Supero SC815TQ-700V, SC815TQ-700CVB, SC815S-700VB, SC815S-700V, SC815S-700CV User Manual

...

SC815 CHASSIS

Series

SC815TQ-700V(B) SC815S-700V(B)

SC815TQ-700CV(B) SC815S-700CV(B)

SC815TQ-R650CV(B) SC815S-R650CV(B)

SC815TQ-560V(B) SC815S-560V(B)

SC815TQ-560CV(B) SC815S-560CV(B)

USER’S MANUAL

SUPER

SC815 Chassis Manual

ii

The information in this User’s Manual has been carefully reviewed and is believed to be accurate.

The vendor assumes no responsibility for any inaccuracies that may be contained in this document,

makes no commitment to update or to keep current the information in this manual, or to notify any

person or organization of the updates. Please Note: For the most up-to-date version of

this manual, please see our web site at www.supermicro.com.

SUPERMICRO COMPUTER reserves the right to make changes to the product described in this

manual at any time and without notice. This product, including software, if any, and documentation may not, in whole or in part, be copied, photocopied, reproduced, translated or reduced to any

medium or machine without prior written consent.

IN NO EVENT WILL SUPERMICRO COMPUTER BE LIABLE FOR DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE

OR INABILITY TO USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES. IN PARTICULAR, THE VENDOR SHALL NOT HAVE

LIABILITY FOR ANY HARDWARE, SOFTWARE, OR DATA STORED OR USED WITH THE

PRODUCT, INCLUDING THE COSTS OF REPAIRING, REPLACING, INTEGRATING, INSTALLING

OR RECOVERING SUCH HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa

Clara County in the State of California, USA. The State of California, County of Santa Clara shall

be the exclusive venue for the resolution of any such disputes. Supermicro's total liability for all

claims will not exceed the price paid for the hardware product.

Manual Revision 1.0

Release Date: November 15, 2006

Unless you request and receive written permission from SUPER MICRO COMPUTER, you may not

copy any part of this document.

Information in this document is subject to change without notice. Other products and companies

referred to herein are trademarks or registered trademarks of their respective companies or mark

holders.

Copyright © 2006 by SUPER MICRO COMPUTER INC.

All rights reserved.

Printed in the United States of America

iii

Preface

Preface

About This Manual

This manual is written for professional system integrators and PC technicians. It

provides information for the installation and use of the SC815 1U chassis. Installa-

tion and maintenance should be performed by experienced technicians only.

Supermicro’s SC815 1U chassis features a unique and highly-optimized design for

dual-core Xeon platforms. The chassis is equipped with a 700W, 650W or 560W high

effi ciency power supply for superb power savings. High performance fans provide

ample optimized cooling for FB-DIMM memory modules and 4 hot-swap drive bays

offers maximum storage capacity in a 1U form factor.

This document lists compatible parts available when this document was published.

Always refer to the our Web site for updates on supported parts and confi gura-

tions.

SC815 Chassis Manual

iv

Notes

v

Preface

Manual Organization

Chapter 1: Introduction

The fi rst chapter provides a checklist of the main components included with this

chassis and describes the main features of the SC815 chassis. This chapter also

includes contact information.

Chapter 2: System Safety

This chapter lists warnings, precautions, and system safety. You should thoroughly

familiarize yourself with this chapter for a general overview of safety precautions

that should be followed before installing and servicing this chassis.

Chapter 3: Chassis Components

Refer here for details on this chassis model including the fans, bays, airfl ow shields,

and other components.

Chapter 4: System Interface

Refer to this chapter for details on the system interface, which includes the functions

and information provided by the control panel on the chassis as well as other LEDs

located throughout the system.

Chapter 5: Chassis Setup and Installation

Refer to this chapter for detailed information on this chassis. You should follow the

procedures given in this chapter when installing, removing, or reconfi guring your

chassis.

Chapter 6: Rack Installation

Refer to this chapter for detailed information on chassis rack installation. You should

follow the procedures given in this chapter when installing, removing or reconfi guring

your chassis into a rack environment.

SC815 Chassis Manual

vi

Compatible Backplanes

This section lists compatible cables, power supply specifi cations, and compatible

backplanes. Not all compatible backplanes are listed. Refer to our Web site for the

latest compatible backplane information.

