Superior VRE3236ZENWS, VRE3236ZENWH, VRE3236ZEPWS, VRE3236ZEPWH, VRE3242ZENWH Installation And Operation Instructions Manual

...Page 1

P900990-00

PFS

USC

Installation and Operation Instructions

OUTDOOR DECORATIVE GAS FIREPLACE

P/N 900990-00 REV. C 06/2019

Ce manuel est disponible en francais,

simplement en faire la demande. Numéro

de la pièce 900990-03.

Report No. F14-020

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

WHEN USED AS AN OUTDOOR APPLIANCE

CARBON MONOXIDE WARNING

DANGER

• This appliance can produce

carbon monoxide which has

no odor.

• Using it in an enclosed space

can kill you.

• Never use this appliance in

an enclosed space such as a

camper, tent, car or home.

Models

VRE3236ZENWS

®

VRE3236ZENWH

VRE3236ZEPWS

VRE3236ZEPWH

VRE3242ZENWS

VRE3242ZENWH

VRE3242ZEPWS

VRE3242ZEPWH

Installateur : Laissez cette notice avec l’appareil.

Consommateur : Conservez cette notice pour consultation ultérieure.

WARNING: For Outdoor Use Only.

DANGER

IF YOU SMELL GAS:

1. Shut off gas to appliance.

2. Extinguish any open flame.

3. If odor continues, keep away from the appliance and

immediately call your gas supplier or fire department.

WARNING: Do not store gasoline or other flammable vapors and liquids in the vicinity of this or any other appli-

ance. An LP-cylinder not connected for use shall not be stored in the vicinity of this or any other appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage.

Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could

result in serious injury, death, or property damage.

AVERTISSEMENT:

RISQUED’INDENDIE OU D’EXPLOSION

Le non-respect Des avertissements de sécurité pourrait

d’entraîner des blessures graves, la mort ou des dommages matériels.

- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the

fire department.

- Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

- Ne pas entreposer ni utilizer d’essence ni d’autres vapeurs

ou liquides inflammables dans le voisinage de cet appareil

ou de tout autre appareil.

- QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucan interrupteur. Ne pas vous servir des

téléphones se trouvant dans le bâtiment où vous trouvez.

• Sortez immédiatement de bâtiment.

• Appelez immédiatement votre fournisseur de gaz depuis

un voisin. Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de gaz, appelez

le service des incindies.

- L’installation et l’entretien doivent être assurés par un

installateur ou un service d’entretien qualifié ou par le

fournisseur de gaz.

1

Page 2

Thank you for your purchase. We appreciate your business!

Please carefully read and follow all instructions in this manual. Pay special attention to

all warnings and safety information.

Following these safety, care, and operation instructions will help ensure many years of

dependable and enjoyable service from your fireplace.

Please read and understand these instructions before installing or operating.

GENERAL INFORMATION

These appliances are designed to operate

on natural or propane gas only. An electronic

intermittent pilot ignition system provides safe,

efficient operation. A battery pack is required

to operate these units (4 "AA" batteries).

TABLE OF CONTENTS

Packaging .........................................Page 2

Introduction ......................................Page 2

General Information ..........................Page 2

Massachusetts Requirements ...........Page 3

Location ............................................Page 4

Pre-Installation Notes .......................Page 4

Assembly Steps ................................Page 4

Waterproofing the Fireplace ..............Page 4

Appliance Clearances ........................Page 5

Clearance Specifications ...................Page 6

Fireplace Installation .........................Page 7

Routing Gas Line ..............................Page 7

Fireplace Specifications .....................Page 8

Framing Specifications ......................Page 9

Field Wiring .......................................Page 10

Connecting Gas Line ........................Page 10

Installing The Logs ............................Page 11

Burner Air Shutter Adjustments ........Page 14

Flame Appearance and Sooting .........Page 14

Checking Appliance Operation ..........Page 15

Firebox Finishes ................................Page 15

Gas Conversion Kits ..........................Page 16

Operation/Care of Your Appliance .....Page 17

Variable Flame Adjustment ................Page 18

Maintenance ......................................Page 18

Gas Control Module System .............Page 19

Replacement Parts ............................Page 19

Technical Service ..............................Page 19

Accessory Components ....................Page 20

Lighting Instructions – Electronic .....Page 21

Troubleshooting ................................Page 22

Maintenance Schedule ......................Page 24

Wiring Diagram .................................Page 24

Replacement Parts List .....................Page 25

Warranty ...........................................Page 29

Please read and understand these

instructions before beginning your

installation.

2

PACKAGING

The assembled outdoor gas fireplace is packaged with the following:

1 - the logs are packaged in a carton located

within the firebox.

2 - one envelope containing the literature pack-

age which consists of the Care and Operation

manual and Installation Instructions.

3 - two (2) bags of volcanic stone, envelope is

located in the firebox area.

4 - battery holder (see Field Wiring Page 10).

INTRODUCTION

The Fireplace models covered in this manual are

ventless outdoor gas fireplace heaters designed

for exterior application. Ventless appliances

operate with the combustion chamber completely open to the outside atmosphere. All air

for combustion is brought in through the face

opening and exhaust gases are vented through

the same face opening. These appliances must

be installed outdoors.

The VRE3200 Series Outdoor Gas Fireplace

is designed for outdoor use. It may also be

installed in screened porches and lanais that

meet these minimum requirements:

Minimum porch area - 96 square feet

Minimum ceiling height - 7 feet 8 inches

A minimum of two (2) walls can be screened

but must be open to outside ventilation.

Minimum screen area - 64 square feet

Minimum screen top height - 6 feet 8 inches

Refer to Outdoor Space definition below and

Clearance Specifications on Page 6.

AN OUTDOOR SPACE IS DEFINED AS FOLLOWS PER ANSI Z21.97:

Outdoor spaces - An appliance is considered

to be outdoors if installed with shelter no more

inclusive than:

(a) With walls on all sides, but with no over-

head cover;

(b) Within a partial enclosure which includes an

overhead cover and no more than two side

walls. These side walls may be parallel, as in a

breezeway, or at right angles to each other; or

(c) Within a partial enclosure which includes an

overhead cover and three sidewalls, as long

as 30% or more of the horizontal periphery

of the enclosure is permanently open.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

These appliances comply with National Safety

Standards and are tested by PFS Corporation

(Report No. F14-020) and listed by ANSI Z21.97

in USA and to CSA 2.41 in Canada, as outdoor

gas fireplaces.

The Installation must conform to local codes or,

in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the

Natural Gas and Propane Installation Code,

CAN/CGA B149.1; or Propane Storage and

Handling Code, B149.2, as applicable.

The appliance, when installed, must be electrically grounded in accordance with local codes

or, in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or

the Canadian Electrical Code, CSA C22.1.

DO NOT ATTEMPT TO ALTER OR MODIFY

THE CONSTRUCTION OF THE APPLIANCE OR

ITS COMPONENTS. ANY MODIFICATION OR

ALTERATION MAY VOID THE WARRANTY,

CERTIFICATION AND LISTINGS OF THIS UNIT.

Solid fuels shall not be burned in this appliance.

Any safety guard or screen removed for servicing the appliance must be replaced prior to

operating the appliance.

WARNING

These appliances are not designed

or intended to be used for cooking.

Do not barbecue, heat food, or roast

marshmallows in this appliance. Doing

so could damage the appliance and

cause injury.

WARNING

These fireplaces are gas fireplaces.

Do not burn wood or other material in

these appliances.

Page 3

This appliance is only for use

with the type of gas indicated on

the rating plate. This appliance

is not convertible for use with

other gases, unless a certified

kit is used.

WARNING

DO NOT store or use gasoline or

other flammable vapors or liquids

in the vicinity of this or any other

appliance.

WARNING

Improper installation, adjustment,

alteration, service or maintenance

can cause injury or property damage. Read the installation, operating and maintenance instructions

thoroughly before installing or

servicing this equipment.

WARNING

An LP-cylinder not connected for

use shall not be stored in the vicinity of this or any other appliance.

NOTE: Installation and repair should be

performed by a qualified service person. The

appliance should be inspected annually by

a qualified professional service technician.

More frequent inspections and cleanings may

be required due to yard care, insects, etc. It

is imperative that the control compartment

and burners of the appliance be kept clean.

Provide adequate clearances around air openings and adequate accessibility clearance for

service and proper operation. Never obstruct

the front openings of the appliance.

Due to high temperatures the appliance should

be located out of traffic and away from furniture

and draperies. Locate furniture and window

coverings accordingly.

All Models -

All models have a manually modulated gas valve.

Input is shown in Table 1:

BTU Input (BTU/Hr)

Model No. Input Rate (BTU/Hr)

Natural Gas

VRE3236ZEN 30,000 to 45,000

VRE3242ZEN 30,000 to 45,000

Propane Gas (LP)

VRE3236ZEP 32,000 to 41,000

VRE3242ZEP 32,000 to 41,000

Table 1

Gas Pressure - All Models

Tables 2 and 3 show the appliances' inlet and

manifold gas pressure.

Inlet Gas Supply Pressure

(all models)

Fuel # Minimum Maximum

Natural Gas

Propane

5.0" WC

(1.24 kPa)

11.0" WC

(2.74 kPa)

10.5" WC

(2.61 kPa)

13.0" WC

(3.23 kPa)

Table 2

Manifold Gas Supply Pressure

(all models)

Fuel # High

Natural Gas 3.5" WC (0.87 kPa)

Propane 10.0" WC (2.49 kPa)

Table 3

Test gauge connections are provided on the front

of the gas control valve identified IN for the inlet

and OUT for the manifold side. A 1/8" NPT Test

gauge connection is provided at the inlet and

outlet side of the electronic gas control valve.

The appliance and its appliance main gas

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas

supply piping system by closing its equipment

shutoff valve during any pressure testing of

the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5 kPa).

Orifice Sizes - Sea Level To High Altitude

(All Models)

These appliances are tested and approved

for installation at elevations of 0-4500 feet

(0-1372 meters) above sea level, using the

standard burner orifice (See Table 4). For

elevations above 4500 feet, contact your gas

supplier or qualified service technician. Install

the appliance according to the regulations of

the local authorities having jurisdiction and, in

the USA, the National Fuel Gas Code NFPA 54 /

ANSI Z223.1 - latest edition or , in Canada, the

CAN/CGA-B149.1 and .2 codes - latest edition.

Burner Orifice Sizes

Elevation 0-4500 feet ( 0-1372 meters)

Model

VRE3236 3.25mm (.128") #49 (.073")

VRE3242 3.25mm (.128") #49 (.073")

Nat.Gas

drill size (inches)

Propane

drill size (inches)

Table 4

WARNING

PROPANE TANKS ARE AT PRESSURES

THAT WILL CAUSE DAMAGE TO VALVE

COMPONENTS. VERIFY THAT THE

TANKS HAVE STEP DOWN REGULATORS TO REDUCE THE PRESSURE TO

SAFE LEVELS.

