Page 1

SUPER

SC512 Chassis Series

®

SC512-260B

SC512-200B

SC512F-260(B)

SC512L-260(B)

SC512L-200B

SC512L-260(B)-LCD

SC512C-260(B)

SC512C-200(B)

SC512F-600B

SC512F-520(B)

SC512F-410(B)

SC512F-600LB

SC512F-520L(B)

SC512F-350B

SC512F-280(B)

USER’S MANUAL

1.0b

Page 2

SC512 Chassis Manual

The information in this User’s Manual has been carefully reviewed and is believed to be accurate.

The vendor assumes no responsibility for any inaccuracies that may be contained in this document,

makes no commitment to update or to keep current the information in this manual, or to notify any

person or organization of the updates. Please Note: For the most up-to-date version of this

manual, please see our web site at www.supermicro.com.

Super Micro Computer, Inc. ("Supermicro") reserves the right to make changes to the product

described in this manual at any time and without notice. This product, including software and

documentation, is the property of Supermicro and/or its licensors, and is supplied only under a

license. Any use or reproduction of this product is not allowed, except as expressly permitted by

the terms of said license.

IN NO EVENT WILL SUPERMICRO BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO

USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. IN PARTICULAR, SUPERMICRO SHALL NOT HAVE LIABILITY FOR ANY

HARDWARE, SOFTWARE, OR DATA STORED OR USED WITH THE PRODUCT, INCLUDING THE

COSTS OF REPAIRING, REPLACING, INTEGRATING, INSTALLING OR RECOVERING SUCH

HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa

Clara County in the State of California, USA. The State of California, County of Santa Clara shall

be the exclusive venue for the resolution of any such disputes. Super Micro's total liability for all

claims will not exceed the price paid for the hardware product.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate

warning applies only to products containing CR (Manganese Dioxide) Lithium coin cells. “Perchlorate

Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate”

WARNING: Handling of lead solder materials used in this

product may expose you to lead, a chemical known to

the State of California to cause birth defects and other

reproductive harm.

Manual Revision 1.0b

Release Date: April 21, 2010

Unless you request and receive written permission from Super Micro Computer, Inc., you may not

copy any part of this document.

Information in this document is subject to change without notice. Other products and companies

referred to herein are trademarks or registered trademarks of their respective companies or mark

holders.

Copyright © 2010 by Super Micro Computer, Inc.

All rights reserved.

Printed in the United States of America

ii

Page 3

Preface

Preface

About This Manual

This manual is written for professional system integrators and PC technicians. It

provides information for the installation and use of the SC512 1U chassis. Installa-

tion and maintenance should be performed by experienced technicians only.

Supermicro’s SC512 1U chassis features a unique and highly-optimized design

for dual-core Xeon platforms. The chassis is equipped with a 200, 260, 280. 350,

410, 520 or 600 Watt high-efciency power supply for superb power savings. High-

performance fans provide ample optimized cooling for FB-DIMM memory modules

in a 1U form factor.

This document lists compatible parts available when this document was published.

Always refer to the our Web site for updates on supported parts and congura-

tions.

iii

Page 4

SC512 Chassis Manual

Manual Organization

Chapter 1: Introduction

The rst chapter provides a checklist of the main components included with this

chassis and describes the main features. This chapter also includes contact infor-

mation.

Chapter 2: System Safety

This chapter lists warnings, precautions, and system safety. You should thoroughly

familiarize yourself with this chapter for a general overview of safety precautions

that should be followed before installing and servicing this chassis.

Chapter 3: Chassis Components

Refer to this chapter for details on this chassis model including the fans, bays,

airow shields, and other components.

Chapter 4: System Interface

Refer to this chapter for details on the system interface, which includes the functions

and information provided by the control panel on the chassis as well as other LEDs

located throughout the system.

Chapter 5: Chassis Setup and Maintenance

Follow the procedures given in this ch apter when installing, removing, or

reconguring your chassis.

Chapter 6: Rack Installation

Refer to this chapter for detailed information on chassis rack installation. You should

follow the procedures given in this chapter when installing, removing or reconguring

your chassis into a rack environment.

Appendix A Cables, Screws, and Other Accessories

Appendix B Power Supply Specications

iv

Page 5

Preface

Table of Contents

About This Manual ............................................................................................. iii

Manual Organization .......................................................................................... iv

Chapter 1 Introduction

1-1 Overview ......................................................................................................... 1-1

1-2 Chassis Features ............................................................................................ 1-2

CPU .................................................................................................................1-2

I/O Expansion slots ......................................................................................... 1-2

Peripheral Drives ............................................................................................. 1-2

Dual Hard Drives ............................................................................................. 1-2

1-3 Contacting Supermicro .................................................................................... 1-3

1-4 Returning Merchandise for Service................................................................. 1-4

Chapter 2 System Safety

2-1 Overview ......................................................................................................... 2-1

2-2 Warnings and Precautions ..............................................................................2-1

2-3 Preparing for Setup ......................................................................................... 2-1

2-4 Electrical Safety Precautions ..........................................................................2-1

2-5 General Safety Precautions ............................................................................ 2-3

2-6 System Safety ................................................................................................. 2-3

Chapter 3 Chassis Components

3-1 Overview ......................................................................................................... 3-1

3-2 Components .................................................................................................... 3-1

Chassis ............................................................................................................ 3-1

Fans ................................................................................................................3-1

Blower .............................................................................................................3-1

Mounting Rails ................................................................................................ 3-1

Power Supply .................................................................................................. 3-2

Air Shroud ....................................................................................................... 3-2

3-3 Where to get Replacement Components ........................................................ 3-2

3-4 Chassis Model Options ................................................................................... 3-2

Identifying Fan and Blower-Cooled Chassis Models ...................................... 3-2

Model SC512 .................................................................................................. 3-4

Model SC512C ................................................................................................ 3-5

Model SC512F ................................................................................................ 3-6

Model SC512L ................................................................................................. 3-9

v

Page 6

SC512 Chassis Manual

Chapter 4 System Interface

4-1 Overview ......................................................................................................... 4-1

4-2 Control Panel Buttons ..................................................................................... 4-2

4-3 Control Panel LEDs ........................................................................................ 4-2

Chapter 5 Chassis Setup and Maintenance

5-1 Overview ......................................................................................................... 5-1

5-2 Installation Procedures .................................................................................... 5-1

General Maintenance ...................................................................................... 5-1

5-3 Removing the Chassis Cover ......................................................................... 5-2

5-4 Installing Hard Drives ...................................................................................... 5-3

5-5 Installing the Motherboard .............................................................................. 5-5

Important Motherboard Installation Information .............................................. 5-5

Standoffs ......................................................................................................... 5-6

5-6 Installing the DVD or CD-ROM Drive ............................................................. 5-7

Expansion Slot Setup ...................................................................................... 5-8

5-7 Installing the Air Shroud .................................................................................. 5-9

Installation Complete ..................................................................................... 5-10

5-8 System Fans ..................................................................................................5-11

System Fan Tray ............................................................................................5-11

System Fan Tray Replacement..................................................................... 5-12

5-9 Power Supply ............................................................................................... 5-13

Power Supply Failure .................................................................................... 5-13

Replacing the Chassis LED Panel ................................................................ 5-15

Chapter 6 Rack Installation

6-1 Overview ......................................................................................................... 6-1

6-2 Unpacking the System .................................................................................... 6-1

6-3 Preparing for Setup ......................................................................................... 6-1

Choosing a Setup Location ............................................................................. 6-1

Rack Precautions ............................................................................................ 6-2

General Server Precautions ............................................................................ 6-2

Rack Mounting Considerations ....................................................................... 6-3

Ambient Operating Temperature ................................................................6-3

Reduced Airow ......................................................................................... 6-3

Mechanical Loading ................................................................................... 6-3

Circuit Overloading ..................................................................................... 6-3

Reliable Ground ......................................................................................... 6-3

6-4 Rack Mounting Instructions ............................................................................. 6-4

Identifying the Sections of the Rack Rails (Optional Item) ............................. 6-4

vi

Page 7

Installing the Inner Rail Extension ..................................................................6-5

Installing the Outer Rails to the Rack ............................................................. 6-6

Installing the Chassis into a Rack................................................................... 6-8

Mid-Mount Telco Rack..................................................................................... 6-9

Installing the Chassis into a Rack in Mid-Mount Position .............................. 6-9

Appendix A Cables, Screws, and Other Accessories

Appendix B Power Supply Specications

Preface

vii

Page 8

SC512 Chassis Manual

Notes

viii

Page 9

Chapter 1: Introduction

Chapter 1

Introduction

1-1 Overview

Supermicro’s SC512 1U chassis features a unique and highly-optimized design.

The chassis is equipped with a high-efciency power supply in a small form factor

for optimized space efciency.

