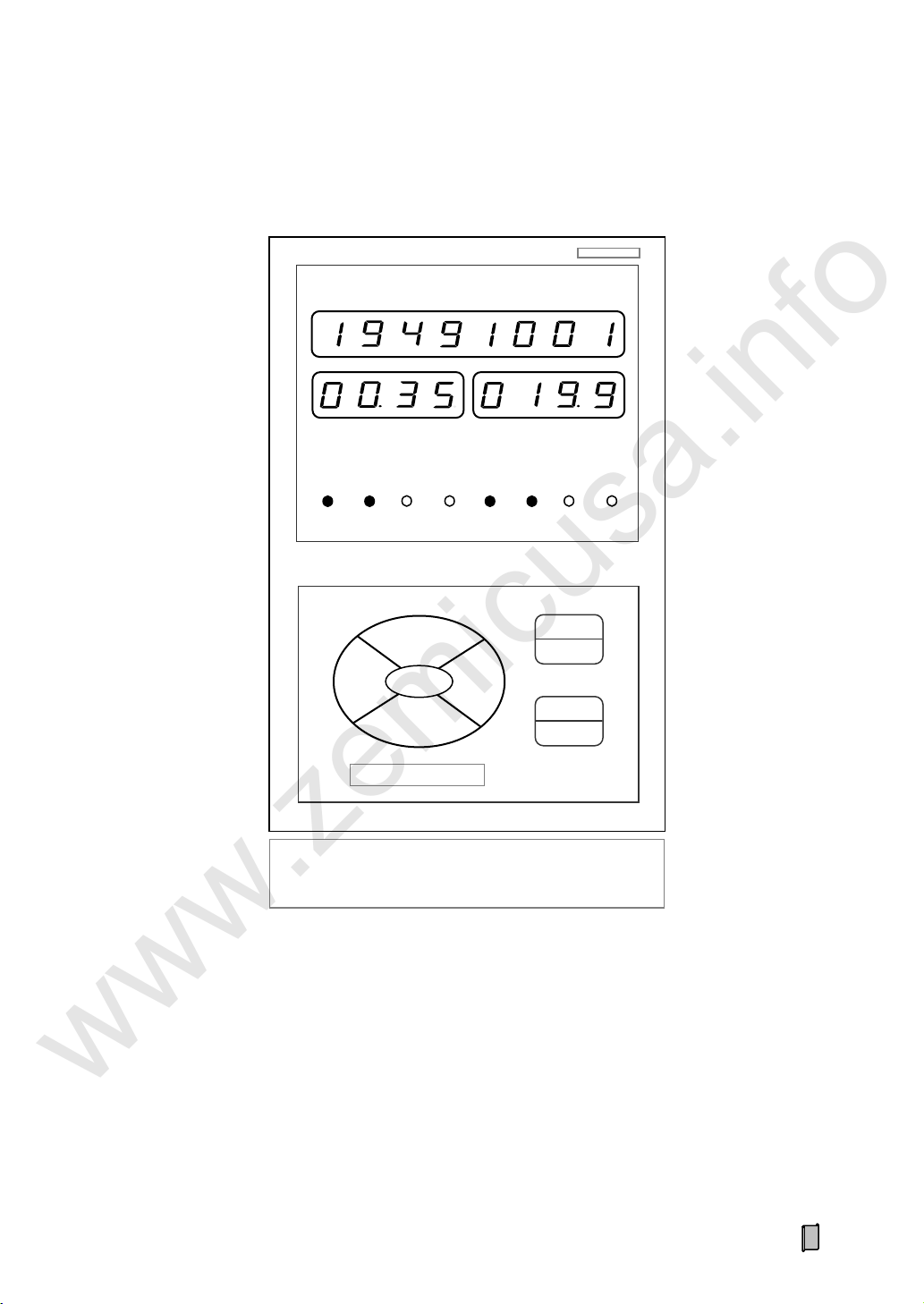

Display Panel A: kg, t, t/h, kg/m

Display Panel B: g, kg, kg/h, g/m

www.zemicusa.info

3.1 Model Panel-mounting Operation Interface

8

3.2 Model Wall-mounting Operation Interface

MENU

ESC

PRINT

ENT

▲

◄

►

▼

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Display Panel A: kg, t, t/h, kg/m

Display Panel B: g, kg, kg/h, g/m

www.zemicusa.info

9

3.3 State Indication

LED Lamp

Description

Note

[RUN]

ON: Weighing state.

OFF: Stopping state.

[AUTO]

Feeding control mode:

ON: Auto [PID].

OFF: Manual.

[EXT]

Flow Set Mode:

ON: External [AI: 4~20mA].

OFF: Internal.

[ALARM]

Alarm. [kg]

Weight Display Unit: kg.

Display Panel A

([P107] Internal Scale Unit=kg)

[t]

Weight Display Unit: t.

[t/h]

Flow Display Unit

ON: t/h.

OFF: kg/min or kg/h.

[kg/m]

Load Display Unit: kg/m.

[g]

Weight Display Unit: g.

Display Panel B

([P107] Internal Scale Unit=g)

[kg]

Weight Display Unit: kg.

[kg/h]

Flow Display Unit

ON: kg/h.

OFF: g/min or g/h.

[g/m]

Load Display Unit: g/m.

www.zemicusa.info

10

3.4 Keypad Operation

Key Name

Description

【MENU】

【ESC】

Enter Main Menu.

Exit.

【ENT】

Enter/Save.

【◄】

Cursor shifts left.

【►】

Cursor shifts right.

【▲】

Cursor shifts up.

Display the previous interface or option.

Digit input: +1.

【▼】

Cursor shifts down.

Display the next interface or option.

Digit input: -1.

Key Name

Description

【MENU】*

(【LOCK】)

Key-locking.

Key-unlocking.

【◄】

(【ADJ+】)

Control Current +1mA.

【►】

(【ADJ-】)

Control Current -1mA.

【◄】*

(【AUTO】)

„Manual/Auto‟ Control Mode Selection.

【►】*

(【EXT】)

„Internal/External‟ Flow Set Mode Selection.

【PRINT】

Print.

www.zemicusa.info

If there is not any keypad operation in one minute and it‟s not in the processes of „F2 Calibration‟ & „F6 Factory

Adj.‟, the controller will return to „Main Display Interface‟ automatically.

3.4.1 Menu Operation

3.4.2 Quick Operation

*: Keep the key pressed for 2 seconds.

11

4. Installation&Connection

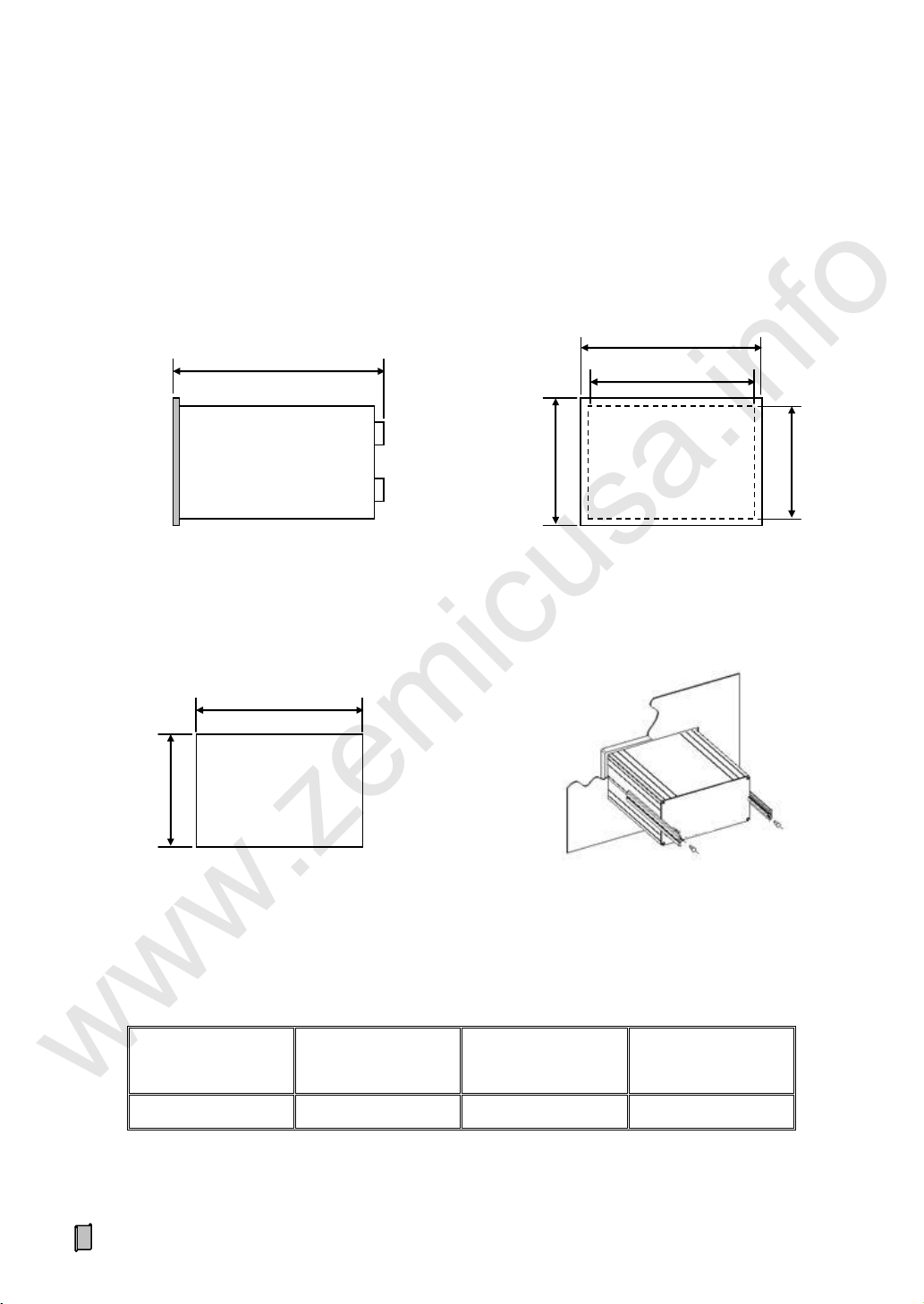

Outline dimension

W×H×D [mm]

Panel dimension

W×H [mm]

Box dimension

W×H [mm]

Cut dimension

W×H [mm]

160×84×188

160×84

150×75

151×76

Installation Mode

151

76

Cut dimension

Outline dimension

Panel dimension

188

84

160

(75)

(150)

www.zemicusa.info

4.1 Installation

4.1.1 Model Panel-mounting Installation

12

4.1.2 Model Wall-mounting Installation

Outline dimension

W×H×D [mm]

Mounting dimension

W×H [mm]

Mounting hole dimension

[mm]

202×305×90

169×271

Ф9

Outline dimension

Installation mode

www.zemicusa.info

13

4.2 Terminal

L

N

POWER

SENSOR

SIG-

SIG+

EXC-

EXC+

SHD

VS-

SIN

VS+

SEN+

SEN-

B- (TXD-)

A+(TXD+)

DP-(RXD+)

(RXD-)

DP+

GND

RXD

TXD

+5V

COM2

COM1

LOADCELL

SPEED

AO/AI/PO

AO1+

AO1-

AO2+

AO2-

AO3+

AO3-

AI+

AI-

VIN

PO

DO/DI

DO1+

DO1-

DO2+

DO2-

DO3+

DO3-

DO4+

DO4-

COM

DI1

DI2

DI3

DC12-24V OR AC220V

DC-

DC+

COM

E

AO/AI/PO

DO/DI

AO1+

AO1-

AO2+

AO2-

AO3+

AO3-

AI+

AI-

VIN

PO

DO1+

DO1-

DO2+

DO2-

DO3+

DO3-

DO4+

DO4-

COM

DI1

DI2

DI3

SENSOR

SIG-

SIG+

EXC-

EXC+

SHD

VS-

SIN

VS+

SEN+

SEN-

POWER

N L E

COM1/2

ETHERNET

www.zemicusa.info

4.2.1 Model Panel-mounting Terminal

4.2.2 Model Wall-mounting Terminal

14

4.3 Connection

No.

Pin

Description

1

SEN+

Voltage Feedback + from Loadcell.

[4-wire connection: short to „EXC+‟]

2

SEN-

Voltage Feedback - from Loadcell.

[4-wire connection: short to „EXC-‟]

3

SIG-

Weighing Signal (mV) Input -.

4

SIG+

Weighing Signal (mV) Input +.

5

EXC-

Excitation Voltage Output - for Loadcell.

6

EXC+

Excitation Voltage Output + for Loadcell (DC10V).

7

SHD

Shield. 8 VS-

Voltage Output - for Speed Sensor.

9

SIN

Pulse Signal Input from Speed Sensor.

10

VS+

Voltage Output + for Speed Sensor (DC12V).

SIG+

EXC+

EXC-

SIG-

SIG+

SIG-

SHD

EXC+

EXC-

SEN-

SEN+

SEN+

SEN-

Controller

Loadcell

www.zemicusa.info

4.3.1 Loadcell & Speed Sensor Connector (SENSOR)

The shielded cable must be used and kept separate from the AC cable and other noise generating

cables. Please use loadcells with the same capacity, bridge resistance & sensitivity (mV/V) for parallel

connection.

4.3.1.1 Loadcell Connection (SENSOR/LOADCELL)

15

4.3.1.2 Speed Sensor Connection (SENSOR/SPEED)

VS-

V-

Controller

SIN

VCC

+5~12V

VS+

SIG

V+

SHD

Proximity Switch

2-wire: VS+ will not be connected.

VS-

V-

Controller

SIN

VCC

+5~12V

VS+

SIG

V+

SHD

Photoelectric Encoder

www.zemicusa.info

4.3.1.2.1 Photoelectric Encoder Connection

4.3.1.2.2 Proximity Switch Connection

16

4.3.1.2.3 Speed Generator Connection

No.

Pin

Description

1

AO1+

4~20mA Analog Signal No.1 Output +/-.

2

AO1-

3

AO2+

4~20mA Analog Signal No.2 Output +/-.

4

AO2-

5

AO3+

4~20mA Analog Signal No.3 Output +/- [Optional].

6

AO3-

7

AI+

4~20mA Input +.

8

AI-

4~20mA Input -.

9

VIN

+5~24V Input for PO.

10

PO

Totalized Weight High-speed Pulse Output.

VS-

Controller

SIN

VCC

+5~12V

VS+

SIG

V+

SHD

Speed Generator

www.zemicusa.info

4.3.2 4~20mA Analog Output/Input & Totalized Weight Pulse Connector (AO/AI/PO)

Max.3 definable AOs (4~20mA) are used for outputting „Flow/Control Current /…‟ signals to external

devices. 1 Optional AI (4~20mA) is used for receiving „Flow Setpoint‟ signal from external devices. 1

High-speed Pulse [PO] is used for outputting Totalized Weight signal to external devices.

17

4.3.2.1 4~20mA Analog Output Connection (AO)

Controller

IN+

AOx+

AOx-

Isolator

Load

Max.500Ω

IN-

OUT+

OUT-

mA+

mA-

Controller

VIN

VCC

PO

Receiver

+5~24VDC

Pulse Input

Weight Per Pulse and Pulse Width can be set.

