Supero 7046GT-TRF, Supero 7046GT-TRF-TC4, SUPERSERVER 7046GT-TRF, SUPERSERVER 7046GT-TRF-TC4 User Manual

SUPER

SUPERSERVER

7046GT-TRF

7046GT-TRF-TC4

®

USER’S MANUAL

Revision 1.0

The information in this User’s Manual has been carefully reviewed and is believed to be accurate.

The vendor assumes no responsibility for any inaccuracies that may be contained in this document,

makes no commitment to update or to keep current the information in this manual, or to notify any

person or organization of the updates. Please Note: For the most up-to-date version of this

manual, please see our web site at www.supermicro.com.

Super Micro Computer, Inc. ("Supermicro") reserves the right to make changes to the product

described in this manual at any time and without notice. This product, including software, if any,

and documentation may not, in whole or in part, be copied, photocopied, reproduced, translated or

reduced to any medium or machine without prior written consent.

IN NO EVENT WILL SUPERMICRO BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO

USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. IN PARTICULAR, SUPERMICRO SHALL NOT HAVE LIABILITY FOR ANY

HARDWARE, SOFTW ARE, OR DA TA STORED OR USED WITH THE PRODUCT, INCLUDING THE

COSTS OF REPAIRING, REPLACING, INTEGRATING, INSTALLING OR RECOVERING SUCH

HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa

Clara County in the State of California, USA. The State of California, County of Santa Clara shall

be the exclusive venue for the resolution of any such disputes. Super Micro's total liability for all

claims will not exceed the price paid for the hardware product.

FCC Statement: This equipment has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the manufacturer’s instruction manual, may cause harmful interference

with radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case you will be required to correct the interference at your own expense.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate warning applies only to products containing CR (Manganese Dioxide) Lithium coin cells. “Perchlorate

Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate”

WARNING: Handling of lead solder materials used in this

product may expose you to lead, a chemical known to the

State of California to cause birth defects and other reproductive harm.

Manual Revision 1.0

Release Date: October 25, 2009

Unless you request and receive written permission from Super Micro Computer, Inc., you may not

copy any part of this document.

Information in this document is subject to change without notice. Other products and companies

referred to herein are trademarks or registered trademarks of their respective companies or mark

holders.

Copyright © 2009 by Super Micro Computer, Inc.

All rights reserved.

Printed in the United States of America

Preface

About This Manual

This manual is written for professional system integrators and PC technicians.

It provides information for the installation and use of the SuperServer 7046GTTRF/7046GT-TRF-TC4. Installation and maintenance should be performed by

experienced technicians only.

The SuperServer 7046GT-TRF/7046GT-TRF-TC4 is based on the SC747TQR1400B 4U/T ower rackmount server chassis and the Super X8DTG-QF serverboard.

Please refer to our web site for an up-to-date list of supported operating systems,

processors and memory.

The only difference between the SuperServer 7046GT-TRF and SuperServer

7046GT-TRF-TC4 is that the latter includes the nVidia Tesla Graphics Processor

Unit (GPU).

Preface

Manual Organization

Chapter 1: Introduction

The fi rst chapter provides a checklist of the main components included with the

server system and describes the main features of the Super X8DTG-QF serverboard

and the SC747TQ-R1400B chassis.

Chapter 2: Server Installation

This chapter describes the steps necessary to install the system into a rack and

check out the server confi guration prior to powering up the system. If your server

was ordered without the processor and memory components, this chapter will refer

you to the appropriate sections of the manual for their installation.

Chapter 3: System Interface

Refer to this chapter for details on the system interface, which includes the functions

and information provided by the control panel on the chassis as well as other LEDs

located throughout the system.

Chapter 4: System Safety

You should thoroughly familiarize yourself with this chapter for a general overview

of safety precautions that should be followed when installing and servicing the

system.

iii

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

Chapter 5: Advanced Serverboard Setup

Chapter 5 provides detailed information on the X8DTG-QF serverboard, including

the locations and functions of connectors, headers and jumpers. Refer to this chapter when adding or removing processors or main memory and when reconfi guring

the serverboard.

Chapter 6: Advanced Chassis Setup

Refer to Chapter 6 for detailed information on the SC747TQ-R1400B 4U/Tower

rackmount server chassis. You should follow the procedures given in this chapter

when installing, removing or reconfi guring Serial ATA or peripheral drives and when

replacing system power supply units and cooling fans.

Chapter 7: BIOS

The BIOS chapter includes an introduction to BIOS and provides detailed information on running the CMOS Setup Utility.

Appendix A: BIOS POST Messages

Appendix B: BIOS POST Codes

Appendix C: System Specifi cations

iv

Notes

Preface

v

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

Table of Contents

Chapter 1 Introduction

1-1 Overview .........................................................................................................1-1

1-2 Serverboard Features .....................................................................................1-2

Processors ......................................................................................................1-2

Memory ...........................................................................................................1-2

Serial ATA ....................................................................................................... 1-2

PCI Expansion Slots ....................................................................................... 1-2

Onboard Controllers/Ports .............................................................................. 1-3

IPMI .................................................................................................................1-3

Other Features ................................................................................................1-3

1-3 Server Chassis Features ................................................................................ 1-3

System Power .................................................................................................1-3

Mounting Rails (optional) ................................................................................ 1-3

Hard Drive/Drive Bays ....................................................................................1-4

Front Control Panel ......................................................................................... 1-4

Cooling System ...............................................................................................1-4

Backplane ........................................................................................................ 1-4

1-4 GPU Subsystem (7046GT-TRF-TC4 Only) .....................................................1-4

1-5 Contacting Supermicro ....................................................................................1-6

Chapter 2 System Setup

2-1 Overview .........................................................................................................2-1

2-2 Unpacking the System ....................................................................................2-1

2-3 Setting Up the System ....................................................................................2-2

Checking the Motherboard Setup ...................................................................2-2

Checking the Drive Bay Setup ........................................................................2-2

Rack Precautions ............................................................................................2-4

Rack Mounting Considerations .......................................................................2-5

Removing the Chassis Cover and Feet .......................................................... 2-6

Installing the Chassis Handles and Inner Rails ..............................................2-8

Installing the Outer Rails to the Rack ............................................................. 2-9

Installing the Chassis into a Rack.................................................................2-10

Installing the Chassis Cover ..........................................................................2-11

Installing Feet on the Chassis ...................................................................... 2-12

vi

Table of Contents

Chapter 3 System Interface

3-1 Overview .........................................................................................................3-1

3-2 Control Panel Buttons ..................................................................................... 3-2

3-3 Control Panel LEDs ........................................................................................3-2

3-4 Drive Carrier LEDs .......................................................................................... 3-4

SAS/SATA Drives ............................................................................................ 3-4

Chapter 4 System Safety

4-1 Electrical Safety Precautions .......................................................................... 4-1

4-2 General Safety Precautions ............................................................................ 4-2

4-3 ESD Precautions ............................................................................................. 4-3

4-4 Operating Precautions .................................................................................... 4-4

Chapter 5 Advanced Serverboard Setup

5-1 Handling the Serverboard ............................................................................... 5-1

Precautions .....................................................................................................5-1

Unpacking .......................................................................................................5-2

5-2 Serverboard Installation ..................................................................................5-2

I/O Slot Shield Installation ............................................................................... 5-2

5-3 Connecting Cables .......................................................................................... 5-3

Connecting Data Cables ................................................................................. 5-3

Connecting Power Cables .............................................................................. 5-3

Connecting the Control Panel ......................................................................... 5-3

5-4 I/O Ports ..........................................................................................................5-4

5-5 Installing the Processor and Heatsink ............................................................ 5-6

Installing an LGA1366 Processor ................................................................... 5-6

Installation and Removal of the Heatsink ....................................................... 5-8

5-6 Installing Memory ............................................................................................ 5-9

Memory Support .............................................................................................. 5-9

Memory Support ....................................................................................... 5-10

DIMM Module Population Confi guration ...................................................5-11

5-6 Adding PCI Add-On Cards ............................................................................5-12

