Superior WRT3920WS, 900881-00 Installation And Operation Instructions Manual

SAVE THESE INSTRUCTIONS

CUS

P900881-00

FOR FUTURE REFERENCE

INSTALLATION AND

OPERATION INSTRUCTIONS

WRT3920WS

EPA Wood-Burning Fireplace

P/N 900881-00 REV. NC 02/2018

MODELS

WRT3920WS

This installation manual will enable you to obtain a safe, efficient

and dependable installation of your fireplace system. Please read

and understand these instructions before beginning your installation.

Do not alter or modify the fireplace or its components under any circumstances. Any modification or alteration of the fireplace system,

including but not limited to the fireplace, chimney components and

accessories, may void the warranty, listings and approvals of this system

and could result in an unsafe and potentially dangerous installation.

An French manual is available upon request. Order P/N 900881-01.

Ce manuel est disponible en francais, simplement en faire la demande. Numéro

de la pièce 900881-01.

WARNING

• Hot! Do not touch! The glass and

surfaces of this appliance will be hot

during operation and will retain heat

for a while after shutting off the appliance. Severe burns may result.

• Carefully supervise children in the

same room as appliance.

•

If small children are present in the home, it is

recommended that this appliance be fitted with

an adjustable safety gate or barrier screen.

Listed to standards:

ULC-S610 and UL-127

Report # 14-181

EPA Cert. No. 111-17

IHP wood-burning fireplaces are designed for use as a supplemental

heater. They are not intended for continuous use as a primary heat

source.

WARNING

• The fireplace cannot be operated without a

door. Consult your dealer to select the correct

replacement door.

• The fireplace is equipped with a blower, electrical connection must be made prior to fireplace

installation

• Important! To assure proper alignment of glass

doors: Install this fireplace in a square and

plumb condition, using shims as necessary at

sides and/or bottom.

• Install the fireplace only as described in these

instructions.

IMPORTANT! GENERAL SAFETY

PRECAUTIONS. READ AND

UNDERSTAND THESE SAFETY

RULES BEFORE YOUR FIRST FIRE.

WARNING

THE FIREPLACE MUST BE OPERATED WITH THE DOORS FULLY

OPENED OR DOORS FULLY CLOSED.

IF THE DOORS ARE LEFT PARTLY

OPENED, GAS AND FLAME MAY BE

DRAWN OUT OF THE FIREPLACE

OPENING, CREATING RISKS OF

BOTH FIRE AND SMOKE.

WARNING

Use care when selecting window

treatments for windows located

near the fireplace. Avoid using

combustible flowing window

treatments such as curtains on

nearby windows that are of sufficient length to be blown in front

of an open flame when the window

is opened.

Keep any combustible furniture,

materials or decorative pillows

at least 48" (1219 mm) from the

front fireplace opening.

WARNING

Be careful adding wood fuel to

the fire or handling fireplace tools

such as shovels, tongs or pokers.

WARNING

Never modify or alter your fireplace

system in any way. To do so may

create a potential fire hazard and

void the limited warranty

, listings

and approvals of this system.

WARNING

WARNING

NEVER use gasoline, gasolinetype lantern fuel, kerosene,

charcoal lighter fluid, naphtha,

engine oil or similar liquids to

start or “freshen up” a fire in this

fireplace. Keep any flammable

liquids a safe distance from the

fireplace at all times.

WARNING

THIS FIREPLACE HAS NOT BEEN

TESTED WITH AN UNVENTED

GAS LOGS OR A FIREPLACE

INSERT. TO REDUCE RISK OF

FIRE OR INJURY, DO NOT INSTALL

AN UNVENTED GAS LOG SET OR

FIREPLACE INSERT OR OTHER

PRODUCTS NOT SPECIFIED FOR

USE WITH THIS FIREPLACE.

WARNING

Never leave children unattended

when there is a fire burning in the

fireplace.

WARNING

To avoid the risk of damaging

fireplace materials and increasing the risk of fire, do not use the

fireplace to cook or warm food.

WARNING

Never leave your fireplace unattended while it is burning.

IMPORTANT

When burning wood, use SOLID

NATURAL DRY WELL-SEASONED

WOOD ONLY. Hardwoods are recommended (soft woods tend to burn

very quickly).

• DO NOT burn treated wood,

charcoal, coal, trash, cardboard, driftwood, woods dipped

in tar, Christmas tree greens,

pitch, pine tar, creosote, chemical chimney cleaners, flame

colorants, polystyrene packaging, wood products with synthetic binders (i.e. plywood).

Plywood, lumber and other

misc. materials can produce

abnormally high temperatures,

sputtering and smoking fires

and may contain hazardous

chemicals to treat insects and

fungus.

• Burning unapproved fuels can

produce excessive temperatures, beyond the design capabilities of the fireplace and may

produce excess sparks or may

contain hazardous chemicals.

Burning unapproved fuels can

result in a chimney fire, a house

fire, personal injury, death or

loss of property.

The bottom refractory can be

cracked by excessive abuse such

as tossing heavy logs onto the

grate or gouging with fireplace

tools. Exercise caution when

adding wood to your fireplace.

WARNING

Neither the manufacturer nor the

seller warrants “smoke free”

operation nor are we responsible for inadequate system draft

caused by mechanical systems,

general construction conditions,

inadequate chimney heights,

adverse wind conditions and/or

unusual environmental factors

or conditions beyond our control.

WARNING

Always ensure that the air inlet to

the fireplace is free from debris

and any other obstructions that

can block the entrance of air.

LOCATING THE NAME PLATE

The name plate has been attached to a chain located

inside the front opening below the door. To locate it,

simply place your hand into the center of the opening

and slide it to the right. Locate the chain and pull on

it to access the name plate.

2

CONGRATULATIONS!

PARTS REQUIRED

When you purchased your new fireplace, you joined the ranks of thousands of individuals

whose answer to their home heating needs reflects their concern for aesthetics, efficiency

and our environment. We extend our continued support to help you achieve the maximum

benefit and enjoyment available from your new fireplace.

Thank you for selecting a IHP fireplace as the answer to your home supplemental heating needs.

TABLE OF CONTENTS

Safety Rules ......................................Page 2

Locating the Name Plate ...................Page 2

Introduction ......................................Page 3

Parts Required .................................Page 3

Optional Equipment ...........................Page 3

Operating The Fireplace ....................Page 4

Catalytic Combustor ..........................Page 4

Catalytic Bypass Gauge .....................Page 4

Combustion Control .........................Page 4

Starting And Maintaining A Fire ........Page 6

Refueling For Best Performance .......Page 6

Smoking – Causes And

Troubleshooting ..............................Page 6

Important Cautions ...........................Page 6

Smoke Detector ...............................Page 7

Carbon Monoxide Monitor ................Page 7

Dealing With A Chimney Fire .............Page 7

Achieving Clean Burns ......................Page 7

Well Seasoned Fuel ...........................Page 8

Maintaining Your Fireplace ...............Page 8

Catalytic Combustor ..........................Page 8

Refractory Installation .......................Page 11

Disposing of Ashes ...........................Page 11

Door Removal ...................................Page 12

Door Adjustment ...............................Page 12

Glass Care ........................................Page 12

Fireplace Installation ........................Page 13

Optional Cast Facade Installation ......Page 14

Hearth Extension Requirements .......Page 14

Cold Climate Installations ..................Page 14

Framing Dimensions .........................Page 15

Nailing Flanges .................................Page 16

Facing ..............................................Page 16

Fireplace Blower ................................Page 17

Hot Air Ducting Installation ..............Page 17

Central Forced Air Kit ........................Page 18

Outside Air Kit ...................................Page 19

Draft Requirements ...........................Page 20

Chimney System ...............................Page 20

Offset Chimney Installation ...............Page 22

Angled Wall Radiation Shield ............Page 24

Chimney Support Installation ............Page 25

Chimney Chase And

Multiple Terminations......................Page 25

Chimney Adaptor ..............................Page 25

Masonry Application Instructions .....Page 26

Installation Accessories ....................Page 27

Replacement Parts ...........................Page 28

Specifications ....................................Page

Clearance to Combustibles ...............Page 28

Chimney Components Lists ..............Page 29

Safety/Listing Label ...........................Page 31

Warranty ...........................................Page 33

Product Reference Information .........Page 34

THE FIREPLACE

INTRODUCTION

The WRT3920WS wood-burning fireplace is

an energy efficient, heat circulating, closed

combustion fireplace. You will receive a lifetime

of comfort and enjoyment from your fireplace

provided it is installed, maintained and oper

ated properly.