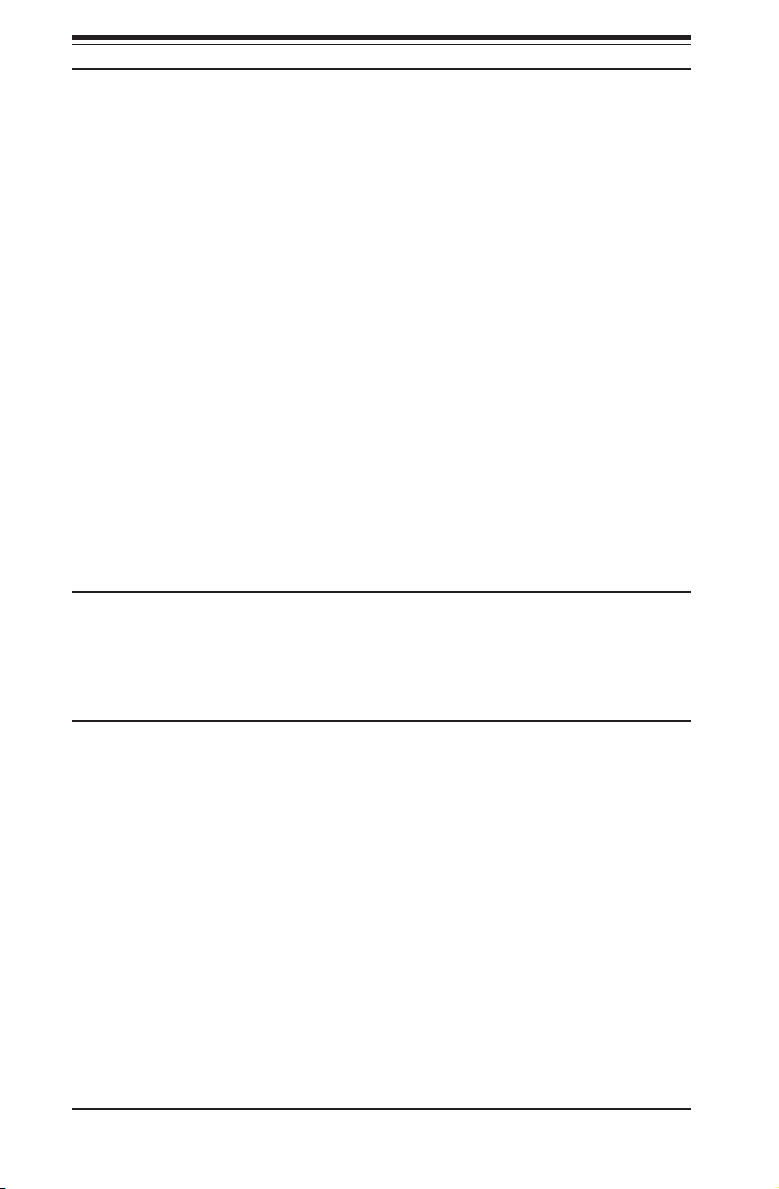

The following chart lists model numbers and features currently available at the

time of printing. For additional information visit the Supermicro Web site at www.

supermicro.com

SC512 Chassis

Model CPU HDD I/O Slots Power Supply

SC512-200B

SC512-260B

SC512C-200(B)

SC512C-260(B)

SC512F-260(B)

SC512L-200B

SC512L-260(B)

SC512L-260(B)-LCD

SC512F-280(B)

SC512F-350B

SC512F-410(B)

SC512F-520(B)

SC512F-600B

SC512F-520L(B)

SC512F-600LB

Legend:

DP = Dual Processor Support UP = Single Processor Support

FF = Full-height, Full-length FH = Full-height, Half-length

LP = Low-prole

UP 1x Fixed 3.5" FH

UP 1x Fixed 3.5" FH 260W

UP 1x Fixed 3.5" FH 200W

UP 1x Fixed 3.5" FH 260W

UP 1x Fixed 3.5" FH 260W

UP 2x Fixed 3.5" FH 200W

UP 2x Fixed 3.5" FH 260W

UP 1x Fixed 3.5" FH 260W

DP/UP 2x Fixed 3.5" FH 280W (High-Efciency)

DP/UP 2x Fixed 3.5" FH 350W (Gold Level)

DP/UP 1x Fixed 3.5" FH 410W DC

DP/UP 1x Fixed 3.5" FH 520W (High-Efciency)

DP/UP 1x Fixed 3.5" FH 600W (Gold Level)

DP/UP 1x Fixed 3.5" FH 520W (High-Efciency)

DP/UP 1x Fixed 3.5" FH 600W (Gold Level)

200W (High-Efciency)

1-1

Page 10

SC512 Chassis Manual

1-2 Chassis Features

The SC512 1U high-performance chassis supports a wide range of features. See

the Chassis Components section of this manual for a list of featues included in

each of the SC512 models.

CPU

The SC512 chassis supports a DP and/or UP Xeon, Pentium D, P3/P4 processors.

Please refer to the motherboard specications pages on our web site for updates

on supported processors.

I/O Expansion slots

Each version of the SC512 chassis includes one full I/O expansion slot

Peripheral Drives

Some SC512 chassis support peripheral dives such as a DVD-ROM, CD-ROM or

oppy disk drive. These drives allow data to be installed or saved quickly.

Dual Hard Drives

Some SC512 chassis models support a second hard disk drive. For more details,

check the Chassis Components section of this manual or the Supermicro Website

at www.supermicro.com.

1-2

Page 11

1-3 Contacting Supermicro

Headquarters

Address: Super Micro Computer, Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email: marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Web Site: www.supermicro.com

Europe

Address: Super Micro Computer B.V.

Het Sterrenbeeld 28, 5215 ML

's-Hertogenbosch, The Netherlands

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

Email: sales@supermicro.nl (General Information)

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

Chapter 1 Introduction

Asia-Pacic

Address: Super Micro Computer, Inc.

4F, No. 232-1, Liancheng Rd.

Chung-Ho 235, Taipei County

Taiwan, R.O.C.

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3991

Web Site: www.supermicro.com.tw

Technical Support:

Email: support@supermicro.com.tw

Tel: 886-2-8226-1900

1-3

Page 12

SC512 Chassis Manual

1-4 Returning Merchandise for Service

A receipt or copy of your invoice marked with the date of purchase is required be-

fore any warranty service will be rendered. You can obtain service by calling your

vendor for a Returned Merchandise Authorization (RMA) number. When returning

to the manufacturer, the RMA number should be prominently displayed on the

outside of the shipping carton, and mailed prepaid or hand-carried. Shipping and

handling charges will be applied for all orders that must be mailed when service

is complete.

For faster service, RMA authorizations may be requested online (http://www.

supermicro.com/support/rma/).

Whenever possible, repack the chassis in the original Supermicro carton, using the

original packaging material. If these are no longer available, be sure to pack the

chassis securely, using packaging material to surround the chassis so that it does

not shift within the carton and become damaged during shipping.

This warranty only covers normal consumer use and does not cover damages in-

curred in shipping or from failure due to the alteration, misuse, abuse or improper

maintenance of products.

During the warranty period, contact your distributor rst for any product problems.

1-4

Page 13

Chapter 2: System Safety

Chapter 2

System Safety

2-1 Overview

This chapter provides a quick setup checklist to get your chassis up and running.

Following the steps in order given should enable you to have your chassis setup and

operational within a minimal amount of time. This quick setup assumes that you are

an experienced technician, famailiar with common concepts and terminology.

2-2 Warnings and Precautions

You should inspect the box the chassis was shipped in and note if it was damaged

in any way. If the chassis itself shows damage, le a damage claim with carrier

who delivered your system.

Decide on a suitable location for the rack unit that will hold that chassis. It should

be situated in a clean, dust-free area that is well venilated. Avoid areas where heat,

electrical noise and eletromagnetic elds are generated.

You will also need it placed near at least one grounded power outlet. When cong-

ured, the SC512 chassis includes one power supply.

2-3 Preparing for Setup

The SC512 chassis includes a set of rail assemblies, including mounting brackets

and mounting screws you will need to install the systems into the rack. Please read

this manual in its entirety before you begin the installation procedure.

2-4 Electrical Safety Precautions

Basic electrical safety precautions should be followed to protect yourself from harm

and the SC512 from damage:

Be aware of the locations of the power on/off switch on the chassis as well •

as the room’s emergency power-off switch, disconnection switch or electrical

outlet. If an electrical accident occurs, you can then quickly remove power from

the system.

Do not work alone when working with high-voltage components.•

2-1

Page 14

SC512F Chassis Manual

Power should always be disconnected from the system when removing or in-•

stalling main system components, such as the serverboard, memory modules

and the DVD-ROM and oppy drives (not necessary for hot-swappable drives).

When disconnecting power, you should rst power down the system with the

operating system and then unplug the power cords from all the power supply

modules in the system.

When working around exposed electrical circuits, another person who is fa-•

miliar with the power-off controls should be nearby to switch off the power, if

necessary.

Use only one hand when working with powered-on electrical equipment. This •

is to avoid making a complete circuit, which will cause electrical shock. Use

extreme caution when using metal tools, which can easily damage any electrical

components or circuit boards they come into contact with.

Do not use mats designed to decrease electrostatic discharge as protection from •

electrical shock. Instead, use rubber mats that have been specically designed

as electrical insulators.

The power cord must include a grounding plug and must be plugged into a •

grounded electrical outlet.