Controller

OUT+

AI+

AI-

Isolator

Host

OUT-

IN+

IN-

mA+

mA-

www.zemicusa.info

4.3.2.2 4~20mA Analog Input Connection (AI)

4.3.2.3 Totalization Weight Pulse Output Connection (PO)

18

4.3.3 Switch Output/Input Connector (DO/DI)

No.

Pin

Description

1

DO1+

Realy or Transistor Switch No.1 Output +/-.

2

DO1-

3

DO2+

Realy or Transistor Switch No.2 Output +/-.

4

DO2-

5

DO3+

Realy or Transistor Switch No.3 Output +/-.

6

DO3-

7

DO4+

Realy or Transistor Switch No.4 Output +/-.

8

DO4-

9

COM

DI Common Terminal [GND].

10

DI1

Switch Input No.1.

11

DI2

Switch Input No.2.

12

DI3

Switch Input No.3.

www.zemicusa.info

4 Definable normally open relay (AC250V/DC24V, 1A) or transistor (DC24V, 500mA) switches are

used for outputting alarm/control signals to external devices. 3 Definable normally open switch inputs are

used for receiving control signals from external devices.

19

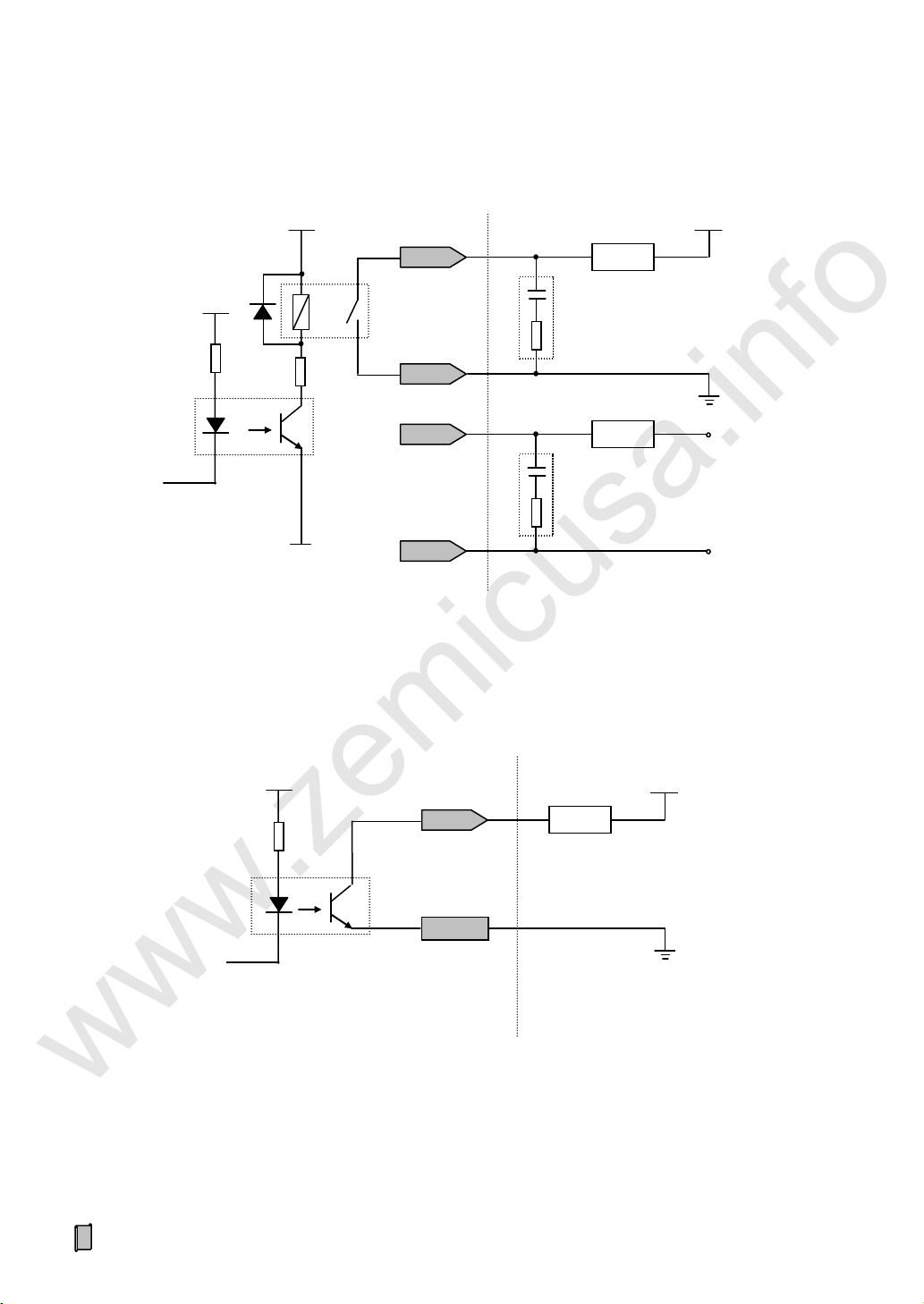

4.3.3.1 Relay Switch Output (DO) to Load Connection

DOx+

DOx-

Controller

Load Circuit

Load

Spark Killer

Load

Spark Killer

AC220V

L

N

DOx+

DOx-

VCC

+5V

+24V

DOx+

VCC

Controller

Load Circuit

Load

DIx

DOx-

+24V

www.zemicusa.info

4.3.3.2 Transistor Switch Output (DO) to Load Connection

20

4.3.3.3 Relay Switch Output (DO) to PLC Connection

PLC

Switch input with common source

IN1

IN2

V+

+24V

DOx+

DOx-

Controller

Controller

IN1

PLC

Switch input with common ground

IN2

COM

+24V

DOx+

DOx-

www.zemicusa.info

21

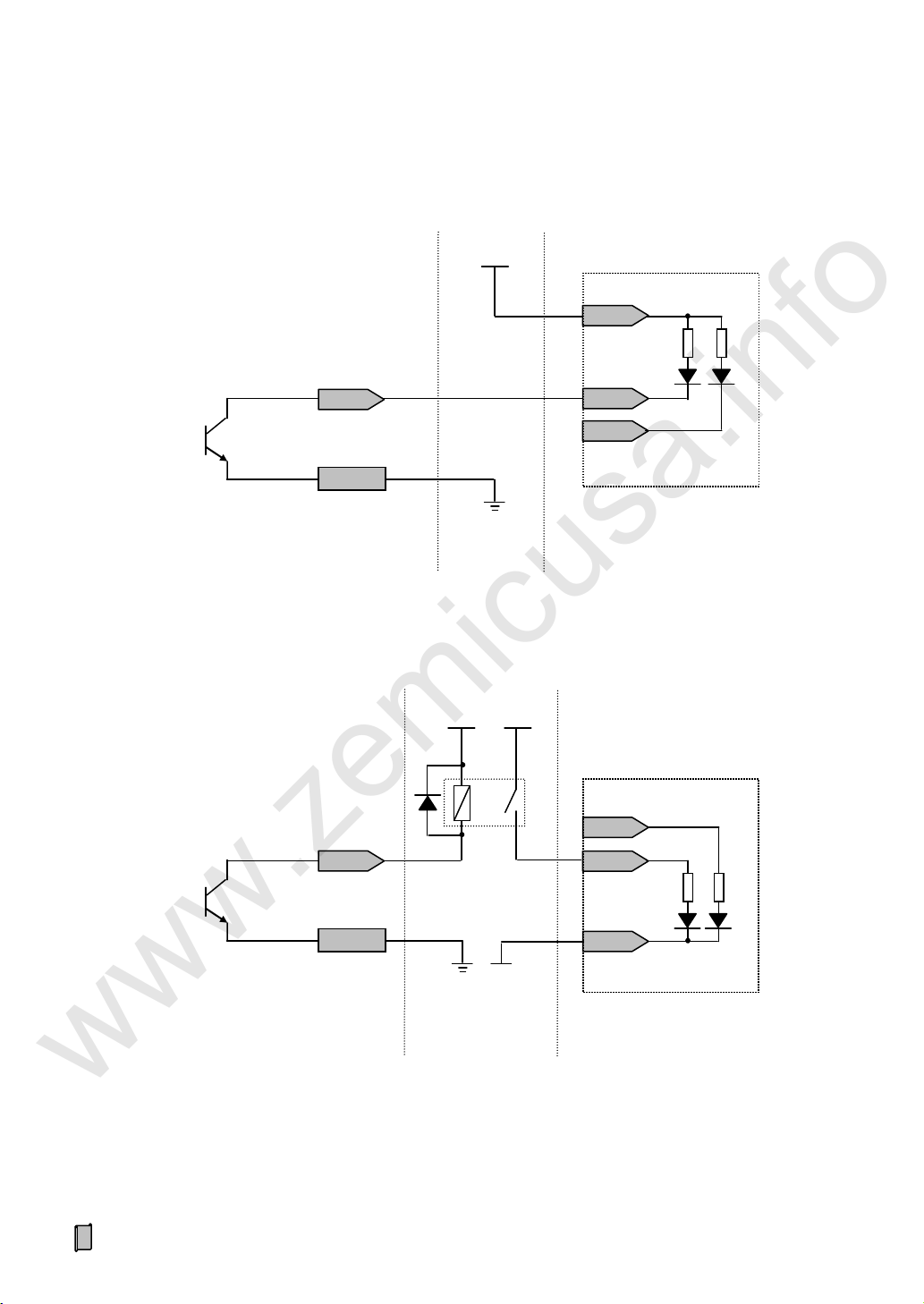

4.3.3.4 Transistor Switch Output (DO) to PLC Connection

Controller

DOx+

IN1

PLC

Switch input with common ground

IN2

DOx-

COM

+24V

Auxiliary Relay

+24V

PLC

Switch input with common source

IN1

IN2

V+

+24V

DOx+

DOx-

Controller

www.zemicusa.info

22

4.3.3.5 Switch Input (DI) to Switch/PLC Connection

DIx

PLC

Switch output with common source

OUT1

V+

Auxiliary Relay

COM

+24V

Controller

VCC

+5V

Controller

VCC

+5V

PLC

Switch output with common ground

OUT1

COM

DIx

OUT1.1

OUT1.2

Switch or

PLC with relay switch output

DIx

COM

COM

www.zemicusa.info

23

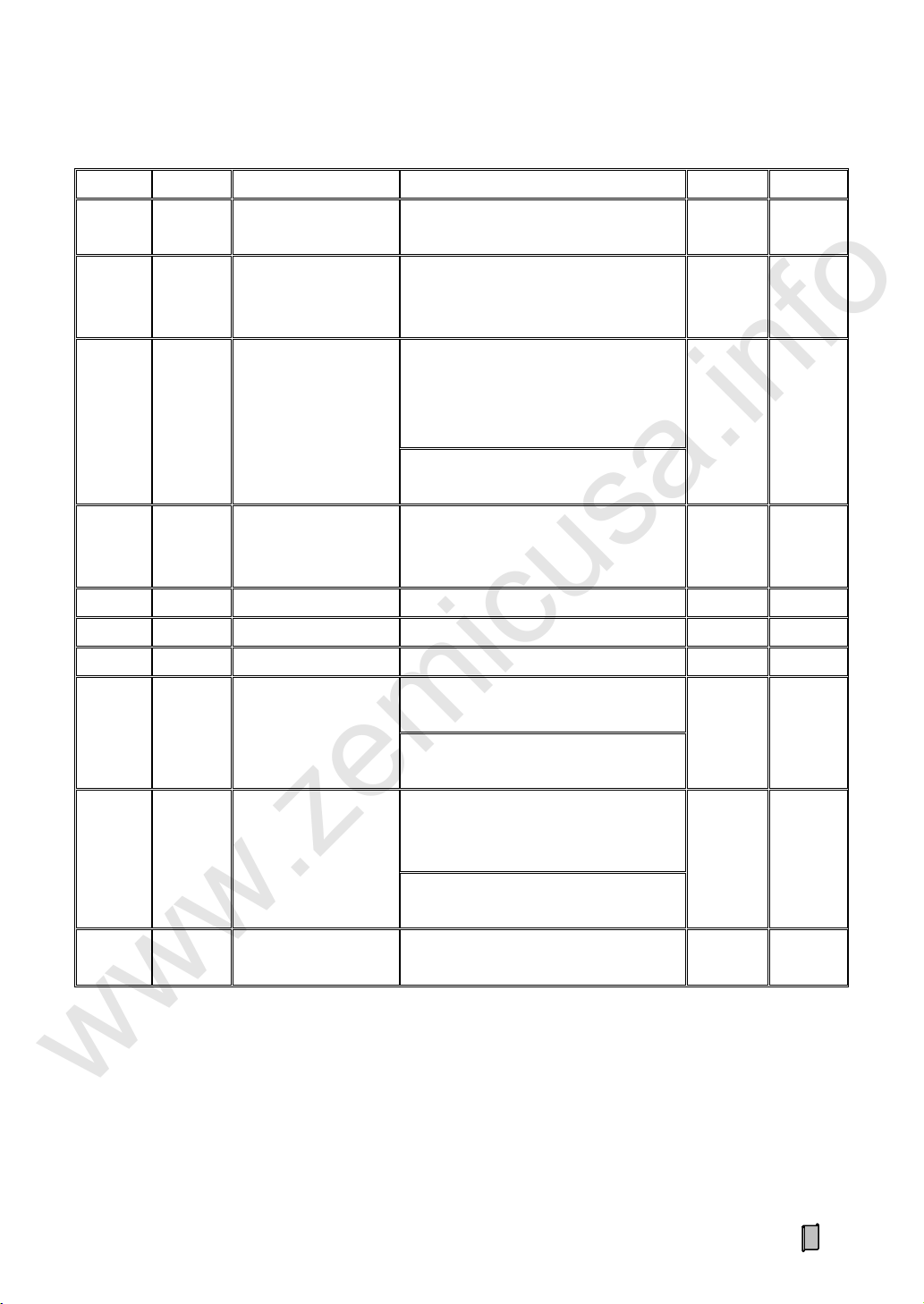

4.3.4 Digital Communication Port Connection (COM1/2)

No.

COM1

COM2

RS232

RS485

CANBUS

Profibus-DP

RS422

Ethernet

RS232

1 B- TXD-

2 RXD

A+ TXD+

3 TXD

DP- (B)

RXD+

4

RXD-

5

GND

GND

GND

GND

GND 6 TXD

7

RXD 8 DP+ (A)

9

+5V (+5V/100mA power supply can be used for external wireless

communication device)

No.

COM1

COM2

RS232

RS485

CANBUS

Profibus-DP

RS422

Ethernet

RS232

1 B- TXD-

2 RXD

A+

TXD+

3

TXD

DP- (B)

RXD+

4

RXD-

5 DP+ (A)

6

GND

GND

GND

GND

GND

7

RXD 8 TXD

9

+5V (+5V/100mA power supply can be used for external wireless

communication device)

www.zemicusa.info

COM1 Optional: RS232/RS485/RS422/Profibus-DP/CANBUS/Ethernet modules.

