Page 1

USER MANUAL

BroadLighter-M Series

Broadband Superluminescent Diode

Benchtop Light Source

Superlum, Unit B3, Fota Point Enterprise Park, Carrigtwohill, Co. Cork, Ireland.

Phone: +353 21 4533666, fax: +353 21 4533026, e-mail: sales@superlum.ie

www.superlumdiodes.com

Superlum reserves the right to change or make corrections to this manual further without notice.

Revision 16

June 2015

Page 2

Page 3

Declaration of Conformity

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name: Superlum Diodes Ltd.

Manufacturer’s Address: Unit B3, Fota Point Enterprise Park

Carrigtwohill, Co Cork

Ireland

Declares that,

Product Name: Broadband Superluminescent Diode Benchtop Light

Source

Product Number: BroadLighter-M

Product Options: This declaration covers all options of the above

product(s).

This product complies with the following standards/ requirements:

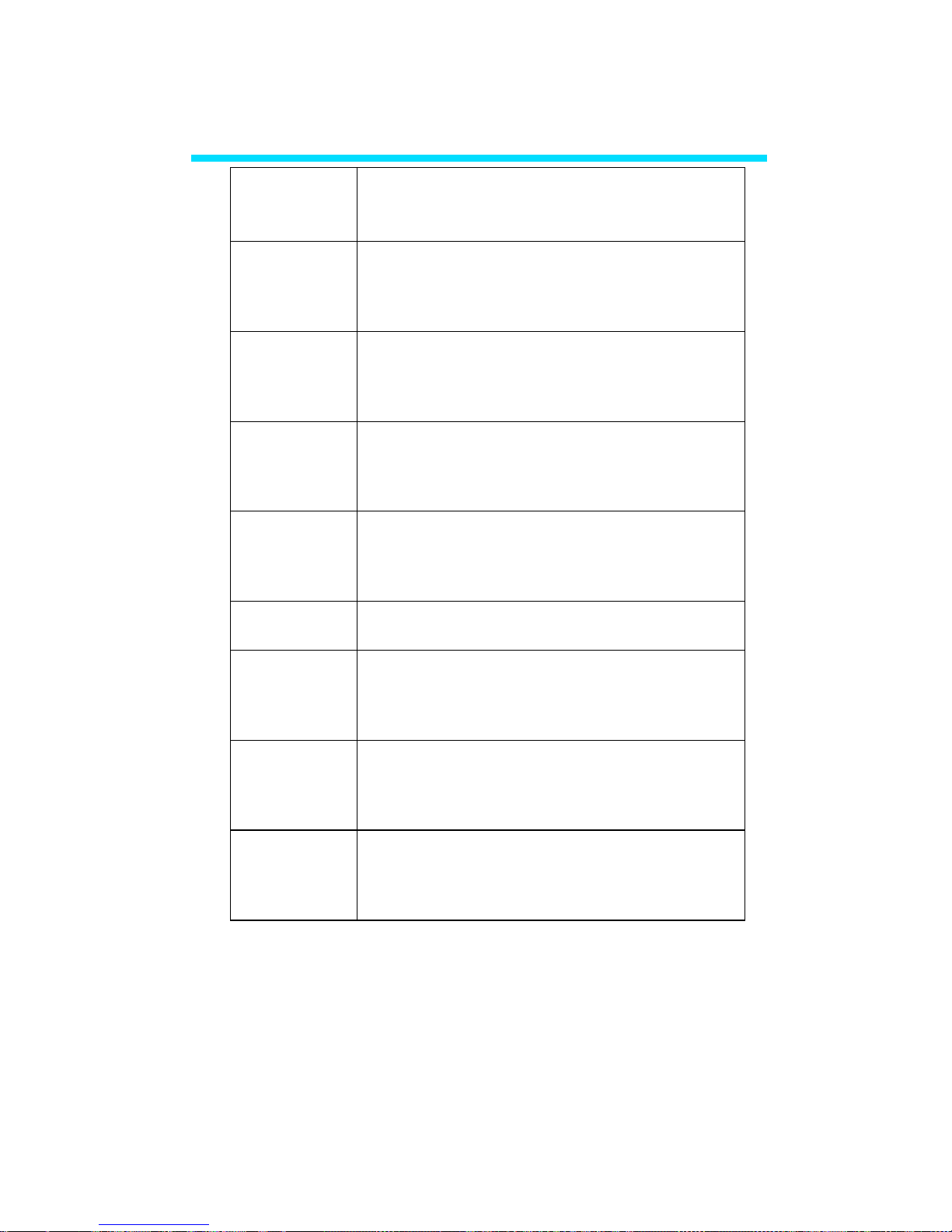

EMC

Standard

Limit

IEC 61326-1:1997+A1:1998 / EN

61326-1:1997+A1:1998

Group 1 Class A

CISPR 11:1990 / EN 55011:1991

4kV CD, 8kV AD

IEC 61000-4-2:1995+A1:1998 /

EN 61000-4-2:1995

3 V/m, 80-1000

MHz

IEC 61000-4-3:1995 / EN 610004-3:1995

0.5kV signal lines,

1kV power lines

IEC 61000-4-4:1995 / EN 610004-4:1995

0.5 kV line-line, 1

kV line-ground

3V, 0.15-80 MHz

IEC 61000-4-5:1995 / EN 610004-5:1995

0.5 kV line-line, 1

kV line-ground

IEC 61000-4-6:1996 / EN 610004-6:1996

Dips: 30% 10ms;

60% 100ms

IEC 61000-4-11:1994 / EN

61000-4-11:1994

Interrupt >

95%@5000ms

The product was tested in a

typical configuration

Safety

IEC 61010-1:1990+A1:1992+A2:1995 /

N 61010-1:1993+A2:1995

Laser

Safety

IEC 60825-1:2014

Page 4

BroadLighter-M Series

User Manual

Revision 16

1

Certificate Exclusions

This Declaration, and all documentation, and all

equipment cited herein, shall cease to conform to and/or

be compliant with the above Directives, Standards and

Specifications unless the following conditions are

complied with and applied by the Purchaser /User:

This Product shall be installed, used and

maintained as directed by Superlum.

The Product shall not be modified and/or changed

without prior written approval of Superlum.

Although every effort is made by Superlum to comply with

the above Directives and Standards, it is the responsibility

of the Purchaser and/or User of the equipment to ensure

that all claims and assurances with regards to such

directives and Standards are complete, correct and

satisfied.

IEC 825-1

Page 5

Warranty

2

Warranty

Warranty

Superlum warrants the BroadLighter-M Broadband SLD

Benchtop Light Source for a period of 12 months from the

date of shipment. During this warranty period Superlum

will repair / exchange any unit proven to be defective.

Repairs are warranted for the balance of the original

warranty period or at least 90 days.

For warranty repairs or service the unit must be

returned to Superlum at the customer’s expense.

Limitation of Warranty

Superlum will not accept liability for any incidental

damage caused by the failure of this product. This

warranty does NOT cover:

Any defect/damage caused by improper

operation.

Accompanying accessories, e.g. fiber optical

patchcables, AC power cords, etc.

Dismantling any part of the unit without prior approval

from Superlum will void the warranty.

Page 6

BroadLighter-M Series

User Manual

Revision 16

3

Statement of Calibration

Superlum certifies that this product has been inspected,

tested, and calibrated to meet its published specifications.

Page 7

TABLE OF CONTENTS

4

TABLE OF CONTENTS

Warranty ...................................................................... 2

TABLE OF CONTENTS ............................................... 4

Safety Symbols and Terms ........................................ 7

General Safety Information ........................................ 9

Acronyms and Abbreviations .................................. 20

1. General Information .............................................. 22

1.In This Manual …………………………………………………………….22

1.2 Instrument Description ................................................. 25

1.3 Product Specifications ................................................. 32

2. Installation ............................................................. 35

2.1 Unpacking and Initial Inspection................................. 35

2.1.1 Unpacking the Instrument ................................ 35

2.1.2 Initial Inspection ................................................. 36

2.2 Preparation for Use ...................................................... 38

3. Local Mode of Operation ...................................... 40

3.1 Front-Panel Features ................................................... 40

Page 8

BroadLighter-M Series

User Manual

Revision 16

5

3.2 Rear-Panel Features .................................................... 42

3.3 Operating Instructions .................................................. 44

3.4 Power OFF Instructions ............................................... 47

3.5 Interface Menu .............................................................. 48

3.5.1 Main Interface Screen....................................... 48

3.5.2 Main Screen Status Messages ....................... 52

3.5.3 Main Screen Status Indicators ........................ 53

3.5.4 Main Menu .......................................................... 54

4. Remote Mode of Operation .................................. 57

4.1 Remote Control Interface ............................................ 58

4.2 USB interface… ............................................................ 60

4.2.1 System Commands ........................................... 62

4.2.2 USB Mode Commands ..................................... 64

4.3 Superlum Companion Software ................................. 77

4.3.1 Minimum System Requirements .................... 78

4.3.2 Installing the USB drivers ................................ 79

4.3.3 Installing Companion Software ...................... 80

Page 9

6

4.3.4 User Interface .................................................... 81

4.3.5 Self Test Procedure .......................................... 84

4.3.6 Uninstalling the Program .................................. 86

5. Cleaning Instructions ........................................... 87

5.1 Safety Precautions ....................................................... 87

5.2 Cleaning………………………………………………………….………….89

6. Service and Support ............................................ 92

6.1 Returning the Instrument for Servicing ...................... 92

6.2 Preparing the Instrument for Shipment ..................... 93

6.3 Instrument Disposal ...................................................... 95

Page 10

BroadLighter-M Series

User Manual

Revision 16

7

Safety Symbols and Terms

This section deals with information on the safety symbols

and terms which are used on the instrument or in the

manual, and gives explanations about what they stand

for. These symbols and terms indicate precautions you

must strictly follow to safely operate the instrument.

Before you begin using your BroadLighter-M,

please read the following explanations:

The WARNING sign denotes a hazard. It

calls attention to a procedure, practice,

or the like, which, if not correctly

performed or adhered to, could result in

personal injury. Do not proceed beyond

a WARNING sign until the indicated

conditions are fully understood and

met.

The CAUTION sign denotes a hazard. It

calls attention to an operating procedure,

or the like, which, if not correctly performed

or adhered to, could result in damage to or

destruction of the entire product or part

thereof. Do not proceed beyond a

CAUTION sign until the indicated

conditions are fully understood and met.

WARNING

CAUTION

Page 11

Safety Symbols and Terms

8

The NOTE sign denotes important

information. It calls attention to

procedures, practice, condition, or the like,

which is essential to highlight.

The CE mark shows that the product

complies with all relevant European Legal

Directives.

The warning label denotes visible and/or

invisible laser radiation.

This label means the compliance with the

requirement of COMPLIANT the RoHS

Directive (Directive 2002/95/EC).

NOTE

Page 12

BroadLighter-M Series

User Manual

Revision 16

9

General Safety Information

High voltage inside. To avoid

electrical shock, before powering

unit, make sure that the protective

conductor of the 3-conductor power

cord is correctly connected to the

protective earth contact of the socket

outlet. Improper grounding can

cause electric shock resulting in

severe injury or even death. Do not

operate without cover installed.

This unit must not be operated in an

explosive environment.

The general safety precautions must be observed during all

phases of operation, service, and repair of the instrument.

Failure to comply with these precautions or with specific

warnings elsewhere in this manual violates safety standards of

design, manufacture, and intended use of the instrument.

Superlum assumes no liability for the customer failure to comply

with these requirements.

Before Applying Power, verify that the product is set to match

the available line voltage.