Installing Double-Width Graphics Cards ....................................................... 5-14

5-7 Serverboard Details ...................................................................................... 5-16

5-8 Connector Defi nitions ................................................................................... 5-18

5-9 Jumper Settings ............................................................................................5-26

5-10 Onboard Indicators ........................................................................................ 5-29

5-11 SATA Ports ....................................................................................................5-30

5-12 Installing Software ......................................................................................... 5-31

Supero Doctor III ........................................................................................... 5-32

vii

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

Chapter 6 Advanced Chassis Setup

6-1 Static-Sensitive Devices ..................................................................................6-2

Precautions .....................................................................................................6-2

6-2 Control Panel ..................................................................................................6-2

6-3 System Cooling ............................................................................................... 6-3

System Fan Failure ......................................................................................... 6-3

Replacing System Fans .................................................................................. 6-3

6-4 Power Supply .................................................................................................. 6-5

Power Supply Failure ...................................................................................... 6-5

Replacing the Power Supply ...........................................................................6-5

Power Supply Connections ............................................................................. 6-6

6-5 Confi guring the the Storage Module .............................................................. 6-7

Tower or Rack Confi guration...........................................................................6-7

Rotating the Storage Module .......................................................................... 6-8

Installing Drives in the Storage Module .......................................................... 6-9

Removing a Drive Carrier ............................................................................. 6-10

Adding Peripheral Drives .............................................................................. 6-12

6-6 Installing Hard Drives in the Chassis ............................................................6-13

Chapter 7 BIOS

7-1 Introduction ......................................................................................................7-1

Starting BIOS Setup Utility .............................................................................. 7-1

How To Change the Confi guration Data ......................................................... 7-1

Starting the Setup Utility ................................................................................. 7-2

7-2 Main Setup ...................................................................................................... 7-2

7-3 Advanced Setup Confi gurations...................................................................... 7-4

7-4 Security Settings ...........................................................................................7-25

7-5 Boot Confi guration ........................................................................................ 7-27

7-6 Exit Options ................................................................................................... 7-28

Appendix A BIOS Error Beep Codes

A-1 BIOS Error Beep Codes ................................................................................. A-1

Appendix B Installing Windows

B-1 Installing Windows for a RAID System ........................................................... B-1

B-2 Installing Windows for a Non-RAID System ................................................... B-2

Appendix C System Specifi cations

viii

Chapter 1: Introduction

Chapter 1

Introduction

1-1 Overview

The SuperServer 7046GT-TRF/7046GT -TRF-TC4 is a supercomputing server that is

comprised of two main subsystems: the SC747TQ-R1400B 4U/Tower server chassis and the X8DTG-QF dual Intel Xeon processor 5500 series serverboard. Please

refer to our web site for information on operating systems that have been certifi ed

for use with the system (www.supermicro.com).

In addition to the serverboard and chassis, various hardware components have

been included with the server, as listed below:

Two 3.8-cm 4-pin PWM fan assemblies (FAN-0082L4)

•

Four 9.2x3.8 cm 4-pin PWM fan assemblies (FAN-0114L4)•

Two 4U active CPU heatsinks (SNK-P0035AP4)•

SATA accessories:•

I/O shield (MCP-260-00025-0N)

One HD backplane (BPN-SAS-747TQ)

Six 35-cm SATA cables (CBL-0061L)

Two 40-cm PBF 8-pin to 8-pin ribbon cable with tube for SGPIO (CBL-0157L)

Eight 3.5" hard disk drive trays (MCP-220-97301-0B)

Three 5.25" drive trays (MCP-220-00073-0B)

Chassis cables:

•

One 30-inch Round 16 to 16-pin ribbon front panel cable (CBL-0071L)

Four 20-cm 4 to 4-pin middle fan power extension cables (CBL-0216L)

Two 30-cm 4 to 4-pin rear fan power extension cables (CBL-0286L)

One 4U 17.2" width rail set (MCP-290-00059-0N) (optional)

•

Four NVidia C1060 Tesla GPU add-on cards •

(AOC-GPU-NVC1060) (SUPERSERVER 7046GT-TRF-TC4 Only)

One Super Server 7046GT-TRF/7046GT-TRF-TC4 User's Manual

•

One (1) Supermicro CD containing drivers and utilities•

1-1

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

1-2 Serverboard Features

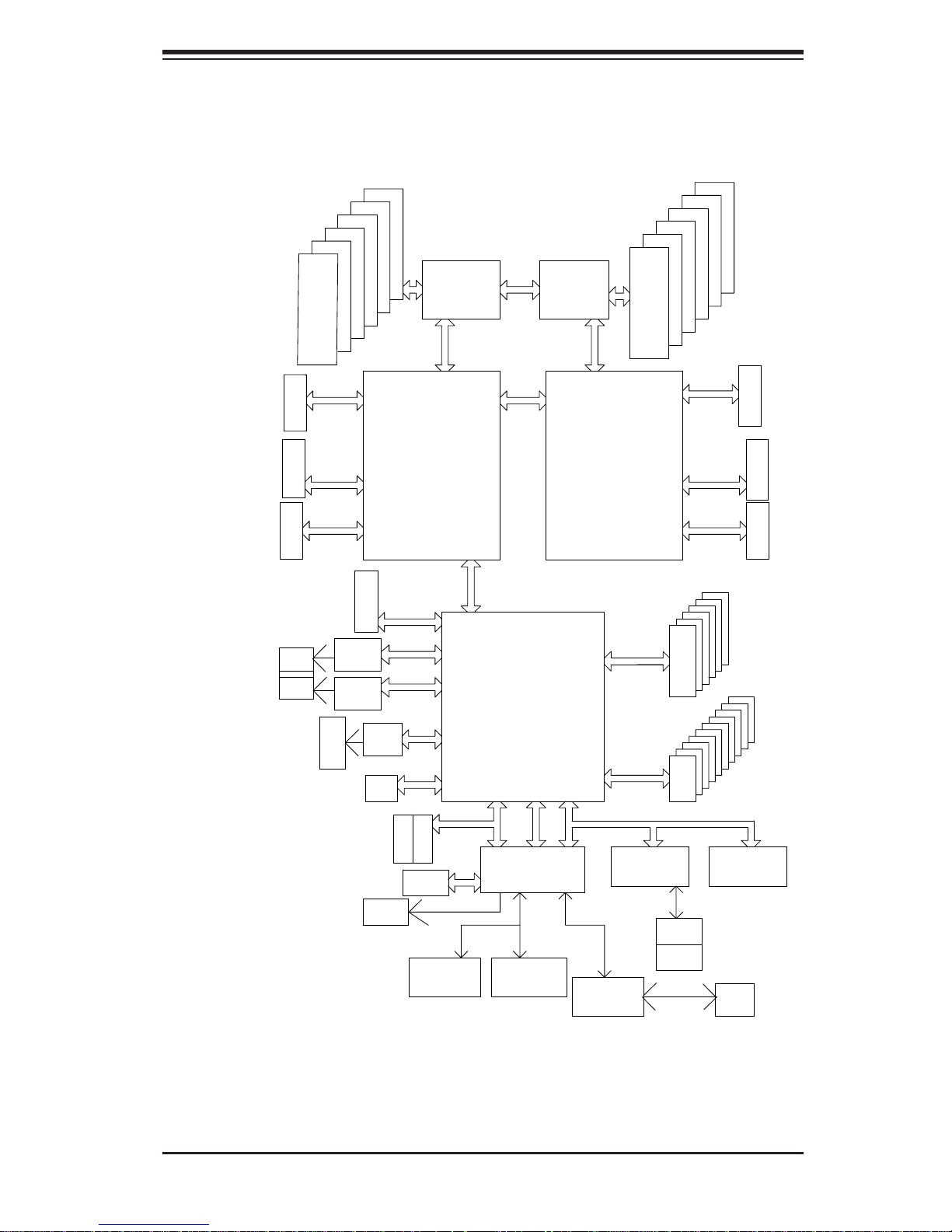

At the heart of the SuperServer 7046GT-TRF/7046GT -TRF-TC4 lies the X8DTG-QF,

a dual processor serverboard based on the Intel 5520 (IOH-36D) chipset. Below

are the main features of the X8DTG-QF. (See Figure 1-1 for a block diagram of

the chipset).

