Page 1

C7C232-CB-ML

USER’S MANUAL

Revision 1.0

Page 2

The information in this User’s Manual has been carefully reviewed and is believed to be accurate. The vendor assumes

no responsibility for any inaccuracies that may be contained in this document, and makes no commitment to update

or to keep current the information in this manual, or to notify any person or organization of the updates. Please Note:

For the most up-to-date version of this manual, please see our website at www.supermicro.com.

Super Micro Computer, Inc. ("Supermicro") reserves the right to make changes to the product described in this manual

at any time and without notice. This product, including software and documentation, is the property of Supermicro and/

or its licensors, and is supplied only under a license. Any use or reproduction of this product is not allowed, except

as expressly permitted by the terms of said license.

IN NO EVENT WILL Super Micro Computer, Inc. BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO USE THIS PRODUCT

OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN PARTICULAR, SUPER

MICRO COMPUTER, INC. SHALL NOT HAVE LIABILITY FOR ANY HARDWARE, SOFTWARE, OR DATA STORED

OR USED WITH THE PRODUCT, INCLUDING THE COSTS OF REPAIRING, REPLACING, INTEGRATING,

INSTALLING OR RECOVERING SUCH HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa Clara County in the

State of California, USA. The State of California, County of Santa Clara shall be the exclusive venue for the resolution

of any such disputes. Supermicro's total liability for all claims will not exceed the price paid for the hardware product.

FCC Statement: This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the manufacturer’s instruction manual,

may cause harmful interference with radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference, in which case you will be required to correct the interference at your own expense.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate warning applies only

to products containing CR (Manganese Dioxide) Lithium coin cells. “Perchlorate Material-special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate”.

WARNING: Handling of lead solder materials used in this product may expose you to lead, a

chemical known to the State of California to cause birth defects and other reproductive harm.

The products sold by Supermicro are not intended for and will not be used in life support systems, medical equipment,

nuclear facilities or systems, aircraft, aircraft devices, aircraft/emergency communication devices or other critical

systems whose failure to perform be reasonably expected to result in signicant injury or loss of life or catastrophic

property damage. Accordingly, Supermicro disclaims any and all liability, and should buyer use or sell such products

for use in such ultra-hazardous applications, it does so entirely at its own risk. Furthermore, buyer agrees to fully

indemnify, defend and hold Supermicro harmless for and against any and all claims, demands, actions, litigation, and

proceedings of any kind arising out of or related to such ultra-hazardous use or sale.

Manual Revision 1.0

Release Date: May 30, 2017

Unless you request and receive written permission from Super Micro Computer, Inc., you may not copy any part of this

document. Information in this document is subject to change without notice. Other products and companies referred

to herein are trademarks or registered trademarks of their respective companies or mark holders.

Copyright © 2017 by Super Micro Computer, Inc.

All rights reserved.

Printed in the United States of America

Page 3

Preface

Preface

About This Manual

This manual is written for system integrators, IT technicians and knowledgeable end users.

It provides information for the installation and use of the C7C232-CB-ML motherboard.

About This Motherboard

The Supermicro® C7C232-CB-ML motherboard supports an Intel® Xeon E3-1200 V5

and 6th Generation Core i3i5/i7 processor in an LGA 1151 socket. With support of the

Intel C232 chipset, DDR4 memory, SATA 3.0, and Trusted Platform Module (TPM), this

motherboard offers exceptional performance for desktop platforms. It also provides securityenhancing technologies such as Intel vPro, Intel Trusted Execution Technology, and Trusted

Platform module. Please note that this motherboard is intended to be installed and serviced

by professional technicians only. For processor/memory updates, please refer to our website

at http://www.supermicro.com/products/.

Conventions Used in the Manual

Special attention should be given to the following symbols for proper installation and to prevent

damage done to the components or injury to yourself:

Warning! Indicates important information given to prevent equipment/property damage

or personal injury.

Warning! Indicates high voltage may be encountered when performing a procedure.

Important: Important information given to ensure proper system installation or to

relay safety precautions.

Note: Additional Information given to differentiate various models or provides information for correct system setup.

3

Page 4

C7C232-CB-ML User's Manual

Contacting Supermicro

Headquarters

Address: Super Micro Computer, Inc.

980 Rock Ave.

San Jose, CA 95131 U.S.A.

Tel: +1 (408) 503-8000

Fax: +1 (408) 503-8008

Email: marketing@supermicro.com (General Information)

support@supermicro.com (Technical Support)

Website: www.supermicro.com

Europe

Address: Super Micro Computer B.V.

Het Sterrenbeeld 28, 5215 ML

's-Hertogenbosch, The Netherlands

Tel: +31 (0) 73-6400390

Fax: +31 (0) 73-6416525

Email: sales@supermicro.nl (General Information)

support@supermicro.nl (Technical Support)

rma@supermicro.nl (Customer Support)

Website: www.supermicro.nl

Asia-Pacic

Address: Super Micro Computer, Inc.

3F, No. 150, Jian 1st Rd.

Zhonghe Dist., New Taipei City 235

Taiwan (R.O.C)

Tel: +886-(2) 8226-3990

Fax: +886-(2) 8226-3992

Email: support@supermicro.com.tw

Website: www.supermicro.com.tw

4

Page 5

Preface

Table of Contents

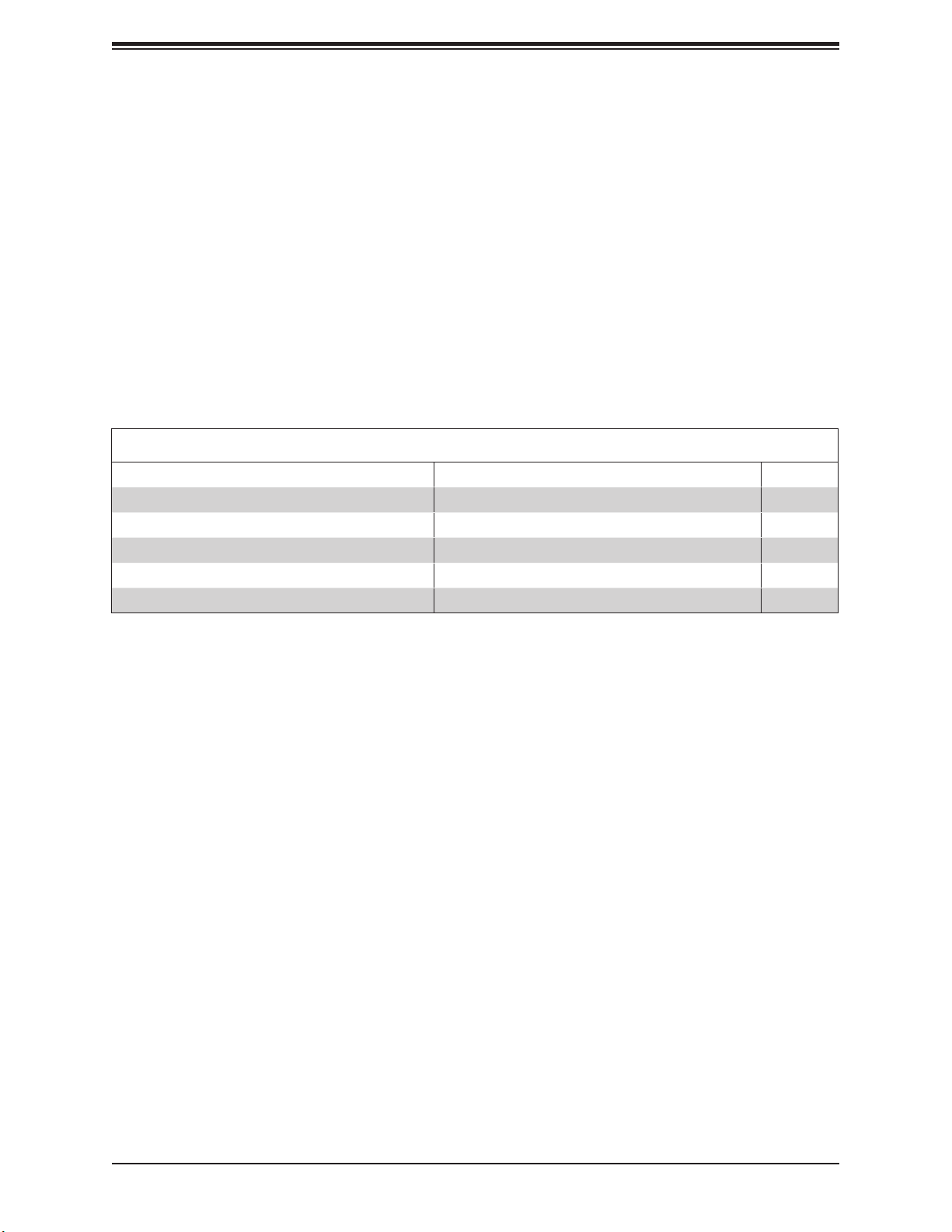

Chapter 1 Introduction

1.1 Checklist ...............................................................................................................................8

Quick Reference ...............................................................................................................11

Quick Reference Table ......................................................................................................12

Motherboard Features .......................................................................................................13

1.2 Processor and Chipset Overview .......................................................................................17

1.3 Special Features ................................................................................................................17

Recovery from AC Power Loss .........................................................................................17

1.4 System Health Monitoring ..................................................................................................18

Onboard Voltage Monitors ................................................................................................18

Fan Status Monitor with Firmware Control .......................................................................18

Environmental Temperature Control .................................................................................18

System Resource Alert......................................................................................................18

1.5 ACPI Features ....................................................................................................................19

1.6 Power Supply .....................................................................................................................19

1.7 Super I/O ............................................................................................................................19

1.8 Advanced Power Management ..........................................................................................20

Intel® Intelligent Power Node Manager (IPNM).................................................................20

Management Engine (ME) ................................................................................................20

Chapter 2 Installation

2.1 Static-Sensitive Devices .....................................................................................................21

Precautions .......................................................................................................................21

Unpacking .........................................................................................................................21

2.2 Motherboard Installation .....................................................................................................22

Tools Needed ....................................................................................................................22

Location of Mounting Holes ..............................................................................................22

Installing the Motherboard.................................................................................................23

2.3 Processor and Heatsink Installation ...................................................................................24

Installing the LGA1151 Processor .....................................................................................24

Installing an Active CPU Heatsink with Fan .....................................................................27

Removing the Heatsink .....................................................................................................29

5

Page 6

C7C232-CB-ML User's Manual

2.4 Memory Support and Installation .......................................................................................30

Memory Support ................................................................................................................30

DIMM Module Population Conguration ...........................................................................30

DIMM Module Population Sequence ................................................................................30

DIMM Installation ..............................................................................................................31

DIMM Removal .................................................................................................................31

2.5 Rear I/O Ports ....................................................................................................................32

2.6 Connectors .........................................................................................................................36

Power Connections ...........................................................................................................36

2.7 Front Control Panel ............................................................................................................38

Headers .............................................................................................................................41

2.8 Jumper Settings .................................................................................................................47

How Jumpers Work ...........................................................................................................47

Chapter 3 Troubleshooting

3.1 Troubleshooting Procedures ..............................................................................................49

Before Power On ..............................................................................................................49

No Power ..........................................................................................................................49

No Video ...........................................................................................................................50

System Boot Failure .......................................................................................................50

Memory Errors ..................................................................................................................50

Losing the System's Setup Conguration .........................................................................51

When the System Becomes Unstable ..............................................................................51

3.2 Technical Support Procedures ...........................................................................................53

3.3 Frequently Asked Questions ..............................................................................................54

3.4 Battery Removal and Installation .......................................................................................55

Battery Removal ................................................................................................................55

Proper Battery Disposal ....................................................................................................55

Battery Installation .............................................................................................................55

3.5 Returning Merchandise for Service ....................................................................................56

Chapter 4 BIOS

4.1 Introduction .........................................................................................................................57

Starting the Setup Utility ...................................................................................................57

6

Page 7

Preface

4.2 Main Setup .........................................................................................................................58

4.3 Advanced Setup Congurations .........................................................................................61

4.4 Chipset ...............................................................................................................................80

4.5 Security ...............................................................................................................................91

4.6 Boot ....................................................................................................................................94

4.7 Save & Exit .........................................................................................................................95

Appendix A BIOS Codes

Appendix B Software Installation

B.1 Installing Software Programs .............................................................................................99

B.2 SuperDoctor® 5 .................................................................................................................100

Appendix C Standardized Warning Statements

Battery Handling ..............................................................................................................101

Product Disposal .............................................................................................................103

Appendix D UEFI BIOS Recovery

7

Page 8

C7C232-CB-ML User's Manual

Chapter 1

Introduction

Congratulations on purchasing your computer motherboard from an industry leader. Supermicro

boards are designed to provide you with the highest standards in quality and performance.

In additon to the motherboard, several important parts that are included with the system are

listed below. If anything listed is damaged or missing, please contact your retailer.

1.1 Checklist

Main Parts List

Description Part Number Quantity

Supermicro Motherboard C7C232-CB-ML 1

SATA Cables 2

I/O Shield 1

Important Links

For your system to work properly, please follow the links below to download all necessary

drivers/utilities and the user’s manual for your server.

• Supermicro product manuals: http://www.supermicro.com/support/manuals/

• Product drivers and utilities: ftp://ftp.supermicro.com

• Product safety info: http://www.supermicro.com/about/policies/safety_information.cfm

• If you have any questions, please contact our support team at: support@supermicro.com

This manual may be periodically updated without notice. Please check the Supermicro website

for possible updates to the manual revision level.

