Page 1

OWNER’S MANUAL

INSTALLATION AND OPERATION

INSTRUCTIONS FOR

SUBMERSIBLE SUMP PUMPS

Models:

92250, 92260, 92251, 92255

92257, 92330, 92331, 92335

92337, 92341, 92342, 92351

92352, 92501, 92511, 92507

Superior Sump Manual Revised 10/08

Page 2

If for any reason you have questions concerning your new Superior Pump, call us toll free at

1-800-495-9278, or contact us on the web at www.superiorpumpco.com

Carefully read and understand all of the Warnings and installation instructions in this

manual. Failure to follow these instructions could lead to serious bodily injury and/or

property damage. Retain these instructions for future reference.

This pump has been manufactured with your needs in mind. Properly installed in the right

application, your new Superior Pump will give you years of carefree performance.

DANGER Water and electricity can be dangerous if certain precautions are not adhered

to. This pump is designed to operate perfectly safe in a water environment; however,

improper use and installation can result in personal harm from electrical shock. Please pay

attention to the following warnings.

WARNING

Never touch any electrical device, including this pump, when it is touching water, in water, or

even in a moist environment. Always unplug (disconnect the electricity) when working on or

installing the unit.

WARNING

RISK OF ELECTRICAL SHOCK. This pump is supplied with a grounding conductor and

grounding-type attachment plug. To reduce the risk of electrical shock, be certain that it is

connected only to a properly grounded, grounding-type receptacle.

WARNING Do not use the power cord or discharge hose to carry or handle the pump.

Doing so may cause damage to the power cord or discharge hose. Use the carrying handle

supplied with the pump.

WARNING Always use a grounded outlet. A three-prong mating type receptacle is

required for safe use. This should be in accordance with the National Electric Code and any

additional codes or laws required by your local government.

NOTICE It is strongly recommended to use a ground fault interrupt device on any

electrical appliance, including this pump, when used in a wet or moist environment as it

provides a much safer installation and will greatly reduce possible injury from electrical shock.

This is required by many local codes and enforcement agencies.