COM2: RS232.

Connectable: IPC/PLC, Remote Display&Operation Terminal, Serial Printer and Wireless Module.

4.3.4.1 Model Panel-mounting Communication Port

4.3.4.2 Model Wall-mounting Communication Port

24

4.3.4.3 RS232 to IPC/PLC Host-slave&Point-to-point Network

Host (IPC/PLC)

Slave: Controller

TXD

Max. transmission distance: 15m.

Communication mode: Host-slave.

RXD

GND

TXD

RXD

GND

Controller

Serial Printer/Remote Display&Operation Terminal

TXD

Max. transmission distance: 15m.

Communication mode:

To serial printer: Print.

To remote display terminal: Continuous.

To remote operation terminal: Host-slave.

RXD

GND

TXD

RXD

GND

www.zemicusa.info

4.3.4.4 RS232 to Printer, Remote Display&Operation Terminal Point-to-point Network

25

4.3.4.5 RS485/CANBUS/Profibus-DP to IPC/PLC Host-slave Data-bus Network

B A GND

Host (IPC/PLC)

Slave: Controller

…

1#

…

R

B

A

GND

N#

B

A

GND

R

Terminal resistor R=120~150Ω.

RS485 max. transmission distance: 1200m.

Communication mode:

RS485/CANBUS: Host-slave.

Profibus-DP: DP-Modicon/DP-Siemens.

N≤31

B A GND

Controller

Remote Display&Operation Terminal

R

B A GND

R

Terminal resistor R=120~150Ω.

Max. transmission distance: 1200m.

Communication mode:

To remote display terminal: Continuous.

To remote operation terminal: Host-slave.

www.zemicusa.info

4.3.4.6 RS485 to Remote Display&Operation Terminal Point-to-point Network

26

4.3.4.7 RS422 to IPC/PLC Host-slave Data-bus Network

Host (IPC/PLC)

Slave: Controller #1~N, N≤31

R

Terminal resistor R=120~150Ω.

Max. transmission distance: 1200m.

Communication mode: Host-slave.

RXD+

RXD-

GND

TXD-

TXD+

R

RXD+

RXD-

GND

TXD-

TXD+

R

R

Host

Slave #1 (IP1)

IPC/PLC

Controller

Switch

10/100Mbps Fast Ethernet Switch

Controller

Controller

Slave #2 (IP2)

Slave #N (IPn)

…

Ethernet

Ethernet

Communication mode: Host-slave.

www.zemicusa.info

4.3.4.8 Ethernet Host-slave Network

27

4.3.5 Power Supply Connector (POWER)

Pin

Description

Voltage

N

Null Wire.

AC220V±15%.

E

Earth Wire.

L

Live Wire.

Pin

Description

Voltage

DC-

DC Input -.

DC24V±20%.

DC+

DC Input +.

Optional for Model Wall-mounting.

www.zemicusa.info

Please make sure that the power supply is correct before power-on. If the voltage fluctuation exceeds

the allowable range, please use regulated power supply.

4.3.6 Ground Protection

For avoiding electric shocks, the metal shell should be grounded directly.

28

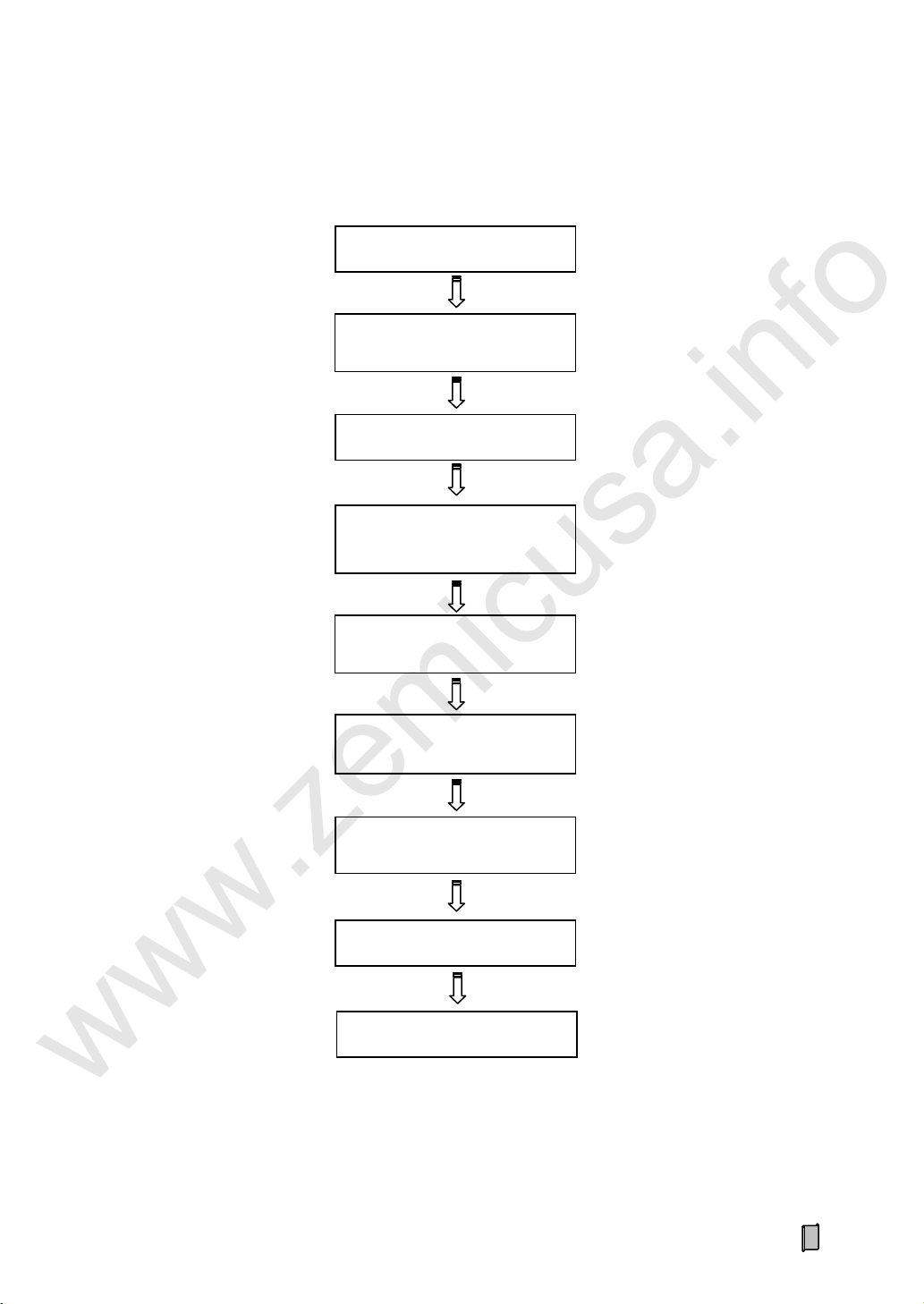

5. Operation Procedure

Connection & Power on

Zero Calibration

I/O Setting

Serial Port Setting

Control Setting

(Used for belt feeder)

Other Settings

„Weighing Dead Band‟ Setting

(Scale Setting)

Key-Locking

„Speed Coeff.‟ & „Belt Length‟

Setting (Scale Setting)

Dynamic Span Calibration

Or Static Span Calibration

www.zemicusa.info

29

6. Function&Operation

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

RUN

EXT

ALARM

kg t t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【ENT】: Set „Flow Setpoint‟ value

www.zemicusa.info

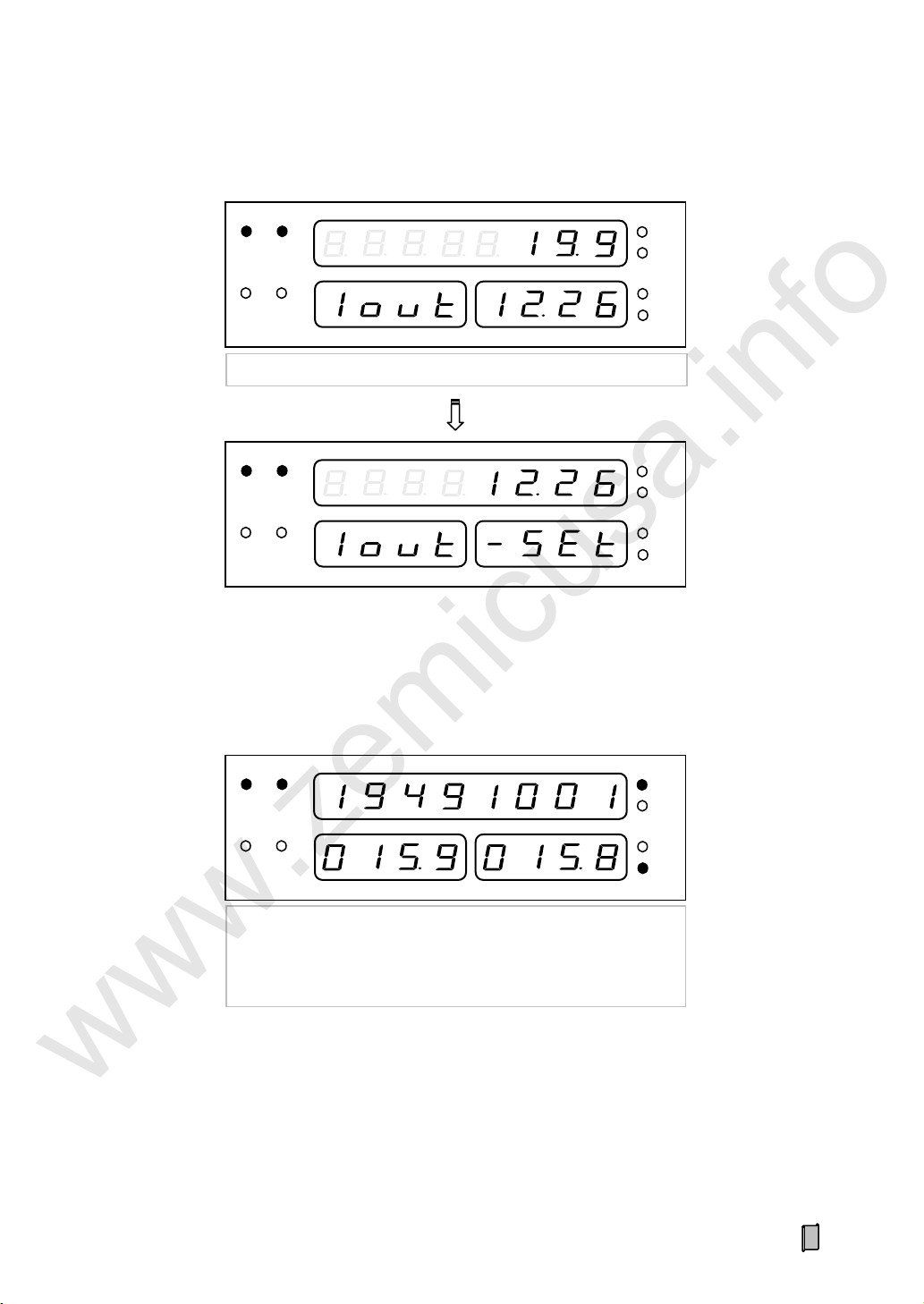

The following display&operation interfaces are described with „kg‟ as the Internal Scale Unit. If the

parameter „[P107] Internal Scale Unit‟ is set to „g‟, the actual Weight Display Unit will be different.

6.1 Main Display Interface

【▲】【 ▼】: Display the next/previous interface.

6.1.1 Totalized Weight, Belt Speed & Flow

Press【PRINT】key to print: 2009-05-20 23:59

19491001kg

6.1.2 Totalized Weight, Flow Setpoint & Flow

30

6.1.3 Flow & Control Current

【◄】【 ►】: Control Current Iout ±1mA

RUN

AUTO

EXT

ALARM

kg

t

t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【ENT】: Set „Control Current‟ value

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Load=Flow / (3.6×Speed)

Load Setpoint=Flow Setpoint / (3.6×Speed)

Load: kg/m; Flow: t/h

Belt Speed: m/s

www.zemicusa.info

6.1.4 Totalized Weight, Load Setpoint & Load

31

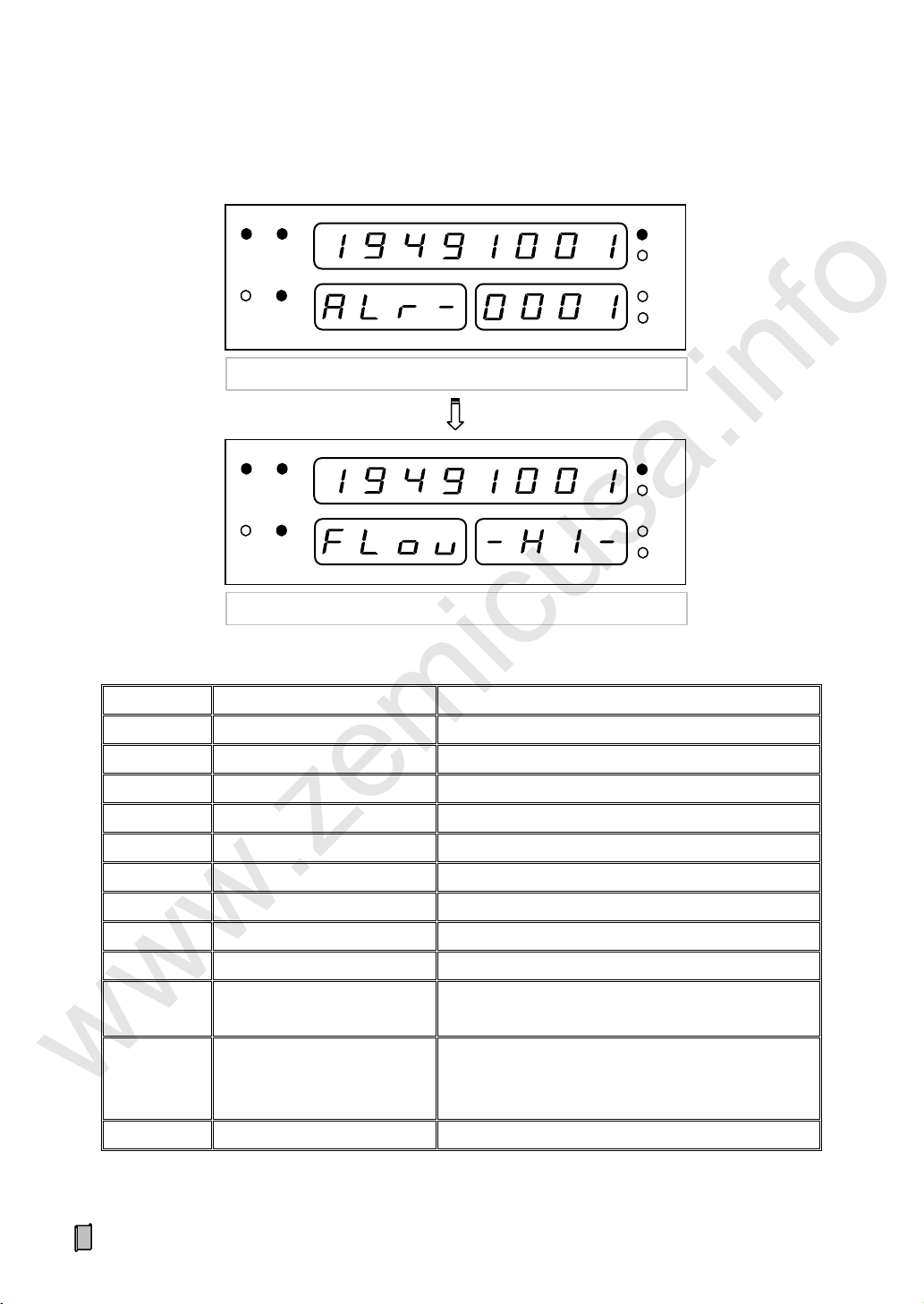

6.1.5 Alarm Items

Sign

Alarm Item

Alarm Condition

FLou -HI-

Flow Upper Limit

Flow ≥ Flow Range × Flow Upper Limit(%)