Processors

The X8DTG-QF supports two Intel® 5500 Series (LGA 1366) processors supporting two full-width Intel QuickPath Interconnect (QPI) links with a total of up to 51.2

GT/s Data Transfer Rate (6.4 GT/s per direction). Please refer to the serverboard

description pages on our web site for a complete listing of supported processors

(www.supermicro.com).

Memory

The X8DTG-QF has twelve 240-pin DIMM slots that can support up to 96 GB of

registered ECC DDR3-1333/1066/800 SDRAM or up to 24 GB of unbuffered ECC/

non-ECC DDR3-1333/1066/800 MHz SDRAM. Modules of the same size and speed

are recommended (for Unbuffered ECC/Non-ECC memory, a maximum of 2 GB per

DIMM is supported). See Chapter 5 for details.

Serial ATA

A SATA controller is integrated into the South Bridge (ICHR10R) section of the

chipset to provide a six-port 3/Gbs SATA subsystem, which is RAID 0, 1, 5 and 10

supported (RAID0, RAID1, RAID10, RAID5 supported in the Windows OS Environment and RAID 0, RAID 1, RAID 10 supported by the Linux OS). The SATA drives

are hot-swappable units.

Note: The operati ng system yo u use must h ave R AID su ppor t to e nable t he hotswap capability and RAI D function of the Serial ATA drives.

PCI Expansion Slots

The X8DTG-QF has four PCI-E Gen. 2.0 x16 slots (Slot 4, Slot 6, Slot 8, Slot 10),

one PCI-E Gen. 2.0 x4 (in x16) slot (Slot 2), one PCI-E 2.0 x4 (in x8) slot (Slot 11),

one PCI-E Gen. 1.0 x4 (in x16) slot (Slot 1) and two PCI 33 MHz slots (Slot 3, Slot

5) for a total of nine (9) PCI expansion slots.

1-2

Chapter 1: Introduction

Onboard Controllers/Ports

The color-coded I/O ports include one COM port (an additional COM header is

located on the serverboard), a VGA (monitor) port, ten USB 2.0 ports (six rear

USB ports, two front headers, and two Type A connections), PS/2 mouse and

keyboard ports, IPMI dedicated LAN port, High Defi nition Audio ports and two

Gb Ethernet ports.

IPMI

IPMI (Intelligent Platform Management Interface) is a hardware-level interface specifi cation that provides remote access, monitoring and administration for Supermicro

server platforms. IPMI allows server administrators to view a server’s hardware

status remotely, receive an alarm automatically if a failure occurs, and power cycle

a system that is non-responsive.

Other Features

Other onboard features that promote system health include onboard voltage

monitors, auto-switching voltage regulators, a chassis intrusion header, keyboar d

wakeup from s o ft- off, con s ol e r e di r e c t i o n, chassis and CPU overheat sensors, fan

status monitor with fi rmware control, Pulse Width M odu lati on (PW M) Fan Co ntrol,

power-up mode control for recovery from AC power loss, main switch override

mecha nism, ACPI Powe r Mana gement , system re sourc e ale rt v ia Supe ro Doc tor

III, virus protection and BIOS rescue.

1-3 Server Chassis Features

The following is a general outline of the main features of the SC747TQ-R1400B

server chassis.

System Power

Each SC747 chassis model includes a Gold level 1400W High-effi ciency redundant

(1+1) power supply (93%), rated at 1400 Watts. In the unlikely event your power

supply fails, replacement is simple and can be done without tools. The AC power

cord should be removed from the system before servicing or replacing the power

supply. See Chapter 6 for details.

Mounting Rails (optional)

The SC747 can be placed in a rack for secure storage and use. To setup your rack,

follow the step-by-step instructions included in this manual in chapter 2.

1-3

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

Hard Drive/Drive Bays

The SC747 Chassis features eight slots for SAS/SATA drives. These drives are hot

-swappable. Once set up correctly, these drives can be removed without powering

down the server.

Each SC747 Chassis provides three 5.25” peripheral drive bays for fl oppy drives,

DVD-ROM/CD-ROM Drives, or additional hard drives

Front Control Panel

The control panel on the server provides you with system monitoring and control.

LEDs indicate system power, HDD activity, network activity, system overheat, UID

and power supply failure. A main power button and a system reset button are also

included.

Cooling System

The SC747 chassis accepts four system fans and two rear exhaust fans. System

fans are powered from the serverboard. These fans are 4U high and are powered

by 4-pin connectors.

Backplane

Each SC747 chassis comes with a 4U backplane. Depending on your order, your

backplane will accept SAS/SATA. For more information regarding compatible backplanes, view the appendices found at the end of this manual. In addition, visit our

Web site for the latest information: http://www.supermicro.com.

1-4 GPU Subsystem (7046GT-TRF-TC4 Only)

The 7046GT-TRF-TC4 is a parallel processing multiple-GPU server. It includes

four NVIDIA® Tesla™ C1060 GPUs with multiple x16 non-blocking native Gen2

PCI-Express connectivity that places these systems at the forefront of today's GPU

computing solutions.

Refer to the NVIDIA web site (www.nvidia.com) for details on Tesla GPUs.

Notes:

The GPUs process complex image calculations and then route the data out through

the VGA port on the serverboard.

The C1060 GPU model includes an active heatsink. Its fans work independently of

the system fans and cooling parameters.

1-4

Chapter 1: Introduction

Figure 1-1. Intel 5520 Chipset:

System Block Diagram

Note: This is a general block diagram. Please see Chapter 5 for details.

Slot2

PCI-E 2.0

Slot4

PCI-E 2.0

Slot6

PCI-E 2.0

LAN1

LAN2

#0-2

#0-1

DDR3

PCI-E x4

x16

PCI-Ex16

x16

PCI-Ex16

x16

#0-6

#0-5

#0-4

#0-3

800/1066/1333

Ports 1,2

Ports 7,8,9,10

Ports 3,4,5,6

Slot1

PCI-E 1.0

x16

Intel

82574L

Intel

82574L

ALC888

AUDIO

CONN

BIOS

QPI

PCI-E x4

PCI-E x1

PCI-E x1

HD

SPI

PCI Slot3

DDR

Processor1

CSI1

Intel

5520

IOH 36D

Ports 1, 2, 3, 4

Port5

Port6

PCI 33MHZ

PCI Slot5

CSI0

ESI

ESI x4

ESI

QPI

Processor2

QPI

ICH10R

USB

WPCM450

BMC

CSI1

QPI

CSI0

Intel

5520

IOH 36D

LPC BUS

#1-3

#1-2

#1-1

DDR3

800/1066/1333

Ports 1,2

Ports 7,8,9,10

Ports 3,4,5,6

#1

#0

SATA2

#1

#0

USB2.0

SIO

W82527HG

#1-4

#4

#3

#2

SATA2

#3

#2

USB2.0

#1-5

#4

#1-6

PCI-E x4

PCI-E x16

PCI-E x16

#5

#0~#5

#9

#8

#7

#6

#5

#0~#9

SLB9635TT

Slot11

PCI-E 2.0

x8

Slot8

PCI-E 2.0

x16

Slot10

PCI-E 2.0

x16

6 FRONT

+ 2 Type A

6 REAR+2 Internal

TPM

VGA1

COM1

External

1-5

COM2

External/SOL

Third LAN

RTL8201N

Mouse

Keyboard

IPMI

LAN

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

1-5 Contacting Supermicro

Headquarters

Address: Super Micro Computer, Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email: marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Web Site: www.supermicro.com

Europe

Address: Super Micro Computer B.V.

Het Sterrenbeeld 28, 5215 ML

's-Hertogenbosch, The Netherlands

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

Email: sales@supermicro.nl (General Information)

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

Asia-Pacifi c

Address: Super Micro, Taiwan

4F, No. 232-1, Liancheng Rd.