Appendix A: Chassis Cables

Appendix C: Power Supply Specifi cations

Appendix C: SAS 815TQ Backplane Manual

Appendix D: SCA 813S Backplane Manual

vii

Preface

Table of Contents

Preface

About This Manual ...................................................................................................... iii

Manual Organization ................................................................................................... iii

Table of Contents ........................................................................................................ iii

Chapter 1: Introduction

1-1 Overview ......................................................................................................... 1-1

1-2 Shipping List ................................................................................................... 1-1

1-3 Chassis Features ............................................................................................ 1-2

1-4 Contacting Supermicro ................................................................................... 1-3

Chapter 2: System Safety

2-1 Overview ......................................................................................................... 2-1

2-2 Warnings and Precautions ............................................................................. 2-1

2-3 Preparing for Setup ......................................................................................... 2-1

2-4 Electrical Safety Precautions ........................................................................... 2-2

2-5 General Safety Precautions .......................................................................... 2-3

2-6 System Safety ............................................................................................... 2-3

Chapter 3: Chassis Components

3-1 Overview ......................................................................................................... 3-1

3-2 External Components ..................................................................................... 3-1

3-3 Internal Components ...................................................................................... 3-1

3-4 Where to Get Components ............................................................................ 3-1

External Components ............................................................................... 3-1

Internal Components ................................................................................ 3-1

Where to get Replacement Components ................................................. 3-1

Chapter 4: System Interface

4-1 Overview ......................................................................................................... 4-1

4-2 Control Panel .................................................................................................. 4-2

4-3 Control Panel LEDs ........................................................................................ 4-2

4-4 Drive Carrier LEDs ......................................................................................... 4-3

SAS/SATA ................................................................................................ 4-3

SCSI ......................................................................................................... 4-4

SC815 Chassis Manual

viii

Chapter 5: Chassis Setup

5-1 Overview ......................................................................................................... 5-1

5-2 Installation Steps ............................................................................................ 5-1

General Maintenance ............................................................................... 5-1

5-3 lnstallation Step 1: Remove Chassis Cover and Front Bezel ........................ 5-2

To remove the chassis cover .................................................................. 5-2

The Front Bezel ....................................................................................... 5-3

To remove the front bezel ....................................................................... 5-3

5-4 Installation Step 2: Install Hard Drives ........................................................... 5-4

To remove hard drive trays from the chassis ......................................... 5-4

To install a hard drive to the hard drive tray .......................................... 5-5

5-5 Installation Step 3: DVD adn Floppy Drive Installation .................................. 5-7

To install or replace a DVD or Floppy Drive ........................................... 5-7

5-6 Installation Step 4: Installing the Motherboard ............................................... 5-8

Permanent and Optional Standoffs ......................................................... 5-8

To install the motherboard ....................................................................... 5-9

I/O Slot Setup ......................................................................................... 5-10

To remove the I/O panel ........................................................................ 5-10

5-7 Installations Step 5: Installing the Air Shroud and Checking Air Flow ......... 5-11

To install the air shroud ........................................................................ 5-12

To check the server's air fl ow ................................................................ 5-12

5-9 Power Supply ............................................................................................... 5-15

Power Supply Failure ............................................................................ 5-15

Replacing power supply ......................................................................... 5-16

Chapter 6: Rack Installation

6-1 Overview ......................................................................................................... 6-1

6-2 Unpacking the System ................................................................................... 6-1

6-3 Preparing for Setup ........................................................................................ 6-1

Choosing a Setup Location .................................................................... 6-1

Rack Precautions .................................................................................... 6-2

General Server Precautions ................................................................... 6-2

Rack Mounting Considerations ................................................................ 6-2

6-4 Rack Mounting Instructions ............................................................................ 6-3

Identifying the Sections of the Rack Rails .............................................. 6-4

Installing the Inner Rail Extensions ......................................................... 6-5

To install the inner rails ............................................................................ 6-5

Installing the outer rack to the rails ......................................................... 6-6

ix

Preface

Installing the chassis into a rack .............................................................. 6-8

Installing the chassis into a Telco rack ................................................... 5-3

Appendices

Appendix A: SC815 Chassis Cables ........................................................................ A-1

Appendix B: SC815 Power Supply Specifi cations ................................................... B-1

Appendix C: SAS 815TQ Backplane ...................................................................... C-1

Appendix D: SCA 813S Backplane ......................................................................... D-1

SC815 Chassis Manual

Notes

x

Chapter 1: Introduction

Chapter 1

Introduction

1-1 Overview

Supermicro’s SC815 1U chassis features a unique and highly-optimized design.