MASSACHUSETTS REQUIREMENTS

These appliances are approved for installation in the US state of Massachusetts if

the following additional requirements are

met:

• Un-vented Room Heaters shall be installed in accordance with 527 CMR 30.

• Installation and repair must be done by

a plumber or gas fitter licensed in the

Commonwealth of Massachusetts.

• The flexible gas line connector used

shall not exceed 36 inches (92 centimeters) in length.

• The individual manual shut-off must be a

T-handle type valve.

• Unvented appliances may NOT be installed in bedrooms or bathrooms.

• A working smoke detector must be installed in the area where vent-free appliances are installed.

Seller of unvented propane or natural gasfired supplemental room heaters shall provide to each purchaser a copy of 527 CMR

30 upon sale of the unit.

3

Page 4

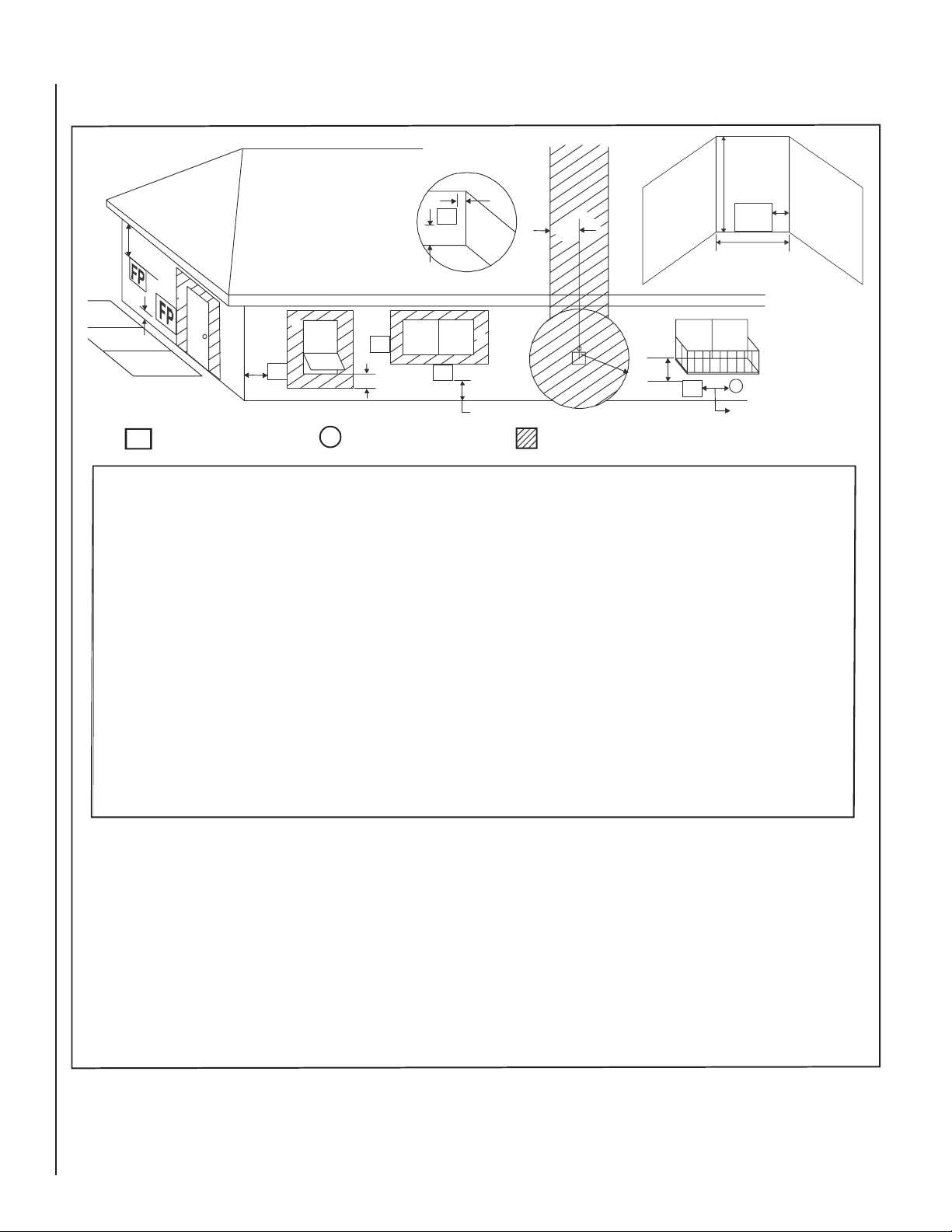

ASSEMBLY OUTLINE

LIVING SPACE

PATIO

Optional

Hearth

Extension

Before You Start

Check your inventory list to be sure you have

all the necessary parts supplied in good usable

condition. Check also for any concealed damage.

LOCATION OF FIREPLACE

Carefully select the proper location for any

obstructions, clearance to side wall(s), air

availability, location and aesthetics. With proper

pre-planning, a slight adjustment of a few inches

can save considerable time and expense later

during construction and assembly. See Figure

1 for some examples.

Figure 1

When choosing a location, care must be taken

to avoid places where flooding or running water

may be a problem.

Do not use this appliance if any part has been

under water. Immediately call a qualified service technician to inspect the appliance and to

replace any part of the control system and any

gas control that has been under water.

Ne pas se servir de cet appareil s'il a été plongé

dans l'eau, complètement ou en partie. Appeler

un technicien qualifié pour inspecter l'appareil et

remplacer toute partie du système de contrôle et

toute commande qui ont été plongés dans l'leau.

If it is evident that the burner is damaged, the

burner must be replaced with one specified by

the manufacturer before the appliance is put

into operation.

Carefully consider the position of the fireplace

opening with respect to the location of adjacent

or nearby stairwells, doors, windows, walkways

and over hanging trees, patios and wires.

When locating the fireplace, consideration must

be given to combustibles and final finishing.

See Figure 24, Page 15 and confine the final

location of combustible finish materials to the

"Safe Zone". Also refer to Clearance Specifications on Page 6.

Consider the effects of heat when locating any

object in front of or near the fireplace opening.

PRE-INSTALLATION NOTES

The fireplace may be installed directly on a

combustible floor or raised on a platform of an

appropriate height. Do not place the fireplace

on vinyl or other soft floor coverings. It may,

however, be placed on flat wood, plywood,

particle board or other hard surfaces.

Be sure the fireplace rests on a solid continuous floor or platform with appropriate framing

for support.

The fireplace may be positioned and then the

framing built around it, or the framing may be

constructed and the fireplace positioned into

the opening.

Usually, no special floor support is needed for

the fireplace, however, to be certain:

1. Estimate the total weight of the fireplace

system including surround materials such

as brick, stone, etc., to be installed. Shipping

weights for the fireplace may be found on

Page 8.

2. Measure the square footage of the floor

space to be occupied by the system, surrounds and hearth extensions.

3. Note the decking construction, i.e. 2 x 6’s,

2 x 8’s or 2 x 10’s, single or double joists,

type and thickness of floor boards.

4. Use this information and consult your lo-

cal building code to determine if you need

additional support.

If you plan to raise the fireplace and hearth

extension, build the platform assembly then

position fireplace and hearth extension on

top. Secure the platform to the floor to prevent

possible shifting.

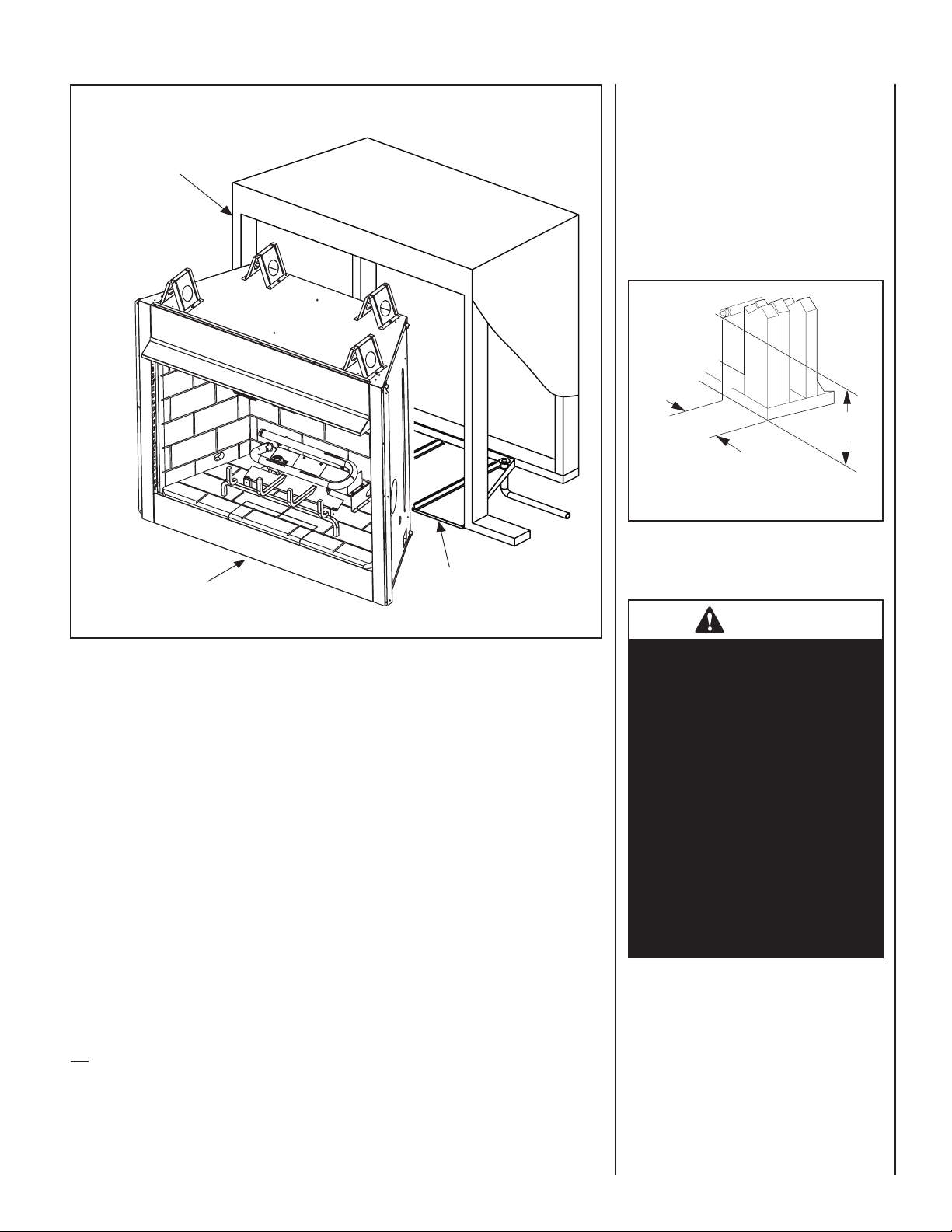

ASSEMBLY STEPS

NOTE: The following steps represent the

normal sequence of installation. Each installation is unique, however, and might require

a different sequence.