Chung-Ho 235, Taipei County

Taiwan, R.O.C.

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3991

Web Site: www.supermicro.com.tw

Technical Support:

Email: support@supermicro.com.tw

Tel: 886-2-8228-1366, ext.132 or 139

1-6

Chapter 2: Server Installation

Chapter 2

System Setup

2-1 Overview

This chapter provides a quick setup checklist to get your SuperServer 7046GTTRF/7046GT-TRF-TC4 up and running. Following the steps in the order given

should enable you to have the system operational within a minimal amount of time.

If your system is not already fully integrated with a motherboard, processor, system

memory etc., please turn to the chapter or section noted in each step for details on

installing specifi c components.

2-2 Unpacking the System

You should inspect the box the SuperServer 7046GT-TRF/7046GT-TRF-TC4 was

shipped in and note if it was damaged in any way . If the server itself shows damage,

you should fi le a damage claim with the carrier who delivered it.

Decide on a suitable location for setting up and operating the SuperServer 7046GTTRF/7046GT-TRF-TC4. It should be situated in a clean, dust-free area that is well

ventilated. Avoid areas where heat, electrical noise and electromagnetic fi elds are

generated. You will also need it placed near a grounded power outlet.

!

Review the electrical and general safety precautions in Chapter 4.•

Use a regulating uninterruptible power supply (UPS) to protect the server from •

power surges, voltage spikes and to keep your system operating in case of a

power failure.

Warnings and Precautions!

!

Allow the power supply units and Serial ATA drives to cool before touching

•

them.

To maintain proper cooling, always keep all chassis panels closed when not

•

being serviced.

2-1

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

2-3 Setting Up the System

You should fi rst open the left side panel (when facing the front of the chassis) to

make sure the motherboard is properly installed and all connections have been

made.

Warning: Only qualifi ed service technicians should access the inside of

the system. Except for short periods of time, do NOT operate the system

!

Checking the Motherboard Setup

Accessing the inside of the system: Begin by disconnecting the chassis from 1.

any power source. (A) Lift up and back on the main cover handle, which

secures the cover to the chassis. (B) Lift the main cover off of the chassis.

See Chapter 5 for details on Chassis covers and how to remove them.

without the cover in place. The chassis cover must be in place to allow

proper airfl ow and prevent overheating.

Check the CPU (processor): You may have a processor already installed into 2.

the system board. The processor should have its own heatsink attached. See

Chapter 5 for instructions on processor installation.

Check the system memory:3. Your system may have come with system

memory already installed. Make sure all DIMMs are fully seated in their slots.

For details on adding system memory, refer to Chapter 5.

Installing add-on cards:4. If desired, you can install up to nine add-on cards to

the system. See Chapter 5 for details on installing PCI- add-on cards.

Note: The SuperServer 7046GT-TRF-TC4 contains four Nvidia C1060 Tesla

GPU add-on card modules that occupy many of these add-on card expansion

slots.

Check all cable connections and airfl ow: Make sure all power and data cables 5.

are properly connected and not blocking the airfl ow. See Chapter 5 for details

on cable connections.

Checking the Drive Bay Setup

Next, you should check to make sure the peripheral drives and the SA T A drives have

been properly installed and all essential connections have been made.

Accessing the peripheral drive bays: To install a component to either of the 1.

two 5.25" drive bays, you will need to remove the side chassis cover. See the

installation and removal sections for the peripheral drives in Chapter 6.

2-2

Chapter 2: Server Installation

Check the SATA disk drives: Depending upon your system's confi guration, 2.

your system may have up to four SATA drives already installed. If you need

to install or remove an SATA drive, please refer to the appropriate section in

Chapter 6.

Check the airfl ow: Cooling air is provided by the chassis fan and the power 3.

supply fan. The system component layout was carefully designed to promote

suffi cient airfl ow throughout the chassis. Also note that all power and data

cables have been routed in such a way that they do not block the airfl ow

generated by the fan. Please keep this in mind when rerouting or adding/

removing cables.

Supplying power to the system: The last thing you must do is to provide input 4.

power to the system. Plug the power cord from the power supply unit into a

high-quality power strip that offers protection from electrical noise and power

surges. It is recommended that you use an uninterruptible power supply

(UPS).

2-4 Preparing for Rack Mounting Setup

The box your chassis was shipped in should include two sets of rail assemblies,

two rail mounting brackets and the mounting screws you will need to install the

system into the rack. Please read this section in its entirety before you begin the

installation procedure outlined in the sections that follow.

Choosing a Setup Location

Leave enough clearance in front of the rack to enable you to open the front •

door completely (~25 inches).

Leave approximately 30 inches of clearance in the back of the rack to allow for

•

suffi cient airfl ow and ease in servicing.

This product is for installation only in a Restricted Access Location (dedicated

•

equipment rooms, service closets and the like).

2-3

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

Warnings and Precautions!

! !

Rack Precautions

Ensure that the leveling jacks on the bottom of the rack are fully extended to •

the fl oor with the full weight of the rack resting on them.

In single rack installation, stabilizers should be attached to the rack.

•

In multiple rack installations, the racks should be coupled together.•

Always make sure the rack is stable before extending a component from the •

rack.

You should extend only one component at a time - extending two or more si-

•

multaneously may cause the rack to become unstable.

General Server Precautions

Review the electrical and general safety precautions that came with the com-•

ponents you are adding to your chassis.

Determine the placement of each component in the rack

• before you install the

rails.

Install the heaviest server components on the bottom of the rack fi rst, and then

•

work up.

Use a regulating uninterruptible power supply (UPS) to protect the server from

•

power surges, voltage spikes and to keep your system operating in case of a

power failure.

Allow the hot plug hard drives and power supply modules to cool before touch-

•

ing them.

Always keep the rack's front door and all panels and components on the servers

•

closed when not servicing to maintain proper cooling.

2-4

Chapter 2: Server Installation

Rack Mounting Considerations

Ambient Operating Temperature

If installed in a closed or multi-unit rack assembly, the ambient operating temperature of the rack environment may be greater than the ambient temperature of the

room. Therefore, consideration should be given to installing the equipment in an

environment compatible with the manufacturer’s maximum rated ambient temperature (Tmra).

Reduced Airfl ow

Equipment should be mounted into a rack so that the amount of airfl ow required

for safe operation is not compromised.

Mechanical Loading

Equipment should be mounted into a rack so that a hazardous condition does not

arise due to uneven mechanical loading.

Circuit Overloading

Consideration should be given to the connection of the equipment to the power

supply circuitry and the effect that any possible overloading of circuits might have

on overcurrent protection and power supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

Reliable Ground

A reliable ground must be maintained at all times. To ensure this, the rack itself

should be grounded. Particular attention should be given to power supply connections other than the direct connections to the branch circuit (i.e. the use of power

strips, etc.).

2-5

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

2-5 Installing the Chassis onto a Rack

This section provides information on installing the SC747 chassis into a rack unit

with the optional 4U 17.2" width rail set (MCP-290-00059-0N). There are a variety

of rack units on the market, which may mean the assembly procedure will differ

slightly. You should also refer to the installation instructions that came with the rack

unit you are using.

NOTE: The outer rail is adjustable from 26" to 38.25".

NOTE: The MCP-290-00059-0N rail kit is an optional accessory.