The chassis is equipped with high effi ciency power supply. High performance fans

provide ample optimized cooling for FB-DIMM memory modules and 4 hot-swap

drive bays offer maximum storage capacity in a 1U form factor.

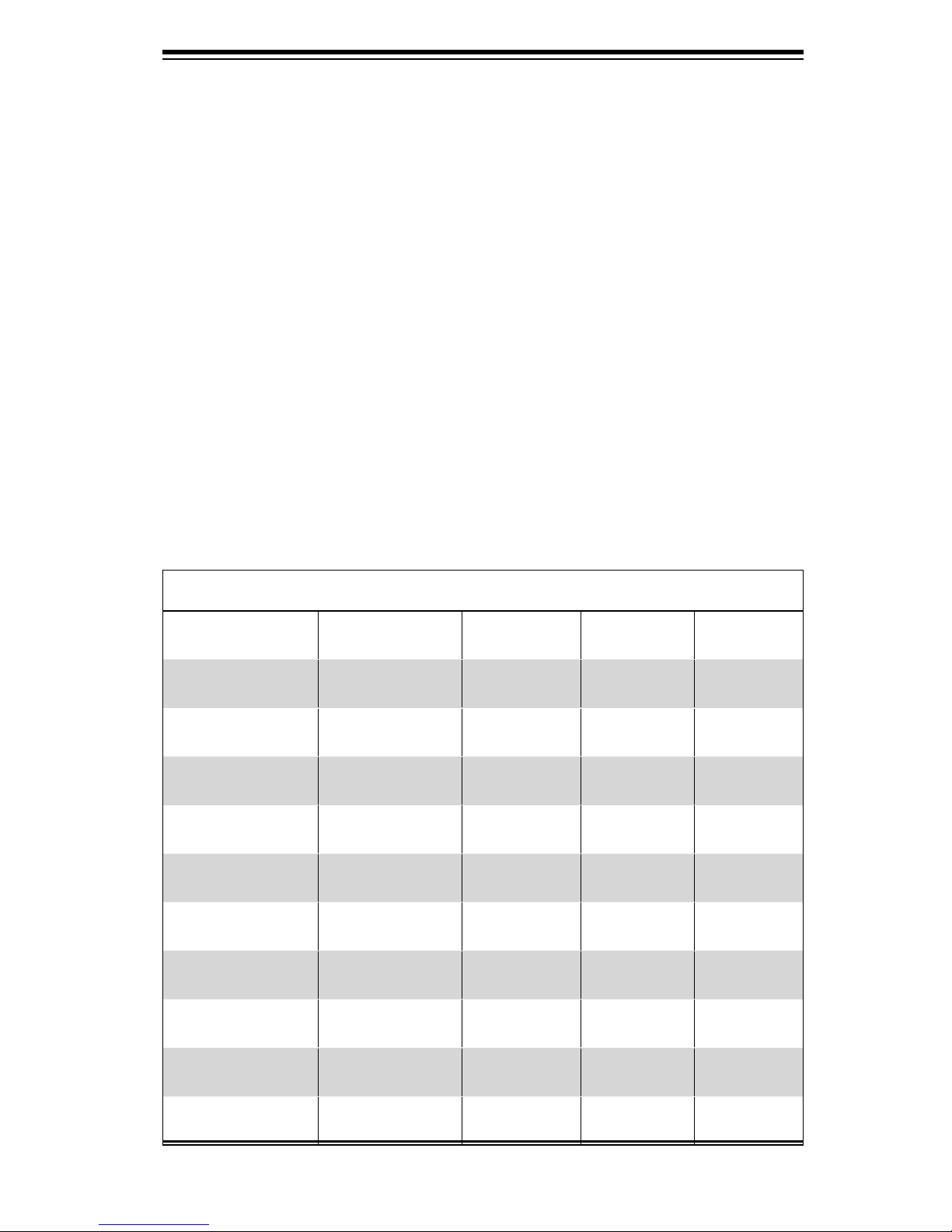

1-2 Shipping List

Part Numbers

Please visit the following link for the latest shiping lists and part numbers for your par-

ticular chassis model http://www.supermicro.com/products/chassis/1U/?chs=815

SC815 Chassis

Model CPU HDD I/O Slots

SC815TQ-700V(B)

SC815TQ-700CV(B)

SC815S-700V(B)

SC815S-700CV(B)

SC815TQ-R650V(B)

SC815S-R650V(B)

SC815TQ-560V(B)

