Supero SuperRack User Manual

®

SUPER

SuperRack™

USER'S MANUAL

Revision 1.0

Manual Revision 1.0

Release Date: September 20, 2011

The information in this User’s Manual has been carefully reviewed and is believed to be accurate.

The vendor assumes no responsibility for any inaccuracies that may be contained in this document,

makes no commitment to update or to keep current the information in this manual, or to notify any

person or organization of the updates. Please Note: For the most up-to-date version of this

manual, please see our web site at www.supermicro.com.

Super Micro Computer, Inc. ("Supermicro") reserves the right to make changes to the product

described in this manual at any time and without notice. This product, including software and

documentation, is the property of Supermicro and/or its licensors, and is supplied only under a

license. Any use or reproduction of this product is not allowed, except as expressly permitted by

the terms of said license.

IN NO EVENT WILL SUPERMICRO BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO

USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. IN PARTICULAR, SUPERMICRO SHALL NOT HAVE LIABILITY FOR ANY

HARDWARE, SOFTW ARE, OR DA TA STORED OR USED WITH THE PRODUCT, INCLUDING THE

COSTS OF REPAIRING, REPLACING, INTEGRATING, INSTALLING OR RECOVERING SUCH

HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa

Clara County in the State of California, USA. The State of California, County of Santa Clara shall

be the exclusive venue for the resolution of any such disputes. Super Micro's total liability for all

claims will not exceed the price paid for the hardware product.

FCC Statement: This equipment has been tested and found to comply with the limits for a Class

A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the manufacturer’s instruction manual, may cause harmful

interference with radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference, in which case you will be required to correct the interference at your

own expense.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate

warning applies only to products containing CR (Manganese Dioxide) Lithium coin cells. “Perchlorate

Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate”

WARNING: Handling of lead solder materials used in this

product may expose you to lead, a chemical known to

the State of California to cause birth defects and other

reproductive harm.

Unless you request and receive written permission from Super Micro Computer, Inc., you may not

copy any part of this document.

Information in this document is subject to change without notice. Other products and companies

referred to herein are trademarks or registered trademarks of their respective companies or mark

holders.

Copyright © 2011 by Super Micro Computer, Inc.

All rights reserved.

Printed in the United States of America

iii

Preface

Preface

About This Manual

This manual is written for professional system integrators and PC technicians. It

provides information for the installation and use of the SuperRack™ system. Setup,

installation and maintainance should be performed by experienced technicians

only.

The SuperRack system is a high-end rack mount system that includes parts for

making different rack systems based upon any one of fi ve standard models of the

SuperRack.

Manual Organization

Chapter 1: Introduction

The fi rst chapter provides a overview of the SuperRack system and its various

models and components.

Chapter 2: SuperRack System Installation

This chapter describes the steps necessary to install the SuperRack system on site

and how to unship the SuperRack from its crate.

Chapter 3: Safety

You should thoroughly familiarize yourself with this chapter for a general overview

of safety precautions that should be followed when installing and servicing the

SuperRack.

Chapter 4: SuperRack Standard Models

This chapter provides detailed information about the features and elements of the

SuperRack system's standard models.

Appendix A: SuperRack System Specifi cations

This appendix contains specifi cations for the standard models of the SuperRack

system.

SuperRack Installation Manual

iv

Notes

v

Table of Contents

Chapter 1 Introduction

1-1 Overview .........................................................................................................1-1

1-2 SuperRack Features .......................................................................................1-2

1-3 Returning Merchandise for Service.................................................................1-2

1-4 Contacting Supermicro ....................................................................................1-3

Chapter 2 System Safety

2-1 Electrical Safety Precautions .......................................................................... 2-1

2-2 General Safety Precautions ............................................................................2-2

2-3 ESD Precautions ............................................................................................. 2-3

2-4 Rack Precautions ............................................................................................2-4

Chapter 3 Rack Setup and Installation

3-1 Overview .........................................................................................................3-1

3-2 Inspecting the Rack and Shipping Crate ........................................................3-1

3-3 Preparing for Setup ......................................................................................... 3-1