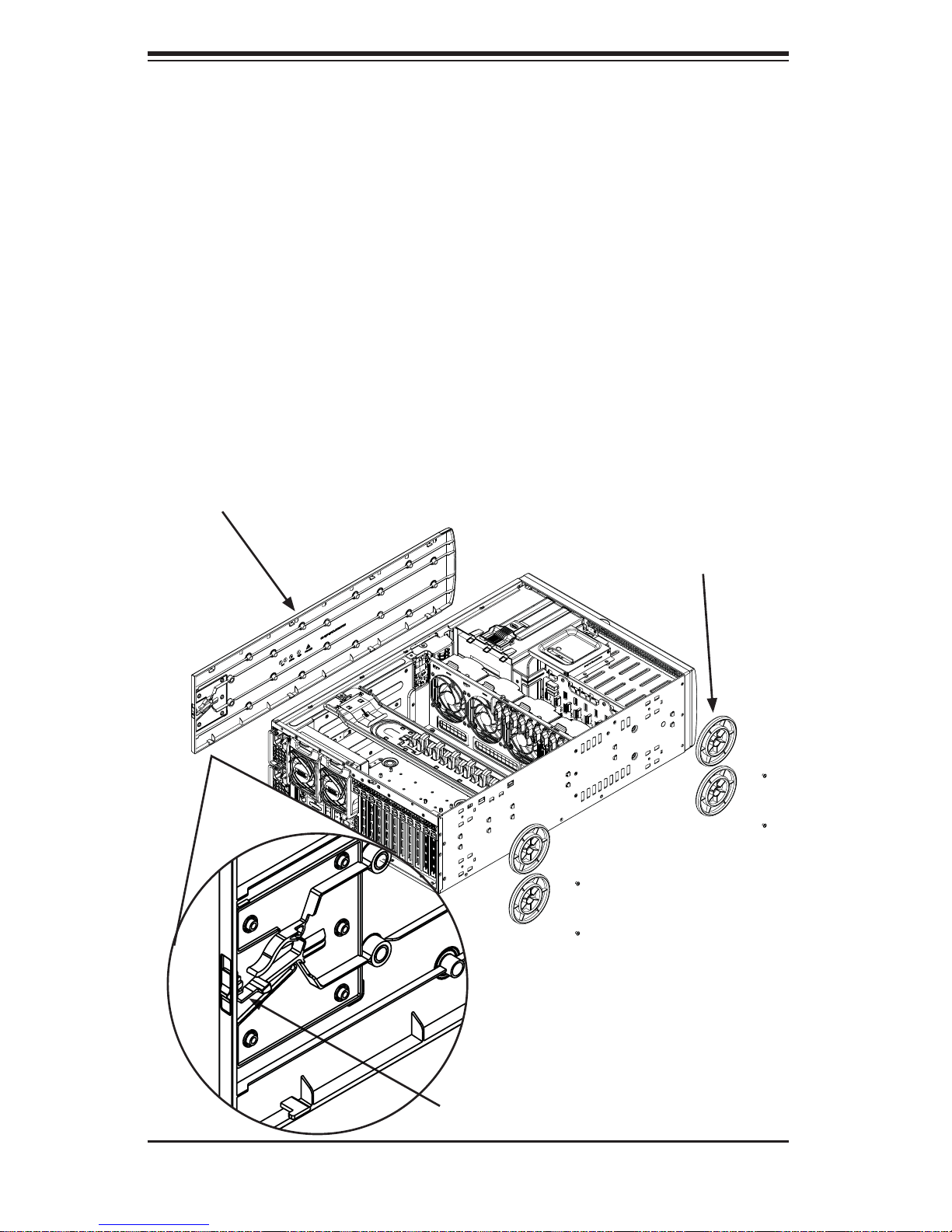

Removing the Chassis Cover and Feet

The SC747 chassis is shipped with the chassis cover and feet pre-installed. Both

the feet and cover must be removed for before installing the rails.

Figure 6-1: Removing the Feet and Chassis Top Cover

Chassis Cover

Chassis Feet

Chassis Cover Lock

2-6

Chapter 2: Server Installation

Removing the Chassis Top Cover

Locate the chassis cover lock (blue lever) at the rear of the chassis cover.1.

Slide the chassis cover lock to the right and push chassis cover forward.2.

Lift the chassis top cover off the chassis. 3.

Removing the Chassis Feet

Place the chassis on its side with the chassis side cover facing upward.1.

Remove the screw holding the chassis foot in place.2.

The foot lock is a tab located in the center of the foot that prevents the foot 3.

from sliding. Using a fl at head screwdriver, gently lift the foot lock upward

and slide the foot toward the rear of the chassis.

Repeat steps 2 and 3 with each remaining foot.4.