•

Please read these instructions and retain

this manual for future reference.

•

Before beginning the fireplace installation,

consult the local authorities to obtain your

building permit and check your local building

codes. Install the fireplace only as described

in these instructions and using only IHP

components.

• This fireplace has been tested for CAN/ULC

S610-M87 and ANSI/UL 127 under report

number 3151759. It has also been tested

for EPA 40 C.F.R Part 60, section 60.532(b).

Certificate number

•

The WRT3920WS fireplace is NOT intended

111-17

for use with a gas log set. Do not use a

fireplace insert or any other product with

this fireplace unless it is specified by IHP

for use with this appliance. Failure to follow

these instructions will void the certification

and the warranty of the fireplace and may

result in an unsafe installation.

• These appliances are designed to provide

supplemental heat to the immediate area

only. Therefore, it is advisable to have an

alternate heat source when installed in a

dwelling.

• These appliances are NOT approved for

Manufactured Home installations.

CAUTION: BURN UNTREATED WOOD

ONLY. OTHER MATERIALS SUCH AS

WOOD PRESERVATIVES, METAL FOILS,

COAL, PLASTIC, GARBAGE, SULPHUR OR

OIL MAY DAMAGE THE CATALYST.

CAUTION: DO NOT OPERATE WITHOUT

THE CATALYTIC COMBUSTOR IN PLACE.

28

CAUTION: NEVER BURN WITH THE BYPASS OPENED EXCEPT FOR FIRE STARTUP AND WHEN RELOADING THE STOVE.

.

Fireplace Model WRT3920WS

• 6” diameter chimney* - Model ASHT+,

S-2100+, HT6000+, HT6103+ or AC manufactured by Security Chimneys® only.

• 6” diameter chimney ** - Models DuraTech

/ DuraTech DTC manufactured by DuraVent®

only, including:

- Chimney lengths

- Elbows (where necessary)

- Associated components as per these

installation instructions

OR

• 7” diameter chimney* - Model ASHT and

HT6103 manufactured by Security Chimneys® only.

6” and 7” Chimneys Includes:

- Chimney lengths

-

- Elbows (where necessary)

- Associated components as per these

installation instructions

• Decorative Door (included in the fireplace)

• Blower (Included w/Fireplace)

• Outside Air Kit (Included w/Fireplace)

OPTIONAL EQUIPMENT

Order Separately - See Pages 27 through 30

• Additional Equipment (optional)

- AC Chimney Starter Section

AC Chimney

- Chimney Adaptor 7 inch (6AW7*)

(If you choose to use 7 inch ASHT

HT6103

- Forced Air Kit

- Cast Facade Kit

- Blower Speed Control (VRUW)

- Blower Thermodisc Heat Switch

Control (VTU)

*

*

chimney)

u

uNot tested under EPA certification. If

installed, this appliance no longer quali

fies for EPA certification. Check with local

authorities having jurisdiction for require

ments in your area.

Available from Security Chimneys

*

Available from DuraVent

**

*

and

®

*

or

-

-

3

®

®

OPERATING THE FIREPLACE

USE SOLID NATURAL WOOD FUEL

Fuel -

This appliance is designed to burn dry

ONLY.

seasoned natural wood only (see Page 8 for a

list of prohibited fuels). Failure to burn proper

fuels only will void the certification and the

warranty of the appliance. Hardwoods

preferred to softwoods since the energy content

of wood is relative to its density. Hardwoods

will result in a longer burning fire and less

frequent refueling.

A moisture content of 15% to 20% (seasoned)

is recommended. Wood that has been cut and

split and let to dry under a cover for a period

of one year will usually meet that criteria. The

required drying time will vary depending on the

climate. Wood that is packed tight together will

take longer to dry. Seasoned wood is darker in

color than wet wood and will have visible cracks

in the grain on the ends.

Excessively wet wood

are

will be difficult to burn and will result in lower

efficiency, increased creosoting and plugging

of the catalytic combustor.

wood will burn well but will also have higher

emissions and shorter burning time.

Excessively dry

DO NOT OVERFIRE THIS HEATER

Catalytic Combustor

This fireplace is equipped with a catalytic combustor. Unburned by-products of the wood fire

are burned as they pass through the combustor

resulting in less pollution, reduced creosote and

higher efficiency. In order to have the catalyst

working, temperatures of the flue gases entering

the combustor have to be higher than 500° F

(260° C). That is why the unit is equipped with

a CAT bypass damper that allows the draft air

to bypass the catalytic combustor. Opening the

CAT bypass damper control increases the draft

allowing the unit to achieve proper operating

temperatures during a cold start-up. It also

provides more draft to prevent smoke spillage

when the door is opened.