1

4

5

7

8

6

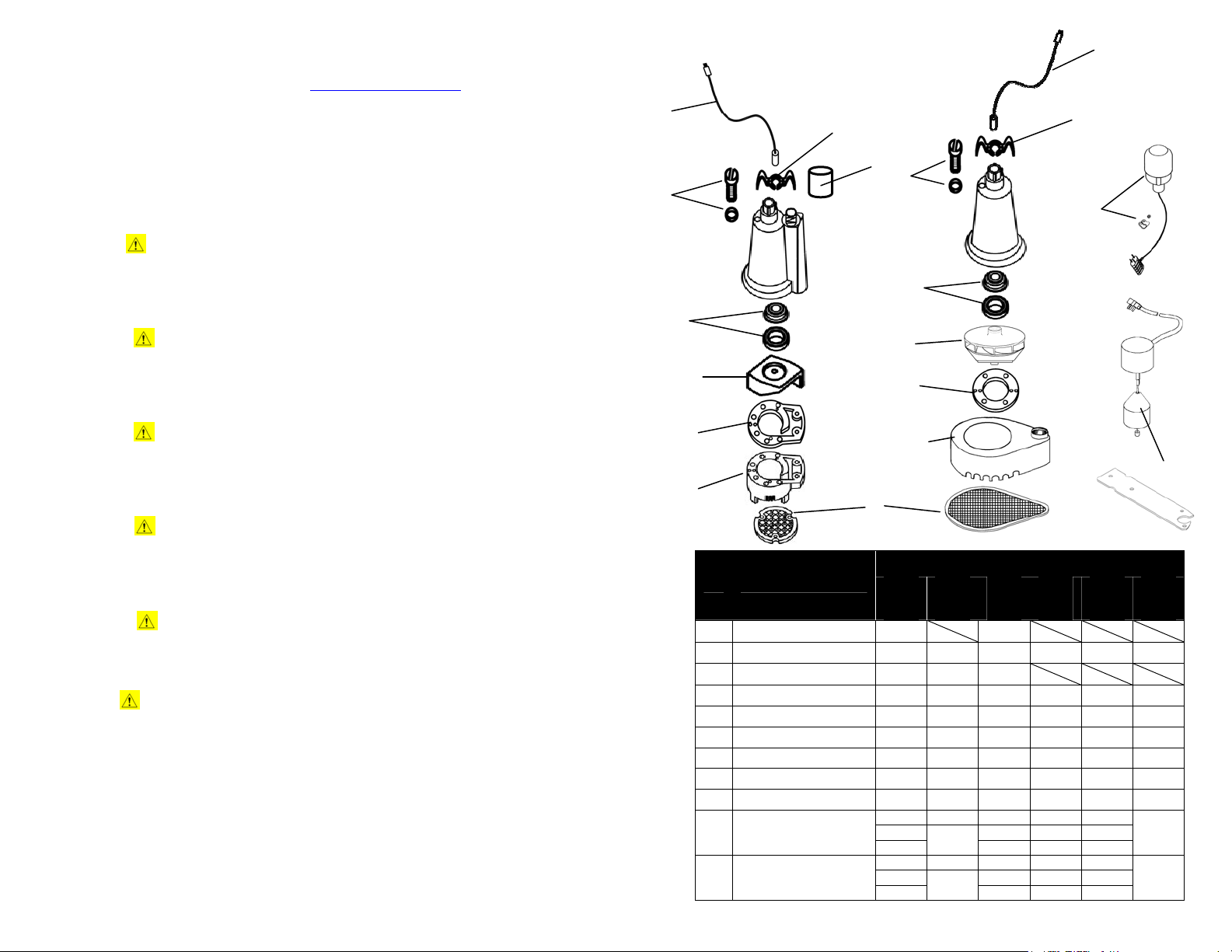

Ref Description

1 Power Cord 99008

2 Handle 99050 99051 99050 99051 99051

3 Hose Coupling/Adapter 99007 99007 99007

4 Oil Fill Plug with O-ring 99056 99056 99056 99056 99056

5 Shaft Seal 99057 99057 99057 99057 99057

6 Impeller 99060 99087 99065 99096 99070

7 Gasket 99062 99062 99062 99088 99064

8 Volute/Base 99067 99078 99069 99078 99071

9 Intake Screen 99073 99076 99073 99076 99074 99074

10 Float Switch

11 Vertical float Switch Bracket

REPLACEMENT PARTS

To order replacement parts,

Call 1-800-495-9278

2

3

4

5

6

7

8

9

92250

92255

92260

92000

92010

N/A

99105

92251

92257

92000 92000 92000 92000

92005

N/A

N/A

2 7

2

PARTS FOR MODEL#

92330

92342

92335

99008

92331

92341

92337

N/A

N/A

92010 92000

N/A

99105 N/A

N/A

92010

92005 92005 92005

99105

1

10

92351

92501

92507

N/A

N/A

10

11

92352

92511

99051

99056

99057

99070

99064

99071

92010 92000

99105 N/A

Page 3

NOTICE Height and/or piping restriction will reduce the pump output performance. See

the performance chart below to insure you have the proper pump for your application.

Whenever possible use the same size or larger pipe as the pump discharge for optimum

performance. Reducing the pipe size will not harm your pump; it will just reduce the output.

PERFORMANCES

DANGER Do not use this pump to pump chemicals, flammable liquids, sewage or

corrosive liquids. You could injure yourself and the pump will fail. Pumping these types of

liquids voids the warranty. Decko Products manufactures pumps for these types of liquids.

Make sure you purchase a pump designed for your specific needs. This pump will handle

fluids with the same characteristics as water. If you have any questions call us at

1-800-495-9278 or contact us on the web at www.superiorpumpco.com

Output in gallons per minute at listed discharge

Model #

0’ 5’ 10’ 15’ 20’ 25’

92250, 92251, 92260, 92255, 92257 30 22 20 16 9 2

92330, 92342, 92335 40 34 28 22 12 2

92331, 92337, 92341 46 36 30 25 12 1

92351, 92352 60 56 50 35 15 6

92501, 92511, 92507 70 66 58 48 25 10

height above pumping level

SPECIFICATIONS

92250

Model #

HP 1/4 1/4 1/3 .3 1/3 1/2

Amps 3.82 3.82 4.1 4.1 7.6 7.6

Solids Handling 1/8” 1/8” 1/8” 3/8” 1/2” 1/2”

Warranty

(Years)

Discharge Size 1 ¼” 1 ¼” 1 ¼” 1 ½” 1 ½” 1 ½”

Power supply requirements 120V, 60 Hz (15 amp)

Motor Continuous Duty, Capacitor Start,

Liquid Temperature Range 32° F - 120° F (0° C - 49° C)

92255

92260

1 3 1 3 3 3

92251

92257

92330

92342

92335

Thermally Protected

92331

92341

92337

92351

92352

92501

92511

92507

WARNING

Your pump has thermal over-loa

liquids over 120 F. The thermal overload protector will automatically shut down the pump in

an overheat situation. It will then reset itself once the pump cools down. This overload is

designed as a safety device and it will fail after repeated use. Normal operation is for fluids

between 32 F & 120 F.

DO NOT RUN THE PUMP DRY. The pump depends on water for cooling and lubrication.

Operating the pump without water may cause the motor to overheat or cause damage to parts

of the pump. It may also shorten the life of your pump.

d protection built in. It is not recommended for pumping

NOTICE

EXTENSION CORDS

For best performance, it is recommended to connect the power cord directly to the grounded

GFCI outlet. If the use of an extension cord is necessary, always use a grounded waterproof

type cord. Never use longer than a 25-ft. cord that is lighter than 14/3 gauge.