1. Position firebox prior to framing or into

prepared framing (non-combustible framing is recommended).

2. Waterproof the fireplace or install the

optional drip pan (see Waterproofing The

Fireplace and Figure 2 on Page 5).

3. Plumb gas line. (Gas connections should

only be performed by an experienced,

licensed/certified tradesman.)

4. Complete the installation, finish wall mate-

rial, surround and hearth extension to your

individual taste.

5. Assemble and attach optional accessories.

Study the three dimensional illustration (Fig-

ure 5, Page 7) to get a general idea of each

element of your fireplace system.

WATERPROOFING THE FIREPLACE

Although this fireplace is designed to operate

safety outdoors, rain may enter the hearth area

(along with condensation) that could cause

an undue amount of water to collect in the

fireplace bottom.

To prevent water collection, the builder must

provide a means to drain water from under

the fireplace by building or installing a water

collector of the builders choice, before positioning the fireplace in its location.

Special care must be taken when the fireplace is

installed against an exterior wall. The enclosure

surrounding the fireplace on the sides and back

must be treated as an exterior wall.

Innovative Hearth Products (IHP) provides an

optional drain pan to assist weatherproofing

the fireplace.

H4651 DPSS36 Drain Pan for VRE3236, H4652

DPSS42 Drain Pan for VRE3242.

4

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 5

1/2” Airspace Clearance

To Sides And Back

No Material Within

The Face Opening

Combustible Materials

Allowed Flush With

The Face Front

No Combustibles

Below The Top Spacers

Non-combustible Material

Only (field provided)

Do NOT Overlap

Material Within

The Face Opening

1/2”

Airspace

Clearance

To Back

TOP VIEW

SIDE VIEW

5”

Combustible Material

May Overlap The

Face Bottom Up To 2”

Below The Face Opening

No Material

Allowed in

This Area

1/2” Clearance

1/2” Airspace Clearance

To Sides And Back

Nailing Flange May

Make Direct Contact

With Combustible

Framing

Non-combustible Material

Only (field provided) May

Overlap the Top Face

Non-combustible Material

Only (field provided) May

Overlap the Face

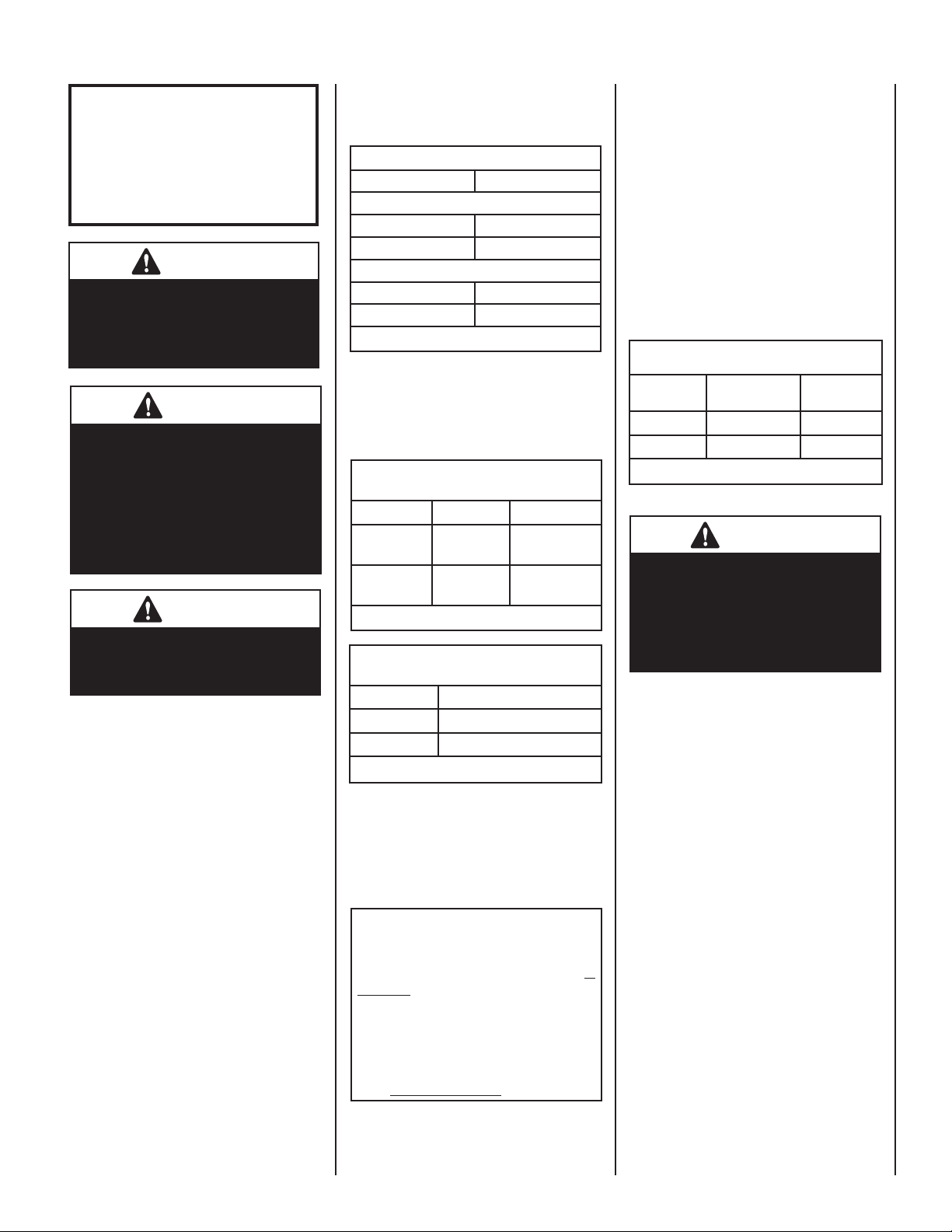

When Planning for the installation of the fireplace, the framing height must be increased

from 46-1/2" to 47-1/4", when installing the

drain pan. An additional space below the

fireplace will also be required to plumb a

drain line.

Step 1. Seal all joints, gaps and corners around

the bottom of the drain pan before

positioning the fireplace on its location

(Figure 2).

Step 2. On the exposed drain hole, install a PVC

threaded coupling reducer, 3/4" x 1/2"

going from the top of the pan down

through the hole. Apply a siliconebased sealant around the base and

threads before installation.

Step 3. Holding the reducer coupling with a

wrench, thread a 3/4", 90 degree, PVC

elbow to the reducer until it is tight to

the metal.

Step 4. Add additional piping to route the drain

to an appropriate location.

Threaded

Reducer

3/4 x 1/2

(PVC)

Drain Connector Detail

47 1/4

Threaded

Elbow 3/4

@ 90

º

(PVC)

NOTE: To assure proper drainage, the fireplace

must be installed on a leveled surface.

CLEARANCES

Minimum clearance to combustibles for the

fireplace is as follows; sides and back – 1/2"

(13mm), combustible floor – 0" (0mm), adjacent wall 6" (152mm), ceiling – 72" (1829mm).

Refer to Figure 3 on this Page and Figure 24

on Page 15 for more detail.

NOTE: Clearance behind the nailing flange

for both fireplace models is 1/2" (13mm).

NOTE: Adjacent wall considerations are for

an adjacent wall to only a single side. Walls

should not be placed at the minimum distance

on both sides of the fireplace. Allow at least

4 feet on one side of the fireplace.

Mantel Clearances

See Page 9.

Figure 2

Figure 3

5

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 6

CLEARANCE SPECIFICATIONS

FP

= FIREPLACE OPENING

X

= AIR SUPPLY INLET

= AREA WHERE FIREPLACE IS NOT PERMITTED

FP

(See Note 2)

D

L

A

H

M

X

J or K

I

G

F

FP

FP

FP

FP

FP

B

B

B

A = 2 in. . . . . . . . . . clearances above grade,

veranda, porch, deck or

balcony.

B = 12 in. . . . . . . . . . clearances to window or door

that may be opened, or to

permanently closed window.

36 in. . . . . . . . . . vinyl windows or siding.

D = 47 in. . . . . . . . . . vertical clearance to unventi-

lated soffit or to ventilated soffit

located above the fireplace.

60 in. . . . . . . . . . vinyl clad soffits.

F = 9 in. . . . . . . . . . clearance to outside corner.

G = 6 in. . . . . . . . . . clearance to inside corner.

48 in. . . . . . . . . . vinyl windows or siding.

H = 3 ft. (Canada). not to be installed above a gas

meter/regulator assembly within

3 ft (914 mm) horizontally from

the center line of the regulator.

I = 3 ft. (USA)

6 ft. (Canada)

clearance to service regulator

vent outlet and electric service.

J = 9 in. (USA)

12 in. (Canada)

clearance to non-mechanical air

supply inlet to building or the

combustion air inlet to any other

appliance.

K = 3 ft. (USA)

6 ft. (Canada)

clearance to a mechanical air

supply inlet.

L* = 54 in. . . . . . . . . . clearance above paved sidewalk

(See note 1) or a paved driveway located on

public property.

M** = 47 in. . . . . . . . . . clearance under veranda, porch,

deck, balcony or overhang.

Not allowed: . . . . . . vinyl.

P = 92 in.

* A fireplace shall not open directly above a sidewalk or paved

driveway which is located between two single family dwellings

and services both dwellings.

* * Only permitted if veranda, porch, deck or balcony is fully open

on a minimum of 2 sides beneath the floor, or if the screened

porch guidelines are followed.

Note 1: Local codes or regulations may require different clearances.

Note 2: Fireplaces

in an alcove space (spaces open only on one

side and with an overhang) are permitted with the dimensions

specified for vinyl or non-vinyl siding and soffits. 1) There must

be a 3 ft minimum between terminations or between the

fireplace and termination. 2) All mechanical air intakes within

10 ft of the top of the fireplace opening must be a minimum of

3 ft below the top of the fireplace opening.

3)

All gravity air intakes within 3 ft of the fireplace must

be a minimum of 1 ft below the face top opening.

This fireplace is approved for installation in screened porches with the

following guidelines:

Minimum porch area - 96 sq ft

Minimum ceiling height - 92 in.

Minimum of two walls must be screened or open

Minimum top of screen height, side walls - 6 ft 8 in.

Minimum screen area - 64 sq ft

Note: There may be some odor and small amounts of soot associated

with burning the fireplace in a screened porch. Ensuring good cross

draft ventilation and routine maintenance of the fireplace will maximize

comfort and cleanliness.

. . . .

