SUPER

SUPER P3TDLR

®

USER’S MANUAL

Revision 1.0a

The information in this User’s Manual has been carefully reviewed and is believed to be

accurate. The vendor assumes no responsibility for any inaccuracies that may be contained

in this document, makes no commitment to update or to keep current the information in this

manual, or to notify any person or organization of the updates.

Please Note: For the

most up-to-date version of this manual, please see our web site at

www.supermicro.com.

SUPERMICRO COMPUTER reserves the right to make changes to the product described in

this manual at any time and without notice. This product, including software, if any, and

documentation may not, in whole or in part, be copied, photocopied, reproduced, translated or

reduced to any medium or machine without prior written consent.

IN NO EVENT WILL SUPERMICRO COMPUTER BE LIABLE FOR DIRECT, INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR

INABILITY TO USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES. IN PARTICULAR, THE VENDOR SHALL NOT HAVE

LIABILITY FOR ANY HARDWARE, SOFTWARE, OR DATA STORED OR USED WITH THE

PRODUCT, INCLUDING THE COSTS OF REPAIRING, REPLACING, INTEGRATING,

INSTALLING OR RECOVERING SUCH HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of

Santa Clara County in the State of California, USA. The State of California, County of Santa

Clara shall be the exclusive venue for the resolution of any such disputes. Supermicro's total

liability for all claims will not exceed the price paid for the hardware product.

Unless you request and receive written permission from SUPER MICRO COMPUTER, you

may not copy any part of this document.

Information in this document is subject to change without notice. Other products and

companies referred to herein are trademarks or registered trademarks of their respective

companies or mark holders.

Copyright © 2001 by SUPER MICRO COMPUTER INC.

All rights reserved.

Printed in the United States of America.

Preface

About This Manual

This manual is written for system integrators, PC technicians and

knowledgeable PC users. It provides information for the installation and use

of the SUPER P3TDLR motherboard. The SUPER P3TDLR supports single or

dual Pentium® III FCPGA 500 MHz-1.26 GHz+ processors, including low

power Pentium III® processors, at front side bus speeds of 133 and 100

MHz. Please refer to the support section of our web site (http://

www.supermicro.com/TechSupport.htm) for a complete listing of supported

processors. Intel FCPGA processors are housed in a 370-pin package.

Manual Organization

Chapter 1 includes a checklist of what should be included in your

mainboard box, describes the features, specifications and performance of

the SUPER P3TDLR mainboard and provides detailed information about the

chipset.

Chapter 2 begins with instructions on handling static-sensitive devices.

Read this chapter when you want to install the processor and DIMM memory

modules and when mounting the mainboard in the chassis. Also refer to

this chapter to connect the floppy and hard disk drives, SCSI drives, the IDE

interfaces, the parallel and serial ports and the twisted wires for the power

supply, the reset button, the keylock/power LED, the speaker and the keyboard.

Preface

If you encounter any problems, read Chapter 3, which describes trouble-

shooting procedures for the video, the memory and the setup configuration

stored in CMOS. For quick reference, a general FAQ [Frequently Asked

Questions] section is provided. Instructions are also included for contacting technical support. In addition, you can visit our web site at:

< www.supermicro.com/techsupport.htm >

for more detailed information.

Chapter 4 includes an introduction to BIOS and provides detailed information on running the CMOS Setup utility.

Appendix A gives information on BIOS error beep codes and messages.

Appendix B provides post diagnostic error messages.

iii

SUPER P3TDLR User’s Manual

Table of Contents

Preface

About This Manual ...................................................................................................... iii

Manual Organization ................................................................................................... iii

Chapter 1: Introduction

1-1 Overview ......................................................................................................... 1- 1

Checklist .................................................................................................... 1 - 1

Contacting Supermicro ............................................................................ 1 - 2

SUPER P3TDLR Image ............................................................................. 1-3

SUPER P3TDLR Layout ........................................................................... 1-4

SUPER P3TDLR Quick Reference .......................................................... 1-5

Server Works LE Chipset: System Block Diagram ............................. 1- 6

SUPER P3TDLR Motherboard Features................................................ 1-7

1-2 Chipset Overview........................................................................................... 1-9

1-3 Special Features ............................................................................................. 1-9

ATI Graphics Controller ........................................................................... 1 -9

BIOS Recovery ......................................................................................... 1-9

Recovery from AC Power Loss ........................................................... 1-9

1-4 PC Health Monitoring.................................................................................... 1-10

1-5 ACPI/PC 98 Features ................................................................................... 1-11

1-6 Power Supply ............................................................................................... 1-13

1- 7 Super I/O......................................................................................................... 1-13

Chapter 2: Installation

2-1 Handling the P3TDLR Motherboard.............................................................. 2-1

Preca utio ns ............................................................................................... 2-1

Unpacking .................................................................................................. 2 -2

2-2 Motherboard Installation ................................................................................ 2-2

2-3 Connecting Cables ......................................................................................... 2- 3

Connecting Data Cables .......................................................................... 2 - 3

Connecting Power Cables....................................................................... 2 -3

Connecting the Control Panel ................................................................. 2 -4

2-4 I/ O P o rt s ............................................................................................................ 2- 5

2-5 Installing Processors ...................................................................................... 2 -5

2-6 Installing Memory ............................................................................................ 2-7

2-7 Connector Definitions .................................................................................... 2-9

Power Supply Connectors ..................................................................... 2-9

Power Supply Fail Enable/Disable ......................................................... 2 - 9

iv

Table of Contents

Power LED ............................................................................................... 2-10

HDD LED .................................................................................................. 2-10

NIC1 LED .................................................................................................. 2-10

NIC2 LED .................................................................................................. 2-10

Overheat LED .......................................................................................... 2-11

Reset......................................................................................................... 2-11

PWR_ON ................................................................................................... 2-11

Fan Headers ............................................................................................ 2-12

Serial Ports .............................................................................................. 2-12

Universial Serial Bus .............................................................................. 2-13

Extra USB Connectors ........................................................................... 2-13

LAN1/LAN2 Ports .................................................................................... 2-13

SLED1 (SCSI LED) Indicator.................................................................. 2-13

Wake-On-Modem ..................................................................................... 2-14

Wake-On-LAN ......................................................................................... 2-14

2- 8 DIP Switch Settings ..................................................................................... 2-14

DIP Switch 1: Core/Bus Ratio.............................................................. 2-14

2-9 Jumper Settings ............................................................................................ 2-15

Explaination of Jumpers ........................................................................ 2-15

Front Side Bus Speed ........................................................................... 2-15

PCI64 Speed Setting ...............................................................................2-15

CMOS Clear............................................................................................. 2-16

Over Heat Alarm ..................................................................................... 2-16

LAN1 Enable/Disable .............................................................................. 2-16

LAN2 Enable/Disable .............................................................................. 2-16

SCSI Enable/Disable................................................................................ 2-17

Onboard VGA Enable/Disable ............................................................... 2-17

Watchdog Reset Enable/Disable .......................................................... 2-17

2-10 Floppy/Hard Disk and SCSI Connections ................................................. 2-18