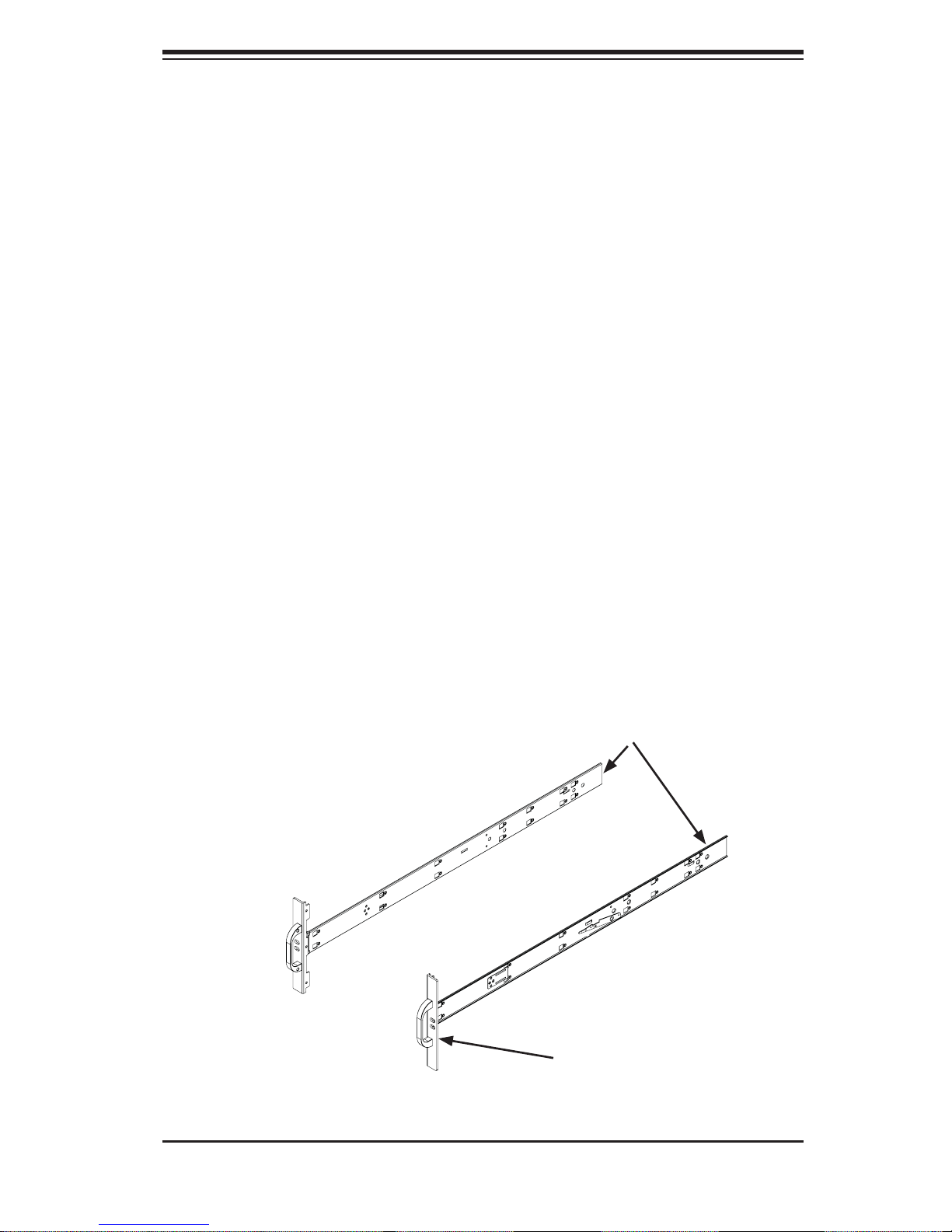

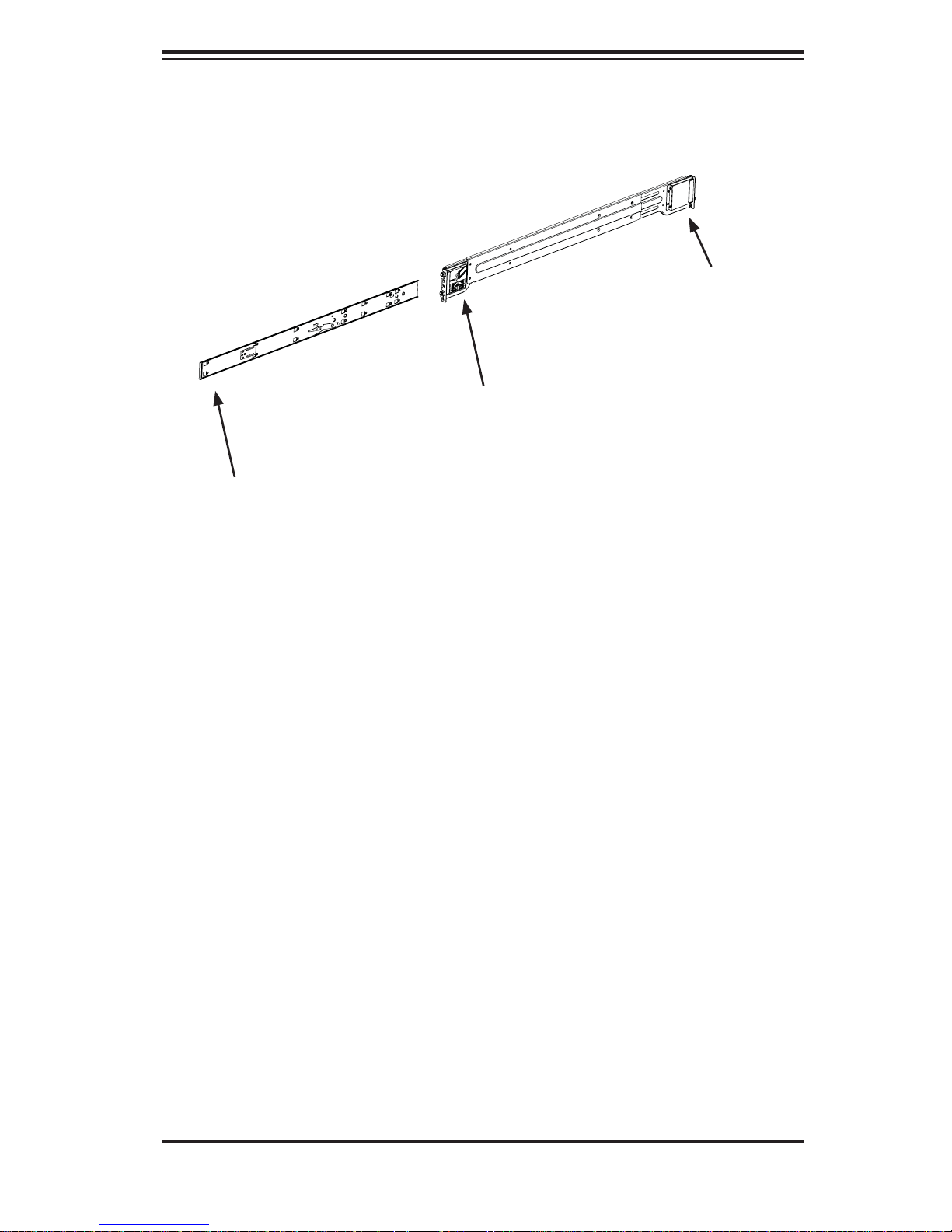

Identifying the Sections of the Rack Rails

The chassis package includes two rack rail assemblies in the rack mounting kit.

Each assembly consists of two sections: an inner fi xed chassis rail that secures

directly to the server chassis and an outer fi xed rack rail that secures directly to

the rack itself.

Inner Rails

Figure 6-2: Identifying the Inner Rails and Chassis Handles

Chassis Handle

2-7

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

Figure 6-3: Installing the Inner Rack Rails

Installing the Chassis Handles and Inner Rails

Installing the Inner Rails

Locate the chassis handles and handle screws.1.

Align the chassis handle with the front of the chassis and secure with the 2.

three chassis handle screws.

Repeats steps 1 and 2 with the other handle.3.

Locate the inner rails and screws in the shipping package.4.

Align the inner rails against the chassis, as shown. Confi rm that the rails are 5.

fl ushed against the edge of the chassis.

Tighten the screws. Do not over-tighten.6.

Repeat steps 5 and 6 with the other inner rail.7.

2-8

Attach to Middle Rail

Chapter 2: Server Installation

Secure to the

Rear of the Rack

Slide into the Inner Rail

Figure 6-4: Assembling the Outer Rails

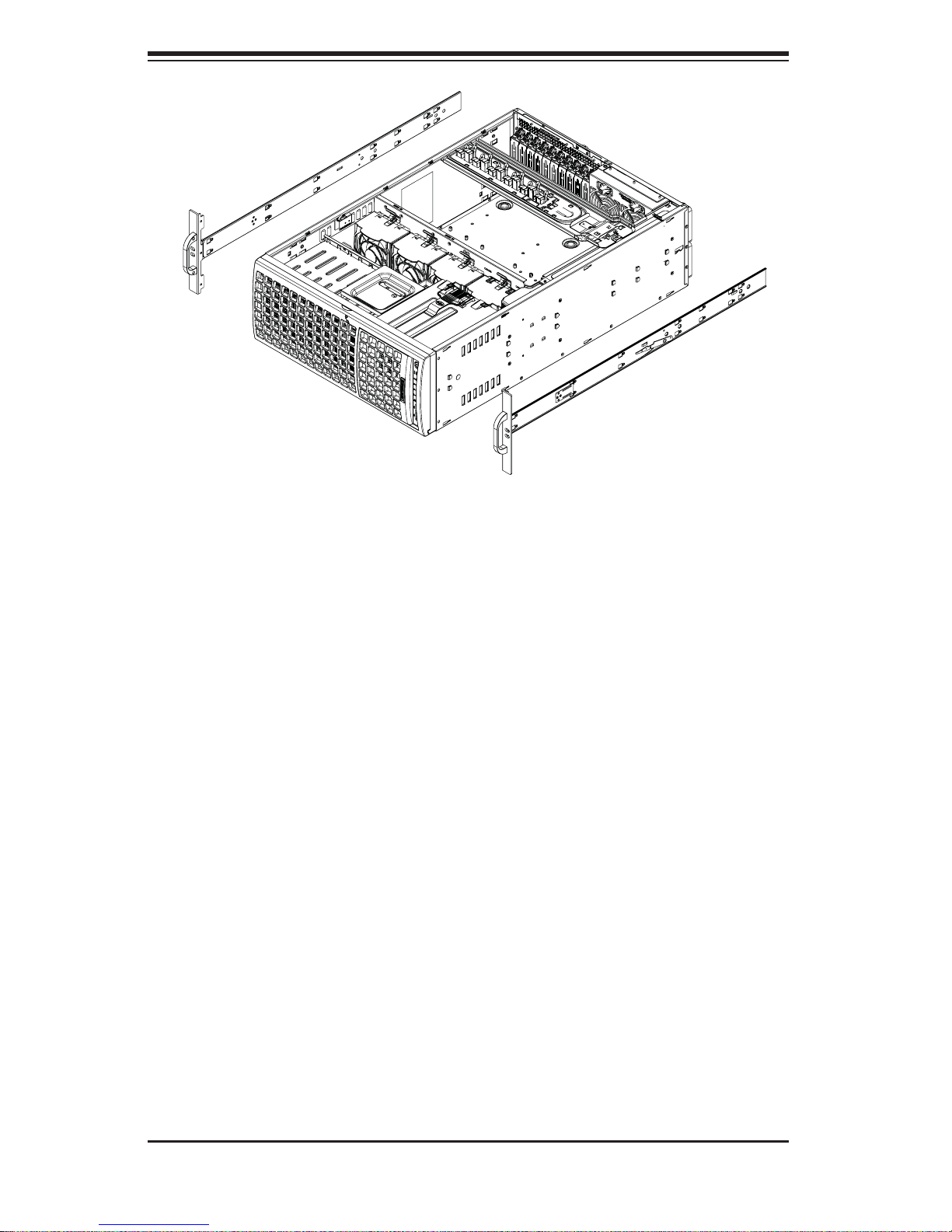

Installing the Outer Rails to the Rack

Installing the Outer Rails

1. Attach the rear bracket to the middle bracket.

2. Adjust both the brackets to the proper distance so that the rail fi ts snugly into

the rack.