DP Dual-core

Xeon

DP Dual-core

Xeon

DP Dual-core

Xeon

DP Dual-core

Xeon

DP Dual-core

Xeon

DP Dual-core

Xeon

DP Dual-core

Xeon

4x SAS /

SATA

4x SAS /

SATA

4x U320

SCSI

4x U320

SCSI

4x SAS /

SATA

4x U320

SCSI

4x SAS /

SATA

1x FF, 1x LP 700W

1x FF 700W

1x FF, 1x LP 700W

1x FF 700W

1x FF, 1x LP 650W

1x FF 650W

1x FF, 1x LP 560W

Power

Supply

(Redundant)

(Redundant)

SC815TQ-560CV(B)

SC815S-560V(B)

SC815S-560CV(B)

DP Dual-core

Xeon

DP Dual-core

Xeon

DP Dual-core

Xeon

4x SAS /

SATA

4x U320

SCSI

4x U320

SCSI

1-1

1x FF 560W

1x FF, 1x LP 560W

1x FF 560W

SC815 Chassis Manual

1-2

1-3 Chassis Features

The SC815 1U high performance chassis includes the following features:

CPU

The SC815 Chassis supports a DP Dual-core Xeon processor. Please refer to

the motherboard specifi cations pages on our web site for updates on supported

processors.

Hard Drives

The SC815 Chassis features 4 slots for U320 SCSI or SAS/SATA drives. These

drives are hot swappable. Once setup correctly, these drives can be removed

without powering down the server. In addition, these drives support SAF-TE (SCSI)

and SES2 (SAS/SATA).

I/O Expansion slots

Each version of the SC815 Chassis includes one full I/O expansion slot and one low

profi le I/O slot The "C" versions include only the full I/O expansion slot.

Peripheral Drives

Each SC815 Chassis supports one slim DVD-ROM Drive (included) and one slim

Floppy Drive (optional). These drives allow you to quickly install or save data. Both

DVD Drive and Floppy Drives are optional in 560 models.

Other Features

Other onboard features are included to promote system health. These include

various four cooling fans, a convenient power switch, reset button, and 5 LED

indicators.

1-3

Chapter 1: Introduction

1-4 Contacting SuperMicro

Headquarters

Address: SuperMicro Computer, Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email: marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Web Site: www.supermicro.com

Europe

Address: SuperMicro Computer B.V.

Het Sterrenbeeld 28, 5215 ML

's-Hertogenbosch, The Netherlands

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

Email: sales@supermicro.nl (General Information)

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

Asia-Pacifi c

Address: SuperMicro, Taiwan

4F, No. 232-1, Liancheng Rd.

Chung-Ho 235, Taipei County

Taiwan, R.O.C.

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3991

Web Site: www.supermicro.com.tw

Technical Support:

Email: support@supermicro.com.tw

Tel: 886-2-8228-1366, ext.132 or 139

SC815 Chassis Manual

Notes

1-4

Chapter 2: System Safety

Chapter 2

System Safety

2-1 Overview

This chapter provides a quick setup checklist to get your chassis up and running.

Following the steps in order given should enable you to have your chassis setup and

operational within a minimal amount of time. This quick set up assumes that you

are an experienced technician, famailiar with common concepts and terminology.

2-2 Warnings and Precautions

You should inspect the box the chassis was shipped in and note if it was damaged

in any way. If the chassis itself shows damage, fi le a damage claim with carrier

who delivered your system.

Decide on a suitable location for the rack unit that will hold that chassis. It should

be situated in a clean, dust-free area that is well venilated. Avoid areas where heat,

electrical noise and eletromagnetic fi elds are generated.

You will also need it placed near at least one grounded power outlet. When con-

fi gured, the SC815 chassis includes one power supply. "R" models (i.e. SC815S-

R650V Chassis) include a redundant power supply and require two grounded

outlets.

2-3 Preparing for Setup

The SC815 Chassis includes a set of rail assemblies, including mounting brackets

and mounting screws you will need to install the systems into the rack. Please read

this manual in its entirety before you begin the installation procedure.