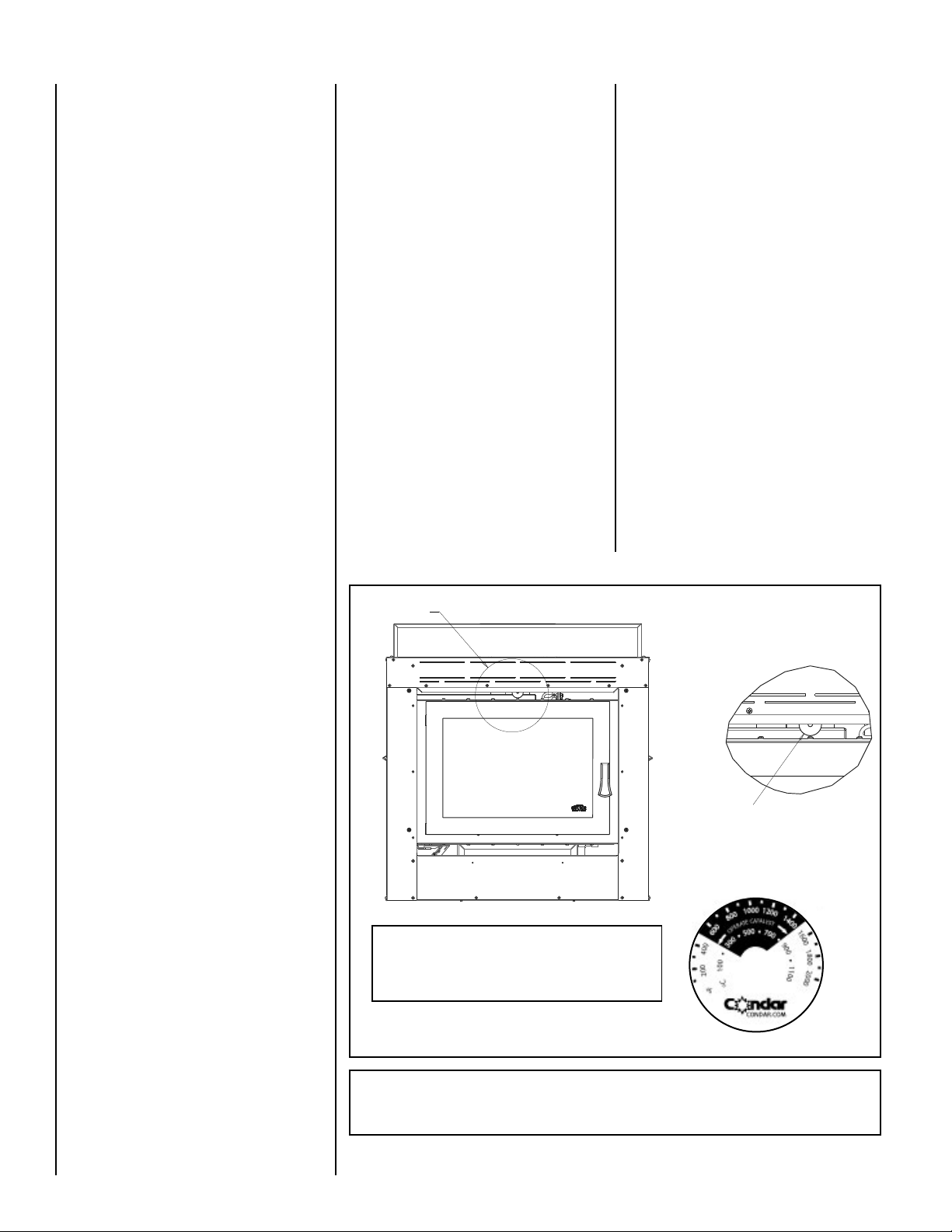

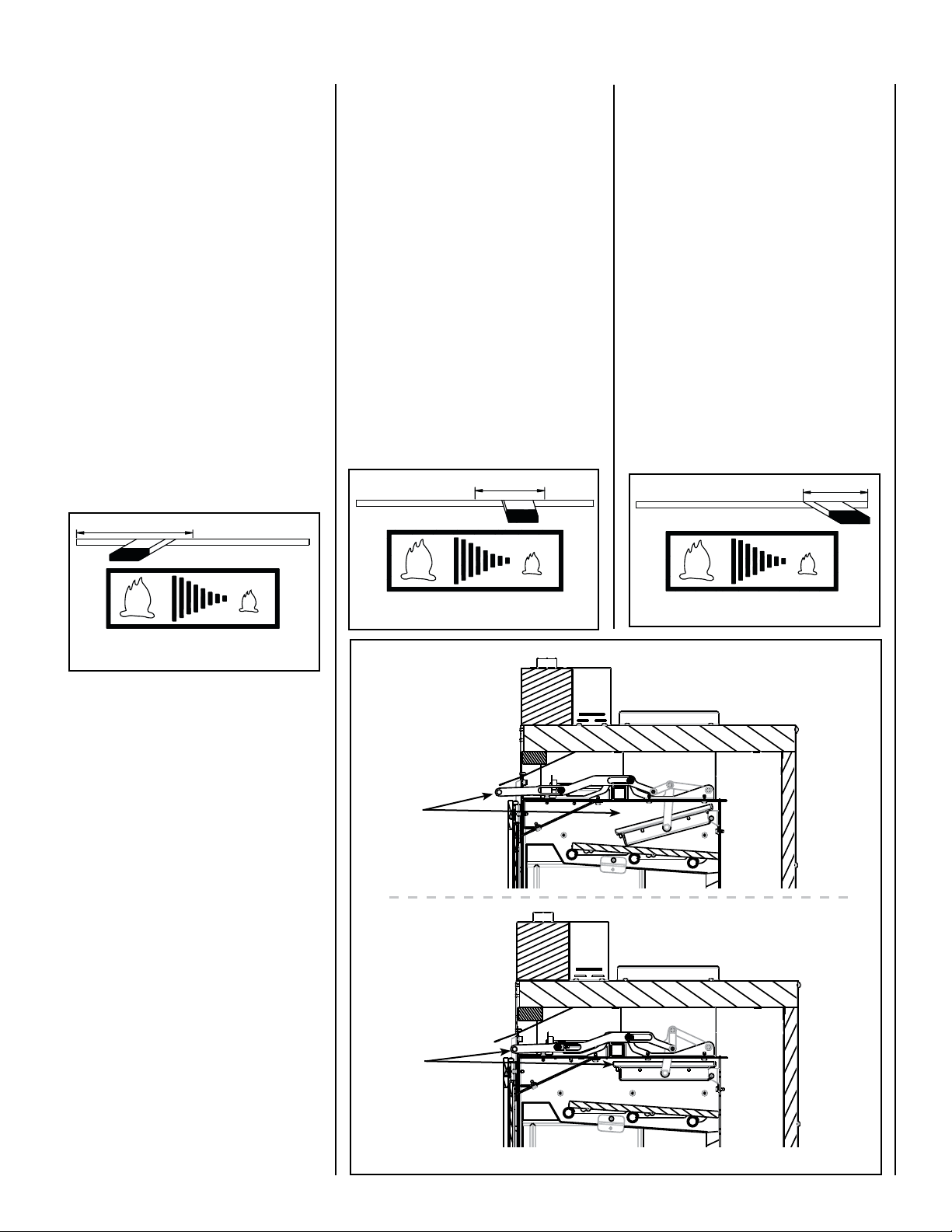

Catalytic CAT Bypass Gauge

To determine when to close the CAT bypass,

the unit is equipped with a gauge (see Figure

1). Once you can see the gauge needle in the

catalytic combustor operating range, you may

push to close the CAT bypass lever, about 15-30

minutes after initial light-off.

When the catalyst light-off conditions are

achieved, the combustor will keep on going

until it runs out of smoke. Note that the catalyst

does not need to be glowing to be working, it

can work very well at temperatures well below

the 538° C (1000° F) level at which it will begin

to glow. The best way to see if the catalyst is

active is to take a look at what is coming out

of the chimney. If the catalytic combustor is

working you will see some white water vapor

coming out, compared to a more brown/gray

smoke when the CAT bypass is opened. Do

not burn any chemical chimney cleaner; it can

make the catalyst inactive.

COMBUSTION CONTROLS

Primary Air Control

There is no flue damper in the fireplace. As is

common with air tight stoves, the combustion

air control sets the flow of air entering the firebox. This allows for a more precise control of

the fire. The combustion air control is located

below the door on the left side. The main source

of air (primary air) entering the firebox can

be diminished by moving the air combustion

control from left to right. The primary air is

fully opened when the air control is completely

moved to the left.

Attempts to achieve heat output rates that

exceed heater design specifications can result

in permanent damage to the heater.

First Fires

The first five or six fires should be small fires

of short duration (about 30 to 60 minutes).

This will help cure the refractory bricks.

the first few fires of this appliance there may

be some odor and smoke due to the curing of

the paint, dust accumulation and burning off of

lubricants used in the manufacturing process

It may set off a smoke alarm located in the same

room. For this reason the room should be well

ventilated for the first few fires.

During

.

See Detail A

This wood heater has a manufacturer-set minimum low

burn rate that must not be altered. It is against federal

regulations to alter this setting or otherwise operate

this wood heater in a manner inconsistent with the

operating instructions in this manual.

Thermometer

Detail A

Figure 1

This manual describes the installation and operation of the IHP model WRT3920WS catalytic equipped

wood heater. This heater meets the 2020 U.S. Environmental Protection Agency’s certified to comply

with 2020 particulate emission standards using crib wood. Under specific test conditions this heater

has been shown to deliver heat at rates ranging from 10,900 to 35,600 Btu/hr.

4

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

The combustion air control should be in the

closed position when the fireplace is not in use.

This will minimize air leakage up the chimney.

The combustion air control and the CAT bypass

damper control must be opened before opening

the door to minimize the possibility of back

draft coming into the room.