WARNING

Page 13

General Safety Information

10

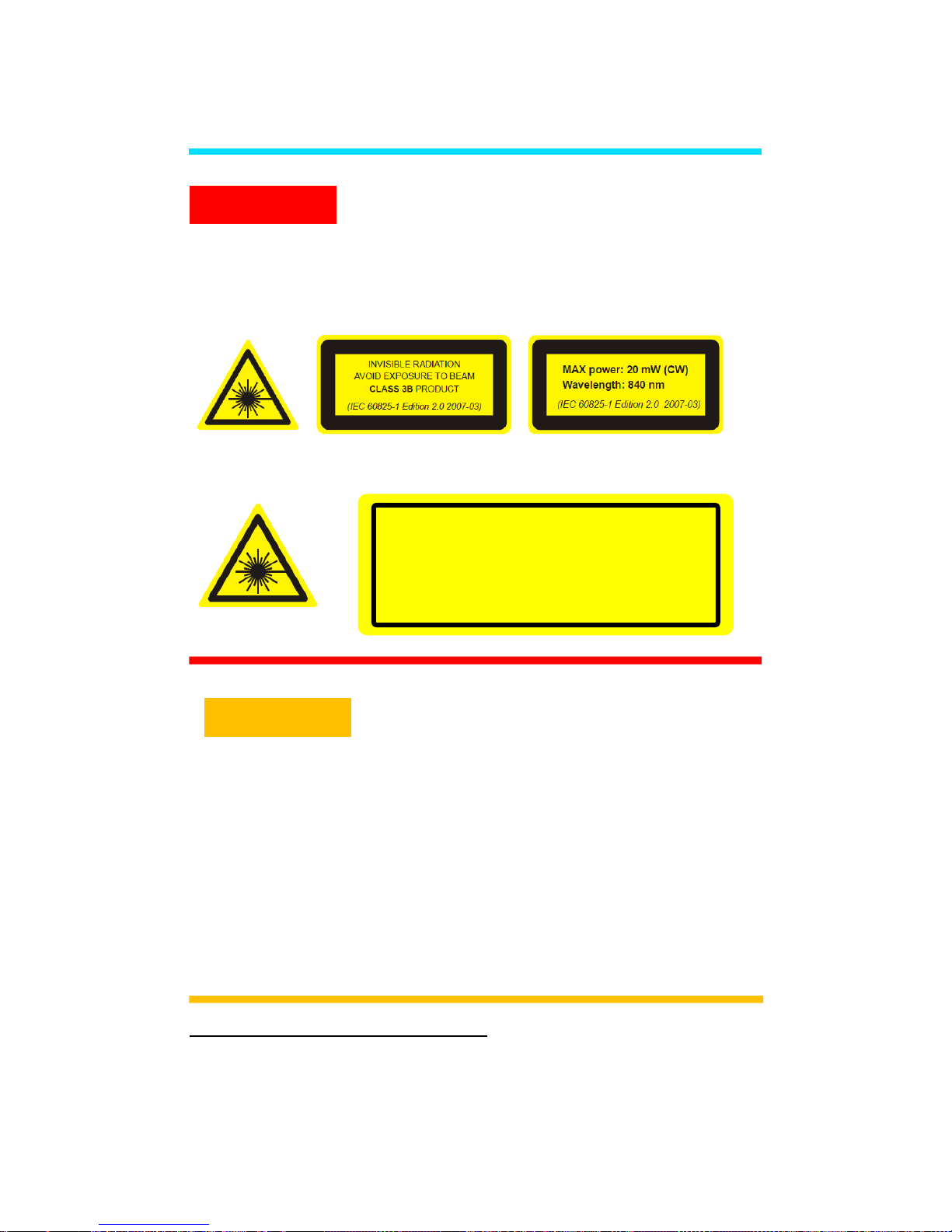

Avoid Exposure – Laser Radiation emitted from

optical aperture. BroadLighter-M contains one of

the following sets of Laser Safety Information

Labels

1

.

Set 1:

Set 2:

Depending on the configuration of the

BroadLighter-M, the instrument can be assigned

to Class 1, Class 3R or Class 3B laser product in

accordance with IEC 60825-1:2014. Refer to Laser

Safety label placed on the top panel and read the

safety information related to the safety class of

your instrument. Use of controls or adjustments

or performance of procedures other than those

specified herein may result in hazardous

radiation exposure.

1

The labels shown are the examples and for reference only. The actual labels and their position

may differ.

WARNING

CAUTION

WARNING – CLASS 3B INVISIBLE LASER RADIATION

AVOID EXPOSURE TO BEAM CLASS 3B LASER

PRODUCT

Wavelength: 750-1100 nm

CW/Pulsed: CW

Max Average Power: < 50 mW

Complies with IEC/EN 60825-1:(2014)

Page 14

BroadLighter-M Series

User Manual

Revision 16

11

Output Aperture for BroadLighter-M is a

single mode optical fiber with

numerical aperture2 (NA) = 0.14.

Laser Safety Labeling

Depending on configuration, BroadLighter-M can be attributed

to different classes of Laser Safety according to IEC 608251:2014. The interior of BroadLighter-M contains Laser Safety

labels. Laser safety information label is located on the lid of the

instrument. Laser aperture label is located next to FC/APC

connector on the front panel of an instrument. Laser Hazard

label is located on the lid of an instrument.

CLASS 1 Laser Product

Light sources assigned to Class 1 are safe during the use,

including the long-term direct intrabeam viewing, even if the

exposure with optical viewing instruments (e.g. eye loupes or

binoculars) occurs. Extra care must be taken to the following:

Using controls, adjustments, or operating procedures that are

different from those specified in this manual may result in

radiation exposure hazardous to the user.

When the instrument is used with certain optical elements—

such as optical amplifiers, lenses, collimators, and the like—

which are not supplied with the product as original accessories,

or the product is integrated into a high-level system, it is strictly

2

Parameter may vary for a custom version of BroadLighter-M

NOTE

Page 15

General Safety Information

12

recommended to reclassify the final optical system in order to

determine its total degree of optical radiation hazard. The

reason for this is that the Class may increase under these

conditions. It is the responsibility of a person (or organization)

who performs such integration to provide correct

reclassification for the optical system at the final stage.

It must be noted that it is the user who is responsible for being

aware of possible risk associated with using Class 1 laser

products as well as being adequately trained for working with

such light sources. Superlum is not liable for any personal

injury, property damage, or other (direct or indirect) damage of

any nature caused by personal faults, improper and/or

inadequate using of the instrument coming from disregarding

the necessary aspects of laser safety.

According to IEC 60825-1, this product

has been classified for an exposure

duration of up to 100 ms. For other

practical applications in which the

exposure duration is greater than 100

ms, the product must be reclassified.

CLASS 3R Laser Product

Light sources assigned to Class 3R emit optical radiation that

can exceed the MPE (Maximum Permissible Exposure) under

NOTE

Page 16

BroadLighter-M Series

User Manual

Revision 16

13

the direct intrabeam viewing, but in most cases the risk of injury

is relatively small because the AEL (Accessible Emission Limit)

for Class 3R is only 5 times greater than the AEL for Class 1,

which is safe for the user. The risk of injury rises as the

exposure duration increases. The exposure will be safe for the

user unless it is a deliberate ocular exposure.

The risk of injury is actually minimized due to the following facts:

Unintentional exposures would rarely reflect worst-

case conditions, for example, of beam alignment with

the pupil or worst-case accommodation.

The inherent safety margin in the MPE.

Natural aversion behavior for exposure to bright light

for the case of visible radiation and by the response to

heating of the cornea for far infrared radiation.

The direct intrabeam viewing is supposed to be unlikely for

possible practical applications of this instrument. Otherwise, the

user should reclassify the instrument. If you are unsure about

providing the correct reclassification, contact Superlum on this

issue.

Using controls, adjustments or operating procedures that are

different from those specified in this manual may result in

radiation exposure hazardous to the user. When the instrument

is used with certain optical elements, such as optical amplifiers,

lenses, collimators, etc., which are not supplied with the product

as original accessories, or the product is integrated into a high-

Page 17

General Safety Information

14

level system, it is strictly recommended to reclassify the final

optical system. The reason for this is that the Class may

increase under these conditions. It is the responsibility of an

end-user who performs such integration to provide correct

reclassification for the optical system at the final stage. It must

be noted that it is the user who is responsible for being aware

of possible risk associated with using Class 3R laser products

as well as being adequately trained for working with such lighter

sources. Superlum is not liable for any personal injury, property

damage, or other (direct or indirect) damage of any nature

caused by personal faults, improper and/or inadequate using of

the instrument coming from disregarding the necessary aspects

of laser safety. These features are as follows:

Key-operated master control

Remote interlock connector

Illuminated indicator on the pushbutton for the output

emission activation

Audible and visible warning signals for the output

emission activation

Protective metal cap for the optical output

Laser safety labeling

This manual contains the most comprehensive information on

the laser safety controls (and measures) built into the

instrument.

Page 18

BroadLighter-M Series

User Manual

Revision 16

15

According to IEC 60825-1, this product

has been classified for an exposure

duration of up to 100 ms. The product

must be reclassified for practical

applications in which the exposure

duration is greater than 100 ms.

CLASS 3B Laser Product

Light sources assigned to Class 3B are always hazardous for

the intra beam ocular viewing even if an accidental short-time

exposure occurs. Viewing them through optical elements with

diffuse-reflecting properties is usually safe for the user. Pay

close attention to the following information: Using controls,

adjustments, or operating procedures that are different from

those specified in this manual may result in radiation exposure

hazardous to the user.

When the instrument is used with certain optical elements such

as optical amplifiers, lenses, collimators, etc., which are not

supplied with the product as the original accessories, or the

product is integrated into a high-level system, it is strictly

recommended to reclassify the final optical system in order to

determine its total degree of optical radiation hazard.. It is the

responsibility of an end user who performs such integration to

provide correct reclassification for the optical system. It must be

noted that it is the end-user who is responsible for being aware

NOTE

Page 19

General Safety Information

16

of possible risk associated with using Class 3B laser products

as well as being adequately trained or working with such lighter

sources. Superlum is not liable for any personal injury, property

damage, or other (direct or indirect) damage of any nature

caused by personal faults, improper and/or inadequate using of

the instrument coming from disregarding the necessary aspects

of laser safety. Incorporated into BroadLighter-M are the

following laser safety features:

Key-operated master control

Remote interlock connector

Illuminated indicator on the pushbutton for the output

emission activation

Audible and visible warning signals for the output

emission activation

Protective metal cap for the optical output

Laser safety labeling

This manual contains the most comprehensive information on

the laser safety controls (and measures) built into the

instrument. Please read thoroughly this manual to acquaint

yourself with all features and functions for laser safety before

you start working with the BroadLighter-M.

Page 20

BroadLighter-M Series

User Manual

Revision 16

17

According to IEC 60825-1, this product

has been classified for an exposure

duration of up to 100 ms. The product

must be reclassified for practical

applications in which the exposure

duration is greater than 100 ms.

NOTE

Page 21

General Safety Information

18

Safety Earth Ground

To minimize shock hazard, the instrument chassis and cabinet

must be connected to an electrical ground. The instrument must

be connected to the AC power line through a three-conductor

power cable, with the third wire firmly connected to an electrical

ground (safety ground) at the power outlet. Any interruption of

the protective (grounding) conductor or disconnection of the

protective earth terminal will cause a potential shock hazard

that could result in personal injury.

DO NOT operate the instrument in an explosive

atmosphere or in the presence of flammable

gases or fumes.