Location Setup Recommendations .................................................................3-1

Rack Precautions ............................................................................................3-2

Server or Component Precautions..................................................................3-2

3-4 Unpacking the SuperRack from its Shipping Carton ......................................3-3

3-5 Installing EIA Mounting Posts .........................................................................3-7

Chapter 4 SuperRack Models

4-1 SuperRack Model SRK-42BF-01 ...................................................................4-1

4-2 SuperRack Model SRK-42OR-01 .................................................................. 4-3

4-3 SuperRack Model SRK-42OR-02 .................................................................. 4-5

4-4 SuperRack Model SRK-42SE-01 ................................................................... 4-7

4-5 SuperRack Model SRK-42SE-02 ................................................................... 4-9

Chapter 5 Optional Accessories

5-1 Tools ................................................................................................................ 5-2

Screw Bag ....................................................................................................... 5-2

5-2 Accessories and Modifi cation Procedures ...................................................... 5-3

Doors ...............................................................................................................5-3

Top and Side Panels .......................................................................................5-6

Installing and Uninstalling Top Panels ....................................................... 5-8

Types of Top Panels ................................................................................... 5-9

Expansion Units ............................................................................................5-10

EIA Posts .......................................................................................................5-12

Changing Casters ......................................................................................... 5-15

SuperRack Installation Manual

vi

Shelves and Slide Rails ................................................................................ 5-16

Component Installation .................................................................................5-18

Fan Modules ................................................................................................. 5-18

Cable Management Troughs and Fiber Optic Pipes .................................... 5-18

Mounting a Vertical Plate ......................................................................... 5-20

Mounting a Cable Management Trough to a Vertical Plate ..................... 5-21