2-1

SC815 Chassis Manual

2-2

2-4 Electrical Safety Precautions

Basic electrical safety precautions should be followed to protect yourself from harm

and the SC815 from damage:

l Be aware of the locations of the power on/off switch on the chassis as well

as the room’s emergency power-off switch, disconnection switch or electri-

cal outlet. If an electrical accident occurs, you can then quickly remove

power from the system.

l Do not work alone when working with high voltage components.

l Power should always be disconnected from the system when removing

or installing main system components, such as the serverboard, memory

modules and the DVD-ROM and fl oppy drives (not necessary for hot swap-

pable drives). When disconnecting power, you should fi rst power down the

system with the operating system and then unplug the power cords from all

the power supply modules in the system.

l When working around exposed electrical circuits, another person who is fa-

miliar with the power-off controls should be nearby to switch off the power,

if necessary.

l Use only one hand when working with powered-on electrical equipment.

This is to avoid making a complete circuit, which will cause electrical shock.

Use extreme caution when using metal tools, which can easily damage any

electrical components or circuit boards they come into contact with.

l Do not use mats designed to decrease electrostatic discharge as protection

from electrical shock. Instead, use rubber mats that have been specifi cally

designed as electrical insulators.

l The power supply power cord must include a grounding plug and must be

plugged into grounded electrical outlets.

l Serverboard Battery: CAUTION - There is a danger of explosion if the

onboard battery is installed upside down, which will reverse its polarities

This battery must be replaced only with the same or an equivalent type

recommended by the manufacturer. Dispose of used batteries according to

the manufacturer’s instructions.

2-3

Chapter 2: System Safety

l DVD-ROM Laser: CAUTION - this server may have come equipped with a

DVD-ROM drive. To prevent direct exposure to the laser beam and hazard-

ous radiation exposure, do not open the enclosure or use the unit in any

unconventional way.

2-5 General Safety Precautions

l Keep the area around the chassis clean and free of clutter.

l Place the chassis top cover and any system components that have been

removed away from the system or on a table so that they won’t accidentally

be stepped on.

l While working on the system, do not wear loose clothing such as neckties

and unbuttoned shirt sleeves, which can come into contact with electrical

circuits or be pulled into a cooling fan.

l Remove any jewelry or metal objects from your body, which are excellent

metal conductors that can create short circuits and harm you if they come

into contact with printed circuit boards or areas where power is present.

l After accessing the inside of the system, close the system back up and

secure it to the rack unit with the retention screws after ensuring that all

connections have been made.

2-6 System Safety

Electrostatic discharge (ESD) is generated by two objects with different electrical

charges coming into contact with each other. An electrical discharge is created to

neutralize this difference, which can damage electronic components and printed

circuit boards. The following measures are generally suffi cient to neutralize this

difference before contact is made to protect your equipment from ESD:

l Do not use mats designed to decrease electrostatic discharge as protection

from electrical shock. Instead, use rubber mats that have been specifi cally

designed as electrical insulators.

l Use a grounded wrist strap designed to prevent static discharge.

SC815 Chassis Manual

l Keep all components and printed circuit boards (PCBs) in their antistatic

bags until ready for use.

l Touch a grounded metal object before removing any board from its anti-

static bag.

l Do not let components or PCBs come into contact with your clothing, which

may retain a charge even if you are wearing a wrist strap.

l Handle a board by its edges only; do not touch its components, peripheral

chips, memory modules or contacts.

l When handling chips or modules, avoid touching their pins.

l Put the serverboard and peripherals back into their antistatic bags when

not in use.

l For grounding purposes, make sure your computer chassis provides excel-

lent conductivity between the power supply, the case, the mounting fasten-

ers and the serverboard.

2-4

Chapter 3: Chassis Components

Chapter 3

Chassis Components

3-1 Overview

This chapter describes the most common components included with your chassis.

Some components listed may not be included or compatible with your particular

chassis model. For more information, see the installation instructions detailed later

in this manual.

3-2 Components

Chassis

Chassis include 1 slim CD-ROM bay, 1 slim fl oppy disc drive bay, and/or 4 hard

drive bays. Most chassis models include a DVD-ROM. Floppy disc drives and hard

drives must be purchased separately. For the latest shipping lists, visit our Web

site at: http://www.supermicro.com.

This chassis accepts a 1U backplane, 4 fans (with an optional fi fth fan) and one

(sometimes two) power supplies. SC815 models come in silver and black.

Backplane

Each SC815 chassis comes with a 1U backplane. Depending on our order, you

backplane will accept SAS/SATA or SCSI. For more information regarding compat-

ible backplanes, view the appendices found at the end of this manual. In addition,

visit our Web site for the latest information: http://www.supermicro.com.

Fans

The SC815 chassis accepts four system fans with an optional fi fth fan. System fans

for SC815 chassis are powered from the serverboard. These fans are 1U high and

are powered by 3-pin connectors.