8

Page 9

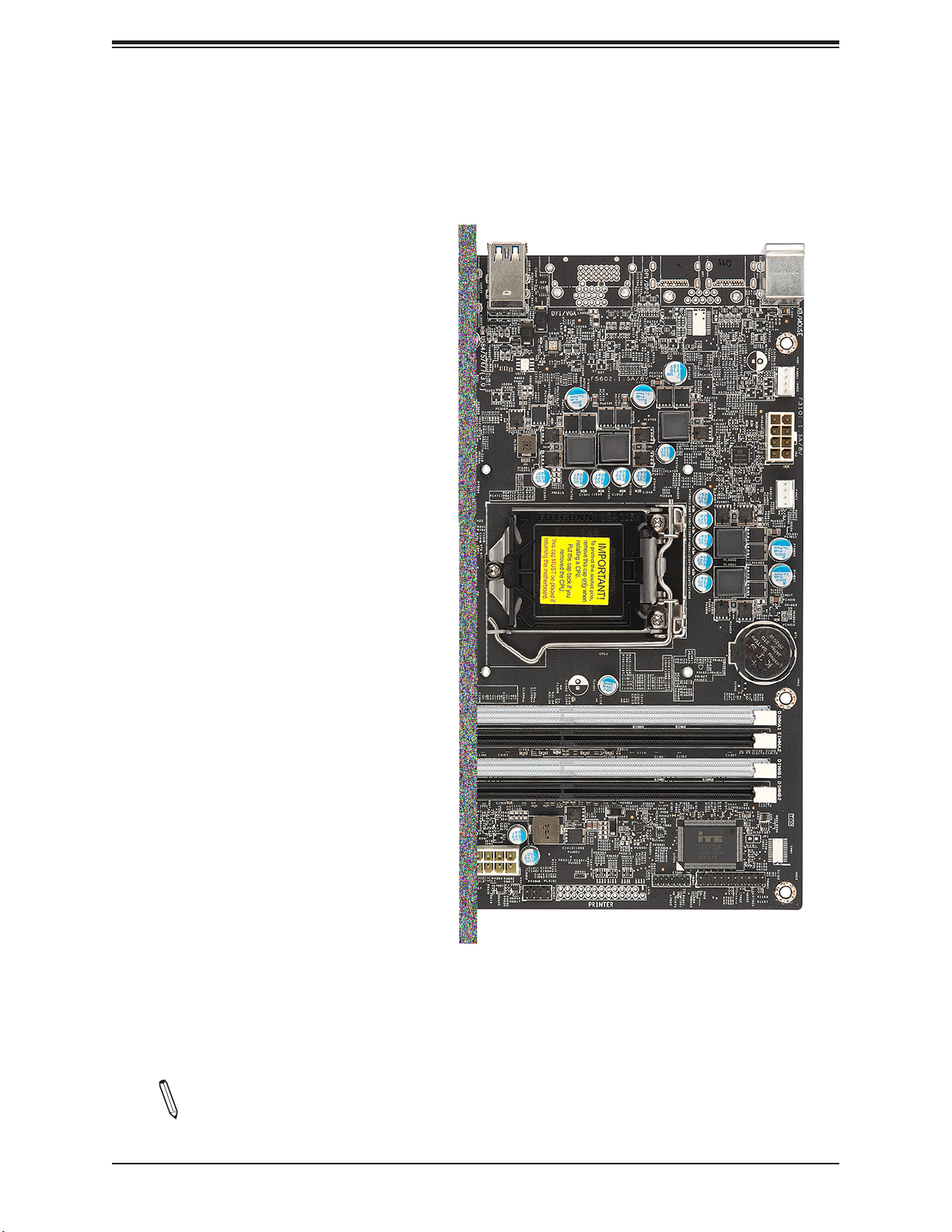

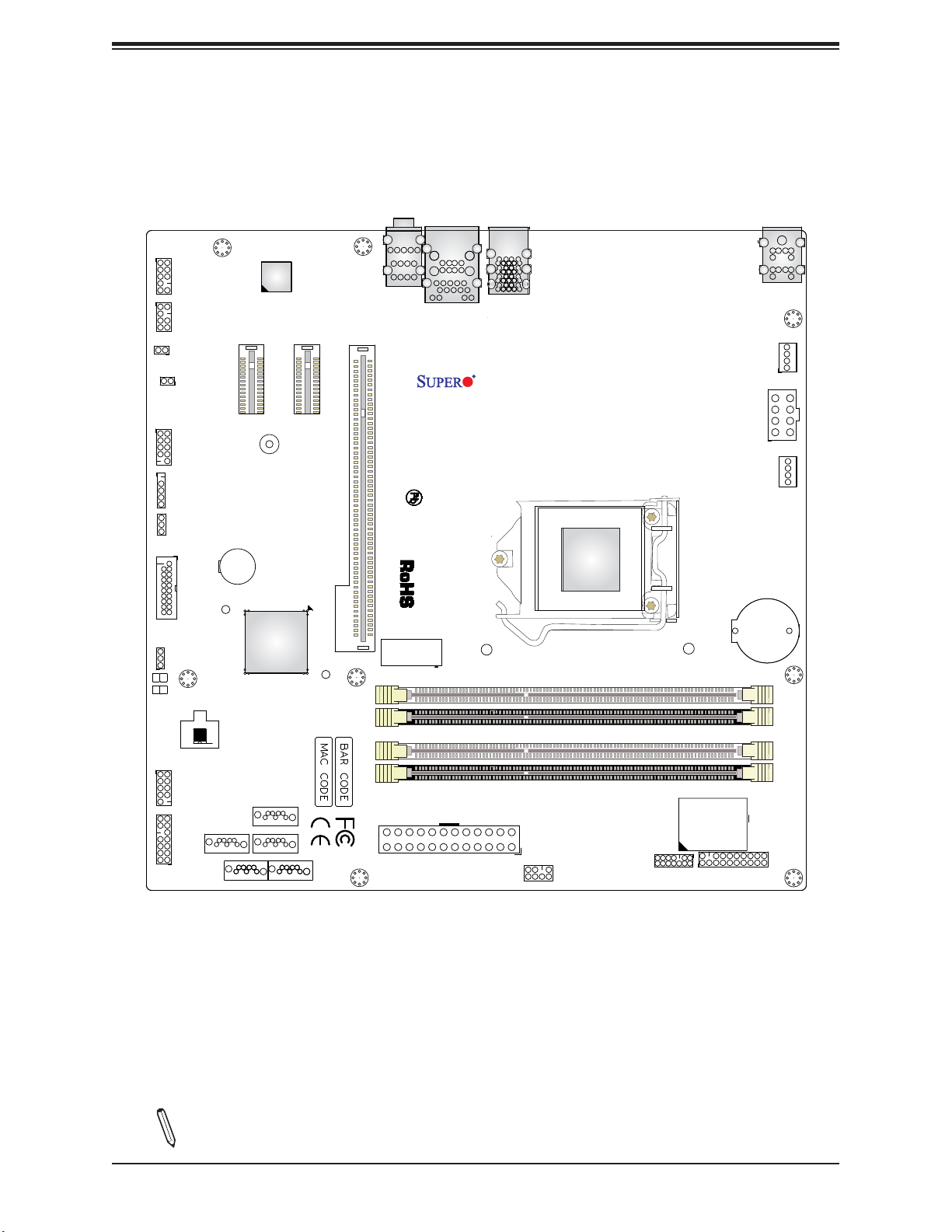

Figure 1-1. C7C232-CB-ML Motherboard Image

Chapter 1: Introduction

Note: All graphics shown in this manual were based upon the latest PCB revision

available at the time of publication of the manual. The motherboard you received may

or may not look exactly the same as the graphics shown in this manual.

9

Page 10

C7C232-CB-ML User's Manual

AUDF1 SPK1

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

USB3F1

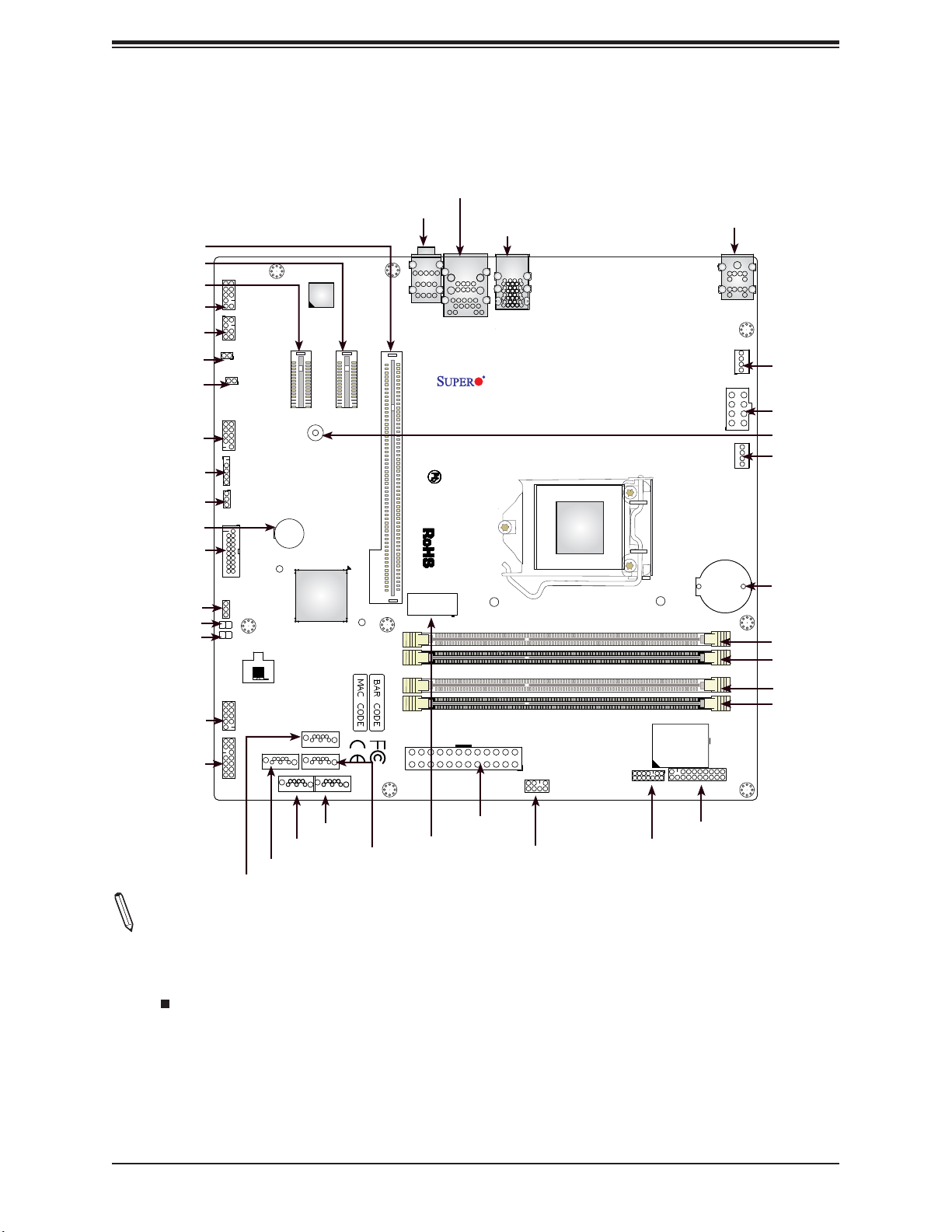

Figure 1-2. C7C232-CB-ML Motherboard Layout

PCH SLOT5 PCI-E 3.0 X1

PCH SLOT6 PCI-E 3.0 X1

HS1

(not drawn to scale)

AUDIO

USB0/1

LAN1

CPU SLOT7 PCI-E 3.0 X16

USB4/5/6/7

(3.0)

C7C232-CB-ML

Rev. 1.00

CPU

KB/MOUSE

FANS1

FANS2

CN2

FANC1

CMOS1

COM1

LEDH1

GPIO2

GPIO1

BUZ1

I-SATA4

I-SATA1

PCH

I-SATA5

I-SATA3

I-SATA0

NGFFB1

CN1

PCHDR1

DBGH1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

TPMH1

Note: Components not documented are for internal testing only.

10

Page 11

Quick Reference

SLOT7

SLOT6

SLOT5

AUDF1

CSOPN1

OBR1

USB2/3

USB8/9

(3.0)

CMOS1

GPIO2

GPIO1

COM1

LEDH1

SPK1

CRF1

WP1

BUZ1

AUDF1 SPK1

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

LEDH1

PCH SLOT5 PCI-E 3.0 X1

BUZ1

I-SATA4

I-SATA1

PCH SLOT6 PCI-E 3.0 X1

HS1

PCH

I-SATA5

I-SATA3

I-SATA0

USB0/1

LAN1

AUDIO

AUDIO

CPU SLOT7 PCI-E 3.0 X16

NGFFB1

USB4/5/6/7

(3.0)

USB4/5/6/7

USB0/1

(3.0)

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

PCHDR1

CPU

Chapter 1: Introduction

KB/MOUSE

KB/MOUSE

DBGH1

TPMH1

FANS1

FANS2

CN2

FANC1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

FANS1

FANS2

CN2

HS1

FANC1

BT1

DIMMA1

DIMMA2

DIMMA2

DIMMB1

DIMMB2

I-SATA1

I-SATA4

I-SATA0

I-SATA3

NGFFB1

CN1

PCHDR1

DBGH1

TPMH1

I-SATA5

Notes:

• See Chapter 2 for detailed information on jumpers, I/O ports, and JF1 front panel con-

nections.

• " " indicates the location of Pin 1.

• Jumpers/LED indicators not indicated are used for testing only.

• Please refer to the table on Page 1-3 to see model variations.

• Use only the correct type of onboard CMOS battery as specied by the manufacturer. Do

not install the onboard battery upside down to avoid possible explosion.

11

Page 12

C7C232-CB-ML User's Manual

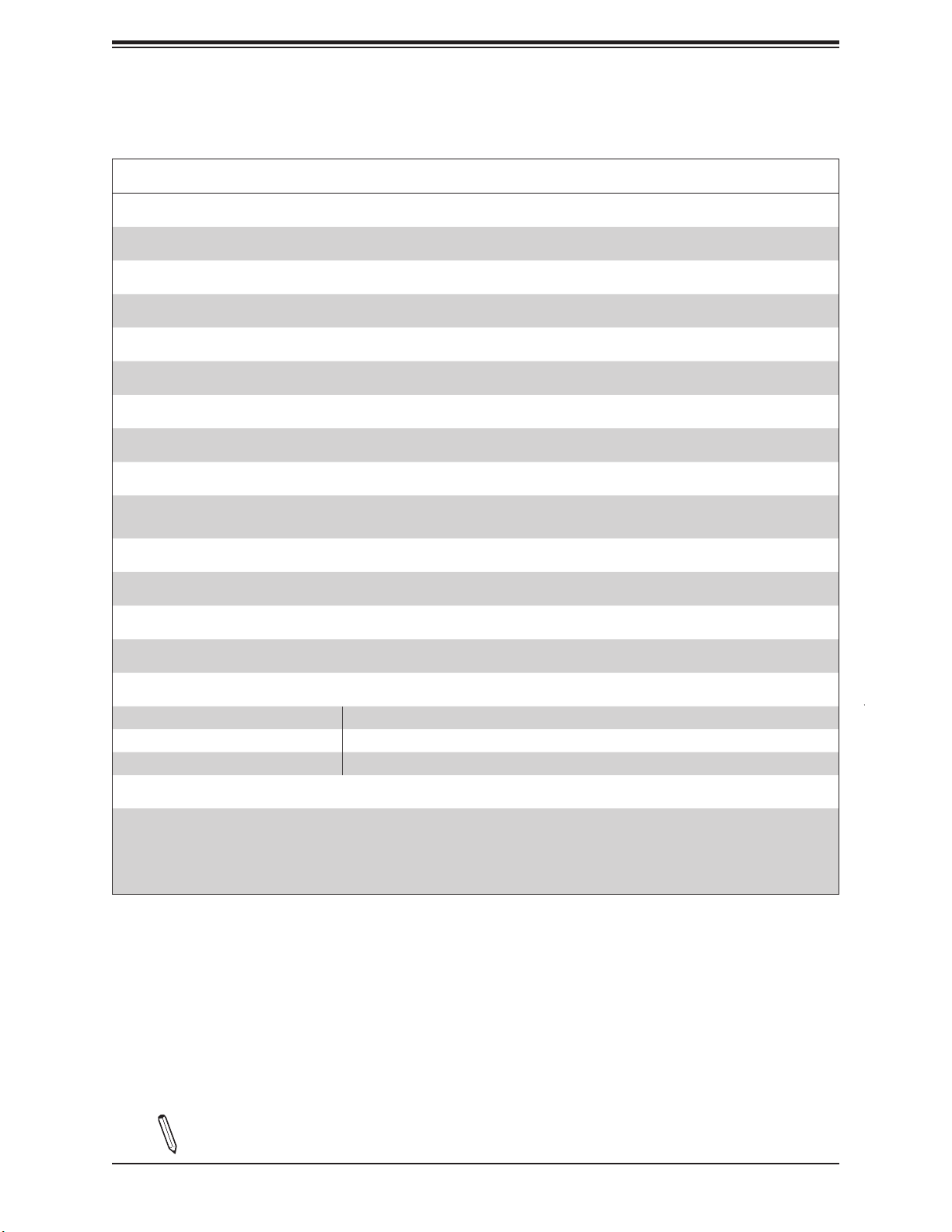

Quick Reference Table

Jumper Description Default Setting

CMOS1 CMOS Clear Pins 1-2 (Normal), Pins 2-3 (Clear CMOS)