FLou -Lo-

Flow Lower Limit

Flow ≤ Flow Range × Flow Lower Limit(%)

LoAd -HI-

Load Upper Limit

Load ≥ Load Range × Load Upper Limit(%)

LoAd -Lo-

Load Lower Limit

Load ≤ Load Range × Load Lower Limit(%)

SPEd -HI-

Speed Upper Limit

Speed ≥ Speed Range × Speed Upper Limit(%)

SPEd -Lo-

Speed Lower Limit

Speed ≤ Speed Range × Speed Lower Limit(%)

PId- -HI-

Control Current Upper Limit

Control Current ≥ PID Control Current Upper Limit

PId- -Lo-

Control Current Lower Limit

Control Current ≤ PID Control Current Lower Limit

dEV- -HI-

Flow Positive Deviation Limit

Flow Deviation [E%] > Flow Positive Deviation Limit

dEV- -Lo-

Flow Negative Deviation Limit

Flow Deviation [E%] < (-Flow Negative Deviation

Limit)

dEV=XXX.X

Flow Deviation Value [E%]

0.0~999.9%

Flow Deviation [E%] = ((Flow - Flow Setpoint) /

Flow Setpoint) × 100%

XXXX ----

Normal

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【ENT】: Alarm Query

【▲】【 ▼】: Query Switch; 【MENU】: Exit

ALr- Alarm Count

www.zemicusa.info

32

6.1.6 Other Display Interface

NO.

Display iterms

Sign

Range

6

Totalized Weight of

Current Batch

P=

0~999999

7

AD Value

Ad=

0~65535

8

Zero Value

Zr=

0~60000

9~11

DI State

dI1-/dI2-/dI3-

-oFF/-on-

12~15

DO State

do1-/do2-/do3-/do4-

-oFF/-on-

16

AI Signal

AI1=

4.00~20.00mA

17~19

AO Signal

Ao1=/Ao2=/Ao3=

4.00~20.00mA

20

Totalized Weight High

Speed Pulse

HP

0~999999 Pulse

21

Totalized Weight Low

Speed Pulse

LP

0~999999 Pulse

22

Date

20YY.MM.DD

Year. Month. Day

23

Time

HH.MM.SS-W

Hour. Minute. Second-Week

24

Totalized Weight of

Current Shift

t=

0~99999.9t

www.zemicusa.info

The Numeric Display 1 displays Totalized Weight value and the Numeric Display 2-3 displays the following data:

33

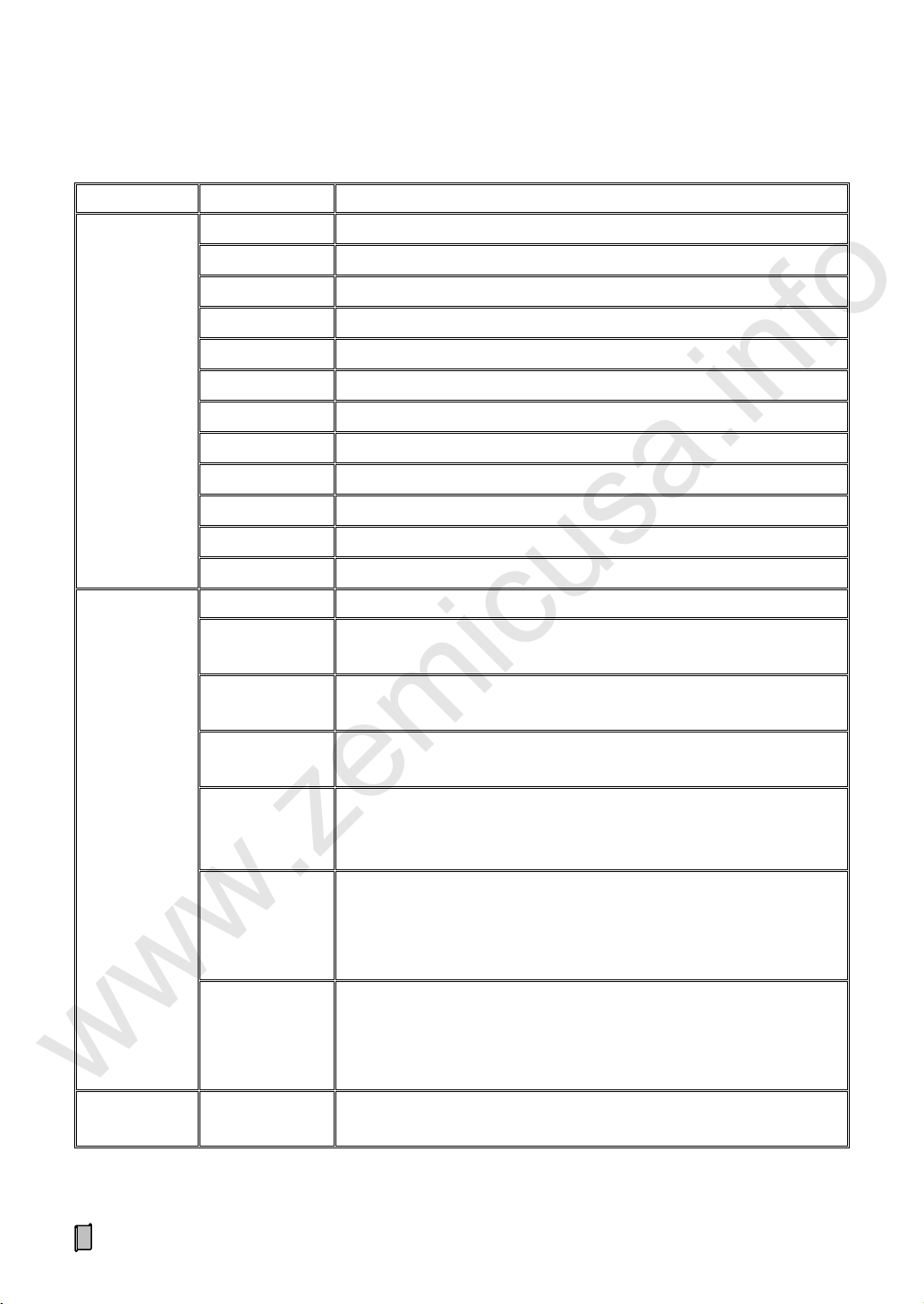

6.2 Main MENU

Main Menu

Second Menu

Description

≡F1-SEt≡

Setting

--SCAL--

Basic scale parameters setting.

--SCAL1-

Extra scale parameters setting.

--CtrL--

Basic feeding control parameters setting.

--CtrL1-

Extra feeding and batching control parameters setting.

--Flou--

Flow parameters setting.

--SPEd-

Speed parameters setting.

--LoAd--

Load parameters setting.

--SAVE--

Weight record parameters setting.

--SErP--

Communication parameters setting.

---Io---

Input/output parameters setting.

--dISP--

Display and operation interface parameters setting.

--tIEE--

Date/Time parameters setting.

≡F2-CAL≡

Calibration

--ZEro--

Zero Calibration without loading for correcting Zero Value.

--LoAd--

Dynamic Span Calibration with loading materials or Poise Weights for

correcting Span Coefficient.

-CHAn--

Static Span Calibration with a measured chain weight as a continuous and

steady load on the running belt weigher for correcting Span Coefficient.

--HAng--

Static Span Calibration with a measured Hanging Weight as a steady load

on the running belt weigher for correcting Span Coefficient.

--SEgC--

Segmenting Span Correction. After doing Dynamic or Static Span

Calibration, further corrections for 3 [AD Value: 0~60000] linear segments

are optional for correcting Correction Coefficient 1~3.

--SPEd--

Speed Coefficient Calibration.

Keep the belt weigher running at a constant speed. After the running time of

a revolution being measured with using a stopwatch, do this operation for

correcting Speed Coefficient.

--LEnS--

Belt Length Calibration.

Keep the belt weigher running at a constant speed. After the running time of

a revolution being measured with using a stopwatch, do this operation for

correcting Belt Length.

≡F3-rEC≡

Weight Record

Query and print Weight Records.

www.zemicusa.info

34

Main Menu

Second Menu

Description

≡F4-CLS≡

Data Clearing

---CLS--

Clear Screen: Clear Totalized Weight and Totalized Weight Pulse Count.

But Totalized Weight of Current Shift will not be cleared, so this operation

has no effect on recording of weight per shift.

---CLt--

Clear Weight: Clear Totalized Weight, Totalized Weight Pulse Count and

Totalized Weight of Current Shift.

The cleared value of Totalized Weight of Current Shift will not be recorded.

---CLr--

Clear Records: Clear History Records of Totalized Weight.

But Current Totalized Weight, Totalized Weight Pulse Count and Totalized

Weight of Current Shift will not be cleared.

≡F5-SAF≡

Security

--ALoc--

Auto-locking: If there is not any keypad operation in one minute and it‟s not

in the processes of „F2 Calibration‟ & „F6 Factory Adj.‟, the controller will

lock the keypad and return to „Main Display Interface‟ automatically.

--Locc--

Locking keypad.

--oPEn--

Unlocking keypad.

--PASS--

Set Password.

Exfactory Password: 001.

--dEFU--

RAM Reset: Restore to factory defaults.

≡F6-FAC≡

Factory Adj.

--Ao1E--

AO1 Zero Adjustment.

--Ao1F--

AO1 Full Range Adjustment.

--Ao2E--

AO2 Zero Adjustment.

--Ao2F--

AO2 Full Range Adjustment.

--Ao3E--

AO3 Zero Adjustment.

--Ao3F--

AO3 Full Range Adjustment.

--AI1E--

AI Zero Adjustment.

--AI1F--

AI Full Range Adjustment.

≡F7-InF≡

Product Info.

---VEr--

Version No.: Only for query.

---Sn---

Serial No.: Only for query.

--dAtE--

Exfactory Date: Only for query.

--AudIt-

Audit Counter: Audit Trail Counter [0~99999999] for Scale parameter‟s

modification. Only for query.

--AutH--

Authorization Code: Only for query.