Floppy Connector ................................................................................... 2-18

IDE Connectors ...................................................................................... 2-18

Ultra160 SCSI Connector ....................................................................... 2-19

2-11 Installing Software Drivers ......................................................................... 2-20

v

SUPER P3TDLR User’s Manual

Chapter 3: Troubleshooting

3-1 Troubleshooting Procedures ........................................................................ 3-1

Before Power On .................................................................................... 3-1

No Power .................................................................................................. 3-1

No Video ................................................................................................... 3-1

Memory Errors .......................................................................................... 3-2

Losing the System’s Setup Configuration ........................................... 3- 2

3-2 Technical Support Procedures .................................................................... 3-2

3-3 Frequently Asked Questions ........................................................................ 3-3

3-4 Returning Merchandise for Service ............................................................ 3-5

Chapter 4: BIOS

4-1 Introduction....................................................................................................... 4 -1

4-2 BIOS Features.................................................................................................. 4-2

4-3 Running Setup.................................................................................................. 4-2

Main BIOS Setup Menu ............................................................................ 4-3

4-4 Advanced BIOS Setup .................................................................................... 4 -4

4-5 Chipset Setup ................................................................................................. 4-15

4-6 PCI PnP Setup ................................................................................................ 4-17

4-7 Power Setup .................................................................................................. 4-21

4-8 Boot Setup ...................................................................................................... 4-24

4-9 Security Setup ............................................................................................... 4-26

4-10 Exit Setup ....................................................................................................... 4-28

Appendices:

Appendix A: BIOS Error Beep Codes and Messages ....................................... A - 1

Appendix B: AMIBIOS Post Checkpoint Codes .................................................... B- 1

vi

Chapter 1: Introduction

Chapter 1

Introduction

1-1 Overview

Checklist

Congratulations on purchasing your computer motherboard from an acknowledged leader in the industry. Supermicro boards are designed with

the utmost attention to detail to provide you with the highest standards in

quality and performance.

Please check that the following items have all been included with your

motherboard. If anything listed here is damaged or missing, contact your

retailer.

One (1) Supermicro Mainboard

Two (2) Supermicro Heatsinks (Retail Only)

Introduction

One (1) ribbon cable for IDE devices

One (1) floppy ribbon cable for (1) 5.25-inch floppy and (2) 3.5-inch floppy

drives

One (1) I/O backpanel shield

SCSI Accessories (depending on motherboard)

One (1) 68-pin LVD SCSI cable

One (1) set of SCSI driver diskettes

One (1) SCSI manual

One (1) Supermicro CD or diskettes containing drivers and utilities

One (1) BIOS User's Manual

1-1

SUPER P3TDLR User's Manual

CONTACTING SUPERMICRO

Introduction

Headquarters

Address: Super Micro Computer, Inc.

980 Rock Avenue

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

E-mail: marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Web site: www.supermicro.com

European Office

Address: Super Micro Computer B.V.

Het Sterrenbeeld 28, 5215 ML,

's-Hertogenbosch, The Netherlands

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

E-mail: sales@supermicro.nl (General Information) support@supermicro.nl

(Technical Support)

rma@supermicro.nl (Customer Support)

Asia-Pacific

Address: F3, #753 Chung-Cheng Road

Chung-Ho City, Taipei Hsien, Taiwan, R.O.C.

Tel: +886-(2) 8221-1690

Fax: +886-(2) 8221-2790

www : www.supermicro.com.tw

Email: support@supermicro.com.tw

Technical Support:

Tel : 886-2-8228-1366, ext.132

1-2

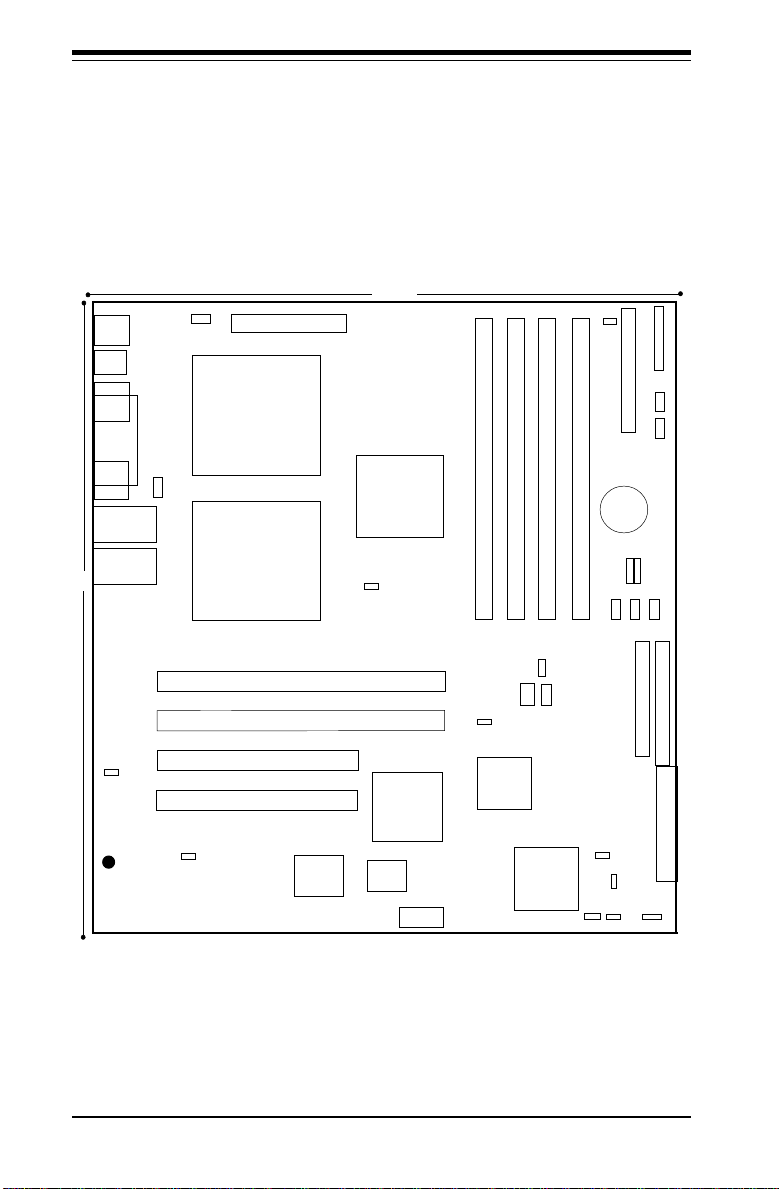

SUPER P3TDLR

Figure 1-4A. SUPER P3TDLR Image

Chapter 1: Introduction

Introduction

1-3

SUPER P3TDLR User's Manual

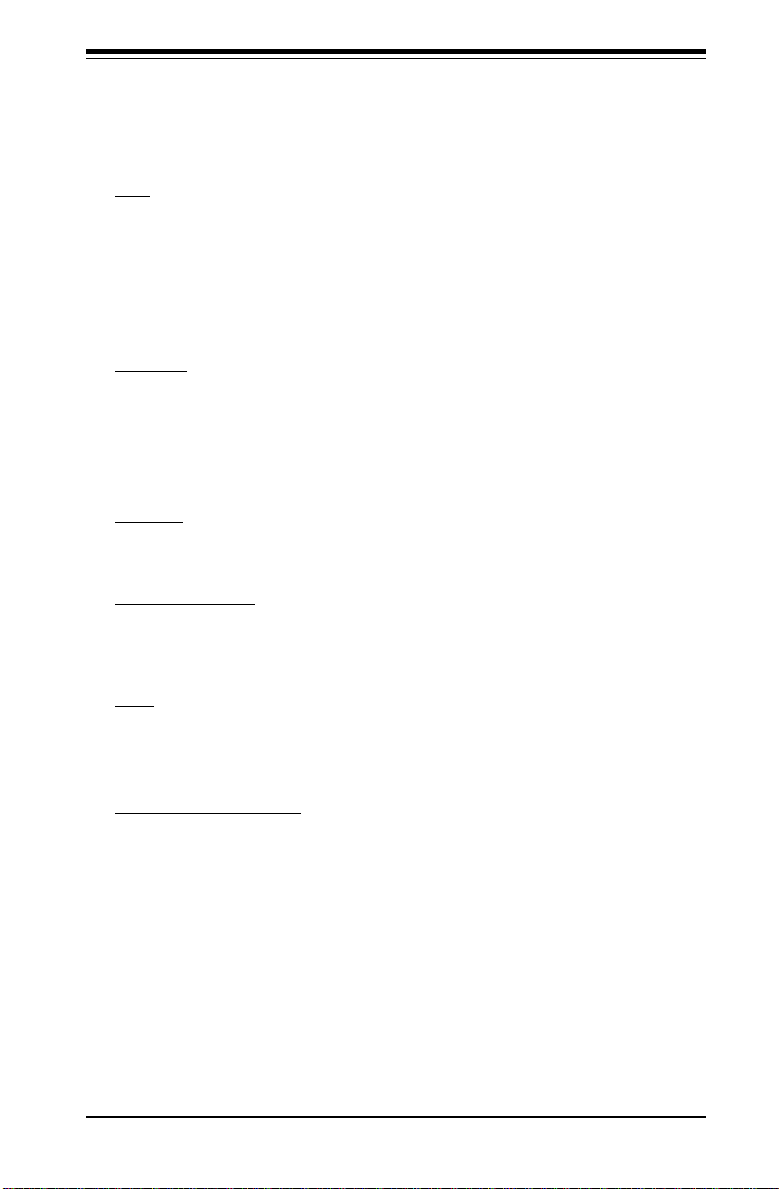

Introduction

PS/2 KB/

MOUSE

COM1

Parallel

VGA

12"

JP8

®

J28

USB

J27

Port

NIC1

NIC2

CPU FAN

J14

J15

J11

J12

JP24

CPU

FAN

SUPER P3TDLR

Figure 1-8A. SUPER P3TDLR Layout

(not drawn to scale)

10.5"

ATX POWER

FCPGA

Processor

BANK1

1

JP1

BANK0

AIC7892

SW1

FCPGA

Processor

PCI64 #1

PCI64 #2

PCI 1

PCI 2

ATI

RAGE

XL

NORTH

BRIDGE

1

JP2

SOUTH

BRIDGE

BIOS

COM2

SUPER

I/O

BANK2

JP7

JP11

JP7

BANK3

WOM

1

JBT1

JA21 SLED

WOL

IDE #1

J23

BATTERY

J106

CH FAN

THRM FAN

J26 J24

JF1

BLOWER FAN

CHASSIS FAN

J105

CH FAN

FLOPPY

IDE #2

ULTRA160 LVD SCSI

JA1

Also see the figure on page 2-7 for the locations of the I/O ports and

2-8 for the Front Control Panel (JF1) connectors.

1-4

Chapter 1: Introduction

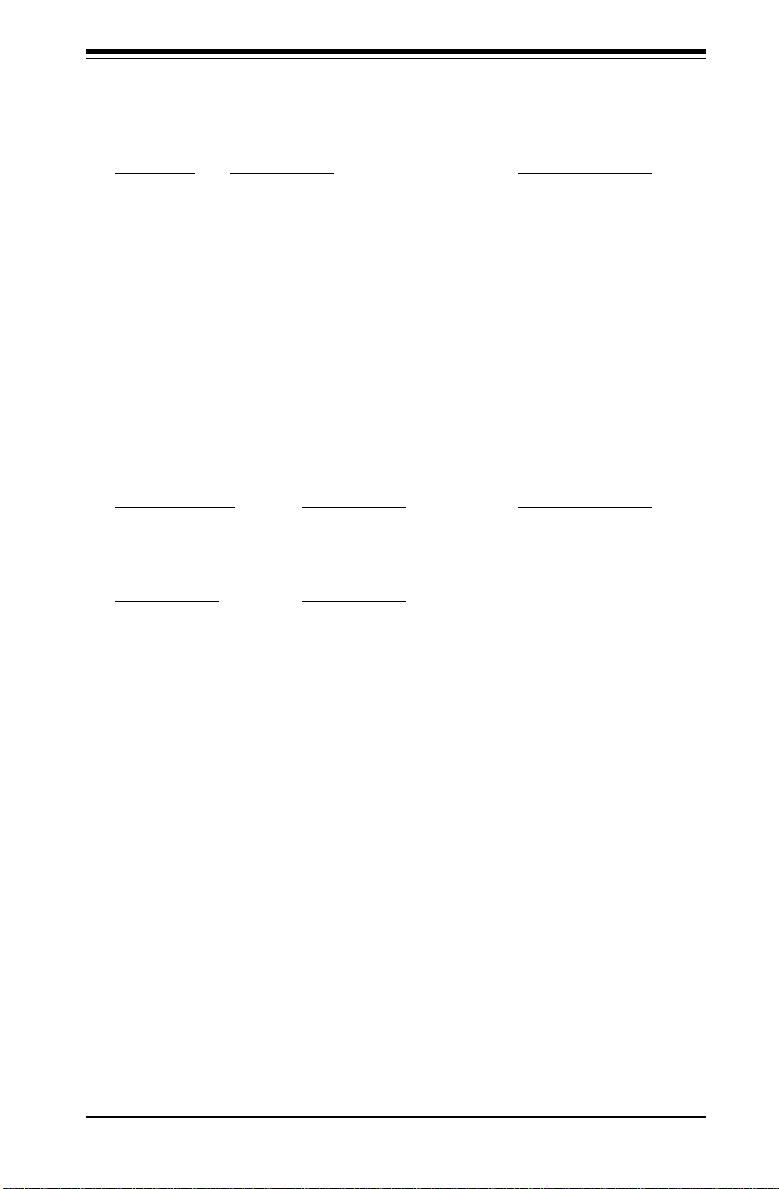

P3TDLR Quick Reference

Jumpers Description Default Setting

JBT1 CMOS Clear (p. 2-18) Pins 1-2 (Normal)

JP1 SCSI (p. 2-19) Pins 1-2 (Enabled)