WP1 BIOS Write Protect Header Pins 2-3 (Enable)

Connector Description

AUDF1 Front Panel Audio Header

AUDIO Back Panel Audio Port

BT1 Onboard Battery

BUZ1 Internal Speaker/Buzzer

CN1 24-pin ATX Power Connector

CN2 12V 8-pin Processor Power Connector

COM1 COM Header

CRF1 Front Accessible USB 2.0 Header

CSOPN1 Case Open Detection

FANC1, FANS1/FANS2 System/CPU Fan Headers (FANC1: CPU Fan)

HS1 Mounting Hole

I-SATA0~1, I-SATA3~5 Intel® PCH SATA 3.0 Ports

KB/MOUSE PS2 Keyboard and Mouse ports

LAN1 LAN (RJ45) Port

LEDH1 Front Panel Header

NGFFB1 M.2 Slot

OBR1 System recovery

PCHDR1 PC Health Header

SLOT5/SLOT6 PCH PCI-E 3.0 X1 Slots

SLOT7 CPU PCI-E 3.0 X16 Slot

SP1 Internal Speaker/Buzzer

SPK1 Speaker Header

TPMH1 Trusted Platform Module/Port 80 Header

USB0/1 Back panel Universal Serial Bus (USB) 2.0 Ports

USB2/3 Front Accessible USB 2.0 Headers

USB4/56/7 Back panel USB 3.0 Ports

USB8/9 Front Accessible USB 3.0 Headers

12

Page 13

Chapter 1: Introduction

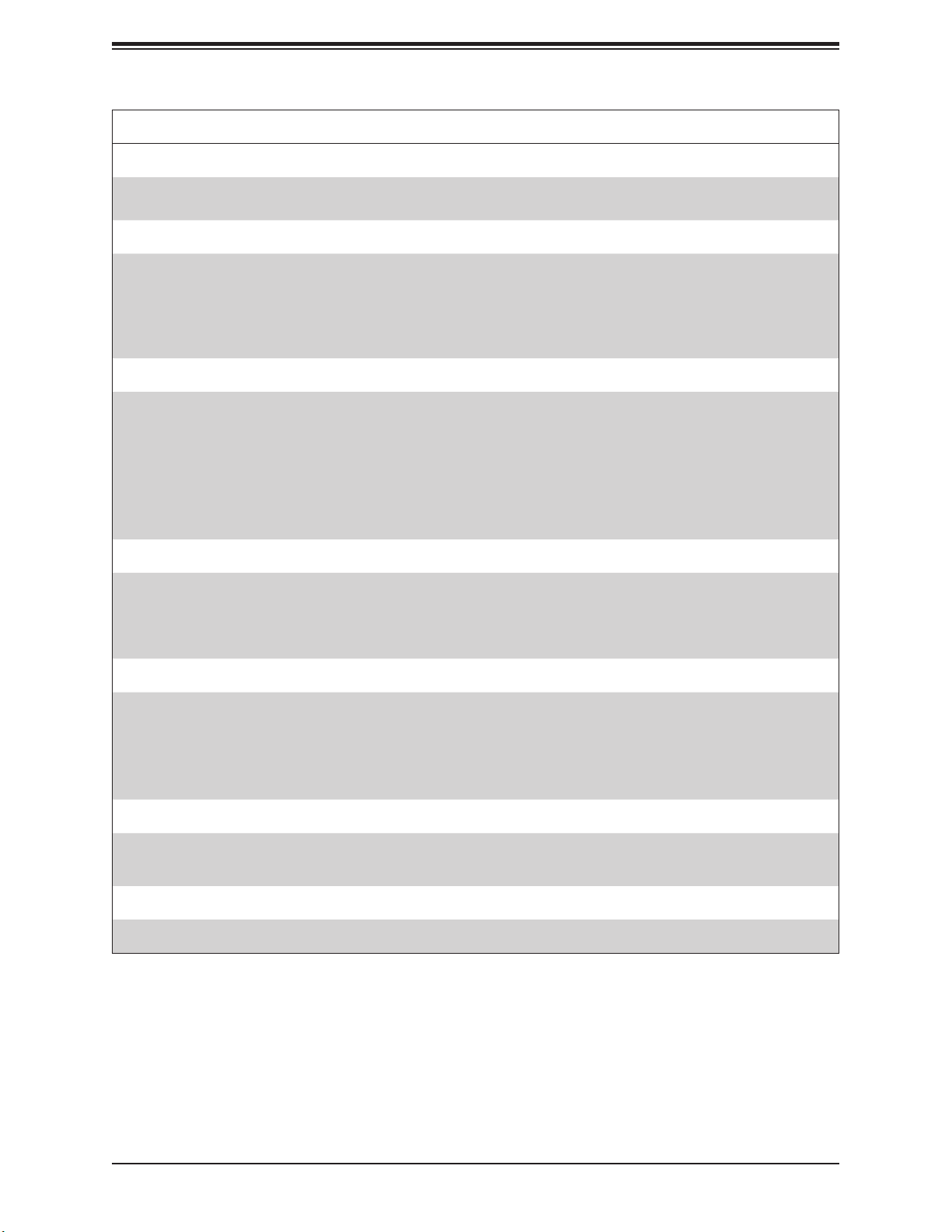

Motherboard Features

Motherboard Features

CPU

• Intel® Xeon E3-1200 V5 processor and Intel 6th Generation Core i3/i5/i7 processor in an LGA1151 socket.

Memory

• Up to 64GB of DDR4 Non-ECC UDIMM 2133MHz memory, two DIMMs per channel.

DIMM Size

• Up to 16GB at 1.2V

Chipset

• Intel PCH C232

Expansion Slots

• One (1) PCI-E 3.0 X16 Slot

• Two (2) PCI-E 3.0 X1 Slots

Network

• Intel i219LM and i219V

Graphics

• Intel IGD

I/O Devices

• Serial (COM) Port • One (1) serial header

• SATA 3.0 • Five (5) SATA 3.0 ports supported by Intel PCH C232

• RAID • RAID 0, 1, 5, 10

Peripheral Devices

• Two (2) USB 2.0 ports on the rear I/O panel (USB0/1)

• Four (4) USB 3.0 ports on the rear I/O panel (USB4/5/6/7)

• One (2) USB 2.0 header on the rmotherboard for front access (USB2/3)

• One (1) USB 3.0 header on the rmotherboard for front access (USB8/9)

Note: The table above is continued on the next page.

13

Page 14

C7C232-CB-ML User's Manual

Motherboard Features

BIOS

• 128 Mb SPI AMI BIOS

• ACPI 4.0, SMBIOS 3.0, Plug-and-Play (PnP), RTC (Real Time Clock) wakeup

Power Management

• Main switch override mechanism

• Power-on mode for AC power recovery

• Intel® Intelligent Power Node Manager 3.0 (available when the Supermicro Power Manager [SPM] is installed and a

special power supply is used. See the note on page 22.)

• Management Engine (ME)

System Health Monitoring

• Onboard voltage monitoring for +1.8V, +3.3V, 3.3V standby, +5V, +5V standby, +/-12V, VBAT, HT, Memory, PCH Temp.,

System Temp., Memory Temp.,

• CPU/system overheat LED and control

• CPU Thermal Trip support

• Status monitor for speed control

• Status monitor for on/off control

• CPU Thermal Design Power (TDP) support of up to 145W (See Note 1 on next page.)

®

SM Flash UEFI BIOS

Fan Control

• Fan status monitoring via IPMI connections

• Dual cooling zone

• Low-noise fan speed control

• Pulse Width Modulation (PWM) fan control

System Management

• Trusted Platform Module (TPM) support

• PECI (Platform Environment Control Interface) 2.0 support

• System resource alert via SuperDoctor® 5

• SuperDoctor® 5, Watch Dog, NMI

• Chassis intrusion header and detection

LED Indicators

• Power/suspend-state indicator LED

• HDD activity.

Dimensions

• 9.6" (L) x 9.6" (W) (243.84 mm x 243.84 mm)

14

Page 15

Chapter 1: Introduction

Note 1: The CPU maximum thermal design power (TDP) is subject to chassis and

heatsink cooling restrictions. For proper thermal management, please check the chas-

sis and heatsink specications for proper CPU TDP sizing.

Note 2: For IPMI conguration instructions, please refer to the Embedded IPMI Conguration User's Guide available at http://www.supermicro.com/support/manuals/.

Note 3: It is strongly recommended that you change BMC login information upon initial

system power-on. The manufacture default username is ADMIN and the password is

ADMIN. For proper BMC conguration, please refer to http://www.supermicro.com/

products/info/les/IPMI/Best_Practices_BMC_Security.pdf

15

Page 16

C7C232-CB-ML User's Manual

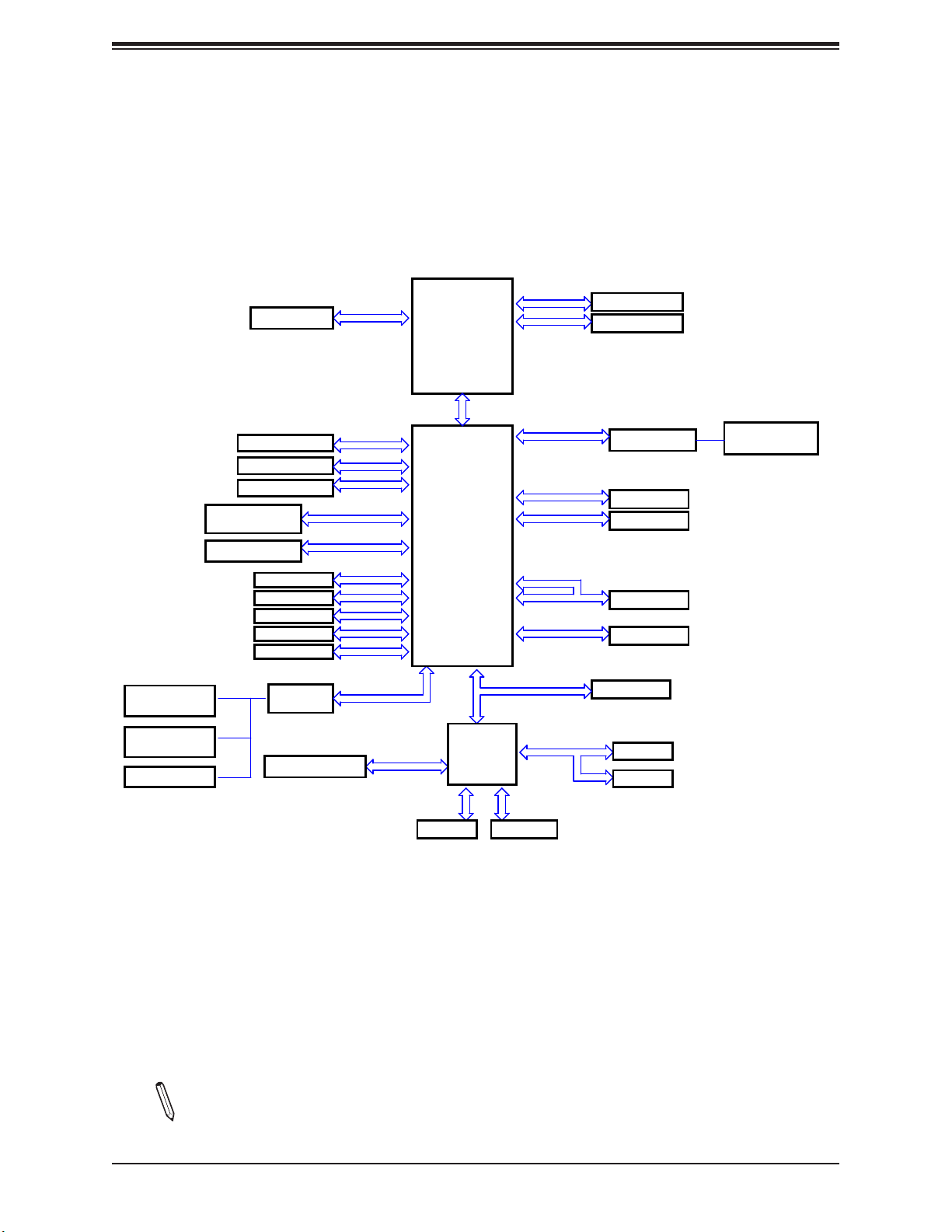

Figure 1-3.

System Block Diagram

Rear JACK

HP/MIC/LINE IN

Front header

HP/MIC

internal SPK

PCIEx16 slot

Front USB 3.0 *2

Front USB 2.0 *2

Front USB 2.0 *1

Rear USB 2.0 *2

(RJ45 USB conn)

Rear USB 3.0 *4

SATA PORT0

SATA PORT1

SATA PORT3

SATA PORT4

SATA PORT5

Audio

ALC662

COM port Header

PCIE 3.0

USB 3.0

USB 2.0

USB 2.0

USB 2.0

USB 3.0

SATA 3.0

SATA 3.0

SATA 3.0

SATA 3.0

SATA 3.0

HDA

E3-1200 V5

C232

COM

Intel

CPU

DMI

PCH

SIO

IT8732

LPC

DDR4 CHA

DDR4 CHB

PCIE3.0

PCIE3.0

PCIE3.0

PCIE3.0

SATA 3.0

SPI

FAN CTRL

DDR4 DIMM *1

DDR4 DIMM *1

Intel LAN I219V

PCIE x1 Slot

PCIE x1 Slot

M.2 B-Key

FLASH

TPM Header

CPU FAN

SYS FAN

RJ45 CONN/

USB2.0 x2 stack

PS2 KB/MSPrint Port

Note: This is a general block diagram and may not exactly represent the features on

your motherboard. See the previous pages for the actual specications of your motherboard.

16

Page 17

Chapter 1: Introduction

1.2 Processor and Chipset Overview

Built upon the functionality and capability of the Intel E3-1200 V5 series processors (Socket

LGA 1151) and the Intel C232 PCH, the C7C232-CB-ML motherboard offers maximum I/O

expandability, energy efciency, and data reliability in a 14-nm process architecture and is

optimized for desktop solutions.

The Intel E3-1200 V5 and PCH C232 platform supports the following features:

• ACPI Power Management Logic Support, Rev. 4.0a

• Intel Turbo Boost Technology

• Congurable TDP (cTDP) and Lower-Power Mode

• Adaptive Thermal Management/Monitoring

• PCI-E 3.0 and SATA 3.0 w/transfer rates of up to 6 Gb/s

• Intel Trusted Execution Technology (Intel TXT)

• Intel Virtualization Technology for Directed I/O (Intel VT-d)

1.3 Special Features

This section describes the health monitoring features of the C7C232-CB-ML motherboard.

The motherboard has an onboard System Hardware Monitor chip that supports system health

monitoring.