Accelerated Combustion

The maximum heat output for the WRT3920WS

fireplace is achieved by burning with the door

closed and the combustion air opened. By this

method, the WRT3920WS fireplace can produce

the maximum BTU of heat per hour. However,

it will be necessary to reload with wood every

one or two hours. This is the least efficient

method of burning the WRT3920WS fireplace.

Use caution when firing with the combustion

air control wide open. Only burn cord wood

in this manner. Small dry pieces of softwood

and construction scraps will burn very intensely

using this method and may damage the firebox.

Medium Combustion

This is the recommended mode of operating

the WRT3920WS fireplace and should be the

one normally used since it will deposit the least

amount of creosote on the glass and in the

chimney. The combustion air control must be

3/4 closed. The precise setting will depend on

many factors, including chimney length and the

moisture content of the wood.

For instance, a long chimney will necessitate

closing the damper more. To obtain the proper

combustion, close the damper completely, then

open it about 1/4” to 1/2” (6.4mm to 13mm).

Two medium size pieces of wood should be

burning on a bed of hot coals. The heat output

will be approximately 25,000 BTU per hour and

the loading time will be about every 3-4 hours.

Softwoods may be burned using this method

but the burn time will be substantially reduced.

Slow Combustion

When the air combustion control is completely

closed, the fireplace is in a slow combustion phase.

If the hearth is hot enough, slow combustion will

not extinguish the fire, but there will be a noticeable change in the flame pattern. The flames will

be slow and may appear dirty if the wood is too

wet (moisture content of 20% and more). Do not

allow the wood to burn without flame, since this

will produce excessive creosote in the unit.

Creosote may accumulate on the glass door.

This method of burning should be used only

after operating the WRT3920WS fireplace with

the air control opened to produce a hot fire for

about an hour or at medium pace for at least

three (3) hours. Slow combustion can be used

at night in order to reduce the heat output and

to prolong the burn. The loading time will be

between 6-8 hours.

Figure 2 - Accelerated Combustion

Figure 3 - Medium Combustion

Open

Closed

Figure 4 - Slow Combustion

Figure 5 - CAT Bypass

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

5

STARTING AND MAINTAINING A FIRE

Step 1. Place several crumpled up balls of

newspaper in the firebox. Place small dry pieces

of kindling on top of the paper, criss-crossing

the kindling so that there are air spaces in

between. The kindling should be placed at the

center of the firebox so as to allow for sufficient

air circulation.

Step 2. Adjust the primary air control into the

OPEN position. Light the newspaper. Leave the

door partially opened to facilitate the start-up.

Step 3. Once kindling fire is well established,

cord wood can be added. You may set the

primary air control to the desired level (see

Primary Air Combustion Control section for

proper operation of the air controls). Close the

door and maintain an accelerated combustion

air set up in order to achieve combustor lightoff conditions.

Step 4. When the fire is burning well, and you

can see the gauge needle in the catalytic combustor operating range, close the CAT bypass

damper control by pushing the control rod in. It

takes about 15–30 minutes with the CAT bypass

opened to reach proper light-off temperatures

for the catalytic combustor.

Step 5. Set the primary control to the desired

burn level. The fireplace will automatically go

to that level after the fire is fully established.

The unit will burn best with 2-3 pieces of cord

wood spaced 1 to 2 inches apart and allowing

air to get under the fuel. Criss-crossing or arranging the fuel so that air can get underneath

will help the fire to get started easily. The unit

should be operated with the air control fully open

long enough to get the cord wood well ignited.

REFUELING FOR BEST PERFORMANCE

To refuel the fireplace at the end of a burn cycle

when only hot embers remain and flames are

gone (not enough heat to maintain catalyst

operating temperatures):

Step 1. Open the CAT Bypass fully (see Figure 5).

Step 2. Completely open the air control level.

See Figure 2.

REFUELING: During the refueling and

rekindling of a cool fire, or a fire that has

burned down to the charcoal phase, operate

the stove at a medium to high firing rate for

about 10 minutes to ensure that the catalyst

reaches approximately 500°F.

6

Step 3. Open the door about 1” and wait 5

seconds until the air flow has stabilized. Then

open the door completely, put the logs in and

close the door.

Step 4. Set the air control to the desired burn

level. Open the CAT bypass damper for 10 minutes before closing it. It will ensure sufficient

temperatures for combustor light-off.

To refuel the

WRT3920WS fireplace when the

unit is still hot (some burning fuel remaining

or a glowing combustor)

A. Open the air control and the CAT bypass

completely.

B. Open the door about 1” and wait 5 seconds

until the air flow has stabilized. Load the fuel,

close the door and CAT bypass (temperatures

within the firebox should be enough to

maintain catalytic operation).

C. Set the air control to the desired burn level.

NOTES:

• For spectacular fire and optimization of the

fireplace efficiency, we recommend that the

wood load be placed as far back as possible.

• It may be necessary to turn off any blower(s)

in operation during the refueling process in

order to minimise smoking in the room. It

is recommended to wait 15 to 30 minutes

before turning the blower back on to ensure

successful rekindling.

SMOKING –

CAUSES AND TROUBLESHOOTING

To reduce the likelihood of smoke coming

into the room when opening the door, set the

combustion air controls to the left (“Accelerated Combustion”) and open the CAT bypass

before opening the door. Your fireplace has

been designed and tested to provide smoke

free operation.

As the fire burns, air goes up the chimney.

This air must be replaced through the outside

air duct. When operating the fireplace, open a

nearby window temporarily to check if there is

adequate replacement air supply. Occasionally,

there may be a small amount of smoking upon

lighting the fire, until the chimney heats up but

this should not last. If the fireplace continues

to smoke it is probably for one of the following reasons:

A. The door is partially opened - When you

open the door, open them completely.

B. Negative pressure in the house

As the fire burns, air goes up the chimney.

This air must be replaced through leakage

into the house or through the outside air duct

(included with fireplace). When operating the

fireplace, open a nearby window temporarily

to check if there is adequate replacement air

supply.

C. Fans operating (e.g.: range hood)

These fans draw air out of the house and

may actually cause a negative pressure in the

house. Turn off all fans and open a nearby

window to determine if this is the cause of

the problem.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

D. Wet wood

Wet or tarred wood will smoulder and smoke

instead of burning properly. Your dealer can

help you determine if you have properly

seasoned wood for burning.

E. Dirty or blocked chimney

Check to make sure the chimney is clear and

clean. If dirty call a certified chimney sweep

or use a properly sized chimney brush to

clean.