JP2 Front Side Bus Speed (p. 2-17) Pins 1-2 (Auto)

JP7 Overheat Alarm (p. 2-18) Closed (Enabled)

JP8 LAN1 Enable/Disable (p. 2-18) Open (Enabled)

JP11 Power Supply Fail (p. 2-11) Pin 4 (Reset)

JP12 Power Supply Fail (p. 2-11) Closed (Enabled)

JP13 Speed for 64-bit PCI (2-17) Closed (33 MHz)

JP24 LAN2 Enable/Disable (p. 2-18) Open (Enabled)

JP62 Onboard VGA (p. 2-19) Pins 1-2 (Enabled)

J210 Watchdog Reset (p. 2-19) Open (Disabled)

DIP Switches Description Default Setting

SW1(1-4) CPU Core/Bus Ratio (see p. 2-16)

Connectors Description

ATX Power 24-pin ATX Power Connector (p. 2-11)

DIMM0-DIMM3 Memory (SDRAM) Slots (p. 2-9)

COM1/2 COM1/COM2 Serial Port Connector (p. 2-14)

CPU FAN (2 ea) CPU1/CPU2 Fan Header (p. 2-14)

Fan Headers (5 ea) Chassis, thermal and blower (p. 2-14)

J23/J24 IDE Hard Disk Drive 1/2 Connectors (p. 2-20)

J26 Floppy Disk Drive Connector (p. 2-20)

J28 PS/2 Keyboard/Mouse (p. 2-9)

J105/106 USB3/USB4 (p. 2-15)

JA1 Ultra160 LVD SCSI Connector (p. 2-21)

JF1 Front Control Panel (p. 2-4)

JP61 PWR_LED (p. 2-4)

LAN1/2 Ethernet Ports 1/2 (p. 2-15)

SLED1 SCSI LED header (p. 2-15)

USB 1/2 Universal Serial Bus 1/2 Ports (p. 2-15)

WOL Wake-on-LAN Header (p. 2-16)

WOM Wake-on-Modem Header (p. 2-16)

Introduction

1-5

SUPER P3TDLR User's Manual

Introduction

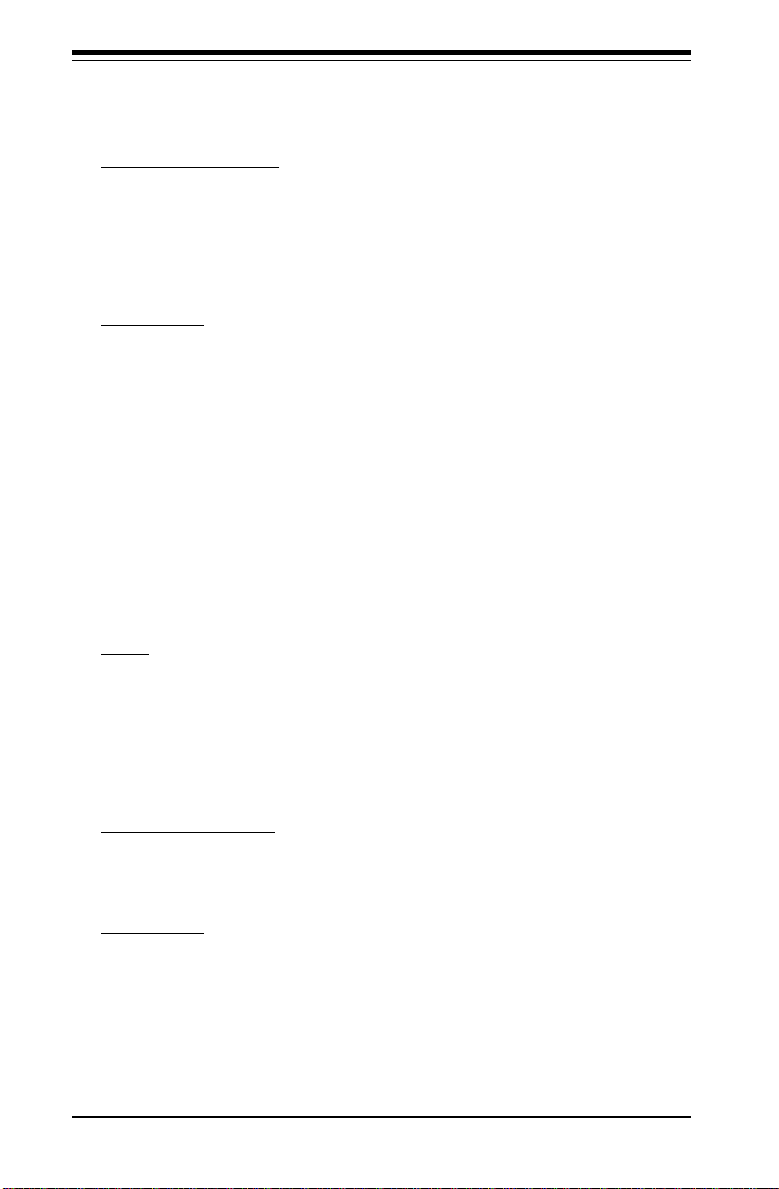

64-bit

PCI Slots

Ultra160

SCSI Slot

USB

Ports

Pe ntiu m III

FCPGA

CPU

133/100 MHz Ho st Bus

66/33 MHz

Host (North) Bridge

1.5 Mb/sec

OSB4/OSB5

South Bridge

CNB30LE

BIOS 4Mb

Flash ROM

Pe ntiu m III

FCPGA

CPU

PC133/PC100

Registered

DIMMs

133/100 MHz

33 MHz

32-bit

PCI Slots

ATA33 IDE

Ports

Figure 1-9. ServerWorks LE Chipset:

System Block Diagram

*Note: This is a general block diagram. See next page for details on

actual processor support and PCI slots for your motherboard.

1-6

Chapter 1: Introduction

Features of the SUPER P3TDLR

CPU

• Single or dual Intel Pentium® III FCPGA 500 MHz-1.26+ GHz processors

and single or dual low power Pentium® III processors at front bus

speeds of 133 and 100 MHz

Note: Please refer to the support section of our web site for a complete listing of supported

processors. (http://www.supermicro.com/TechSupport.htm)

Memory

• Four 168-pin DIMM sockets supporting up to 4 GB registered ECC

DIMMs

Note: The memory and front side bus speeds are synchronized. If PC133 memory is used with a

100 MHz FSB, the memory will run at 100 MHz. See page 3-3 for details.

Chipset

• ServerWorks ServerSet III LE (see page 1-19 for details)

Expansion Slots

• Two 64-bit, 66/33 MHz PCI slots

• Two 32-bit, 33 MHz PCI slots

Introduction

BIOS

• 4 Mb AMI® Flash BIOS

• APM 1.2, DMI 2.1, PCI 2.2, ACPI 1.0, Plug and Play (PnP)