Serverboard battery: CAUTION - There is a danger of explosion if the onboard •

battery is installed upside down, which will reverse its polarities This battery

must be replaced only with the same or an equivalent type recommended by

the manufacturer. Dispose of used batteries according to the manufacturer’s

instructions.

DVD-ROM laser: CAUTION - This server may have come equipped with a •

DVD-ROM drive. To prevent direct exposure to the laser beam and hazardous

radiation exposure, do not open the enclosure or use the unit in any uncon-

ventional way.

2-2

Page 15

Chapter 2: System Safety

2-5 General Safety Precautions

Keep the area around the chassis clean and free of clutter.•

Place the chassis top cover and any system components that have been re-•

moved away from the system or on a table so that they won’t accidentally be

stepped on.

While working on the system, do not wear loose clothing such as neckties and •

unbuttoned shirt sleeves, which can come into contact with electrical circuits or

be pulled into a cooling fan.

Remove any jewelry or metal objects from your body, which are excellent metal •

conductors that can create short circuits and harm you if they come into contact

with printed circuit boards or areas where power is present.

After accessing the inside of the system, close the system back up and secure •

it to the rack unit with the retention screws after ensuring that all connections

have been made.

2-6 System Safety

Electrostatic discharge (ESD) is generated by two objects with different electrical

charges coming into contact with each other. An electrical discharge is created to

neutralize this difference, which can damage electronic components and printed

circuit boards. The following measures are generally sufcient to neutralize this

difference before contact is made to protect your equipment from ESD:

Do not use mats designed to decrease electrostatic discharge as protection from •

electrical shock. Instead, use rubber mats that have been specically designed

as electrical insulators.

Use a grounded wrist strap designed to prevent static discharge.•

Keep all components and printed circuit boards (PCBs) in their antistatic bags •

until ready for use.

Touch a grounded metal object before removing any board from its antistatic •

bag.

2-3

Page 16

SC512F Chassis Manual

Do not let components or PCBs come into contact with your clothing, which may •

retain a charge even if you are wearing a wrist strap.

Handle a board by its edges only; do not touch its components, peripheral chips, •

memory modules or contacts.

When handling chips or modules, avoid touching their pins.•

Put the serverboard and peripherals back into their antistatic bags when not •

in use.

For grounding purposes, make sure your computer chassis provides excellent •

conductivity between the power supply, the case, the mounting fasteners and

the serverboard.

2-4

Page 17

Chapter 3: Chassis Components

Chapter 3

Chassis Components

3-1 Overview

This chapter describes the most common components included with your chassis.

Some components listed may not be included or compatible with your particular

chassis model. For more information, see the installation instructions detailed later

in this manual.

3-2 Components

Chassis

Depending on the model, the SC512 chassis may include one slim DVD-ROM/CD-

ROM bay, at least one xed hard drive, a oppy drive, and/or two USB ports. For

the latest shipping lists, visit our Web site at: http://www.supermicro.com.

Fans

The SC512 model chassis accepts two or three system fans powered by the moth-

erboard. These fans are 1U high and are powered by 3-pin connectors.

Blower

The SC512, SC512L and SC512C model chassis use a single blower unit for

system cooling.

Mounting Rails

The SC512 can be placed in a rack for secure storage and use. To set up your

rack, follow the step-by-step instructions included in this manual. SC512 models

with narrow chassis designs include specialized rails for mounting in a standard

rack. See the Rack Installation section of this manual for details.

3-1

Page 18

SC512 Chassis Manual

Power Supply

Each SC512 chassis model includes a high-efciency power supply rated at 200,

260, 280, 350, 410 or 580 Watts. In the unlikely event your power supply fails,

replacement is simple and can be done without tools.

Air Shroud

Air shrouds are shields, usually plastic, that funnel air directly to where it is needed.

Always use the air shroud included with your chassis.

3-3 Where to get Replacement Components

Though not frequently, you may need replacement parts for your system. To en-

sure the highest level of professional service and technical support, we strongly

recommend purchasing exclusively from our Supermicro Authorized Distributors/

System Integrators/Resellers. A list of Supermicro Authorized Distributors/System

Integrators/Reseller can be found at: http://www.supermicro.com. Click the Where

to Buy link.

3-4 Chassis Model Options

The following section lists the different options which are available for each of the

different chassis models in the SC512 chassis family of products.

Identifying Fan and Blower-Cooled Chassis Models

Your SC512 chassis is equipped with either a blower unit or a set of system fans

for optimized chassis cooling.

The SC512, SC512C and most SC512L model chassis use a blower unit for chas-

sis cooling.

The SC512F model chassis are cooled with system fans. The number of system

fans included in your specic system may vary.

See the following page for illustrations of blower units and system fans. For detailed

instructions on replacing a blower unit or system fans, see the Chassis Setup and

Maintenance section of this manual.

3-2

Page 19

Chapter 3: Chassis Components

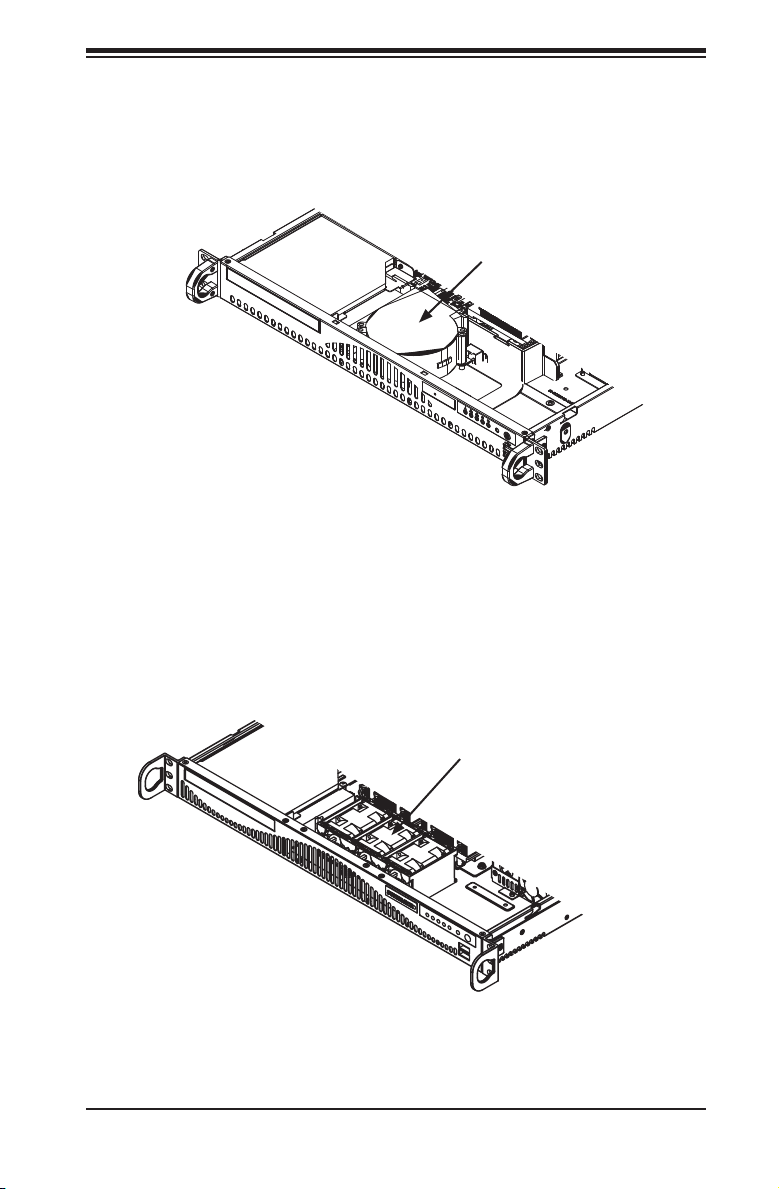

Air blower unit

included in chassis

models SC512,

SC512C and SC512L

Figure 3-1: Blower-Cooled Chassis Model

System fans included

in chassis model

SC512F

Figure 3-2: Fan-Cooled Chassis Model

3-3

Page 20

SC512 Chassis Manual

Model SC512

Includes a slot with a dummy cover plate where an optional DVD-ROM drive may

be installed, and a 200 or 260 Watt power supply. The SC512 model chassis is

cooled with an internal blower unit.

Dummy Cover

Plate for Optional

DVD Drive

Figure 3-3: Chassis Model SC512-200, SC512-260

SC512-200

Chassis Blower/

Fan

Standard Blower Optional

DVD/CD Floppy USB CPU I/O

DVD

- 2x

USB

Slots

UP FH 1x

HDD Power

Fixed

3.5"

Supply

200 Watt

Efciency

High-

Chassis Blower/

Fan

Standard Blower Optional

DVD/CD Floppy USB CPU I/O

DVD

SC512-260

- 2x

USB

3-4

Slots

HDD Power

UP FH 1x

Fixed

3.5"

Supply

260 Watt

Page 21

Chapter 3: Chassis Components

Model SC512C

The SC512C includes a CD-ROM drive, oppy drive, USB ports and a 200 or 260

Watt power supply. The SC512C model chassis is cooled with an internal blower

unit.