www.zemicusa.info

35

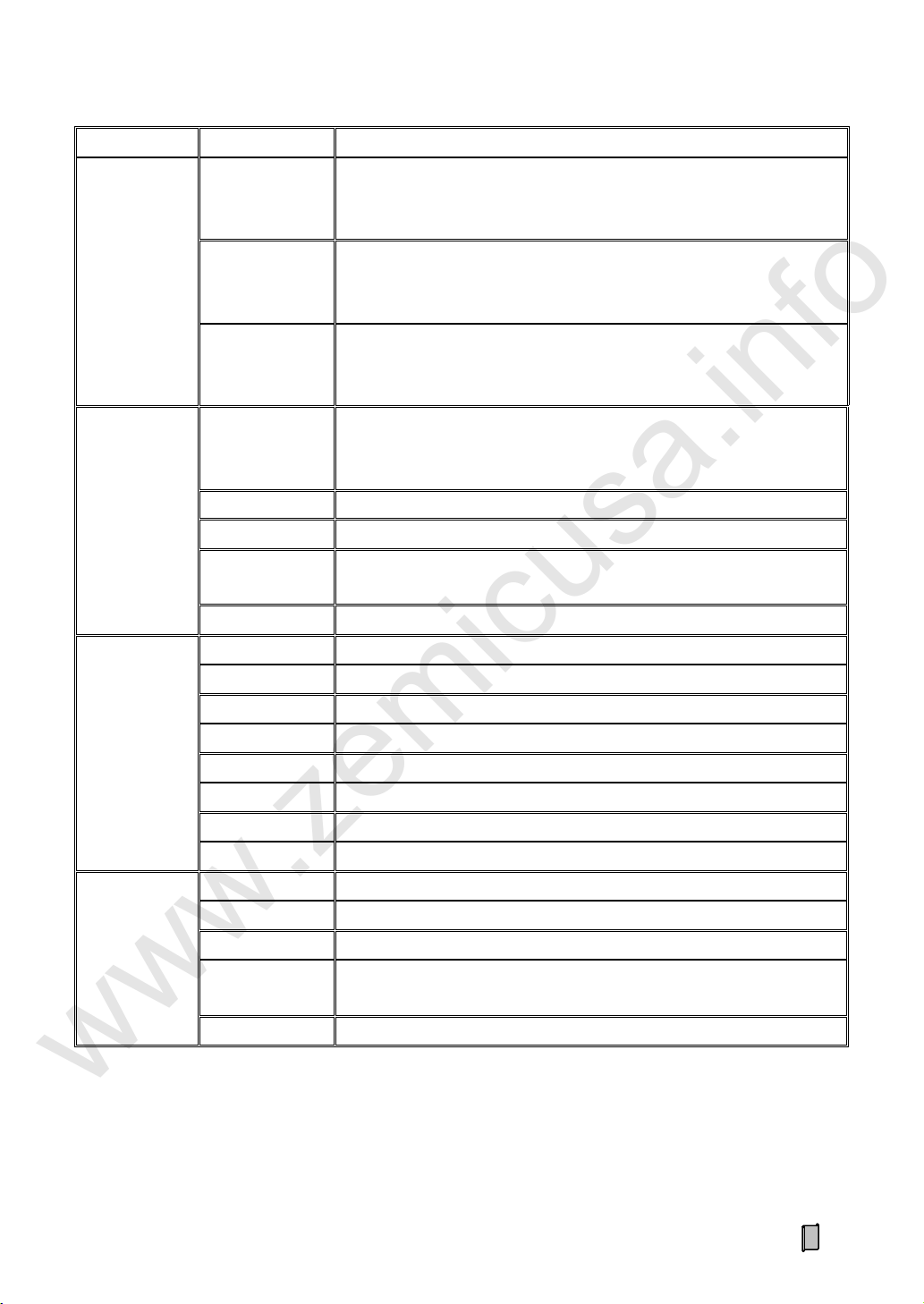

6.3 F1-SET Setting

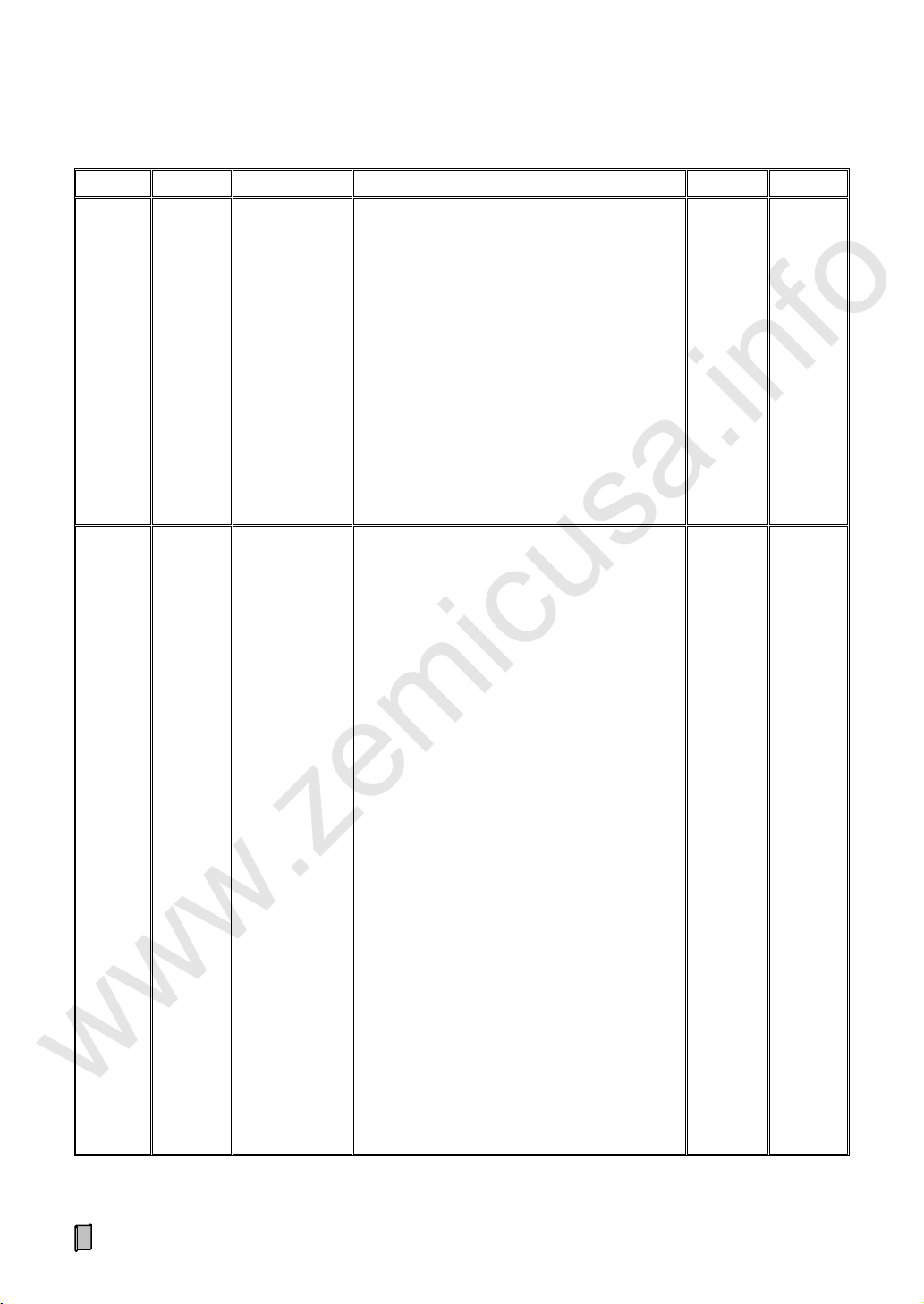

No.

Sign

Parameter

Range

Default

Set

P100

UnIt

Weight Display Unit

0: kg

1: t

([P107] Scale Unit = kg)

0

0: g

1: kg

([P107] Scale Unit = g)

P101

-dot

Weight Decimal Point

0: o

1: o.o

2: o.oo

When [P100]=1, it‟s valid.

1

P102

--L-

Belt Length

0.01~5000.00m

10.00[*]

P103

--C-

Speed Coefficient

1.0~99999.9 pulse/m

100.0[*]

P104

ZEro

Zero Value

0~60000 (Max. AD Value)

15000[*]

P105

CALC

Span Coefficient

1~99999999

200000

[*]

P106

dEAd

Weighing Deadband

±(0.00~200.00) t/h

([P107] Scale Unit = kg)

If Flow < Deadband value, the variance of

Totalized Weight will be ignored.

±0.00

±(0.00~200.00) kg/h

([P107] Scale Unit = g)

P107

SCAL

Internal Scale Unit

0: kg

1: g

0/1[*]

www.zemicusa.info

6.3.1 Basic Scale Parameters (SCAL)

* „RAM Reset‟ operation has no effect on this parameter.

36

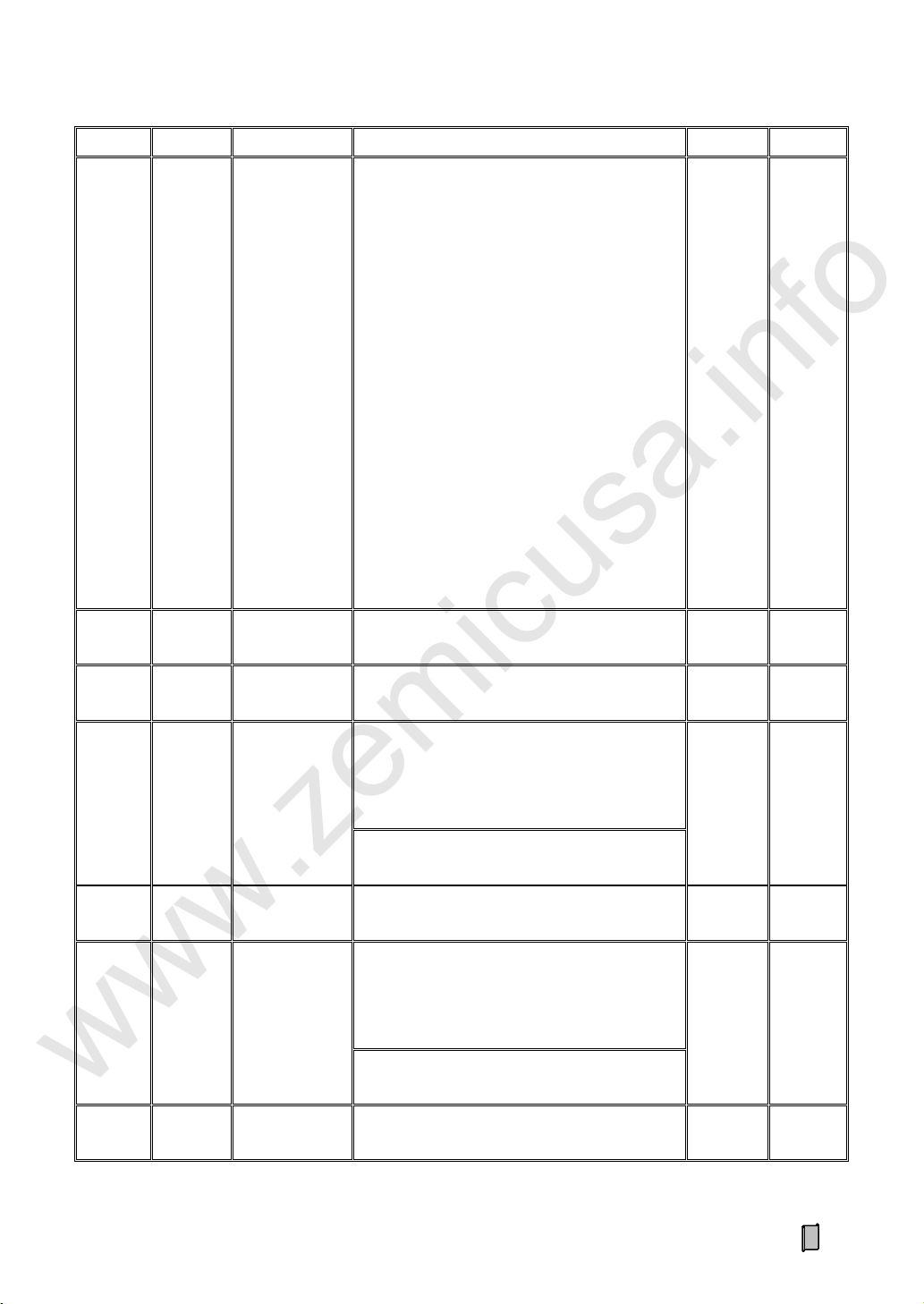

6.3.2 Extra Scale Parameters (SCAL1)

No.

Sign

Parameter

Range

Default

Set

P110

-Cn-

Calibration Revolutions

1~99R (1R=1 Belt Length)

3

P111

CHAn

Chain Weight

0.1~1000.0kg/m

([P107] Scale Unit = kg)

Chain Weight for Span Calibration

10.0

0.1~1000.0g/m

([P107] Scale Unit = g)

P112

HAng

Hanging Weight

0.1~1000.0kg

([P107] Scale Unit = kg)

Hanging Weight for Span Calibration

10.0

0.1~1000.0g

([P107] Scale Unit = g)

P113

SCLL

Weigh Length

0.001~50.000m

1.000

P114

CALI

Calibration Current

4.00~20.00mA

Control Current for System Calibration

12.00

P115

-Zt-

Zero Tracking

Permission

0: OFF; 1: ON

0

P116

-tr-

Zero Tracking Range

±(0~10%) × [P302] Flow Range

±5%

P117

-ZA-

Zero Adjusting Range

±(0~10%) × [P104] Zero Value

±5%

P118

-Zr-

Zero Refresh

0: RAM (Only Refresh RAM Zero Value)

1: FLASH/RAM (Refresh Original Zero

Value)

0

P119

-SP1

Breakpoint1

0~[P120] (AD Value: 0~60000)

Breakpoint1 of Segmenting Span

Correction

18000

P120

-SP2

Breakpoint2

[P119]~Max. AD Value (60000)

Breakpoint2 of Segmenting Span

Correction

42000

P121

-C1-

Span Correction

Coefficient 1

0.500~2.000; Span Correction Coefficient

of AD Value Linear Segment 1: 0~[P119]

1.000

P122

-C2-

Span Correction

Coefficient 2

0.500~2.000; Span Correction Coefficient

of AD Value Linear Segment 2:

[P119]~[P120]

1.000

P123

-C3-

Span Correction

Coefficient 3

0.500~2.000; Span Correction Coefficient

of AD Value Linear Segment 3:

[P120~Max. AD Value

1.000

P124

CAdd

Totalizing While

Calibrating

0: OFF

1: ON [In the process of „Load

Calibration‟, the inputted actual weight

value will be added to Totalized Weight]

0

P125

nAdd

Negative Totalizing

0: OFF [The negative variance

of Totalized Weight will be ignored]

1: ON

1

www.zemicusa.info

37

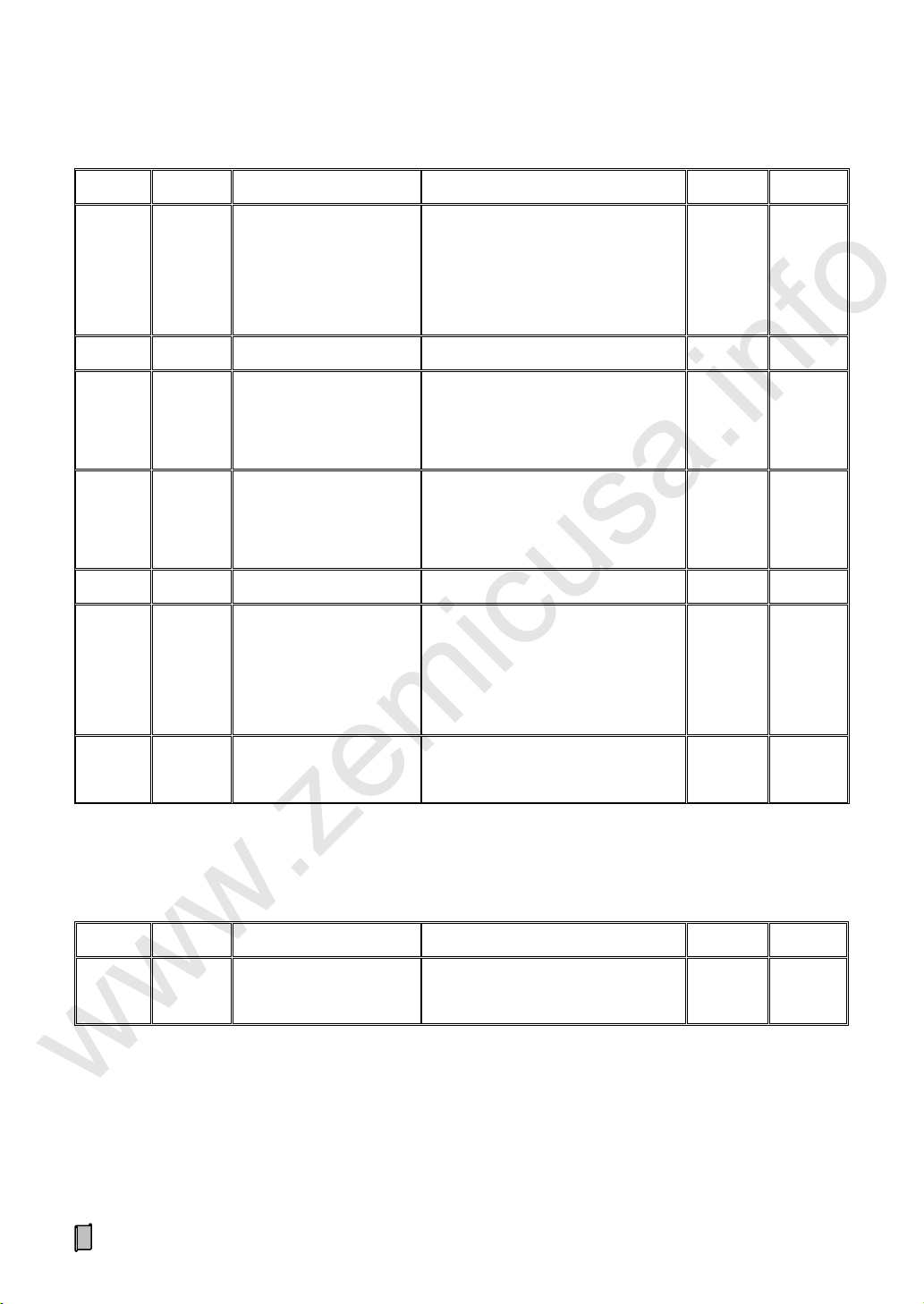

6.3.3 Basic Control Parameters (CtrL)

No.

Sign

Parameter

Range

Default

Set

P200

SEtF

Flow Setpoint

0.00~5000.00t/h

([P107] Scale Unit = kg)

20.00

0.00~5000.00kg/h

([P107] Scale Unit = g)

P201

--P-

P Value

0.1~5000.0

A bigger P value indicates a higher-precision

feeding adjustment but a longer time for flow

to reach the target value [Flow Setpoint].

100.0

P202

--I-

I Value

0.1-9.9s

A smaller I value indicates a higher-frequency

feeding adjustment but a potential flow

over-adjustment.