PC Health Monitoring

• Seven onboard voltage monitors for CPU core, chipset voltage, +5V

and +12V

• Fan status monitor with firmware/software on/off control

• Environmental temperature monitor and control

• CPU fan auto-off in sleep mode

• Power-up mode control for recovery from AC power loss

• System overheat LED and control

• System resource alert

1-7

SUPER P3TDLR User's Manual

Introduction

ACPI/PC 98 Features

• Microsoft OnNow

• Slow blinking LED for suspend state indicator

• Main switch override mechanism

• External modem ring-on

Onboard I/O

• AIC-7892 for single channel Ultra160 SCSI

• 66 MHz SCSI supported

• Integrated ATI Rage XL Graphics Controller

• Intel 82559 for integrated onboard Ethernet

• 2 EIDE bus master interfaces support Ultra DMA/33

• 1 floppy port interface (up to 2.88 MB)

• 2 Fast UART 16550A compatible serial ports

• 1 EPP (Enhanced Parallel Port) and ECP (Extended Capabilities Port)

• PS/2 mouse and PS/2 keyboard ports

• 4 USB (Universal Serial Bus) ports

Other

• Selectable CPU and chassis fan speed control (set in BIOS)

• Internal/external modem ring-on

• Recovery from AC power loss control

• Wake-on-LAN (WOL)

• Multiple FSB clock frequency selections (set in BIOS)

supported parallel port

CD/Diskette Utilities

• BIOS flash upgrade utility

• Device Drivers

Dimensions

• SUPER P3TDLR - Full ATX: 12" x 10.5" (305 x 267 mm)

1-8

Chapter 1: Introduction

1-2 Chipset Overview

The ServerWorks ServerSetTM III LE is a high-performance core logic chipset

that consists of a North Bridge and a South Bridge.

The North Bridge includes an integrated main memory subsystem and a dual

channel PCI bus that bridges the processor bus to a 64-bit PCI bus and a

32-bit PCI bus. The North Bridge also packs and unpacks data for PCI

accesses, which reserves more processor bandwidth for multiprocessor

motherboards.

The South Bridge provides various integrated functions, including the PCI to

ISA bridge and support for UDMA33, security (passwords and system protection), Plug & Play, USBs, power management, interrupt controllers and

the SMBus.

The North and South Bridges communicate over a serial bus that uses the

PCI clock as a timing reference. This serial bus uses a single pin on both

bridges to send a 4-bit word for transmitting commands back and forth.

1-3 Special Features

Introduction

ATI Graphics Controller

The P3TDLR has an integrated ATI video controller based on the Rage XL

graphics chip. The Rage XL fully supports sideband addressing and AGP

texturing. An 8 MB graphics memory chip has been integrated aboard the

P3TDLR to provide graphics memory. This onboard graphics package can

provide a bandwidth of up to 512 MB/sec over a 32-bit graphics memory

bus.

BIOS Recovery

The BIOS Recovery function allows you to use an image file to recover your

BIOS if the BIOS flashing procedure fails (see Section 3-3).

Recovery from AC Power Loss

BIOS provides a setting for you to determine how the system will respond

when AC power is lost and then restored to the system. You can choose

for the system to remain powered off (in which case you must press the

1-9

SUPER P3TDLR User's Manual

power switch to turn it back on) or for it to automatically return to a power

on state. See the Power Lost Control setting in the BIOS chapter of this

manual to change this setting. The default setting is "Always OFF."

Introduction

1-4 PC Health Monitoring

This section describes the PC health monitoring features of the SUPER

P3TDLR. All have an onboard System Hardware Monitor chip that supports

PC health monitoring.

Seven Onboard Voltage Monitors for the CPU Core, Chipset

Voltage, +5V and +12V

The onboard voltage monitor will scan these seven voltages continuously. Once

a voltage becomes unstable, it will give a warning or send an error message to

the screen. Users can adjust the voltage thresholds to define the sensitivity of

the voltage monitor.

Fan Status Monitor with Firmware/Software On/Off Control

The PC health monitor can check the RPM status of the cooling fans. The

onboard 3-pin CPU and chassis fans are controlled by the power management

functions. The thermal fan is controlled by the overheat detection logic.

Environmental Temperature Control

The thermal control sensor monitors the CPU temperature in real time and will

turn on the thermal control fan whenever the CPU temperature exceeds a userdefined threshold. The overheat circuitry runs independently from the CPU. It

can continue to monitor for overheat conditions even when the CPU is in sleep

mode. Once it detects that the CPU temperature is too high, it will automatically

turn on the thermal control fan to prevent any overheat damage to the CPU. The

onboard chassis thermal circuitry can monitor the overall system temperature

and alert users when the chassis temperature is too high.

CPU Fan Auto-Off in Sleep Mode

The CPU fan activates when the power is turned on. It can be turned off when

the CPU is in sleep mode. When in sleep mode, the CPU will not run at full

power, thereby generating less heat.

1-10

Chapter 1: Introduction

CPU Overheat LED and Control

This feature is available when the user enables the CPU overheat warning

function in the BIOS. This allows the user to define an overheat temperature. When this temperature is exceeded, both the overheat fan and the

warning LED are triggered.

System Resource Alert

This feature is available when used with Intel's LANDesk Client Manager (optional). It is used to notify the user of certain system events. For example, if

the system is running low on virtual memory and there is insufficient hard drive

space for saving the data, you can be alerted of the potential problem.

Hardware BIOS Virus Protection

The system BIOS is protected by hardware so that no virus can infect the BIOS

area. The user can only change the BIOS content through the flash utility

provided by SUPERMICRO. This feature can prevent viruses from infecting the

BIOS area and destroying valuable data.

Auto-Switching Voltage Regulator for the CPU Core

The auto-switching voltage regulator for the CPU core can support up to 20A

current and auto-sense voltage IDs ranging from 1.4V to 3.5V. This will allow the

regulator to run cooler and thus make the system more stable.

1-5 ACPI/PC 98 Features

ACPI stands for Advanced Configuration and Power Interface. The ACPI specification defines a flexible and abstract hardware interface that provides a standard way to integrate power management features throughout a PC system,

including its hardware, operating system and application software. This enables

the system to automatically turn on and off peripherals such as CD-ROMs,

network cards, hard disk drives and printers. This also includes consumer

devices connected to the PC such as VCRs, TVs, telephones and stereos.

Introduction

In addition to enabling operating system-directed power management, ACPI provides a generic system event mechanism for Plug and Play and an operating

system-independent interface for configuration control. ACPI leverages the Plug

and Play BIOS data structures while providing a processor architecture-independent implementation that is compatible with both Windows 98 and Windows NT

1-11

SUPER P3TDLR User's Manual

5.0. Note: To utilize ACPI, you must reinstall Windows 98/2000. You can

check to see if ACPI has been properly installed by looking for it in the

Introduction

Device Manager, which is located in the Control Panel in Windows.

Microsoft OnNow

The OnNow design initiative is a comprehensive, system-wide approach to

system and device power control. OnNow is a term for a PC that is always

on but appears to be off and responds immediately to user or other requests.

Slow Blinking LED for Suspend-State Indicator

When the CPU goes into a suspend state, the chassis power LED will start

blinking to indicate that the CPU is in suspend mode. When the user presses

any key, the CPU will wake-up and the LED will automatically stop blinking and

remain on.