USB Ports

Chassis Blower/

Standard Blower 1x CD 1x

Chassis Blower/

Standard Blower 1x CD 1x

CD-ROM Drive

Figure 3-4: Chassis Model SC512C

SC512C-200

DVD/CD Floppy USB CPU I/O

Fan

Floppy

SC512C-260

DVD/CDFloppy USB CPU I/O

Fan

Floppy

Floppy Drive

2x

UP FH 1x

USB

2x

UP FH 1x

USB

Slots

Slots

HDD Power

Fixed

Fixed

Supply

200

Watt

3.5"

HDD Power

Supply

260

Watt

3.5"

3-5

Page 22

SC512 Chassis Manual

Model SC512F

The SC512F models may include a DVD-ROM drive, USB ports and a 260, 280,

350, 410, 520 or 600 Watt power supply. The SC512F-280 and 350 models can sup-

port a second optional hard disk drive. The SC512F-280/350/410/520/ 600 model

chassis have a wider chassis design, which mounts in a standard rack utilizing

special mounting rails. See the Rack Installation section of this manual for details.

All SC512F model chassis are cooled with system fans.

DVD-ROM Drive

Figure 3-5: Chassis Model SC512F-260

SC512F-260

Chassis Blower/

Narrow* 2x Fan 1x DVD - 2x

* Note: Narrow chassis models include specialized mounting rails to t into a stan-

dard rack. See the Rack Installation section of this manual for details.

DVD/CD Floppy USB CPU I/O

Fan

USB

DVD-ROM Drive

Slots

HDD Power

UP FH 1x

Fixed

3.5"

Supply

260 Watt

Figure 3-6: Chassis Model SC512F-280

SC512F-280

Chassis Blower/

Fan

Standard 2x Fan 1x DVD - - DP/UPFH 2x

Chassis Blower/

Fan

Standard 2x Fan Optional

DVD/CD Floppy USB CPU I/O

Slots

Optional DVD-ROM Drive

Figure 3-7: Chassis Model SC512F-350

SC512F-350

DVD/CD Floppy USB CPU I/O

Slots

- - DP/UPFH 2x

DVD

HDD Power

Fixed

3.5"

HDD Power

Fixed

3.5"

3-6

Supply

280 Watt

High-

Efciency

Supply

350 Watt

Gold-

Level

Page 23

Chapter 3: Chassis Components

DVD-ROM Drive

Figure 3-8: Chassis Models SC512F-410 and SC512F-520

SC512F-520

Chassis Blower/

Fan

Standard 3x Fans 1x DVD - 2x

Chassis Blower/

Standard 3x Fans 1x DVD - 2x

DVD/CD Floppy USB CPU I/O

USB

SC512F-410

DVD/CDFloppy USB CPU I/O

Fan

USB

USB Ports

HDD Power

Slots

DP/UPFH 1x

Fixed

3.5"

HDD Power

Slots

DP/UPFH 1x

Fixed

3.5"

Supply

520 Watt

High-

Efciency

Supply

410 DC

Optional DVD-ROM

Figure 3-9: Chassis Model SC512F-600

Chassis Blower/

Fan

Standard 3x Fan Optional

DVD/CDFloppy USB CPU I/O

DVD

SC512F-600

- 2x

USB

3-7

Slots

HDD Power

DP/UPFH 1x

Fixed

3.5"

Supply

600

Watt

Gold

Level

Page 24

SC512 Chassis Manual

Figure 3-10: Chassis Model SC512F-520L and SC512F-600L

SC512F-520L

Chassis Blower/

Fan

Standard 3x Fans - - - DP/UPFH 1x

Chassis Blower/

Fan

Standard 3x Fans - - - DP/UPFH 1x

DVD/CD Floppy USB CPU I/O

Slots

SC512F-600L

DVD/CD Floppy USB CPU I/O

Slots

HDD Power

Fixed

HDD Power

Fixed

3.5"

3.5"

Supply

520 Watt

High

Efciency

Supply

600 Watt

Gold

Level

3-8

Page 25

Chapter 3: Chassis Components

Model SC512L

The SC512L models include two 3.5" hard disk drives and a 200 or 260 Watt power

supply. The SC512L model chassis is cooled with an internal blower unit.

Figure 3-11: Chassis Models SC512L-200 and SC512L-260

SC512L-200

Chassis Blower/

Fan

Standard Blower - - - UP FH 2x

Chassis Blower/

Fan

Standard Blower - - - UP FH 2x

DVD/CD Floppy USB CPU I/O

Slots

SC512L-260

DVD/CD Floppy USB CPU I/O

Slots

HDD Power

Fixed

HDD Power

Fixed

Supply

200

Watt

3.5"

Supply

260

Watt

3.5"

Figure 3-12: Chassis Model SC512L-260-LCD

SC512L-260(B)-LCD

Chassis Blower/

Fan

Standard Blower - - - UP FH 1x

DVD/CD Floppy USB CPU I/O

Slots

HDD Power

Fixed

3.5"

3-9

Supply

260

Watt

Page 26

SC512 Chassis Manual

Notes

3-10

Page 27

Chapter 4: System Interface

Chapter 4

System Interface

4-1 Overview

There are several LEDs on the control panel and on the drive carriers to keep you

constantly informed of the overall status of the system, as well as the activity and

health of specic components. Most SC512 models have two buttons on the chassis

control panel: a reset button and an on/off switch. This chapter explains the mean-

ings of all LED indicators and the appropriate response you may need to take.

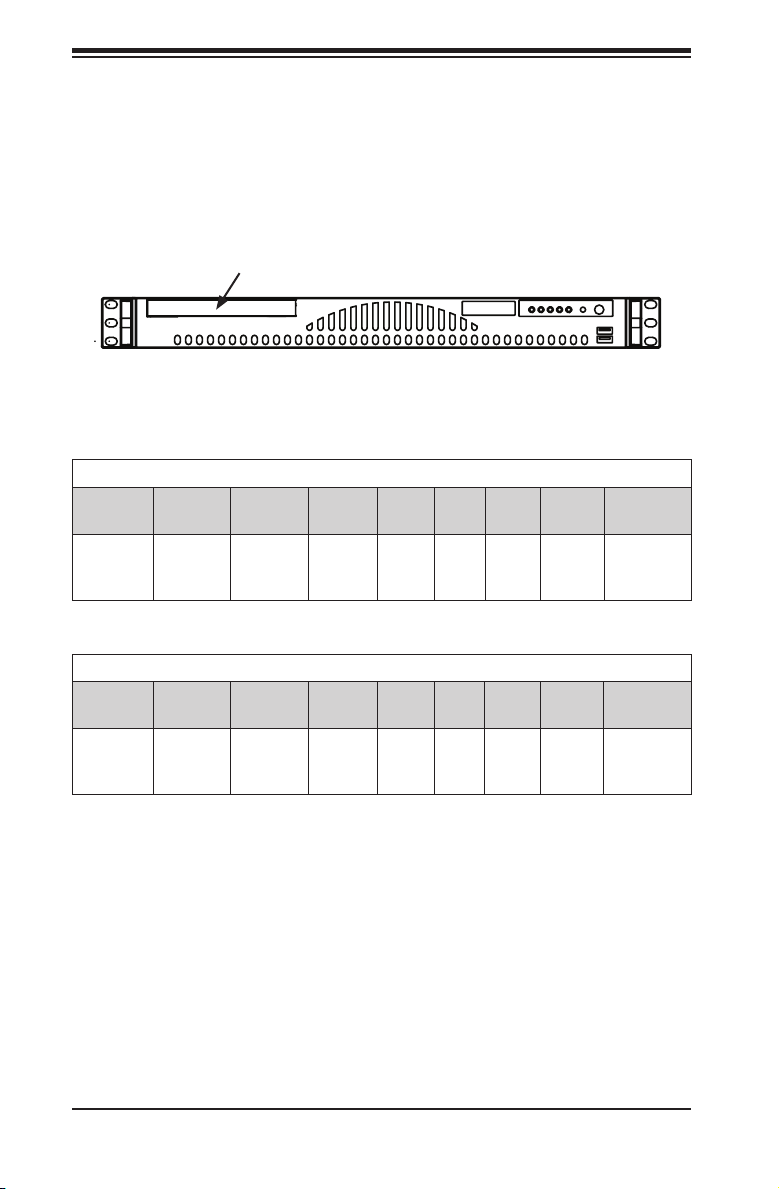

Figure 4-1: Chassis LED and Buttons

4-1

Page 28

SC512 Chassis Manual

4-2 Control Panel Buttons

There are two push-buttons located on the front of the chassis. These are a reset

button and a power on/off button.

Reset: The reset button is used to reboot the system.

Power: The main power switch is used to apply or remove power from the

power supply to the server system. Turning off system power with this button re-

moves the main power but keeps standby power supplied to the system. Therefore,

you must unplug system before servicing.

4-3 Control Panel LEDs

The control panel located on the front of the SC512 chassis has ve LEDs. These

LEDs provide you with critical information related to dif ferent parts of the system.

This section explains what each LED indicates when illuminated and any corrective

action you may need to take.

