Superior Electric SLO-SYN Micro Series, SLO-SYN 3180-PI10, SLO-SYN 3180-PI, SLO-SYN 3180 Series, SLO-SYN 3180-PI125 Instructions Manual

The Only Factory Authorized Repair Center for Superior Electric

Motor Systems Inc.

460 Milford Parkway

Milford, OH . 45150

www.motorsystems.com

513-576-1725

Stepper Drive & Motor Repair

PRICE:

$25.00

ecticut

060110-7488

1987

The Superlor Eleclr~c

Company

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

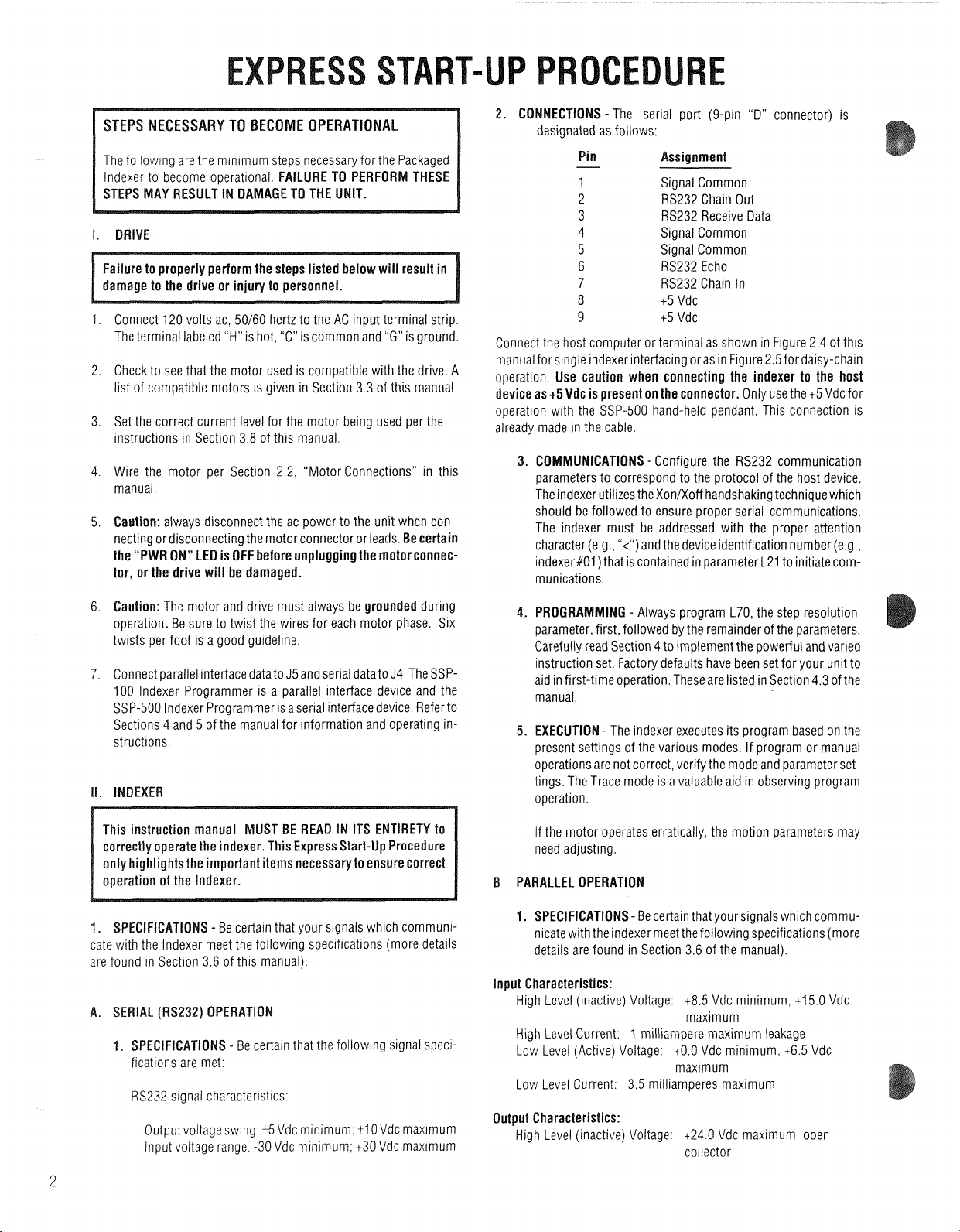

The following are the minimum steps necessary for the Packaged

become operational.

Y

RESULT IN DAMAGE TO THE UNIT.

I.

DRIVE

Connect 120 volts ac, 50160 hertz to the AC input terminal strip.

The terminal labeled "H" is hot, "C" is common and

Check to see that the motor used is compatible with the drive. A

list of compatible motors is given in Section 3.3 of this manual.

Set the correct current level for the motor being used per the

instructions in Section 3.8 of this manual.

Wire the motor per Section 2.2, "Motor Connections" in this

manual.

Caution:

necting or disconnecting the motor connector or leads.

always disconnect the ac power to the unit when con-

FAILURE TO PERFORM THESE

"G"

is ground,

Be certain

the "PWR ON" LED is OFF before unplugging the motorconnector, or the drive will be damaged.

2. CONNECTIONS

designated as follows:

-

The serial port (9-pin "D" connector) is

Pin ssignment

Signal Common

RS232 Chain Out

RS232 Receive Data

Signal Common

Signal Common

6232 Echo

RS232 Chain In

t5 Vdc

t5 Vdc

Connect the host computer or terminal as shown in Figure 2.4 of this

manual for single indexer interfacing oras in Figure 2.5fordaisy-chain

operation,

device as

operation with the SSP-500 hand-held pendant. This connection is

already made in the cable.

Use caution when connecting the indexer to the host

+5

Vdc is present on the connector.

3. COMMUNICATIONS

parameters to correspond to the protocol of the host device.

The indexer utilizes the XonKoff handshaking technique which

should be followed to ensure proper serial communications.

The indexer must

character(e.g., "<")and the device identification number (e,g.,

indexer#Ol) that is contained in parameter L21 to initiate communications.

-

Configure the RS232 communication

be

addressed with the proper attention

Only use the t5 Vdc for

Caution:

operation. Be sure to twist the wires for each motor phase. Six

twists per foot is a good guideline.

Connect parallel interface data to J5 and serial datato J4. The SSP100 lndexer Programmer is a parallel interface device and the

SSP-500 lndexer Programmer is aserial interface device. Referto

Sections 4 and 5 of the manual for information and operating instructions.

The motor and drive must always be

grounded

during

This instruction manual MUST BE READ IN ITS ENTIRETY to

correctly operate the indexer. This Express Start-Up Procedure

only highlights the important items necessary to ensure correct

operation of the Indexer.

S

-

Be certain that your signals which communicate with the lndexer meet the following specifications (more details

are found in Section 3.6 of this manual).

.

SERIAL (RS232) OPERATIO

S

-

Be certain that the following signal speci

fications are met:

RS232 s~gnal characterrstics:

6

Output voltage swing:

lnput voltage range: -30 Vdc mlnimum: t30 Vdc maximum

Vdc minimum:

ltlO

Vdc maximum

4.

PROGRAMMING

parameter, first, followed by the remainder of the parameters.

Carefully read Section 4 to implement the powerful and varied

instruction set. Factory defaults have been set for your unit to

aid in first-time operation. These are listed in Section 4.3 of the

manual.

5.

EXECUTION

present settings of the various modes. If program or manual

operations are not correct, verify the mode and parameter settings. The Trace mode is a valuable aid in observing program

operation.

If the motor operates erratically, the motion parameters may

need adjusting.

-

Always program L70, the step resolution

-

The indexer executes its program based on the

PARALLEL OPERATION

1.

SPECIFICATIONS-

nicate with the indexer meetthe following specifications (more

details are found in Section 3.6 of the manual).

Be certain that yoursignals which commu-

lnput Characteristics:

High Level (inactive) Voltage: 4.5 Vdc minimum, t15.0 Vdc

maximum

1

High Level Current:

Low Level (Active) Voltage: tO.O Vdc minimum, t6.5 Vdc

Low Level Current: 3.5 milliamperes maximum

milliampere maximum leakage

maximum

Output Characteristics:

High Level (inactive) Voltage: t24.0 Vdc maximum, open

collector

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

High Level Leakage Current: 250 microamperes maximum

leakage

Low Level Output: t0.4 Vdc at 16 milliamperes sink current

+0.7 Vdc at 40 milliam~eres sink current

2.

CONNECTIONS

pin "D" type connector. The pin assignments are as follows:

-The parallel signals are obtained via the 25-

I

General Comments

Pin Assignment

-

Signal Common 14

D7 Input* 15

D5 Input* 16

03 Input* 17

Dl Input* 18

Motion

Busy*? 19

Strobe 7* 20

5* 21

Strobe

Strobe 3" 22

Strobe 1

Output 2*t 24

All Windings Off Output't 25

Direction

*

Signals are active when low, inactive when high

t

Open collector output.

An example of a switch panel interface is displayed in Figure 5.2. The

diodes must be included

3.

COMMUNICATIONS

the timing requirements as shown in Figure 5.3. The LO7

parameter determines the timing of the strobes during the load

sequence.

4.

PROGRAMMING

be programmed first, after which the rest of the parameters

may be programmed. Carefully read Sections 4 and 5 of the

manual to learn how to implement the powerful and varied

instruction set. Factory default values have been set for your

unit to aid in first-time operation. These default values are

listed in Section 4.3 of the manual.

settings of the various modes.

tions are not correct, verify the mode and parameter settings.

If the motor operates erratically, adjust the motion parameters.

*

Outputet

for the indexer to operate successfully.

-

Proper parallel operation must observe

-

170. the step resolution parameter, must

-The indexer executes based on the present

Pin Assignment

-

Signal Common

05 Input*

D4 Input"

D2 lnput*

DO Input*

Not Used

Strobe

6*

Strobe 4*

Strobe 2*

23

If program or manual opera-

Strobe O*

I

Output

Pulse Output*t

*t

SLO-SYN Micro Serles drives use modern solld-state electronics such

as microprocessors to provide the features needed for- advanced

motion control applications. In some cases, these applications produce electromagnetic interference (EMI, or electrical "noise") that

may cause inappropriate operation of the microprocessor logic used

in the Micro Series product, or in any other computer-type equipment

in the user's system.

This guide is aimed toward helping users avoid such problems by

applying "good engineering practices" when designing their systems.

Following these guidelines will usually prevent

fering l~ith drive operation.

li

Noise Sources

What causes electrical norse? In general, any equrpment that causes

arcs or sparks or that switches voltage or current at high frequencies

can cause interference. In addition, ac utility lines are often "polluted"

with electrical noise from sources outside a user's control (such as

equipment in the factory next door).

The following are some of the more common causes of electrical

interference:

*

power from the utility ac line

*

relays. contactors and solenoids

*

hght dimmers

*

arc welders

*

motors and motor starters

*

induction heaters

*

radio controls or transmitters

sw~tch-mode power supplies

*

computer-based equipment

EM1 noise from inter-

FUSE AND MOTOR CONNECTOR PART NUMBERS

FOR

3180

SERIES UNITS

FUSE:

Littelfuse part number 225005

2AG. 5 amperes. 125 volts, fast acting

MOTOR CONNECTOR

Male connector body: AMP part number 206434-1

(5

required): AMP part number 66506-8

Pins

Cable clamp: AMP part number 206062-1

(mates with female motor connector on

drive)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

*

high frequency llghting equipment

*

dc servo and stepper motors and drives

Ill

Mounting Location

When selecting a mounting location ~t is preferable to keep the drive

away from obvious noise sources

possible locate the drive in rts own metal enclosure to shield it and its

wrmg from noise sources If this cannot be done keep the dr~ve at

least three feet from any nolse sources

such as those listed above If

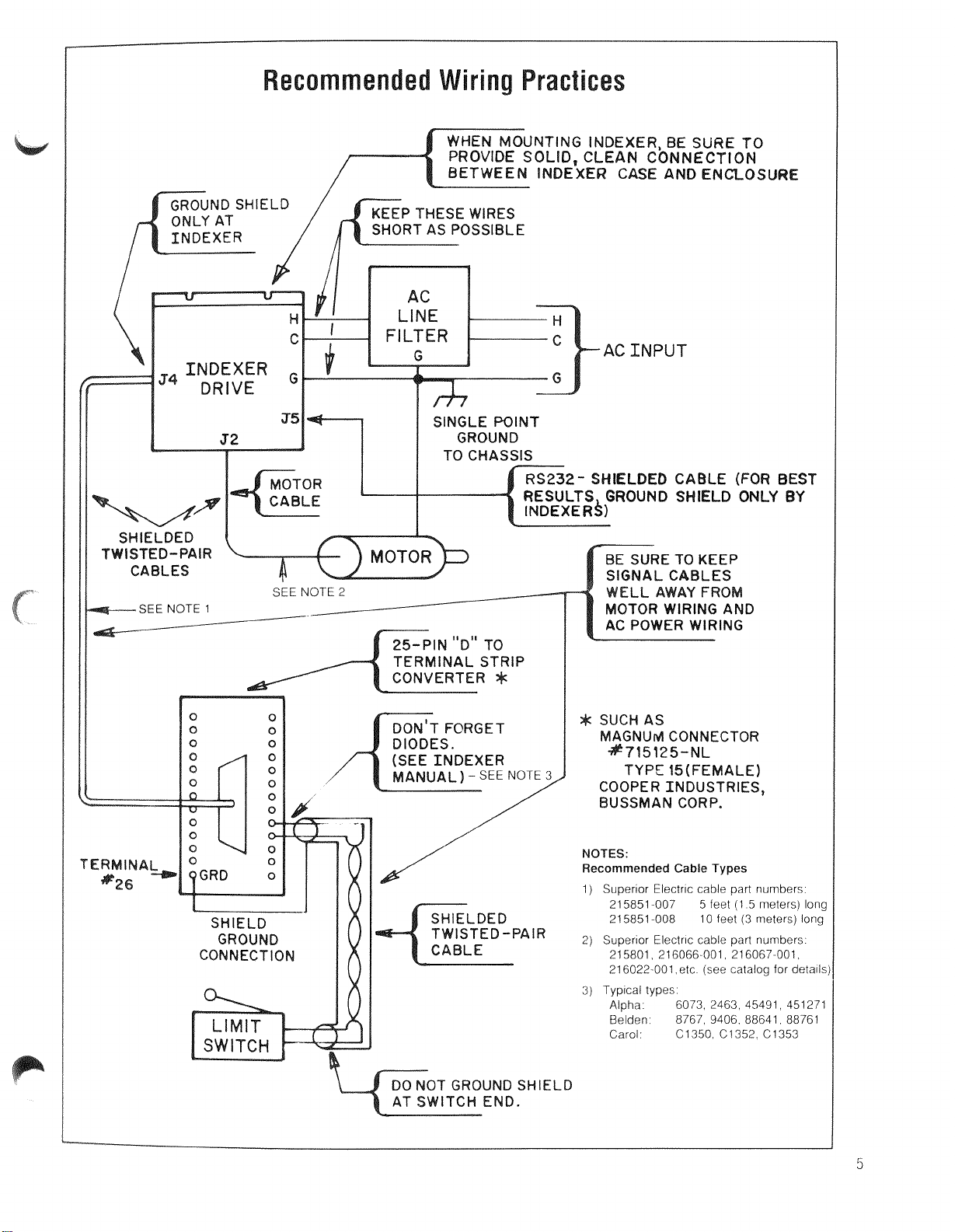

WHEN

MOUNTING

EXER,

BE

SURE TO

PROVIDE

SOLID,

AN CONNECTION

E

AND

ENCLOSU

P THESE WIRES

C

INPUT

I

I

J5

SINGLE POINT

I

GROUND

S

TWI

SEE

NOTE

1

SEE NOTE

2

-

BE SURE TO KEEP

OM

AND

AC POWER WIRING

Ud

CONNECTOR

TYPE

15(FEMALE)

OOPER INDUSTRIES,

USSMAN CORP.

NOTES:

Recommended Cable Types

1)

Superior Electr~c cable part numbers

215851 007

5

feet

(1 5

meters) Ions

21 5851 008

10

feet

(3

meters) long

2)

Superior Electric cable part numbers

215801 216066 001 216067 001

216022 001

etc

(see catalog for details

3)

Typ~cal types

Alpha

6073 2463 45491 451271

Belden

8767 9406 88641 88761

Carol

C1350 C1352 C1353

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

IV

Wiring Practices - "Dos and Don'ts"

Do

the folloviing when installing or wiring your drive or indexer

*

Do

keep the drive and its wiring as far away from noise sources

as possible

4

Do

provide a good solid ground connection to the ac system

earth ground conductor Bond thedrive case to the system enclosure

Do

use a srngle-point grounding scheme for ail related cornponents of a system (this looks like a hub and spokes arrangement)

Do

keep the ground connection short and direct

*

Do

use a line filter on the ac input (Corcorn type

or

lOK1

or eqwalent) for noisy ac lines Particularly bad ac

lines inay need to be conditioned with a ferroresonant type

isolation transformer to provide clean power to the drive or

indexer

Do

keep signal and drive wiring well separated If the wires

inust cross they should do so at right angles to minimize cou-

pling Power wiring includes ac wiring motor wiring etc and

srgnal wiring includes inputs and outputs (110) serial coinrnunicatrons

(RS232

lines) etc

10B1 10S1

*

Do

use separate conduits or ducts for signal and I10 wiring

Keep all power wiring out of these signal line conduits

*

Do

use shielded twisted-pair cables for indexer

*

Do

ground shields only at

*

Do

use twisted-pair shielded cable for the motor wiring

*

Do

use solid-state relays instead of electromechanical contact

types wherever possible to minimize noise generat~on

*

Do

suppress all relays to prevent noise generation Typical

suppressors are capacitors or MOVs See manufacturers

lrterature for complete

Do not

do the following when installing your drive or indexer:

Do not

install sensitive computer-based equipment (such as

an indexer1drive) near a source of

*

Do not

bundle power and signal lines together.

*

Do not

bundle motor cables and signal lines together.

*

Do not

fail to use shielded. twisted-pair cables for signals.

Do not

fail to properly connect the system grounds.

*

Do not

use "daisy-chained" grounds.

*

Do not

fail to ground signal cable shields at only one end.

*

Do not

assume that power from the ac line is adequately

"clean".

one end

information

the indexeridri~e end

electromagnetic

110

lmes

noise.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

V

AC

Line Filter

Use of an AC lhne filter on

Proper installation of the

31

80

and

61

80

Ser~es drlves

AC

Line Filter is essential

is recommended.

Asuitable filter is included with each unit supplied for sale in North America.

WARNING: Improper installation of the ac line filter may cause electrical shock, which could result in death, serious bodily

injury or property damage. To avoid electrical shock:

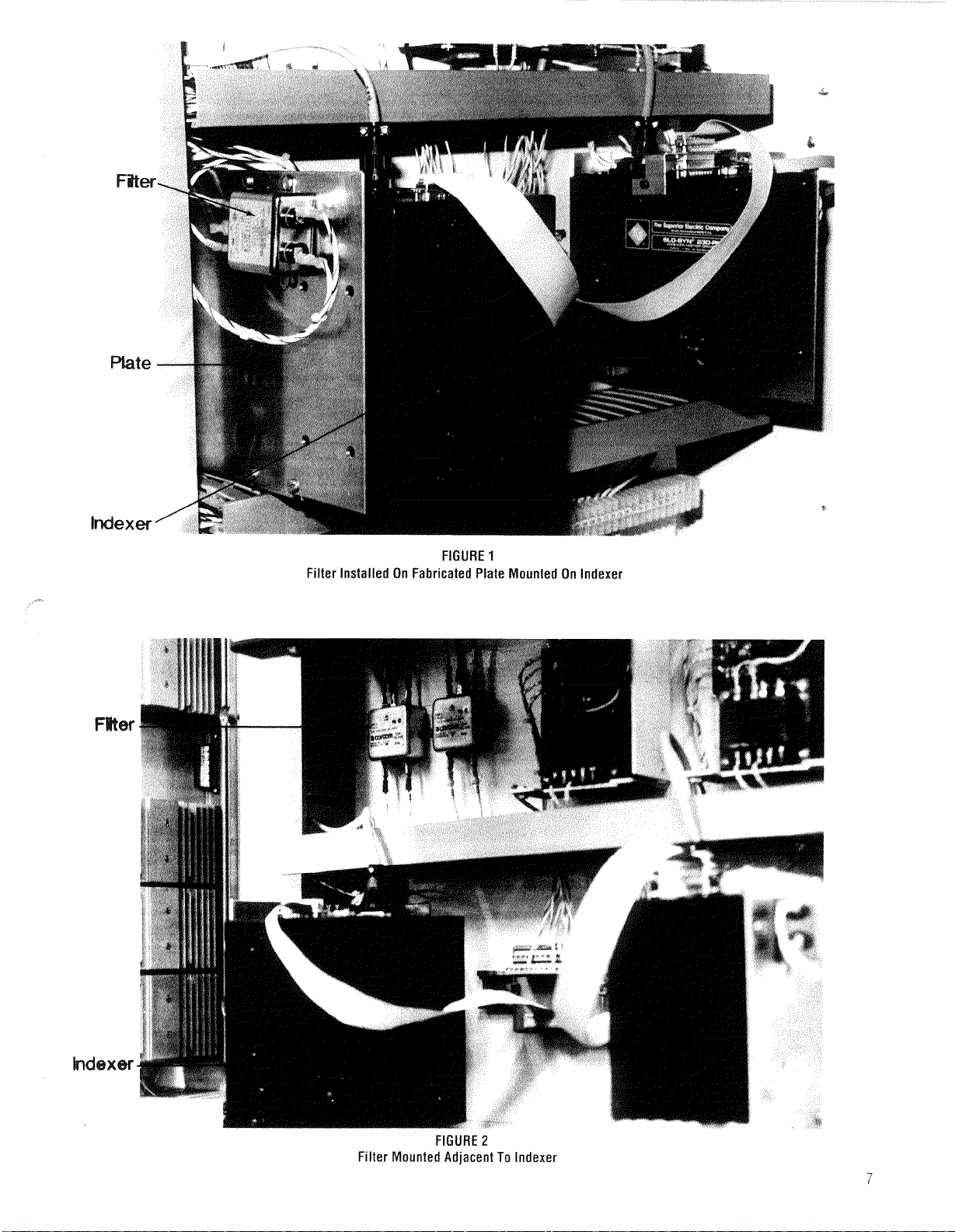

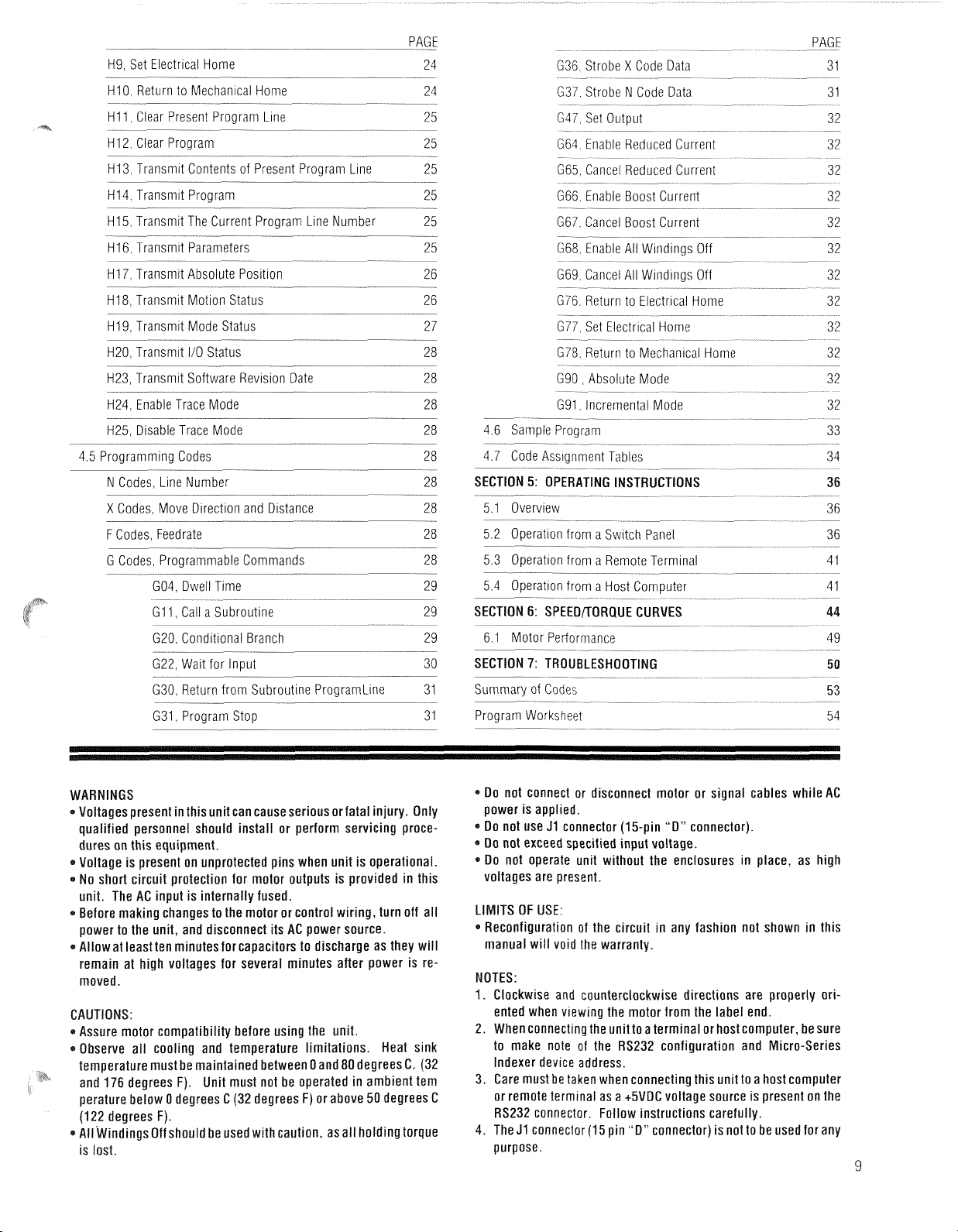

*The ac line filter must be installed by qualified personnel. Typical methods of locating and installing the line filter are

shown in Figures

1

and

2.