Recovery from AC Power Loss

The Basic I/O System (BIOS) provides a setting that determines how the system will respond

when AC power is lost and then restored to the system. You can choose for the system to

remain powered off (in which case you must press the power switch to turn it back on), or

for it to automatically return to the power-on state. See the Advanced BIOS Setup section

for this setting. The default setting is Last State.

17

Page 18

C7C232-CB-ML User's Manual

1.4 System Health Monitoring

This section describes the health monitoring features of the C7C232-CB-ML motherboard. The

motherboard has an onboard Baseboard Management Controller (BMC) chip that supports

system health monitoring. Once a voltage becomes unstable, a warning is given or an error

message is sent to the screen. The user can adjust the voltage thresholds to dene the

sensitivity of the voltage monitor.

Onboard Voltage Monitors

The onboard voltage monitor will continuously scan crucial voltage levels. Once a voltage

becomes unstable, it will give a warning or send an error message to the screen. Users can

adjust the voltage thresholds to dene the sensitivity of the voltage monitor. Real time readings

of these voltage levels are all displayed in BIOS.

Fan Status Monitor with Firmware Control

The system health monitor embedded in the BMC chip can check the RPM status of the

cooling fans. The CPU and chassis fans are controlled via lPMI.

Environmental Temperature Control

System Health sensors in the BMC monitor the temperatures and voltage settings of onboard

processors and the system in real time via the IPMI interface. Whenever the temperature of

the CPU or the system exceeds a user-dened threshold, system/CPU cooling fans will be

turned on to prevent the CPU or the system from overheating.

Note: To avoid possible system overheating, please be sure to provide adequate air-

ow to your system.

System Resource Alert

This feature is available when used with SuperDoctor 5®. SuperDoctor 5 is used to notify the

user of certain system events. For example, you can congure SuperDoctor 5 to provide you

with warnings when the system temperature, CPU temperatures, voltages and fan speeds

go beyond a predened range.

18

Page 19

Chapter 1: Introduction

1.5 ACPI Features

ACPI stands for Advanced Conguration and Power Interface. The ACPI specication denes

a exible and abstract hardware interface that provides a standard way to integrate power

management features throughout a computer system including its hardware, operating system

and application software. This enables the system to automatically turn on and off peripherals

such as network cards, hard disk drives and printers.

In addition to enabling operating system-directed power management, ACPI also provides a

generic system event mechanism for Plug and Play and an operating system-independent

interface for conguration control. ACPI leverages the Plug and Play BIOS data structures

while providing a processor architecture-independent implementation that is compatible with

Windows 8/R2, and Windows 2012/R2 operating systems.

1.6 Power Supply

As with all computer products, a stable power source is necessary for proper and reliable

operation. It is even more important for processors that have high CPU clock rates. In areas

where noisy power transmission is present, you may choose to install a line lter to shield

the computer from noise. It is recommended that you also install a power surge protector to

help avoid problems caused by power surges.

1.7 Super I/O

The Super I/O (ITE8732F) includes a data separator, write pre-compensation circuitry, decode

logic, data rate selection, a clock generator, drive interface control logic and interrupt and

DMA logic. The wide range of functions integrated onto the Super I/O greatly reduces the

number of components required for interfacing with oppy disk drives.

The Super I/O provides two high-speed, 16550 compatible serial communication ports

(UARTs), one of which supports serial infrared communication. Each UART includes a 16-byte

send/receive FIFO, a programmable baud rate generator, complete modem control capability

and a processor interrupt system. Both UARTs provide legacy speed with baud rate of up to

115.2 Kbps as well as an advanced speed with baud rates of 250 K, 500 K, or 1 Mb/s, which

support higher speed modems.

The Super I/O provides functions that comply with ACPI (Advanced Conguration and Power

Interface), which includes support of legacy and ACPI power management through a SMI

or SCI function pin. It also features auto power management to reduce power consumption.

The IRQs, DMAs and I/O space resources of the Super I/O can be exibly adjusted to meet

ISA PnP requirements, which support ACPI and APM (Advanced Power Management).

19

Page 20

C7C232-CB-ML User's Manual

1.8 Advanced Power Management

The following new advanced power management features are supported by the motherboard.

Intel® Intelligent Power Node Manager (IPNM)

Available when the Supermicro Power Manager (SPM) is installed, Intel's Intelligent Power

Node Manager (IPNM) provides your system with real-time thermal control and power

management for maximum energy efciency. Although IPNM Specication Version 2.0/3.0

is supported by the BMC (Baseboard Management Controller), your system must also have

IPNM-compatible Management Engine (ME) rmware installed to use this feature.

Note: Support for IPNM 2.0/3.0 support is dependent on the power supply used in

the system.

Management Engine (ME)

The Management Engine, which is an ARC controller embedded in the IOH (I/O Hub), provides

Server Platform Services (SPS) to your system. The services provided by SPS are different

from those provided by the ME on client platforms.

20

Page 21

Chapter 2: Installation

Chapter 2

Installation

2.1 Static-Sensitive Devices

Electrostatic Discharge (ESD) can damage electronic com ponents. To prevent damage to your

motherboard, it is important to handle it very carefully. The following measures are generally

sufcient to protect your equipment from ESD.

Precautions

• Use a grounded wrist strap designed to prevent static discharge.

• Touch a grounded metal object before removing the board from the antistatic bag.

• Handle the board by its edges only; do not touch its components, peripheral chips, memory

modules or gold contacts.

• When handling chips or modules, avoid touching their pins.

• Put the motherboard and peripherals back into their antistatic bags when not in use.

• For grounding purposes, make sure that your chassis provides excellent conductivity be-

tween the power supply, the case, the mounting fasteners and the motherboard.

• Use only the correct type of CMOS onboard battery as specied by the manufacturer. Do

not install the CMOS battery upside down, which may result in a possible explosion.

Unpacking

The motherboard is shipped in antistatic packaging to avoid static damage. When unpacking

the motherboard, make sure that the person handling it is static protected.

21

Page 22

C7C232-CB-ML User's Manual

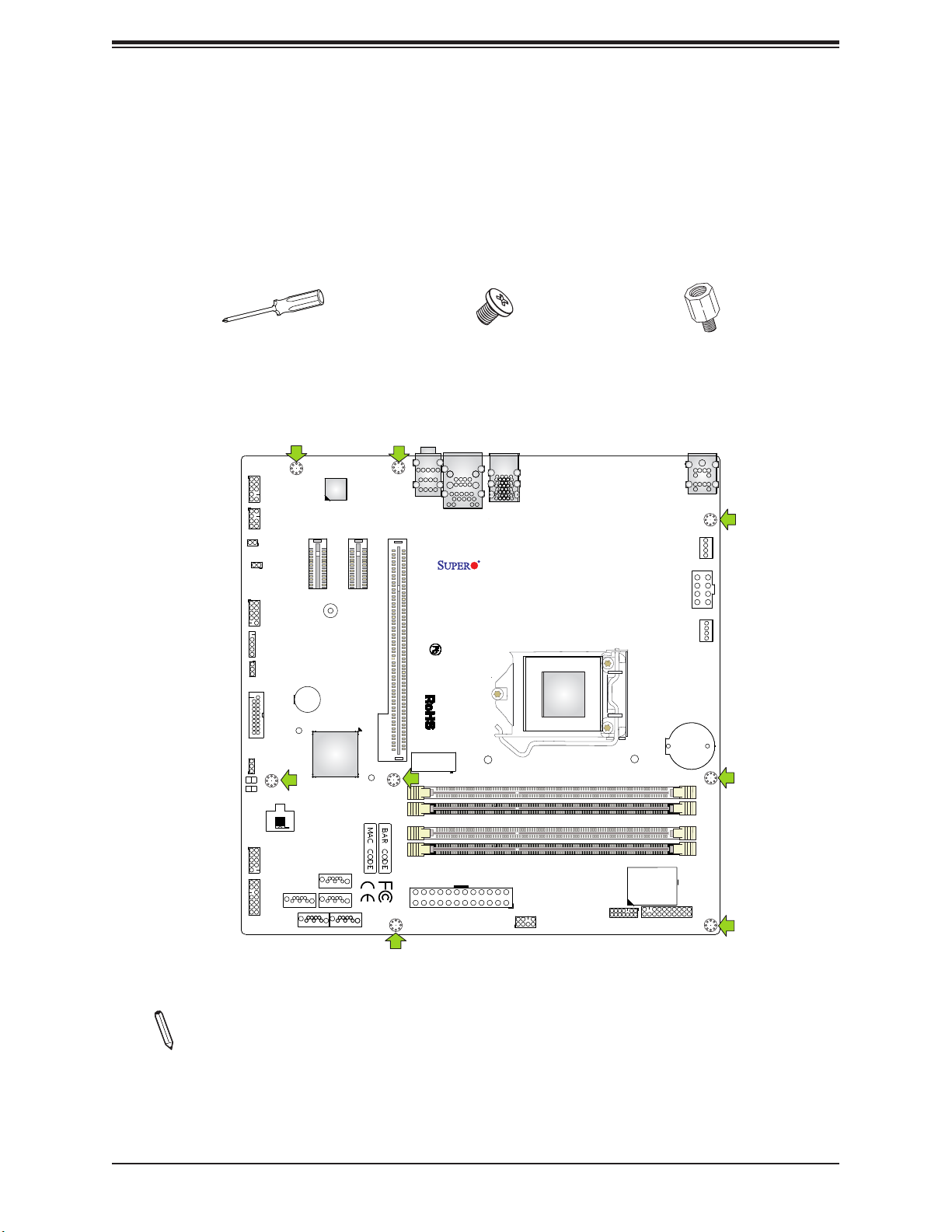

2.2 Motherboard Installation

All motherboards have standard mounting holes to t different types of chassis. Make sure

that the locations of all the mounting holes for both the motherboard and the chassis match.

Although a chassis may have both plastic and metal mounting fasteners, metal ones are

highly recommended because they ground the motherboard to the chassis. Make sure that

the metal standoffs click in or are screwed in tightly.

Phillips Screwdriver (1)

Tools Needed

AUDF1 SPK1

CSOPN1

OBR1

USB2/3 (2.0)

CRF1

WP1

USB8/9 (3.0)

CMOS1

COM1

LEDH1

PCH SLOT5 PCI-E 3.0 X1

USB2F1

USB3F1

BUZ1

GPIO2

GPIO1

I-SATA4

I-SATA1

PCH SLOT6 PCI-E 3.0 X1

HS1

PCH

I-SATA5

I-SATA3

I-SATA0

Phillips Screws (8)

AUDIO

USB0/1

LAN1

CPU SLOT7 PCI-E 3.0 X16

C7C232-CB-ML

Rev. 1.00

NGFFB1

CN1

USB4/5/6/7

(3.0)

PCHDR1

CPU

Standoffs (8)

Only if Needed

KB/MOUSE

FANS1

FANS2

CN2

FANC1

BT1

TPMH1

DBGH1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

Location of Mounting Holes

Note: 1) To avoid damaging the motherboard and its components, please do not use

a force greater than 8 lb/inch on each mounting screw during motherboard installation.

2) Some components are very close to the mounting holes. Please take precautionary

measures to avoid damaging these components when installing the motherboard to

the chassis.

22

Page 23

Chapter 2: Installation

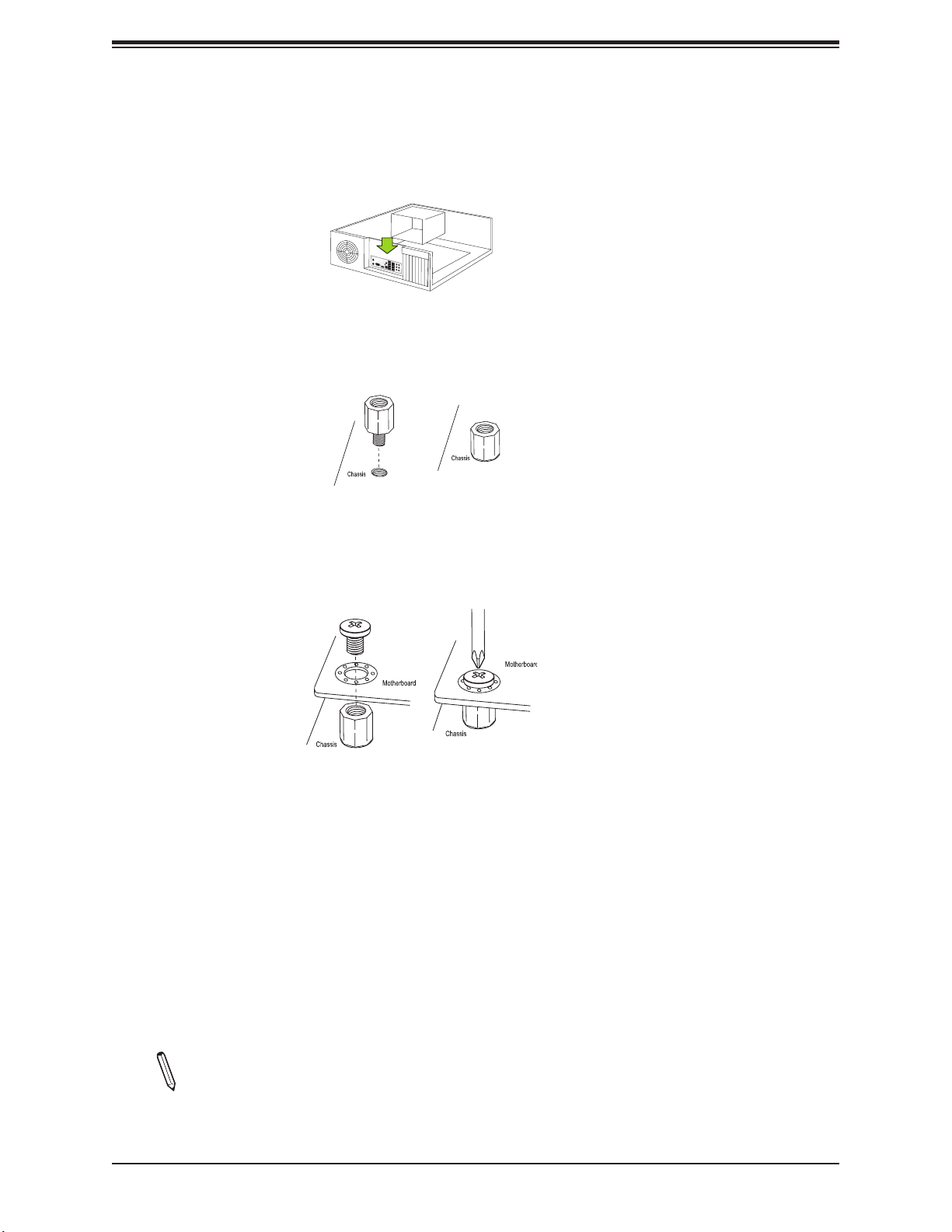

Installing the Motherboard

1. Install the I/O shield into the back of the chassis.

2. Locate the mounting holes on the motherboard. See the previous page for the location.

3. Locate the matching mounting holes on the chassis. Align the mounting holes on the

motherboard against the mounting holes on the chassis.

4. Install standoffs in the chassis as needed.

5. Install the motherboard into the chassis carefully to avoid damaging other motherboard

components.

6. Using the Phillips screwdriver, insert a Phillips head #6 screw into a mounting hole on

the motherboard and its matching mounting hole on the chassis.