DO NOT perform procedures involving cover or

shield removal unless you are qualified to do

so. Operating personnel must not remove

equipment covers or shields. Procedures

involving the removal of covers and shields are

to be performed by service-trained personnel

only.

DO NOT operate damaged equipment.

Whenever it is possible that the safety

protection features built into this product have

been impaired, either through physical

Page 22

BroadLighter-M Series

User Manual

Revision 16

19

damage, excessive moisture or any other

reason, remove power and do not use the

product. Return the product to Superlum to

ensure the safety features are operational.

DO NOT substitute parts or modify equipment.

Because of the danger of introducing additional

hazards, do not install substitute parts or

perform any unauthorized modification to the

product. Return the product to Superlum for

service and repair.

Page 23

Acronyms and Abbreviations

20

Acronyms and Abbreviations

The necessary information on acronyms and abbreviations is

summarized in the following table:

TABLE A. Acronyms and Abbreviations Used

Abbreviation

Definition

O

C

Degree Celsius

mW

Milliwatt

nm

Nanometre

dB

Decibel

AC

Alternating Current

AEL

Accessible Emission Limit

APC

Automatic Power Control

BLS

Broadband Light Source

CW

Continuous Wave

DC

Direct Current

LED

Light Emitting Diode

MPE

Maximum Permissible Emission

NA

Numerical Aperture

PC

Personal Computer

SLD

Superluminescent Diode

TEC Thermoelectric Cooler

Page 24

BroadLighter-M Series

User Manual

Revision 16

21

If you see a term for which the definition

is not given here, refer to special

reference books for the necessary

explanations or consult with Superlum

on this issue.

NOTE

Page 25

1. General Information

22

1. General Information

This chapter contains general information concerning the

BroadLighter-M Broadband SLD Benchtop Light Source.

Included in this chapter are a description of the instrument, an

outline of this manual, general specifications, information on the

Laser Class to which your BroadLighter-M is assigned, and a

description of the laser safety measures employed in this

equipment.

1.1 In This Manual

This manual contains the most comprehensive information

required to install, operate, and clean your Superlum

BroadLighter-M Broadband SLD Benchtop Light Source.

The goal of this section is to give a short overview of the

chapters and sections comprising this document. Knowing the

layout of the manual helps you find answers to the vast majority

of questions you may have about installing, using,

programming, cleaning, and servicing your BroadLighter-M.

The manual consists of six chapters. Detailed information about

the principles of operation, installing, and using the

BroadLighter-M is provided in four chapters which are placed at

the beginning of the manual. At the end of the document there

are two chapters containing additional information (i.e. detailed

Page 26

BroadLighter-M Series

User Manual

Revision 16

23

instructions) about cleaning and obtaining service. Use the

manual as a reference book when you are installing and

operating with the instrument.

Please, carefully read this manual before using your

BroadLighter-M. You should pay attention to the warnings and

cautions presented in this manual. If necessary, refer to section

"Safety Symbols and Terms" for definitions of these terms. If,

after reading this manual, some of the explanations remain

unclear to you or you need extra information on a particular

issue, do not hesitate to contact Superlum for more details or

additional explanations.

The chapters in this manual are set out as follows:

Chapter 1, "General Information", begins with outlining

the scope of this manual. After that, you will find background

information concerning the BroadLighter design and the

principles of operation. Following this are technical

specifications on the product and laser safety information,

which are provided in the corresponding sections of the

chapter.

Chapter 2, "Installation", takes you through unpacking

and inspection procedures and explains how to prepare the

BroadLighter-M for use.

Page 27

1. General Information

24

Chapter 3, "Local Mode of Operation", introduces frontand rear-panel features and provides detailed operating

instructions to demonstrate how to use the BroadLighter-M.

Chapter 4, "Remote Mode of Operation", explains how to

control the instrument remotely via a PC. It provides a full

description of each command and query supported by the

instrument and the most comprehensive information on the

Superlum BroadLighter-M Companion Software, which comes

with the instrument.

Chapter 5, "Cleaning Instructions", deals with a

description of the proper cleaning procedures that you should

regularly apply to both the BroadLighter-M and optical

accessories, such as optical patchcables, adapters, optical

connectors, etc.

Chapter 6, "Service and Support", explains what you

should do if you encounter a problem with the instrument. It also

gives detailed recommendations for repacking the instrument

before returning it to Superlum for servicing.

Page 28

BroadLighter-M Series

User Manual

Revision 16

25

1.2 Instrument Description

For a number of optical applications, such as optical coherence

tomography, optical metrology, characterization of optical

components etc., broadband light sources based on the use of

SLD modules are considered to be best suited. The reason for

choosing these optical modules is related to their remarkable

performance parameters. Among all types of modules

presented on the market, the SLD modules best combine high

optical power similar to that emitted by laser diodes with

broadband optical spectra characteristics of LEDs. These

advantages of SLDs allow the user to avoid unwanted

interference effects, like speckle or ghost signals. In contrast,

narrowband light sources such as laser diodes often give rise

to such effects due to a high temporal coherence of their output

emission.

The BroadLighter-M is an advanced SLD-based

broadband light source intended for a benchtop applications.

Among other broadband light sources of this kind, it features

excellent performance parameters, easy-to-use front-panel

operation, and long-term stability of its technical characteristics,

high reliability, minimal maintenance, and many others. The

instrument can be controlled either manually by using its frontpanel controls or remotely via PC. For remote control, the

instrument is equipped with USB and REMOTE CONTROL

interface. Superlum BroadLighter-M Companion Software,

Page 29

1. General Information

26

which is supplied with the instrument, has a user-friendly

interface that permits the user to put the instrument under

remote control immediately after its installation.