Appendix A SuperRack System Parts List

Table of Contents

Chapter 1

Introduction

1-1 Overview

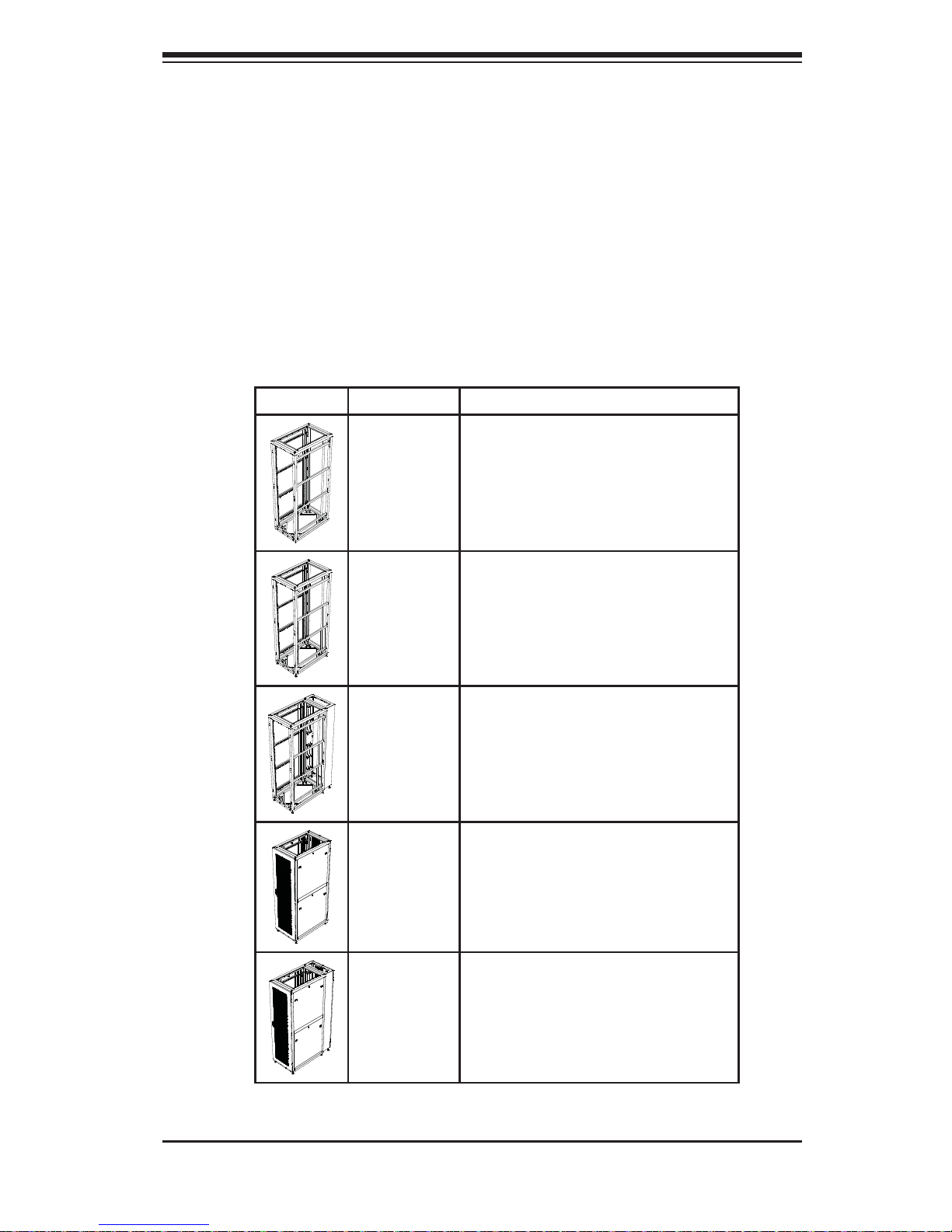

The SuperRack system consists of fi ve standard models of racks that are assembled

from the same pool of components and accessories. The below table lists the

available standard rack models in the SuperRack system and their described

uses.

Picture Rack Model Description

SBK-42BF-01 42U Basic Frame system

SRK-42OR-01 42U Open Frame system

SRK-420R-02 42U Open Frame with Rear Expansion system

SRK-42SE-01 42U Enclosure system

SRK-42SE-02 42U Enclosure with Rear Expansion system

For details on these models see Chapter 4. Additional components or accessories

can be added or subtracted from these standard models by the user.

Chapter 1: Introduction

1-1

1-2

SuperRack Installation Manual

1-2 SuperRack Features

The SuperRack system offers the following features:

• Supports quick release square mounting holes with adapters for round screw

mounts

• User conventional cabling and cabling identifi cation designs

• Front, rear and side expansion units provide modular solutions for any system

confi guration

• Static load rating of 551 1.55lbs (2500kg) to support high density rack components

• EIA standard 310D hardware

• Sturdy fully welded construction

• Wide range of fl exible accessory options

1-3 Returning Merchandise for Service

A receipt or copy of your invoice marked with the date of purchase is required

before any warranty service will be rendered. You can obtain service by calling your

vendor for a Returned Merchandise Authorization (RMA) number. When returning

to the manufacturer, the RMA number should be prominently displayed on the

outside of the shipping carton, and mailed prepaid or hand-carried. Shipping and

handling charges will be applied for all orders that must be mailed when service

is complete.

For faster service, RMA authorizations may be requested online at:

http://www. supermicro.com/support/rma/

Whenever possible, repack the chassis in the original Supermicro carton, using the

original packaging material. If these are no longer available, be sure to pack the

chassis securely, using packaging material to surround the chassis so that it does

not shift within the carton and become damaged during shipping.

This warranty only covers normal consumer use and does not cover damages

incurred in shipping or from failure due to the alteration, misuse, abuse or improper

maintenance of products. During the warranty period, contact your distributor fi rst for

any product problems. The Supermicro warranty can be found on our website at:

http://www.supermicro.com/support/Warranty/

1-3

Chapter 1: Introduction

1-4 Contacting Supermicro

Headquarters

Address: Super Micro Computer, Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email: marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Web Site: www.supermicro.com

Europe

Address: Super Micro Computer B.V.

Het Sterrenbeeld 28, 5215 ML

's-Hertogenbosch, The Netherlands

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

Email: sales@supermicro.nl (General Information)

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

Asia-Pacifi c

Address: Super Micro Computer, Inc.

4F, No. 232-1, Liancheng Rd.