3-1

Chassis Manual

Mounting Rails

The SC815 can be placed in a rack for secure storage and use. To setup your

rack, follow the step-by-step instructions included in this manual.

Power Supply

Each SC815 chassis model includes a high-effi ciency power supply rated between

560, 650, or 700 Watts. In the unlikely event your power supply fails, replacement

is simple and can be done without tools.

The SC815TQ-R650V(B) and SC815S-R650V(B) include a redundant, hot-swap-

pable power supply.

Air Shroud

Air shrouds are shields, usually plastic, that funnel air directly to where it is needed.

Always use the air shroud included with your chassis.

3-3 Where to get Replacement Components

Though not frequently, you may need replacement parts for your system. To en-

sure the highest level of professional service and technical support, we strongly

recommend purchasing exclusively from our Supermicro Authorized Distributors /

System Integrators / Resellers. A list of Supermicro Authorized Distributors / Sys-

tem Integrators /Reseller can be found at: http://www.supermicro.com. Click the

Where to Buy link.

3-2

Chapter 4: System Interface

Chapter 4

System Interface

4-1 Overview

There are several LEDs on the control panel as well as others on the drive carriers

to keep you constantly informed of the overall status of the system as well as the

activity and health of specifi c components. Most SC815 models are two buttons

on the chassis a control panel: a reset button and an on/off switch. This chapter

explains the meanings of all LED indicators and the appropriate response you may

need to take.