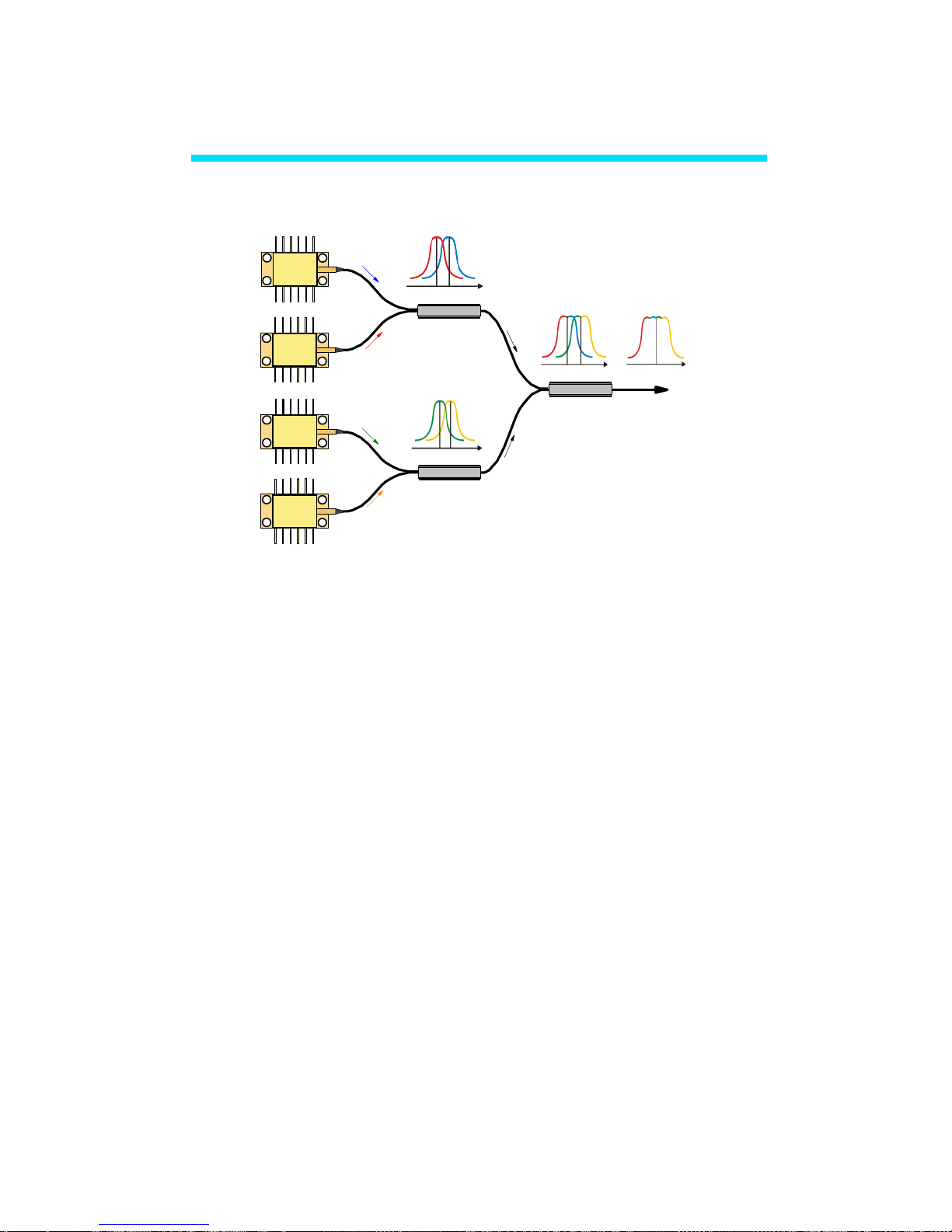

In comparison to a standalone SLD module, the

BroadLighter-M demonstrates the extended optical spectrum

with an extremely wide -3 dB bandwidth, which in turn

corresponds to very low temporal coherence. This occurs due

to combination of the optical emissions of up to four spectrally

matched SLD modules. The actual number of SLDs depends

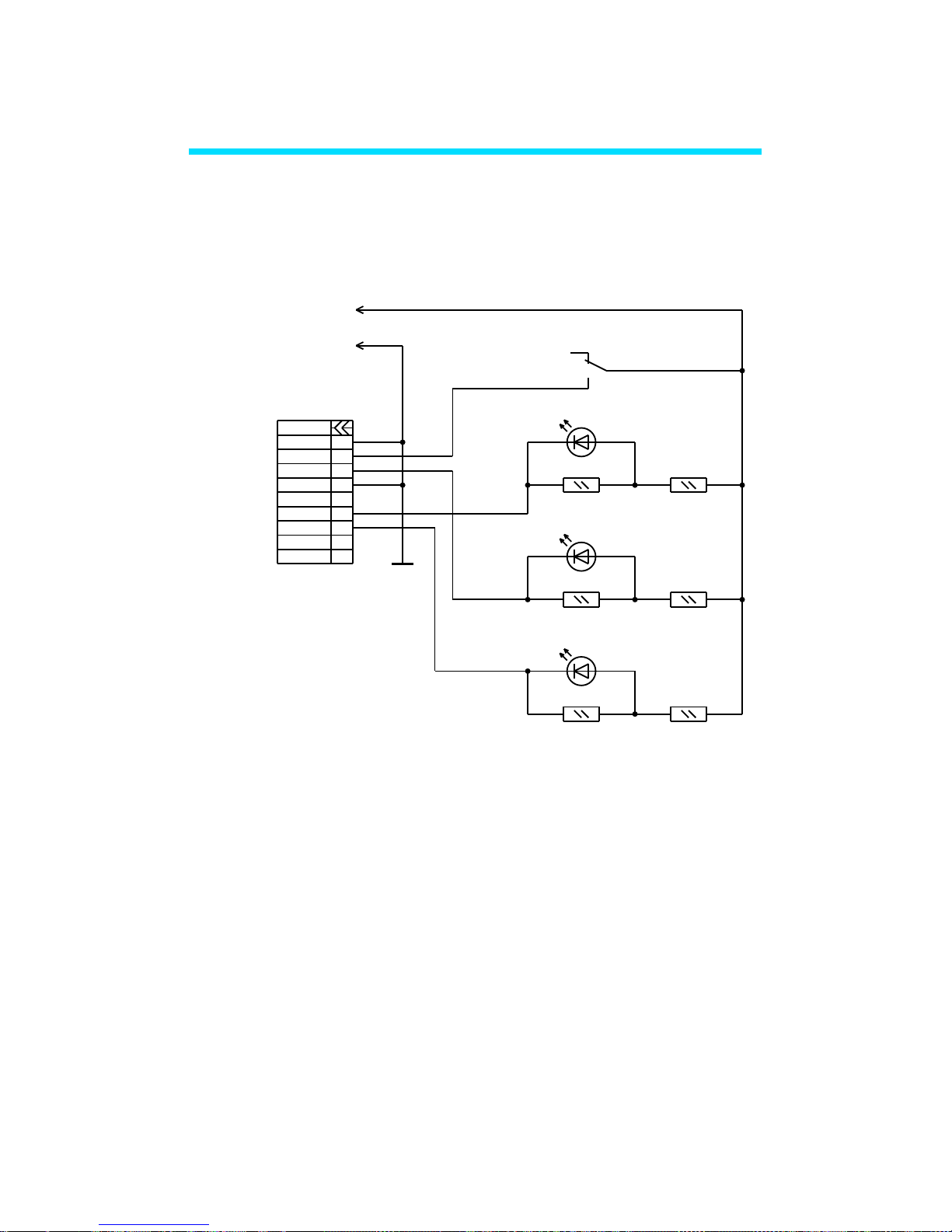

on your instrument configuration. Figure 1.1 sketches the

principle of light combining in the BroadLighter-M. To combine

broadband emissions of the SLDs broadband fiber-optic

couplers are utilized. The couplers feature low insertion losses

and small changes in the coupling ratio for the necessary range

of wavelengths.

Page 30

BroadLighter-M Series

User Manual

Revision 16

27

Coupler 3

SLD 1

SLD 2

Coupler 1

Output

SLD 3

SLD 4

Coupler 2

Figure 1.1. Schematic of the Principle of Light Combining in the

BroadLighter-M. The actual number of SLDs depends on your

instrument configuration.

The internal structure of the BroadLighter-M has a

modular design. The instrument consists of an optical unit,

driver unit and a main unit. Optical unit has optical components

comprising the optical scheme of the instrument. It also stores

the information about the SLD operating parameters, the driver

unit has an integrated DC power supply, as well as driving

electronics and temperature control for SLDs. The main unit

acts as a motherboard for optical and driver units. This design

principle provides the possibility for a flexible exchange of unit

and the ability to adapt and upgrade the instrument to a

particular customer application.

Page 31

1. General Information

28

Superlum SLD modules used in the BroadLighter-M are

fiber-coupled optical modules with a built-in thermoelectric

cooler (TEC) and a temperature sensor which are both

necessary for active temperature control. Superlum current-and

temperature controller is used to control the driving current and

operating temperature of an SLD module.

The instrument has a wide-range voltage power supply

suitable for the 100-240 V AC power lines. All essential

information about AC power requirements is shown on the rear

panel of the instrument. It is important to note that the

BroadLighter-M is intended for indoor use only. For more

information on environmental conditions, refer to section

"Specifications".

This equipment is intended for fiber-optic applications.

To serve this purpose, it is equipped with FC/APC fiber output.

Each BroadLighter-M is shipped with an individual optical

patchcable which is used to deliver the optical output power of

the instrument to the user measuring equipment. It is important

to note that the patchcable provided with the instrument is

specially selected to best match the optical output of the

instrument. With the patchcable attached, a low-loss

connection between the BroadLighter-M and the patchcable is

obtained. Connecting user-selected patchcables to the

BroadLighter-M output is permitted but not recommended,

Page 32

BroadLighter-M Series

User Manual

Revision 16

29

because in this case the minimum optical losses in the

instrument-to-patchcable connection can hardly be ensured.

FC/APC connectors of its ends is the crucial requirement for the

patchcable to be used. Contact Superlum first if you would like

to use other types of optical connections.

The BroadLighter-M incorporates the following safety

features required by IEC 60825-1:

Key-operated master control — located on the

front panel of the instrument, this switch provides

access to activation of the optical output. The

BroadLighter-M is inoperable when the key is

removed. Using the key-operated master control

prevents unauthorized activation of the optical

output emission.

Emission indicator — the LED integrated with

SLD emission activation ON/OFF button, lights up

green when the optical power is enabled, thereby

warning the user about the output emission. The

LED will switch to red when the SLD emergency

switch-off occurs.

Emission time delay – there is a 3 second time

delay between pressing the emission ON/OFF

button and the emission activation.

Page 33

1. General Information

30

Remote Interlock connector — this feature is

located on the rear panel of the instrument. It

allows the instrument to be connected to your local

external controls for laser safety. In order to enable

the BroadLighter-M, a short circuit must be applied

across the terminals of the Remote Interlock

connector. The instrument remains inoperable

unless the Interlock connection is made.

BroadLighter-M is shipped with a shorting device

installed in the Interlock connector. If you are not

going to use this feature then you can leave the

shorting device installed. With this device installed,

you will be able to use the instrument

independently of your local laser safety system. If

you wish to make use of the Interlock feature you

will need to acquire the appropriate connector mate

and wire it your remote Interlock switch. Next,

remove the shorting device by carefully unscrewing

it from the socket and install the connector into the

Interlock input. The BroadLighter-M interlock input

only accepts a 2.5 mm monophonic jack.

Visual and audible warning about optical

output emission — these features start to operate

when the user activates the optical output by

Page 34

BroadLighter-M Series

User Manual

Revision 16

31

pressing the ON/OFF button. Remote IF

connection can be used to transfer a warning

signal from BroadLighter-M to the external warning

system.

Optical radiation hazard labeling — the cabinet

of each BroadLighter-M contains a set of warning

labels informing the user about the Class of

radiation hazard to which the instrument is

assigned. Classification is based on the rules

specified in standard IEC 60825-1:2014 "Safety of

laser products — Part 1: Equipment classification

and requirements". Each BroadLighter-M that is

assigned to this Class of laser products carries on

the instrument's cabinet a set of warning labels with

the necessary information according to its laser

hazard.

Overshooting protection — BroadLighter-M

contains a safety circuit preventing the signal from

overshooting by shutting down the output.

Using controls, adjustments, or operating

procedures that are different from those

specified in this manual may result in

radiation exposure that is hazardous to the

user.

CAUTION

Page 35

1. General Information

32

Each BroadLighter-M is assigned to a

particular Class only if it completely meets

the requirements specified in IEC 608251:2014 for that Class. According to IEC

60825-1, Class 1, Class 3R and Class 3B

products have been classified for an

exposure duration of 100 ms, which is

estimated to be a worst-case scenario. For

other practical applications in which the

exposure duration is greater than 100 ms,

the product must be reclassified.

1.3 Product Specifications

Contained in this section are general specifications for the

BroadLighter-M which are summarized in the tables below.

Note that the information given here covers general and

mechanical specifications only. For the technical information

concerning optical characteristics for your BroadLighter, please

refer to its Acceptance Test Report or contact Superlum on this

issue.

NOTE

Page 36

BroadLighter-M Series

User Manual

Revision 16

33

TABLE 1.1 General and Mechanical Specifications

Parameter

Value or Description

General:

Power Requirements

100-240VAC, 50/60Hz

40 VA MAX

AC Power Cord Plug

IEC 320 compatible

Operating Temperature Range

+5 to +35 OC

Storage Temperature Range

-30 to +70 OC

Humidity

< 80% relative humidity, noncondensing

Warm-up Time

30 min

Mechanical:

Dimensions (WxHxL)

251×112×192 mm

Weight (max)

4 kg

Enclosure

Metal case

Applicable Optical Connector

FC/APC

USB Interface Connector

Remote Control Interface

Connector

USB 2.0 Type B

9-pin DSUB for external logic

Remote Interlock Connector

2.5 mm mono phono jack

Page 37

1. General Information

34

Included in the package is one of each of the following:

TABLE 1.3 List of Contents

Item

Qty.

BroadLighter-M Broadband SLD Light Source

1 pc.

AC Power Cord

1 pc.

Master Key

1 pc.

Remote interlock jack connector

1 pc.

Optical Patchcable

1 pc.

Quick Start Guide

1 pc.

Acceptance Test Report

1 pc.

USB Cable

1 pc.

CD-ROM with User Manual and Software

1 pc.

Optical performance parameters

including 3 dB bandwidth, central

wavelength, output power, etc., are

specified and measured for each

instrument individually. For detailed

information on this issue, refer to the

Acceptance Test Report (ATR) provided

with an instrument. Specifications are

subject to change without notice.

NOTE

Page 38

BroadLighter-M Series

User Manual

Revision 16

35

2. Installation

This chapter will guide you through the unpacking and initial

preparation required in order to set-up your BroadLighter-M.

2.1 Unpacking and Initial Inspection

2.1.1 Unpacking the Instrument

To unpack the instrument, proceed as follows:

1. Place the shipping container on a flat rigid surface.

2. Cut the adhesive tapes over the top of the carton

exterior with a sharp knife and open the top flap.

3. Remove the cushioning material around the

instrument.

4. Lift the instrument and set it aside.

5. Lift the accessories and set them aside.

After unpacking the instrument, verify the receipt of the

BroadLighter-M Broadband SLD Benchtop Light Source. Refer

to the list of contents in section "Specifications" if necessary.

Page 39

2. Installation

36

2.1.2 Initial Inspection

To perform the initial inspection, proceed as follows:

1. After unpacking the instrument, check the shipping

container and its contents thoroughly to be certain

nothing was damaged during shipment.

2. If the contents are damaged or defective, contact

Superlum immediately. Keep the shipping materials for

the carrier inspection.

After transiting or handling the container in

cold weather, it must be stored at room

temperature for about two hours before

being opened. Avoid sharp changes in

temperature that might cause water

condensation on the internal parts of the

instrument. Any amount of water

condensation can be destructive for optical

components inside the BroadLighter-M.

CAUTION

Page 40

BroadLighter-M Series

User Manual

Revision 16

37

1. The BroadLighter-M is a sophisticated

optical instrument containing delicately

aligned optical equipment;

consequently, it should be handled with

great care.

2. Retain the original container for

possible future use. If the instrument is

to be sent to Superlum for servicing and

the original container is not available,

use an equal replacement for repacking.

Refer to section "Service and Support"

for further instructions.

NOTE

Page 41

2. Installation

38

2.2 Preparation for Use

Your BroadLighter-M has been configured to operate with the

AC power supply specified on the rear panel of the instrument.

The instrument is supplied with a 3-conductor detachable

power cord which grounds the instrument cabinet when it is

connected to an appropriate receptacle. The type of possible

plugs acceptable for the AC power cord are specified in the

section titled "Specifications". Before connecting the instrument

to your AC power source, check that the power line/power

supply supports the ground terminal.

To perform preparation for use, proceed as follows:

1. Place the BroadLighter-M on a flat surface, e.g. on

a table or in a rack, close to your measurement

equipment in a location with sufficient ventilation.

Make sure that no obstructions are provided for

ventilation openings of the instrument and the

optical patchcable can be easily attached to the

instrument without strain.

2. Connect AC power cord to the rear-panel power

receptacle. Use the power cord supplied with

instrument.

3. Insert the key provided with the instrument into the

MASTER KEY lock and leave it in position "O".