7. Repeat Step 5 to insert #6 screws into all mounting holes.

8. Make sure that the motherboard is securely placed in the chassis.

Note: Images displayed are for illustration only. Your chassis or components might

look different from those shown in this manual.

23

Page 24

C7C232-CB-ML User's Manual

2.3 Processor and Heatsink Installation

Warning: When handling the processor package, avoid placing direct pressure on the label

area of the fan.

Important:

• Always connect the power cord last, and always remove it before adding, removing or

changing any hardware components. Make sure that you install the processor into the

CPU socket before you install the CPU heatsink.

• If you buy a CPU separately, make sure that you use an Intel-certied multi-directional

heatsink only.

• Make sure to install the motherboard into the chassis before you install the CPU heatsink.

• When receiving a motherboard without a processor pre-installed, make sure that the plastic

CPU socket cap is in place and none of the socket pins are bent; otherwise, contact your

retailer immediately.

• Refer to the Supermicro website for updates on CPU support.

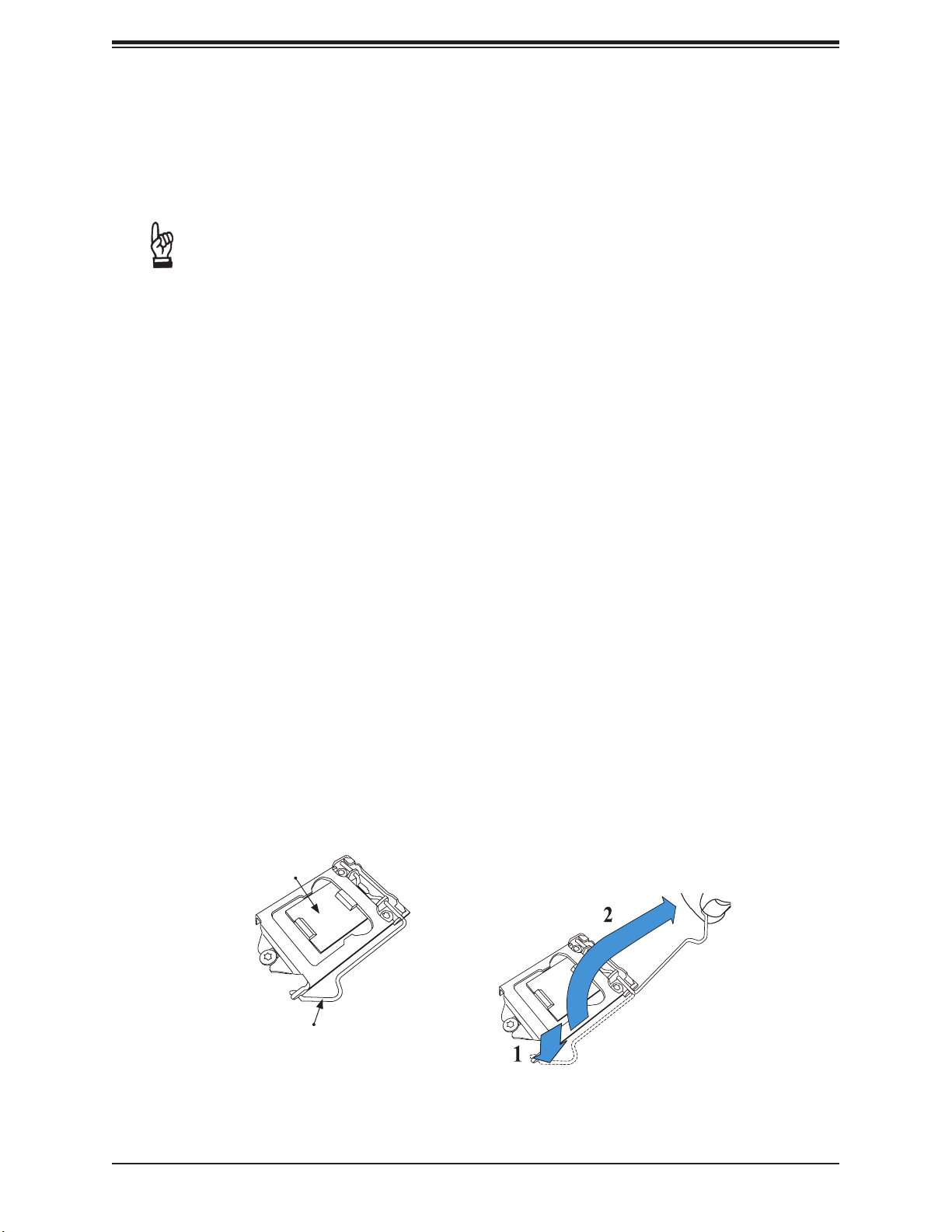

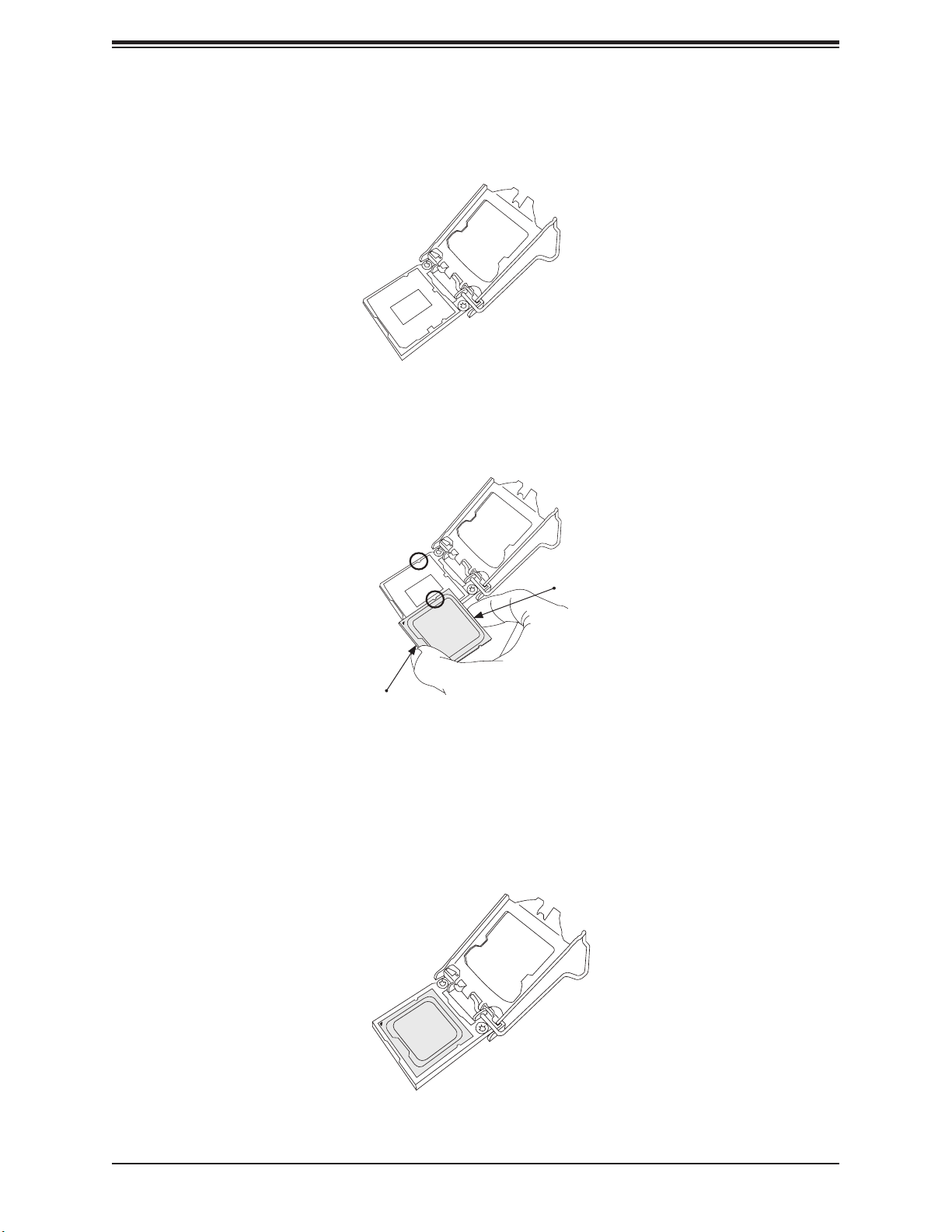

Installing the LGA1151 Processor

1. Press the load lever to release the load plate, which covers the CPU socket, from its

locking position.

Load Plate

Load Lever

24

Page 25

Chapter 2: Installation

2. Gently lift the load lever to open the load plate. Remove the plastic cap.

3. Use your thumb and your index nger to hold the CPU at the north center edge and the

South center edge of the CPU.

North Center Edge

South Center Edge

4. Align the CPU key that is the semi-circle cutouts against the socket keys. Once it is

aligned, carefully lower the CPU straight down into the socket. (Do not drop the CPU on

the socket. Do not move the CPU horizontally or vertically.

25

Page 26

C7C232-CB-ML User's Manual

5. Do not rub the CPU against the surface or against any pins of the socket to avoid

damaging the CPU or the socket.

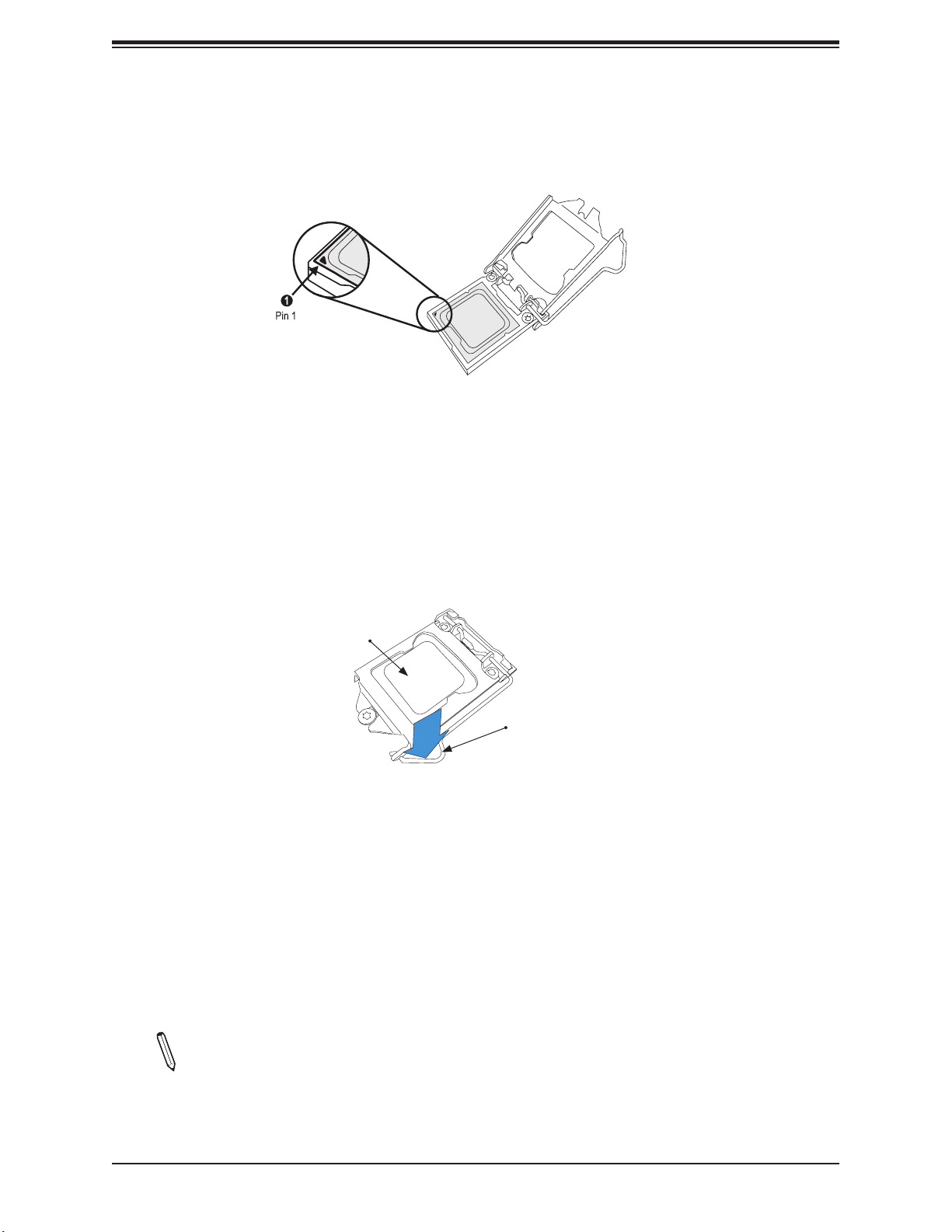

6. With the CPU inside the socket, inspect the four corners of the CPU to make sure that

the CPU is properly installed.

7. Use your thumb to gently push the load lever down to the lever lock.

CPU properly

installed

Load lever locked into

place

Note: You can only install the CPU inside the socket in one direction. Make sure that

it is properly inserted into the CPU socket before closing the load plate. If it doesn't

close properly, do not force it as it may damage your CPU. Instead, open the load

plate again and double-check that the CPU is aligned properly.

26

Page 27

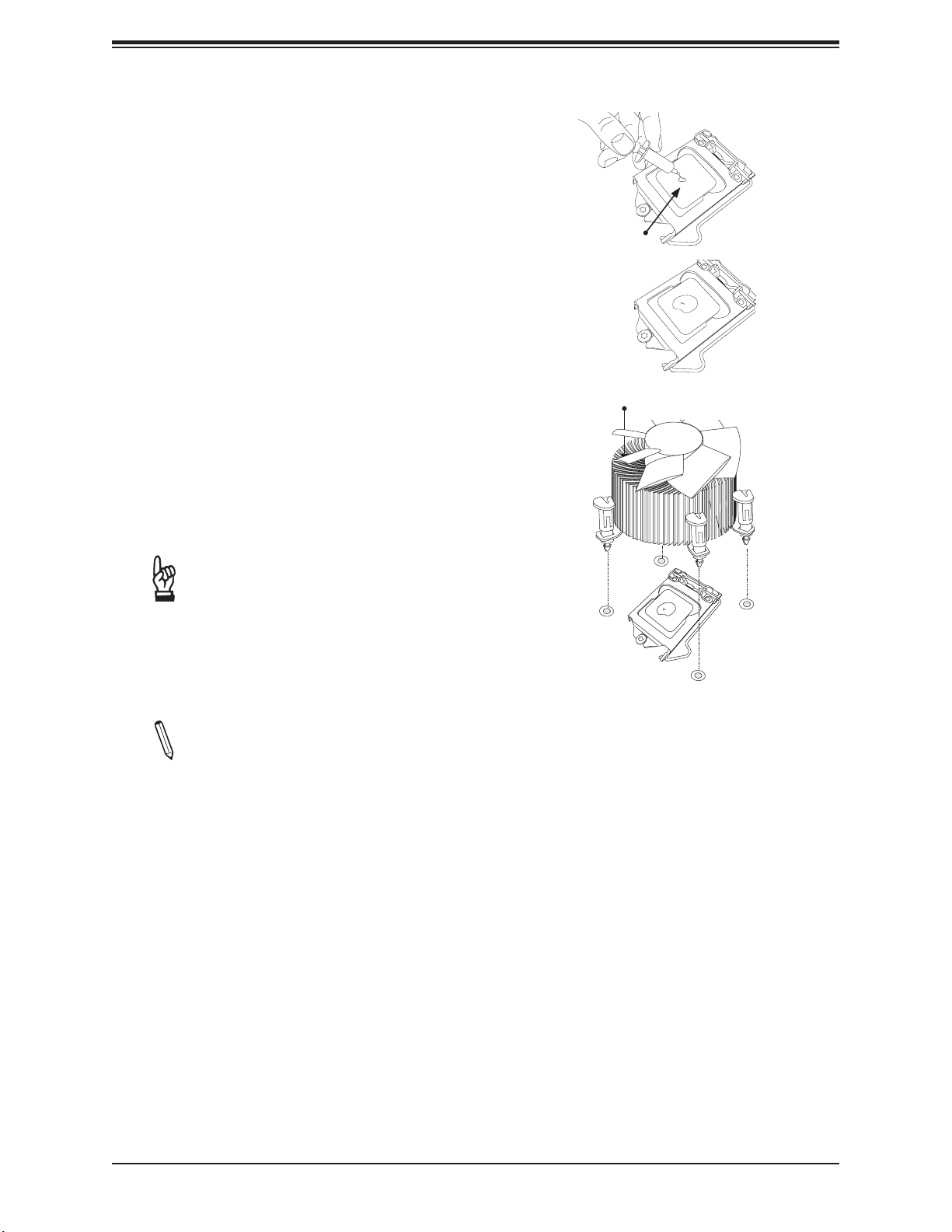

Installing an Active CPU

Heatsink with Fan

1. Locate the CPU fan power connector on

the motherboard. (Refer to the layout on

the right for the CPU Fan location.)