. . . .

Q = 72

in.

C = 72 in. . . . . . . . . . clearance below an

opperable window.

.

. . . .

C

P

G

Q

A

Figure 4

6

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 7

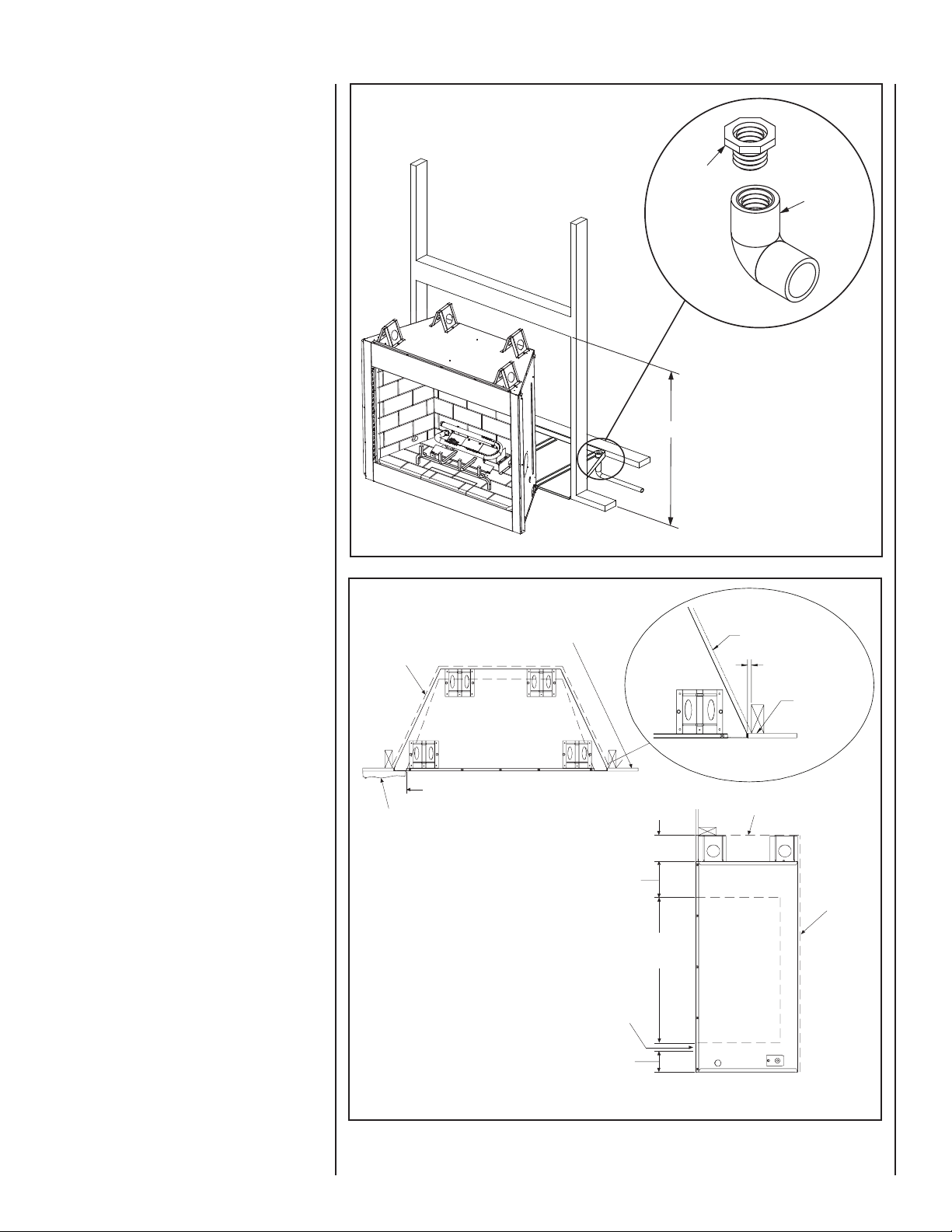

Right Side

Front Corner

Of Fireplace

Framing

3-3/4"

(95 mm)

1-3/4"

(44 mm)

Weatherproof

TYPICAL INSTALLATION

Enclosure

ROUTING GAS LINE

Route a 1/2" (13 mm) gas line along the inside

of the right side framing as shown in Figure 5.

Gas lines must be routed, constructed and made

of materials that are in strict accordance with

local codes and regulations.

All appliances are factory-equipped with a

flexible gas line connector and 1/2" shutoff

valve. (See Figure 12, Page 10).

Figure 6

FIREPLACE INSTALLATION

Step 1. Frame these appliances as illustrated in

Figures 8-10, Page 9. All framing details must

allow for a minimum clearance to combustible

framing members, as shown in Figure 3, Page

5. Also refer to Fireplace Specifications on Page

8. Headers may be in direct contact with the

appliance top spacers but must not be supported by them or notched to fit around them.

All construction above the appliance must be

self supporting. DO NOT USE THE APPLIANCE

FOR STRUCTURAL SUPPORT.

NOTE: The framed depth from a framed wall,

must always be measured from a finished

surface. If a wall covering such as Durock® is

to be attached to the rear wall, then the depth

must be measured from the wall surface. It

is important that this dimension be exact.

Figure 5

Fireplace

Optional Drain Pan

Step 2. Level the firebox by checking the top

edge of the firebox. Shim if necessary.

Step 3. The fireplace should be secured to the

side framing members, using the full length

nailing flange located on both sides of the

fireplace. Use 8d nails, or screws.

IMPORTANT: UNDER NO CIRCUMSTANCES

SHALL THE FIREBOX TOP SPACERS BE REMOVED OR MODIFIED. THE HEADER MAY BE

IN DIRECT CONTACT WITH THE TOP SPACERS

BUT MUST NOT BE SUPPORTED BY THEM OR

NOTCHED TO FIT AROUND THEM.

NOTE: An additional inlet has been provided

on the left side (see Figure 7, Page 8).

CAUTION

If propane is used, be aware

that with a tank that is too

small (i.e., under 100 lbs, if

this is the only gas appliance

in the dwelling—see NPFA

58), there may be a loss of

pressure. This can result in

insufficient fuel delivery that

can cause sooting, delayed

ignition, or other malfunctions.

Any damage resulting from

an improper installation is

not covered by the limited

warranty.

NOTE: Non-combustible framing members are

not required, but are recommended.

7

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 8

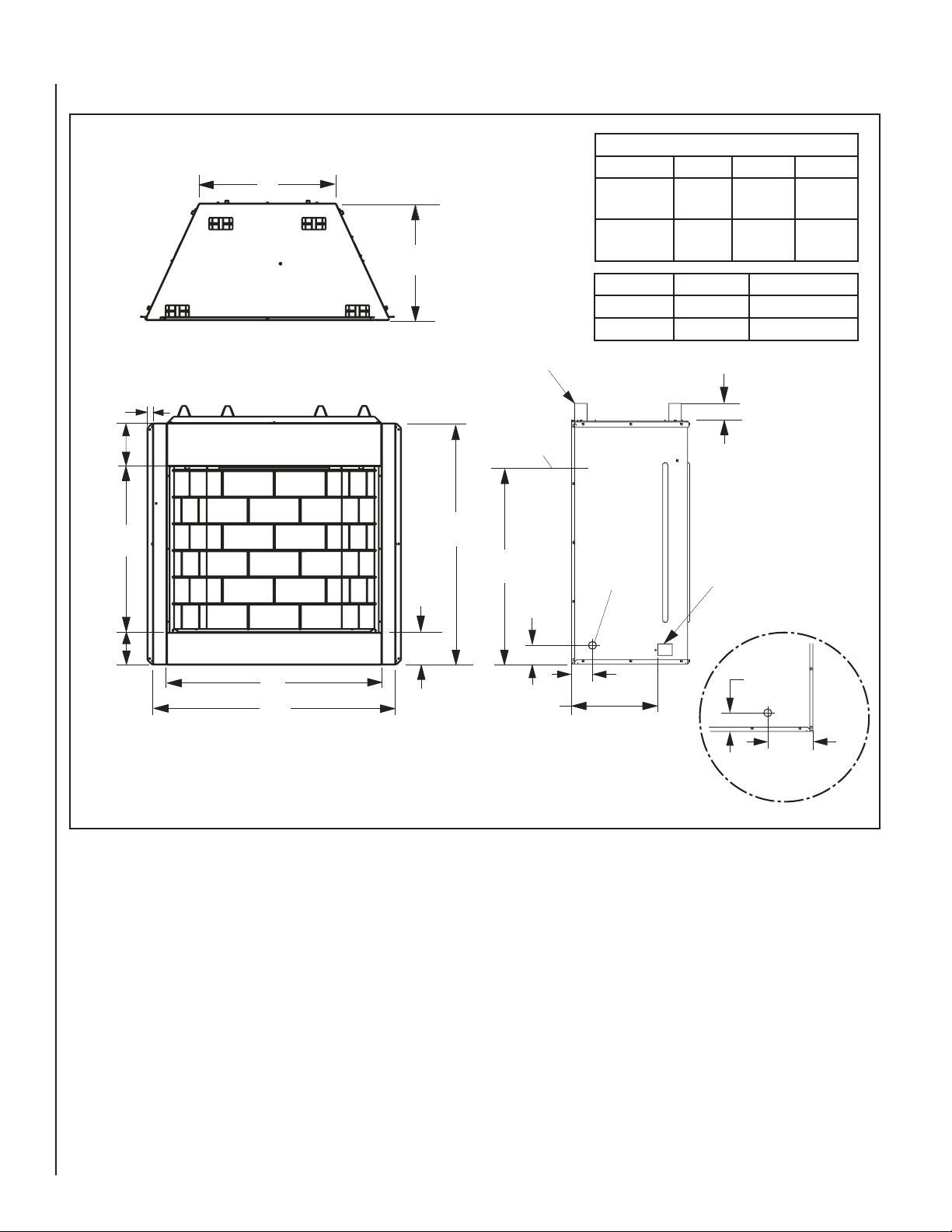

FIREPLACE SPECIFICATIONS

Gas Line

Access (Both Sides)

Access Opening for

Umbilical Cord -

Right Side Only

Top View

A

C

B

1 (25)

7-1/8

(181)

Front View

Right Side View

Top Stand-Off

Spacers

(4 places)

5-3/4

(146)

5-3/4

(146)

To p of Firebox

Opening

Bottom of

Firebox

Opening

Dimensions - Inches (millimeters)

Model No.A BC

37

(940)

41-3/4

(1061)

23-1/2

(597)

43

(1092)

47-3/4

(1213)

29-1/2

(749)

1-3/4

28-1/2

(724)

41-3/8

(1051)

34-1/4

(870)

5

(127)

20

(508)

12

(305)

4-3/8

(111)

Left Side Gas Inlet

8-1/4

(210)