4. The instrument is plugged in.

Page 42

BroadLighter-M Series

User Manual

Revision 16

39

1. Do not block cooling vents at the

rear panel of the instrument. Failure

to do so may result in device

malfunction.

2. Before applying AC power to the

BroadLighter-M, check the rearpanel label for the line voltage. If it

does not meet your power source

requirements, contact Superlum on

this issue. Failure to obey this rule

may cause permanent damage to

the instrument.

CAUTION

Page 43

3. Local Mode of Operation

40

3. Local Mode of Operation

This chapter details the front- and rear-panel features of the

BroadLighter-M and provides step-by-step instructions on how

to operate the instrument in the local operating mode.

3.1 Front-Panel Features

To feel at ease with the instrument, familiarize yourself with its

front-panel and rear-panel controls, connectors, and indicators

shown in the figures which follow. Refer to Figure 3.1 for the

illustration of the front-panel controls of the BroadLighter-M.

Figure 3.1. Front-Panel Features.

2 3 4

6

1

5

7 8

7

Page 44

BroadLighter-M Series

User Manual

Revision 16

41

1—KEY OPERATED POWER SWITCH. This is a keyoperated master control used as a laser safety measure

specified in IEC 60825-1 (Edition 2.0 2007-03). Turning the key

to position "I" allows the operator to power on the instrument

and get access to SLD emission activation. When the key is in

"O" position, the instrument is OFF and the output emission of

the instrument cannot be enabled.

2—POWER LED. This LED illuminates green when the

instrument is turned ON. When the instrument is turned OFF,

the LED goes blank. The LED illuminates RED during self-test

start running if an error is present.

3—MULTIFUNCTINOAL LCD DISPLAY. This display

provides the status information for the instrument: connection

status, SLD status, output power, etc.

4—NAVIGATION BUTTONS. They are used to

navigate through the interface on the LCD screen. LCD screen

menu is described in Section 5 of this Guide.

5—MENU BUTTON. This button is used to enter the

instrument interface menu or to select the feature.

6—ON/OFF BUTTON. This button is used to

enable/disable the instrument emission. When the emission is

activated, the button LED illuminates green.

Page 45

3. Local Mode of Operation

42

7—FC/APC OUTPUT CONNRCTOR WITH A

PROTECTIVE CAP. This socket is an optical output of the

instrument. The patchcable supplied with the instrument is

connected here. The cap is used to protect the optical output

(FC/APC adapter) from dust and dirt. Always recap the optical

output, when the instrument is not in use and has no patchcable

attached.

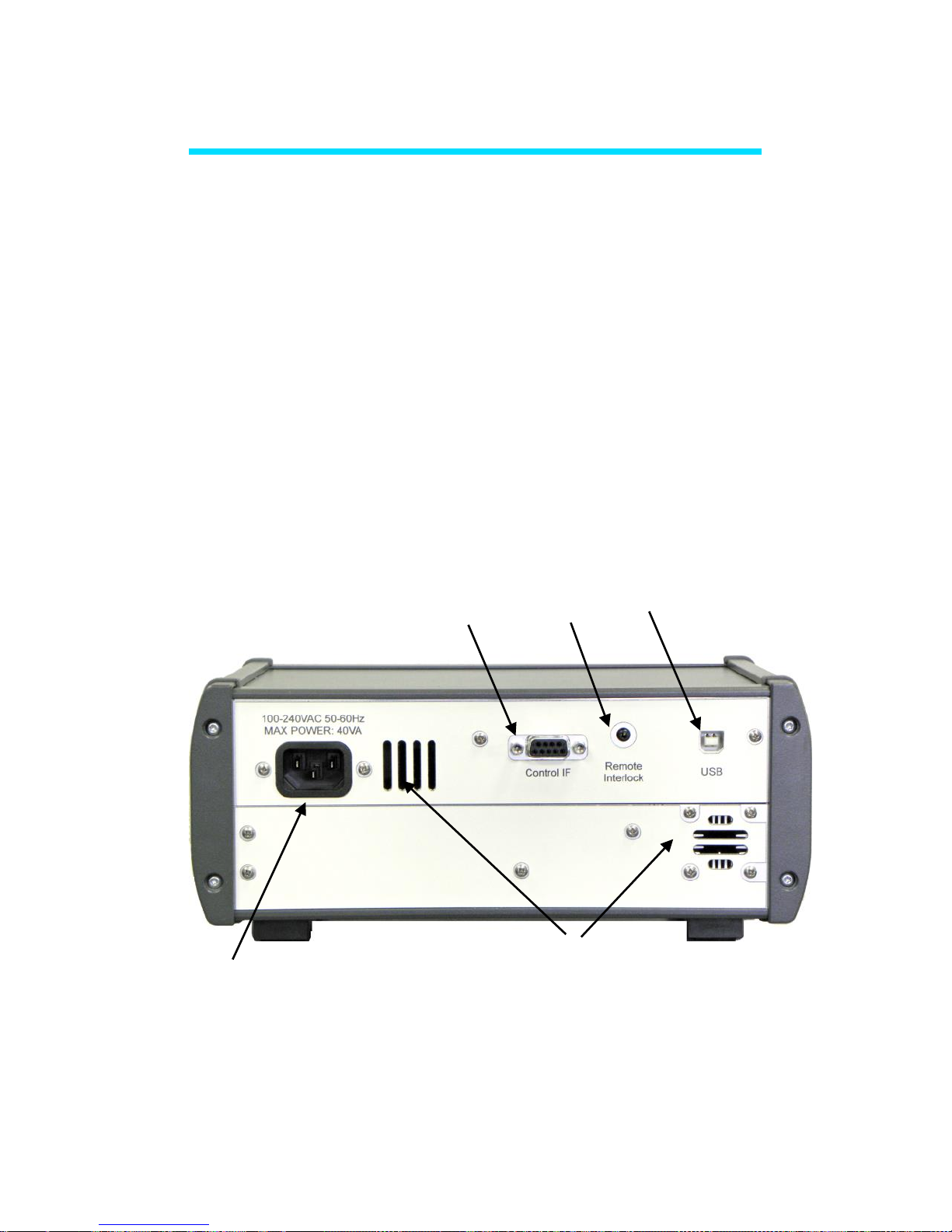

3.2 Rear-Panel Features

Refer to Figure 3.2 for the illustration of the rear-panel controls

of the BroadLighter-M.

Figure 3.2. Rear-Panel Features.

2

3

4 5 1

Page 46

BroadLighter-M Series

User Manual

Revision 16

43

1—AC POWER INPUT RECEPTACLE. It accepts a 3conductor power cord used to connect the instrument to your

local AC power line.

2—CONTROL IF CONNECTOR. Remote monitoring

of the instrument status and turning the output power on/off by

external logic. Connection cable can be provided by request.

3—REMOTE INTERLOCK (Laser Safety Measure).

This is an audio monophonic jack that is used to connect the

instrument to your local external controls for laser safety. Refer

to page 23 of this Manual for more details.

4—USB CONNECTOR. It is used to connect the

BroadLighter-M to a PC.

5—COOLING VENTS. The temperature control

system utilizes the air from the cooling vent holes.

Do not block cooling vents at the rear

panel of the instrument. Failure to do so

may result in device malfunction.

CAUTION

Page 47

3. Local Mode of Operation

44

3.3 Operating Instructions

To get started with your BroadLighter-M, carry out the following

steps in the following order:

1. Perform preparation for use. Consult section

"Preparation for Use" for more information if necessary.

2. If you have the external controls for laser safety in your

local area, connect the BroadLighter-M to your local

external controls for laser safety. Use the REMOTE

INTERLOCK jack on the rear panel of the instrument

for this connection.

3. Connect the optical patchcable supplied with the

BroadLighter-M to the front-panel FC-APC socket. The

other end of the patchcable goes to your measuring

equipment, e.g. an optical power meter. To obtain low

insertion optical losses in the instrument-to-patchcable

connection, always keep the connectors clean.

4. Turn the MASTER KEY control clockwise to position

"I". Once the key has been turned, the instrument boots

and runs an internal test to verify the statuses of the

internal components. It also checks whether the remote

interlock connection or shortening device installation is

made or not. If the test passes, POWER LED glows

green and you are able to activate the optical output of

the instrument. If the test fails, the instrument POWER

LED glows red. In this case turn the MASTER KEY to

Page 48

BroadLighter-M Series

User Manual

Revision 16

45

position “O”. Please, contact Superlum if the error

remains.

5. Enable the optical output power by pressing the

ON/OFF button. The internal speaker produces a beep

signal. There is a 3 second delay between pressing the

button and the emission activation. The button LED

switches to steady green light and the audible signal is

automatically cut off; the output emission appears at

the optical output of the instrument.

6. Verify the output power of the BroadLighter-M to be

certain that the current reading of your power meter

corresponds to the value stated in the acceptance test

report.

In order to keep the end faces of the

optical patchable clean and

protected, it is highly recommended

to avoid unnecessary

disconnections of the patchcable

from the BroadLighter-M and your

measuring equipment.

CAUTION

Page 49

3. Local Mode of Operation

46

NEVER connect optical connectors

different from those specified for your

BroadLighter-M, because they are not

intended for use with the instrument

and can seriously damage its optical

output.

1. If there is no connection between

your laser safety controls and the

instrument, remote interlock circuit

will ignore any attempt to activate

the output power.

2. Once the BroadLighter-M is turned

on, the optical output power of the

instrument can slightly drift over

time. In order to achieve greater

stability of the output power, a 30minute warm-up period is highly

recommended.

NOTE

CAUTION

Page 50

BroadLighter-M Series

User Manual

Revision 16

47

By default, the ON/OFF button

enables ALL the SLDs installed in

your instrument. You can also

select the particular SLDs to lase

by using the instrument interface

menu or via remote control

software.

3.4 Power OFF Instructions

To turn off the instrument, proceed as follows:

1. If the optical output of the instrument is active,

disable the output by pressing ON/OFF

button or via remote control if connected. The

LED on the button will go blank.

2. Turn the MASTER KEY control

counterclockwise to position "O".

3. POWER LED will go blank. The instrument is

now off.

Always disable the optical output before

turning the instrument off.