2. Position the heatsink so that the heatsink

fan wires are closest to the CPU fan

power connector and are not interfered

with other components.

Chapter 2: Installation

Thermal Grease

3. Inspect the CPU fan wires to make sure

that the wires are routed through the

bottom of the heatsink.

4. Remove the thin layer of the protective

lm from the heatsink.

Important: CPU overheating may oc-

cur if the protective lm is not removed

from the heatsink.

5. Apply the proper amount of thermal

grease on the CPU.

Note: If your heatsink came with a thermal pad, please ignore this step.

6. If necessary, rearrange the wires to

make sure that the wires are not pinched

between the heatsink and the CPU. Also

make sure to keep clearance between the

fan wires and the ns of the heatsink.

Heatsink

Fins

27

Page 28

C7C232-CB-ML User's Manual

7. Align the four heatsink fasteners with

the mounting holes on the motherboard.

Gently push the pairs of diagonal

fasteners (#1 & #2, and #3 & #4) into

the mounting holes until you hear a click.

Also, make sure to orient each fastener

so that the narrow end of the groove is

pointing outward.

8. Repeat step 7 to insert all four heatsink

fasteners into the mounting holes.

9. Once all four fasteners are securely

inserted into the mounting holes, and

the heatsink is properly installed on the

motherboard, connect the heatsink fan

wires to the CPU fan connector.

28

Page 29

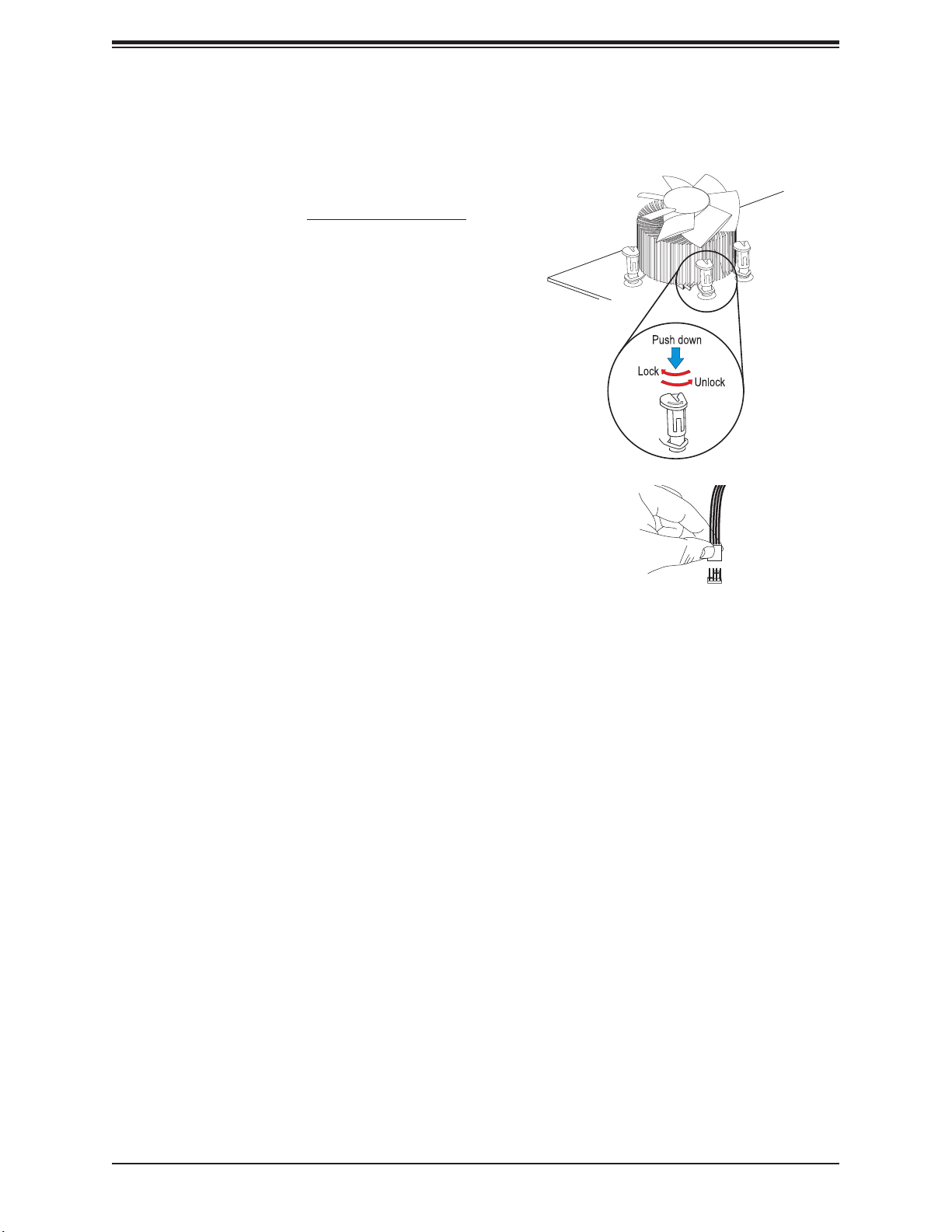

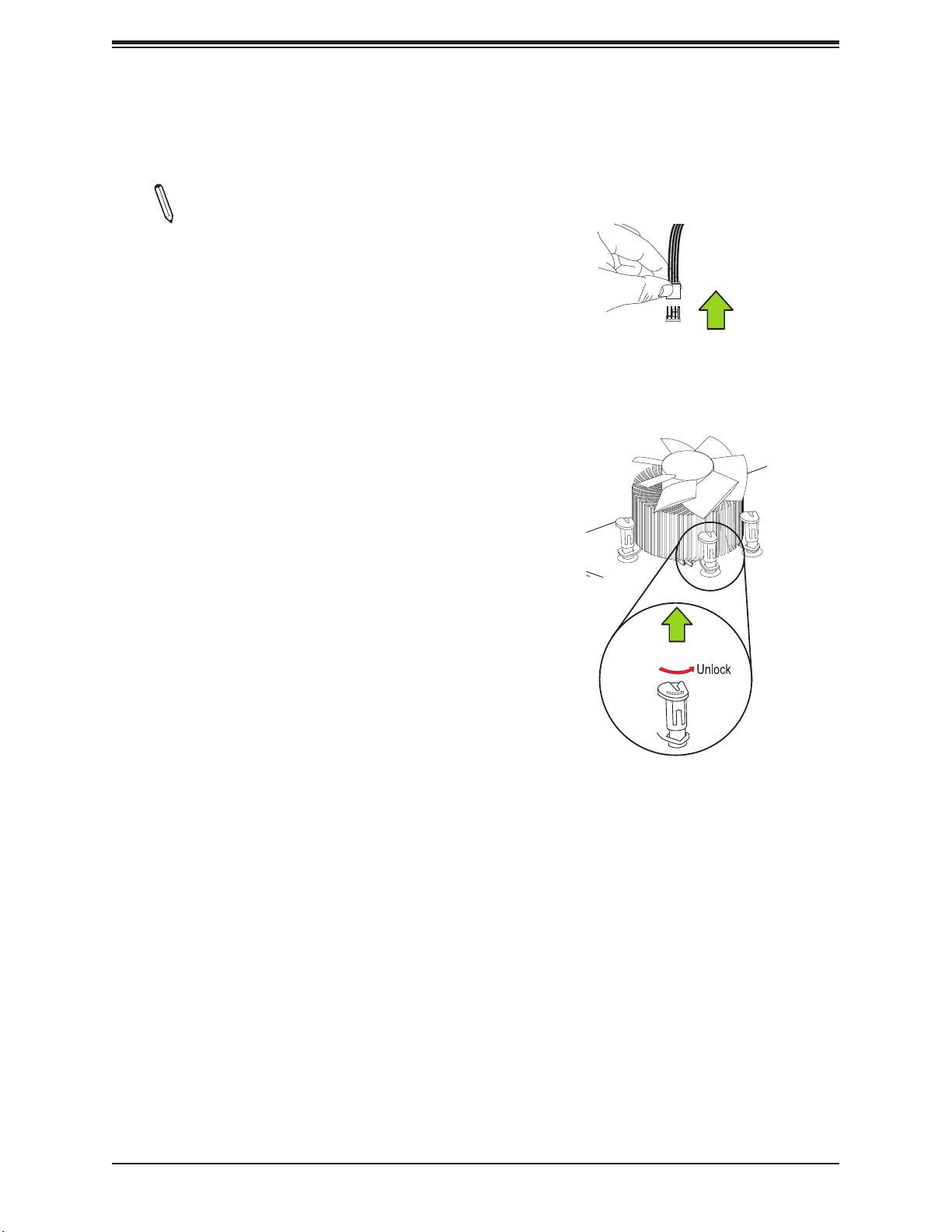

Removing the Heatsink

Note: We do not recommend that

the CPU or the heatsink be removed.

However, if you do need to remove the

heatsink, please follow the instructions

below to remove the heatsink and to

prevent damage done to the CPU or

other components.

Active Heatsink Removal

1. Unplug the power cord from the power

supply.

Chapter 2: Installation

Unplug the

PWR cord

2. Disconnect the heatsink fan wires from

the CPU fan header.

3. Gently press on the fastener cap, turn it

counterclockwise to make a 1/4 (900) turn

and pull the fastener upward to loosen it.

4. Repeat step 3 to loosen all fasteners from

the mounting holes.

5. With all fasteners loosened, remove the

heatsink from the CPU.

Pull Up

29

Page 30

C7C232-CB-ML User's Manual

NGFFB1

BT1

CN2

FANC1

FANS1

FANS2

DIMMA2

DIMMB1

KB/MOUSE

USB0/1

LAN1

USB4/5/6/7

(3.0)

AUDIO

C7C232-CB-ML

DIMMA1

DIMMB2

Rev. 1.00

CPU

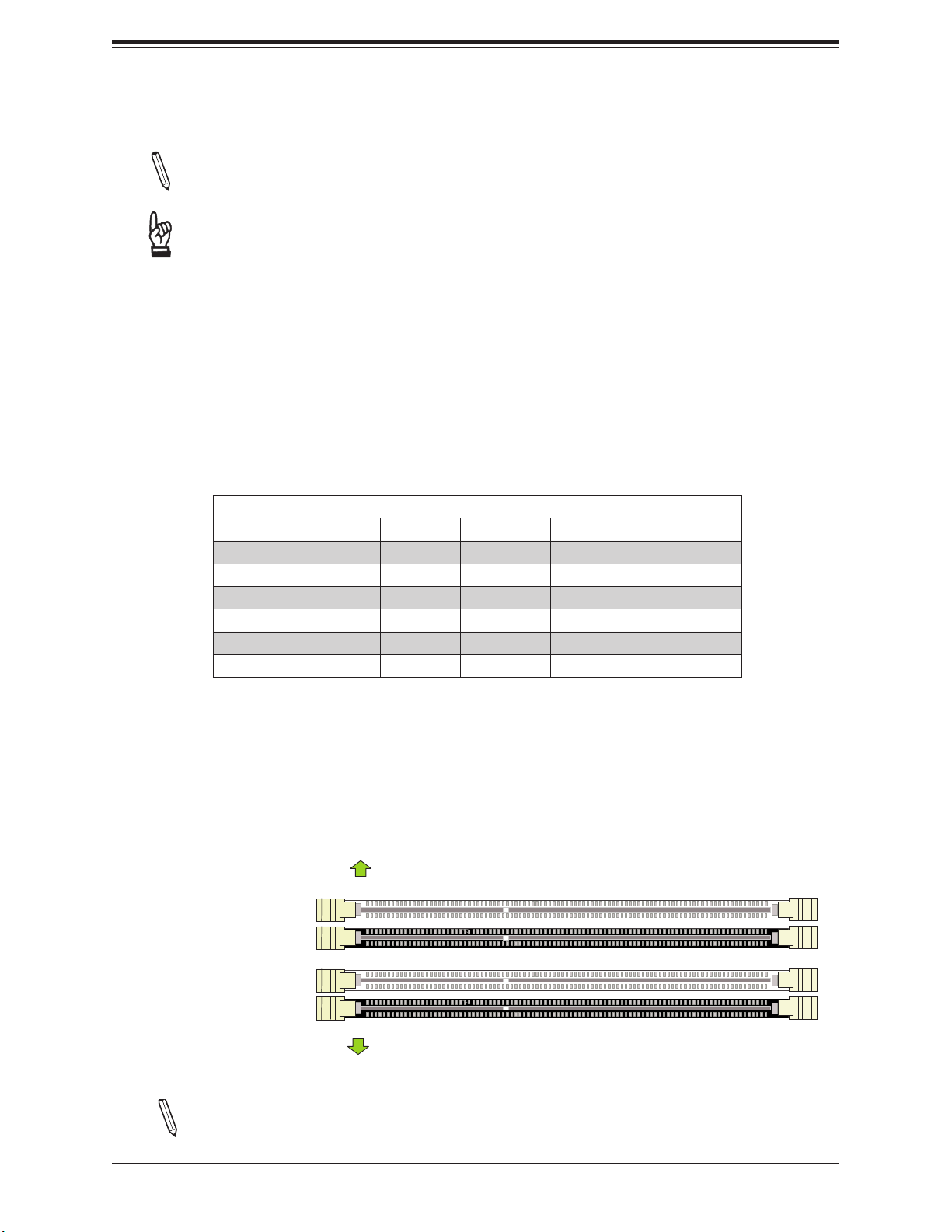

2.4 Memory Support and Installation

Note: Check the Supermicro website for recommended memory modules.

Important: Exercise extreme care when installing or removing DIMM modules to pre-

vent any possible damage.