DANGER Keep all electrical connections away from wet and moist environm ents. Wet

connections can cause electrical shock resulting in personal injury.

USE AND INSTALLATION

WARNING ALWAYS DISCONNECT THE POWER SOURCE BEFORE ATTEMPTING TO INSTALL,

SERVICE OR PERFORM MAINTENANCE ON THE PUMP

ELECTRICAL SHOCK

Your Superior Pump is designed and built to give you reliable performance and long life. It will

pump water auto

.

matically for years when properly installed in the right environment.

. FAILURE TO DO SO MAY RESULT IN FATAL

REMOVING OLD PUMP. (If necessary)

1. Make sure power supply is disconnected.

2. After the power is off, remove

types of insta

3. It is best to remove all old p

debris and dirt out of the sump basin before insta

Be sure to have a grounded 120V AC outlet mounted within 6 ft. of your sump basin. Again,

is highly recommended that a GFCI (ground fault circuit interrupter) outlet be installed in the

receptacle box.

llati

ons.

the old pump. There are many different possibl

iping and start over with new piping. Be sure to clean a

lling your new pu

mp.

it

e

ll

NOTICE A qualified electrician must perform all wiring.

6 3

Page 4

INSTALLATION (New Pump)

A

1. Set your new pump in the bottom of the sump basin off to one side. The pump should be

placed on a solid foundation. Do not place the pump directly on the ground or sandy or

rocky surfaces. Sand and small stones may clog or cause damage to your pump.

2. Make sure the float switch will swing freely from the bottom to top without coming in

contact with the side of the sump basin. Contact with the side of the sump basin may

cause the switch to malfunction. See figure below.

Wide Angle Switch Installations

. Grounded Outlet. A GFCI outlet

is strongly recommended.

B. Full-flow swing type check valve

C. Discharge Pipe

D. Sump basin. Min. 14” diameter

E. Position pump so the float switch

operates freely without touching

the sides of the basin.

3. It is highly recommended to install a full flow, swing type check valve (not included)

as close to the discharge outlet on the pump as possible. A new check valve will

greatly increase the life of your pump. The check valve should be the same size as

Vertical Switch Installations

PROBLEM POSSIBLE CAUSES HOW TO CORRECT

If the pump does not

start or run

The pump starts and

stops too often

If the pump runs but

moves little or no water

TROUBLESHOOTING

Pump is not plugged in, switch or

breaker is off

Check for blown fuses or tripped circuit

breakers or tripped GFCI outlets

Float switch is defective Check and replace if necessary

Motor thermal protector tripped Allow pump to cool. Pump will reset

Float switch is stuck or obstructed

Backflow of water from discharge

hose/pipe

Float switch is defective Replace float switch

Clogged intake screen Clean or replace screen

Clogged discharge hose/pipe Remove clog

Frozen discharge hose/pipe Allow hose/pipe to thaw

Pump is air locked

Low line voltage

Check valve is stuck in the closed

position

Check valve is installed backwards

Worn, damaged or clogged pump parts

the pump discharge.

4. Connect the pump and check valve together using schedule 40 PVC pipe and

fittings. You can also use DWV or ABS pipe, as this is not a pressure installation.

Corrugated drain hose is intended for temporary use and should not be used in a

permanent installation. Although there are many types of pipe that work adequately

Pump does not

shut off

Discharge head exceeds pump

capacity

Float switch is obstructed or stuck Remove obstruction

Defective Float Switch Replace switch

for this installation, PVC is recommended.

5. Test your installation after you have completed setting up the pump. Plug the cord

from the pump into the piggyback plug of the float switch, then plug that into your

grounded outlet. The pump should not run at this point. If the pump runs, the

switch is stuck in the upright position or the pump is plugged directly into the outlet

and not through the piggyback switch plug. Fill the sump basin with water using

buckets or a hose. When the switch floats to the upright position, the pump will turn

on. The switch will turn off the pump when it reaches the down position. You may

adjust the switch to meet your particular needs. Remember the switch must swing

freely without touching the sides of the sump basin. NOTE: The cut out (turn off)

setting is the only adjustment available on vertical type switches.

4 5

Plug pump in or turn on

switch/breaker

Replace fuse, reset breaker, reset

GFCI outlet

Remove obstruction or position pump

so it will not become stuck

Install or replace check valve

Clean out airlock hole with a paper

clip or pipe cleaner

Check wire size and increase if

necessary

Inspect, repair or replace if necessary

Make sure check valve is installed in

the correct direction of flow

Inspect for wear, damage or clog and

clean or replace if necessary

If pumping height is over 25’, the

pump will not move water. See

performance chart

Loading...

Loading...