Main Switch Override Mechanism

When an ATX power supply is used, the power button can function as a system

suspend button. When the user depresses the power button, the system will

enter a SoftOff state. The monitor will be suspended and the hard drive will spin

down. Depressing the power button again will cause the whole system to wakeup. During the SoftOff state, the ATX power supply provides power to keep the

required circuitry in the system alive. In case the system malfunctions and you

want to turn off the power, just depress and hold the power button for 4 seconds.

The power will turn off and no power will be provided to the motherboard.

External Modem Ring-On

Wake-up events can be triggered by a device such as the external modem ringing

when the system is in the SoftOff state. Note that external modem ring-on can

only be used with an ATX 2.01 (or above) compliant power supply.

Wake-On-LAN (WOL)

Wake-On-LAN is defined as the ability of a management application to remotely

power up a computer that is powered off. Remote PC setup, updates and

1-12

Chapter 1: Introduction

asset tracking can occur after hours and on weekends so that daily LAN

traffic is kept to a minimum and users are not interrupted. The motherboards

have a 3-pin header (WOL) to connect to the 3-pin header on a Network

Interface Card (NIC) that has WOL capability. Wake-On-LAN must be enabled in BIOS. Note that Wake-On-Lan can only be used with an ATX 2.01

(or above) compliant power supply.

1-6 Power Supply

As with all computer products, a stable power source is necessary for

proper and reliable operation. It is even more important for processors that

have high CPU clock rates.

The SUPER P3TDLR accommodates ATX power supplies. Although most

power supplies generally meet the specifications required by the CPU, some

are inadequate. You should use one that will supply at least 300W of

power - or even higher wattage power supply is recommended for highload configurations. Also your power supply must provide a +5V standby

voltage that supplies at least 1.5A of current.

It is strongly recommended that you use a high quality power supply that

meets ATX power supply Specification 2.02 or above. Additionally, in areas where noisy power transmission is present, you may choose to install

a line filter to shield the computer from noise. It is recommended that you

also install a power surge protector to help avoid problems caused by

power surges.

1-7 Super I/O

The disk drive adapter functions of the Super I/O chip include a floppy disk

drive controller that is compatible with industry standard 82077/765, a data

separator, write pre-compensation circuitry, decode logic, data rate selection, a clock generator, drive interface control logic and interrupt and DMA

logic. The wide range of functions integrated onto the Super I/O greatly

reduces the number of components required for interfacing with floppy disk

drives. The Super I/O supports 360 K, 720 K, 1.2 M, 1.44 M or 2.88 M disk

drives and data transfer rates of 250 Kb/s, 500 Kb/s or 1 Mb/s. It also

provides two high-speed, 16550 compatible serial communication ports

(UARTs), one of which supports serial infrared communication. Each UART

includes a 16-byte send/receive FIFO, a programmable baud rate generator,

complete modem control capability and a processor interrupt system.

Each UART includes a 16-byte send/receive FIFO, a programmable baud

Introduction

1-13

SUPER P3TDLR User's Manual

rate generator, complete modem control capability and a processor interrupt system. Both UARTs provide legacy speed with baud rate of up to

115.2 Kbps as well as an advanced speed with baud rates of 250 K, 500 K,

Introduction

or 1 Mb/s, which support higher speed modems.

The Super I/O supports one PC-compatible printer port (SPP), Bi-directional

Printer Port (BPP) , Enhanced Parallel Port (EPP) or Extended Capabilities Port

(ECP).

The Super I/O provides functions that comply with ACPI (Advanced Configuration

and Power Interface), which includes support of legacy and ACPI power management through an SMI or SCI function pin. It also features auto power management to reduce power consumption.

The IRQs, DMAs and I/O space resources of the Super I/O can flexibly adjust to

meet ISA PnP requirements, which suppport ACPI and APM (Advanced Power

Management).

1-14

Chapter 2: Installation

Chapter 2

Installation

This chapter covers the steps required to install the P3TDLR motherboard

into a chassis, connect the data and power cables and install add-on cards.

All motherboard jumpers and connections are also described. A layout and

quick reference chart are on pages 1-4 and 1-5. Remember to completely

close the chassis when you have finished working with the motherboard to

better cool and protect the system.

Tools Required

The only tools you will need to install the P3TDLR into the chassis are

a long and a short Philips screwdriver.

2-1 Handling the P3TDLR Motherboard

Static electrical discharge can damage electronic components. To prevent

damage to any printed circuit boards (PCBs), it is important to handle them

very carefully (see previous chapter). Also note that the size and weight

of the motherboard can cause it to bend if handled improperly, which may

result in damage. To prevent the motherboard from bending, keep one

hand under the center of the board to support it when handling. The following measures are generally sufficient to protect your equipment from

static discharge.

Precautions

• Use a grounded wrist strap designed to prevent static discharge.

• Touch a grounded metal object before removing any board from its antistatic bag.

• Handle a board by its edges only; do not touch its components, peripheral chips, memory modules or gold contacts.

• When handling chips or modules, avoid touching their pins.

• Put the motherboard, add-on cards and peripherals back into their antistatic bags when not in use.

2-1

SUPER P3TDLR User's Manual

• For grounding purposes, make sure your computer chassis provides excellent conductivity between the power supply, the case, the mounting

fasteners and the motherboard.

Unpacking

The motherboard is shipped in antistatic packaging to avoid static electrical

damage. When unpacking the board, make sure the person handling it is

static protected.

2-2 Motherboard Installation

This section explains the first step of physically mounting the P3TDLR into

a chassis. Following the steps in the order given will eliminate the most

common problems encountered in such an installation. To remove the

motherboard, follow the procedure in reverse order.

1. Check compatibility of motherboard ports and I/O shield:

The P3TDLR requires a chassis big enough to support a 12" x 10"

motherboard, such as Supermicro's SC810 1U rackmount. Make sure

that the I/O ports on the motherboard properly align with their

respective holes in the I/O shield at the back of the chassis.

2. Mounting the motherboard onto the motherboard tray:

Carefully mount the motherboard to the motherboard tray by aligning

the board holes with the raised metal standoffs that are visible on

the bottom of the chassis. Insert screws into all the mounting holes

on your motherboard that line up with the standoffs and tighten until

snug (if you screw them in too tight, you might strip the threads).

Metal screws provide an electrical contact to the motherboard ground

to provide a continuous ground for the system.

2-2

Chapter 2: Installation

2-3 Connecting Cables

Now that the motherboard is installed, the next step is to connect the cables

to the board. These include the data (ribbon) cables for the peripherals and

control panel and the power cables.

Connecting Data Cables

The ribbon cables used to transfer data from the peripheral devices

have been carefully routed to prevent them from blocking the flow of

cooling air that moves through the system from front to back. If you

need to disconnect any of these cables, you should take care to

keep them routed as they were originally after reconnecting them

(make sure the red wires connect to the pin 1 locations). The

following data cables (with their locations noted) should be connected. (See the layout on page 5-10 for connector locations.)

l IDE Device Cables (J23 and J24)

l Floppy Drive Cable (J26)

l Ultra 160 LVD SCSI Connector (JA1)

l Control Panel Cable (JF1 Supplied with Supermicro Servers, see

next page)

Connecting Power Cables

The P3TDLR has a 24-pin primary power supply connector designated "ATX Power" for connection to the ATX power supply. The

ATX Power connector also is keyed to accept 20-pin power connectors if the power supply you are using has that type. See Section 58 for power connector pin definitions.