Memory Support

The C7C232-CB-ML supports up to 32GB of DDR4 Non-ECC UDIMM 2133MHz memory.

Populating these DIMM modules with a pair of memory modules of the same type and size

will result in interleaved memory, which will improve memory performance.

DIMM Module Population Conguration

For optimal memory performance, follow the table below when populating memory.

DIMM Module Population Sequence

When installing memory modules, the DIMM slots must be populated in the following order:

DIMMB2, DIMMA2, then DIMMB1, DIMMA1. The blue slots must be populated rst.

DIMMA1

DIMMA2 (Black Slot)

Recommended Population (Balanced)

DIMMA1 DIMMB1 DIMMA2 DIMMB2 Total System Memory

4GB 4GB 8GB

4GB 4GB 4GB 4GB 16GB

8GB 8GB 16GB

8GB 8GB 8GB 8GB 32GB

16GB 16GB 32GB

16GB 16GB 16GB 16GB 64GB

Towards the CPU

DIMMB1

DIMMB2 (Black Slot)

Towards the edge of the motherboard

Note: Be sure to use memory modules of the same type and speed. Mixing of memory

modules of different types and speeds is not allowed.

30

Page 31

Chapter 2: Installation

I-SATA0

I-SATA1

PCHDR1

DIMM Installation

1. Insert DIMM modules in the following

order: DIMMB2, DIMMA2, then DIMMB1,

DIMMA1. For the system to work properly,

please use memory modules of the same

type and speed on the motherboard.

2. Push the release tabs outwards on both

ends of the DIMM slot to unlock it.

3. Align the key of the DIMM module with the

receptive point on the memory slot.

4. Align the notches on both ends of the

module against the receptive points on the

ends of the slot.

5. Use two thumbs together to press the

notches on both ends of the module

straight down into the slot until the module

snaps into place.

AUDF1 SPK1

CSOPN1

OBR1

USB2/3 (2.0)

CRF1

WP1

USB8/9 (3.0)

CMOS1

COM1

LEDH1

USB2F1

USB3F1

GPIO2

GPIO1

PCH SLOT5 PCI-E 3.0 X1

HS1

BUZ1

PCH

I-SATA5

I-SATA4

I-SATA3

PCH SLOT6 PCI-E 3.0 X1

CPU SLOT7 PCI-E 3.0 X16

AUDIO

USB4/5/6/7

USB0/1

(3.0)

LAN1

C7C232-CB-ML

Rev. 1.00

CPU

NGFFB1

CN1

KB/MOUSE

FANS1

FANS2

CN2

FANC1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

TPMH1

DBGH1

Notches

6. Press the release tabs to the lock positions

to secure the DIMM module into the slot.

DIMM Removal

Reverse the steps above to remove the DIMM

modules from the motherboard.

Release Tabs

Press both notches

straight down into

the memory slot.

31

Page 32

C7C232-CB-ML User's Manual

2.5 Rear I/O Ports

See Figure 2-2 below for the locations and descriptions of the various I/O ports on the rear

of the motherboard.

AUDF1 SPK1

TPMH1

KB/MOUSE

FANS1

FANS2

CN2

FANC1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

CMOS1

GPIO2

GPIO1

COM1

LEDH1

USB3F1

I-SATA4

PCH SLOT6 PCI-E 3.0 X1

PCH SLOT5 PCI-E 3.0 X1

HS1

BUZ1

PCH

I-SATA5

I-SATA3

I-SATA0

I-SATA1

AUDIO

CPU SLOT7 PCI-E 3.0 X16

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

USB4/5/6/7

(3.0)

PCHDR1

CPU

DBGH1

Figure 2-2. I/O Port Locations and Denitions

3

1

4

2

5

6

7

8

9

Rear I/O Ports

# Description # Description # Description

1. Keyboard 5. USB6 (3.0) 9. USB1

2. Mouse 6. USB7 (3.0) 10. Audio Line In

3 USB4 (3.0) 7. LAN1 11. Audio Line Out

4. USB5 (3.0) 8. USB0 12. Audio Mic In

10

11

12

32

Page 33

Chapter 2: Installation

LAN Port

One LAN port (LAN1) is located on the I/O back panel. This port accepts RJ45 type cables.

Serial Port

There is one COM header (COM1) on the motherboard to provide front side access.

1

1. LAN1

AUDF1 SPK1

2. COM1

TPMH1

KB/MOUSE

FANS1

FANS2

CN2

FANC1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

AUDIO

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

2

LEDH1

PCH SLOT5 PCI-E 3.0 X1

HS1

BUZ1

PCH

I-SATA5

I-SATA4

I-SATA3

I-SATA0

I-SATA1

PCH SLOT6 PCI-E 3.0 X1

CPU SLOT7 PCI-E 3.0 X16

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

USB4/5/6/7

(3.0)

PCHDR1

CPU

DBGH1

33

Page 34

C7C232-CB-ML User's Manual

KB/MOUSE

The PS2 keyboard and mouse ports are located on the I/O back panel.

KB/MOUSE

Pin Denitions

Keyboard Mouse

Pin Dention Pin Dention

1 KB Data 1 Mouse Data

2 No Connection 2 No Connection

3 Ground 3 Ground

4

Mouse/KB VCC

(+5V)

4

Mouse/KB VCC

(+5V)

5 KB Clock 5 Mouse Clock

6 No Connection 6 No Connection

AUDIO Port

The audio ports on the I/O back panel provide three connections. From top to bottom: Audio

Line In (blue), Audio Line Out (green), and Audio Mic In (pink).

2

1

1. KB/MOUSE

AUDF1 SPK1

2. AUDIO

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

LEDH1

PCH SLOT5 PCI-E 3.0 X1

HS1

BUZ1

PCH

I-SATA5

I-SATA4

I-SATA3

I-SATA0

I-SATA1

PCH SLOT6 PCI-E 3.0 X1

CPU SLOT7 PCI-E 3.0 X16

AUDIO

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

USB4/5/6/7

(3.0)

PCHDR1

KB/MOUSE

FANS1

FANS2

CN2

FANC1

CPU

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

TPMH1

DBGH1

34

Page 35

Chapter 2: Installation

Universal Serial Bus (USB) Ports

There are two USB 2.0 ports (USB0/1) and four USB 3.0 ports (USB4/5/6/7) on the I/O back

panel. The motherboard also has one USB 2.0 header (USB2/3) and one USB 3.0 header

(USB8/9). The onboard headers can be used to provide front side USB access with a cable

(not included).

Front Panel USB (3.0) (USB8/9)

Pin Denitions

Pin# Denition Pin# Denition

1 5V_USB30H1 11 USB_CON_PP6

2 USB_RX_CON_N1 12 USB_CON_PN6

3 USB_RX_CON_P1 13 GND

4 GND 14 USB_TX_CON_P2

5 USB_TX_CON_N1 15 USB_TX_CON_N2

6 USB_TX_CON_P1 16 GND

7 GND 17 USB_RX_CON_P2

8 USB_CON_PN5 18 USB_RX_CON_N2

9 USB_CON_PP5 19 5V_USB30H1

10 GND 20 X

1 2

AUDF1 SPK1

AUDIO

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

3

CRF1

WP1

PCH SLOT6 PCI-E 3.0 X1

PCH SLOT5 PCI-E 3.0 X1

HS1

CPU SLOT7 PCI-E 3.0 X16

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

USB4/5/6/7

(3.0)

CPU

Front Panel USB 2.0 (USB2/3)

Pin Denitions

Pin# Denition Pin# Denition

1 5V_USB20H2 2 5V_USB20H2

3 USB_CON_PN9 4 USB_CON_PN7

5 USB_CON_PP9 6 USB_CON_PP7

7 Ground 8 Ground

9 X 10 Ground

1. USB0/1

KB/MOUSE

FANS1

FANS2

2. USB4/5/6/7

3. USB2/3

4. USB8/9

CN2

FANC1

USB8/9 (3.0)

USB3F1

GPIO2

GPIO1

I-SATA4

BUZ1

I-SATA1

PCH

I-SATA5

I-SATA3

I-SATA0

NGFFB1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

CN1

PCHDR1

DBGH1

TPMH1

4

CMOS1

COM1

LEDH1

35

Page 36

C7C232-CB-ML User's Manual

I-SATA1

PCHDR1

CRF1

AUDF1 SPK1

CSOPN1

2.6 Connectors

Power Connections

Main ATX Power Supply Connector

The primary power supply connector (CN1) meets the ATX SSI EPS 24-pin specication. You

must also connect the 8-pin (CN2) processor power connector to your power supply.

ATX Power 24-pin Connector

Pin Denitions

Pin# Denition Pin# Denition

13 +3.3V 1 +3.3V

14 -12V 2 +3.3V

15 COM 3 COM

16 PS_ON 4 +5V

17 COM 5 COM

18 COM 6 +5V

19 COM 7 COM

20 Res (NC) 8 PWR_OK

21 +5V 9 5VSB

22 +5V 10 +12V

23 +5V 11 +12V

24 COM 12 +3.3V

OBR1

USB2/3 (2.0)

USB2F1

WP1

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

LEDH1

PCH SLOT5 PCI-E 3.0 X1

HS1

BUZ1

PCH

I-SATA5

I-SATA4

I-SATA3

I-SATA0

PCH SLOT6 PCI-E 3.0 X1

CPU SLOT7 PCI-E 3.0 X16

AUDIO

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

Required Connection

USB4/5/6/7

(3.0)

CPU

1

DBGH1

TPMH1

KB/MOUSE

FANS1

FANS2

CN2

FANC1

BT1

1. 24-Pin ATX Main PWR

DIMMA1

DIMMA2

DIMMB1

DIMMB2

36

Page 37

Chapter 2: Installation

Secondary Power Connector

CN2 must also be connected to the power supply. This connector is used to power the

processor.

+12V 8-pin Power

Pin Denitions

Pin# Denition

1 - 4 Ground

5 - 8 +12V

Required Connection

AUDF1 SPK1

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

LEDH1

PCH SLOT5 PCI-E 3.0 X1

HS1

BUZ1

PCH

I-SATA5

I-SATA4

I-SATA3

I-SATA0

I-SATA1

PCH SLOT6 PCI-E 3.0 X1

CPU SLOT7 PCI-E 3.0 X16

AUDIO

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

USB4/5/6/7

(3.0)

PCHDR1

1. 8-Pin PWR

KB/MOUSE

FANS1

FANS2

CN2

FANC1

CPU

BT1

TPMH1

DBGH1

1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

37

Page 38

C7C232-CB-ML User's Manual

21

2.7 Front Control Panel

LEDH1 contains header pins for various buttons and indicators that are normally located on

a control panel at the front of the chassis. These connectors are designed specically for use

with Supermicro chassis. See the gure below for the descriptions of the front control panel

buttons and LED indicators.

AUDF1 SPK1

KB/MOUSE

FANS1

FANS2

CN2

FANC1

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

PCH SLOT6 PCI-E 3.0 X1

PCH SLOT5 PCI-E 3.0 X1

HS1

AUDIO

CPU SLOT7 PCI-E 3.0 X16

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

USB4/5/6/7

(3.0)

CPU

USB8/9 (3.0)

USB3F1

BUZ1

PCH

CMOS1

COM1

LEDH1

GPIO2

GPIO1

I-SATA4

I-SATA1

I-SATA5

I-SATA3

I-SATA0

NGFFB1

CN1

PCHDR1

DBGH1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

TPMH1

Figure 2-3. LEDH1 Header Pins

SATA LED (+)

SATA LED (-)

Ground

FP Reset

PWR LED (+)

PWR LED (-)

PWR Button

Ground

+5V AUX

X

X

LAN LED

X

Ground

1413

38

Page 39

Chapter 2: Installation

21

Power Button

The Power Button connection is located on pins 5 and 6. Attach it to a power switch on the

computer case to power on the system.

Power Button

Pin Denitions

Pins Denition

5 Ground

6 PWR BTN

FP Reset Button

The Reset Button connection is located on pins 7 and 8. Attach it to a hardware reset switch

on the computer case to reset the system.

Reset Button

Pin Denitions

Pins Denition

7 FP Reset

8 Ground

LAN LED

The LAN LED connection for LAN ports is located on pins 11 and 12. Attach an NIC LED

cable to display network activities. Refer to the table below for pin denitions.

HDD LED

Pin Denitions

Pins Denition

11 +5V AUX

12 LAN LED

1. PWR Button

SATA LED (+)

SATA LED (-)

Ground

2

FP Reset

X

+5V AUX

PWR LED (+)

PWR LED (-)

PWR Button

Ground

X

LAN LED

2. Front Panel Reset

3. LAN LED

1

3

X

Ground

1413

39

Page 40

C7C232-CB-ML User's Manual

21

Power LED

The Power LED connection is located on pins 2 and 4.

Power LED

Pin Denitions

Pins Denition

2 PWR LED (+)

4 PWR LED (-)

HD LED PWR/SATA LED

The SATA LED connection is located on pins 1 and 3. Attach a cable here to indicate the

status of SATA-related activities.

SATA LED

Pin Denitions

Pins Denition

1 SATA LED (+)

3 SAT LED (-)

1. PWR LED

SATA LED (+)

SATA LED (-)

Ground

FP Reset

PWR LED (+)

PWR LED (-)

PWR Button

Ground

12

2. SATA HDD LED

+5V AUX

X

X

X

LAN LED

Ground

1413

40

Page 41

Chapter 2: Installation

I-SATA1

PCHDR1

CSOPN1

Headers

Fan Headers

There are two fan headers on the motherboard. FANC1 is the CPU fan, and FANS1 is the

system fan. These are 4-pin fan headers; pins 1-3 are backward compatible with traditional

3-pin fans. The onboard fan speeds are controlled by Thermal Management (via Hardware

Monitoring) in the BIOS. When using Thermal Management setting, please use all 3-pin fans

or all 4-pin fans.

Fan Header

Pin Denitions

Pin# Denition

1 Ground

2 +12V (Red)

3 Tachometer

4 PWM Control

Speaker Header

SPK1 is the internal audio speaker header.

Speaker header

Pin Denitions

Pin# Denition Pin# Denition

1 MONO_L 2 AUDIO_GROUND

3 MONO_R 4 X

5 AUDIO_GROUND 6 AUDIO_GROUND

7 MUTE_C 8 5V

AUDF1 SPK1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

LEDH1

3

PCH SLOT5 PCI-E 3.0 X1

BUZ1

I-SATA4

PCH SLOT6 PCI-E 3.0 X1

HS1

PCH

I-SATA5

I-SATA3

I-SATA0

AUDIO

CPU SLOT7 PCI-E 3.0 X16

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

USB4/5/6/7

(3.0)

CPU

DBGH1

TPMH1

KB/MOUSE

FANS1

FANS2

CN2

FANC1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

1. FANC1

2. FANS1

2

1

3. Speaker Header

41

Page 42

C7C232-CB-ML User's Manual

PCHDR1

Front Panel Audio Header

A 10-pin audio header at AUDF1 allows you to use the onboard sound for audio playback.

Connect an audio cable to the audio header to use this feature. See the table below pin

denitions.