2

(51)

Model

Ship. Weight (lbs)

Shipping Volume

230 lbs

38 Cu. Ft.

Weight And Volume

200 lbs

35 Cu. Ft.

Polaris36

Polaris42

Polaris36

Polaris42

Dimensions - Inches (millimeters)

Model A B C

VRE3236

VRE3242

37

(940)

43

(1092)

41-3/4

(1061)

47-3/4

(1213)

23-1/2

(597)

29-1/2

(749)

Model Ship. Wt. Shipping Volume

VRE3236

VRE3242

260 lbs

290 lbs

28.424 Cu. Ft.

32.184 Cu. Ft.

Figure 7

8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 9

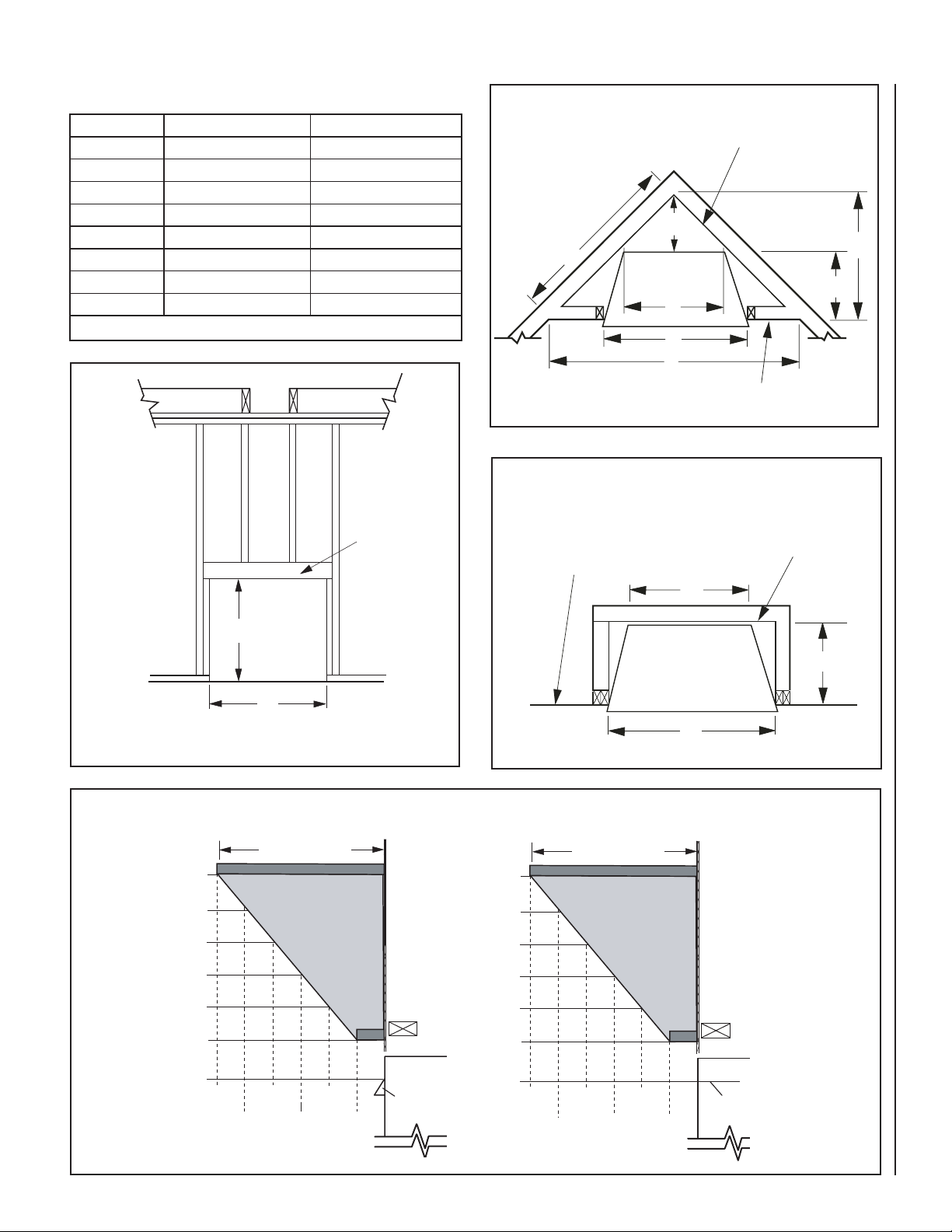

FRAMING SPECIFICATIONS

Corner

Installation

A

C

D

H

F

G

E

Back Wall Of

Chase/Enclosure

Including Finishing

Materials If Any

Rough Framing Face

(Unfinished Shown)

C

G

A

Parallel Installation

Rough Framing Face

(Unfinished Shown)

Back Wall Of

Chase/Enclosure

Including Finished

Materials - If Any

Opening VRE3236 VRE3242

A

B

C

D

E

F

G

H

Table 5 - This Table Corresponds To Figures 8, 9 and 10

42-3/4" (1086) 48-3/4" (1238)

46-1/2" (1181) 46-1/2" (1181)

23-5/8" (600) 29-5/8" (753)

11-1/4" (286) 14-1/4" (362)

63-1/2" (1613) 69-1/2" (1765)

31-3/4" (807) 34-3/4" (883)

20-1/2"( 521) 20-1/2"( 521)

44-1/4" (1124) 49-1/8" (1248)

Header

Figure 9

*Increase Framing Height by 34" when using an Optional Drain Pan

Figure 8

Figure 11

19 (483)

17 (432)

15 (381)

13 (330)

11 (280)

9 (229)

B*

A

Mantel depth

INSTALLED

12

(305)

8

(203)

10

(254)

6

(152)

WITH

HOOD

4

(102)

Figure 10

Mantel Clearances

23 (585)

21 (534)

19 (483)

17 (432)

15 (381)

13 (330)

Fireplace

Hood

2

(51)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

12

(305)

Mantel depth

8

(203)

10

(254)

WITHOUT

HOOD

INSTALLED

4

(102)

6

(152)

2

(51)

inches (millimeters)

Fireplace

Top of Firebox

Opening

9

Page 10

Gas Flex Line Connector

Gas

Stub

1/2" x 3/8" Flare

Shut-Off Valve

3/8" Flex Tubing

3/8" NPT x 3/8"

Flare Fitting

3/8" Nipple

3/8" Union

3/8" Close Nipple

3/8" Shut-Off Valve

1/2" x 3/8"

Reducer

Gas

Valve

10

FIELD WIRING

CAUTION: LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS.

WIRING ERRORS CAN CAUSE IMPROPER AND

DANGEROUS OPERATION. VERIFY PROPER

OPERATION AFTER SERVICING.

Refer to Figure 32, Page 24 for the wiring

schematic for these fireplaces. Two brown wires

are for the connection of the switch. These are

labeled SW and SW. A black and red pair are

for connection to the battery pack. These are

labeled (+) and (–). These wires are for low

voltage current.

Wiring diagrams are provided (Figure 32, Page

24) for reference purposes only. This information

is also provided on schematics attached directly

to the appliance on a pullout panel located within

the control compartment.

CONNECTING GAS LINE

Codes require a shut-off valve mounted in the

supply line. Figure 12 illustrates two methods for

connecting the gas supply. The flex-line method

is acceptable in the U.S., however, Canadian

requirements vary depending on locality. Installation must be in compliance with local codes.

These appliances are equipped with a gas flex

line for use (where permitted) in connecting the

unit to the gas line. A gas flex line is provided to

aid in attaching the outdoor appliance to the gas

supply. The gas flex line can only be used where

local codes permit. See Figure 12 for flex line

description. The flex line is rated for both natural

and propane gas. A manual shut off valve is also

provided with the flex line.

The gas control valve is located under the refractory cover in front of the burner.

To access the valve, lift out the center refractory

and remove the rain shield (see Figure 13).

The control valves have a 3/8" (10 mm) NPT

thread inlet port.

Secure all joints tightly using appropriate

tools and sealing compounds (ensure propane

resistant compounds are used in propane applications).

Turn on gas supply and test for gas leaks, using a

gas leak test solution (also referred to as bubble

leak solution). NOTE: Using a soapy water solution (50% dish soap, 50% water) is an effective

leak test solution but it is not recommended,

because the soap residue that is left on the pies/

fittings can result in corrosion over time. Never

use an open flame to check for leaks.

A. Light the appliance (refer to the lighting in-

structions label in the control compartment

or in the Care and Operation Instructions).

B. Brush all joints and connections with the gas

leak test solution to check for leaks. If bubbles

are formed, or gas odor is detected, turn the

gas control knob to the “OFF” position. Either

tighten or refasten the leaking connection and

retest as described above.

C. When the gas lines are tested and leak free,

be sure to rinse off the leak testing solution.

Figure 12 - Gas Connection

Figure 13 - Valve Access

Gas Shutoff

Valve

1/2" NPT Incoming

Gas Line

NOTE:

1) Wire connections not shown for clarity

2) * 1/8" NPT Plugged Tapping

Figure 14 - Connecting Incoming Gas Line to Flex Gas Line

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Flexible Gas Line Do

NOT Kink

Inlet Pressure Tap

IN

PILOTADJ

Outlet Pressure Tap

Pilot Adjustment

MAIN

PILOT

OUT

Set Screw

Page 11

Install the Logs and Glowing Embers

WARNING

• Turn OFF all gas and electricity to the appliance before installing the embers, and logs.

• Do NOT install the logs until the appliance has been completely installed, the gas line connected and

tested for leaks, and the initial burner operation has been confirmed.

• Use of an unapproved log set in the fireplace will void the warranty and will result in incomplete

combustion, sooting, and poor flame quality.

• Logs get very hot and will remain hot up to one hour after gas supply is turned off. Handle only when

logs are cool. Turn off all electricity to the appliance before you install grate and logs.

• This appliance is not designed to burn wood. Any attempt to do so could cause irreparable damage to

appliance and prove hazardous.

• If the logs are not installed according to these instructions, improper combustion could occur. This

could result in the excessive production of soot and/or the colorless, odorless, toxic gas carbon

monoxide (CO).

• The size and position of the log set was engineered to give your appliance a safe, reliable and

attractive flame pattern. Any attempt to use a different log set in the fireplace will void the warranty

and will result in incomplete combustion, sooting, and poor flame quality.

NOTE: It is important to ensure proper log placement per the manual when installing these units. Verify pilot flame is not

obstructed. See Verifying Appliance Operation on Page 42.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

11

Page 12

Installing the VRE3200 Series Log Set

The logs have notches/tabs to assist proper positioning. Upper logs rest on lower logs via notches/tabs. Proper log placement

is critical to prevent sooting. Place the logs in the gaps between flame peaks, so they do not impinge the flames. Follow the log

placement instructions precisely. NOTE: Do not cover the burner ports.