NOTE

NOTE

Page 51

3. Local Mode of Operation

48

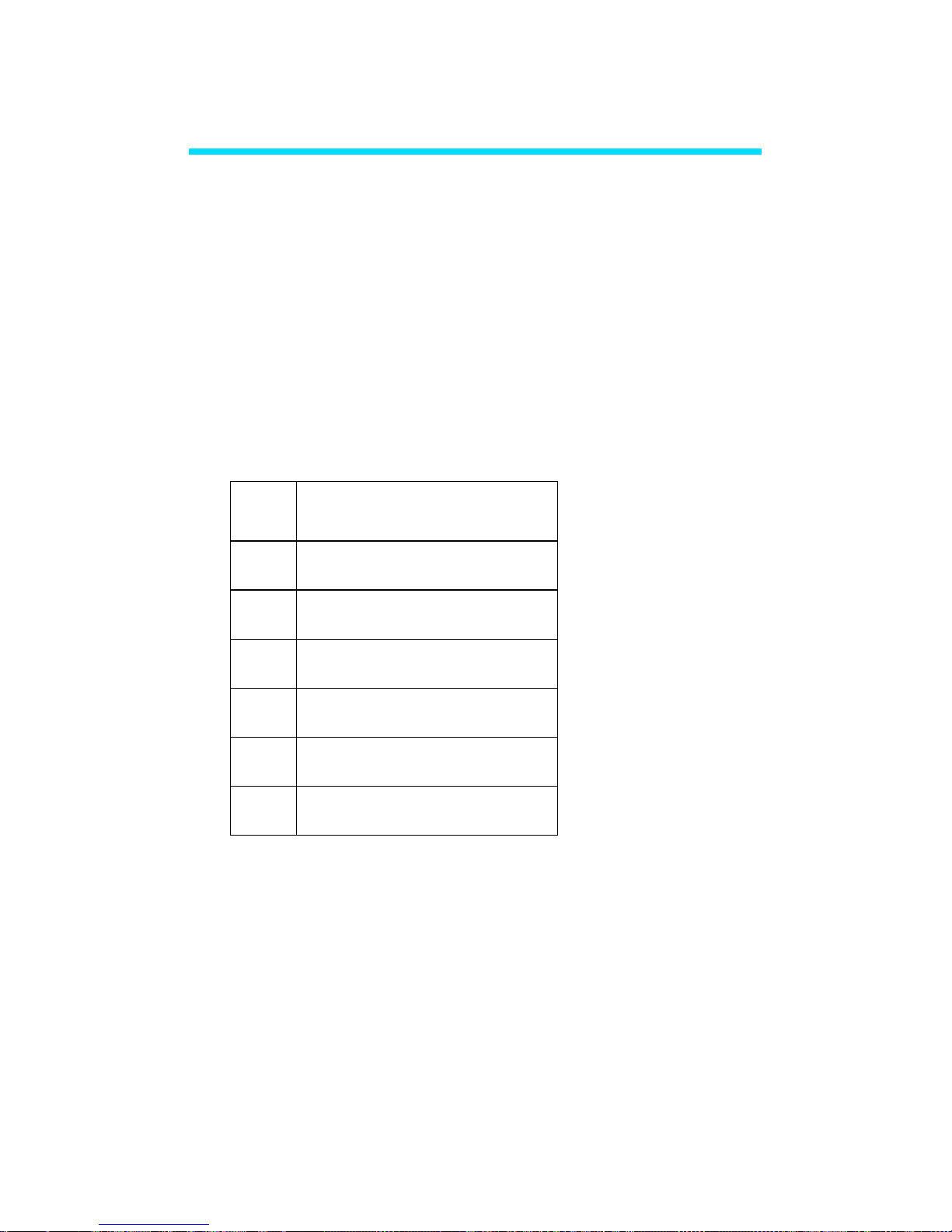

3.5 Interface Menu

LCD screen of BroadLighter-M enables the interface menu that

allows access to the instrument features. To feel at ease with

the instrument, familiarize yourself with its main interface

screen elements and menu screen elements shown in the

figures that follow. Explanations for each feature are in the

order that they are indexed in the corresponding figures.

3.5.1 Main Interface Screen

Interface screen may vary depending on your configuration of

BroadLighter-M: standard version (Figure 3.3.1) and a version

with variable optical attenuator (VOA) / output power control

(Figure 3.3.2).

Figure 3.3.1 BroadLighter-M main interface screen. Standard

version.

1

2 3

4 5 4

5

Page 52

BroadLighter-M Series

User Manual

Revision 16

49

Figure 3.3.2 BroadLighter-M main interface screen. Version with

variable optical attenuator / output power control.

1 - INSTRUMENT STATUS BAR. This tells you the

current status of the instrument. If BroadLighter-M is ready for

emission in the local mode, status bar will display “OUTPUT

ENABLED”. Please refer to Section 3.5.2.

2 - CHANNEL STATUS. This tells you the current

status of the SLDs installed in the instrument. “SLD” refers to

the light emission by corresponding SLD. “TEC” refers to the

thermal stabilization status of the particular SLD. The actual

number of the installed SLDs depends on your particular

configuration. BroadLighter-M supports up to four SLDs. Please

refer to Section 3.5.3.

1

2

3 4 6

5

Page 53

3. Local Mode of Operation

50

3 – OUTPUT POWER. Displays the status of the output

emission. Can be “ON” or “OFF”. Version with VOA/power

control shows the output power value measured with an

integrated optical power monitor.

4—EMISSION LEVEL STATUS. This indicator is

available if your BroadLighter-M is configured with variable

optical attenuator. If the maximum output power level is

reached, the “HP” indicator will appear. If the minimum output

power level is reached, “LP” indicator will appear.

5—REMOTE CONTROL STATUS. Indicates if

REMOTE CONTROL feature is enabled.

6—OUTPUT LEVEL STATUS BAR. This indicator is

available if your BroadLighter-M is configured with variable

optical attenuator (VOA) or output power control options.

Optical output level of the output is controlled with discrete 10%

steps. Power level is controlled with NAVIGATION CONTROL

BUTTONS “Left” and “Right”. Full green bar corresponds to the

maximum output emission level. Power level can be also

controlled via remote software – see the corresponding section

in this Manual.

The BroadLighter-M version with

VOA/power control is preset to start in low

power mode. If you wish to modify that,

use Remote Control Software. Refer to

Section 4.3 of this Manual for more details.

NOTE

Page 54

BroadLighter-M Series

User Manual

Revision 16

51

1. The actual number of the installed

SLDs depends on your particular

configuration. BroadLighter-M

supports up to four SLDs.

2. BroadLighter-M has one SLD per

channel.

3. The readings of the integrated

optical power monitor are for

reference purpose only.

NOTE

Page 55

3. Local Mode of Operation

52

3.5.2 Main Screen Status Messages

Following status messages may appear on the BroadLighter-M

screen:

Instrument is ready for

emission

Device is connected to PC via

USB.

Emission is disabled. Check

TEC indicator in section 3.5.3.

Emission is disabled. Check

interlock connection.

Device malfunction. Contact

Superlum if the error persists

and reboot doesn’t help.

Temperature error. Turn off

the device and let it cool down.

Contact Superlum if the error

persists.

Page 56

BroadLighter-M Series

User Manual

Revision 16

53

3.5.3 Main Screen Status Indicators

Following status indicator may appear on the BroadLighter-M

main screen:

SLD is on. Status is ok.

SLD is on. Service is required. The emission may

remain, though performance parameters may degrade.

Contact Superlum if this indicator remains.

SLD malfunction. Contact Superlum if this indicator

remains.

SLD is disabled.

TEC is on. Temperature is stabilized

TEC is on. Temperature is being stabilized Please wait

until TEC is stabilized. Contact Superlum if this

indicator remains on permanently.

TEC malfunction. Contact Superlum if this indicator

remains and instrument OFF/ON doesn’t help.

TEC is disabled.

Feature is enabled.

Feature is disabled.

Page 57

3. Local Mode of Operation

54

The actual indicators and statuses are

subjects to change without notice.

Please, contact Superlum if you notice

status messages or indicators not

described in this manual.

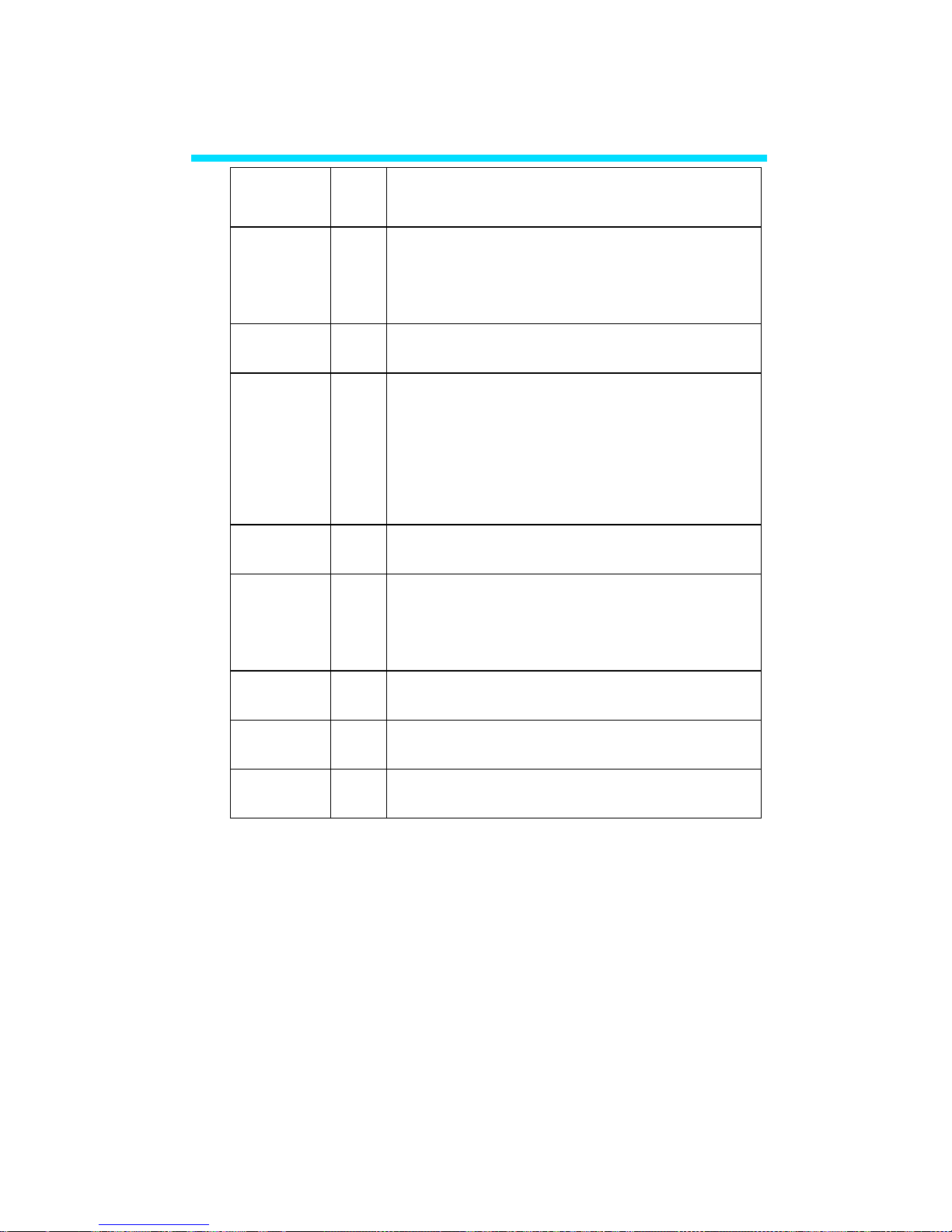

3.5.4 Main Menu

From the main screen you can get access to the menu screen

by pressing the MENU BUTTON. You can select the interface

elements with the MENU BUTTON.

Figure 3.4. BroadLighter-M main menu.

4

1

2

3

NOTE

Page 58

BroadLighter-M Series

User Manual

Revision 16

55

1 - EXIT TO MAIN SCREEN. This brings you back to

the main interface screen.

2 - INFORMATION MENU. This provides you

information about your particular BroadLighter-M.

3 - REMOTE CONTROL. This enables or disables

REMOTE CONTROL feature.

4 - CHANNEL CONTROL. This enables or disables

particular SLDs. The number of active CHANNEL CONTROL

buttons will depend on the number of SLDs installed in your

particular BroadLighter-M.

Information Menu allows you to read the status of the

components of your BroadLighter-M:

Page 59

3. Local Mode of Operation

56

Figure 3.5. BroadLighter-M System Information menu.

It shows the information on SLDs installed in your

BroadLighter-M.

MENU CONTROL BUTTON is disabled

when the BroadLighter-M emits light.

Always turn off light emission before

modifying features in the instrument

interface.

Menu elements are subject to change

without notice. Please, contact

Superlum if you notice menu elements

not described in this manual.