Overheat/Fan Fail: When this LED ashes it indicates a fan failure. When

continuously on (not ashing) it indicates an overheat condition, which may be

caused by cables obstructing the airow in the system or the ambient room tem-

perature being too warm. Check the routing of the cables and make sure all fans

are present and operating normally. You should also check to make sure that the

chassis covers are installed. Finally, verify that the heatsinks are installed properly.

This LED will remain ashing or on as long as the overheat condition exists.

4-2

Page 29

Chapter 4: System Interface

NIC2: Indicates network activity on GLAN2 when ashing.

NIC1: Indicates network activity on GLAN1 when ashing.

HDD: Indicates IDE channel activity. SAS/SATA drive, SCSI drive, and/or

DVD-ROM drive activity when ashing.

Power: Indicates power is being supplied to the system's power supply units.

This LED should normally be illuminated when the system is operating.

4-3

Page 30

SC512 Chassis Manual

Notes

4-4

Page 31

Chapter 5: Chassis Setup and Maintenance

!

!

Chapter 5

Chassis Setup and Maintenance

5-1 Overview

This chapter covers the steps required to install components and perform mainte-

nance on the chassis. The only tool you will need to install components and perform

maintenance is a Phillips head and a athead screwdriver. Print this page to use

as a reference while setting up your chassis.

5-2 Installation Procedures

Removing the Chassis Cover

Installing the Hard Drive

Installing the Motherboard (includes I/O Shield and Expansion Card Slot setup)

Installing the DVD or CD-ROM Drive

Installing the Air Shroud

General Maintenance

Systems Fans

Power Supply

Certain motherboards and heatsinks may not be compatible

with this chassis. Before installation, review the motherboard

installation procedures in this chapter.

Review the warnings and precautions listed in the manual before setting up or servicing this chassis. These include information in Chapter 2: System Safety and the warning/precautions listed in the setup instructions.

5-1

Page 32

SC512 Chassis Manual

!

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

5-3 Removing the Chassis Cover

Remove these screws

Remove these screws

Remove this screw

Removing the Chassis Cover

Figure 5-1: Removing the Chassis Cover

Remove the screws holding the chassis cover in place.1.

Apply pressure to the middle front of the chassis cover.2.

Slide the cover toward the rear of the chassis.3.

Warning: Except for short periods of time, do NOT operate the

server without the cover in place. The chassis cover must be in

place to allow proper airow and prevent overheating.

5-2

Page 33

5-4 Installing Hard Drives

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

Remove these screws

Chapter 5: Chassis Setup and Maintenance

DVD-ROM/CD-ROM

Drive

Installing a Hard Drive

Before adding a hard drive, you must remove the DVD-ROM/CD-ROM drive.

Figure 5-2: Removing the CD-ROM Drive to Access the Hard Drive

Open the chassis cover.1.

If you have not already done so, remove the fan tray. For more information on 2.

removing the fan tray, see the Maintenance section located at the end of this

chapter.

Remove the CD-ROM drive. To do this, remove the two screws holding the 3.

drive in place. One screw is external. The other is internal.

5-3

Page 34

SC512 Chassis Manual

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

Hard Drive

Figure 5-3: Adding the Hard Drive

4. Place the hard drive in the chassis as illustrated. Make sure the hard drive con-

nectors face the inside of the chassis.

5. Secure the hard drive to the chassis using the four screws.

6. SC512F-280, SC512L and SC512L-260 model users: These chassis can support

a second hard drive. Insert the second hard drive at this time. If you are are not

using the models listed above, skip this step.

Hard Drive

Second Hard

Drive

Figure 5-4: Adding a Second Hard Drive

5-4

Page 35

Chapter 5: Chassis Setup and Maintenance

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

5-5 Installing the Motherboard

Figure 5-5: The SC512 Backplate (I/O Shield)

Before installing the motherboard, be aware of the following:

The backplate holds the motherboard ports in place. Your motherboard must match

SC512 backplate. If your motherboard does not match, you must choose a different

motherboard.

Some compatible motherboards require heatsinks to lower the temperature of the

components. Heatsinks for the SC512 chassis must be rated for 1U or less.

Important Motherboard Installation Information

I/O Shield Backplate

Heatsinks

5-5

Page 36

SC512 Chassis Manual

Round head

3 x 5 mm

[0.197]

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

Round head

2.6 x 5 mm

[0.197]

Standoffs

Standoffs prevent short circuits by securing space between the motherboard and

the chassis surface. The SC512 chassis includes permanent standoffs in locations

used by most motherboards. These standoffs accept the rounded Phillips head

screws included in the SC512 accessories packaging.

Installing the Motherboard

Figure 5-6: Installing the Motherboard

Review the documentation that came with your motherboard. Become familiar 1.

with component placement, requirements, precautions, and cable connec-

tions.

Open the chassis cover.2.

Align the motherboard with the chassis standoffs and carefully, place the 3.

motherboard in the chassis. Make sure rear ports line up with the I/O shield.

Secure the motherboard to the chassis using the ten rounded, Phillips head 4.

screws supplied with the accessories kit.

Secure the CPU(s), heatsinks, and other components to the motherboard as 5.

described in the motherboard documentation. Do not exceed eight pounds of

torque when tightening down the motherboard.

Connect the cables between the motherboard, backplane, chassis, front 6.

panel, and power supply, as needed.

5-6

Page 37

Chapter 5: Chassis Setup and Maintenance

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

5-6 Installing the DVD or CD-ROM Drive

Replace these screws

DVD-ROM/CD-ROM

Drive

Replacing the DVD or CD-ROM

Hard Drive

Figure 5-7: Replace the DVD-ROM/CD-ROM Drive

Place the DVD-ROM or CD-ROM drive in the chassis above the hard drive.1.

Secure the drive with two screws. One screw is external. The other screw is 2.

internal.

5-7

Page 38

SC512 Chassis Manual

Expansion Slot Setup

SC512 chassis includes a slot for one full height/full length add-on card and a riser

card. The riser card allows the expansion card to t within the small 1U form.

The expansion card slot does not require a screw to hold the card in place.

Add-on Card Slot Latch

Expansion Card

Slot Shield

Figure 5-8: Installing the Expansion Card

Installing Expansion Cards

Disconnect the power supply, lay the chassis on a at surface, and open the 1.

chassis cover.

Slide the add-on card clip upward.2.

Slide the add-on card slot shield toward the side of the chassis and remove 3.

the Shield.

Secure the riser card to the motherboard.4.

Slide the add-on card (with "L" bracket) into the add-on card slot and the riser 5.

card.

Replace the add-on card slot clip to secure the add-on card.6.

5-8

Page 39

Chapter 5: Chassis Setup and Maintenance

5-7 Installing the Air Shroud

The air shroud helps cool the chassis by directing heated air through the rear of

the chassis. When installing the air fan, be aware of the following:

The air shroud is designed to t within the chassis. The sides of the air •

shroud should remain straight in relation to the top. Do not fold or bend the

air shroud.

The air shroud has perforated tabs that can be removed if motherboard com-•

ponents prevent proper air shroud installation. Do not remove a tab unless it

is necessary.

Incorrect Incorrect Correct

Figure 5-9: Air Shroud Placement

Perforated Tabs

Figure 5-10: Installing the Air Shroud in the SC512 Chassis

Installing The Air Shroud

Conrm that the air shroud matches your chassis model.1.

Place the air shroud in the chassis. The shroud sets directly behind the sys-2.

tem fans. If necessary, remove some perforated tabs to ensure a snug t.

5-9

Page 40

SC512 Chassis Manual

Checking the Airow in the Chassis

Make sure there are no objects to obstruct airow in and out of the server. 1.

Do not operate the server without drives or drive trays in the drive bays. Use 2.

only recommended server parts.

Make sure no wires or foreign objects obstruct air ow through the chassis. 3.

Pull all excess cabling out of the airow path or use shorter cables.

The control panel LEDs inform you of system status. See “Chapter 3: System

Interface” for details on the LEDs and the control panel buttons.

Installation Complete

In most cases, the chassis power supply and fans are pre-installed. If you need to

install fans continue to the Systems Fan section of this chapter. If the chassis will be

installed into a rack, continue to the next chapter for rack installation instructions.

5-10

Page 41

Chapter 5: Chassis Setup and Maintenance

5-8 System Fans

Three heavy duty fans provide cooling for the chassis. These fans circulate air

through the chassis as a means of lowering the chassis internal temperature.

The SC512F-280 chassis accepts two fans instead of three.

System Fan Tray

Fan Tray Support Pin

Rubber Grommet

Figure 5-11: Placing the System Fan

System Fan Tray

Systems fan trays are components that house groups of fans. The system fan tray

is held in place by two rivets permanently attached to the chassis surface. Each

rivet is encircled by a rubber grommet to reduce vibration.

5-11

Page 42

SC512 Chassis Manual

System Fan Tray Replacement

Installing the System Fan Tray

Power down the system.1.

Disconnect each fan from the motherboard.2.

Lift the system fan tray and fans from the chassis. Retain the rubber mount-3.

ings that encircle the tray rivets.

Place the fans into the new system fan tray. Make all the fans face the correct 4.

direction.

Conrm the the rubber mountings are in place around the chassis rivets.5.

Align the fan tray with rivets and place the new fan tray (and system fans) 6.

into the chassis.