*The ac line filter must be firmly fastened near the Indexer. Failure to do so may result in damage to the filter and system.

*The installer must properly insulate and protect the ac connections to assure that the wires are not exposed. Exposed

wires could cause electrical shock, resutting in death, bodily injury or property damage.

If you have any questions regarding installation of the line filter, contact an electrician before installing the device.

For best performance:

*

The wlre between the Filter and the Drive should be less than two feet

(0.61

meter) long

Proper AC Line Filter Connections

VI

Troubleshooting Guide

Electrical interference problems are common with today's computer-based controls, and such problems are often difficult to diagnose and cure.

If such a problem occurs with your system. it is recommended that the following checks be made to locate the cause of the problem.

1.

Check the quality of the ac line voltage using an oscilloscope and a line monitor. such as the Superior Electric

age problems exist, use appropriate line conditioning, such as line filters or isolation transformers.

2.

Be certaln all of the previous Do's and Don'ts are followed for location, grounding, wring and relay suppression

3.

Double check the grounding connections to be sure they are good electrical connections and are as short and direct as possible.

4

Try

operating the drive wlth all suspected noise sources switched off If the drlve functions properly switch the noise sources on again

one at a time and try to Isolate whlch ones are causing the Interference problems When a noise source is located try rerouting wirlng

suppressing

relays or other measures to eliminate the problem

VMS

series. If linevolt-

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

FIGURE

1

Filter installed On Fabricated Plate Mounted On Indexer

FIGURE

2

Filter Mounted Adjacent To Indexer

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PAGE

PRECAUTIONS

WARNINGS CAUTIONS. LIMITS OF USE. ETC 9

SECTION

1:

INTRODUCTION

1.1 Features Overview 10

1.2 Inspection parts list 10

1.3 Using this manual 10

1.3.1 Organization

9

10

4.1.3 Programming Chart

~

--

--

-.-

4.2 Immediate Commands

-

Clear 19

Freehold 19

Device Attention Character 19

Cycle Stop 19

Backspace and Delete 19

PAGE

1.3.2 Logic voltage and programming conventions 10 Delete Line 19

1.3.3 Indicator lights and AC fuse 10

SECTION

2:

MOUNTING, CONNECTIONS & PIN ASSIGNMENTS

11

4.3 L Codes: Indexer Parameters 19

L06, Program Execution Format

2.1 Mounting 11 107, Strobe Delay Time 20

2.2 Motor connections 11 L08, Mechanical Home Direction 20

2.3 Connection Diagrams 13 L09, Jog Speed 20

17

19

2.3.2 J2: Motor 13

2.3.3 J3: Power lnuut

2.3.4 34: Parallel

2.3.5 J5: Serial

2 4 Serial Communication Connection Diagrams

Single lndexer System

2 4

1

Multiple lndexer System

2 4 2

-

110

110

.

..

--

-

-.

--

-

--

-

-

2 5 Memory Protect Switch

SECTION

3:

SPECIFICATIONS

3 1 Drive Description

3 2 Drive Performance

--

-

3 3 Motor Compatibility

--

-

-

--

-

--

---

--

-

3 4 Drive Mechanical Specifications 15

3.5 Electrical Specifications 15

AC

35 1

3 5 2

-

3 6 Micro-Series-Indexer 110 Signal Interfaces

--

lnput

-

Output to Motor

-

--

--

3 6 1 Parallel I10

3 6 1 1 Parallel Output Characteristics 16

3 6 1 2

-

Parallel lnput Characteristics

--

--

3 6 2 Serial I10 16

3.7 Environmental Specifications 16

3

8 Current Settings

4

1 2 General Programming Comments 17

-

GUIDE

-

--

-

-

-

-

-

--

--

13

13

13

15

15

15

15

16

16

17

17

L1 2. Low Speed

L14, Home Speed 2

117, Offset Direction and Distance from

Mechanical Home 21

L18, Clockwise Software Travel Limit

119. Counterclockwise Software Travel Limit

L21. Assign Device Identification Number

L22, Baud Rate 22

L23, Character Length 22

L25, Parity 2 2

126, Indexer Ready Acknowledge 22

141, Auto Start Line Number

L44 Program Line Delay

--

L45 Limit Switch Enable 23

L48. Program Line Transfer Count

L49, Parameter Transfer Designation

-.

170, Translator Resolution 23

4 4 Codes Commands for Modes of Operation

--

-

-

-

- - - - -

-

HI Cycle Start

H2 Step Mode

H3 Jog Mode

H4. High Speed Mode 24

H5. Low Speed Mode 24

H6. Turn in CW Direction

Hi. turn in CCW Direction

H8 Return to Electrical Home 24

2 1

1

2 1

3

2

2 3

2 3

2 3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

H9, Set Electr~cal Home

-

--

--

HI0 Return to Mechanical Home 24

HI 1, Clear Present Program Line

HI 2. Clear Program 25

H13. Transmit Contents of Present Program L~ne

HI4 Transm~t Program

-.

--

-

H15, Transmit The Current Program Line Number

H16, Transmit Parameters 25

H17, Transmit Absolute Position 26

HI 8, Transmit Motion Status 2 6

HI 9, Transmit Mode Status 2 7

H20, Transmit I/O Status 28

H23, Transmit Software Revision Date 2 8

H24, Enable Trace Mode 28

H25, Disable Trace Mode 28

4 5 Programming Codes

--

N Codes Line Number 28

X

Codes, Move Direction and Distance

F

Codes, Feedrate

G Codes Programmable Commands

--

GO4 Dwell Time 29

-

GI 1 Call a Subrout~ne

--

G20 Conditional Branch

-

-

--

G22 Wait for Input 30

G30, Return from Subroutine ProgramLine 31

G31. Program Stop 3 1

PAGE

---

24

G36 Strobe X Code Data

31

G37 Strobe N Code Data 31

25

2 5

25

.-

25

G47 Set Output 3 2

G64 Enable Reduced Current

-

---

-

32

-

G65 Cancel Reduced Current 3 2

G66 Enable Boost Currerlt 32

G67 Cancel Boost Current 32

G68 Enable All Wmdings Off

--

-

32

G69 Cancel All Windings Off 32

G76 Return to Electrical Home

-

-

--

--

-

-

3 2

G77 Set Electrical Home 32

G78 Return to Mechanical Home

--

-

-

3 2

-

--

G90 Absolute Mode 32

G91, Incremental Mode 32

4.6 Sample Program 33

2 8

-

28

4.7 Code Assignment Tables 34

5:

SECTION

5

1 Overview

OPERATING INSTRUCTIONS 36

-

-

-

5 2 Operation from a Sw~tch Panel

28

--

5.3 Operation from a Remote Terminal 4 1

5.4 Operation from a Host Computer

6:

29

29

--

SECTION

6.1 Motor Performance 49

SECTION

Summary of Codes

-

SPEEORORQUE CURVES

7:

TROUBLESHOOTING

--

-

-

50

53

-

-

Program Worksheet 54

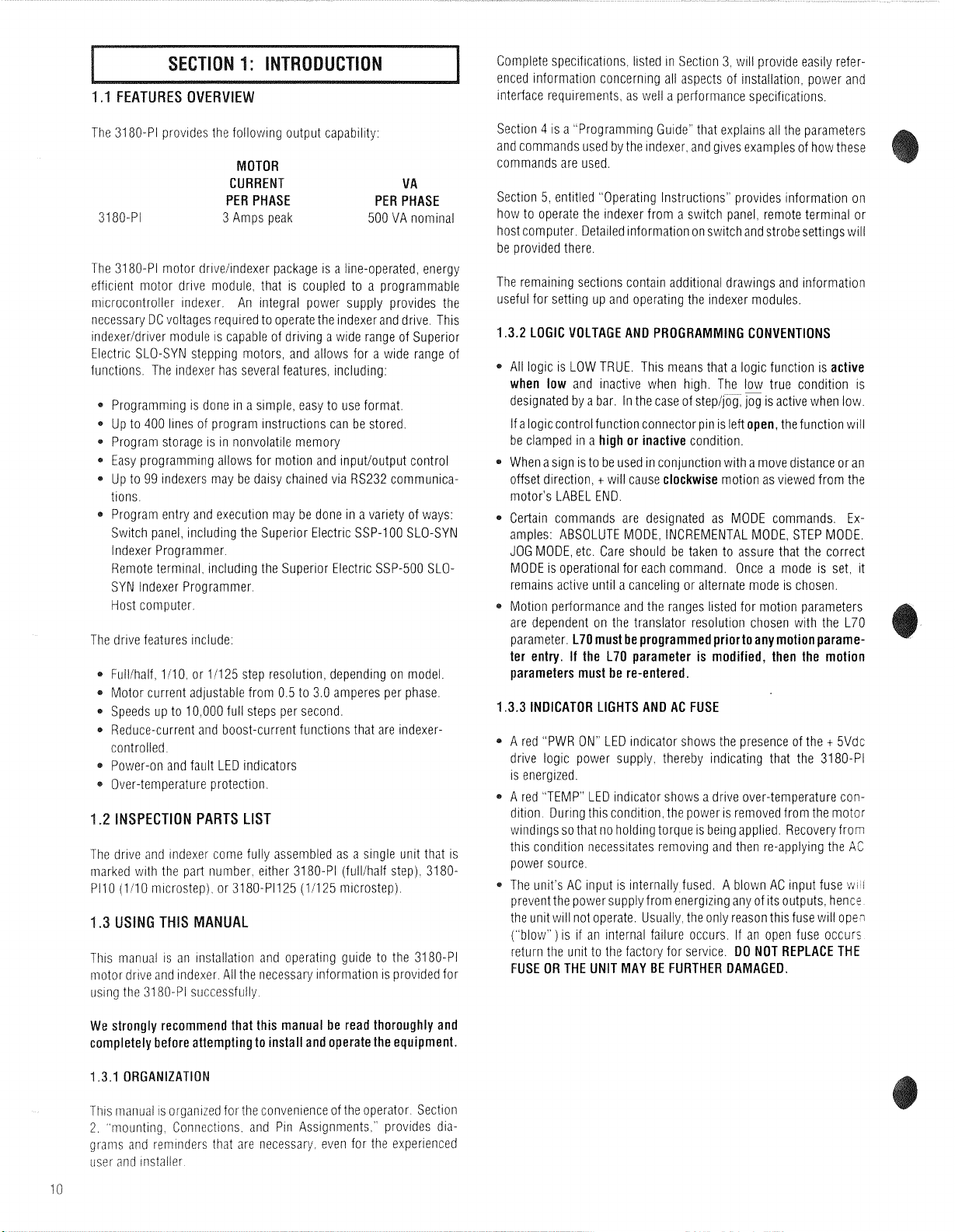

WARNINGS

*

Voltagespresent in this unit can causeserious or fatal injury. Only

qualified personnel should install or perform servicing procedures on this equipment.

*

Voltage is present on unprotected pins when unit is operational.

a

No short circuit protection for motor outputs is provided in this

unit. The AC input is internally fused.

*

Before making changes to the motor or control wiring, turn off all

power to the unit, and disconnect its AC power source.

*

Allow at least ten minutes for capacitors to discharge as they will

remain at high voltages for several minutes after power is removed.

*Assure motor compatibility before using the unit.

*Observe all cooling and temperature limitations. Heat sink

temperature must be maintained between Oand 80 degrees C. (32

and

176

degrees F). Unit must not be operated in ambient tern

perature below 0 degrees C (32 degrees F) or above 50 degrees

C

(122 degrees F).

*

All Windings Off should be used with caution, asall holding torque

is lost.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

*Do not connect or disconnect motor or signal cables while AC

power is applied.