3. Secure the rear of the outer rail with two M5 screws and the rear of the rack.

NOTE: The outer rail is adjustable from approximately 26" to 38.25".

4. Repeat steps 1-3 for the left outer rail.

2-9

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

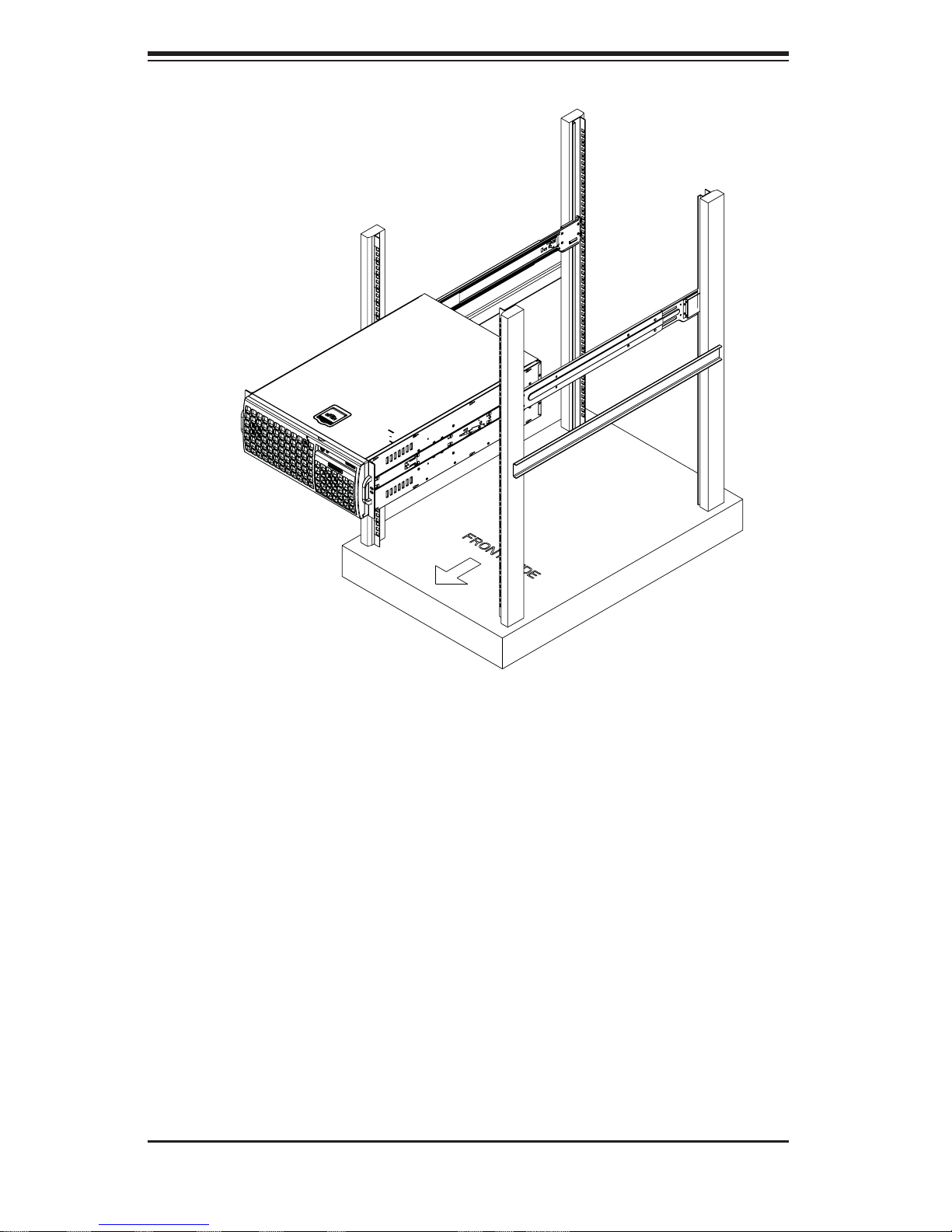

Figure 6-5: Installing the Rack Rails

Installing the Chassis into a Rack

Installing the Chassis

1. Confi rm that chassis includes the inner rails and the outer rails.

2. Align the inner chassis rails with the front of the outer rack rails (C).

3. Slide the inner rails into the outer rails, keeping the pressure even on both

sides (you may have to depress the locking tabs when inserting). When the

chassis has been pushed completely into the rack, you should hear the locking

tabs "click" into the locked position.

2-10

Chapter 2: Server Installation

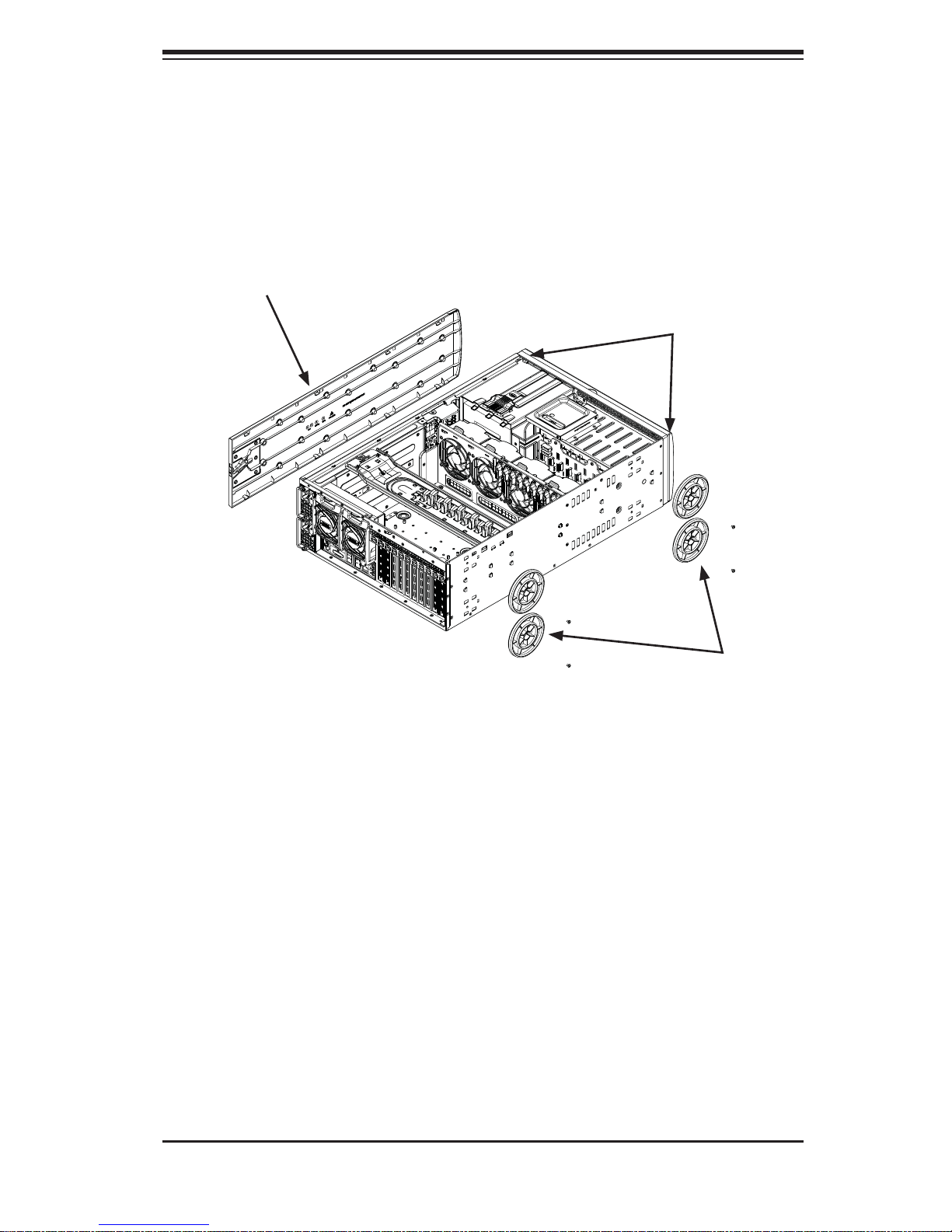

2-6 Tower Mounting Instructions

The SC747 chassis is shipped with the chassis cover and feet pre-installed. To use

the chassis as a desktop server, no other installation is required.