Reconnect the system fans to the motherboard7.

Replacing Individual System Fans

Fans can be replaced individually without removing the system fan tray. There is

no need to power down the system when replacing a system fan.

Replacing System Fans

If necessary, open the chassis while the power is running to determine which 1.

fan has failed. (Never run the server for an extended period of time with the

chassis open.)

Remove the failed fan's power cord from the serverboard.2.

Lift the failed fan completely from the chassis.3.

Place the new fan into the vacant space. Make sure the arrows on the top of 4.

the fan (indicating air direction) point in the same direction as the arrows on

the other fan(s).

Conrm that the fan is working properly and replace the chassis cover..5.

5-12

Page 43

Chapter 5: Chassis Setup and Maintenance

5-9 Power Supply

Depending on your chassis model the SC512 chassis has a 200, 269, 280, 350,

410 or 520 Watt power supply. This power supply is auto-switching capable. This

enables it to automatically sense and operate at a 100v to 240v input voltage. An

amber light will be illuminated on the power supply when the power is off. An il-

luminated green light indicates that the power supply is operating.

Power Supply Failure

The SC512 series chassis has one power supply. In the unlikely event that the power

supply unit fails, the system will shut down and you will need to replace it.

Replacement units can be ordered directly from Supermicro (see contact information

in the preface) or an authorized reseller.

5-13

Page 44

SC512 Chassis Manual

M/B

HARD DRIVE

Pan Head

6-32 x 5mm

[0.197]

Figure 5-12: Removing the Power Supply

Replacing the Power Supply

Disconnect the power cord from the from the chassis to ensure that the unit is 1.

not accidentally plugged in.

Remove these screws

Power Supply

Remove this screw

Place the chassis on a stable hard surface and remove the chassis cover.2.

Disconnect the power supply from the motherboard and other chassis compo-3.

nents.

Remove the screws securing the power supply. Two screws are in the back 4.

of the chassis and one underneath. Retain the screws and the internal brace

that connects the power supply to the chassis from underneath.

Pull the power supply out of the chassis. 5.

Place the new power supply into the chassis and secure the power supply 6.

using the three screws and internal brace.

Connect the power supply to the motherboard and other chassis components.7.

Connect the power cord to the power supply and power up the chassis/server.8.

Once you conrm that the power supply has been installed correctly, replace 9.

the chassis cover.

5-14

Page 45

Chapter 5: Chassis Setup and Maintenance

Figure 5-13: Replacing the LED Panel

Replacing the Chassis LED Panel

In the unlikely event that the chassis LED and buttons fail, you can replace the panel.

Replacement parts can be ordered from Supermicro or an authorized reseller.

Replacing the Chassis LED Panel

Power down and unplug the system.1.

Remove the chassis cover.2.

Disconnect the cord to the front panel.3.

Locate and remove three screws holding the panel in place. (If your chassis 4.

supports dual hard drives, you may have to remove the second hard drive

from the chassis).

Install the new LED panel and secure the unit with three screws.5.

Reconnect the cables to the LED panel and if necessary, replace the hard 6.

drive.

5-15

Page 46

SC512 Chassis Manual

Notes

5-16

Page 47

Chapter 6: Rack Installation

Chapter 6

Rack Installation

6-1 Overview

This chapter provides a quick setup checklist to install the chassis into a rack.

6-2 Unpacking the System

You should inspect the box the chassis was shipped in and note if it was damaged

in any way. If the chassis itself shows damage you should le a damage claim with

the carrier who delivered it.

Decide on a suitable location for the rack unit that will hold your chassis. It should

be situated in a clean, dust-free area that is well ventilated. Avoid areas where

heat, electrical noise and electromagnetic elds are generated. You will also need

it placed near a grounded power outlet. Be sure to read the Rack and Server Pre-

cautions in the next section.

6-3 Preparing for Setup

The box your chassis was shipped in should include two sets of rail assemblies,

two rail mounting brackets and the mounting screws you will need to install the

system into the rack. Please read this section in its entirety before you begin the

installation procedure outlined in the sections that follow.

Choosing a Setup Location

Leave enough clearance in front of the rack to enable you to open the front •

door completely (~25 inches).

Leave approximately 30 inches of clearance in the back of the rack to allow for •

sufcient airow and ease in servicing.

This product is for installation only in a Restricted Access Location (dedicated •

equipment rooms, service closets and the like).

6-1

Page 48

SC512 Chassis Manual

!

!

Warnings and Precautions!

Rack Precautions

Ensure that the leveling jacks on the bottom of the rack are fully extended to •

the oor with the full weight of the rack resting on them.

In single rack installation, stabilizers should be attached to the rack.•

In multiple rack installations, the racks should be coupled together.•

Always make sure the rack is stable before extending a component from the •

rack.

You should extend only one component at a time - extending two or more si-•

multaneously may cause the rack to become unstable.

General Server Precautions

Review the electrical and general safety precautions that came with the com-•

ponents you are adding to your chassis.

Determine the placement of each component in the rack • before you install the

rails.

Install the heaviest server components on the bottom of the rack rst, and then •

work up.

Use a regulating uninterruptible power supply (UPS) to protect the server from •

power surges, voltage spikes and to keep your system operating in case of a

power failure.

Allow the hot plug hard drives and power supply modules to cool before touch-•

ing them.

Always keep the rack's front door and all panels and components on the servers •

closed when not servicing to maintain proper cooling.

6-2

Page 49

Chapter 6: Rack Installation

Rack Mounting Considerations

Ambient Operating Temperature

If installed in a closed or multi-unit rack assembly, the ambient operating tempera-

ture of the rack environment may be greater than the ambient temperature of the

room. Therefore, consideration should be given to installing the equipment in an

environment compatible with the manufacturer’s maximum rated ambient tempera-

ture (Tmra).

Reduced Airow

Equipment should be mounted into a rack so that the amount of airow required

for safe operation is not compromised.

Mechanical Loading

Equipment should be mounted into a rack so that a hazardous condition does not

arise due to uneven mechanical loading.

Circuit Overloading

Consideration should be given to the connection of the equipment to the power

supply circuitry and the effect that any possible overloading of circuits might have

on overcurrent protection and power supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

Reliable Ground

A reliable ground must be maintained at all times. To ensure this, the rack itself

should be grounded. Particular attention should be given to power supply connec-

tions other than the direct connections to the branch circuit (i.e. the use of power

strips, etc.).

6-3

Page 50

SC512 Chassis Manual

6-4 Rack Mounting Instructions

This section provides information on installing the SC512 chassis into a rack unit

with the rails provided. There are a variety of rack units on the market, which

may mean the assembly procedure will differ slightly. You should also refer to the

installation instructions that came with the rack unit you are using.

NOTE: The SC512F-280/350/410/520/600 chassis models are designed with a

wider chassis. The rails for these chassis will t a rack between 25.6" and 33.05"

deep. The following shows how to mount these chassis to a standard rack.

Identifying the Sections of the Rack Rails (Optional Item)

The chassis package includes two rack rail assemblies in the rack mounting kit.

Each assembly consists of two sections: an inner xed chassis rail that secures

directly to the server chassis, and an outer xed rack rail that secures directly to

the rack itself.

The SC512F comes with "chassis ears" that allow the chassis to use generic

rails.

Chassis Ears

Inner Rails

Outer Rails

Figure 6-1: Identifying the Sections of the Rack Rails

(Right side rail shown)

6-4

Page 51

Chapter 6: Rack Installation

Flat head

M4 x 4 mm

[0.157]

RAIL

Round head

M4 x 4 mm

[0.157]

Flat head

M5 x 12 mm [0.472]

DVD-ROM CD-ROM FLOPPY DRIVE

Flat head

6-32 x 5 mm

[0.197]

Pan head

6-32 x 5 mm

[0.197]

Round head

3 x 5 mm

[0.197]

Pan head

6-32 x 5 mm

[0.197]

M/B

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

Round head

2.6 x 5 mm

[0.197]

Installing the Inner Rail Extension

The SC512F includes chassis ears that you must remove before installing the

rails.

Removing the Chassis Ears

Locate and remove the three screws holding the chassis ear in place.1.

Repeat step on with the other chassis ear.2.

Installing the Inner Rails

Place the inner rail on the side of the chassis aligning the hooks of the chas-1.

sis with the rail holes.

Slide the rail toward the front of the chassis to secure the rail in place.2.

Secure the chassis with four screws.3.

Repeat steps 1-3 for the other inner rail extension.4.

Figure 6-2: Installing Inner Rails to the Chassis

6-5

Page 52

SC512 Chassis Manual

Flat head

M5 x 12 mm [0.472]

Washer for M5

Flat head

6-32 x 5 mm

[0.197]

Round head

2.6 x 5 mm

[0.197]

Secure to the

Front of the Rack

Secure to the

Rear of the Rack

Attach Outer Racks

together

Figure 6-3: Assembling the Outer Rails

Installing the Outer Rails to the Rack

Installing the Outer Rails

Attach the short bracket to the outside of the long bracket. You must align the 1.

pins with the slides. Also, both bracket ends must face the same direction.