*

00 not use J1 connector (15-pin "0" connector).

*

Do not exceed specified input voltage.

*Do not operate unit without the enclosures in place, as high

voltages are present.

LIMITS OF USE:

*

Reconfiguration of the circuit in any fashion not shown in this

manual will void the warranty.

NOTES:

1.

Clockwise and counterclockwise directions are properly oriented when viewing the motor from the label end.

2. When connecting the unit to a terminal or host computer, be sure

to make note of the

RS232 configuration and Micro-Series

Indexer device address.

3.

Care must be taken when connecting this unit to a host computer

or remote terminal as a +5VDC voltage source is present on the

RS232 connector. Follow instructions carefully.

4.

The

J1

connector (15 pin "D" connector) is not to be used for any

purpose.

9

1.1

FEATURES OVERVIEW

Complete specifications listed in Section 3 will provide easily referenced information concerning all aspects of installation power and

interface requirements as well a performance specifications

The 3180-PI provides the following output capability:

MOTOR

CURRENT

VA

PER PHASE PER PHASE

3180-PI 3 Amps peak 500 VA nominal

The 3180-PI motor drivelindexer package is a line-operated, energy

efficient motor drive module, that is coupled to a programmable

m~crocontrolier indexer. An integral power supply provides the

necessary DC voltages required to operate the indexer and drive. This

indexeridriver module

Electric SLO-SYN stepping motors, and allows for a wide range of

functions, The indexer has several features, including:

Programming is done in a s~mple easy to use format

Up to 400 lines of program instructions can be stored

Program storage

Easy programming allows for motion and input/output control

99

Up to

tions

Program entry and execution may be done

Switch panel including the Superior Electric SSP-100 SLO-SYN

lndexer Programmer

Remote terminal including the Superlor Electric SSP-500 SLOSYN Indexer Programmer

Host computer

The drive features include.

Full/half 1/10 or 11125 step resolution depending on model

Motor current adjustable from 0

*

Speeds up to I0 000 full steps per second

*

Reduce-current and boost-current functions that are indexercontrolled

*

Power-on and fault LED indicators

*

Over-temperature protection

1.2

INSPECTION PARTS LIST

The drive and indexer come fully assembled as a single unit that is

inarked with the part number either 3180-PI (fullihalf step) 3180PI10 (1110 microstep) or 3180-PI125 (11125 microstep)

1.3

USING THIS MANUAL

This manual is an installation and operating guide to the 3180-PI

motor drive and indexer All the necessary information is provided for

using the 3180-Pi successfully

indexers may be daisy chained via RS232 communica-

is capable of driving a wide range of Superior

is in nonvolatile memory

in a variety of ways

5

to 3 0 amperes per phase

Section 4

and commands used by the indexer and gives examples of how these

commands are used

Section 5 entitled Operating Instructions provides information on

how to operate the indexer from a switch panel remote terminal or

host computer Detailed information on switch and strobesettings will

be provided there

The remaining sections contain additional drawings and information

useful for setting up and operating the indexer modules.

1.3.2

is a Programmrng Guide' that explains all the parameters

LOGIC VOLTAGE AND PROGRAMMING CONVENTIONS

All logic is LOW TRUE. This means that a logic function is

when low

designated by a bar. In the case of step/Eg,

If a logiccontrol function connectorpin is left

be clamped in a

When a sign is to be used in conjunction with a move distance or an

offset direction.

motor's LABEL END.

Certain commands are designated as MODE commands. Examples: ABSOLUTE MODE. INCREMENTAL MODE, STEP MODE.

JOG MODE, etc. Care should be taken to assure that the correct

MODE is operational for each command. Once a mode is set.

remains active until a canceling or alternate mode is chosen.

Motion performance and the ranges listed for motion parameters

are dependent on the translator resolution chosen with the L70

parameter.

and inactive when high. The low true condition is

jog

is active when low.

open,

the function will

high or inactive

+

will cause

condition.

clockwise

motion as viewed from the

L70 must be programmed priorto any motionparame-

active

it

ter entry. If the L70 parameter is modified, then the motion

parameters must be re-entered.

3.3

INDICATOR LIGHTS AND AC FUSE

A red "PWR ON" LED indicator shows the presence of the t 5Vdc

drive logic power supply. thereby indicating that the 3180-PI

is energized.

A red "TEMP" LEO indicator shows a drive over-temperature condition. During this condition. the power is removed from the motor

v~indings so that no holding torque is being applied. Recovery from

tlirs condition necessitates removing and then re-applying the

power source.

The unit s AC input is internally fused A blown AC input fuse

prevent the power supply from energizing any of its outputs hencs

the unit will not operate Usually theonly reason thlsfuse will ope?

(

blow ) is if an internal failure occurs If an open fuse occurs

return the unit to the factory for service

DO NOT REPLACE THE

AC

w

I

FUSE OR THE UNIT MAY BE FURTHER DAMAGED.

We strongly recommend that this manual be read thoroughly and

completely before attempting to install and operate the equipment.

1.3.1

ORGANIZATION

This inianuai is organized for the convenience of the operator Section

2

mounting Connections and Pin Assignments provides diagraiiis and reminders that are necessary even for the experienced

user and iiistaller

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

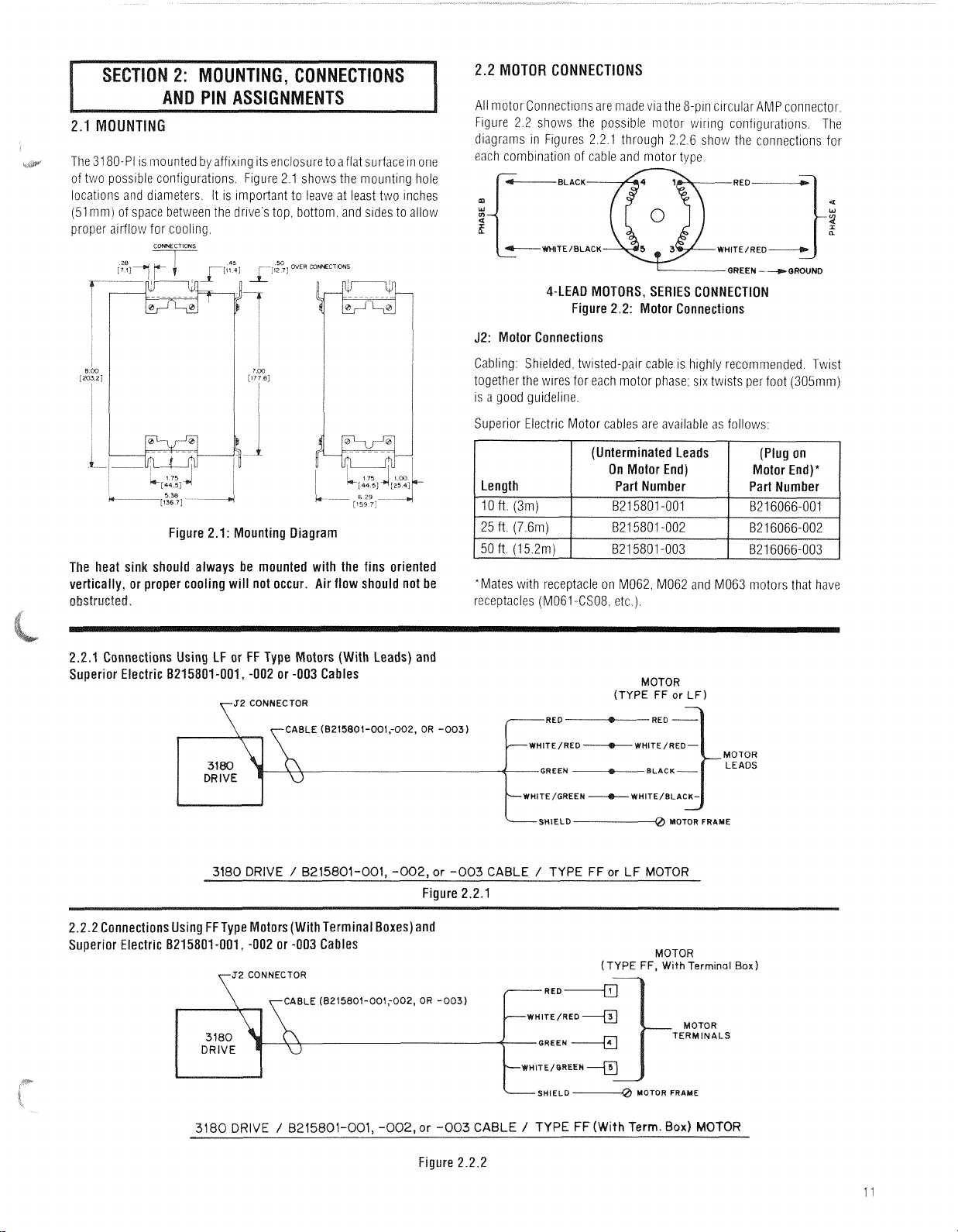

The 31 80-PI is mounted by afflxing ~ts enclosure to aflat surface in one

of two possible

locations

configurations

and

diameters

Figure 2 1 shows the mounting hole

It is important to leave at least two inches

(51 rnm) of space between the drive stop bottom and sides to allow

2.2

MOTOR CONNECTIONS

All motor Connectioris are made vla the 8-pin circular AMP connector.

Figure 2.2 shows the possible rnotor wiring configurations. The

diagrarns in Figures 2.2.1 through 2.2.6 show the connections for

each comblnatiori of cable and motor type

BLACK

m

w

WHlTElBLACK

-QUEEN

-+

a

QRWND

4-LEA0 MOTORS, SERIES CONNECTION

Figure 2.2: Motor Connections

J2: Motor Connections

Figure 2.1: Mounting Diagram

The heat sink should always be mounted with the fins oriented

vertically, or proper cooling will not occur. Air flow should not be

2.2.1 Connections Using LF or FF Type Motors (With Leads) and

Superior Electric 8215801-001, -002 or -003 Cables

ZCONNECTOR

CABLE

(8215801-001;002,

OR

-003)

Cabling: Shielded. twisted-par cable

IS

highly recommended. Tw~st

together the wlres for each motor phase; six twists per foot (305mm)

IS

a good guideline.

Superior Electric Motor cables are available as follows.

Length

loft (3m)

(Unterminated Leads

On Motor End)

Part Number

821 5801 -001

(Plug on

Motor End)*

I

Part Number

1

B216066-001

*Mates wlth receptacle on M062, M062 and M063 motors that have

receptacles (M061 -CS08. etc

RED -RED

TE/RED bWHITE/RED-

GREEN -BLAC

WHITE/GREEN

SHIELD-@ MOTOR

--+---

)

MOTOR

(TYPE

WHITE/BLA

FF

or

LF)

FRAME

3180 DRIVE / 8215801-001,

-002,

Figure 2.2.1

2.2.2 Connections Using FFType Motors (With Terminal Boxes) and

Superior Electric B215801-001, -002 or -003 Cables

2

CONNECTOR

CABLE

3180

DRIVE

(8215801-001;002,

/

8215001-001, -002,or -003 CABLE / TYPE FF

OR

Figure 2.2.2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

or -003 CABLE / TYPE

-003)

WHITE/QREEN

SHIELD

~-0

FF

or LF MOTOR

(TYPE

(With

MOTOR

FF,

MOTOR

Term. Box) MOTOR

With

Terminal

MOTOR

TERMINALS

FRAME

Box)

