USE AND WARRANTY DISCLAIMER

SuperTrapp Industries, Inc. of 4540 W. 160th Street, Cleveland, Ohio 44135 (SuperTrapp),

warrants its SuperTrapp products against defects in factory materials and workmanship for one

year from the date of purchase or until ownership in the product is transferred, whichever

occurs first, subject to limitations below.

Under this warranty, SuperTrapp will repair or replace defective, covered parts, at option, or

provide a replacement unit. SuperTrapp makes no warranty with respect to components of the

SuperTrapp product not manufactured by SuperTrapp, including, but not limited to the

following: clamps, nuts, bolts, packing, boots and hoses. Repair by SuperTrapp or replacement

are the exclusive remedies under this written warranty or any implied warranty. SuperTrapp

will not pay for the cost of removal or re-installation of the unit from any vehicle or for

delivery and pick up of the unit. To obtain service under this warranty, the original purchaser

must give specific written notice to his or her dealer within fifteen (15) days after discovery of

any claimed defect in the unit, and must return such unit to the dealer within a reasonable

time thereafter at the cost of the original purchaser.

This limited warranty is the only express warranty applicable to SuperTrapp product. Any

implied warranty of merchantability or fitness for a particular purpose is limited in duration to

the duration of this written warranty. Some states do not allow limitations on how long an

implied warranty lasts, so the above limitation may not apply to you.

SuperTrapp shall not be responsible for any consequential, special or incidental damages of

any nature including but not limited to the loss of use of any vehicle on which the unit may be

installed and the cost of obtaining another substitute product. Some states do not allow the

exclusion or limitation of incidental or consequential damages so this limitation or exclusion

may not apply to you.

This warranty is valid only if proper size of the unit is installed, operated and maintained in

accordance with factory instructions. This warranty does not cover any damage caused by (i)

modification or alteration of the unit; (ii) improper installation, maintenance, operation or use;

(iii) accident; (iv) servicing or repair by anyone other than SuperTrapp or its authorized agents.

CAUTION!: Warranty does not cover chrome discoloration. You can minimize this problem by

thoroughly cleaning and polishing the system before initial start-up, being sure the fuel

mixture is not too lean, and preventing long periods of engine idle.

This warranty gives you specific legal rights and you may also have other rights which vary

from state to state. Outside the United States, a different warranty may apply. For details,

please contact your authorized SuperTrapp distributor.

003-7172 11.20.08

SuperTrapp® Industries, Inc.

4540 W. 160th St. Cleveland, OH 44135

Phone: (216) 265-8400 fax: (216)265-0130

E-mail: sales@SuperTrapp.com www.SuperTrapp.com

Since 1975, SuperTrapp has built a reputation on innovation and technical superiority.

SuperTrapp

®

R&D is constantly designing, testing and improving; providing you with

the latest in state of the art performance engineering. SuperTrapp® products are

absolutely the best performance items available. They will provide years of troublefree service.

Installation Instructions

SuperTrapp SuperMeg 2:1

828-71572 Chrome 2:1 For Harley-Davidson® FLST/FXST

Softail® Models

827-71572

Black 2:1 For Harley-Davidson® FLST/FXST

Softail® Models

STOCK SYSTEM REMOVAL:

1. On 2007 and later models: Disconnect the oxygen sensors

from the front and rear head pipes.

2. Remove the stock exhaust system as described in your

owner’s manual. Retain the flange nuts for the new system

installation.

3. Remove the stock snap rings and flanges from the head pipes

and retain for the new system installation.

4. On 2007 and later models: Remove the oxygen sensors from

the front and rear head pipes and retain for new system

installation.

5. FLST MODELS ONLY. Remove right side floorboard. The

floorboard will be re-installed once the new system installation

is complete.

6. Remove the stock mount bracket and retain screws for new

system installation.

7. The exhaust gaskets should be inspected and replaced to

achieve a proper fit and seal. Replacement gaskets are available

from your Harley Davidson dealer, part number 65324-83A.

SYSTEM INSTALLATION:

1. Mount discs/end cap on muffler.

See disc installation diagram

2. Using stock muffler bracket mounting screws, install the new

muffler mount support bracket in the stock location. Torque

the screws to Harley Davidson specifications.

See owner’s

manual.

3. Install stock flanges on both head pipes.

4.

1984-2006 models: Apply anti-seize to the threads of the

oxygen sensor port plugs, supplied. Install the plugs into the

head pipes and tighten.

2007-later models: Apply anti-seize to the threads of the

oxygen sensors and install in new head pipes. (*VERY

IMPORTANT* Apply anti-seize to the threads of the oxygen

sensor ONLY. Contamination of the sensor probe can

adversely affect engine performance.)

5. Mount the head pipes using the stock nuts. DO NOT TIGHTEN.

6. Slide two T-bolts (supplied) into the slotted bracket on the back

of the muffler and install the T-bolt clamp (supplied) onto the

inlet end of the muffler.

7. Slide the muffler onto the outlet end of the head pipe. Align the

T-bolts with the holes in the mounting bracket. Install the flat

washers and locknuts onto the T-bolts. DO NOT TIGHTEN.

8. Align the system and tighten all fasteners and clamps starting

at the muffler and working up to the flange nuts.

9. On 2007 and later models: Reconnect oxygen sensors to

wiring harness.

HEAT SHIELD INSTALLATION:

1. Slide the hose clamps into the slots on the back of each

shield. Orient the clamps to gain the easiest access to tighten

them while in position on the head

pipe.