Chung-Ho 235, Taipei County

Taiwan, R.O.C.

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3991

Web Site: www.supermicro.com.tw

Technical Support:

Email: support@supermicro.com.tw

Tel: +886-(2) 8226-5990

1-4

SuperRack Installation Manual

Notes

Chapter 2: Safety

2-1

2-1 Electrical Safety Precautions

!

Basic electrical safety precautions should be followed to protect yourself from harm

and the SuperRack system from damage:

• Be aware of the locations of the power on/off switch on the chassis as well

as the room's emergency power-off switch, disconnection switch or electrical

outlet. If an electrical accident occurs, you can then quickly remove power from

the system.

• Do not work alone when working with high voltage components.

• Power should always be disconnected from the system when removing

or installing main system components, such as a server system. When

disconnecting power, you should fi rst power down the operating system fi rst

and then unplug the power cords.

• When working around exposed electrical circuits, another person who is

familiar with the power-off controls should be nearby to switch off the power if

necessary.

• Use only one hand when working with powered-on electrical equipment. This

is to avoid making a complete circuit, which will cause electrical shock. Use

extreme caution when using metal tools, which can easily damage any electrical

components or circuit boards they come into contact with.

• Do not use mats designed to decrease static electrical discharge as protection

from electrical shock. Instead, use rubber mats that have been specifi cally

designed as electrical insulators.

• The power supply power cords must include a grounding plug and must be

plugged into grounded electrical outlets.

!

!

Warnings and Precautions!

Chapter 2

System Safety

SuperRack Installation Manual

2-2

• This product may be connected to an power system. In all cases, make sure

that the unit is also reliably connected to Earth (ground).

2-2 General Safety Precautions

!

Follow these rules to ensure general safety:

• Keep the area around the SuperRack system clean and free of clutter.

• The SuperRack system weighs up to 258.91 lbs (117.44 kg) empty, and has a

shipping weight of up to 331.08 lbs (150.18 kg). The system should be moved

on its casters.

• Place any system components and accessories that have been removed away

from the system or on a table so that they won't accidentally be stepped on.

• While working on the system, do not wear loose clothing such as neckties and

unbuttoned shirt sleeves, which can come into contact with electrical circuits or

be pulled into a cooling fan.

• Remove any jewelry or metal objects from your body, which are excellent metal

conductors that can create short circuits and harm you if they come into contact

with printed circuit boards or areas where power is present.

• After accessing the inside of the system, close the system back up and secure

it after ensuring that all connections have been made.

Chapter 2: Safety

2-3

2-3 ESD Precautions

!

Electrostatic discharge (ESD) is generated by two objects with different electrical

charges coming into contact with each other. An electrical discharge is created to

neutralize this difference, which can damage electronic com ponents and printed

circuit boards. The following measures are generally suffi cient to neutralize this

difference before contact is made to protect your equipment from ESD:

• Use a grounded wrist strap designed to prevent static discharge.

• Keep all components and printed circuit boards (PCBs) in their antistatic bags

until ready for use.

• Touch a grounded metal object before removing the board from the antistatic

bag.

• Do not let components or PCBs come into contact with your clothing, which may

retain a charge even if you are wearing a wrist strap.

• Handle a board by its edges only; do not touch its components, peripheral chips,

memory modules or contacts.

• When handling chips or modules, avoid touching their pins.

• Put the serverboard and peripherals back into their antistatic bags when not

in use.

• For grounding purposes, make sure your computer chassis provides excellent

conductivity between the power supply, the case, the mounting fasteners and

the serverboard.

SuperRack Installation Manual

2-4

2-4 Rack Precautions

!

Warning: To reduce the risk of personal injury or damage to the equipment, do not

attempt to move large equipment racks alone. Obtain adequate assistance to stabilize

the rack during movement or hire professional equipment riggers to move it.

Make sure to follow the below rack precautions:

• Ensure that the leveling jacks on the bottom of the rack are fully extended to

the fl oor with the full weight of the rack resting on them when the SuperRack

is setup in its location.