Front panel controls are typically

disabled in Remote mode.

NOTE

Page 60

BroadLighter-M Series

User Manual

Revision 16

57

4. Remote Mode of Operation

Your BroadLighter-M Broadband Light Source is designed to

communicate with a PC or terminal via USB 2.0 or Remote

Control interfaces. This chapter discusses information that

explains how to control the BroadLighter-M using these

interfaces. At the end of this chapter, you will find a description

of the Superlum BroadLighter-M Companion Software, which is

supplied with the Instrument. To best serve these purposes, this

chapter has been split up into four sections covering the

following topics:

Description of Data Communication via

Remote Control Interface

Description of Data Communications via

USB Interface

Remote Command Set

Superlum BroadLighter-M Companion

Software

Section "Remote Command Set" includes subsections

that detail each command and query supported by this

equipment.

Page 61

4. Remote Mode of Operation

58

Switch OFF the BroadLighter-M before

connecting or disconnecting the

REMOTE CONTROL or USB cables.

Use only USB 2.0 Type B compatible

cable when using USB interface.

4.1 Remote Control Interface

The BroadLighter-M is equipped with the Control IF connector

located on the rear panel of the instrument. This allows the user

to operate the instrument remotely by using Logic Level

discrete signals.

The BroadLighter-M uses a female 9-pin DSUB connector for

communication via Remote Control interface.

CAUTION

Page 62

BroadLighter-M Series

User Manual

Revision 16

59

DSUB

Pin

No.

Signal

name

Description

Electrical Circuit

1

SCOM

Remote SLD

ON/OFF input,

common wire

2

SI

Remote SLD

ON/OFF input,

positive wire

3

EN

Output Enabled. If

this signal is active

– instrument is

ready for emission

4

COM

Outputs common

wire

6

PG

Power Good. If this

signal is active –

instrument is turned

on and no errors

detected.

7

ON

Emission ON. If this

signal is active –

the emission is

activated

Pin 1

Pin 2

1K

2

1

3

4

470

Pin 3

Pin 7

Pin 4

Pin 6

2

1

3

4

2

1

3

4

2

1

3

4

Page 63

4. Remote Mode of Operation

60

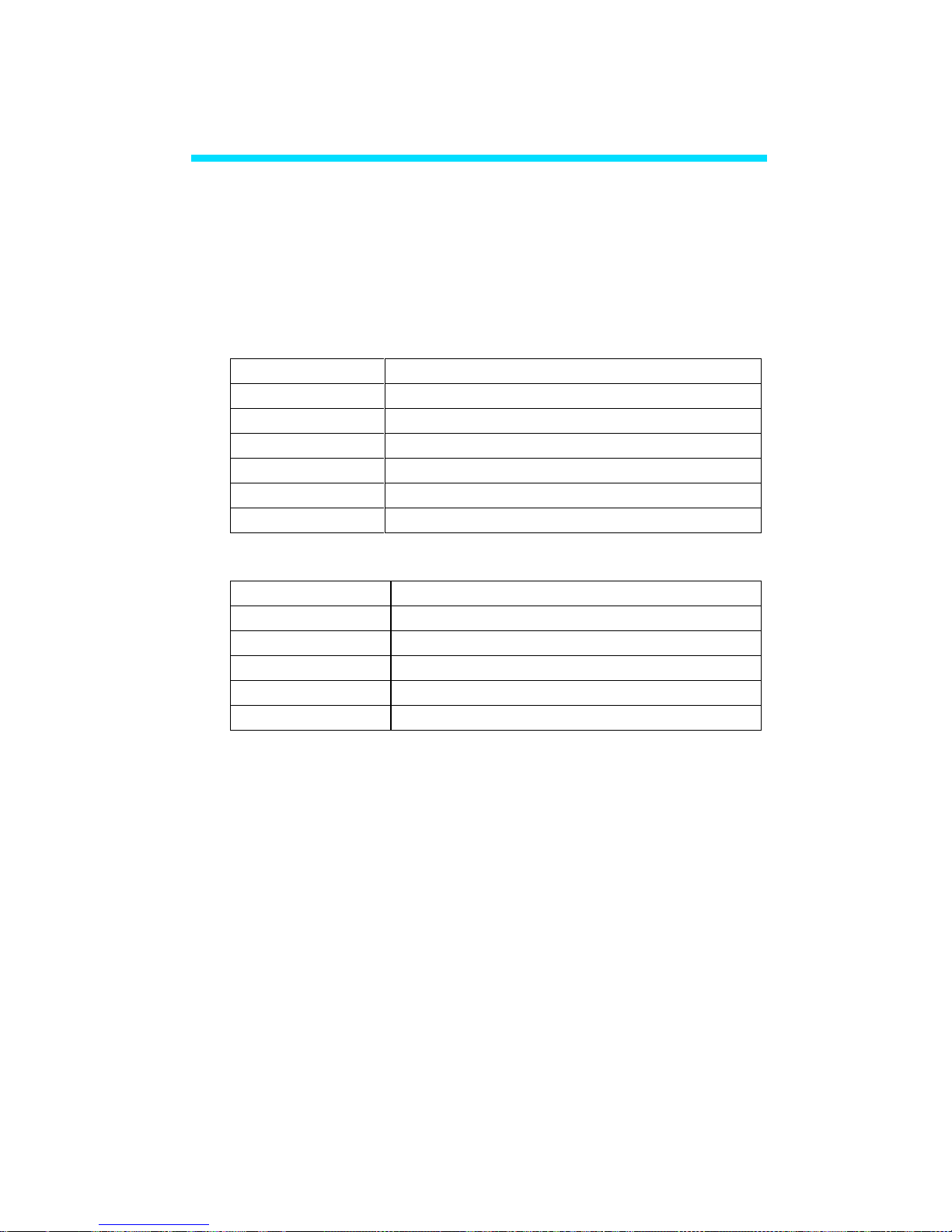

The Figure below illustrates the circuit diagram of simple

remote control terminal. This unit should be powered from

external power supply with 5 VDC output.

Figure 4.1. BroadLighter-M sample remote control circuit

diagram.

4.2 USB interface

To verify the functionality of the BroadLighter-M through the

USB interface, you can use the commands for Hyper Terminal

program commonly available on a PC. The commands are

described later in this Chapter.

ON

EN

COM

9

7

5

3

1

PG

SI

DSUB

COM

6

8

2

4

+5V

"OFF"

"PG"

X1

COM

TO

POWER

SUPPLY

"ON"

"ON"

"EN"

HL3

HL2

HL1

1

2

3

SW1

R6

1K

R5

1K

R4

1K

R3

10K

R2

10K

R1

10K

Page 64

BroadLighter-M Series

User Manual

Revision 16

61

USB connection is accomplished via virtual COM port.

The BroadLighter-M uses the FT230X USB to Serial converter

chip made by FTDI Company. Necessary drivers for common

operating systems can be downloaded using the link:

Before operating the instrument with your PC, you need

to configure the following parameters for terminal

configuration/UART configuration:

Baud Rate = 57600;

Start Bits = 1;

Stop Bits = 1;

Parity = None;

Flow Control = None.

Page 65

4. Remote Mode of Operation

62

4.2.1 System Commands

4.2.1.1 Read BroadLighter-M type, firmware version and

serial number.

Request: [I] [CR] [LF]

Acknowledge: [I] [:] [TYPE] [:] [VH] [VL] [:] [SN] [CR] [LF]

Error message: [!] [E] [CR] – common error message.

Where:

[TYPE] – Device Type, five ASCII printable chars:

“BLM-S” - one channel BroadLighter-M;

“BLM-D” - two channels BroadLighter-M;

“BLM-T” - three channels BroadLighter-M;

“BLM-Q” - four channels BroadLighter-M.

“BLM-E” – one channel BroadLighter-M with

electronic output power control option.

[VH] – Major part of firmware version [0…9], one ASCII chars;

[VL] – Minor part of firmware version [0…9], one ASCII chars;

[SN] – Serial number, six ASCII printable chars.

Page 66

BroadLighter-M Series

User Manual

Revision 16

63

4.2.1.2 Set device operation mode. Read current mode.

Request: [M] [CMD] [CR] [LF]

Acknowledge: [M] [MODE] [CR] [LF]

Error message: [!] [E] [CR] [LF] – common error message.

[CMD]

DESCRIPTION

[?]

Read current mode

[L]

Set LOCAL mode

[U]

Set USB CTRL mode

[S]

Set SERVICE mode

[MODE]

DESCRIPTION

[L]

Device operated in LOCAL mode

[U]

Device operated in USB CTRL mode

[E]

FATAL ERROR mode

[S]

Device operated in SERVICE mode

[ACCESS CODE] – [?] [?] [?] [?] Four ASCII chars needed

for entering to USB SERVICE mode

only.

Page 67

4. Remote Mode of Operation

64

4.2.2 USB Mode Commands

4.2.2.1 Switch SLD ON/OFF. Read Channel status data

Request: [U] [C] [CH] [CR] [LF]

Acknowledge: [U] [C] [IL] [ST1] [ST2] [ST3] [ST4] [CR] [LF]

Error message: [!] [E] [CR] [LF] – common error message;

[!] [M] [CR] [LF] – wrong mode set message.

[CH]

DESCRIPTION

[?]

Read Channel status data

[1]

Switch SLD#1 ON/OFF

[2]

Switch SLD#2 ON/OFF

[3]

Switch SLD#3 ON/OFF

[4]

Switch SLD#4 ON/OFF

[9]

Switch all SLDs ON/OFF

[IL] – Remote interlock data [0] or [1]:

[0] – output disabled by interlock;

[1] – output enabled.

[ST1]…[ST4] – Channel [1…4] status, [00…FF], two ASCII

chars in hexadecimal code. See table below for signal

identification.

Page 68

BroadLighter-M Series

User Manual

Revision 16

65

SIGNAL

BIT

DESCRIPTION

OME

0

‘1’ – Optical module enabled

‘0’ – Optical module disabled

TON 1 ‘1’ – TEC ON; ‘0’ – TEC OFF

TGD

2

‘1’ – Optical module temperature

stabilized

‘0’ – Optical module temperature not

stabilized

TER 3 ‘1’ – TEC (Thermistor) error

SMD

4

‘1’ – SLD operated in ACC mode

‘0’ – SLD operated in APC mode

SON 5 ‘1’ – SLD ON; ‘0’ – SLD OFF

SLM 6 ‘1’ – SLD current limit reached

SER

7

‘1’ – SLD error

Page 69

4. Remote Mode of Operation

66

4.2.2.2 Switch control

Request: [U] [S] [CMD] [CR] [LF]

Acknowledge: [U] [S] [SWDATA] [CR] [LF]

Error message: [!] [E] [CR] [LF] – common error message;

[!] [M] [CR] [LF] – wrong mode set message.

[CMD]

DESCRIPTION

[?]

Read current Switch Data

[1]

Switch Channel #1 (CH1)

[2]

Switch Channel #2 (CH2)

[3]

Switch Channel #3 (CH3)

[4]

Switch Channel #4 (CH4)

[5]

Reserved

[6]

Switch Remote Control (RC)

[7]

Switch External Modulation (EM)

[8]

Switch power meter mode (Service

mode only)

[S]

Store current Switch Data to

EEPROM

[SWDATA] – Switch status, [00…FF], two ASCII chars in

hexadecimal code. See table below for signal identification.