2-3

SUPER P3TDLR User's Manual

Connecting the Control Panel

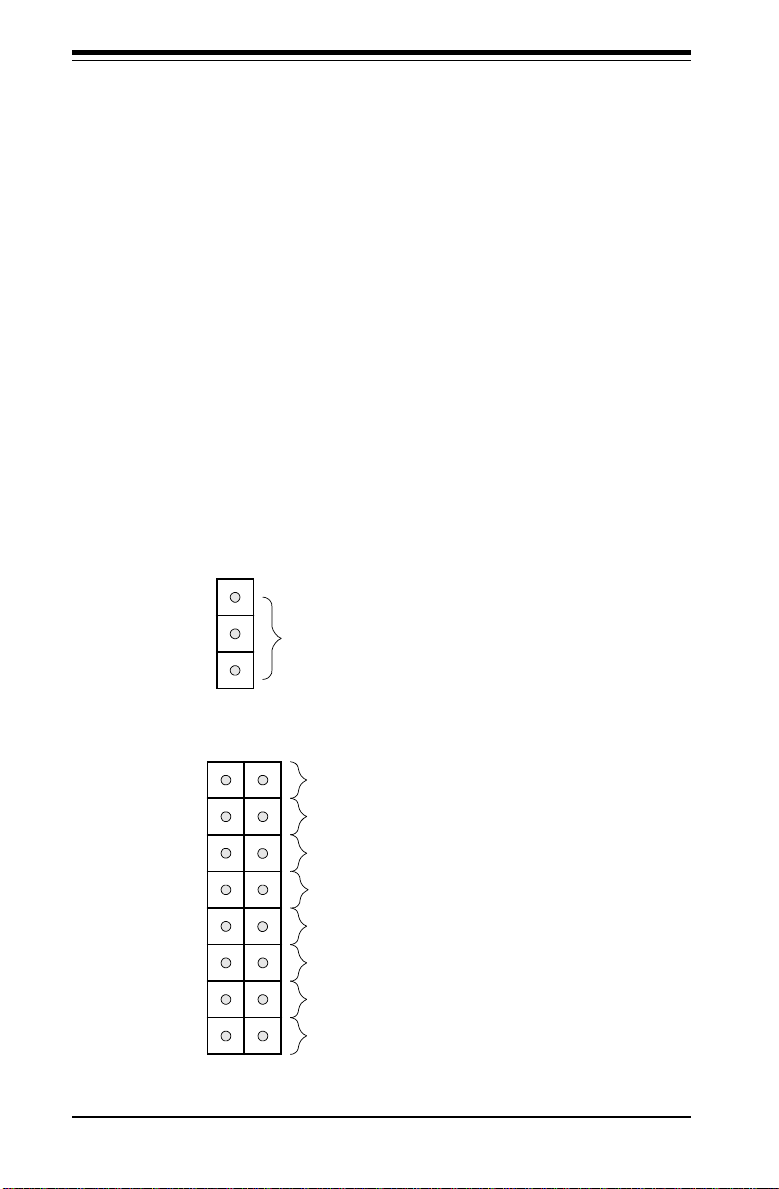

JF1 contains header pins for various front control panel connectors.

See Figure 5-1 for the pin locations of the various front control panel

buttons and LED indicators. Please note that even and odd numbered

pins are on opposite sides.

All JF1 wires have been bundled into a single ribbon cable to simplify

this connection. Make sure the red wire plugs into pin 1 as marked on

the board. The other end connects to JP4 of the Control Panel PCB

board, located just behind the system status LEDs on the chassis.

The control signals are all on the even numbered pins. See pages 512 to 5-14 for details and pin descriptions.

In addition to the 2-pin Power LED header on JF1, there is a 3-pin

header for the same function at JP61 on the motherboard, which is

located near JF1.

Figure 2-1. Control Panel Header Pins

JP61

2

JF1

Power LED (pins 1-3)

Power LED (pins 15-16)

HDD LED (pins 13-14)

NIC1 LED (pins 11-12)

NIC2 LED (pins 9-10)

Overheat LED (pins 7-8)

X (Key)

Reset Button (pins 3-4)

Power Button (pins 1-2)

1

2-4

Chapter 2: Installation

2-4 I/O Ports

The I/O ports are color coded in conformance with the PC 99 specification.

See Figure 2-2 below for the colors and locations of the various I/O ports.

Mouse

(Green)

LAN1

Keyboard

(Purple)

Note: The COM2 Port is a header on the motherboard, located next to the

mounting hole between the Super I/O chip and the RAGE XL chip.

USB

Ports

(Black)

COM1 Port

(Turquoise)

Figure 2-2. I/O Ports

VGA Graphics

Port (Blue)

2-5 Installing Processors

Avoid placing direct pressure to the top of the pro

cessor package. Always connect the power cord last

!