4-1

Chassis Manual

4-2

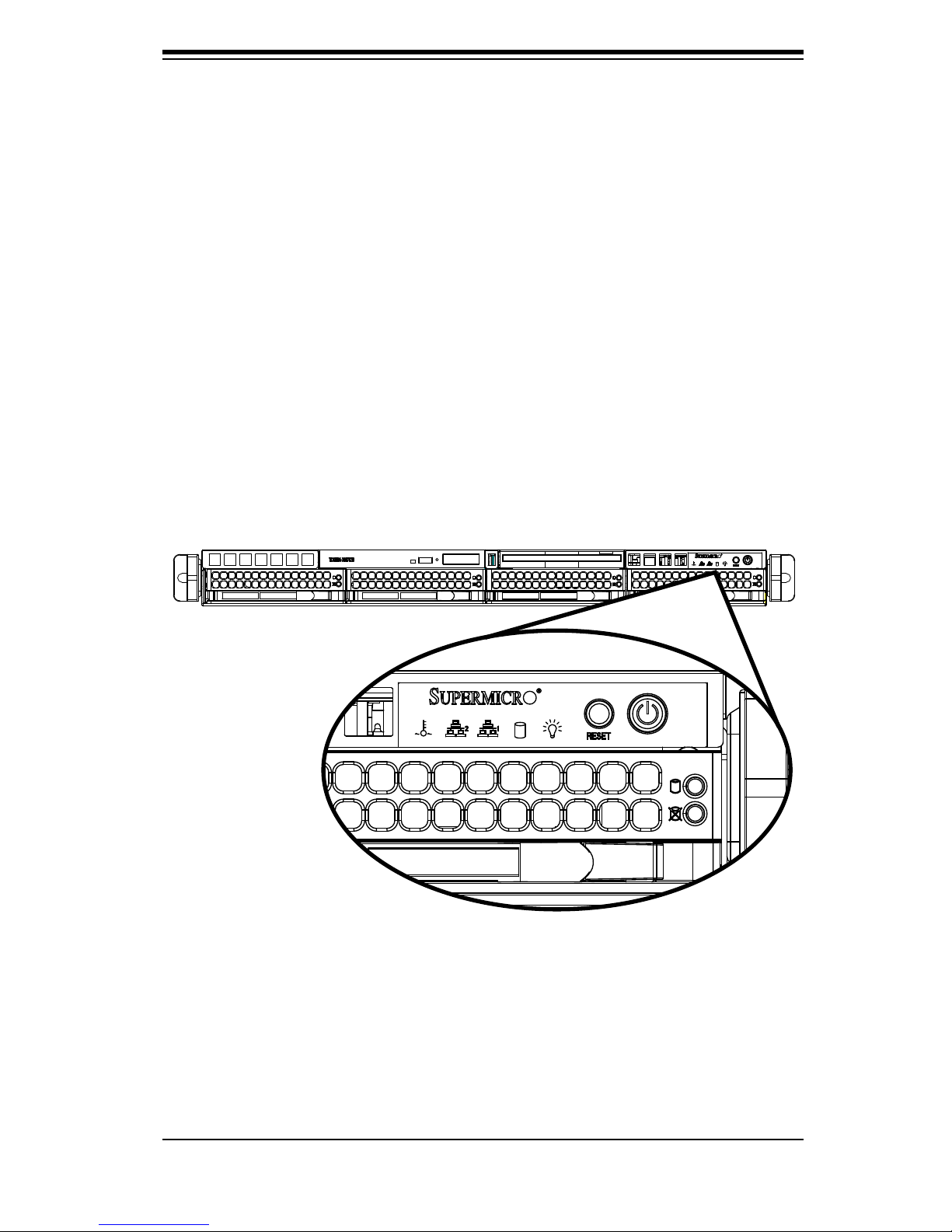

4-2 Control Panel Buttons

There are two push-buttons located on the front of the chassis. These are (in

order from left to right) a reset button and a power on/off button.

l Reset: The reset button is used to reboot the system.

l Power: The main power switch is used to apply or remove power from

the power supply to the server system. Turning off system power with this but-

ton removes the main power but keeps standby power supplied to the system.

Therefore, you must unplug system before servicing.

4-3 Control Panel LEDs

The control panel located on the front of the SC815 chassis has fi ve LEDs. These

LEDs provide you with critical information related to different parts of the system.

This section explains what each LED indicates when illuminated and any corrective

action you may need to take.

l Overheat/Fan Fail: When this LED fl ashes it indicates a fan failure. When

continuously on (not fl ashing) it indicates an overheat condition, which may be

caused by cables obstructing the airfl ow in the system or the ambient room tem-

perature being too warm. Check the routing of the cables and make sure all fans

are present and operating normally. You should also check to make sure that the

chassis covers are installed. Finally, verify that the heatsinks are installed properly.

This LED will remain fl ashing or on as long as the overheat condition exists.

4-3

Chapter 4: System Interface

l NIC2: Indicates network activity on GLAN2 when fl ashing.

l NIC1: Indicates network activity on GLAN1 when fl ashing.

l HDD: Indicates IDE channel activity. SAS/SATA drive, SCSI drive, and/or

DVD-ROM drive activity when fl ashing.

l Power: Indicates power is being supplied to the system's power supply

units. This LED should normally be illuminated when the system is operating.

4-4 Drive Carrier LEDs

Your chassis uses SAS/SATA or SCSI drives, but not both.

SAS/SATA Drives

Each SAS/SATA drive carrier has two LEDs.

l Green: Each Serial ATA drive carrier has a green LED. When illuminated,

this green LED (on the front of the SATA drive carrier) indicates drive activity. A

Chassis Manual

4-4

connection to the SATA backplane enables this LED to blink on and off when that

particular drive is being accessed.

l Red: The red LED to indicate an SAS/SATA drive failure. If one of the SAS/

SATA drives fail, you should be notifi ed by your system management software.

SCSI Drives

Each SCSI drive carrier has two LEDs.

l Green: When illuminated, the green LED on the front of the SCSI drive car-

rier indicates drive activity. A connection to the SCSI SCA backplane enables this

LED to blink on and off when that particular drive is being accessed.

l Red: The SAF-TE compliant backplane activates the red LED to indicate a

drive failure. If one of the SCSI drives fail, you should be notifi ed by your system

management software.

Chapter 5: Chassis Setup and Maintenance

Chapter 5

Chassis Setup and Maintenance

5-1 Overview

This chapter covers the steps required to install components and perform

maintenance on the chassis. The only tool you will need to install components and

perform maintenance is a Phillips screwdriver. Print this page to use as a reference

while setting up your chassis.

5-2 Installation Steps

Step 1: Remove Chassis Cover and Front Bezel

A. Remove the Chassis Cover

B. Remove the Front Bezel

Step 2: Install Hard Drives

A. Remove Hard Drive Trays from the Chassis

B. Install a Hard Drive to the Hard Drive Tray

Step 3: DVD and Floppy Drive Installation

Step 4: Install the Motherboard (includes I/O Slot Setup)

Step 5: Install Air Shroud and Check Airfl ow

A. Install Air Shroud.

B. Check Airfl ow

General Maintenance

General Maintenance: Systems Fans

A. Adding a New System Fan

B. Replacing a System Fan

General Maintenance: Replace Power Supply

Review the warnings and precautions listed in the manual before setting up or servicing this chassis. These include information in Chapter 2: System Safety and the warning/precautions listed in the setup instructions.