Caution: To reduce the risk of damage to the casters make sure that the full

weight of the rack rests on the leveling feet, and not on the casters. The casters

are designed only as an aid in moving the rack into position and are not designed

to support the weight of the rack, and may become damaged if relied upon to

support the rack.

• In single rack installation, stabilizers should be attached to the rack. In multiple

rack installations, the racks should be coupled together.

• Always make sure the rack is stable before extending a component from the

rack.

• You should extend only one component at a time – extending two or more

simultaneously may cause the rack to become unstable.

Chapter 3: Rack Setup and Installation

3-1

Chapter 3

Rack Setup and Installation

3-1 Overview

This chapter provides information on setting up and installing your SuperRack

system. It is assumed in this chapter that your SuperRack system is shipped

assembled and ready for installation on site. .

3-2 Inspecting the Rack and Shipping Crate

You should inspect the crate the SuperRack system was shipped in and note if it

was damaged in any way. After unshipping the SuperRack from the crate inspect

the SuperRack itself for any damage. If the rack itself shows damage you should

fi le a damage claim with the carrier who delivered it.

3-3 Preparing for Setup

Before setting up your SuperRack system, please review the following setup

information and considerations for the location where the SuperRack system will

be installed.

Location Setup Recommendations

Below are recommended requirements for the setup location:

• Location should have reliable local power and the utility should have the

availability to provide two alternate electrical feeds preferably from separate

sources

• Have a minimum of two routes for data and phone infrastructure into the

building

• Minimum one hour fi re rated walls

• Minimum 100+ PSF fl oor loading, or 200+ PSF fl oor loading to be determined

by equipment load

• Nine (9) feet raised fl oor to ceiling clear height minimum

3-2

SuperRack Installation Manual

• No exterior windows

• No overhead water pipes

• Power and Data cabling shall be in separate raceways overhead.

Rack Precautions

Equipment should be mounted into a rack so that a hazardous conditions do not

arise due to uneven mechanical loading.

Observe the following rack precautions

• Leave enough clearance in front of the rack to enable you to open the front

door completely (~25-inches).

• Allow approximately 30-inches of clearance in the back of the rack to allow for

suffi cient airfl ow and ease in servicing.

• Ensure that the leveling jacks on the bottom of the rack are fully extended to

the fl oor, with the full weight of the rack resting upon them.

• In single rack installation, stabilizers should be attached to the rack. In multiple

rack installations, the racks should be coupled together.

• Always make sure the rack is stable before extending a component from the

rack.

• You should extend only one component at a time – extending two or more

simultaneously may cause the rack to become unstable.

Server or Component Precautions

Below are server and component precautions to observe for all components installed

in the SuperRack system:

• Review the electrical and general safety precautions in Chapter 2.

• Determine the placement of each component in the rack before you install the

rails.

• Install the heaviest server components on the bottom of the rack fi rst, and then

work up.

Chapter 3: Rack Setup and Installation

3-3

• Use a regulating uninterruptible power supply (UPS) to protect the rack's servers

from power surges, voltage spikes and to keep your system operating in case

of a power failure.

• Allow any hot plug drives and power supply modules to cool before touching

them.

• Always keep the rack's front door (if installed) and all panels and components

on the servers closed when not servicing to maintain proper cooling.