Table 6 - Log Set

I.D.

No.

1 Rear Log

2 Middle Log

3 Right Front Log

4 Front Left Log

5 Top Right Log

6 Middle Twig Log

7 Top Rear Log

8 Top Left Log

1. Place rear log (1) being pilot in-between the tube burner. (Figure 15)

2. Place middle log (2) directly in front of tube burner (Figure 16).

Description

1

5

2

8

4

3

6

7

8

7

4

1

2

5

6

3

1

2

Square Protrusion

for Log 7

Pin for Log 7

Figure 15 - Place Rear Log (1)

1

Round Protrusion

for Log 5

Front View Front View

Square Protrusion

for Log 8

Figure 16 - Place Middle Log (2)

3. Place front right log (3) onto grate. The notch on the "charred section" will fit around the grate(Figure 17).

4. Place front left log (4) onto grate. The notch on the "charred section" will fit around the grate (Figure 18).

1

2

2

3

4

Square Protrusion

for Log 5

1

3

12

Figure 17 - Place Front Right Log (3)

Top

View

Figure 18 - Place Front Left Log (4)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Top

View

Page 13

Installing the VRE3200 Series Log Set (continued)

5. Position top right log (5) using the round protrusion on the rear log (1) and the square protrusion on the middle log (2) (Figure 19).

6. Position middle twig log (6) using the pin on top right log (5) (Figure 20).

5

6

3

Top View

Cut-out fits over

protrusion on Log 1

(See Figure 15)

4

Cut-out fits over

protrusion on Log 2

(See Figure 16)

Bottom View

1

2

3

Top View

5

Pin for Log 6

4

Bottom View

1

2

Fits ove Pin on Log 5

(see Figure 19)

Figure 19 - Place Top Right Log (5) Figure 20 - Place Middle Twig Log (6)

7. Position top rear log (7) over the square protrusion and pin on the rear log (See Figure 15 and G).

8. Position Top Left log (8) onto the landings on the top rear log (7) (Figure 21) and the protrusion on the middle log (2) (Figure 22).

Landing for Log 8

5

8

7

1

5

Protrusion

for Log 8

7

1

Notch fits over

pin on Log 1

4

Cut-out fits over

protrusion on Log 1

Bottom View

2

6

Top View

2

3

4

Cut-out fits over

protrusion on Log 2

(see Figure 16)

Bottom View

Figure 21 - Place Top Rear Log (7) Figure 22 - Place Top Left Log (8)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

6

3

Top View

13

Page 14

FLAME APPEARANCE AND SOOTING

Sooting is indicated by black puffs developing

at the tips of very long orange flames. Sooting

results in black deposits forming on the logs,

appliance inside surfaces and on exterior surfaces adjacent to the face opening.

These appliances should not smoke. Small

amounts of soot will accumulate over time

and should be expected. This soot adds to the

realism of the firebox interior. The logs can be

cleaned, when cool, with a soft brush and small

amounts of water.

Keep in mind that this is an outdoor appliance. Wind and air currents cannot be strictly

controlled.

If the flame acts too erratically, we recommend

that the screens be closed.

Figure 23 - Proper Burner Flame Appearance

14

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 15

CHECKING APPLIANCE OPERATION

must be non-combustible materials.

With gas line installed run initial system checkout before installing any additional accessories.

Follow the lighting instructions on Page 21.

NOTE: Lighting Instructions are also found

on the literature tag tied to the gas piping

next to the gas valve. To access the tag,

open the lower control compartment door

(refer to Figure 13, Page 10 - Valve Access).

When first lighting the appliance, it will take a few

minutes for the line to purge itself of air. Once

purging is complete, the burner will light and

operate as indicated in the instruction manual.

Subsequent lighting of the appliance will not

require such purging. Inspect the pilot flame

(remove logs, if necessary, handling carefully).

After the logs have been placed and the fireplace

has been checked for proper flame presentation.

Electronic Appliance Checkout

Carbon Monoxide Poisoning: Early signs

of carbon monoxide poisoning are similar

to the flu with headaches, dizziness and/

or nausea. If you have these signs, obtain

fresh air immediately. Turn off the gas supply to the appliance and have it serviced by

a qualified professional, as it may not be

operating correctly.

FIREBOX FINISHES

Only noncombustible materials like marble,

stone, tile, brick, etc. may overlap the top and

sides of the front facing. Seal all joints between

the black facing and wall surrounds to prevent

air intrusion.

6 (153) Minimum

For Combustible

Materials

See Note

Use noncombustible caulking materials only to

seal the metal facing to the surround material

on the finished wall. See Figure 24.

CAUTION: DO NOT BLOCK THE FACE OPENING ON THESE FIREBOXES. DOING SO MAY

CREATE A POTENTIAL FIRE HAZARD.

Mantel

Review mantel clearances

Figure 11, Page 9

3-3/4 (95)

Max.

NOTE: The area above the face to the top of the spacers

Figure 24 - Clearances To Combustibles

15

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 16

GAS CONVERSION KITS

Gas conversion kits are available to adapt your

appliance from the use of one type of gas to

the use of another. These kits contain all the

necessary components needed to complete the

task including labeling that must be affixed to

ensure safe operation.

Kit part numbers are listed here:

Natural to Propane Gas Conversion Kits

Cat. # Model Fireplace

F4126 CKAF4004SLLXNP VRE32 36/42

Propane to Natural Gas Conversion Kits

Cat. # Model Fireplace

F4127 CKAF4004SLLXPN VRE32 36/42

Table 7

See the following Table for orifice sizes for

natural and propane models. Figure 26 illustrates the orifice. Use pipe joint compound or

Teflon tape on all pipe fittings before installing

(ensure propane resistant compounds are used

in propane applications, do not use pipe joint

compounds on flare fittings).

Burner Orifice Sizes

Elevation 0-4500 feet ( 0-1372 meters)

Model

VRE3236 3.25mm (.128") #49 (.073")

VRE3242 3.25mm (.128") #49 (.073")

Nat.Gas

drill size (inches)

Propane

drill size (inches)

Table 8

WARNING

This conversion kit shall be installed by a qualified service agency in

accordance with the manufacturer’s instructions and all applicable codes

and requirements of the authority having jurisdiction. If the information in

these instruction is not followed exactly, a fire, explosion or production of

carbon monoxide may result causing property damage, personal injury

or loss of life. The qualified service agency is responsible for the proper

installation of this kit. The installation is not proper and complete until the

operation of the converted appliance is checked as specified in the manufacturer’s instructions supplied with the kit. The qualified service agency

performing this installation assumes responsibility for this conversion.

AVERTISSEMENT

Cette trousse de conversion doit être installée par un technicien agréé,

selon les instructions du fabricant et selon toutes les exigences et tous les

codes pertinents de l’autorité compétente. Assurez-vous de bien suivre

les instructions dans cette notice pour réduire au minimum le risque

d’incendie, d’explosion ou la production de monoxyde de carbone pouvant

causer des dommages matériels, des blessures ou la mort. Le tecnicien

agréé est responsable de l’installation de cette trousse. L’installation n’est

pas adéquate ni complète tant que le bon fonctionnement de l’appareil

converti n’a pas été vérifié selon les instructions du fabricant fournies avec

la trousse. Le fournisseur de service qualifié ayant réalisé l'installation

assume les responsabilités liées à la conversion.

In Canada:

THE CONVERSION SHALL BE CARRIED OUT IN ACCORDANCE WITH THE REQUIREMENTS

OF THE PROVINCIAL AUTHORITIES HAVING JURISDICTION AND IN ACCORDANCE WITH THE

REQUIREMENTS OF THE CAN/CGA-B149.1 AND .2 INSTALLATION CODE.

LA CONVERSION DEVRA ÊTRE EFFECTUÉE CONFORMÉMENT AUX RECOMMANDATIONS DES

AUTORITÉS PROVINCIALES AYANT JURIDICTION ET CONFORMÉMENT AUX EXIGENCES DU

CODE D'INSTALLATION CAN/CGA-B149.1 ET .2.

16

Figure 26

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 17

OPERATION AND CARE OF YOUR

APPLIANCE

Appliance operation may be controlled by a

remotely located wall switch.

Gas Controls/Control Compartment Access

The gas controls can be found beneath the

bottom refractory. Remove the bottom refractory by lifting it up. Remove the access cover

(refer to Figure 27).

Note: Adjustment screws are provided to level

refractory access cover (refer to Figure 27a).

All Models -

To light these appliances refer to the detailed

lighting instructions found on Page 21. The

appliance lighting instructions may also

be found on the pull out lighting instruction

labels attached to the gas control valve (see

Figure 27).

WARNING

FAILURE TO COMPLY WITH THE INSTALLATION AND OPERATING INSTRUCTIONS PROVIDED IN THIS DOCUMENT

WILL RESULT IN AN IMPROPERLY INSTALLED AND OPERATING APPLIANCE,

VOIDING ITS WARRANTY. ANY CHANGE

TO THIS APPLIANCE AND/OR ITS OPERATING CONTROLS IS DANGEROUS.

IMPROPER INSTALLATION OR USE OF

THIS APPLIANCE CAN CAUSE SERIOUS

INJURY OR DEATH FROM FIRE, BURNS,

EXPLOSION OR CARBON MONOXIDE

POISONING.

Carbon Monoxide Poisoning: Early signs

of carbon monoxide poisoning are similar

to the flu with headaches, dizziness and/

or nausea. If you have these signs, obtain

fresh air immediately. Turn off the gas supply to the appliance and have it serviced by

a qualified professional, as it may not be

operating correctly.

Figure 27 - Control Compartment Access

Refractory access cover

adjustment screws

WARNING

DO NOT PLACE CLOTHING OR OTHER

FLAMMABLE MATERIALS ON OR NEAR

THIS APPLIANCE.

AVERTISSEMENT

SURVEILLER LES ENFANTS. GARDER

LES VÊTEMENTS, LES MEUBLES,

L'ESSENCE OU AUTRES LIQUIDES À

VAPEUR INFLAMMABLES LOIN DE

L'APPAREIL.

WARNING

CHILDREN AND ADULTS SHOULD BE

ALERTED TO THE HAZARDS OF HIGH

SURFACE TEMPERATURES. USE CAUTION AROUND THE APPLIANCE TO

AVOID BURNS OR CLOTHING IGNITION. YOUNG CHILDREN SHOULD BE

CAREFULLY SUPERVISED WHEN THEY

ARE IN THE SAME ROOM AS THE APPLIANCE.

Figure 27a - Adjustment Screws

17

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 18

Variable Flame Height Adjustment

1. All appliances are equipped with a variable

gas control valve. Flame height for these

models may be adjusted from high to low

settings, alternately, while the appliance is

in operation.

Adjust the flame height as desired after

lighting the appliance by pressing high or

low on the remote control.