2. Install the heat shields on the head pipes and collector. The

tabs on the front of the collector shield must fit into the clips

on the end of the front and rear shields.

3. Tighten the shields starting with the rear shield, then the

collector shield, and finally the front shield. Align the shields

as you tighten to minimize the gap between the head pipe and

collector shields.

4. FLST SOFTAILS ONLY: Re-install the right side floorboard.

IMPORTANT: AFTER A SHORT RIDE CHECK AND RETIGHTEN ALL

FASTENERS.

TUNING TIPS:

For maximum performance gains, we suggest using 20 discs and

a free-flowing air filter kit with this exhaust system. As always,

making performance modifications may affect the fuel delivery

system of your motorcycle. It is recommended by Supertrapp to

have your fuel delivery system tuned to ensure maximum

performance and reliability. This work should always be

performed by a certified technician.

We DO NOT suggest removing the muffler packing material to

“get more noise”. Removing the packing will result in a loss of

power, discoloration of the finish on the muffler, and potential

failure of the mechanical portion of the core .

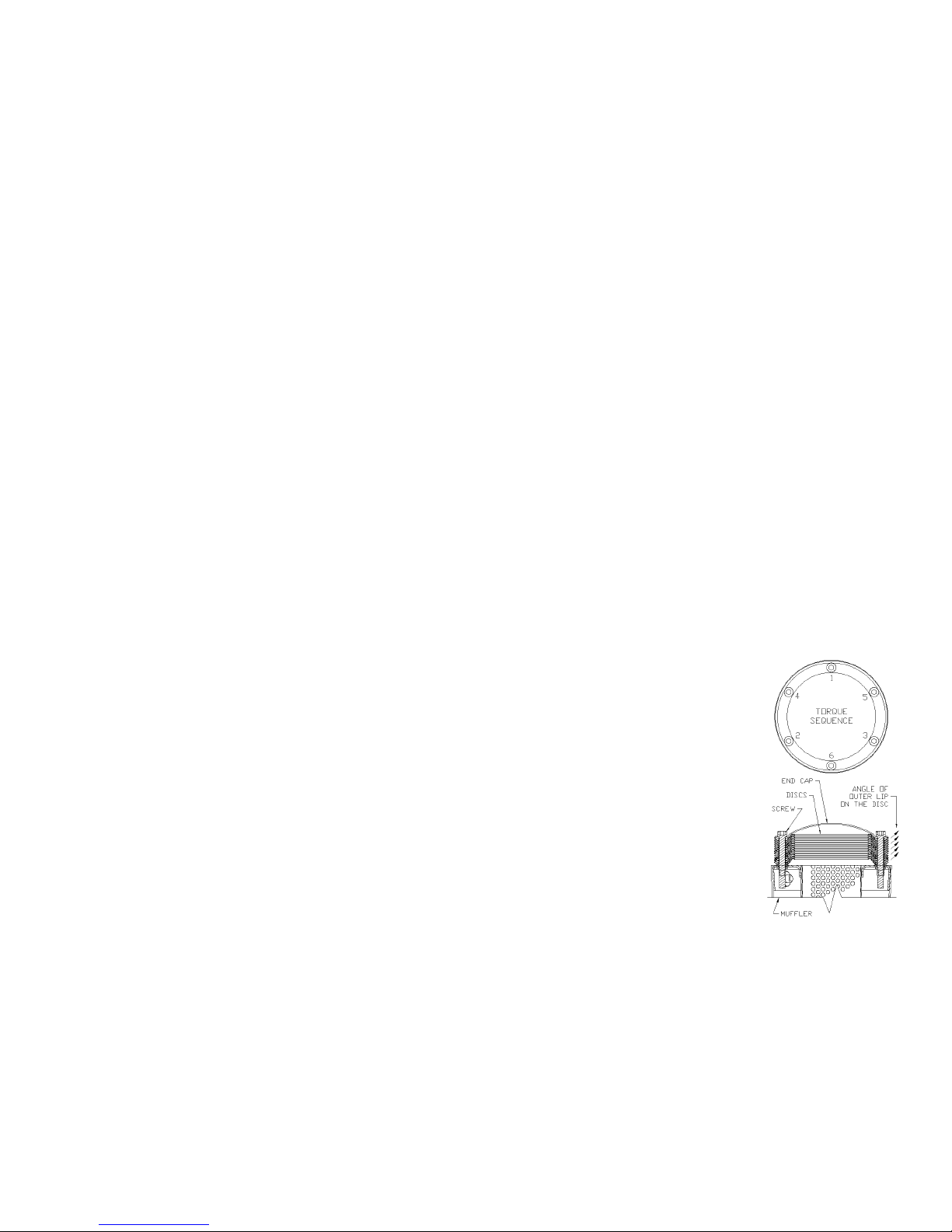

END CAP & DISC INSTALLATION:

1. Stand the muffler on the bench with

the outlet end pointing up.

2. Place the appropriate amount of

discs and end cap on the outlet of

the muffler. The flat surface of the

discs should be against the core

with the outer lip angled away from

the muffler. Align the (6) screw holes

with the threaded inserts in the

muffler outlet. (SEE DIAGRAM)

3. Insert the screws through the end

cap and discs and into the threaded

inserts in the muffler outlet. (SEE

DIAGRAM)

4. Tighten the screws evenly in a cross

pattern, SEE DIAGRAM. 4” discs

should be tightened to 15-25 in/lbs

and 5” discs to 40-50 in/lbs or once

the screw head contacts the end cap

tighten 2 full turns.

Loading...

Loading...