0.5

P203

PIHI

PID Upper Limit

[P204]~20.00mA

Auto[PID]/Manual Control Current Upper

Limit

20.00

P204

PILo

PID Lower Limit

4.00~[P203]mA

Auto[PID]/Manual Control Current Lower

Limit

5.00

P205

rAtE

PID Control Ratio

1~500%

The 2nd&3rd Control Current=Control

Ratio×(The 1st Control Current-4.00)+4.00

[mA]

100%

P206

oVEr

Flow Positive

Deviation Limit

(0.5~100.0)%

10.0%

P207

Undr

Flow Negative

Deviation Limit

(0.5~100.0)%

10.0%

P208

CtrL

Feeding Control

Mode

0: Auto[PID]

1: Manual

2: Communication

1

P209

FLSt

Flow Set Mode

0: Internal/Communication

1: External AI: 4~20mA

0

www.zemicusa.info

38

6.3.4 Extra Control Parameters (CtrL1)

No.

Sign

Parameter

Range

Default

Set

P210

PIdL

PID Initial Current

Hold Time

0.0-999.9s

2.0

P211

InIC

PID Initial Current

0: Present (Present Current Value)

1: Fuzzy (Fuzzy Current Value)

2: Set [P219] (Set Value of [P219])

0

P212

FuZE

Fuzzy Equivalent

0.01~100.00 [t/h]/mA

([P107] Scale Unit = kg)

Flow Increment per Increasing 1mA

Adjusting Current.

2.50

0.01~100.00 [kg/h]/mA

([P107] Scale Unit = g)

P213

StdL

Start/Stop Delay

0.0~999.9s

Delay Time of Feeder Starting

Delay Time of Scale Stopping

0.0

P214

bCon

Batch Permission

0: OFF; 1: ON

0 P215

-bSt

Batch Loop Mode

0: Manual Mode; 1: Auto Mode

0 P216

-bdL

Batch Interval

0.0-9999.9s

60.0

P217

SEtb

Batch Weight Setpoint

0~99999999kg

([P107] Scale Unit = kg)

0

0~99999999g

([P107] Scale Unit = g)

P218

SEtP

Batch Preact Weight

0~[P217] kg

([P107] Scale Unit = kg)

Batch Preact Weight

0

0~[P217] g

([P107] Scale Unit = g)

P219

SEtI

Set Value of PID

Initial Current

4.00~20.00mA

12.00

www.zemicusa.info

Note:

[P213] Start/Stop Delay:

1. Delay Time of Feeder Starting: When there is a “DI.Start” pulse signal input, „DO. Scale Start&Stop Control‟ will

turn on to start the belt weigher, and after delaying this time, „DO. Feeder Start&Stop Control‟ will turn on to start the

feeder.

2. Delay Time of Scale Stopping: When there is a “DI.Stop” pulse signal input, „DO. Feeder Start&Stop Control‟ will

turn off to stop the feeder, and after delaying this time, „DO. Scale Start&Stop Control‟ will turn off to stop the belt

weigher.

39

6.3.5 Flow Parameters (Flou)

No.

Sign

Parameter

Range

Default

Set

P300

UnIt

Flow Display Unit

0: t/h

1: kg/min

2: kg/h

([P107] Scale Unit = kg)

0

0: kg/h

1: g/min

2: g/h

([P107] Scale Unit = g)

P301

-dot

Flow Decimal Point

0: o; 1: o.o; 2: o.oo

1

P302

rAng

Flow Range

0.01~5000.00t/h

([P107] Scale Unit = kg)

100.00

0.01~5000.00kg/h

([P107] Scale Unit = g)

P303

-HI-

Flow Upper Limit

(0.0~100.0)% Flow Range

100.0%

P304

-Lo-

Flow Lower Limit

(0.0~100.0)% Flow Range

0.0%

P305

FILt

Flow Filter

1~200

10

P306

FLt2

Flow Filter 2

1~100

The secondary filter for flow display.

1

P307

FdEV

Flow Deviation Range

for Filter2

±(0~20)%

When Flow Deviation [E%] is within

this range, the secondary filter will

work.

±2%

www.zemicusa.info

40

6.3.6 Speed Parameters (SPEd)

No.

Sign

Parameter

Range

Default

Set

P400

-dot

Speed Decimal Point

0: o

1: o.o

2: o.oo

3: o.ooo

2

P401

rAng

Speed Range

0.100~5.000m/s

3.000

P402

-HI-

Speed Upper Limit

(0.0~100.0)% Speed Range

100.0%

P403

-Lo-

Speed Lower Limit

(0.0~100.0)% Speed Range

0.0%

P404

FILt

Speed Filter

1~200

10

P405

PuLS

Speed Source

0: Ext. Speed (Weighing by the external

speed)

1: Int. Speed1 (Weighing by the internal

speed)

2: Int. Speed2 (Connect a normally open

switch related to the running state of the

weighing belt between the terminals „SIN‟

and „VS-‟. Switch ON with Belt‟s

Running: Weighing by the internal speed;

Switch OFF with Belt‟s Stopping: Stop

weighing)

3: Int. Speed3 (Weighing by the internal

speed while the external speed pulse

inputting)

Note: If a DI signal is defined as „1:

Weighing‟, then only when this DI turns

on, the weighing process is allowed.

0

P406

InPL

Internal Speed

0.001~5.000m/s

0.500

P407

FrEH

Speed Pulse Frequency

Upper Limit

0.1~3.0kHz

If the frequency of speed pulse exceeds

this set value, the speed pulse will be

invalid.

1.0

www.zemicusa.info

41

6.3.7 Load Parameters (LoAd)

No.

Sign

Parameter

Range

Default

Set

P500

-dot

Load Decimal Point

0: o

1: o.o

2: o.oo

1

P501

rAng

Load Range

0.01~5000.00kg/m

([P107] Scale Unit = kg)

100.00

0.01~5000.00g/m

([P107] Scale Unit = g)

P502

-HI-

Load Upper Limit

(0.0~100.0)% Load Range

100.0%

P503

-Lo-

Load Lower Limit

(0.0~100.0)% Load Range

0.0%

P504

FILt

Load Filter

1~20

10

P505

LdCA

Speed for Calculation

0.000 (Use external speed for Load

calculation)

0.001~5.000m/s (Used for Load

calculation)

0.000

No.

Sign

Parameter

Range

Default

Set

P600

SHFn

Shifts per Day

1: One Shift; 2: Two Shifts;

3: Three Shifts; 4: Four Shifts

3

P601

SHF1

Shift1 Time

00:00~23:59

07:59

P602

SHF2

Shift2 Time

00:00~23:59

15:59

P603

SHF3

Shift3 Time

00:00~23:59

23:59

P604

SHF4

Shift4 Time

00:00~23:59

23:59

P605

APrt

Auto-print

0: OFF; 1: Per Hour

2: Per Shift; 3: Per Day

0

P606

ACLn

Auto Clear Screen

0: OFF; 1: Per Shift

2: Per Day; 3: Per Month

„Auto-clear‟ has no effect on recording of

weight per shift.

0

www.zemicusa.info

6.3.8 Weight Record Parameters (SAVE)

42

6.3.9 Communication Parameters (SErP)

No.

Sign

Parameter

Range

Default

Set

P700

-Adr

Communication Address

00~99

01

P701

P702

bPS1

bPS2

COM1 Baud Rate

COM2 Baud Rate

0: 1200bps

1: 2400bps

2: 4800bps

3: 9600bps

4: 19200bps

5: 115200bps

3

3

P703

P704

CHC1

CHC2

COM1 Parity Check

COM2 Parity Check

0: None

1: Even

2: Odd

0

0

P705

Con1

COM1 Communication

Mode

0: Host-slave Modbus ASCII

1: Continuous Sending ASCII

2: DP-Modicon (Profibus-DP; Data

Format: 4321)

3: DP-Siemens (Profibus-DP; Data

Format: 1234)

4: Print[A]

5: Print[B]

6: Host-slave Modbus RTU

7: Continuous Sending RTU

8: TCP

9: User1

0

P706

Con2

COM2 Communication

Mode

0: Host-slave Modbus ASCII

1: Continuous Sending ASCII

2: Unused

3: Unused

4: Print[A]

5: Print[B]

6: Host-slave Modbus RTU

7: Continuous Sending RTU

8: TCP

9: User1

0

P707

dAtF

Data Format

0: 4321

1: 3412

2: 1234

3: 2143

0

www.zemicusa.info

43

6.3.10 I/O Parameters (-Io-)

No.

Sign

Parameter

Range

Default

Set

P800

P801

P802

-Ao1

-Ao2

-Ao3

AO1 Signal

AO2 Signal

AO3 Signal

0: None

1: Flow

2: Control Current

3: Load

4: Speed

5: From AI [4~20mA]

6: From Communication Port

7: Totalized Weight High-speed Pulse (4mA→

20mA→4mA)

8: Totalized Weight Low-speed Pulse (4mA→

20mA→4mA)

9: Batch Weight (Output Capacity: [P217]

„Batch Weight Setpoint‟)

1

2 0

P803

P804

P805

P806

-do1

-do2

-do3

-do4

DO1 Signal

DO2 Signal

DO3 Signal

DO4 Signal

0: None

1: Flow Upper Limit Alarm

2: Flow Lower Limit Alarm

3: Load Upper Limit Alarm

4: Load Lower Limit Alarm

5: Speed Upper Limit Alarm

6: Speed Lower Limit Alarm

7: PID Upper Limit Alarm

8: PID Lower Limit Alarm

9: Flow Positive Deviation Limit Alarm

10: Flow Negative Deviation Limit Alarm

11: Totalized Weight Low-speed Pulse

12: Auto Feeding Control Mode

13: Calibrating State

14: Running State

15: From DI1

16: From DI2

17: From DI3

18: From Communication Port

19: Feeder Start&Stop Control

20: Belt Weigher Start&Stop Control)

21: BatchEnd[ON] (Totalized Weight reaches to

Batch Weight Setpoint)

22: BatchEnd[OFF] (Totalized Weight reaches

to Batch Weight Setpoint)

0

0

0

0

www.zemicusa.info

44

No.

Sign

Parameter

Range

Default

Set

P807

P808

P809

-dI1

-dI2

-dI3

DI1 Signal

DI2 Signal

DI3 Signal

0: None

1: Weighing (ON: Weighing; OFF: No

Weighing)

2: PID Start (ON: Start PID; OFF: Stop PID)

3: Sys. Ready (ON: System Ready, DI.Start

Signal is valid)

4: Zero Calibration (OFF→ON→OFF)

5: Clear Screen (OFF→ON→OFF)

6: Start (OFF→ON→OFF)

7: Stop (OFF→ON→OFF)

8: Feeding Control Mode (ON: Auto Control;

OFF: Manual Control)

9: Flow Set Mode (ON: Internal; OFF: External)

10: Clear Batch (OFF→ON→OFF, Clear Batch

Weight)

11: Batch Permit (ON: Batch Control)

12: End Batch (OFF→ON→OFF)

0

0 0

P810

ALSo

Alarm Sound

0: OFF

1: ON

0 P811

ALdL

Alarm Delay

0.0~9.9s

Alarm Delay Time

1.0

P812

HIPL

HP Weight

1~1000kg

([P107] Scale Unit = kg)

Weight value per high-speed pulse outputting

from PO/AO port

100

1~1000g

([P107] Scale Unit =kg)

P813

HIPt

HP Width

50~500ms

Width of high-speed pulse

100

P814

LoPL

LP Weight

10~10000kg

([P107] Scale Unit = kg)

Weight value per low-speed pulse outputting

from DO/AO port

1000

10~10000g

([P107] Scale Unit = g)

P815

LoPt

LP Width

50~1000ms

Width of low-speed pulse

200

www.zemicusa.info

45

6.3.11 Display Parameters (dISP)

No.

Sign

Parameter

Range

Default

Set

P900

LAng

Printing Language

0: Chinese

1: English

* „RAM Reset‟ operation has no

effect on this parameter.

0/1[*]

P901

dSPt

Display Refreshing Time

0.1~2.0s

0.5

P902

runL

LED Brightness While

Running

5~15

* „RAM Reset‟ operation has no

effect on this parameter.

10[*]

P903

StPL

LED Brightness While

Stopping

5~15

* „RAM Reset‟ operation has no

effect on this parameter.

10[*]

P904

InId

Initial Display Interface

1~6[#] 1

P905

dSPS

Display Item

(Displayable Interfaces)

0: 1

1: 1~5

2: 1~6

3: All

1

P906

FAnr

Cooling Fan Running

0: OFF

1: ON

1

No.

Sign

Parameter

Range

Default

Set

P998

20YY. MM. DD

HH. MM. SS-Week [7: Sunday]

Local

Time

www.zemicusa.info

6.3.12 Date/Time Parameters (tIEE)

46

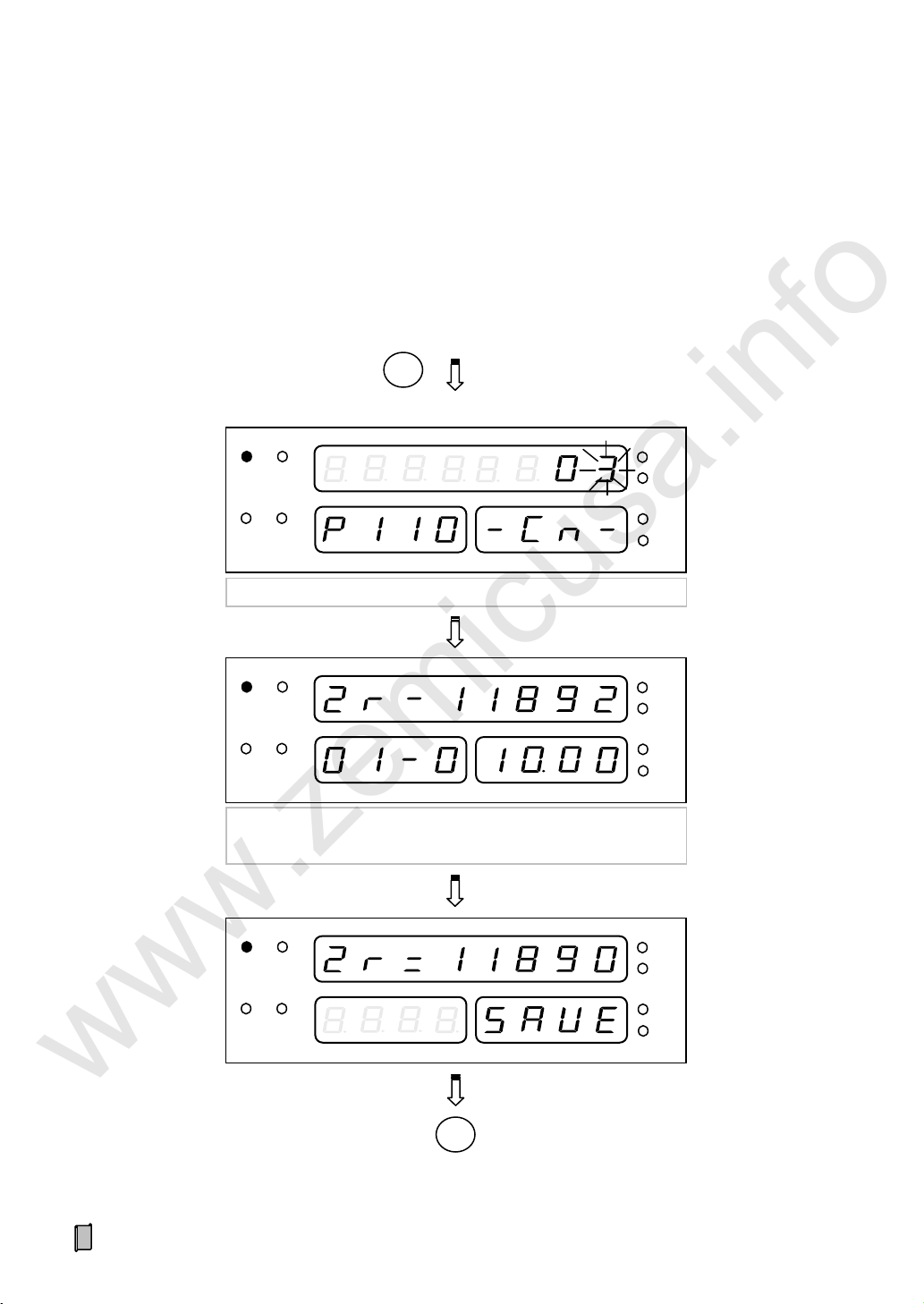

6.3.13 A Sample of Parameter Setting

Main Display Interface

【MENU】+【▲】【 ▼】

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【ENT】+【▲】【 ▼】

【MENU】: Exit 【ENT】: Save

M

【ENT】+【▲】【 ▼】

M

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【ENT】+【▲】【 ▼】

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【◄】【 ►】: Moving cursor. 【▲】【 ▼】: Digit input.

www.zemicusa.info

Modify the parameter „[P103] Speed Coefficient‟.