2. When lit for the first time, this appliance will

emit a slight odor for an hour or two. This

is due to the “burn-in” of internal paints

and lubricants used in the manufacturing

process.

3. Keep lower control compartment clean by

vacuuming or brushing at least twice a year.

More frequent cleaning may be required due

to excessive lint from carpeting, bedding

materials, etc. It is important that control

compartments, burners and circulating air

passageways of the appliance be kept clean.

S'assurer que le brùleur et le compartiment

des commandes sont propres. Voir les instructions d'installation et d'utilisation qui

accompagnent l'appareil.

4. Always keep the appliance area clear and

free from combustible materials, gasoline

and other flammable liquids.

WARNING

• Turn off gas and any electrical

power before servicing the appliance.

• Let fireplace completely cool

before cleaning.

• Failure to keep the primary

air opening(s) of the burner(s)

clean may result in sooting and

property damage.

• Burner Flame Pattern - If yellow

tipping occurs, your fireplace

could produce increased levels

of carbon monoxide. Do not

mistake orange flames with

yellow tipping. Dirt or other fine

particles enter the fireplace and

burn causing brief patches of

orange flame.

Verify proper operation after servicing.

S'assurer que l'appareil fonctionne

adéquatement une fois l'entretien

terminé.

IGNITER ASSEMBLY

The igniter assembly is factory preset for

proper ignition of the burner. Alterations may

have occurred during shipping and handling.

Call a qualified service person to readjust the

igniter assembly if necessary.

The igniter should be positioned as shown in

Figure 28.

NOTE: Figure 28, shows the correct positioning

of the igniter and sensing rod.

If your igniter assembly does not meet these

requirements:

• Turn appliance off (see To Turn Off Gas to

Appliance, Page 21).

• See Troubleshooting, Page 22.

Sensing Rod

Igniter

Cleaning and Maintenance

The appliance should be thoroughly inspected

before initial use and at least annually by a qualified service technician. However, more frequent

periodic inspections and cleanings should be

performed by the homeowner. Homeowner

must contact a qualified service technician at

once if any abnormal condition is observed.

Refer to the maintenance schedule (Page 24) for

maintenance tasks, procedures, periodicity and

by whom they should be performed. Always verify

proper operation of the appliance after servicing.

NOTE: Make sure you have new batteries.

CAUTION

You must keep control areas,

burner and circulating air passageways of fireplace clean.

Inspect these areas of fireplace

before each use. Have fireplace

inspected yearly by a qualified

service person.

Inspect Burner Flame and Pilot Flame

Appearance

Periodically do a visual check of the burner

flame and the pilot flame. Ensure that the burner

flame appearance resembles the flame shown in

Figure 23, Page 14 and as described in Flame

Appearance and Sooting on Page 14.

Battery Replacement

NOTE: All batteries loose voltage when frozen

or left for prolonged periods. It may be wise

to remove batteries during extended periods

of disuse.

Inspect Burner Assembly

If it is evident that the burner is damaged, the

burner must be replaced with one specified by

the manufacturer before the appliance is put

into operation.

Igniter

Burner

Tube

Figure 28 - Igniter Assembly

18

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 19

GAS CONTROL MODULE SYSTEM

REMOTE CONTROL FEATURE

The module has a built in remote control receiver that allows the user

to program the remote transmitter at any time during or after the installation of the burner.

1. There is a switch located on the right side of the module that reads

REMOTE/OFF (Figure 29).

2. When the remote/off switch is in the OFF position, the burner will

operate from the rocker switch or wall switch connected to the two

BROWN wires on the module.

3. When the remote/off is in the REMOTE position the burner will operate

from the Remote Control Transmitter.

NOTE: The module must be programmed to the Remote Control Trans-

mitter.

• To program the module (make sure the system has power), locate

the learn button (Figure 30) on the module. Locate the metal shield

that is covering the module and remove the screw on top. Use a

small thin object like a paper clip (not sharp points) to press and

release the learn button. There will be a beep sound from the module.

Then press any button on the remote transmitter. Once the module's

internal receiver accepts the transmitter code, there will be a series

of confirming beeps.

• The remote system is ready for use.

• Pushing and holding the LEARN button for 6 seconds will result in

clearing the transmitter security code from the module's memory.

The module will make three long beeps in succession when it has

been cleared.

REMOTE CONTROL "DRY-OUT" FEATURE

The remote/Ignitor has a special feature. It will allow heat from the burner

to dry the probe and burner assembly due to excess moisture, caused

by rain, humidity or condensation. To activate:

• Press and hold the HI and LO buttons on the transmitter for 30-45

seconds. This allows the sparking to start and the burner to ignite.

• Release the HI and LO buttons, after the allotted time, sparking will

stop and the burner will go out.

• Press and hold the ON button and sparking will start again and

burner should ignite.

• Release the ON button. The sparking will stop, and the burner

should stay ON.

• Repeat if necessary.

Learn Button

Figure 30 - Gas Module Left Side

AUX Connection

REPLACEMENT PARTS

NOTE: Use only original replacement parts. This will protect your

warranty coverage for parts replaced under warranty.

Normally, all parts should be ordered through your IHP distributor

or dealer. Parts will be shipped at prevailing prices at time of order.

NEVER USE SUBSTITUTE MATERIALS. USE OF NON-APPROVED

PARTS CAN RESULT IN POOR PERFORMANCE AND SAFETY

HAZARDS.

TECHNICAL SERVICE

You may have further questions about installation, operation, or

troubleshooting. Please contact your IHP dealer for any questions

or concerns. When contacting your dealer please have your model

and serial numbers of your appliance ready. You can also visit our

web site at SuperiorFireplaces.us.com

Remote/Off Switch

“S” Pilot Connection

Figure 29 - Gas Module Right Side

ADJ.

“I” Pilot Connection

19

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 20

ACCESSORY COMPONENTS

Drain Pan

The drain pan is used with the appliance.

Outdoor Weather Cover

This attractive stainless steel Outdoor Weather

Cover is easy to install and protects the firebox

interior from adverse weather.

Outdoor Weather Cover *

Cat. No. Model Description

F4130 WC36SL

F4131 WC42SL

36” SS Outdoor

Weather Cover

42” SS Outdoor

Weather Cover

Drain Pan

Cat. No. Model Description

H4651 DPSS36 Drain Pan (36)

H4652 DPSS42 Drain Pan (42)

Hood Kit

This attractive brushed stainless Hood Kit is

easy to install and enhances the appearance

of the appliance.

Outdoor Hood Kit

Cat. No. Model Description

F4128 Hood36ODSL

F4129 Hood42ODSL

36” Hood Kit

Outdoor Gas

42” Hood Kit

Outdoor Gas

* Cannot be used with 36/42LBFOD-BS doors in place

Decorative Volcanic Stone

The decorative volcanic stone, Model FDVS, can

be used to enhance the look of your appliance.

Order model FDVS for replacement of stone

when needed. Spread the decorative volcanic

stone evenly around the bottom ofthe firebox.

Decorative Volcanic Stone

Cat. No. Model Description

80L42 FDVS

Bag of Volcanic

Stone

Creamer Rust Cappuccino

Refractory Stain Kits

Use the Refractory Stain Kits to give white

refractory panels a new look.

Kit includes foam roller, roller handle, paint tray,

and one can of stain. Available stain colors are

Creamer (ivory), Rust (terra cotta), and Cappuccino (rosy taupe).

Refractory Stain Kits

Cat. No. Model Description

H8176 BSK-CR Creamer

H8177 BSK-RT Rust

H8178 BSK-CP Cappuccino

20

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 21

LIGHTING INSTRUCTIONS, ELECTRONIC

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result caus-

ing property damage, personal injury or loss of life.

A. This appliance does not have a pilot, it is equipped

with an ignition device which automatically lights the

pilot. Do not light pilot by hand.

B. BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information first.

2. Do not attempt to light the burner by hand.

3. Turn equipment shutoff valve clockwise to the OFF

position (see Figure 31). Do not force.

4. Wait five (5) minutes to clear out any gas. Then smell for

gas, including near the floor. If you smell gas, STOP! Follow “B” in the safety information. If you don't smell gas,

go to the next step.

5. Turn equipment shutoff valve counterclockwise to

the ON position. Do not force.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

C. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

6. Push remote control ''ON'' button.

7. Visually locate igniter. Igniter should begin to spark and

main burner should ignite once flame appears at pilot.

• If lighting appliance for the first time each season, it

may take several attempts before supply gas can reach

pilot and main burners.

• If appliance will not stay lit after several attempts, follow

instructions under To Turn Off Gas To Appliance and

call your service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Push remote control ''OFF'' button.

2. Turn equipment shutoff valve clockwise to OFF. Do not force.

Incoming Gas

Line

Figure 31 - Turning Equipment Shutoff Valve to the OFF Position

Equipment Shutoff Valve

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

PILOTADJ

IN

MAIN

PILOT

OUT

21

Page 22

TROUBLESHOOTING

WARNING: Turn off appliance and let cool before servicing. Only a qualified service person should

service and repair appliance.

NOTE: All troubleshooting items are listed in order of operation.

OBSERVED PROBLEM POSSIBLE CAUSE REMEDY

When ''ON'' button on remote control

is pressed, there is no spark at igniter

assembly

When ''ON'' button on remote control

is pressed, there is spark at igniter. but

no ignition

Delayed ignition of burner 1. Manifold pressure is too low

Burner backfiring during combustion 1. Burner orifice is clogged or damaged

Slight smoke or odor during initial

operation

Appliance produces a whistling noise

when burners are lit

1. Igniter electrode not connected to

igniter cable

2. Igniter cable pinched or wet

3. Broken igniter cable

4. Bad igniter

5. Igniter electrode positioned wrong

6. Igniter is wet

7. Igniter electrode broken

8. Battery not installed, battery power

low or battery not installed correctly

(electronic ignition models only)

1. Gas supply turned off or equipment

shutoff valve closed

2.

Air in gas lines when installed

3. Depleted gas supply (propane/LP

only)

4. Control module not in REMOTE position

5. Gas control valve pressure setting is

not correct

6. Inlet gas pressure is too low

7. Burner orifice(s) clogged

8. Wire disconnected from gas control

9. Ground wire issue

2. Burner orifice clogged

2. Damaged burner

1. Residues from manufacturing processes and logs curing

1. Air in gas line

2. Air passageways on appliance blocked

3. Dirty or partially clogged burner orifice.

1. Reconnect igniter cable

2. Free igniter cable if pinched by any metal or tubing. Keep igniter cable dry

3. Replace igniter

4. Replace igniter

5. Adjust igniter wires as shown in Figure 28 on Page

18. Replace igniter assembly if repositioning does

not correct the problem

6. See page 19 (Dry-Out Feature)

7. Replace igniter

8. Install new alkaline battery in remote control

and battery pack. Verify batteries are installed

correctly (5.4 volts batteries required to operate

valve system).