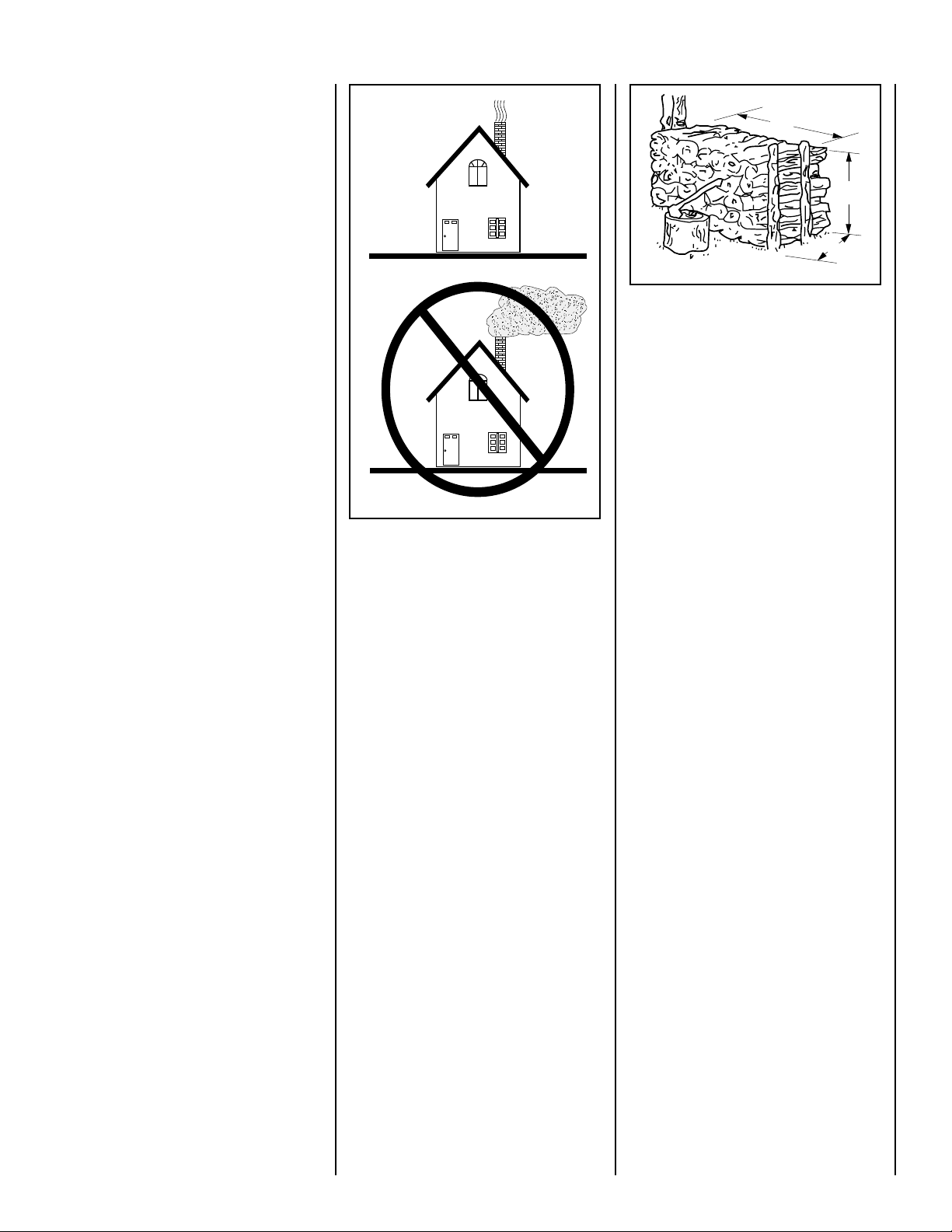

F. Chimney not long enough

The minimum chimney height is twelve

(12) feet (3.7 m) not including the fireplace

height. The chimney must extend at least

three (3) feet (915 mm) above its point

of contact with the roof and at least two

(2) feet (610 mm) higher than any roof or

wall within ten (10) feet (3 m) of it. When

installed with offsets, the minimum chimney

height is fifteen (15) feet (4.6 m). Additional

height will increase draft and will decrease

the tendency to smoke.

G. Poor chimney draft

With no fire, there should be sufficient draft to

exhaust cigarette smoke introduced under the

baffle. Chimneys installed against an outside

wall without protection or a basement installa

tion may generate back draft problems which

will cause start-up problems. To prevent this,

open a nearby window, roll up a piece of paper

and light it. Then, hold it in the upper part of

the firebox to warm up the chimney. Wait until

the draft is sufficient, then start the fire.

H. Blower for forced air kit operating - Make

sure that the blower is at the “off” position

when you open the fireplace door for reloading.

IMPORTANT CAUTIONS

A. Do not block any hot air vents from the

fireplace as this will cause the fireplace

to overheat.

B. Never use gasoline, gasoline-type lantern

fuel, kerosene, charcoal lighter fluid, or

similar liquids to start or ‘freshen up’ a fire

in this fireplace. Keep all such liquids well

away from the fireplace while it is in use.

C. Do not burn coal. The sulphur in coal will

corrode the firebox.

D. Do not burn driftwood which has been in the

ocean or salt water. The salt will corrode

the firebox and chimney.

E. Do not operate the unit with the door partly

open since this may cause smoke to be

drawn into the room.

F. Do not burn wood in the area in front of the

andirons.

G. Do not abuse the unit by burning paper, or

cardboard or construction material such as

pressed wood, plywood or lumber. Wood

protectors, metallic paper, coal, plastic,

waste, sulphur and/or oil will damage the

fireplace.

H. Do not allow the wood to smoulder or burn

without flame, since this will produce

excessive creosote in the unit

increased particulate emissions.

as well as

-

SMOKE DETECTORS RECOMMENDED

OK

Since there are always several potential sources

of fire in any home, we recommend installing

smoke detectors. If possible, install the smoke

detector in a hallway adjacent to the room

(to reduce the possibility of occasional false

activation from the heat produced by these

appliances). If your local code requires a smoke

detector be installed within the same room, you

must follow the requirements of your local code.

Check with your local building department for

requirements in your area.

CARBON MONOXIDE MONITOR RECOMMENDED

Carbon Monoxide Poisoning: Early signs of

carbon monoxide poisoning are similar to the

flu with headaches, dizziness and/or nausea.

If you have these symptoms, obtain fresh air

immediately. Some people are more affected

by carbon monoxide than others, including

pregnant women, people with heart or lung

disease or anemia, those under the influence

of alcohol, and those at high altitudes.

It is against federal regulations to operate

wood heaters in a manner inconsistent with

the operating instructions in the manual.

Dealing With a Chimney Fire

Regular chimney maintenance and inspection

can prevent chimney fires. If you have a chimney

fire, follow these steps:

1. Close the fireplace door and the combustion

air controls.

2. Alert your family of the possible danger.

3. If you require assistance, alert your fire

department.

4. If possible, use a dry chemical fire extinguisher, baking soda or sand to control the

fire. Do not use water as it may cause a

dangerous steam explosion.

5. Check outside to ensure that sparks and hot

embers coming out of the chimney are not

igniting the roof.

6. Do not use the fireplace again until your

chimney and fireplace have been inspected

by a qualified chimney sweep or a Fire

Department Inspector.

ACHIEVING CLEAN BURNS

Check the exhaust after engaging the catalyst

(see Figure 6). Large amounts of smoke indicate

an improper burn setting (either too high, or too

low of a temperature to operate the catalyst).

Adjust and recheck in 5 to 10 minutes.