Use the instructions in this section if you have converted the chassis for rack use

and need to return the chassis to tower mounting.

Chassis Cover

Chassis Rack Mount

Ears

Chassis Feet

Figure 6-6: Adding Chassis Feet and Top Cover

Installing the Chassis Cover

Installing the Cover

Remove the rack mount ears.1.

Align the cover post with the corresponding holes on the top of the chassis 2.

and place the cover on top of the chassis. The cover should overhang

approximately one-half inch over the front of the chassis.

Slide the chassis cover toward the rear of the chassis to lock the cover into 3.

place.

2-11

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

Chassis Foot

Receptacle

Chassis Foot

Chassis Screw

Figure 6-7: Placing Chassis Feet

Installing Feet on the Chassis

Installing the Chassis Feet

Place the chassis foot in the foot receptacle and slide the foot toward the 1.

front of the chassis. The foot should lock into place.

Secure the foot to the chassis using one screw enclosed in the packaging.2.

Repeat steps 1 and 2 for the remaining three chassis fee3.

2-12

Chapter 3: System Interface

Chapter 3

System Interface

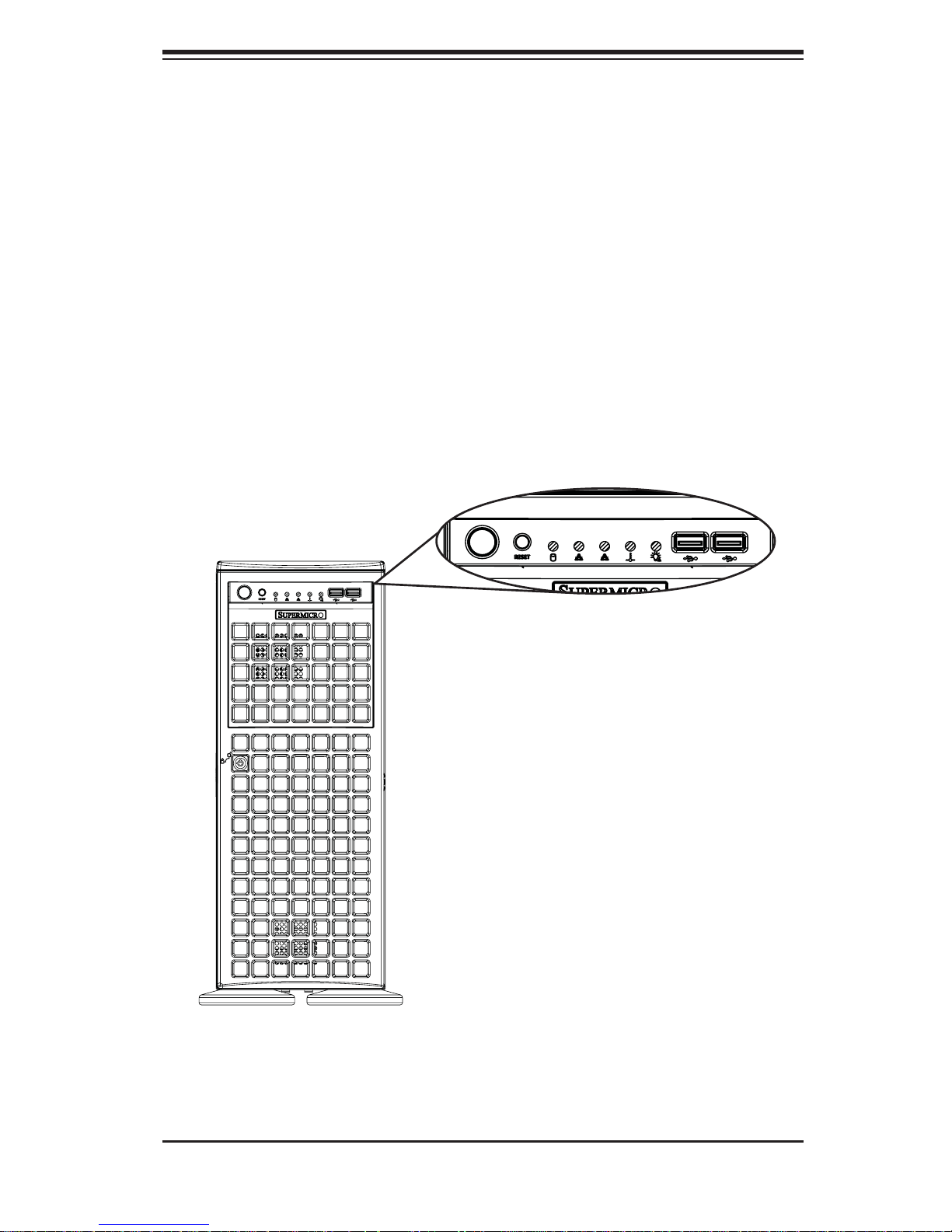

3-1 Overview

There are several LEDs on the control panel as well as others on the drive carriers

to keep you constantly informed of the overall status of the system as well as the

activity and health of specifi c components. Most SC747 models are two buttons

on the chassis a control panel: a reset button and an on/off switch. This chapter

explains the meanings of all LED indicators and the appropriate response you may

need to take.

Figure 4-1: Front LEDs

3-1

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

3-2 Control Panel Buttons

There are two push-buttons located on the front of the chassis. These are power

on/off button and a reset button.

Power:• The main power switch is used to apply or remove power from the power

supply to the server system. Turning off system power with this button removes

the main power but keeps standby power supplied to the system. Therefore,

you must unplug system before servicing.

Reset:• The reset button is used to reboot the system.

3-3 Control Panel LEDs

The control panel located on the front of the SC747 chassis has fi ve LEDs. These

LEDs provide you with critical information related to different parts of the system.

This section explains what each LED indicates when illuminated and any corrective

action you may need to take.

HDD:• Indicates IDE channel activity. SAS/SATA drive, SCSI drive, and/or DVD-

ROM drive activity when fl ashing.

NIC1:• Indicates network activity on GLAN1 when fl ashing.

3-2

Chapter 3: System Interface

NIC2:• Indicates network activity on GLAN2 when fl ashing.

Overheat/Fan Fail:• When this LED fl ashes it indicates a fan failure. When

continuously on (not fl ashing) it indicates an overheat condition, which may be

caused by cables obstructing the airfl ow in the system or the ambient room

temperature being too warm. Check the routing of the cables and make sure

all fans are present and operating normally. You should also check to make

sure that the chassis covers are installed. Finally, verify that the heatsinks are

installed properly. This LED will remain fl ashing or on as long as the overheat

condition exists.

!

Power Fail:• Indicates a power failure to the system's power supply units.

3-3

SUPERSERVER 7046GT-TRF/7046GT-TRF-TC4 User's Manual

3-4 Drive Carrier LEDs

Your chassis uses SAS/SATA drives.

SAS/SATA Drives

Each SAS/SATA drive carrier has two LEDs.

Green: Each Serial ATA drive carrier has a green LED. When illuminated, this

•

green LED (on the front of the SATA drive carrier) indicates drive activity. A connection to the SATA backplane enables this LED to blink on and off when that

particular drive is being accessed.

Red: The red LED to indicate an SAS/SATA drive failure. If one of the SAS/SATA

•

drives fail, you should be notifi ed by your system management software.

3-4

Loading...

Loading...