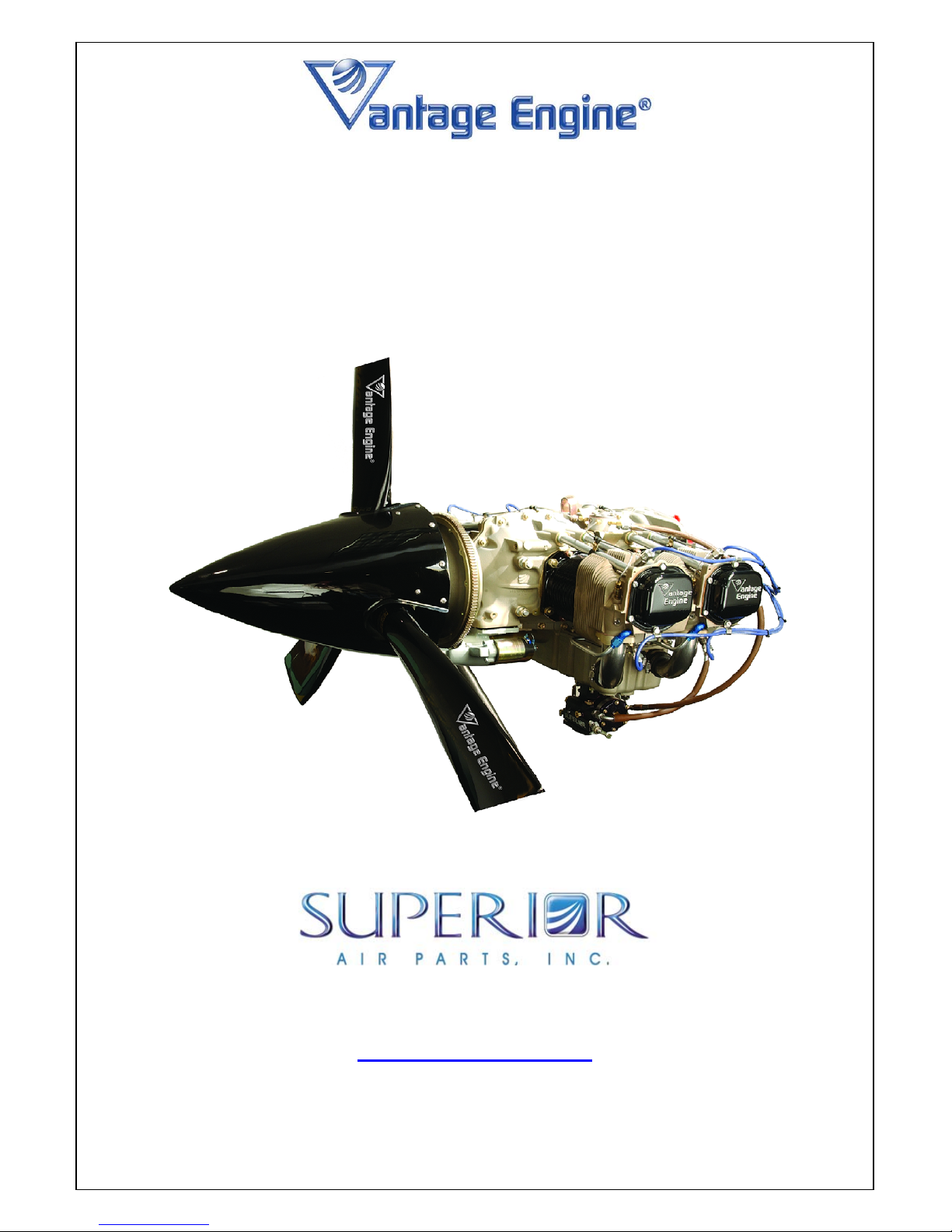

Superior O-360 SERIES, IO-360 SERIES, Vantage Engine O-360 SERIES, Vantage Engine IO-360 SERIES Overhaul Manual

Page 1

O-360 & IO-360 SERIES ENGINES

OVERHAUL MANUAL

621 South Royal Lane, Suite 100 / Coppell, TX 75019 / 800-277-5168

Manual P/N SVOHM01 Revision A, March 2005

www.superiorairparts.com

Page 2

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

© March 2005 Superior Air Parts Inc.