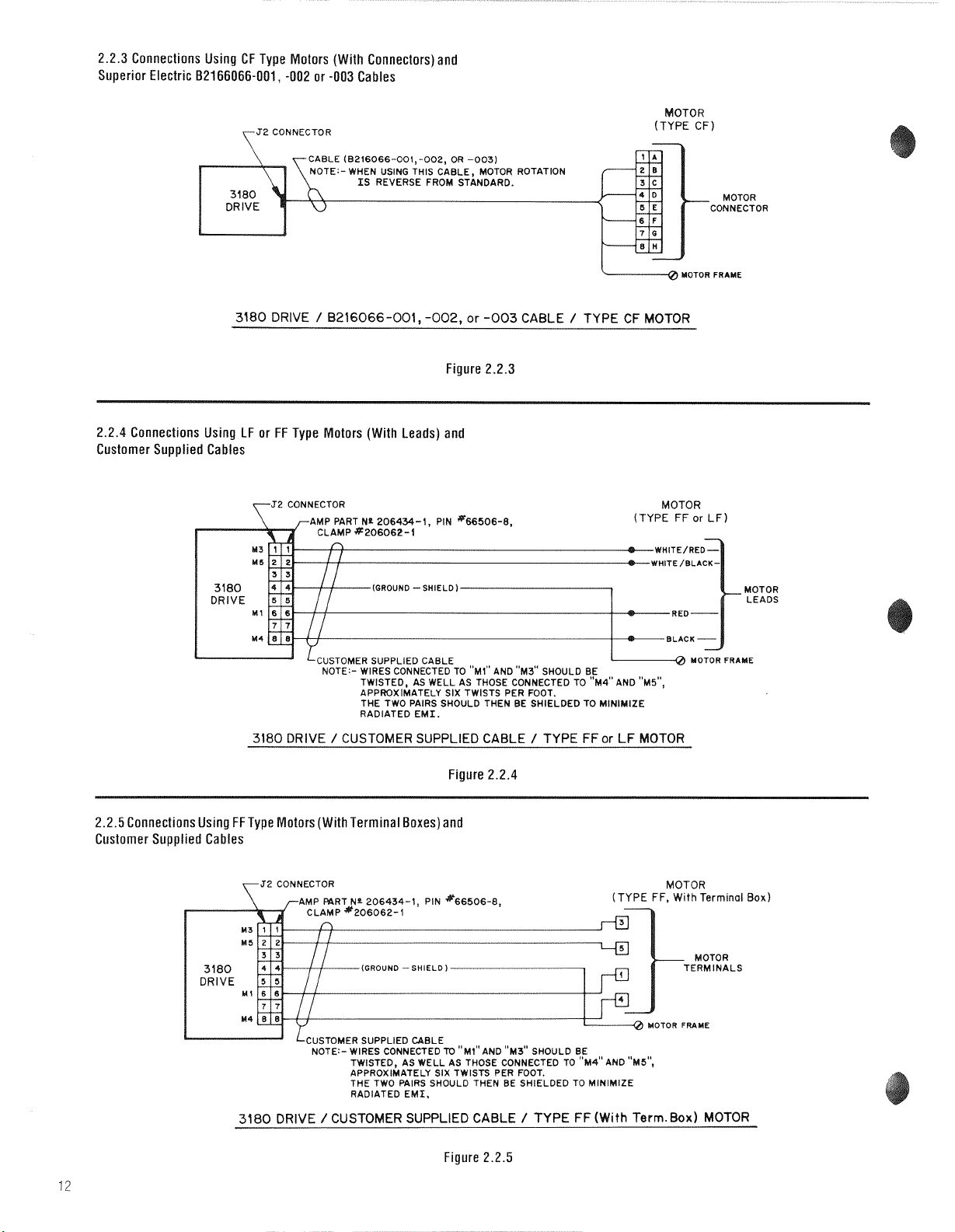

2.2.3 Connections Using CF Type Motors (With Connectors) and

Superior Electric 82166066-001, -002 or -003 Cables

CABLE (8216066-001,-002, OR -003)

OTOR

(TYPE CF)

-

MOTOR

CONNECTOR

3180 DRIVE / B216066-001, -002,

Figure 2.2.3

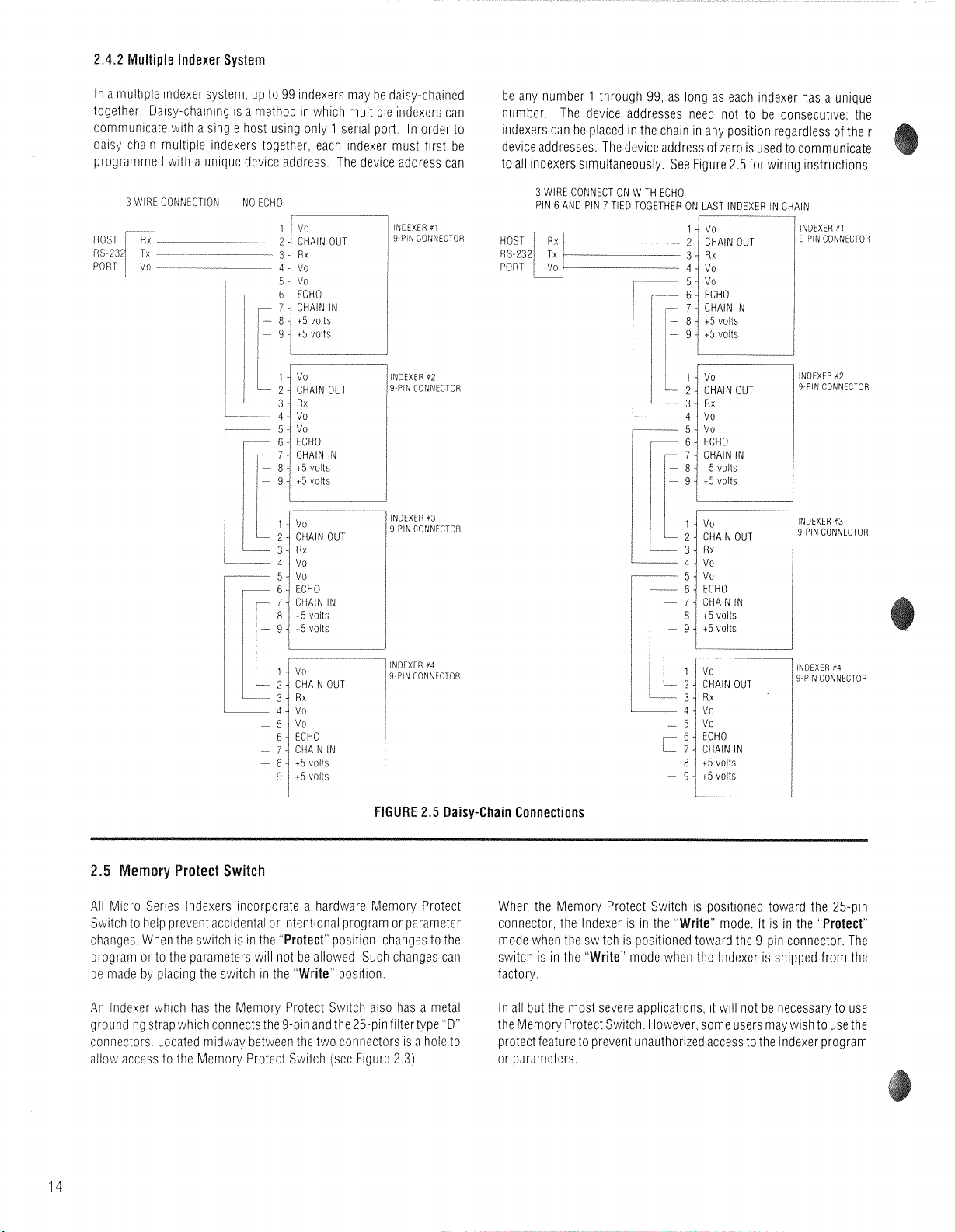

2.2.4 Connections Using LF or FF Type Motors (With Leads) and

Customer Supplied Cables

2 CONNECTOR

AMP PART Nr 206434-1, PIN "66506-8,

CLAMP *206062-1

(GROUND -SHIELD

L----------d

LCUSTOMER

NOTE:- WIRES CONNECTED TO "~1" AND "~3" SHOULD BE

SUPPLIED

TWISTED,

APPROXIMATELY SIX TWISTS PER FOOT.

THE TWO PAIRS SHOULD THEN BE SHIELDED TO MINIMIZE

RADIATED EMI.

CABLE

AS

WELL AS THOSE CONNECTEO TO "~4'' AND "M5",

3180 DRIVE / CUSTOMER SUPPLIED CABLE / TYPE FF

or

-003

CABLE / TYPE CF MOTOR

or

MOTOR

(TYPE FF

I-0

LF MOTOR

or

LF)

MOTOR

MOTOR

LEADS

FRAME

Figure 2.2.4

2.2.5 Connections Using FFType Motors (With Terminal Boxes) and

Customer Supplied Cables

NOTE:- WIRES CONNECTEO

TWISTED, AS WELL AS THOSE CONNECTED TO "M4"AND "M5",

APPROXIMATELY SIX TWISTS PER FOOT.

THE TWO PAIRS SHOULD THEN BE SHIELDED TO

RADIATED EMI.

3180

DRIVE / CUSTOMER SUPPLIED CABLE / TYPE FF(With Term.Box) MOTOR

TO

"Ml" AND "~3" SHOULD BE

Figure 2.2.5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MINIMIZE

F,

With

Terminal

MOTOR FRAME

Box)

2.2.6 Connections Using CF Type Motors (With Connectors) and

Customer Supplied Cable

2

CONNECTOR

GROUND

-SHIELD)

LcusToMER SUPPLIED CABLE

NOTE:- WIRES CONNECTED TO "~1" AND "~3" SHOULD

TWISTED, AS WELL AS THOSE CONNECTED TO

APPROXIMATELY SIX TWISTS PER

THE TWO WlRS SHOULD THEN BE SHIELDED TO MINIMIZE

RADIATED EMI.

3180 DRIVE / CUSTOMER SUPPLIED CABLE / TYPE CF MOTOR

Figure 2.2.6

2.3

CONNECTION DIAGRAMS

2.3.1 J1: DO NOT USE (15-pin "0" type)

otor (see 3.5.2.1 for pin assignments)

53: Power Input (see 3.5.1.2 for terminal assignments)

2.3.3

2.3.4 J4: Parallel I10 Connections (25 pin. "0" type) (see 3.6.1 for

pin assignments)

2.3.5 55: Serial IlO(9-pin, "0"

type)(see3.6.2forpinassignments)

'7LoIoR

BE

"~4"

FOOT.

2.4

SERIAL COMMUNICATION CONNECTION DIAGRAMS

AND "M5",

rmw

2.4.1 Single lndexer System

In

a

slngie

~ndexer

systeln

~t

IS

init~ally transrnlttlng

Ing devlce

Flgure

HOST

RS

PORT

232

address

2

4

for

wlrlng Instructtons

3WlRE CONNtCIlON NO ECHO

ax

TI

VO

the

dev~ce

A

new

necessary

attentton

indexer

to actlvate

character

has

a

devlce

the

and

~ts

correspond-

address

INDEXER

9

lridexer

of

PIN CONNECTOR

1

by

See

/

I

Figure 2.3 3180-PI Connections

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SERIAL

CONNECTOR

110

J5

MEMORY PROTECT

SWITCH

PARALLEL

CONNECTOR

I10

J4

PWR. ON LED

TEMP. LED

AC INPUT

TERMINAL STRIP

J3

MOTOR CONNECTOR

J2

3

WlR€ CONNECTION WITH ECIi0

I

Figure 2.4 Single Indexer Connections

INDEXER

9

PIN CONNCCTOR

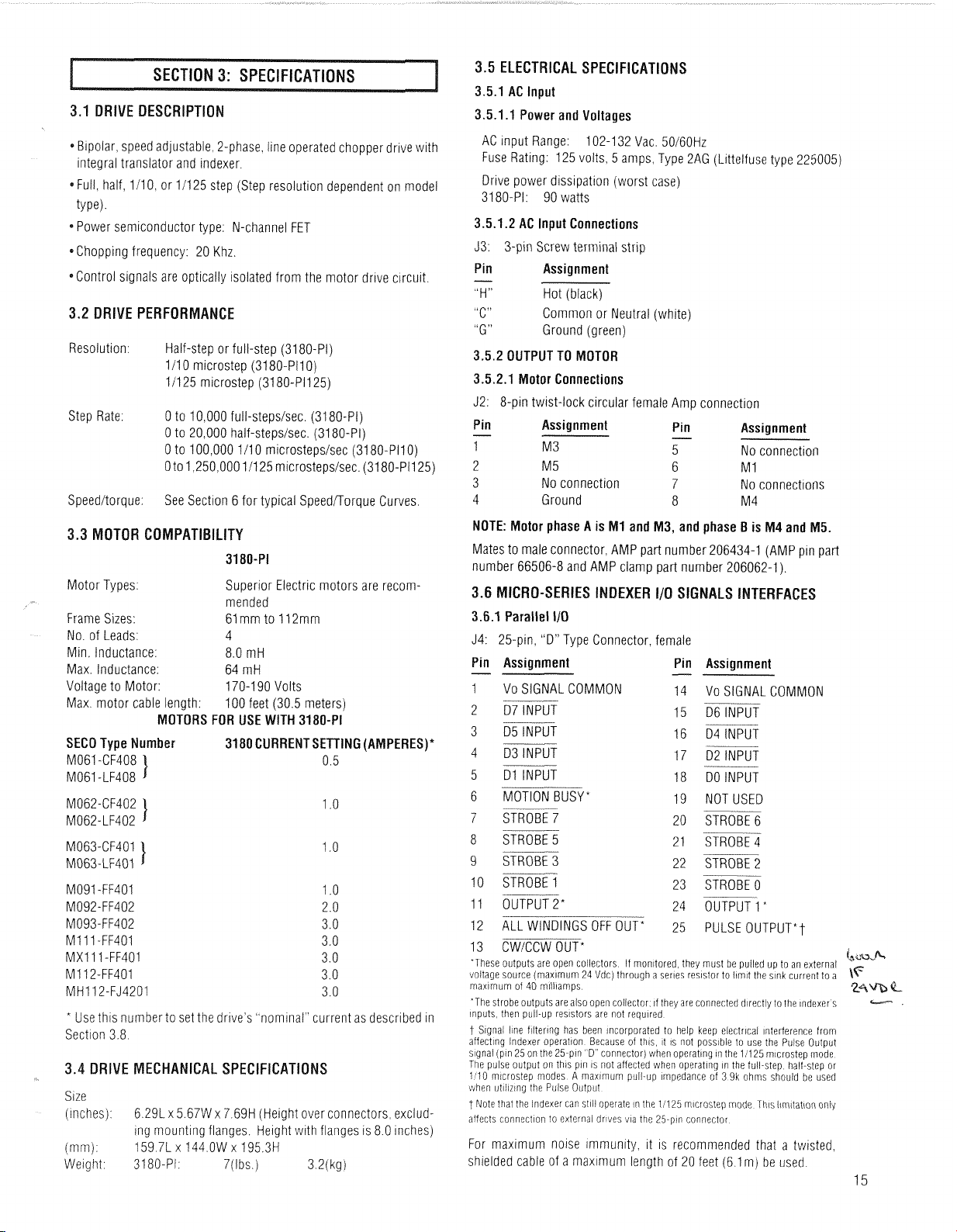

2.4.2

Multiple lndexer System

In a multiple indexer system. up to

99

indexers may be day-chained

together Dalsy-chaining

IS

a method in which muhple indexers can

communicate

with

a singie host uslng only 1 sera port. In order to

dalsy chaln multiple Indexers together, each indexer must first be

progran~med with a unlque device address. The device address can

3

WIRE

CONhECTlON

NO

ECHO

7-1

IPdEXER

#I

2.