Figure 6

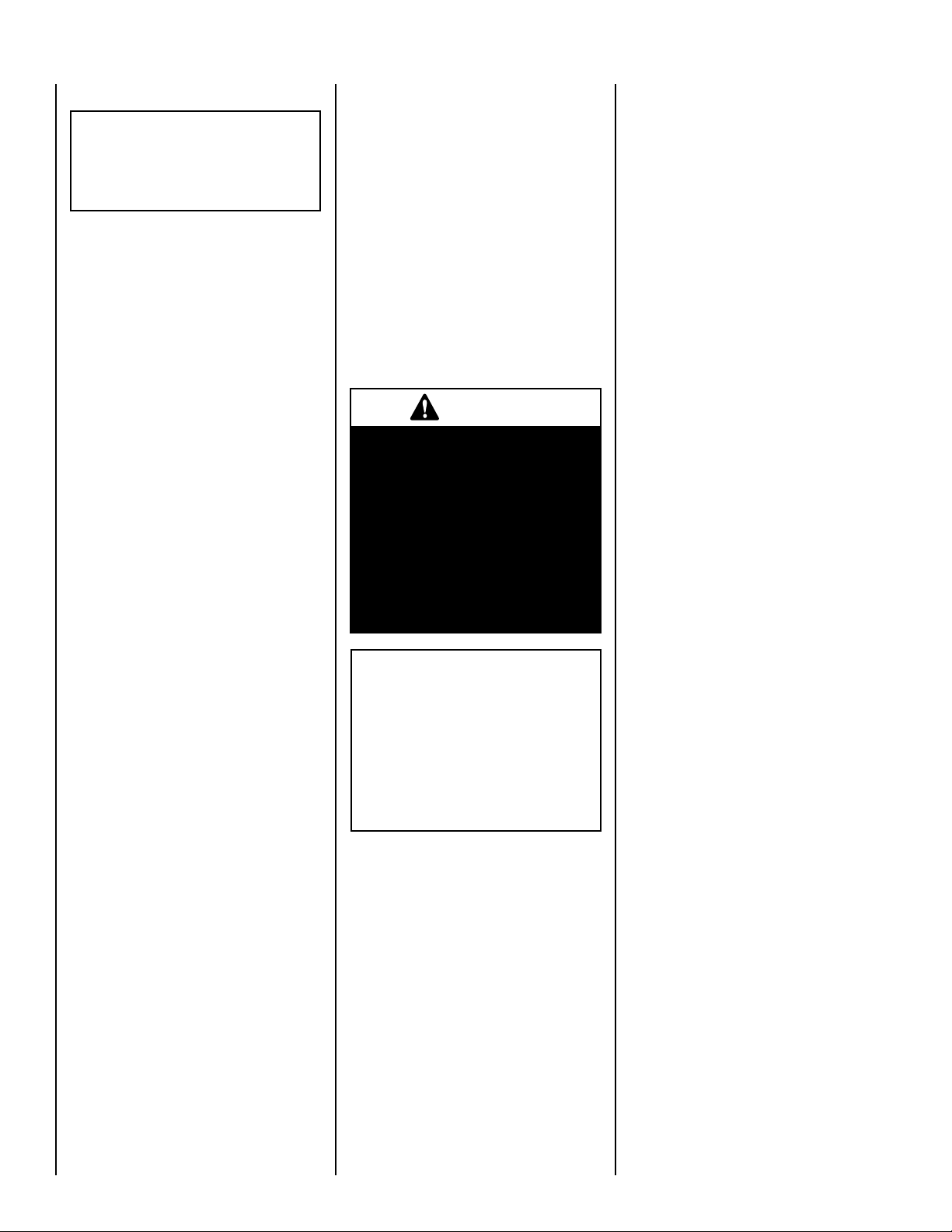

WHAT DOES “WELL-SEASONED” MEAN?

When a tree is cut down, the wood is green,

full of sap and moisture. This moisture content

can exceed 80%, which must be reduced to

less than 20%. Wood properly seasoned is

then capable of generating the heat the stove

was designed to provide.

Green wood does not burn easily. Attempting to

burn green wood often results in a lot of smoke

and very little fire. Time is the most important

factor in seasoning wood. Ideally the moisture

content should be reduced to 11-20%. NOTE:

The use of a firewood moisture meter is rec

ommended to ensure the firewood contains

less than 20% moisture.

Seasoning Guide

Softwoods - 6 months to 18 months

Hardwoods - 12 months to 24 months

Logs that are 5” diameter across or larger should

be split in half, three pieces if over 8 inches, and

four pieces when over a foot across. If a tree

has been dead for 2 - 4 years it still needs to

be cut, split, and seasoned for 6 to 24 months

depending on the wood.

8 Ft.

8'

(2.4M)

Figure 8

Prohibited Fuels

This heater is designed to burn natural wood

only. Higher efficiencies and lower emissions

generally result when burning air dried seasoned

hardwoods, as compared to softwoods or to

green or freshly cut hardwoods. DO NOT BURN:

• Garbage;

• Lawn clippings or yard waste;

• Materials containing rubber, including tires;

• Materials containing plastic;

• Waste petroleum products, paints or paint

thinners, or asphalt products;

• Materials containing asbestos;

• Construction or demolition debris;

• Railroad ties or pressure-treated wood;

• Manure or animal remains;

• Salt water driftwood or other previously salt

water saturated materials;

• Unseasoned wood;

• Christmas tree branches;

• Paper products, colored paper, cardboard,

plywood, or particleboard;

• gasoline;

• naphtha;

-

• engine oil;

• flammable liquids;

• solvents;

• grease; or

• coal

The prohibition against burning these materials

does not prohibit the use of fire starters made

from paper, cardboard, saw dust, wax and

similar substances for the purpose of starting

a fire in an affected wood heater.

Burning these materials may result in release

of toxic fumes or render the heater ineffective

and cause smoke.

materials may overheat the fireplace, causing

damage to the unit, a fire or even possibly ignit

ing a chimney fire if the chimney is creosoted.

Burning unapproved fuel, resulting in excessive

pollutants being emitted, may be prohibited and

subject to a fine or other penalty by the authority

having jurisdiction in your area.

Intense firing with these

Standard

Cord of

Wood

(1.2M)

4 Ft. (1.2M)

4'

4 Ft.

4'

-

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

7

MAINTAINING YOUR FIREPLACE

Have your product inspected at least once

a year by a qualified service technician to

ensure gaskets, air tubes, baffles, and venting are in good repair to ensure proper performance. Have degraded items replaced

by a qualified service technician.

This wood heater needs periodic inspection

and repair for proper operation. Consult the

owner’s manual for further information. It is

against federal regulations to operate this

wood heater in a manner inconsistent with

the operating in this manual.

Creosote - Formation and Need for Removal

When wood is burned slowly, it produces tar

and other organic vapors, which combine

with expelled moisture to form creosote. The

creosote vapors condense in the relatively

cool chimney flue of a slow-burning fire. As

a result, creosote residue accumulates on the

flue lining. When ignited this creosote makes

an extremely hot fire.

The chimney shall be inspected at least twice

a year during the heating season to determine

when a creosote buildup has occurred.

When creosote has accumulated it shall be

removed to reduce the risk of a chimney fire.

When the creosote accumulation is large, a

creosote fire in the chimney can damage the

chimney and overheat the surrounding wood

framing. Creosote formation in a chimney can

be minimized by making sure there is always

visible flame burning, avoid smouldering fires

and by proper refuelling techniques.

Chimney Maintenance

Regular chimney inspection and maintenance

combined with proper operation will prevent

chimney fires. Keep your chimney clean. Do

not allow more than 1/16” (1.6 mm) creosote

build up in your chimney.

The amount of creosote will depend on variables

such as frequency of use and type of fire. We

recommend that you:

A. Initially inspect the chimney system weekly.

From this, you will learn how often it will be

necessary to clean your chimney.

B. Have your chimney cleaned by a qualified

chimney sweep. If you wish to clean it

yourself, we recommend using a stiff plastic

or non-metallic brush. If a metal brush is

used, its size should be slightly smaller than

the flue to avoid damaging the chimney. Do

not use a brush that will scratch the stainless

steel interior of the chimney.

C. Do not expect chemical cleaners to keep

your chimney clean. The rain cap can be

removed for inspection and/or cleaning of

the chimney.

Before performing chimney sweep, open

the CAT bypass and remove the combustor.

Remove dust accumulation after chimney

sweep and put the combustor back in place.

CATALYTIC COMBUSTOR

This fireplace is designed with a catalytic combustor which will reduce pollution emissions

and creosote build up while improving thermal

efficiency. In order to optimize and maintain

the combustor performance, it is important to

visually check the combustor at least 3 times

during the heating season to determine if physical degradation has occurred.

Catalytic combustors require little maintenance.

Cleaning the combustor once a year, preferably

when your flue system is serviced, is sufficient

for most users.

WARNING

To prevent damage to your combustor, do not:

• Drop the combustor (which is

fragile compared to the rest of

the unit – so handle with care)

• Run water or compressed air

through the combustor

• Try to clean the combustor with

any sharp tool

The combustor supplied with this heater is

a Healthy Hearth Combustor. Consult the

catalytic combustor warranty also supplied

with this wood heater. Warranty claims

should be addressed to:

The packaging of the combustor must be

robust enough to protect against any ship

ping damage that may occur.