47

6.4 F2-CAL System Calibration

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F2-CAL≡

【ENT】+【▲】【 ▼】: --ZEro-【ENT】

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【MENU】: Exit 【ENT】: Save

M

【ENT】

M

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

After running Calibration Revolutions:

Input Calibration Revolutions

Zr: Zero Value

Revolution Count &Remainder length of a revolution

www.zemicusa.info

6.4.1 Zero Calibration (ZEro)

Keep the belt weigher running without load for correcting Zero Value.

48

6.4.2 Dynamic Span Calibration (LoAd)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Stop loading & Press【ENT】to run the last revolution:

Totalized Weight; Revolution Count & Remainder length of a

revolution (【▲】【 ▼】: Display Flow or AD value)

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F2-CAL≡

【ENT】+【▲】【 ▼】: --LoAd-【ENT】& Start loading

M

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

After running the last revolution:

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

≡: Running the last revolution

【ENT】

www.zemicusa.info

Let the belt weigher run with loading measured materials or Poise Weights for correcting Span

Coefficient.

49

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【MENU】: Exit 【ENT】: Save

M

【ENT】

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Input Calibrating Weight [kg]

www.zemicusa.info

50

6.4.3 Static Span Calibration with Chain Weight (CHAn)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【ENT】

Input Calibration Revolutions

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Input Chain Weight [kg/m]

Totalized Weight; Revolution Count & Remainder length of a

revolution (【▲】【 ▼】: Display Flow or AD value)

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F2-CAL≡

【ENT】+【▲】【 ▼】: --CHAn-【ENT】

M

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

【ENT】

After running the last revolution

www.zemicusa.info

Keep the belt weigher running with loading a chain weight for correcting Span Coefficient.

Put a measured chain weight as a continuous and steady load on the belt weigher and then start the

belt weigher.

51

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【MENU】: Exit 【ENT】: Save

M

【ENT】

RUN

AUTO

EXT

ALARM

kg

t

t/h

kg/m

【ENT】

Input Calibrating Weight [kg] = Calibration Revolutions × Belt

Length × Chain Weight

www.zemicusa.info

52

6.4.4 Static Span Calibration with Hanging Weight (HAng)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【ENT】

Input Calibration Revolutions

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Input Hanging Weight [kg]

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F2-CAL≡

【ENT】+【▲】【 ▼】: --HAng-【ENT】

M

【ENT】

【ENT】

Input Weigh Length [m]

www.zemicusa.info

Keep the belt weigher running with loading hanging weights for correcting Span Coefficient.

Put a measured hanging weight as a steady load on the belt weigher and then start the belt weigher.

53

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【MENU】: Exit 【ENT】: Save

M

【ENT】

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【ENT】

Input Calibrating Weight [kg] = Calibration Revolutions × Belt

Length × Hanging Weight / Weigh Length

Totalized Weight; Revolution Count & Remainder length of a

revolution (【▲】【 ▼】: Display Flow or AD value)

AUTO

EXT

ALARM

kg

t

t/h

kg/m

RUN

After running the last revolution

www.zemicusa.info

54

6.4.5 Segmenting Span Correction (SEgC)

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F2-CAL≡

【ENT】+【▲】【 ▼】: --SEgC-【ENT】

M

AD Value Linear Segment: 1~3; SEG1:0~[P119]; SEG2:

[P119]~[P120]; SEG3: [P120]~ Max. AD Value

【ENT】& Start loading

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Stop loading & Press【ENT】to run the last revolution:

Totalized Weight; Revolution Count & Remainder length of a

revolution (【▲】【 ▼】: Display Flow or AD value)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

After running the last revolution

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

≡: Running the last revolution

www.zemicusa.info

After doing Dynamic or Static Span Calibration, further corrections for 3 [AD Value: 0~60000] linear

segments are optional for correcting Correction Coefficient 1~3.

55

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【MENU】: Exit 【ENT】: Save

M

【ENT】

RUN

AUTO

EXT

ALARM

kg

t

t/h

kg/m

【ENT】

Input Calibrating Weight [kg]

[P121]/[P122]/[P123] Span Correction Coefficient:

0.500~2.000

www.zemicusa.info

56

6.4.6 Speed Calibration (SPEd)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F2-CAL≡

【ENT】+【▲】【 ▼】: --SPEd-【ENT】

【ENT】

M

Input Belt Length [m]

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

P: Pulse Count; tI: Run-timer [s]

【MENU】: Exit 【ENT】: Save

M

Run-Timer over

【ENT】

Input Running Time of a Revolution [s]

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

【▲】【 ▼】:

Display Speed Coefficient [C=] or

Pulse Count [P=]

[P103]: Speed Coefficient [pulse/m]

www.zemicusa.info

Keep the belt weigher running at a constant speed. After the belt running time of a revolution being

measured by stopwatch, do this operation for correcting Speed Coefficient.

57

6.4.7 Belt Length Calibration (LEnS)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F2-CAL≡

【ENT】+【▲】【 ▼】: --LEnS-【ENT】

【ENT】

M

Input Running Time of a Revolution [s]

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

L: Belt Length Detected [m]

tI: Run-timer [s]

RUN

AUTO

EXT

ALARM

kg

t

t/h

kg/m

【MENU】: Exit 【ENT】: Save

M

Run-Timer over or【ENT】

[P102]: Belt Length [m]

【▲】【 ▼】: Display Belt Length [L=] or Pulse Count [P=]

www.zemicusa.info

Keep the belt weigher running at a constant speed. After the belt running time of a revolution being

measured by stopwatch, do this operation for correcting Belt Length.

58

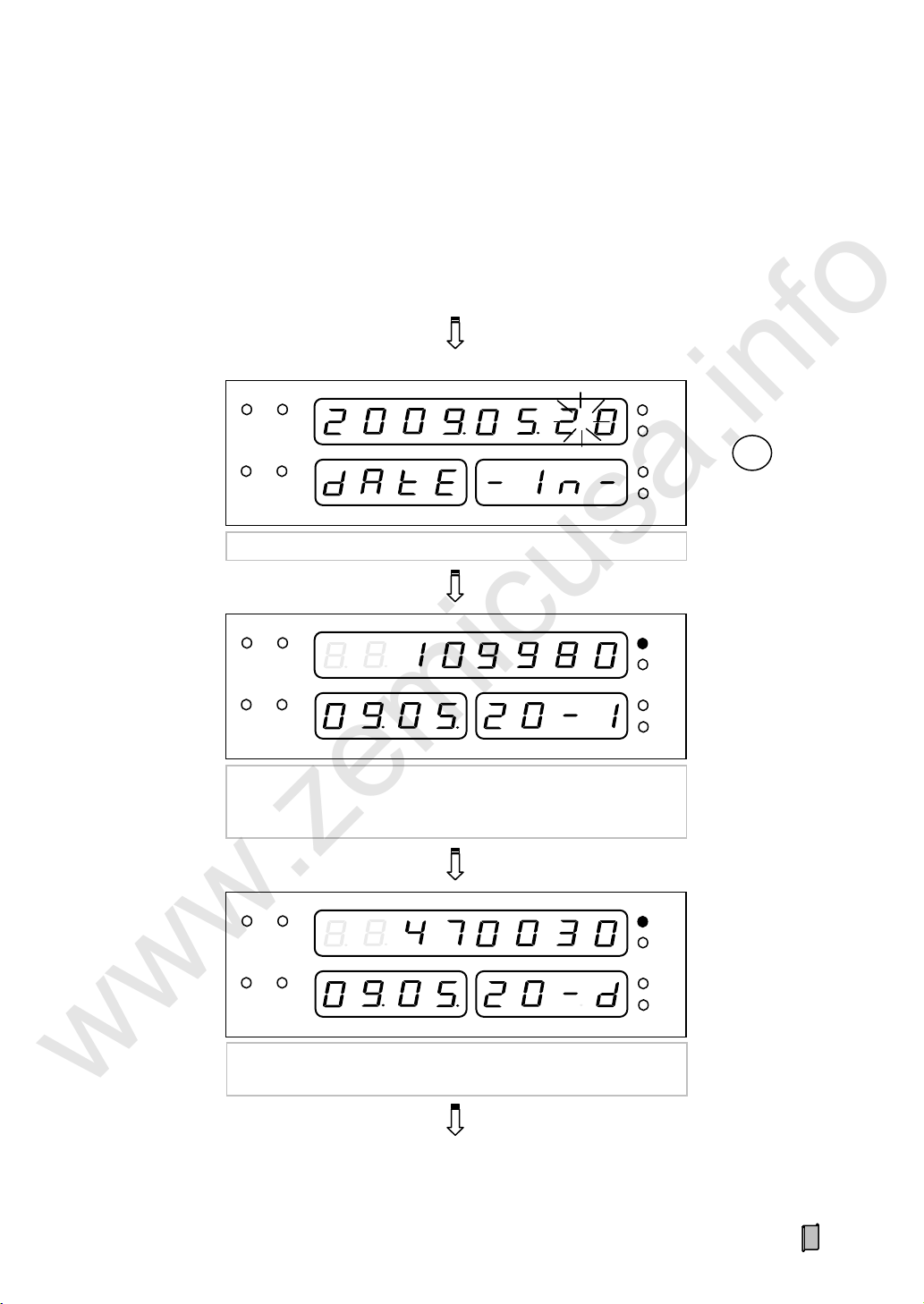

6.5 F3-REC Weight Record for Querying&Printing

Main Display Interface

【MENU】+【▲】/【▼】: ≡F3-REC≡

【ENT】

【ENT】

M

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Totalized Weight of a Shift, YY.MM.DD-Shift No.1~4

【◄】【 ►】: Previous/next day; 【▲】【 ▼】: Previous/next record

【PRINT】:Print weight records of this shift, See Appendix A.Table 1

RUN

AUTO

EXT

ALARM

kg

t

t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Totalized Weight of a Day, YY.MM.DD-d

【PRINT】:Print weight records of this day. See Appendix A.Table 2

Input Date

www.zemicusa.info

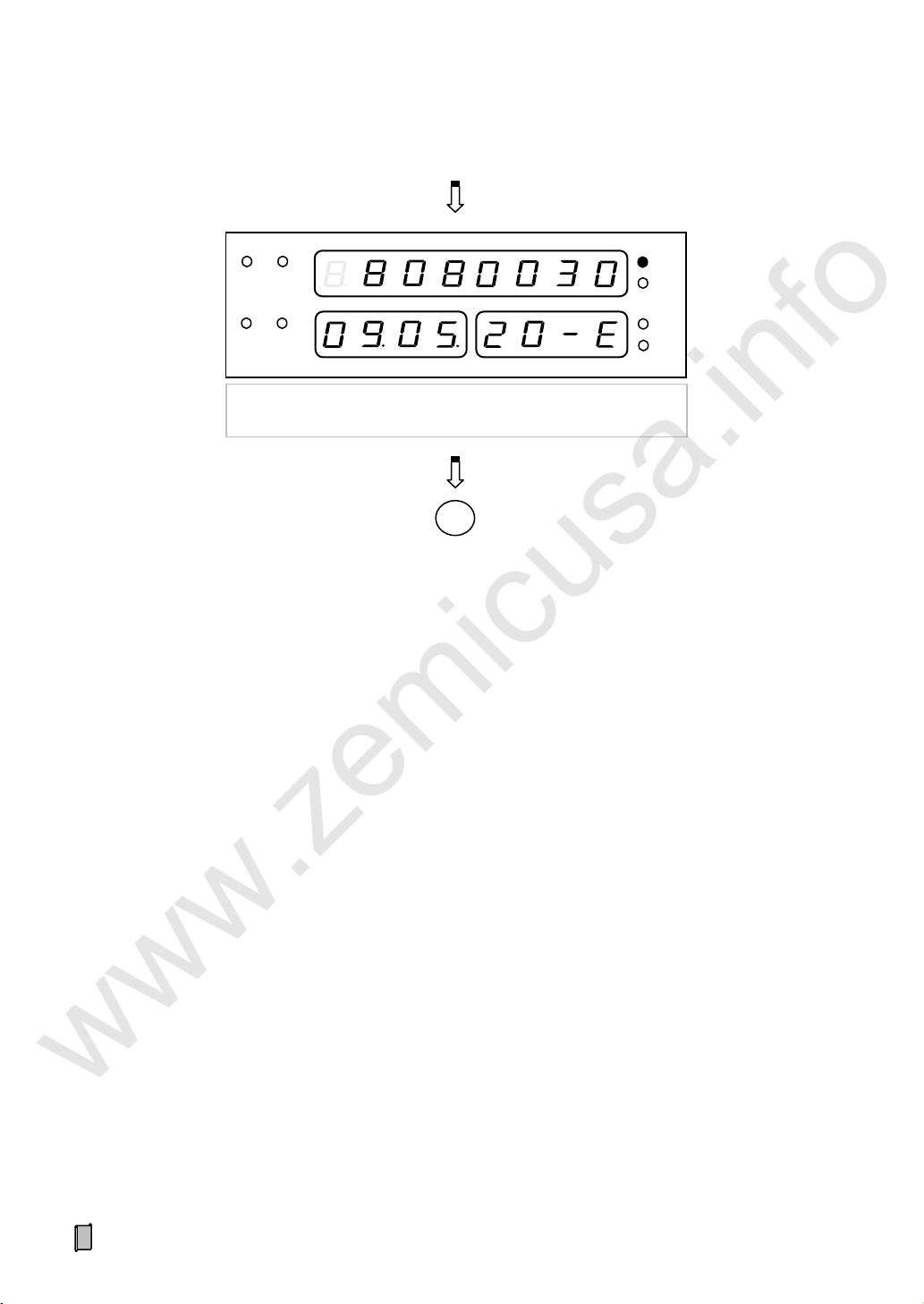

Weight records per shift/day/month of a year can be queried and printed.