Adjust both the short and long brackets to the proper distance so that the rail 2.

ts snugly into the rack.

Secure the long bracket to the front side of the outer rail with two M5 screws 3.

and the short bracket to the rear side of the outer rail with three M5 screws.

Use a washer with each screw.

Repeat steps 1-4 for the left outer rail.4.

6-6

Page 53

Chapter 6: Rack Installation

3

1

3

1

2

1

Figure 6-4: Installing the Outer Rails to the Server Rack

6-7

Page 54

SC512 Chassis Manual

Figure 6-5: Installing the Chassis into a Rack

Installing the Chassis into a Rack

Installing the Chassis

Conrm that the inner rails are attached to the chassis. Also, conrm that the 1.

outer rails are installed on the rack.

Align chassis rails with the front of the rack rails.2.

Slide the chassis rails into the rack rails, keeping the pressure even on both 3.

sides (you may have to depress the locking tabs when inserting). When the

server has been pushed completely into the rack, you should hear the locking

tabs "click" into the locked position.

(Optional) Insert and tightening the thumbscrews that hold the front of the 4.

server to the rack.

6-8

Page 55

Chapter 6: Rack Installation

Flat head

M4 x 4 mm

[0.157]

RAIL

Round head

M4 x 4 mm

[0.157]

Flat head

M5 x 12 mm [0.472]

DVD-ROM CD-ROM FLOPPY DRIVE

Flat head

6-32 x 5 mm

[0.197]

Pan head

6-32 x 5 mm

[0.197]

Round head

3 x 5 mm

[0.197]

Pan head

6-32 x 5 mm

[0.197]

M/B

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

Round head

2.6 x 5 mm

[0.197]

Mid-Mount Telco Rack

The SC512.supports Telco rack installation. The SC512 chassis compact design

allows the chassis to be installed into a Telco rack without the use of rails.

Place chassis

ears here

Figure 6-6: Moving the Chassis Ears for Telco Rack Installation

Installing the Chassis into a Rack in Mid-Mount Position

Instaling into a Mid-Mount Position Rack

If it is necessary to install the chassis in a mid-mount Telco rack, remove the 1.

chassis rails and the chassis ears (if the ears are installed at the front of the

chassis).

Locate the three screw holes in the middle of the chassis and secure the ears 2.

to the chassis with three at head screws. Make sure the screws are secure,

but do not over tighten the screws.

6-9

Page 56

SC512 Chassis Manual

SCALE 1:2

SCALE 1:2

Flat head

M5 x 12 mm [0.472]

Washer for M5

Flat head

6-32 x 5 mm

[0.197]

Round head

2.6 x 5 mm

[0.197]

Hold the chassis in the telco rack and screw the chassis to the rack using the 3.

three screw holes located in the chassis ears.

The chassis is held in place by the chassis ears and does not slide in and out 4.

of place.

Figure 6-7: Installing the Server into a Telco Rack

6-10

Page 57

Appendix A: SC512 Chassis Cables

Appendix A

Cables, Screws,

and Other Accessories

A-1 Overview

This appendix lists supported cables for your chassis system. It only includes the

most commonly used components and congurations. For more compatible cables,

refer to the manufacturer of the motherboard you are using and our Web site at:

www.supermicro.com.

A-2 Cables Included with SC512 Chassis

SC512-200 and SC512-260

Part # Type Length Description

CBL-0049L Cable Front cable 16-pin to 16-pin

CBL-0084L Wire 9 cm DVD cable (lead free).

CBL-0260L US power cord 18 AWG

CBL-0261L Cable 40cm 40cm 7-pin SATA cable S-RA

CBL-0262L Cable

CBL-0263L Cable 77cm 9-pin to 9-pin internal USB cable

4-pin to 1x SATA (RA) + 1x 4-pin

(RA) + 1x FPD PWS

SC512F-260

Part # Type Length Description

CBL-0049L Cable Front cable 16-pin to 16-pin

CBL-0084L Wire 9 cm DVD cable (lead free).

CBL-0260L US power cord 18 AWG

CBL-0262L Cable

CBL-0263L Cable 77cm 9-pin to 9-pin internal USB cable

4-pin to 1x SATA (RA) + 1x 4-pin

(RA) + 1x FPD PWS

A-1

Page 58

SC512 Chassis Manual

SC512F-280

Part # Type Length Description

CBL-0142L Cable 30 cm (~12")

CBL-0156L Cable 40 cm 16-pin to 16-pin FP cable. Lead free.

CBL-0084L Wire 9 cm DVD cable. Lead free.

- Cable 6' Regional power cord

SC512F-350

Part # Type Length Description

CBL-0142L Cable 30cm 7-pin 2-side SATA RA-RA cable

CBL-0156L Cable 40cm Front ctrl cable round 16 to 16-pin

CBL-0260L Cord 6 feet US power cord 18AWG

CBL-0261L Cable 40cm 7pin SATA cable S-RA

CBL-0262L Cable -

SC512F-410

Part # Type Length Description

CBL-0142L Cable 30 cm (~12")

CBL-0156L Cable 40 cm 16-pin to 16-pin FP cable. Lead free.

CBL-0084L Wire 9 cm DVD cable. Lead free.

7-pin SATA with two 90 degree side

connectors (lead free).

4-pin to 1x SATA (RA) + 1x4-pin

(RA) + 1x FPD PWS EXT. cable

7-pin SATA with two 90 degree side

connectors (lead free).

SC512F-520

Part # Type Length Description

CBL-0142L Cable 30 cm (~12")

CBL-0156L Cable 40 cm 16 pin to 16 pin FP cable. Lead free.

CBL-0084L Wire 9 cm DVD Cable. Lead free.

- Cable 6' Regional power cord

SC512F-600

Part # Type Length Description

CBL-0142L Cable 30 cm (~12")

CBL-0156L Cable 40 cm

- Cable 6' Regional power cord

7-pin SATA with two 90 degree side

connectors (lead free).

7-pin SATA with two 90 degree side

connectors (lead free).

16-pin to 16-pin FP Cable. Lead

Free.

A-2

Page 59

Appendix A: SC512 Chassis Cables

SC512F-520L and SC512F-600L

Part # Type Length Description

CBL-0142L Cable 30 cm (~12")

CBL-0156L Cable 40 cm

- Cable 6' Regional power cord

SC512L-200 and SC512L-260

Part # Type Length Description

CBL-0049L Cable Front cable 16-pin to 16-pin

CBL-0084L Wire 9 cm DVD cable (lead free).

CBL-0260L US power cord 18 AWG

CBL-0261L Cable 40cm 40cm 7-pin SATA cable S-RA

CBL-0262L Cable

CBL-0263L Cable 77cm 9-pin to 9-pin internal USB cable

SC512L-260-LCD

Part # Type Length Description

CBL-0049 Cable 9 cm 16-pin to 16-pin ribbon cable

CBL-0121 USB 2.0 10-pin to 4-pin cable for LCD

7-pin SATA with two 90 degree side

connectors (lead free).

16-pin to 16-pin FP Cable. Lead

Free.

4-pin to 1x SATA (RA) + 1x 4-pin

(RA) + 1x FPD PWS

A-3

Page 60

SC512 Chassis Manual

Extending Power Cables

Although Supermicro chassis are designed with to be efcient and cost-effective,

some compatible motherboards have power connectors located in different areas.

To use these motherboards you may have to extend the power cables to the mother

boards. To do this, use the following chart as a guide.

Power Cable Extenders

Number of Pins Cable Part # Length

24-pin CBL-0042 7.9”(20 CM)

20-pin CBL-0059 7.9”(20 CM)

8-pin CBL-0062 7.9”(20 CM)

4-pin CBL-0060 7.9”(20 CM)

Front Panel to the Motherboard

The SC512 chassis includes a cable to connect the chassis front panel to the

motherboard. If your motherboard uses a different connector, use the following list

to nd a compatible cable.

Front Panel to Motherboard Cable (Ribbon Cable)

Number of Pins

(Front Panel)

16-pin 16-pin CBL-0049

16-pin 20-pin CBL-0048

20-pin 20-pin CBL-0047

16-pin varies* CBL-0068

20-pin varies* CBL-0067

Number of Pins

(Motherboard)

Cable Part #

* Split cables: Use these cable if your motherboard requires several different con-

nections from the front panel.

A-4

Page 61

Appendix A: SC512 Chassis Cables

RIGHT MIDDLE BRACKET

MIDDLE BRACKET

FA N

PWR

SATA PWR

(RIGHT ANGLE)

SATA PWR

(RIGHT ANGLE)

S AT A

(STRAIGHT)

HDD

HDD

LEFT

S AT A

(RIGHT ANGLE)

MB SATA

PORTS

MOTHERBOARD

AREA

A-3 Routing the Chassis Cables

In order for the SC512 chassis to perform safely and efciently, it is important that the

cables are routed correctly. Follow the instructions below and review both the cabling

diagram and photograph to ensure that the cabling has been properly routed.

Preparing the Chassis for Cable Routing

Unplug the chassis from any power source.1.

Review the diagram on the following page, taking note of the naming of each 2.

cable.

Remove the screws securing the fan platform to the bottom of the chassis.3.