10-pin Audio

Pin Denitions

Pin# Denition Pin# Denition

1 MIC2_L 2 AUDIO_GROUND

3 MIC2_R 4 FP_AUDIO_PRESENCE

5 FP_OUTR_R 6 MIC2_JD

7 FP_OUTR_SENSE 8 X

9 FP_OUTR_L 10 LINE2_JD

AUDF1 SPK1

1

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

LEDH1

PCH SLOT5 PCI-E 3.0 X1

HS1

BUZ1

PCH

I-SATA5

I-SATA4

I-SATA3

I-SATA0

I-SATA1

PCH SLOT6 PCI-E 3.0 X1

AUDIO

CPU SLOT7 PCI-E 3.0 X16

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

USB4/5/6/7

(3.0)

CPU

DBGH1

TPMH1

KB/MOUSE

FANS1

FANS2

CN2

FANC1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

1. Front Panel Audio

42

Page 43

Chapter 2: Installation

TPM Header

The TPMH1 header is used to connect a Trusted Platform Module (TPM), which is available

from a third-party vendor. A TPM is a security device that supports encryption and authentication

in hard drives. It enables the motherboard to deny access if the TPM associated with the hard

drive is not installed in the system. See the table below for pin denitions.

AUDF1 SPK1

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

PCH SLOT6 PCI-E 3.0 X1

PCH SLOT5 PCI-E 3.0 X1

HS1

Trusted Platform Module Header

Pin Denitions

Pin# Denition Pin# Denition

1 CLK_PCI_LPC 2 GND

3 LPC_FRAME# 4 No Pin

5 PL_TRST#_PCH 6 X

7 LPC_AD3 8 LPC_AD2

9 3.3VS) 10 LPC_AD1

11 LPC_AD0 12 GND

13 X 14 X

15 P3V3_S5 16 LPC_SERIRQ_PCH

17 GND 18 GND

19 SUS_STAT-N 20 X

AUDIO

CPU SLOT7 PCI-E 3.0 X16

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

USB4/5/6/7

(3.0)

CPU

KB/MOUSE

FANS1

FANS2

CN2

FANC1

1. TPM Header

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

LEDH1

I-SATA4

BUZ1

I-SATA1

PCH

I-SATA5

I-SATA3

I-SATA0

NGFFB1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

1

CN1

PCHDR1

DBGH1

TPMH1

43

Page 44

C7C232-CB-ML User's Manual

PC Health Header

PC health header at PCHDR1 monitors the power supply, fan and system temperatures. See

the table below for pin denitions.

PC Health Header

Pin Denitions

Pin# Denition Pin# Denition

1 5V_S0 2 3D3V_S0

3 SMB_CLK_PCHD 4 PLTRST#_PCH

5 SMB_DATA_PCHD 6 No Pin

7 Ground 8 Ground

Case Open Detection

A case open detection header is located at CSOPN1. Attach a cable from the chassis to the

header to inform you when the chassis is opened.

Chassis Intrusion

Pin Denitions

Pins Denition

1 Intrusion Input

2 Ground

AUDF1 SPK1

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

LEDH1

PCH SLOT5 PCI-E 3.0 X1

2

BUZ1

I-SATA4

I-SATA1

PCH SLOT6 PCI-E 3.0 X1

HS1

PCH

I-SATA5

I-SATA3

I-SATA0

AUDIO

CPU SLOT7 PCI-E 3.0 X16

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

USB4/5/6/7

(3.0)

1

PCHDR1

1. PC Health Header

KB/MOUSE

FANS1

FANS2

CN2

FANC1

CPU

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

TPMH1

DBGH1

2. Case Open Detection

44

Page 45

Chapter 2: Installation

SATA and SAS Ports

The C7C232-CB-ML has ve SATA 3.0 ports that are supported by the Intel PCH C232 chipset.

M.2 Slot

The M.2 slot at NGFFB1 is designed for internal mounting devices. The C7C232-CB-ML

motherboard deploys an M key only dedicated for SSD devices with the ulitmate performance

capability in a PCI Express 3.0 X4 interface for native PCI-E SSD support.

AUDF1 SPK1

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

LEDH1

4 3

PCH SLOT5 PCI-E 3.0 X1

HS1

BUZ1

PCH

5

I-SATA5

I-SATA4

I-SATA3

I-SATA0

I-SATA1

PCH SLOT6 PCI-E 3.0 X1

12

AUDIO

CPU SLOT7 PCI-E 3.0 X16

6

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

USB4/5/6/7

(3.0)

PCHDR1

1. I-SATA0

KB/MOUSE

2. I-SATA1

3. I-SATA3

FANS1

FANS2

CN2

FANC1

CPU

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

TPMH1

DBGH1

4. I-SATA4

5. I-SATA5

6. M.2 Slot

45

Page 46

C7C232-CB-ML User's Manual

CSOPN1

Internal Speaker/Buzzer

The Internal Speaker/Buzzer at BUZ1 is used to provide audible indications for various beep

codes. See the table below for pin denitions.

Internal Buzzer

Pin Denitions

Pin# Denition

1 Pos (+) Beep In

2 Neg (-) Alarm Speaker

Front Accessible USB 2.0 Header

CRF1 is a USB header used to provide front access USB 2.0 connection. See the table below

for pin denitions.

USB 2.0 Header

Pin Denitions

Pin# Denition

1 X

2 Ground

3 USB_CON_PP8

4 USB_CON_PN8

5 5V_USB20H1

AUDF1 SPK1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

GPIO1

COM1

LEDH1

PCH SLOT5 PCI-E 3.0 X1

2

BUZ1

I-SATA4

I-SATA1

PCH SLOT6 PCI-E 3.0 X1

HS1

1

PCH

I-SATA5

I-SATA3

I-SATA0

AUDIO

CPU SLOT7 PCI-E 3.0 X16

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

USB4/5/6/7

(3.0)

PCHDR1

1. Internal Speaker

2. USB 2.0 Header

KB/MOUSE

FANS1

FANS2

CN2

FANC1

CPU

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

TPMH1

DBGH1

46

Page 47

Chapter 2: Installation

PCHDR1

USB2/3 (2.0)

CRF1

WP1

AUDF1 SPK1

CSOPN1

COM1

LEDH1

2.8 Jumper Settings

How Jumpers Work

To modify the operation of the motherboard, jumpers can be used to choose between optional

settings. Jumpers create shorts between two pins to change the function of the connector.

Pin 1 is identied with a square solder pad on the printed circuit board. See the diagram

at right for an example of jumping pins 1 and 2. Refer to the motherboard layout page for

jumper locations.

Note: On two-pin jumpers, "Closed" means the jumper is on and "Open" means the

jumper is off the pins.

Connector

Pins

3 2 1

Jumper

3 2 1

Setting

System Recovery

OBR1 is the system recovery jumper. Leave the jumper off (Open) this two-pin jumper for

normal operation. Close it for system recovery.

System Recovery

Jumper Settings

Jumper Setting Denition

Open Normal

Closed System recovery

1. System Recovery

DBGH1

TPMH1

KB/MOUSE

FANS1

FANS2

CN2

FANC1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

AUDIO

USB4/5/6/7

USB0/1

(3.0)

CPU SLOT7 PCI-E 3.0 X16

NGFFB1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

CPU

PCH SLOT6 PCI-E 3.0 X1

PCH SLOT5 PCI-E 3.0 X1

OBR1

1

USB2F1

HS1

USB8/9 (3.0)

USB3F1

BUZ1

PCH

CMOS1

GPIO2

GPIO1

I-SATA5

I-SATA4

I-SATA3

I-SATA0

I-SATA1

47

Page 48

C7C232-CB-ML User's Manual

CMOS Clear

CMOS1 is used to clear CMOS, which will also clear any passwords.

CMOS Clear

Jumper Settings

Jumper Setting Denition

Pins 1-2 Normal

Pins 2-3 Clear CMOS

Write Protect Header

WP1 allows you to enable or disable the SPI Flash ROM write protection.

Write Protect header

Jumper Settings

Jumper Setting Denition

Pins 1-2 Disabled (default)

Pins 2-3 Enabled

AUDF1 SPK1

TPMH1

KB/MOUSE

FANS1

FANS2

CN2

FANC1

BT1

DIMMA1

DIMMA2

DIMMB1

DIMMB2

AUDIO

CSOPN1

OBR1

USB2/3 (2.0)

USB2F1

CRF1

WP1

2

USB8/9 (3.0)

USB3F1

CMOS1

GPIO2

1

GPIO1

COM1

LEDH1

PCH SLOT5 PCI-E 3.0 X1

HS1

BUZ1

PCH

I-SATA5

I-SATA4

I-SATA3

I-SATA0

I-SATA1

PCH SLOT6 PCI-E 3.0 X1

CPU SLOT7 PCI-E 3.0 X16

NGFFB1

USB0/1

LAN1

C7C232-CB-ML

Rev. 1.00

CN1

USB4/5/6/7

(3.0)

PCHDR1

CPU

DBGH1

1. CMOS Clear

2. Write Protect Header

48

Page 49

Chapter 3: Troubleshooting

Chapter 3

Troubleshooting

3.1 Troubleshooting Procedures

Use the following procedures to troubleshoot your system. If you have followed all of the

procedures below and still need assistance, refer to the ‘Technical Support Procedures’ and/

or ‘Returning Merchandise for Service’ section(s) in this chapter. Always disconnect the AC

power cord before adding, changing or installing any non hot-swap hardware components.

Before Power On

1. Check that the power LED on the motherboard is on.

2. Make sure that the power connector is connected to your power supply.

3. Make sure that no short circuits exist between the motherboard and chassis.

4. Disconnect all cables from the motherboard, including those for the keyboard and

mouse.

5. Remove all add-on cards.

6. Install a CPU, a heatsink*, and connect the internal speaker and the power LED to the

motherboard. Check all jumper settings as well. (Make sure that the heatsink is fully

seated.)

7. Use the correct type of onboard CMOS battery (CR2032) as recommended by the

manufacturer. To avoid possible explosion, do not install the CMOS battery upside down.

No Power

1. Make sure that no short circuits exist between the motherboard and the chassis.

2. Verify that all jumpers are set to their default positions.

3. Check that the 115V/230V switch on the power supply is properly set.

4. Turn the power switch on and off to test the system.

5. The battery on your motherboard may be old. Check to verify that it still supplies

~3VDC. If it does not, replace it with a new one.

49

Page 50

C7C232-CB-ML User's Manual

No Video

1. If the power is on but you have no video, remove all the add-on cards and cables.

2. Use the speaker to determine if any beep codes exist. Refer to Appendix A for details on

beep codes.

Note: If you are a system integrator, VAR or OEM, a POST diagnostics card is recommended. For I/O port 80h codes, refer to Appendix B.

System Boot Failure

If the system does not display POST (Power-On-Self-Test) or does not respond after the

power is turned on, check the following:

1. Check for any error beep from the motherboard speaker.

• If there is no error beep, try to turn on the system without DIMM modules installed. If there

is still no error beep, replace the motherboard.

• If there are error beeps, clear the CMOS settings by unplugging the power cord and

contacting both pads on the CMOS Clear Jumper (JBT1). Refer to chapter 2.

2. Remove all components from the motherboard, especially the DIMM modules. Make

sure that system power is on and that memory error beeps are activated.

3. Turn on the system with only one DIMM module installed. If the system boots, check for

bad DIMM modules or slots by following the Memory Errors Troubleshooting procedure

in this Chapter.

Memory Errors

1. Make sure that the DIMM modules are properly and fully installed.

2. Conrm that you are using the correct memory. Also, it is recommended that you use

the same memory type and speed for all DIMMs in the system. See Section 2.4 for

memory details.

3. Check for bad DIMM modules or slots by swapping modules between slots and noting

the results.

4. Check the power supply voltage 115V/230V switch.

50

Page 51

Chapter 3: Troubleshooting

Losing the System's Setup Conguration

1. Make sure that you are using a high quality power supply. A poor quality power supply

may cause the system to lose the CMOS setup information. Refer to Section 1.5 for

details on recommended power supplies.

2. The battery on your motherboard may be old. Check to verify that it still supplies

~3VDC. If it does not, replace it with a new one.

3. If the above steps do not x the setup conguration problem, contact your vendor for

repairs.

When the System Becomes Unstable

A. If the system becomes unstable during or after OS installation, check the following:

1. CPU/BIOS support: Make sure that your CPU is supported and that you have the latest

BIOS installed in your system.

2. Memory support: Make sure that the memory modules are supported by testing the

modules using memtest86 or a similar utility.

Note: Refer to the product page on our website at http:\\www.supermicro.com for

memory and CPU support and updates.

3. HDD support: Make sure that all hard disk drives (HDDs) work properly. Replace the

bad HDDs with good ones.

4. System cooling: Check the system cooling to make sure that all heatsink fans and CPU/

system fans, etc., work properly. Check the hardware monitoring settings in the IPMI

to make sure that the CPU and system temperatures are within the normal range. Also

check the front panel Overheat LED and make sure that it is not on.

5. Adequate power supply: Make sure that the power supply provides adequate power to

the system. Make sure that all power connectors are connected. Please refer to our

website for more information on the minimum power requirements.

6. Proper software support: Make sure that the correct drivers are used.

B. If the system becomes unstable before or during OS installation, check the following:

1. Source of installation: Make sure that the devices used for installation are working

properly, including boot devices such as CD/DVD and CD/DVD-ROM.

2. Cable connection: Check to make sure that all cables are connected and working

properly.

51

Page 52

C7C232-CB-ML User's Manual

3. Using the minimum conguration for troubleshooting: Remove all unnecessary

components (starting with add-on cards rst), and use the minimum conguration (but

with a CPU and a memory module installed) to identify the trouble areas. Refer to the

steps listed in Section A above for proper troubleshooting procedures.

4. Identifying bad components by isolating them: If necessary, remove a component in

question from the chassis, and test it in isolation to make sure that it works properly.

Replace a bad component with a good one.

5. Check and change one component at a time instead of changing several items at the

same time. This will help isolate and identify the problem.

6. To nd out if a component is good, swap this component with a new one to see if the

system will work properly. If so, then the old component is bad. You can also install the

component in question in another system. If the new system works, the component is

good and the old system has problems.

52

Page 53

Chapter 3: Troubleshooting

3.2 Technical Support Procedures

Before contacting Technical Support, please take the following steps. Also, note that as a

motherboard manufacturer, we do not sell directly to end-users, so it is best to rst check with

your distributor or reseller for troubleshooting services. They should know of any possible

problem(s) with the specic system conguration that was sold to you.

1. Please review the ‘Troubleshooting Procedures’ and 'Frequently Asked Questions'

(FAQs) sections in this chapter or see the FAQs on our website before contacting

Technical Support.

2. BIOS upgrades can be downloaded from our website. Note: Not all BIOS can be

ashed depending on the modications to the boot block code.

3. If you still cannot resolve the problem, include the following information when contacting

us for technical support:

• Motherboard model and PCB revision number

• BIOS release date/version (this can be seen on the initial display when your system rst

boots up)

• System conguration

An example of a Technical Support form is posted on our website.

Distributors: For immediate assistance, please have your account number ready when

contacting our technical support department by e-mail.

53

Page 54

C7C232-CB-ML User's Manual

3.3 Frequently Asked Questions

Question: What type of memory does my motherboard support?

Answer: The motherboard supports up to 64 GB of DDR4 2133MHZ ECC UDIMM memory.

See Section 2.4 for details on installing memory.

Question: How do I update my BIOS?

Answer: It is recommended that you do not upgrade your BIOS if you are not experiencing

any problems with your system. Updated BIOS les are located on our website at http://www.