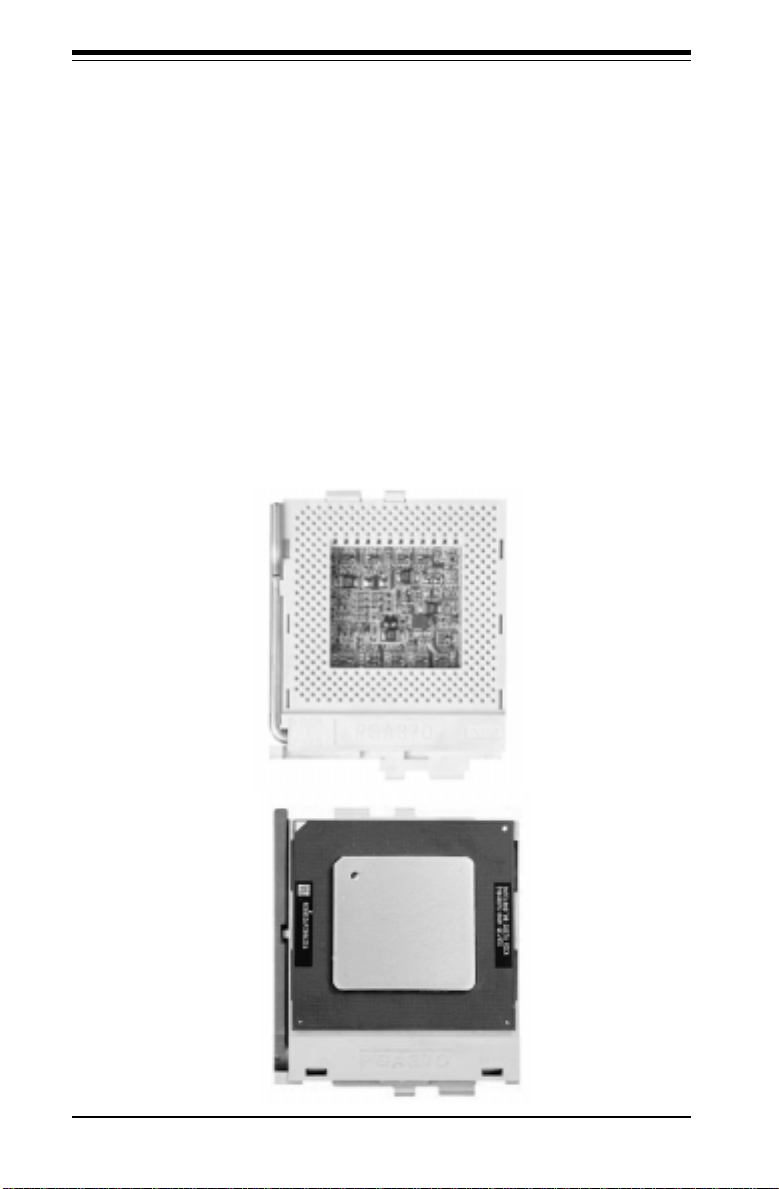

1. Installing the FCPGA processors:

The P3TDLR has two 370-pin sockets, which support single or dual Intel

Pentium® III FCPGA 500 MHz-1.26+ GHz processors and single or dual

low power Pentium® III processors at front bus speeds of 133 and 100

MHz. Lift the lever on the FCPGA socket and insert the processor (with

the heat sink attached) keeping the notched corner oriented toward pin

one on the socket. Make sure the processor is fully seated in the socket

and then close the lever. You can also install a single processor on the

motherboard without changing any jumper settings. (See Figure 5-4 for

views of a 370-pin FCPGA socket before and after processor installation.)

and always remove it before adding, removing or

changing any hardware components.

LAN2

2-5

SUPER P3TDLR User's Manual

2. Attaching heat sinks to the processors:

Two passive heat sinks (one for each processor) have been included

with your SUPER P3TDLR. Secure a heat sink to each processor with a

suitable thermal compound to best conduct the heat from the processor to

the heat sink. Make sure that you apply the compound evenly and that

good contact is made between the CPU chip (the die) and the heat sink.

Insufficient contact or improper types of heat sinks and thermal compounds can cause the processor to overheat, which may crash the

system.

4. Removing the processors:

To remove the processors from the motherboard, simply follow the

installation process in reverse order.

Figure 2-3. FCPGA Socket: Empty and with Processor Installed

(low power Pentium III shown)

2-6

Chapter 2: Installation

2-6 Installing Memory

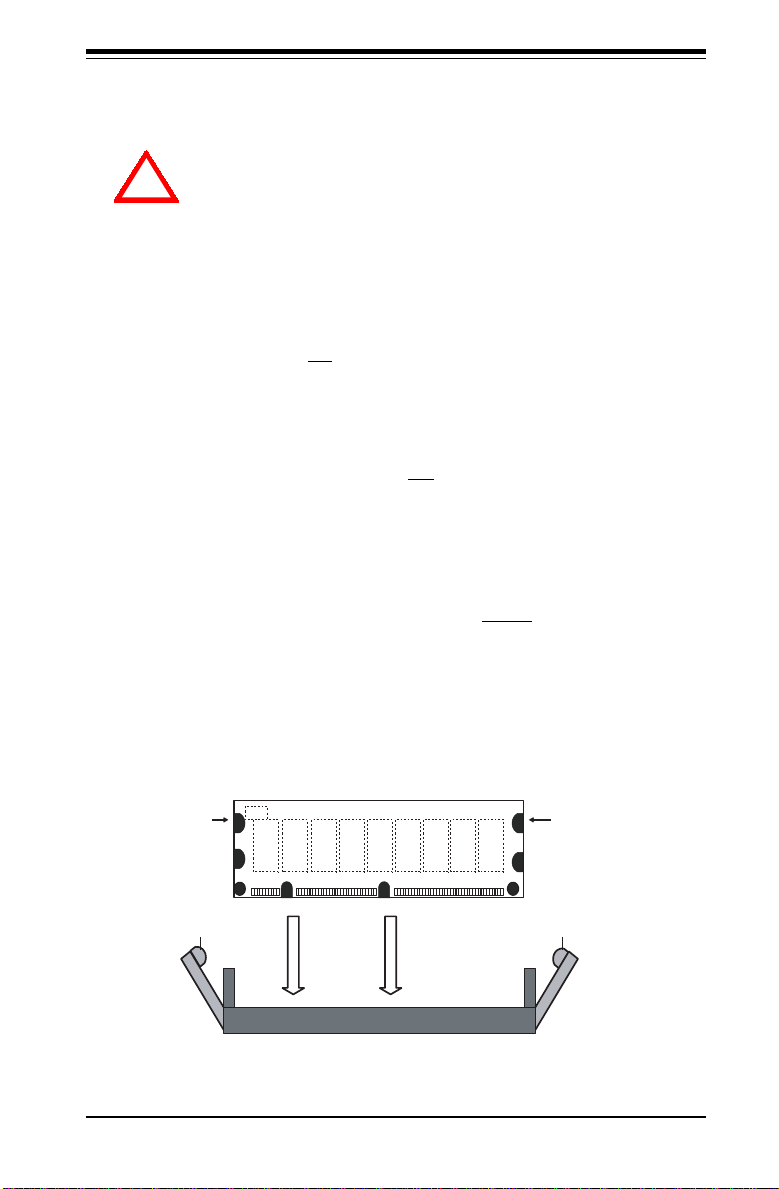

CAUTION! Exercise extreme care when install-

!

1. Memory support:

The P3TDLR supports 128/256/512 MB and 1 GB registered ECC SDRAM

DIMMs. PC133 and PC100 memory are both supported at their respective

speeds. However, the memory bus is synchronized to the front side bus

speed meaning you can not use PC100 with a 133 MHz FSB. Using

PC133 with a 100 MHz FSB will result in 100 MHz memory operation.

2. Memory Slots:

The P3TDLR has four DIMM slots. There is no need to install the DIMM

modules in pairs. The P3TDLR is not sensitive to the installed

position of the memory DIMMs in the DIMM slots.

3. Installing memory modules:

Insert each DIMM module parallel to its slot's guide rails. Pay attention to

the orientation of the two notches along the bottom of the module to

prevent inserting a DIMM module incorrectly. Gently press down on the

DIMM module until it snaps into place in the slot (see Figure 5-4).

ing or removing DIMM modules to prevent any

possible damage. The MEC must be populated

in the manner described in Step 2 below.

4. Memory Position:

The capacity of the memory modules can be mixed; however, the

memory speeds should all be the same for best results.

Figure 2-4. Side View of DIMM Installation into Slot

Notch

Release

Tab

To Install: Insert module vertically and press down until it snaps into

place. Pay attention to the bottom notches. T o Remove:

Use your thumbs to gently push each release tab outward to free the

DIMM from the slot.

DIMM

Note: Notch

should align

with the

receptive point

on the slot

Notch

Release

Tab

2-7

Loading...

Loading...