1C

1

1A

1

2C

1

2B

1

2A

1

Figure A-1: Chassis Cable Routing Diagram (SC512L-200/260)

4A

1

3B

1

3A

1

A-5

1B

3C

1

5A

1

1

Page 62

SC512 Chassis Manual

Routing Cable (1A) from Hard Drive (1B)

Plug cable (1A) into the SATA port of hard drive (1B).1.

Lift up the fan and run cable (1A) straight out from the port and under the fan.2.

Route cable (1A) over the hard drive and through the left middle bracket.3.

Plug cable (1A) into upper SATA port (1C) on the motherboard.4.

Routing Cable (2A) from Hard Drive (2B)

Plug cable (2A) into the SATA port of hard drive (2B).1.

Run cable (2A) upwards at a right angle, up and over the top of hard drive 2.

(2B).

Route cable (2A) through the left middle bracket.3.

Plug cable (2A) into lower SATA port (2C) on the motherboard.4.

Routing Split Cable (3A)(4A) from Hard Drives (1B)(2B) to the Power Supply

Plug the end of the split cable (3A) into hard drive (2B).1.

Route the end of the split cable (3A) straight up at a right angle, beside the 2.

fan, and over the top of cable (1A).

Plug the end of the split cable (3A) into connector (3B).3.

Plug the other end of the split cable (4A) into hard drive (1B). 4.

Route the end of the split cable (4A) straight up at a right angle, along the top 5.

of the fan.

Route cable (5A) through the right middle bracket and plug it into connector 6.

(3B).

A-6

Page 63

Appendix A: SC512 Chassis Cables

Checking the Cable Routing

Check the cable routing by following out each cable in the previous steps and 1.

comparing them to the diagram in Figure A-1, and the photograph in Figure

A-2.

Figure A-2: Chassis Cable Routing

A-7

Page 64

SC512 Chassis Manual

Flat head

M4 x 4 mm

[0.157]

RAIL

Round head

M4 x 4 mm

[0.157]

Flat head

M5 x 12 mm [0.472]

Washer for M5

DVD-ROM CD-ROM FLOPPY DRIVE

Flat head

6-32 x 5 mm

[0.197]

Pan head

6-32 x 5 mm

[0.197]

Round head

3 x 5 mm

[0.197]

Pan head

6-32 x 5 mm

[0.197]

M/B

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

Thumb screw

6-32 x 5 mm [0.197]

M/B standoff

6-32 to 6-32

M/B STANDOFF

M/B (CPU) standoff

M5 to 6-32

Round head

2.6 x 5 mm

[0.197]

A-4 Chassis Screws

The Chassis and accessory box include all the screws needed to setup your

chassis. This section include descriptions of the most common screws used. Your

chassis may not require all the parts listed.

Figure A-3: Chassis Screws

A-8

Page 65

Appendix B: SC512F Power Supply Specications

Appendix B

Power Supply Specications

This appendix lists power supply specications for your chassis system.

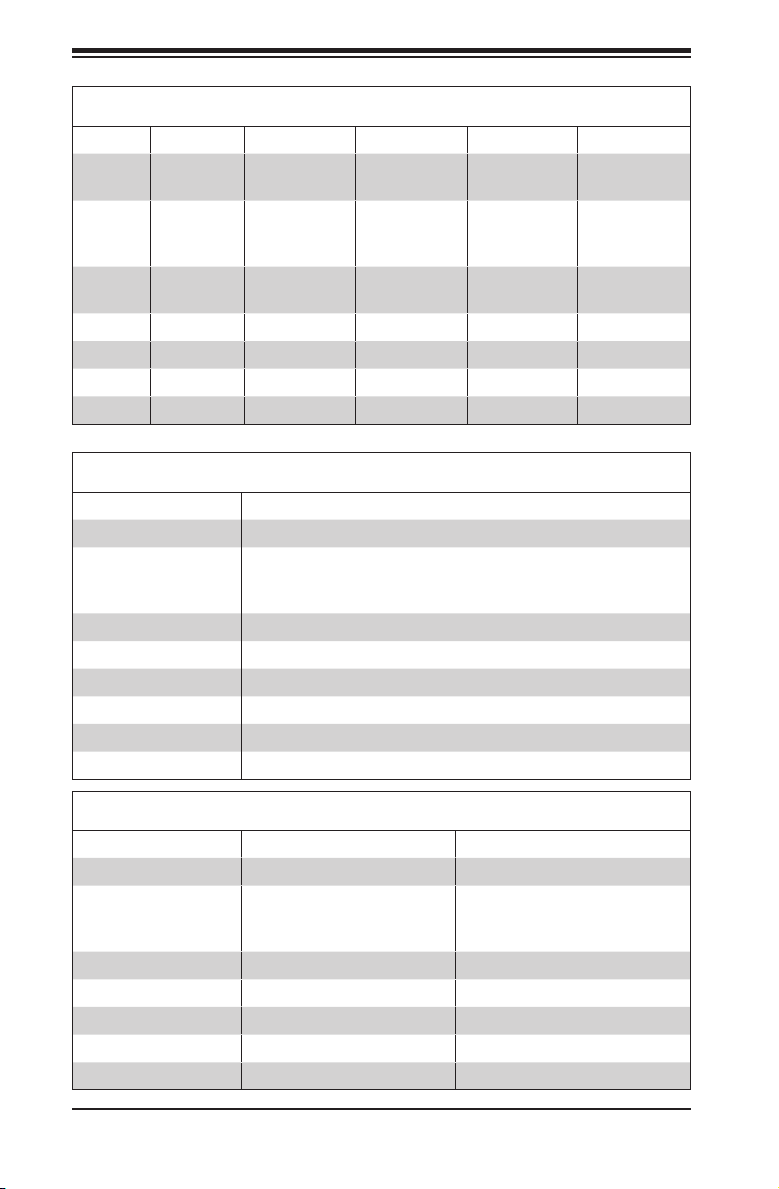

SC512 Chassis Model

200 260

MFR Part # PWS-201-1H PWS-0055

Rated AC Voltage

+5V standby 2.0A 2.0A

100 - 240V

50 - 60Hz

4 - 2A Max

+12V 16.0A 18.0A

+5V 8.0A 25.0A

+3.3V 8.0A 15.0A

-12V 0.5A 1.0A

100 - 240V

60 - 50Hz

4A Max

SC512C Chassis Models

200 260

MFR Part # PWS-0043 PWS-0055

Rated AC Voltage

+5V standby 2.0A 2.0A

100 - 240V

60 - 50Hz

5 - 3A

+12V 12.0A 18.0A

+5V 20A 25.0A

+3.3V 17.0 A 15.0A

-12V 0.8A 1.0A

100 - 240V

60 - 50Hz

4A Max

B-1

Page 66

SC512 Chassis Manual

SC512F Chassis Models (See below for 410 model)

260 280 350 520/520L 600/600L

MFR

Part #

Rated

AC

Voltage

standby

MFR Part # PWS-0061

DC Voltage

PWS-0055 PWS-281-1H PWS-351-1H PWS-521-1H PWS-601-1H

100 - 240V

60 - 50Hz

4A Max

+5V

2.0A 2A 3A 3A 3A

+12V 18.0A 23A 29A 39A 49A

+5V 25.0A 18A 18A 20A 20A

+3.3V 15.0A 15A 15A 16A 16A

-12V 1.0A 1A - 0.5A 0.5A

DC Output 5V + 3.3V ≤ 180W

+5V standby 3.0A

100 - 240V

50 - 60Hz

5A Max

SC512F-410 Chassis Model

Voltage Range = -36V to -72V

Nominal Voltage = -48V

Max Input Current = 18A @ -48V

+5V 35.0A

+12V 32.0A

-12V 0.5A

+3.3V 20.0A

100-240 V,

50-60 Hz,

4.2 - 1.8A

100 - 240V

50 - 60Hz

7 - 3A

410

100 - 240V

50 - 60Hz

7.5 - 3.1A

SC512L Chassis Models

200 260/260-LCD

MFR Part # PWS-0043 PWS-0055

Rated AC Voltage

+5V standby 2.0A 2.0A

100 - 240V

60 - 50Hz

5-3A

+12V 12.0A 18.0A

+5V 20A 25.0A

+3.3V 17.0A 15.0A

-12V 0.8A 1.0A

100 - 240V

60 - 50Hz

4A Max

B-2

Page 67

Appendix B: SC512F Power Supply Specications

Notes

B-3

Page 68

SC512 Chassis Manual

The products sold by Supermicro are not intended for and will not be used in life support systems, medical equipment, nuclear facilities or systems, aircraft, aircraft devices,

aircraft/emergency communication devices or other critical systems whose failure to per-

form be reasonably expected to result in signicant injury or loss of life or catastrophic

property damage. Accordingly, Supermicro disclaims any and all liability, and should

buyer use or sell such products for use in such ultra-hazardous applications, it does so

entirely at its own risk. Furthermore, buyer agrees to fully indemnify, defend and hold

Supermicro harmless for and against any and all claims, demands, actions, litigation,

and proceedings of any kind arising out of or related to such ultra-hazardous use or

sale.

Disclaimer (cont.)

B-4

Loading...

Loading...