Page 3

Overhaul Manual

O-360 and IO-360 Series Engines

Manual Number SVOHM01

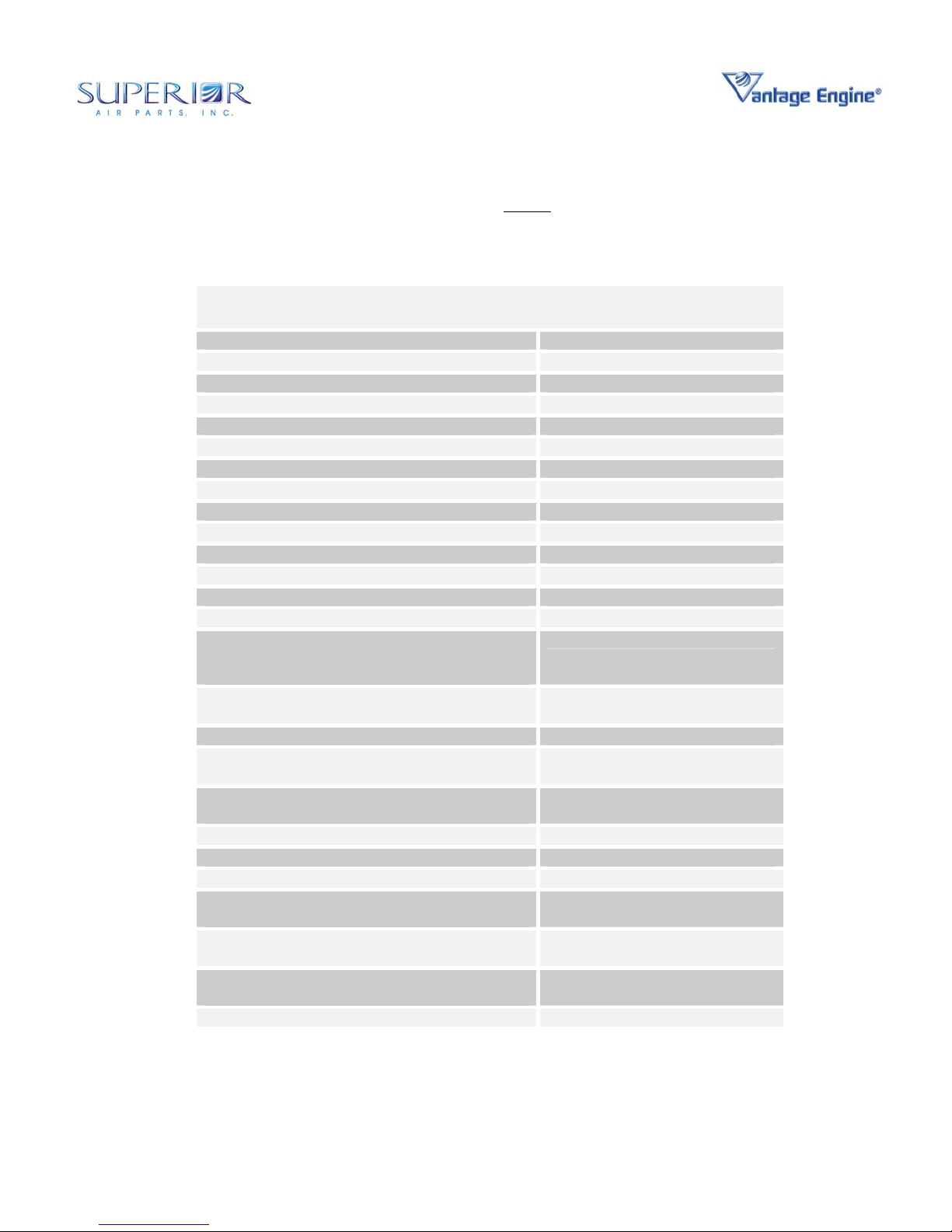

Revision History

Revision

Letter

A 08/31/04 Initial Release All

Effective

Date

Description

Pages

Revised

© March 2005 Superior Air Parts Inc.

iii

General Information

Page 4

Overhaul Manual

O-360 and IO-360 Series Engines

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

© March 2005 Superior Air Parts Inc.

iv

General Information

Page 5

Overhaul Manual

O-360 and IO-360 Series Engines

SAFETY ADVISORY

WARNING: BEFORE MATERIALS CALLED OUT IN THIS PUBLICATION ARE USED, KNOW THE

HANDLING, STORAGE AND DISPOSAL PRECAUTIONS RECOMMENDED BY THE

MANUFACTURER OR SUPPLIER. FAILURE TO COMPLY WITH THE

MANUFACTURERS' OR SUPPLIERS’ RECOMMENDATION CAN RESULT IN PERSONAL

INJURY.

The user must know the manufacturer or supplier information and keep to the procedures,

recommendations, warnings and cautions set forth for the use, handling, storage, and disposal of materials.

The WARNINGS used in this manual inform the user about dangerous materials or equipment that can

cause injury; they do not replace the manufacturer's instructions.

This Safety Advisory has all the warnings included in this manual.