Healthy Hearth LLC

31375 Riverside Drive #214

Lake Elsinore, CA 92530

Phone # 951-264-8725

-

Catalyst Monitoring

It is important to periodically monitor the

operation of the catalytic combustor to ensure

that it is functioning properly and to determine

when it needs to be replaced. A non-functioning

combustor will result in a loss of heating efficiency, and an increase in creosote and emissions. Following is a list of items that should

be checked on a periodic basis:

• Combustors should be visually inspected at

least three times during the heating season

to determine if physical degradation has

occurred. Actual removal of the combustor

is not recommended unless more detailed

inspection is warranted because of decreased

performance.

If any of these conditions exists, refer to Cata-

lyst Troubleshooting section of this owner’s

manual.

• This catalytic heater is equipped with a temperature probe to monitor catalyst operation.

Properly functioning combustors typically

maintain temperatures in excess of 500°F,

and often reach temperatures in excess of

1,000°F. If catalyst temperatures are not in

excess of 500°F, refer to Catalyst Troubleshooting section of this owner’s manual.

• You can get an indication of whether the catalyst is working by comparing the amount of

smoke leaving the chimney when the smoke

is going through the combustor and catalyst

light-off has been achieved, to the amount of

smoke leaving the chimney when the smoke

is not routed through the combustor (CAT

bypass mode).

8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

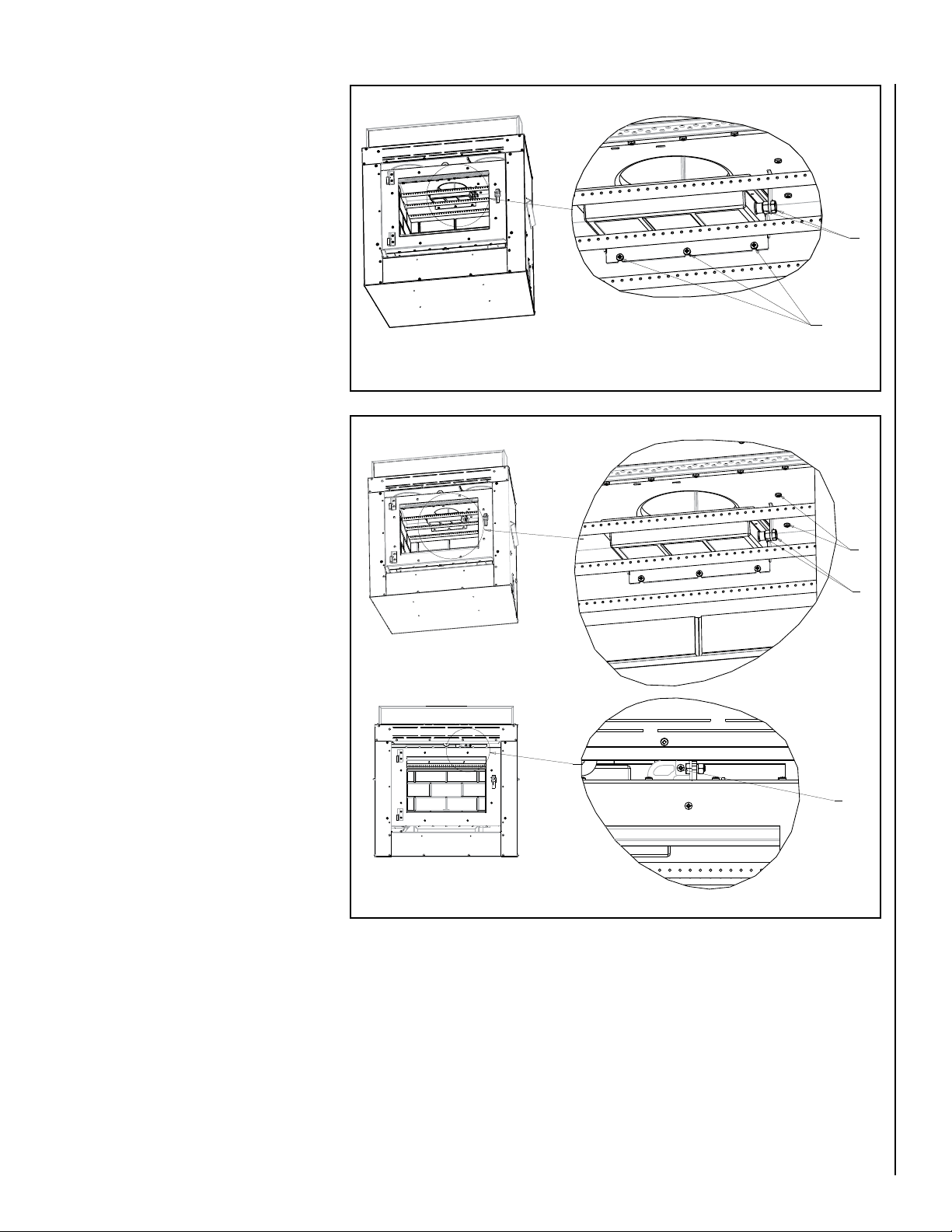

Cleaning Procedure (see Figure 9A):

Tools required: (2) 9/16” wrenches, #2 square

drive bit/driver

With catalyst bypass in closed position, remove

(2) baffle boards from firebox.

1. Using (2) 9/16” wrenches, loosen and

remove the bolt and nut that connects the

linkage arm to the catalyst bypass box

2. Loosen (3) square drive screws mounting

bypass assembly hinge bracket to back of

firebox.

3. In an upward and forward pulling motion,

remove assembly from mount and drop

between the front and middle burn tube.

4. Installation is reverse of disassembly.

NOTE: Ensure bypass assembly is sealed to

ceiling of firebox upon reinstallation. Adjust

ment can be made by loosening (3) mounting

screws and sliding the hinge bracket up or down

to create better seal and then retightening.

Catalyst Bypass linkage replacement

(see Figure 9B):

Tools required: (2) 9/16” wrenches, #2 square

drive bit/driver

With catalyst bypass in closed position, remove

(2) baffle boards from firebox. Place catalyst

bypass in open position.

1

2

Figure 9A - Cleaning Procedure

-

2

1

1. Using (2) 9/16” wrenches, loosen and remove

the bolt and nut that connects the linkage

arm to the catalyst bypass box

2. On ceiling of firebox, adjacent to linkage arm,

locate and remove (2) square drive screws.

3. Outside of unit, just left of bypass engage-

ment lever, remove (1) square drive screw.

Linkage assembly is now free to remove from

above the firebox. Lift linkage assembly up,

while turning clockwise until linkage arm is

removed from slot in firebox. Assembly can

now be removed while on its side.

Installation is reverse of disassembly.

3

Figure 9B - Catalyst Bypass Linkage Replacement

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

9

CATALYTIC COMBUSTOR TROUBLESHOOTING GUIDE

Problem Condition Solution

Ash Build-up on Combustor Surface Normal Ash, a fluffy light gray powder, and soot, accumulate on the com-

bustor surfaces in normal use. Ashes accumulate as a result of the

smoke being burned within the combustor and carried out of the

firebox by the chimney draft. Soot is the result of previous creosote

deposits having been burned off or foreign materials being burned

in the firebox. This is normal and will be eliminated during the next

burn.

Combustor Clogging Creosote Combustor should be cleaned (see Page 11). Do not use air pres-

sure or sharp objects to clean combustor.

Broken Combustor Crack or Break The combustor is manufactured from a ceramic material and there-

fore can crack or break. However, the combustor will still function if

cracked. If combustor is broken into pieces and dis-lodged from the

housing, it will need to be replaced.