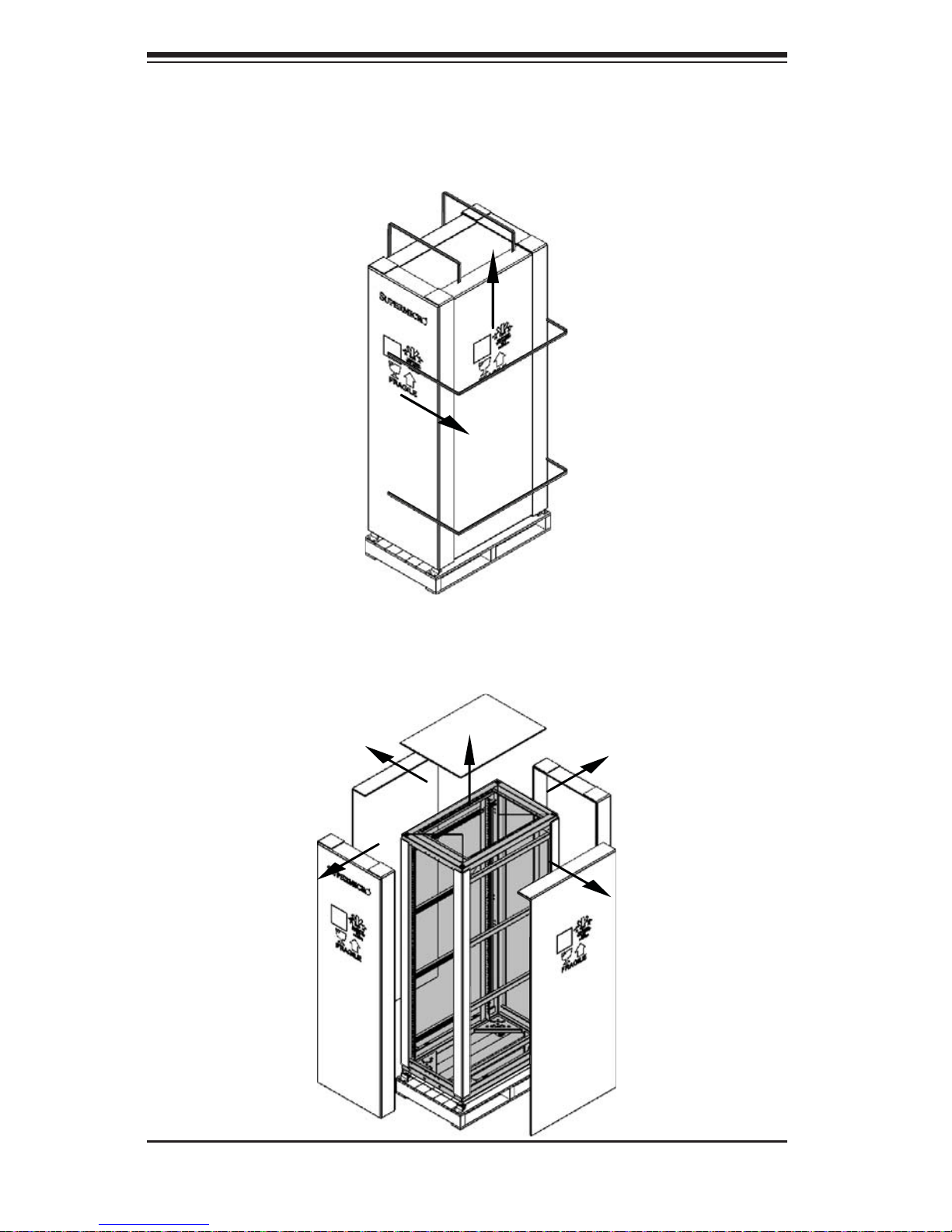

3-4 Unpacking the SuperRack from its Shipping Carton

Use the procedure below to help you unpack the SuperRack system from its

shipping carton. The SuperRack comes mounted on a pallet with steel retaining

brackets, packaged in a cardboard shipping carton. It is reinforced with plastic

strapping, and with both an interior plastic bag and exterior plastic covering that is

secured by tape to protect it from damage.

Note: The drawing for this section are for illustration purposes only. They do not

necessarily refl ect the exact product(s) described in this manual.

Unpacking the SuperRack Shipping Carton

1. Inspect the shipping carton for damage. If you see any damage, contact your

shipping company.

Note: Make sure the crate is upright with the label arrow pointing upward.

2. Move the shipping carton to the SuperRack's deployment location.

Note: It is recommended that you use a lift or forklift for moving the SuperRack

to its fi nal location.

3-4

SuperRack Installation Manual

Figure 3-1. Remove Retaining Straps

3. Remove the outer plastic wrapping from the carton, then cut and remove the

retaining straps from the outside of the shipping carton (see Figure 3-1).

4. Remove the sides from the shipping carton (see Figure 3-2).

Figure 3-2. Remove Shipping Carton Sides

Loading...

Loading...