5-1

Chassis Manual

5-2

5-3 Installation Step 1: Remove the Chassis Cover and

Front Bezel

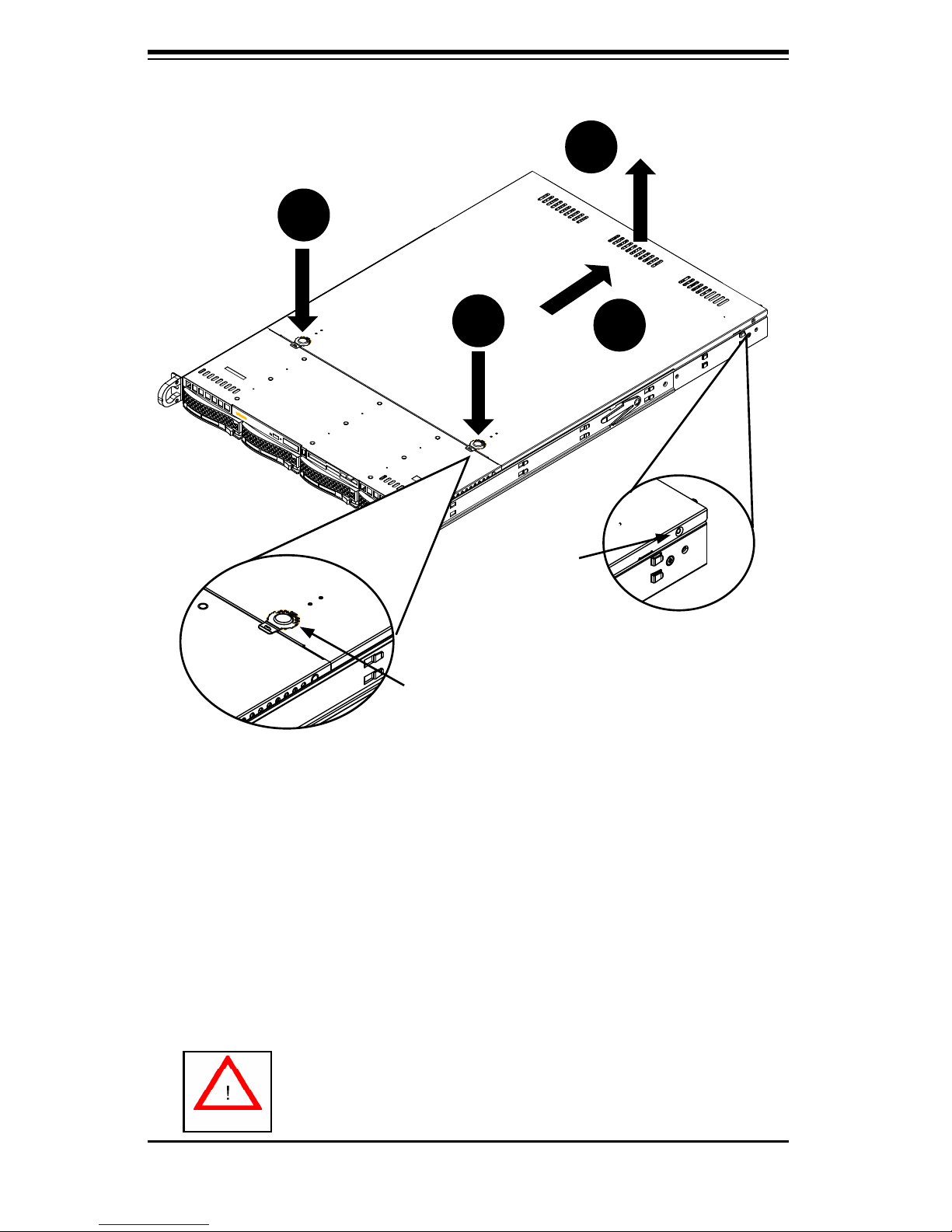

To remove the chassis cover:

1. Press the release tabs to remove the cover from the locked position. Press

both tabs at the same time.

2. Once the top cover is released from the locked position, slide the cover toward

the rear of the chassis.

3. Lift the cover off the chassis.

Warning: Except for short periods of time, do NOT operate the

server without the cover in place. The chassis cover must be

in place to allow proper airfl ow and prevent overheating.

Figure 5-1: Removing the Chassis Cover

1

2

1

3

Release Tab

Remove this screw

(if necessary)

Loading...

Loading...