CHAIN

OUT

I

9

PI4

CONNECTOR

3-

'Ivo

Rx

--

4

-I

vo

i

...

5:

vo

1

r---

6-1

ECHO

7

-

CHAIN

IN

1

1

cB!

15

volts

I

)

-

9

-1

15

volts

Ill

I

I

/

INDEXER

42

/

9

PIN

CONNECTOR

Ill

-

INDEXER

#3

9-PIN

CONNECTOR

1

INDEXER

#4

/

9-PIN

CONNECTOR

l

I

I

i

:

I

r--

--

3-

Rr

4-

vo

be any number

1

through 99, as long as each indexer has a unique

number. The device addresses need not to be consecutive; the

Indexers can be placed ~n the cnain in any position regardless of their

device addresses. The device address of zero is used to communicate

to all indexers simultaneously. See Figure

2.5

for wiring instructions.

-

5-

--

6

-

3

WIRE

CONNECTION

WITH

ECHO

PIN

6

AND

PIN

7

TIED TOGETHER

ON

LAST

INDEXER

IN

CHAIN

vo

ECHO

1

4

vo

INDEXER pl

HOST

I%--.-

---

2

'

CHAIN

OUT

9-PIN

CONNECTOR

RS-232,

Tx

t

3

1

Rx

--

7

4

CHAIN

IN

-

8

-/

15

volts

-

9

-i

45

volts

1

INDEXER

#3

9-PIN

CONNECTOR

FIGURE

2.5

Daisy-Chain Connections

t5

volts

15

volts

INDEXER

#4

9-PIN

CONNECTOR

emory Protect Switch

Ali Micro Series Indexers Incorporate a hardware Memory Protect When the Memory Protect Switch is positioned toward the 25-pin

Switch to help prevent accidental or intentional program or parameter connector, the lndexer is in the

"Write"

mode. It is in the

"Protect"

changes. When the swltch

IS

in the

"Protect"

position. changes to the mode when the switch

IS

positioned toward the 9-pin connector. The

program or to the parameters will not be allowed. Such changes can switch is in the

"Write"

mode when the lndexer is shipped from the

be made by

placing

the swltch in the

"Write"

position. factory.

An Indexer whlch has the Memory Protect Swltch also has a metal

in all but the most severe

applications

~t will not be necessary to use

grounding strap whch connects the 9-pin and the 25-pin filtertype D

'

the Memory Protect S~vitch However some users may wlsh to use the

connectors Located midway between the two connectors 1s a hole to

protect feature to prevent unauthorized access to the lndexer program

allov! access to the Memory Protect Switch (see Figure 2

3)

or parameters

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3.5

ELECTRICAL SPECIFICATIONS

3.5.1 AC lnput

3.1

DRIVE DESCRlPTlO

3.5.1.1 Power and Voltages

AC lnput Range:

102-1 32 Vac. 50160Hz

Fuse Rating: 125 volts, 5 amps, Type 2AG (Littelfuse type 225005)

*

Blpolar, speed adjustable, 2-phase. line operated chopper drive with

integral translator and indexer.

*Full, half, 111 0, or 111 25 step (Step resolution dependent on model

type).

Drive power dissipation (worst case)

3180-PI: 90 watts

3.5.1.2 AC lnput Connections

Power semiconductor type: N-channel FET

J3: 3-pin Screw terminal strip

*Chopping frequency: 20 Khz.

Pin

-

Assignment

"H" Hot (black)

"C"

Common or Neutral

"G" Ground (green)

*Control signals are optically isolated from the motor drive circuit.

3.2

DRIVE PERFORMANCE

(white)

Resolution: Half-step or full-step (3180-Pi)

1/10 microstep (3180-PI1 0)

11125 microstep (3180-P1125)

3.5.2 OUTPUT TO MOTOR

3.5.2.1 Motor Connections

J2: 8-pin twist-lock circular female Amp connection

Step Rate:

0 to 10,000 full-stepsisec. (3180-PI)

0 to 20,000 half-stepsisec. (3180-PI)

0 to 100,000 111 0 microstepsisec (3180-P110)

Oto 1,250,000 11125 microsteps1sec. (3180-PI1 25)

Pin

-

Assignment

-

Pin Assignment

1 M3 5

No connection

2 M 5

6 M 1

3 No connection 7 No

connectioils

4 Ground 8 M4 Speeditorque:

See Section 6 for typical SpeedDorque Curves

NOTE: Motor phase A is MI and M3, and phase B is M4 and M5.

Mates to male connector, AMP part number 206434-1 (AMP pin part

number 66506-8 and AMP clamp part number 206062-1).

Motor Types:

Superior Electric motors are recommended

Frame Sizes:

61 mm to 112mm

No. of Leads: 4

Min. Inductance: 8.0 mH

Max. Inductance: 64 mH

Voltage to Motor:

170-1 90 Volts

Max. motor cable length:

100 feet (30.5 meters)

MOTORS FOR USE WITH 3180-PI

SECO Type Number

3180 CURRENTSETTING (AMPERES)*

M061 -CF408

1

0.5

M061 -LF408

DEXER I10 SIGNALS

I

3.6.1 Parallel 110

J4: 25-pin, "D" Type Connector, female

Pin Assignment

-

1 Vo SIGNAL COMMON

2 07 INPUT

--

3 D5 INPUT

4 03 INPUT

Pin

Assignment

VO SIGNAL COMMON

--

D6 INPUT

-

--

D4 INPUT

--

D2 INPUT

--

-

DO INPUT

NOT USED

--

STROBE 6

STROBE 4

STROBE

2

--

STROBE 0

5 Dl INPUT

--

6 MOTION BUSY

*

--

7 STROBE

7

8 STROBE 5

9 STROBE 3

10 STROBE 1

M091 -FF401

M092-FF402

M093-FF402

MI 11 -FF401

MXl 1 1 -FF401

M1 12-FF401

MHI 12-FJ4201

--

11 OUTPUT2* 24 OUTPUT 1"

12 ALL

WINDINGS

OFF

OUT*

25

PULSE

OUTPUT*^

13 CWiCCW OUT*

in

m.,f+-

'These

outputs

are

open collectors

If

monitored

they

must

be

pulled

up

to

an

external

mltage

source

(maximum

24 Vdc)

through

a

series

resistor

to

limit

the

sink

current

to

a

\F

maximum

of

40

milliamps

'The

strobe

outputs

are

also

open

coliector,

if

they

are

conrlected

directly

to

lhe

indexers

----

inputs

then

pull-up

resistors

are

not

required

t

Signal

line

filtering

has

been

incorporated

to

help

keep

electrical

interference

from

affecting

Indexer

operation

Because

of

this,

it

is

not possibie

to

use

the

Pulse

Output

signai

(pin

25

on

the

25-pin ' D"

connector)

when

operating

in

the

1:125

microstep

mode

The

puise

output

on

this

pin

is

not

affected

when

operatinq

in

the

full-step

half-step

or

1/10

microstep

modes

A

maximum

piiil-up

impedance

of

3 9k

ohriis

should

be

used

vihen

utilizing

the

Puise

Outpu!

t

Note

that

the

Indexer

can

still

operate

in

the

11125

microstep

mode

This

lirnitation

only

affects

connection

to

external

dri'des

via

the

25-pin

connector

*

Use

this

number to set the drlve's

"nominal"

current as described in

Section 3 8

Size

(inches)

immi

Weight

MECHANICAL SPECIFICATIONS

6.291 x 5.67W x 7.69H (Height over connectors, excluding mounting flanges. Helght with flanges is 8.0 inches)

159.71 x 144.OW

x

195.3H

3180-PI: 7(lbs.) 3.2(kg)

For maximum noise

immunity,

it

IS

recommended that a twisted,

shielded cable of a maximum length of 20 feet (6.1 m) be used.

15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3.6.1.1 Parallel Output Characteristics

3.8

CURRENT SETTINGS

The follov~~ng pertain to Output 1 (Pin 24) Output 2 (Pin 11)

Out (Pin 12) CW CCW Out (Pin 13) %L~(PI~ 25) ~:tionX&

(Pin 6) and Strobe 0 through Strobe 7 Outputs

High level output.

124 Vdc max.. open collector

High level leakage current: 250 microamps max.

@

Low level output:

1-0.4 Vdc

t0.7 Vdc

16 mA sink current

@

40 mA sink current

3.6.1.2 Parallel Input characteristics

The following pertain to DO through 07 inputs:

t

High level (inact~ve voltage: t8.5 Vdc min.;

High level current:

1 milliamp maximum leakage

Low level (active) voltage: 0.0 Vdc mln.:

15 Vdc max

t

6.5 Vdc max.

[.ow Level current: 3.5 milliam~ max

3.6.2 Serial

110

35 9-Pin "D" Type Coriiiector female

Pin

1

2

3

4

5

6

7

8

9

Assignment

Vo

RS-232 CHAIN OUT

RS-232 RECEIVE DATA

Vo

Vo

RS-232 ECHO

RS-232 CHAIN IN

t

5 Vdc

t

5 Vdc

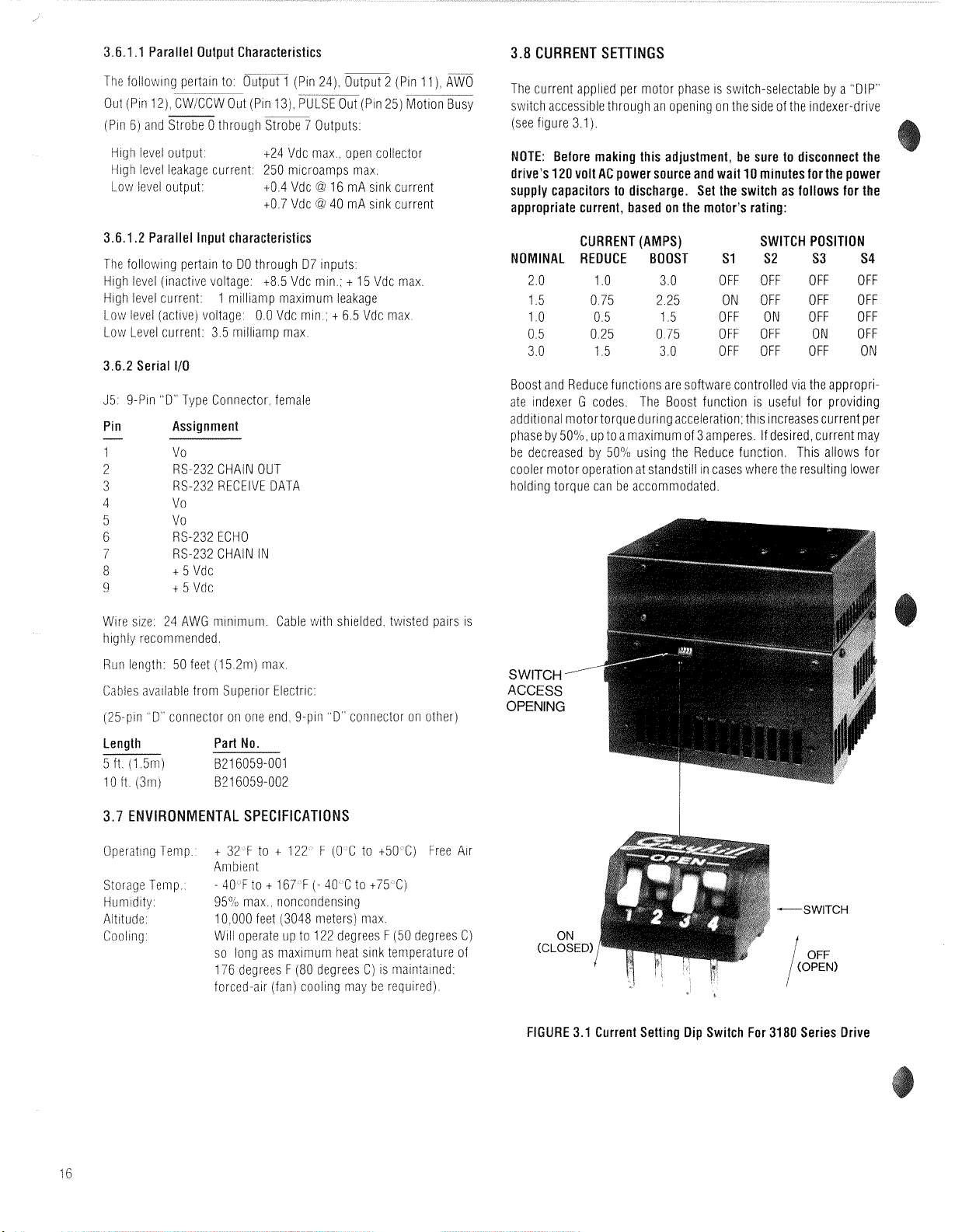

The current applied per motor phase is switch-selectable by a "DIP"

switch accessible through an opening on the s~de of the indexer-drive

(see figure 3.1).

NOTE: Before making this adjustment, be sure to disconnect the

drive's

120

volt AC power source and wait

10

minutes for the power

supply capacitors to discharge. Set the switch as follows for the

appropriate current, based on the motor's rating:

CURRENT (AMPS) SWITCH POSITION

NOMINAL REDUCE BOOST

2.0

1 .O

3.0 OFF OFF OFF OFF

1.5 0.75 2.25 ON OFF

1

.O

0.5 1.5 OFF ON OFF OFF

S1 S2 S3 S4

OFF OFF

0.5 0.25 0.75 OFF OFF ON OFF

3.0 1.5 3.0 OFF OFF OFF ON

Boost and Reduce functions are software controlled

G

ate Indexer

codes The Boost funct~on

via the appropri-

IS

useful for prov~d~ng

additional motortorque during acceleration this increases current per

phase by 50% up to a maximum of 3 amperes If desrred current may

be decreased by 50% using the Reduce functlon Thls allows for

cooler motor operation at standstill in cases where the

resulting

lower

holding torque can be accommodated

Wire size. 24 AWG minimum. Cable with shielded. tw~sted pairs is

higtily recommended.

Ruii length: 50 feet (15.2m) max

Cables available from Superlor Electric:

pin

(25

D

connector on one end 9-pin D connector on other)

Length Part No.

5 ft (1 51n) B216059-001

loft (3x1) 821 6059-002

VIRONMENTAL SPECIFICATIONS

t

Operating Temp

32 F to t 122

Anibient

-

Storage Temp

40 F to t 167 F

Humidity 95% max noncondensing

Altitude

Cooling

10 000 feet (3048 meters) max

Will operate up to 122 degrees

so long as maximuni heat sink temperature of

176 degrees

forced-air (fan) cooling may be required)

F (0 C to t50 C) Free Air

(-

40 C to t75 C)

F (50 degrees C)

F (80 degrees C) is maintained

SWITCH

-

ACCESS

OPENING

FIGURE 3.1 Current Setting Dip Switch For

3180

Series Drive

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This section contains the information necessary to set up,

enter, and edit programs and also to execute programs with the

Micro Series Indexer.

By carefully reading this section through in its entirety, the user

will fully understand the wide range of applications possible

with the Micro Series Indexer.

.1

OVERVIEW AN0 SET-U

EIA (Electronic Industries Association) Standard RS274-D is

the programming guide for numerically controlled machines.

Superior Electric has utilized this standard to form the basis for

the Micro Series Indexer's command structure. It was not

technically desirable to conform to the standard in complete

detail, but it proved beneficial in the program structure to

perform complex and varied operations with a simple format.

Using straightforward programming formats, the Micro Series

lndexer enables the user to program and execute in either

parallel (switch panel) or serial (remote terminal or host

computer) communication modes.

In general, all parameters and commands can be broadly

grouped into four categories, which correspond to these code

groupings:

1.

L

Codes

3.

N,

G,

X and F Codes

2.

H

Codes

4. Immediate Codes

1.

"L Codes" (discussed in Section 4.3) are used to set

parameters for each indexer. These commands are not considered part of an indexer program, that is, they are made prior to

any motion programming and do not have program line

num bers.

It is important to remember that the L codes are used exclu-

sively to set the initial parameters of a particular indexer and

should not be thought of as part of the program option for the

indexer.

Codes" (Section 4.4) are used to set indexer modes,

control manual and program execution and to transmit parameters and indexer status via the serial communications port.

H codes are not part of the programming commands for the

indexer. There are no program line numbers associated with

the

"H"

codes and they are not considered to be part of the

programming function.

and F

Codes" (Section 4.5) are the programming

commands for the indexer. Up to 400 lines of program instruc-

tions can be stored as a unique motion control program.

Each program is in a fixed format, and is composed of a line

number, a "G" code, an

"Xu

code and an

"F"

field.

A line of program has this format:

N[nnn) G[nn] X[snnnnnnnn] F[nnnnnnn]

A space is used to separate the codes.

Not all codes need be programmed for each program line.

The G,

X

and F codes may be programmed in any order.

:

The brackets,

[I,

are used in this manual for clarity

h,

and are not to be used when entering data

or

variables

4. lmmediate Codes (Section 4.2) are executed immediately

upon receipt and are not stored as part of the program. All

commands are highlighted in bold face for easy reference.

4.1.2 General Programming Comments

T PROGRAMMING NOTES**

1.

The indexer contains a 40 character serial buffer

to

accept all data and programming entries.

If

a COMMAND

TERMINATOR (CARRIAGE RETURN and/or LINE FEED) is

not received by the 40th character, the buffer contents art:

dumped and that 40 character strina is lost.

Upon receipt of a CR and/or LF, an XOFF (ASCII Code 19)

character is transmitted to the host; no further data trans-

mission from the host should occur. However, any characters transmitted subsequent to XOFF will be stored in

the buffer until the buffer capacity is reached. if the

capacity is exceeded, the buffer contents are dumped.

The receipt of a COMMAND TERMINATOR character will

cause the commands in the buffer to be executed sequentially. That is, the first command that was entered will be

the first command executed. The COMMAND DELIMITER

for a series of commands is a space. Once all the com-

mands in the buffer have been executed, the indexer will

send an XON (ASCII Code 17) character and will be ready

to receive further data.

2. Whether the indexer is being operated from a switch

panel, remote terminal or host computer, the first task that

faces an operator, after all circuit connections have been

made, is that of setting

"L:

codes", the parameters of each

indexer.

3.

In the following descriptions, it is important to note the

factory default values for each parameter as entry steps

can be eliminated. Upon receipt of a new indexer, the default

ilalues will have been entered for the parameters.

I.

Motor speeds and acceleration will depend on theTRANSLATOR RESOLUTION setting (L70 nnn). Set this parameter

first and then work in ascending numerical order starting

@ith the LO6 parameter.

NOTE: If the L70value is changed, the valuesfor L09, L11,

L12, L14 and the "F" field values must be reentered.

5.

Entry of invalid data for a parameter or program field will

-esult in the previous data being left intact.

3.

If the number of characters entered exceeds the number

~f required characters, the data is truncated to the maxinum field length for the entry.

XoniXoff Protocol:

The Xoff character is transrnitted to the host when a CR or LF is

received The lndexer will process the information it has received and

v!iII transmit an Xon character when it is ready to accept more

information

from the host The lndexer should be polled to determine

when it is ready to accept more information If

L26

3

is selected the

lndexer will transmit an

=

if it is ready to accept more ~nformation

If an Xoff chardcter has been transmitted to the host and the command

received by the lndexer calls for motion or progrdm execution the

lndexer will send an Xon to the host This allo?.!s the host to send any

of the immediate commands such as

*

[Clear) S (Feed Hold) or

#

(Cycle Stop) The host shoiild not send normal commands until

the lndexer is ready to accept more information The lndexer will be

ready to accept more information when motion is stopped program

is stopped and all

previoiis commands have been executed

17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

.1

.3

Programming Chart For lndexer Communications - "On The Fly" Commands

"On The Fly" commands can be sent to the indexer when it is "BUSY" (When motion or program execution is active or when

previously transmitted commands are being processed)."On The Fly" commands allow the indexer to send status or position

information to the host. The sequence for sending "On The Fly" commands is shown below. The host must send an "On The Fly"

command, followed immediately by a carriage return (CR) and/or Line Feed (LF). If the command is not sent in this manner, it will

not be treated as an "On The Fly" command. Instead, it

1

HOST DEVICE SENDS

I

HOST DEVICE WAITS FOR INDEXER TO SEND REQUESTED DATA

The following commands can be sent the lndexer while it is "BUSY":

HI Scrlf Transmit Present Program Line Number

HI 7crlf Transmit Present Absolute Position

HI 8crlf Transmit Mode Status

HI 9crlf Transmit Motion Status

H2Ocrlf Transmit I10 Status

will be placed in the buffer and executed when the indexer is no longer "BUSY".

ON

THE FLY" COMMAND"

I

I

I

Any other commands sent to the lndexer will be executed when the lndexer is no longer "BUSY"

.l,

Program Flow Chart For lndexer Communications

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

.2 IMMEDIATE COMMANDS

The

"X

command is executed immediately upon entry and is

not stored as part of the program.

I

*

CLEAR (ASCII Code 42)

/

(s.

This command IMMEDIATELY halts all motor motion and

program execution and will cause a loss of home position. The

program line pointer

is

reset to the line number specified with

the

L41

parameter.

The RS232 input buffer is also cleared and the indexer transmits an XOFF and then an XON when a CLEAR command is

used.

(ASCII CODE 36)

1

This command will immediately bring current motor motion to

a controlled stop with deceleration determined by the

L11

parameter

(ACCELERATION/DECELERATION).

Motion can be continued without loss of position by using a

NO1

CYCLE START command if the feedhold was applied

during program execution. If a feedhold was applied during

a

H08

(return to electrical home) command, a subsequent

H08

will continue the motion. A feedhold during a

HI0

(return to

mechanical home) command requires a

HI0

to continue the

motion. The line number cannot bealtered during afeedhold as

the remaining move distance needs to be completed. A CLEAR

(*)

can be issued if it is not desired to complete the motion.

TTENTION CHARACTE

If

<[nn] = 00, all indexers will be addressed; otherwise, the

indexer with the value set by the

L21

parameter that matches

the <[nn] value will become the active indexer. The indexer will

respond with

"

=

XON" when the <[nn] value matches the value

set with the

L21

parameter and the indexer is ready for

commands. If the indexer is not ready, the indexer responds

with

":".

If <00 is used, there is no indexer response.

This command halts program execution after the current

program line is completed.

This command is used to stop programs executing with

LO6

[2]

[31

EXECUTION FORMAT settings.

H) BACKSPACE AND DELETE

The CONTROL

H (&H)

command will cause a backspace and

delete one character on the current program line. The

AH

command is executed immediately upon entry and is not stored

as part of the program.

The CONTROL

X

(A

)

command will delete the program line

that has been entered in the line buffer,

This command must be used prior to a COMMAND TERMINA-

TOR.

.3 L Codes: INDEXER PARAMETERS

L codes are used to set parameters for each indexer. These

parameters affect the entire operation of the indexer and cannot

be changed during program execution; therefore, they should

be programmed first. The Lcodes can be categorized into three

areas of interest: motion, execution and serial communication

parameters.

Motion parameters: L08,

L09, L11, L12, L14, L17, L18,

L19, L70

Execution parameters: L06, L07, L41, L44, L45, L48,

L49

Communication parameters: L21, L22, L23, L25, L26

The L codes have been preset at the factory to default values;

these are listed as "Factory Default" settings.