Combustor Malfunction Not Working The combustor should last a minimum of 10,000 hours of opera-

tion. The combustor will lose catalytic capability over time. When

you see continuous smoke coming from the chimney, the combustor should be cleaned. If the smoking persists, the combustor

should be replaced.

Combustor Problem Thermal Erosion This combustor does NOT experience thermal erosion. “Not ap-

plicable.” Applies to honeycomb combustors only.

Combustor Problem Thermal Cracking This combustor does NOT experience thermal cracking. “Not ap-

plicable.” Applies to honeycomb combustors only.

Combustor Problem Combustor Peeling This combustor does NOT experience combustor peeling. “Not

applicable.” Applies to honeycomb combustors only.

Reduced Combustor Performance Combustor Clogging or Fatigue Signs of combustor fatigue include reduced heat output and slug-

gish performance. Inspect and clean combustor. Replacement

may be required. Monitor performance and smoke coming from

chimney.

Combustor not glowing Late stage of burn Combustor does not need to be glowing to be working. Check

smoke exiting chimney to help determine if combustor is working

properly.

Appliance burning too hot or fast Doors are not properly closed. Close doors securely. Check door gasket.

Excessive draft Adjust primary air control to lower setting.

Back-puffing or sudden internal ignitions Operating technique Open bypass and primary air control before opening to reload and

keep it open a few minutes after reloading.

Burn rate too low Open air damper to allow for hotter burn.

Chimney down draft In high wind areas, a specially designed wind cap may be neces-

sary.

Combustor or louvered housing plugged Clean combustor / louvered housing of accumulated fly ash.

Appliance Smokes Operating technique Open bypass and air damper prior to reloading appliance.

Blocked Chimney Examine chimney and vent pipe for blockage and creosote accumu-

lations. Check spark arrestor screen on your cap, if you have one.

Blocked outside air duct Check the outside air inlet for blockage caused by snow, debris, or

insects.

10

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

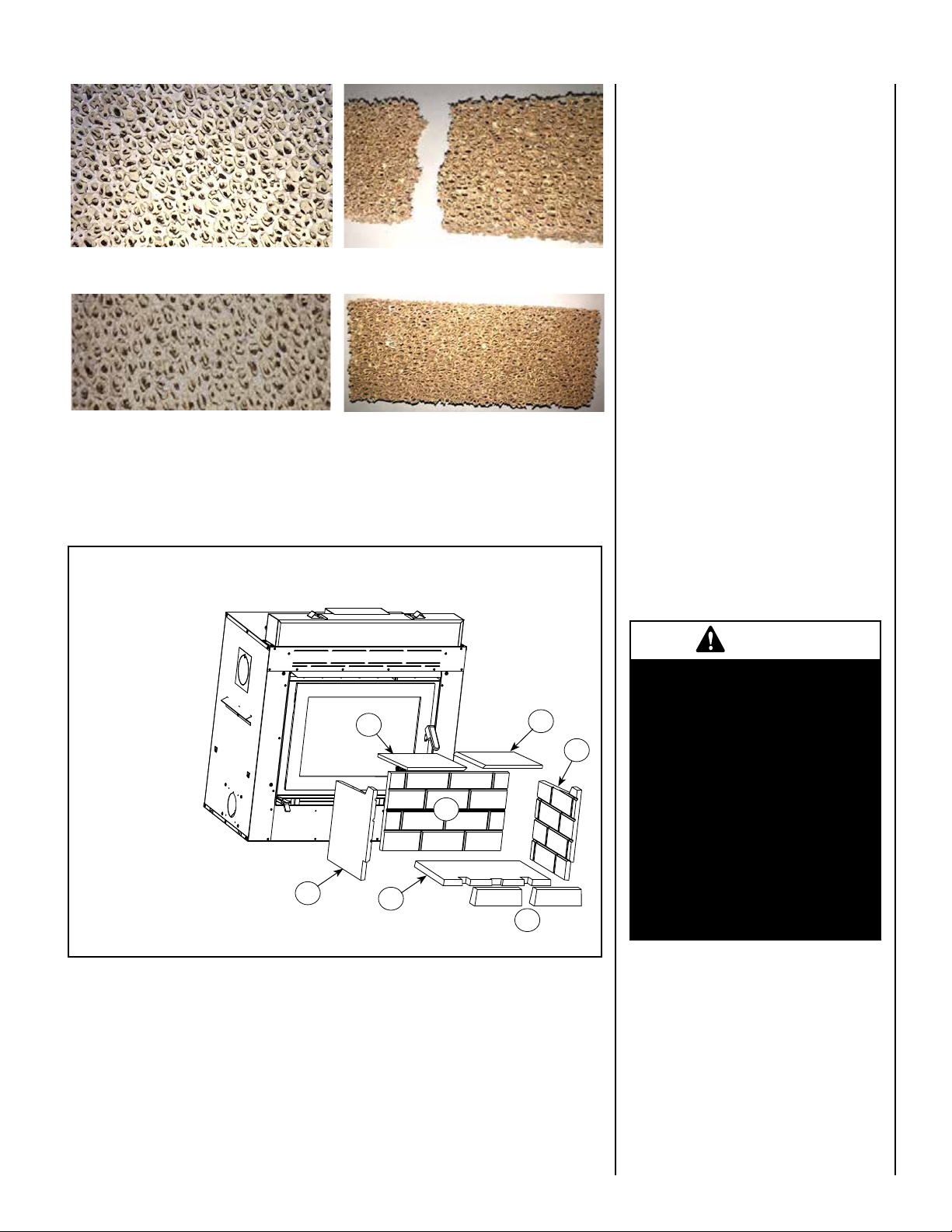

Healthy Combustor - Unused

Combustor Problem - Broken Combustor

The intense heat of the fire will normally cause

hairline cracks in the refractory. These cracks

can be minimized by proper curing as described

in “First Fires”. They will not normally diminish the effectiveness of the refractory. If large

cracks develop, then the refractory should be

replaced. To replace the refractory bricks, follow

these steps (see Figure 10):

1. Remove the bottom refractory

2. Remove the front refractories

3. Remove the left side refractory

4. Remove the right side refractory

5. Remove the back refractory

6. Remove the front ceramic baffle

7. Remove the rear ceramic baffle

To install the new refractories, follow the above

steps in reverse.

DISPOSING OF ASHES

Combustor Problem - Ash, a fluffy light grey powder,

and soot, accumulate on the combustor surfaces in

normal use. In extreme situations combustor can

become clogged and should be cleaned.

REFRACTORY REPLACEMENT

1. Bottom Refractory

2. Front Refractories

3. Left Side Refractory

4. Right Side Refractory

5. Back Refractory

6. Left Ceramic Baffle

7. Right Ceramic Baffle

3

Figure 10

Combustor Problem - Cracked Combustor

6

7

5

1

2

Whenever ashes get 3 to 4 inches deep in your

firebox, and when the fire has burned down and

cooled, remove excess ashes. Leave an ash bed

approximately 1 inch deep on the firebox bottom

to help maintain a hot charcoal bed.

Remove ashes only when the fire is out and

the ashes are cold (24 to 48 hours after the

fire is out).

Do not leave the ashes in the house as they give

off carbon monoxide and other toxic gases.

WARNING

Disposal of Ashes: Ashes should

be placed in a steel container

with a tight fitting lid and moved

outdoors immediately. The

4

closed container of ashes should

be placed on a non-combustible

floor or on the ground well away

from all combustible materials,

pending final disposal. If the

ashes are disposed of by burial

in soil or otherwise locally dispersed, they should be retained

in the closed container until all

cinders have thoroughly cooled.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

11

Loading...

Loading...