59

【MENU】

M

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Totalized Weight from the first day of this month to this day,

【PRINT】: Print weight records (See Appendix A.Table 3)

www.zemicusa.info

60

6.6 F4-CLn Data Clearing

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F4-CLn≡

【ENT】+【▲】【 ▼】: ---CLS--

【ENT】

M

【MENU】: Exit 【ENT】: Enter

M

【▲】【 ▼】:YES/NO

CLS: Clear Screen; CLt: Clear Weight; CLr : Clear Records

www.zemicusa.info

Data Clearing Mode Description:

Manual Clearing Mode

1 Clear Screen: Clear Totalized Weight and Totalized Weight Pulse Count. But Totalized Weight of Current

Shift will not be cleared, so this operation has no effect on recording of weight per shift.

2 Clear Weight: Clear Totalized Weight, Totalized Weight Pulse Count and Totalized Weight of Current

Shift. The cleared value of Totalized Weight of Current Shift will not be recorded.

3 Clear Records: Clear History Records of Totalized Weight. But Current Totalized Weight, Totalized

Weight Pulse Count and Totalized Weight of Current Shift will not be cleared.

Timing Auto Clearing Mode

The parameter „[P606] Auto-clear‟ can be set to „0: OFF / 1: Per Shift / 2: Per Day / 3: Per Month‟, and its

default value is „0: OFF‟.

„Timing Auto Clearing‟ has no effect on recording of weight per shift.

[P606]=„1: Per Shift‟: After recording Totalized Weight per Shift, do operation „Clear Screen‟ automatically.

[P606]=„2: Per Day‟: After recording Totalized Weight of the last Shift per Day, do operation „Clear Screen‟

automatically.

[P606]=„3: Per Month‟: After recording Totalized Weight of the last Shift per Month, do operation „Clear

Screen‟ automatically.

Auto Clearing Before Overflowing Mode

When Totalized Weight value reaches to the maximum value 2×109[Scale Unit], do operation „Clear Screen‟

automatically.

„Auto-clear Before Overflowing‟ has no effect on recording of weight per shift.

61

6.7 F5-SAF Security

RUN

AUTO

EXT

ALARM

kg

t

t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼: ≡F5-SAF≡

【ENT】+【▲】【 ▼】: --ALoc-【ENT】+ Input Password +【ENT】

【MENU】: Exit 【ENT】: Enter

M

M

【▲】【 ▼】: 0[OFF] / 1[ON]

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F5-SAF≡

【ENT】+【▲】【 ▼】: --Locc-【ENT】

【MENU】: Exit 【ENT】: Enter

M

M

Input Password

www.zemicusa.info

6.7.1 Auto-locking (ALoc)

Auto-locking: If there is not any keypad operation in one minute and it‟s not in the processes of „F2 Calibration‟ &

„F6 Factory Adj.‟, the controller will lock the keypad and return to „Main Display Interface‟ automatically.

6.7.2 Key-locking (Locc)

62

6.7.3 Key-unlocking (oPEn)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F5-SAF≡

【ENT】+【▲】【 ▼】: --oPEn-【ENT】

【MENU】: Exit 【ENT】: Enter

M

M

Input Password

www.zemicusa.info

63

6.7.4 Password Set (PASS)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F5-SAF≡

【ENT】+【▲】【 ▼】: --PASS-【ENT】

【MENU】: Exit 【ENT】: Save

M

M

【ENT】

Input Original Password

Please input and remember the new password

www.zemicusa.info

64

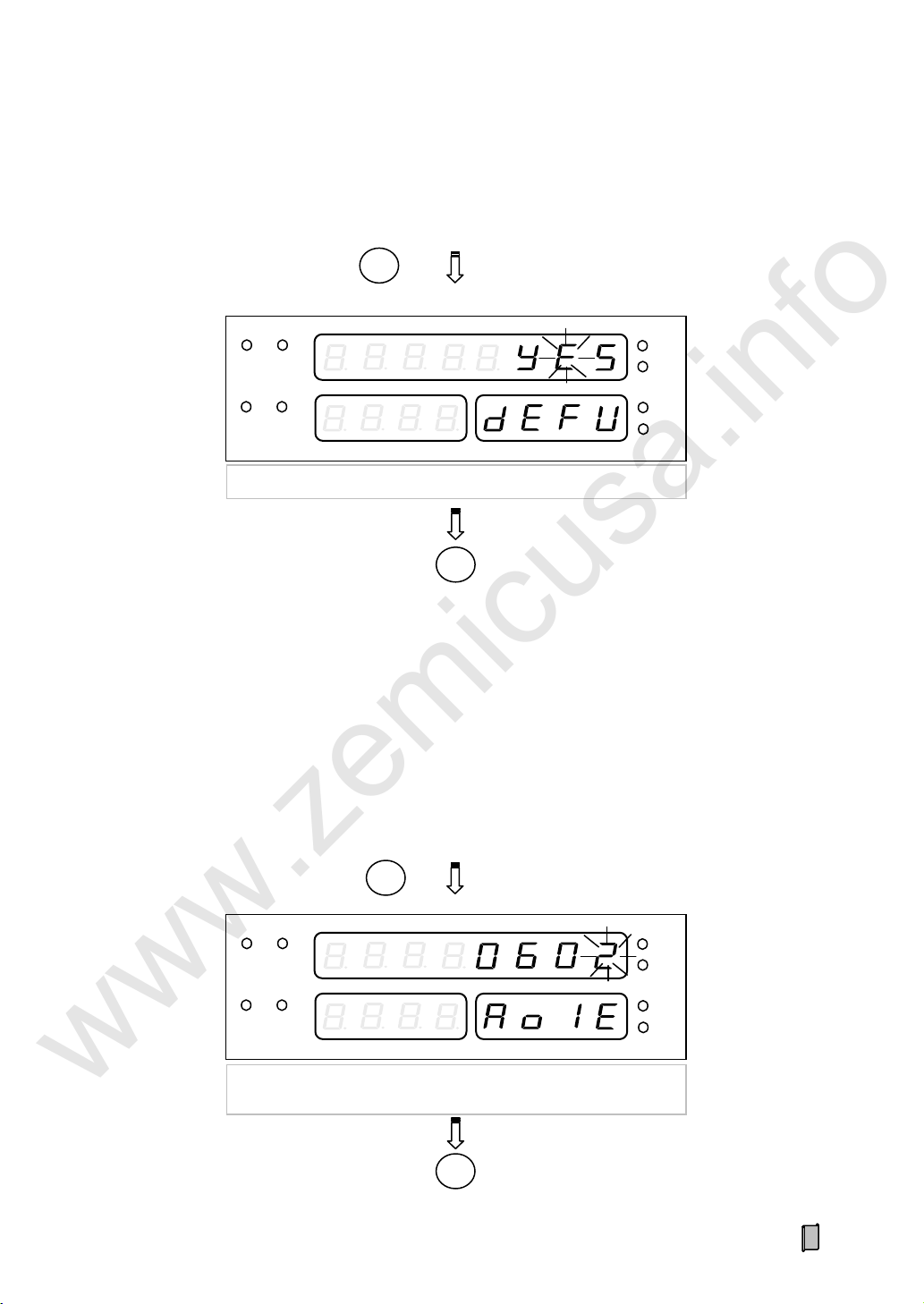

6.7.5 RAM Reset (dEFU)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F6-FAC≡

【ENT】+【▲】【 ▼】: AoxE(x=1~3)

【ENT】

M

【MENU】: Exit 【ENT】: Save

M

Set AOx Zero value (0~2000)

to make AOx output 4.00mA.

RUN

AUTO

EXT

ALARM

kg

t

t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F5-SAF≡

【ENT】+【▲】【 ▼】: --dEFU-【ENT】

【MENU】: Exit 【ENT】: Enter

M

M

【▲】【 ▼】: YES/NO

www.zemicusa.info

6.8 F6-FAC Factory Adjustment

Only after Key-unlocking with the Factory Password, this operation will be valid.

6.8.1 AO Zero Adjustment (AoxE)

65

6.8.2 AO Full Range Adjustment (AoxF)

RUN

AUTO

EXT

ALARM

kg

t

t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F6-FAC≡

【ENT】+【▲】【 ▼】: AI1E

【ENT】

M

【MENU】: Exit 【ENT】: Save

M

Input 4.00mA from AI port to correct AI zero value (0~2000)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F6-FAC≡

【ENT】+【▲】【 ▼】: AoxF(x=1~3)

【ENT】

M

【MENU】: Exit 【ENT】: Save

M

Set AOx Full value (2000~4095)

to make AOx output 20.00mA.

www.zemicusa.info

6.8.3 AI Zero Adjustment (AI1E)

66

6.8.4 AI Full Range Adjustment (AI1F)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F6-FAC≡

【ENT】+【▲】【 ▼】: AI1F

【ENT】

M

【MENU】: Exit 【ENT】: Save

M

Input 20.00mA from AI port to correct AI full value (2000~4095)

RUN

AUTO

EXT

ALARM

kg t t/h

kg/m

Main Display Interface

【MENU】+【▲】【 ▼】: ≡F7-INF≡

【ENT】+【▲】【 ▼】: ---VEr-【ENT】

VEr : Version No.; Sn: Serial No.; dAtE: Exfactory Date

AudIt: Audit Counter; AutH: Authorization Code

【MENU】

M

M

www.zemicusa.info

6.9 F7-InF Product Information

67

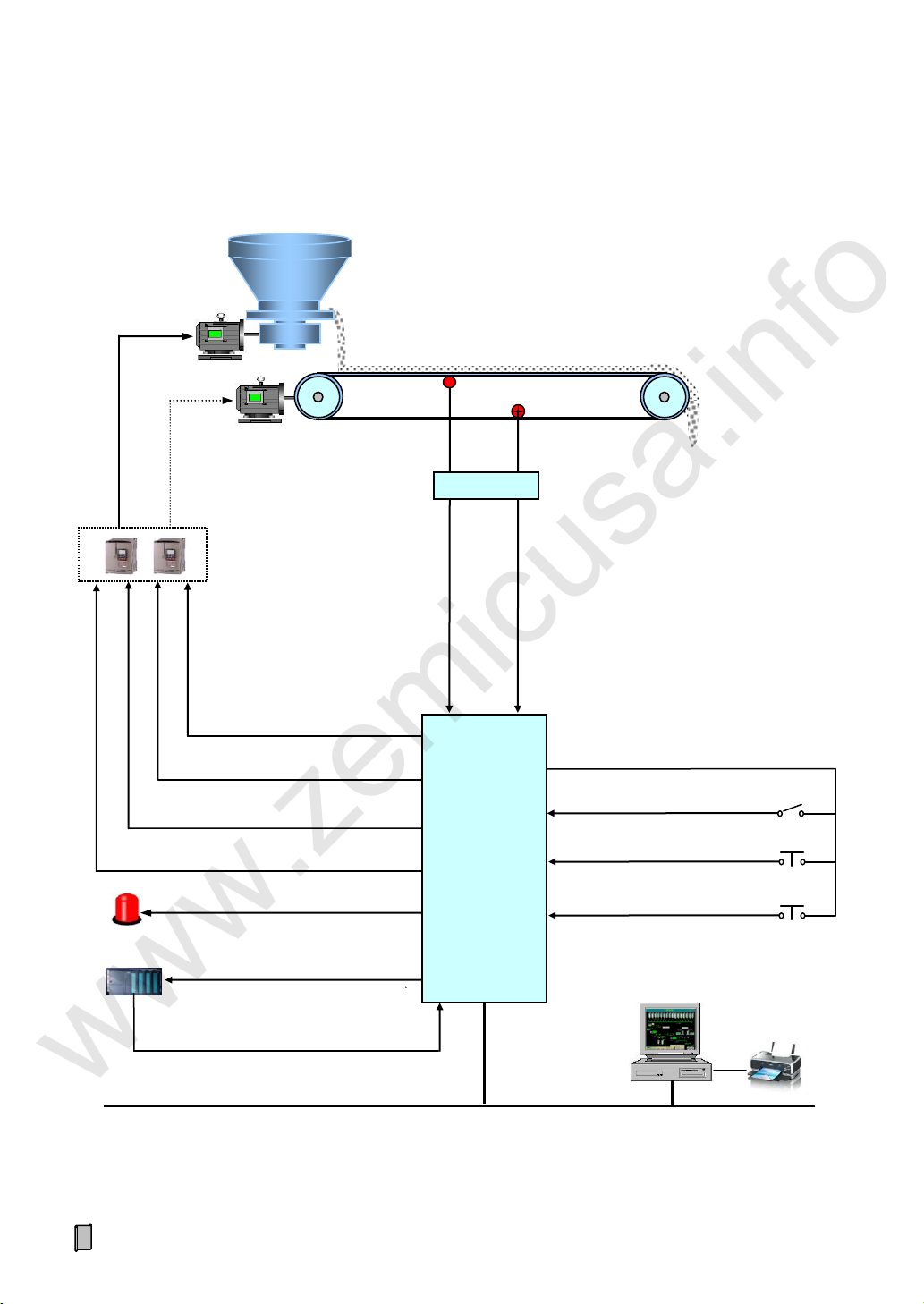

AI.Flow Setpoint

Frequency Convertor

& Relays

AO.Corntrol Current

IPC/ PLC

RS485/RS232/RS422/Profibus-DP/CANBUS

AO.Corntrol Current

DO.Feeder Control

DO.Belt Weigher Control

AO.Flow

PLC/IPC

DI/DO/AO: Definable.

AO3: If you need it, inform us in your order.

Belt Weigher

Speed Sensor

Feeder

Loadcell

Weighing Signal

Speed Signal

Summing Box

DI. Start

COM

DI. System Ready

DI. Stop

Diverter Switch

Reset Button

DO.Alarm

Controller

www.zemicusa.info

7. Ration Flow Auto-Feeding System

68

Appendix A. Print Formats

Table 1. Weight Record For A Shift (SW)

WEIGHT RECORD

-------------------------DATE: 2009-05-20

NAME: SW

TW: 109980kg

-------------------------2009-05-20 23:59

Table 2. Weight Record For A Day (DW)

WEIGHT RECORD

-------------------------DATE: 2009-05-20

NAME: 1W

TW: 109980kg

DATE: 2009-05-20

NAME: 2W

TW: 169900kg

DATE: 2009-05-20

NAME: 3W

TW: 190150kg

DATE: 2009-05-20

NAME: DW

TW: 470030kg

-------------------------2009-05-20 23:59

Table 3. Weight Record For A Month (MW)

WEIGHT RECORD

-------------------------DATE: 2009-05-01

NAME: DW