INDEXER PARAMETER FACTORY DEFAULT VALUES

Full Step

1/10 Step 11125 Step

Translator

Translator Translator

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I

LO8

[sl

MECHANICAL HOME DIRECTION

/

This command determines the fashion in which a program will

(H01)

be executed after a CYCLE START

command is issued.

The options are:

Single-line program execution format

=

1

[n]

When a CYCLE STARTcommand is given, the current program

line is executed. The line pointer is then incremented to the next

program line and the cycle stops. The program line pointer may

be moved to another line by using the N [nnn] command.

(H01)

Another CYCLE START

command will repeat the proc-

ess.

Automatic program execution format

=

2

[n]

In this mode, a CYCLE START command will cause the program to execute from the present program line to line number

G30

400 or to a line command that contains a

of

a

GI1

(subroutine call) command. The program will then halt

that is not a part

execution and the program line pointer will be set to the line

L41

number specified with the

parameter. A second CYCLE

START command will cause the program to start execution

from this line number.

Continuous program execution format

=

3

[n]

In this mode, a CYCLE START command will cause the pro-

gram to execute from the present program line to line number

630

400 or to a line command that contains a

that is not part

(subroutine call) command. The program line pointer

is then set to the line number specified with the

and program execution continues until a

mand or a

Example:

mat. [CRLF

NOTES:

format is ignored as line

CYCLE START

*

CLEAR command is issued.

LO6

2 CRLF sets automatic program execution for-

=

carriage return, line feed].

Factory default:

When line

and the line pointer remains at line

LO6

1

00 (MDI

line) is executed, the execution

00

executes one time for each

L41

parameter

#

CYCLE STOP com-

00.

HI0

or

Sets the direction that the motor will turn when a

678

RETURN TO MECHANICAL HOME command is issued.

A

"t"

will cause the motor to turn clockwise.

"-"

will cause the motor to turn counterclockwise.

A

LO$:

s

=

Factory default

Example:

LO8

t

CRLF sets a clockwise mechanical home

t.

direction.

LO9

[nnnnnnnl

JOG SPEED

Sets the desired speed, in pulseslsecond, to be used when the

motor is run in the JOG mode and the HIGH SPEED mode.

Allowable values for this parameter are:

full step (L70

half step (L70

115 step (L70

111 0 step

111 25 step (L70

=

1) 0 to 115,000 pulses/sec.

=

2) 0 to 115,000 pulses/sec.

=

5) 0 to 115,000 pulses/sec.

=

10) 0 to 11 5,000 pulses/sec.

(L70

=

125) 0 to 1,875,000 pulses/sec.

Factory default:

=

full step (L70

half step

115 step

1/10 step

111 25 step (L70

LO9

Example:

PLEASE NOTE:

L09, L11, L12

1200 CRLF sets a jog speed of 1200 pulseslsec.

The range of values that will be accepted by the

and

1)

=

2) 2,000 pulses/sec.

(L70

=

5) 5,000 pulses/sec.

(L70

=

10) 10,000 pulses/sec.

(L70

=

125)

L14

parameters

1,000 pulseslsec.

125,000 pulses/sec.

IS

set by the

L70

TRANS-

LATOR RESOLUTION value.

L70

is set or changed after setting the

If

parameters, the range may not be valid and

may

occur.

ALWAYS SET THE

L70

PARAMETER FIRST.

L09, L11, L12

incorrect motion

or

L14

This command is transparent when using the SSP-500.The

mode is changed when using specific displays. Refer to the

SSP-500 manual for details.

This sets the length of time, in milliseconds, that the output

strobe line will be ACTIVE (low) before the connected data line

is read.

9999

The delay range is 0 milliseconds to

milliseconds.

See Section 5 for an explanation of the STROBE and DATA

functions.

=

Factory default L07: [nnnn]

100 milliseconds

Strobe delay accuracy is i2.5•‹/0 of the selected value.

Example:

LO7 1000 CRLF sets a 1000 millisecond strobe

delay.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

L14

[nnnnnnn]

HOME SPEED

Sets the value, in pulses/sec/sec, for acceleration and deceleration. The same rate applies to both.

Whenever the indexer initiates motion, it is always at the speed

set with the

L12

LOW SPEED parameter. This is the instanta-

neous starting speed of a motor; it will then ramp up to the JOG

or HOME SPEED value orthe FEED RATE using the acceleration

rate set with the

ACCELERATIONIDECELERATION

pa-

L11

rameter.

When the motor is running at JOG SPEED and a feedhold is

asked for, the motor will decelerate from JOG SPEED using the

L11

deceleration rate set with the

parameter and will then stop.

When a move distance and feed rate have been programmed,

the motor will decelerate to a stop at the end of the move using

L11

the deceleration rate set with the

The ranges for

[nnnnnnn]

ACCELERATIONIDECELERATION

=

25 to

9,999,999

parameter.

are:

pulses/sec/sec.

Factory defaults:

full step (L70

half step (L70

115 step (L70

1110 step (L70

111 25 step (L70

=

1)

=

2) 5,000 pulses/sec/sec

=

5)

=

10)

=

125)

Example: L11 5000 CRLFsets an

2,500 pulses/sec/sec

12,500 pulseslseclsec

25,000 pulses/sec/sec

31 2,500 pulses/sec/sec

accelerationldeceleration

rate

of 5000 pulses/second/second.

This command sets the speed, in pulseslsecond, with which

HI0

or

678

the motor will return home when a

H08

or

MECHANICAL HOME, or a

CAL HOME command

is

executed.

676

RETURN TO ELECTRI-

RETURN TO

The ranges for the HOME SPEED are:

full step (L70

half step (L70

115 step (L70

111 0 step (70

=

111 25 step (L70

1)

=

2) 0 to 115,000 pulseslsec.

=

5) 0 to 115,000 pulseslsec.

10) 0 to 11 5,000 pulseslsec.

=

125) 0 to 1,875,000 pulseslsec.

0 to 11 5,000 pulseslsec.

=

Factory default:

=

full step (L70

half step (L70

115 step

111 0 step (L70

11125 step (L70

1)

=

2) 2,000 pulseslsec.

=

5) 5,000 pulseslsec.

(L70

=

10)

=

125)

Exampie: L14 2000 CRLF sets

1,000 pulseslsec.

10,000 pulseslsec.

125,000 pulseslsec

a

home speed of 2000 pulses1

second.

L17

[snnnnnnnnl

OFFSET DIRECTION AND

DISTANCE FROM ELECTRICAL HOME

This command sets the direction and distance, in pulses, that

HI0

or

678

the motor will automatically move after a

RETURN

TO MECHANICAL HOME command has been issued and the

motor has returned to the HOME LIMIT switch.

This command sets the speed at which the motor will run if the

H05

LOW SPEED MODE command is used, or the speed at

which the motor will start before accelerating to the HIGH

SPEED value.

The ranges for LOW SPEED are:

(L70

=

full step

half step

115 step

1/10 step

11125 step

1) 0 to 115,000 pulseslsec.

(L70

=

2) 0 to 115,000 pulseslsec.

(L70

=

5) 0 to 11 5,000 pulseslsec.

(L70

=

10) 0 to 115,000 pulseslsec.

(L70

=

125) 0 to 1,875,000 pulseslsec

Factory defaults:

full step (L70

half step

115 step

1/10 step

(L70

(L70

(L70

11125 step (L70

=

1)

=

2) 500 pulseslsec.

=

5) 1,250 pulseslsec.

=

10) 2,500 pulseslsec.

=

125)

250 pulseslsec.

31,250 pulseslsec.

Example: L12 300 CRLF sets a low speed of 300 pulseslsec.

See Section 5.2.3 on hardware inputs for a description of the

HOME

LIMIT switch function.

[s] =tor

[nnnnnnnnj = 0 to

Factory default

Example:

-

99,999,999

L17:

[s]

L17

-

1000 CRLF sets an offset of 1000 pulses in the

pulses.

=

t:

[nnnnnnn] pulses = 0.

negative direction.

L18

[snnnnnnnnl

CLOCKWISE SOFTWARE

TRAVEL LIMIT

s

=

t

to enable the feature

s

=

-

to disable the feature

[nnnnnnnn]

=

0 to

99,999,999

pulses

When enabled, motion in the clockwise direction that causes

the absolute position to exceed the

L18

value will result in a

feedhold being activated. Only motion in the opposite direction

is permitted.

L18:

Factory default

[s] = -[nnnnnnnn] = 0 pulses

Example: L18 t5000 CRLF will enact a feedhold should the

absolute position exceed t5000 and no further clockwise

motion is permitted.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

s

=

-

to enable the feature

s

=

t

to disable the feature

[nnnnnnnn]

=

0 to 99,999,999 pulses

When enabled, motion in the counterclockwise direction that

L19

causes the absolute position to exceed the

value will result

in a feedhold being activated. Only motion in the opposite

direction is permitted.

:

[s]

=

t

[nnnnnnnn] = 0 pulses

Example:

L19

-7500 CRLF will enact a feedhold should the

absolute position exceed -7500 and no further counterclockwise motion is permitted.

This will assign a unique device number to each indexer in

situations where multiple indexers (up to 99 are permitted)

have been daisy-chained.

4nnl

This number will be used with the

DEVICE ATTENTION

command to activate a particular indexer.

The range for

Factory default

Example:

L21

L21

is 01 to 99

L21:

inn] = 01

05 CRLF sets an identification number of 5.

This command sets the serial port data transfer rate in bits1

second (baud).

The acceptable values for [nnnn] are:

=

[nnnn]

Factory default

300, 1200,2400 and 9600

L22:

[nnnn] = 9600

ost of the recently manufactured terminals and

9600

baud.

If

desktop computers are set at

9600

terminal used is not

b d, it will not be able to commu-

the computer or

nicate with a new indexer. nondefault rate will have to be

set

either with a compatible switch or with a switch panel as

described in Section

I

L23

[nl

CHARACTER LE

5.

This sets the number of data bits in a character sent via serial

communications.

=

7

or

The acceptable values for [n] are: [n]

Factory default

L23:

[n]

=

8

8

This setting determines whether parity applies to serial communication commands and, if parity is selected, whether odd

or even parity is applied. The acceptable values for [nn] are:

=

1

Parity disabled

[n]

=

2Parity enabled, odd parity

[n]

[n]

=

3parity enabled, even parity

L25:

[n]

=

1,

Factory default

OTE:

When parity is disabled, two stop bits will be sent,

Parity disabled.

regardless of the character length. When odd or even parity

is set, one stop bit will be sent if

is set to [nl = 8.

=

7.

Two stop bits will be sent if

L23 CHARACTER LENGTH

L23

is set to [nl

This parameter selects the transmission protocol which the

lndexer will use when responding to input commands. If the

L26

command

n is issued while the lndexer is busy, the

command will be processed when the lndexer is no longer

busy.

Range:

0 to 7

Factory Default

n Transmission Mode Selected

0 Normal Transmission Mode (No "EOT" or

L26:

[n] = 0

XonRoff Protocol Enabled

"="

characters)

1 "EOT" follows each complete data transmission to the host

2

"="

is transmitted when Indexer is ready for more commands

3

"EOT" follows each complete data transmission to the host

and

"="

is transmitted when thelndexer is ready for more in-

formation

n Transmission Mode Selected

4 Normal Transmission Mode (No "EOT" or

XonRoff Protocol Disabled

"="

characters)

5 "EOT" follows each complete data transmission to the host

6

"="

is transmitted when lndexer is ready for more commands

7 "EOT" follows each complete data transmission to the host

"="

and

is transmitted when thelndexer is ready for more in-

formation

Xon character is ASCll code 17

Xoff character is ASCll code

19

EOT character is ASCll code 04

XonRoff Protocol:

The Xoff character is transmitted to the host when a CR or LF

is received. The lndexer will process the information it has

received and will transmit an Xon character when it is ready to

accept more information from the host. The lndexer should be

polled to determine when it is ready to accept more informa-

L26

tion. If

3 is selected, the lndexer will transmit an

"="

if it is

ready to accept more information. If an Xoff character has been

transmitted to the host and the command received by the

lndexer calls for motion or program execution, the lndexer will

send an Xon to the host. This allows the host to send any of the

"*"

immediate commands such as

"f"

(Cycle Stop). The host should not send "normal" com-

(Clear),

"$"

(Feed Hold) or

mands until the lndexer is ready to accept more information.

The lndexer will be ready to accept more information when

is

motion is stopped, program

stopped and all previous com-

mands have been executed.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This parameter determines the line number to which the

-

program line pointer will automatically be set upon powerup,

during invalid program execution, upon encountering a G30

command that is not part of a GI1 subroutine call or after a

clear command

(*)

has been executed.

The acceptable values for [nnn]

=

0

to

400.

Factory default L41: [nnn] = 0

1

200

CRLF sets the autostart line number to

200.

During program execution, a delay of L44 parameter length in

milliseconds will occur after each line completes executing.