WARNING: OPERATION OF A DEFECTIVE ENGINE WITHOUT A PRELIMINARY EXAMINATION CAN

CAUSE FURTHER DAMAGE TO A DISABLED COMPONENT AND POSSIBLE INJURY TO

PERSONNEL. MAKE SURE THOROUGH INSPECTION AND TROUBLESHOOTING

PROCEDURES ARE ACCOMPLISHED. THIS WILL HELP TO PREVENT INJURIES TO

PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT.

WARNING: FUEL IS TOXIC AND FLAMMABLE. DO NOT BREATHE VAPORS. USE INA A WELL

VENTILATED AREA FREE FROM SPARKS, FLAME, OR HOT SURFACES.AVOID EYE

AND SKIN CONTACT. PUT ON SPLASH GOGGLES, SOLVENT-RESISTANT GLOVES,

AND OTHER PROTECTIVE GEAR. IN CASE OF EYE CONTACT, FLUSH WITH WATER

FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN CONTACT,

WASH WITH SOAP AND WATER.

WARNING: HOT OIL MAY CAUSE BURNS TO EYES AND SKIN. PUT ON SPLASH GOGGLES AND

INSULATED GLOVES, AND OTHER PROTECTIVE GEAR. IN CASE OF EYE CONTACT,

FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF

SKIN CONTACT, WASH WITH SOAP AND WATER.

WARNING: ENGINE OIL IS HAZARDOUS AND MAY CAUSE INJURY TO SKIN AND EYES. PUT ON

PERSONNEL PROTECTIVE GEAR.

WARNING: USE THE CORRECT PERSONAL PROTECTION. HEATED PARTS WILL CAUSE BURNS.

WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT

THE PRESSURE IS NOT MORE THAN 30 PSI. DO NOT DIRECT THE AIRSTREAM AT

PERSONNEL OR LIGHT OBJECTS. PUT ON GOGGLES OR A FACE SHIELD TO

PROTECT YOUR EYES. IF YOU GET AN EYE INJURY, GET MEDICAL ATTENTION.

WARNING: LUBRICANTS ARE TOXIC AND FLAMMABLE. DO NOT BREATHE VAPORS. BEFORE

YOU USE, READ THE MATERIAL SAFETY DATA SHEET (MSDS) FROM THE

MANUFACTURER OR SUPPLIER. USE IN A WELL VENTILATED AREA FREE FROM

SPARKS. WEAR PROTECTIVE GEAR. IN CASE OF EYE CONTACT, FLUSH WITH

WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN

CONTACT, WASH WITH SOAP AND WATER.

WARNING: USE THE CORRECT PERSONAL PROTECTION. POLISHING WILL CAUSE LOOSE

PARTICLES THAT CAN GET IN YOUR EYES.

© March 2005 Superior Air Parts Inc.

v

General Information

Page 6

Overhaul Manual

O-360 and IO-360 Series Engines

WARNING: PUT ON SAFETY GOGGLES WHEN INSTALLING OR REMOVING SAFETY WIRE.

WARNING: USE THE CORRECT PERSONAL PROTECTION EQUIPMENT TO AVOID INJURY.

ENSURE AREA IS FREE OF MOVABLE OBJECTS THAT COULD IMPACT BY

PROPELLER AIR BLAST.

WARNING: ADHESIVE SEALANT IS TOXIC AND FLAMMABLE. DO NOT BREATHE VAPORS.

AVOID EYE AND SKIN CONTACT. USE PROTECTIVE GEAR. IN CASE OF EYE

CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION.

IN CASE OF SKIN CONTACT, WASH WITH SOAP AND WATER.

WARNING: SOLVENT IS TOXIC. USE IN WELL-VENTILATED AREA. PREVENT EYE AND SKIN

CONTACT AND DO NOT BREATHE VAPORS. IN CASE OF EYE CONTACT, FLUSH

WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN

CONTACT, WASH WITH SOAP AND WATER.

WARNING: DO NOT INSTALL THE IGNITION HARNESS “B” NUTS ON THE SPARK PLUGS UNTIL

THE PROPELLER INSTALLATION IS COMPLETED. FAILURE TO COMPLY COULD

RESULT IN BODILY INJURY WHEN THE PROPELLER IS ROTATED DURING

INSTALLATION.

WARNING: IF ONE SURFACE IS POLISHED TO UNDERSIZE, ALL CORRESPONDING SURFACES

MUST BE POLISHED TO THE SAME SIZE.

WARNING: PLACE A SUITABLE STAND UNDER THE AIRCRAFT TAILCONE IF NEEDED BEFORE

REMOVING THE ENGINE. THE LOSS OF WEIGHT MAY CAUSE THE AIRCRAFT TAIL

TO DROP.

WARNING: DO NOT DAMAGE THE NITRIDED SURFACES OF THE CRANKSHAFT.