Page 70

BroadLighter-M Series

User Manual

Revision 16

67

[SWDATA]

DESCRIPTION

Bit#0

‘1’ – Channel #1 (CH1) enabled

‘0’ – Channel #1 (CH1) disabled

Bit#1

‘1’ – Channel #2 (CH2) enabled

‘0’ – Channel #2 (CH2) disabled

Bit#2

‘1’ – Channel #3 (CH3) enabled

‘0’ – Channel #3 (CH3) disabled

Bit#3

‘1’ – Channel #4 (CH4) enabled

‘0’ – Channel #4 (CH4) disabled

Bit#4

Reserved, reads as null

Bit#5

‘1’ – Remote Control (RC) enabled

‘0’ – Remote Control (RC) disabled

Bit#6

‘1’ – External Modulation (EM) enabled

‘0’ – External Modulation (EM) disabled

Bit#7

‘1’ – Output power mode

‘0’ – ON/OFF mode

Page 71

4. Remote Mode of Operation

68

4.2.2.3 Read measurable parameters

Read data from ADC

Request: [U] [M] [CH] [PN] [CR] [LF]

Acknowledge: [U] [M] [CH] [PN] [PDATA] [CR] [LF]

Error message: [!] [E] [CR] [LF] – common error

message;

[!] [M] [CR] [LF] – wrong mode set

message.

[CH] – Channel number [1…4], one ASCII character

[PN] – Parameter number [1…8], one ASCII character

[PDATA] – Parameter value [0000…FFFF], four ASCII

characters in hexadecimal code.

Page 72

BroadLighter-M Series

User Manual

Revision 16

69

[PN]

DESCRIPTION

PDATA RANGE

1

Real TEC current value

[0000] = 0,00A

[00FF]=+2,55A

[01FF]=-2,55A

2

SLD current (maximum

current) set value

[0000]=0,00 mA

[FFFE]=655,34mA

3

Optical module photodiode current (HP) set

value

[0000]=0,0µA

[FFFE]=6553,4µA

4

Optical module photodiode current (LP) set

value

[0000]=0,0µA

[FFFE]=6553,4µA

5

Real Optical module

temperature value

[0000]=0Ω

[FFFE]=65534Ω

6

Real SLD current value

[0000]=0,00 mA

[FFFE]=655,34mA

7

Real PD current value

[0000]=0,0µA

[FFFE]=6553,4µA

8

Optical module

temperature set point

value

[0000]=0Ω

[FFFE]=65534Ω

Page 73

4. Remote Mode of Operation

70

Note: PDATA OVELOAD VALUE IS 0xFFFF!

Temperature:

Request: [U] [T] [CR] [LF]

Acknowledge: [U] [T] [TV] [PV] [CR] [LF]

Error message: [!] [E] [CR] [LF] – common error message;

[!] [M] [CR] [LF] – wrong mode set message.

[TV] – Temperature value [00…FF], two ASCII chars in

hexadecimal code in two’s complement form:

[7F] = +127 ºC;

[00] = 0 ºC;

[FF] = -1 ºC;

[80] = -128 ºC.

[PV] – Output power value [00…FF], two ASCII chars in

hexadecimal code.

[00] = 0 mW;

[FF] = 25.5 mW.

4.2.2.4 Attenuator and output power control

If VOA option is installed, the VOA transmission is controlled.

Otherwise SLD output is controlled.

Page 74

BroadLighter-M Series

User Manual

Revision 16

71

Request: [U] [A] [CMD] [CR] [LF]

Acknowledge: [U] [A] [POS] [CR] [LF]

Error message: [!] [E] [CR] [LF] – common error message;

[!] [M] [CR] [LF] – wrong mode set message.

[CMD]

DESCRIPTION

[?]

Read current attenuator position

[0…9]

Set attenuator position

[S]

Store current position as default

[T]

Switch HP/LP mode (not

implemented)

ATTENUATOR POSITION

[POS]

OUTPUT

POWER

NOTE

0

Max Power

(100 %)

“HP

3

”

1

90 %

--

2

80 %

-- 3 70 %

-- 4 60 %

-- 5 50 %

--

6

40 %

--

7

30 %

-- 8 20 %

--

9

Min Power (10

%)

“LP

4

”

Command not implemented in REV_1.X

BroadLighter-M.

3

HP – high power mode

4

LP – low power mode

Page 75

4. Remote Mode of Operation

72

4.2.2.5 Read Optical unit type, firmware version and

serial number

Request: [U] [O] [CR] [LF]

Acknowledge: [U] [O] [TYPE] [WL] [VERSION] [SN] [CR] [LF]

Error message: [!] [E] [CR] [LF] – common error message;

[!] [M] [CR] [LF] – wrong mode set message.

[TYPE] – Optical unit type [00…FF] two ASCII chars in

hexadecimal code, see table below:

Bit #7

Bit #6

Bit #5

Bit

#4

Bit #3

Bit #2

Bit #1

Bit #0

MOD

ATT

OPM

ISO

OM4

OM3

OM2

OM1

OM [4…1] – optical module presence sign:

– ‘0’ – module not installed;

– ‘1’ – module installed;

ISO – optical isolator presence sign:

– ‘0’ – isolator not installed;

– ‘1’ – isolator installed;

OPM – output power monitor presence sign:

– ‘0’ – OPM not installed;

Page 76

BroadLighter-M Series

User Manual

Revision 16

73

– ‘1’ – OPM installed;

ATT – optical attenuator presence sign:

– ‘0’ – attenuator not installed;

– ‘1’ – attenuator installed;

MOD – optical modulator presence sign:

– ‘0’ – modulator not installed;

– ‘1’ – modulator installed;

[WL] – Central wavelength value [00…FF], two ASCII

chars in hexadecimal code:

[00] = 0 = 0 nm;

[FF] = 255 = 2550 nm;

[VERSION] – Firmware version, [01…99] two ASCII chars;

[SN] – Optical unit serial number, six ASCII printable chars.

4.2.2.6 Read Optical Module parameter

Request: [U] [P] [MN] [PN] [CR] [LF]

Acknowledge: [U] [P] [MN] [PN] [DATA] [CR] [LF]

Error message: [!] [E] [CR] [LF] – common error

message;

Page 77

4. Remote Mode of Operation

74

[!] [M] [CR] [LF] – wrong mode set

message.

[MN] – Optical module number, [1…4] (One ASCII

character);

[PN] – Parameter number, [0…9] (One ASCII

character);

[DATA] – Parameter data, see table below.

[PN]

Description

DATA Range

Comments

0

Optical module

serial number

[XXXXXX]

Six ASCII

printable

characters

1

Optical module

operation mode

[0] or [1], one

ASCII char

[0] – APC mode

[1] – ACC mode

2

Optical module

temperature set

point value

[0000…FFFE],

four ASCII chars

[0000] = 0 ohm

[FFFF] = 65534

ohm

3

Optical module

maximum current

value

[0000…270F],

four ASCII chars

[0000] = 0,0 mA

[270F] = 999,9

mA

4

Optical module

current value

[0000…270F],

four ASCII chars

[0000] = 0,0 mA

[270F] = 999,9

mA

5

Optical module

photo-diode

current value (HP)

[0000…270F],

four ASCII chars

[0000] = 0 µA

[270F] = 9999

µA

6

Optical module

photo-diode

current value (LP)

[0000…270F],

four ASCII chars

[0000] = 0 µA

[270F] = 9999

µA

9

Optical module

operating time

[00000000][FFFFFFFF],

Eight ASCII

chars

00000000 – 0 s;

0000000A – 10

s;

….

Note: Switch off SLD before reading the optical module

operating time value.

Page 78

BroadLighter-M Series

User Manual

Revision 16

75

4.2.2.7 Read temperature and output power

Request: [U] [T] [CR] [LF]

Acknowledge: [U] [T] [TV] [PV] [CR] [LF]

Error message: [!] [E] [CR] [LF] – common error message;

[!] [M] [CR] [LF] – wrong mode set

message.

[TV] – Temperature value [00…FF], two ASCII chars in

hexadecimal code in two’s complement form:

[7F] = +127 ºC;

[00] = 0 ºC;

[FF] = -1 ºC;

[80] = -128 ºC.

For Rev_1.X BroadLighter-M ONLY:

[PV] – Output power value [00…FF], two ASCII chars in

hexadecimal code.

[00] = 0 mW;

[FF] = 25,5 mW.

For Rev_2.X BroadLighter-M:

[PV] – Output power value [000…FFF], three ASCII chars

in hexadecimal code.

[000] = 0 mW;

[FFF] = 409,5 mW.

Page 79

4. Remote Mode of Operation

76

4.2.2.8 Read output power limit

Request: [U] [L] [CR] [LF]

Acknowledge: [U] [L] [PL] [CR] [LF]

Error message: [!] [E] [CR] [LF] – common error message;

[!] [M] [CR] [LF] – wrong mode set

message

[PL] – Output power LIMIT value, [00…FF], two ACSII

characters in hexadecimal code: [00] = 0 mW;

[FF] = 255 mW.

Page 80

BroadLighter-M Series

User Manual

Revision 16

77

4.3 Superlum Companion Software

The interface of this program includes the same features which

you can find on the front panel of the instrument. Using these

features of the program allows you to control the BroadLighterM remotely from your PC system instead of standing in front of

the instrument.

By using this program, you can do the following:

Activate and deactivate each SLD module

individually.

Activate and deactivate several SLD modules

simultaneously.

Monitor the current status of the instrument

controls

By clicking on the necessary button in the

program window, automatically measure and

save all current values of the instrument

performance parameters to a separate file on

your PC which must be forwarded to Superlum

when you suspect problems with the

BroadLighter-M.

Page 81

4. Remote Mode of Operation

78

It is important to note that the last feature in the list

above is accessible through the program only.

The program features very simple installation, nonsevere system requirements, and a user-friendly interface. Use

this program whenever you want to do the following:

To begin to control the BroadLighter-M

remotely as soon as you receive it and do not

want to waste much time for developing the

program of your own.

In the case of a problem: to test the instrument

performance and report the results of the test

to Superlum for getting the necessary

assistance.

4.3.1 Minimum System Requirements

Minimum system requirements are as follows:

Operating system: Windows 95, 95 OSR2, 98, or

98 SE, Windows ME, Windows NT Workstation 4.0

Service Pack 3, Windows 2000 Professional,

Windows XP, Windows Vista, Windows 7.

Memory: 32 MB for Windows 9x and ME, 64 MB

for Windows NT and 128 MB for Windows 2000

Page 82

BroadLighter-M Series

User Manual

Revision 16

79

and XP, 1 gigabyte (GB) (32-bit) or 2 GB (64-bit)

for Windows Vista and Windows 7/8/8.1.

Processor: 100-megahertz (MHz) or faster

processor for Windows 9x and ME, 300-megahertz

(MHz) or faster processor for Windows 2000 and

XP, 1 gigahertz (GHz) or faster 32-bit (x86) or 64bit (x64) processor for Windows Vista and

Windows 7,

Hard disk space: 10MB of free hard disk space.

Miscellaneous: USB 2.0 interface.

4.3.2 Installing the USB drivers

Prior to connecting BroadLighter-M to PC via USB and/or

installing the Companion Software, the USB drivers must be

installed. Necessary drivers for common operating systems can

be downloaded using the link:

http://www.ftdichip.com/Drivers/VCP.htm

BroadLighter-M must not be connected to the PC while

installing the drivers. Insert the CD that was supplied with your

unit into your PC. Select the driver software and run it. Follow

the onscreen prompts to install the driver. After the driver is

installed, connect BroadLighter-M to the PC and power it on.

Page 83

4. Remote Mode of Operation

80

Your PC will detect the new hardware and will prompt you when

the installation is complete.

If you experience problems installing

the USB drivers, please contact your

system administrator.