1. Turn on gas supply or open equipment shutoff

valve

2. Repeat igniting operation until air is removed

3. Contact local propane/LP gas company

4. Set control module to REMOTE position

5. Contact qualified service person to check pressure

6. Contact local natural or propane/LP gas company

7. Clean burner (see Cleaning and Maintenance,

Page 18) or replace burner orifice(s)

8.

See Wiring Diagram, Page 24

9.

Verify black ground wire from module is secured

under screw adjacent to igniter

1. Contact local natural or propane/LP gas company

2. Clean burner (see Cleaning and Maintenance,

Page 18) or replace burner orifice(s)

1. Clean burner (see Cleaning and Maintenance,

Page 18) or replace burner orifice

2. Replace damaged burner

1. Problem will stop after a few hours of operation

1. Operate burners until air is removed from line.

Have gas line checked by local natural or propane/

LP gas company

2. Observe minimum installation clearances (see Pages

5-6)

3. Clean burner (see Cleaning and Maintenance,

Page 18) or replace burner orifice(s)

22

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 23

TROUBLESHOOTING Continued

WARNING: If you smell gas

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

IMPORTANT: Operating appliance where impurities in air exist may create odors. Cleaning supplies, paint, paint remover, cigarette

smoke, cements and glues, new carpet or textiles, etc., create fumes. These fumes may mix with combustion air and create odors.

These odors will disappear over time.

OBSERVED PROBLEM POSSIBLE CAUSE REMEDY

White powder residue forming within

burner box or on adjacent walls or

furniture

Remote does not function 1. Battery is not installed. Battery power

Appliance produces a clicking/ticking noise just after burners are lit or

shut off

Appliance produces unwanted odors 1. Appliance burning vapors from paint, hair

Appliance shuts off in use 1. Low line pressure 1. Contact local natural or propane/LP gas company

Gas odor even when control knob is

in OFF position

Module makes 4 beeps every 2

seconds

Module makes one beep every one

second

Gas odor during combustion

1. When heated, vapors from furniture

polish, wax, carpet cleaners, etc. may

turn into white powder residue

is low

1. Metal expanding while heating or

contracting while cooling

2. Igniter Assembly is out of position

3. Wind is disturbing the burner flame

and the igniter assembly is relighting

the burner

4. Wire connection loose or wire broken

spray, glues, cleaners, chemicals, new

carpet, etc. (See IMPORTANT statement

above)

2. Low fuel supply (propane/LP only)

3. Gas leak. See Warning statement at

top of Page

1. Gas leak. See Warning statement at

top of Page

2. Control valve or gas control defective

1. The module's internal temperature is

too high

1. The burner did not successfully ignite 1. Press OFF then ON buttons to re-attempt ignition.

1. Gas leak. See Warning statement at

top of Page

1. Turn appliance off when using furniture polish, wax,

carpet cleaners or similar products

1. Replace batteries in battery pack and in hand-held

remote

1. This is normal with most appliances. If noise is

excessive, contact qualified service person

2. Check igniter position and adjust if needed. See

Figure 28, Page 18.

3. Should wind disturb the burner flame, the igniter

will automatically spark to relight the burner. This

is normal when the appliance is installed outdoors

in windy conditions.

4. Check wiring connections (see wiring diagram,

Page 24). Replace wire harness if necessary.

1. Open window to ventilate room. Stop using odor

causing products while appliance is running

2. Refill supply tank (propane/LP only)

3. Locate and correct all leaks (see Checking Gas

Connections, Page 10)

1. Locate and correct all leaks (see Checking Gas

Connections, Page 10)

2. Replace control valve or gas control

1. Check to see the minimum fireplace size requirements are met, Page 9

Refer to '' When ''on'' button on remote control is

pressed, there is spark at igniter but no ignition''

on Page 19.

1. Locate and correct all leaks (see Checking Gas

Connections, Page 10)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

23

Page 24

MAINTENANCE SCHEDULE

Orange

Orange

Orange

Red

Brown

Black

Solenoid

White

Brown

Brown

Green

Igniter

Pilot

I

S

AUX

AF-5000MOD

AF-4000

AF-4000B/P

Control Module

Black

Black

Optional DC Battery Back-up

Red

SWI

SWI

(GND)

Black

Red

HI/LO

Main

Black

Annually (Before the onset of the Burning Season)

MAINTENANCE TASK ACCOMPLISHING PERSON PROCEDURE

Inspecting/Cleaning Burner, Logs

and Controls

Inspecting/Cleaning Pilot and Burner Qualified Service Technician

Appliance Checkout Qualified Service Technician

Replacing Volcanic Stone

Replace Spent Batteries Homeowner

Periodically (After the Burning Season)

MAINTENANCE TASK ACCOMPLISHING PERSON PROCEDURE

Cleaning Firebox Interior Homeowner

Replace Spent Batteries Homeowner

Qualified Service Technician Inspect valve and ensure it is properly operating. Check piping for leaks.

Homeowner/Qualified Services

Technician

Vacuum the control compartment, fireplace logs and burner area.

Refer to Page 17. Remove any surface build-up on pilot and burner as-

sembly. Wipe the pilot nozzles, igniter/flame rod and hood. Ensure the

pilot flame engulfs the flame sensor as shown.

Perform the appropriate appliance checkout procedure detailed in this

manual.

Remove old volcanic stone and vacuum the stone placement area. Place

new volcanic stone as described in this document.

Locate and remove the four (4) screws retaining the stainless J-Box

cover. Remove the battery pack and replace the two (2) "D" cell batteries.

Carefully remove logs and decorative volcanic stone. Vacuum out interior

of the firebox. Clean firebox walls and log grate. Replace logs, Rockwool

and volcanic stone as detailed in this manual.

Locate and remove the four (4) screws retaining the stainless J-Box

cover. Remove the battery pack and replace the two (2) "D" cell batteries.

24

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

Figure 32 - Wiring Diagram

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

These wires are not

used on this application

Page 25

REPLACEMENT PARTS

13

12

17

18

3

14

11

3H

16

15

1

2

1H

2H

7

(RIGHT SIDE)

(RIGHT SIDE)

10

Cat.# Model Description

F4118 VRE3236ZENWS 36" White Stacked, NG

F4119 VRE3236ZENWH 36" White Herringbone, NG

F4120 VRE3236ZEPWS 36" White Stacked, LP

F4121 VRE3236ZEPWH 36" White Herringbone, LP

Cat.# Model Description

F4122 VRE3242ZENWS 42" White Stacked, NG

F4123 VRE3242ZENWH 42" White Herringbone, NG

F4124 VRE3242ZEPWS 42" White Stacked, LP

F4125 VRE3242ZEPWH 42" White Herringbone, LP

5

4

25

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 26

REPLACEMENT PARTS LIST

Item No. Description

1, 2, 3, 4, 5 Refractory Set, White Stacked F4155 1 F4157 1

1 Refractory, LH White Stacked --- 1 --- 1

2 Refractory, RH White Stacked --- 1 --- 1

3 Refractory, Rear White Stacked --- 1 --- 1

1H, 2H, 3H, 4H, 5H Refractory Set, White Herringbone F4156 1 F4158 1

1H Refractory, LH White Herringbone --- 1 --- 1

2H Refractory, RH White Herringbone --- 1 --- 1

3H Refractory, Rear White Herringbone --- 1 --- 1

4 Refractory, Hearth Access Cover Insert F4159 1 F4159 1

5 Refractory Floor / Hearth --- 1 --- 1

7 Clip, Refractory H6368 4 H6368 4

10 Top Frame H4933 1 H4934 1

11 Bottom Frame H4935 1 H4936 1

12 Corner Post (LH) H4937 1 H4937 1

13 Corner Post (RH) H4938 1 H4938 1

14 Stand-Off Bracket H2716 4 H2716 4

15 Cover Plate (Gas Access) H4955 1 H4955 1

16 Log Set F0114 1 F0114 1

17 Screen H4926 2 H4927 2

18 Screen Rod H4939 2 H4940 2

22 Flex Connector 93L32 2 93L32 2

23 Volcanic Stone (Not Pictured) 80L42 3 80L42 3

VRE3236 VRE3242

Part No. Qty. Part No. Qty.

WARNING / AVERTISSEMENT

Failure to position the parts in accordance with these diagrams or failure to use only parts specifically

approved with this appliance may result in property damage or personal injury.

Risque de dommages ou de blessures si les pièces ne sont pas installées conformément à ces schémas

et ou si des pièces autres que celles spécifiquement approuvées avec cet appareil sont utilisées.

WARNING

Never use substitute materials. Use of non-approved parts can result in poor performance and safety

hazards.

26

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 27

REPLACEMENT PARTS (continued)

2A

6A

5A

4A

3A

8A

1A

7A

27

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 28

REPLACEMENT PARTS (continued)

Item No. Description

VRE32 36/42 NG VRE32 36/42 LP

Part No. Qty. Part No. Qty.

Gas Train Replacement Parts List

1A Stainless Burner F4151 1 F4151 1

2A Assembly, Igniter and Flame Rod J6548 1 J6548 1

3A Pilot Bracket F4152 1 F4152 1

4A Orifice Holder J6127 1 J6127 1

5A Orifice F4148 1 J3617 1

6A Air Shutter J5198 1

7A Stainless Grate F4150 1 F4150 1

8A Flex Tube 22" F4149 1 F4149 1

not shown Valve J6361 1 F4160 1

not shown Battery Box J6550 1 J6550 1

not shown Control Module J6547 1 J6547 1

not shown Rain Shield F4153 1 F4153 1

not shown Wiring Harness F4154 1 F4154 1

not shown On/Off Switch H3291 1 H3291 1

not shown Remote Control J6549 1 J6549 1

J5197

1

28

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 29

Innovative Hearth Products

®

Superior

Brand Gas Fireplaces, Stoves and Inserts

20 Year Limited Warranty

THE WARRANTY

Innovative Hearth Products ("IHP") 20 Year Limited Warranty warrants your Superior® Brand gas fireplace, Stove or Insert ("Product") to be free from defects in materials

and workmanship at the time of manufacture. The product body, firebox and barrier carry the 20 Year Limited Warranty. Ceramic glass carries the 20 Year Limited Warranty

against thermal breakage only. After installation, if covered components manufactured by IHP are found to be defective in materials or workmanship during the 20 Year

Limited Warranty period and while the Product remains at the site of the original installation, IHP will, at its option, repair or replace the covered components. If repair or

replacement is not commercially practical, IHP will, at its option, refund the purchase price or wholesale price of the IHP product, whichever is applicable. IHP will also

pay IHP prevailing labor rates, as determined in its sole discretion, incurred in repairing or replacing such components for up to five years. THERE ARE EXCLUSIONS AND

LIMITATIONS to this 20 Year Limited Warranty as described herein.