WARNING: USE CORRECT PERSONAL PROTECTION. SOME CHEMICAL SOLUTIONS CAN CAUSE

EYE, SKIN, AND LUNG DAMAGE. FOLLOW THE MANUFACTURER’S INSTRUCTIONS

FOR EACH STRIPPING SOLUTION.

WARNING: USE THE CORRECT PERSONAL PROTECTION. USE OF A HAMMER CAN CAUSE

LOOSE PARTICLES THAT CAN GET IN YOUR EYES.

WARNING: DO NOT ROTATE ENGINE OR CRANKSHAFT BEFORE REMOVAL OF TIMING

LOCATOR PINS.

WARNING: TO PREVENT THE POSSIBILITY OF SERIOUS BODILY INJURY OR DEATH, BEFORE

MOVING THE PROPELLER DO THE FOLLOWING:

VERIFY ALL SPARK PLUG LEADS ARE DISCONNECTED. •

•

VERIFY MAGNETO SWITCHES ARE CONNECTED TO MAGNETOS AND THAT THEY

ARE IN THE “OFF” POSITION AND “P” LEADS ARE GROUNDED.

•

THROTTLE POSITION “CLOSED.”

•

MIXTURE CONTROL “IDLE-CUT OFF.”

•

SET BRAKES AND BLOCK AIRCRAFT WHEELS. ENSURE THAT AIRCRAFT TIE

DOWNS ARE INSTALLED AND VERIFY THAT THE CABIN DOOR LATCH IS OPEN.

•

DO NOT STAND WITHIN THE ARC OF THE PROPELLER BLADES WHILE TURNING

THE PROPELLER.

vi

© March 2005 Superior Air Parts Inc.

General Information

Page 7

Section

Chapter

General Information

Sub-Section

Revision History i

Safety Advisory iii

Table of Contents v

List of Figures ix

List of Tables xi

Overhaul Manual

O-360 and IO-360 Series Engines

TABLE OF CONTENTS

Page Number

01 00 00 Introduction

02 00 00 Description and Operation

04 00 00 Airworthiness Limitations

72 00 03 Testing and Fault Isolation

About This Manual 1

Related Publications 1

Obtaining Service Information 1

Abbreviations 1

Consumable Materials List 3

General Description 1

Continued Airworthiness 1

Model Designations 1

Engine Components General Description 3

Specifications 3

Features and Operating Mechanisms 16

Mandatory Replacement Time 1

Mandatory Inspection Intervals 1

Other Mandatory Intervals or Procedures 1

Distribution of Changes to Airworthiness 1

General 1

Troubleshooting 1

04 Special Procedures

Prior to Break-In Start-Up

Break-In Ground Run

Break-In Flight Operation

© March 2005 Superior Air Parts Inc.

General Break-In Procedures 1

Special Tools and Equipment 1

Break-In Procedures 1

Post Break-In Procedures 2

1

1

1

vii

General Information

Page 8

Overhaul Manual

O-360 and IO-360 Series Engines

Chapter

TABLE OF CONTENTS (cont’d)

Page Number

Section

Sub-Section

05 Engine Removal

06 Engine Disassembly

07 Cleaning

Degreasing

Decarbonizing

Scratch and Corrosion Removal

Accessory Mounts

Fuel Injector and Primer Nozzles

Screens and Filters

Accessories

General 1

Removal 1

Preservation 1

General 1

Disassembly Materials 1

Parts for Discard 1

Special Tools and Equipment 1

General Disassembly Procedures 2

Disassembly 2

General 1

Tools and Materials 1

Cleaning Instructions 1

Preservation and Corrosion Prevention 4

1

2

2

2

3

3

3

© March 2005 Superior Air Parts Inc.

viii

General Information

Page 9

Section

Chapter

72 00 08 Inspection and Check

Sub-Section

General 1

Materials and Tools 1

General Inspection Procedures 2

General Non-Destructive Testing 2

Accessory Housing 3

Crankcase Assembly 3

Cylinder Head 6

Cylinder Head Dimensional Inspections 6

Cylinder Barrel Inspections 6

Cylinder Barrel Dimensional Inspections 7

Cylinder Assembly Inspection 7

Piston Inspections 7

Piston Dimensional Inspections 7

Valve Rockers 11

Pushrod Inspection 11

Valve Springs Inspection 11

Crankshaft 13

Crankshaft Counterbore Face Inspection 13

Camshaft Inspection 14

Connecting Rods Inspection 14

Overhaul Manual

O-360 and IO-360 Series Engines

TABLE OF CONTENTS (cont’d)

Page Number

09 Engine Assembly

10 Engine Installation

© March 2005 Superior Air Parts Inc.

General 1

Fits, Clearances and Torque Values 1

Materials Required for Assembly 1

Special Tools and Equipment 1

Engine Assembly 2

Engine Accessory Assembly Installation 46

Storage After Assembly 58

General 1

Preparing Engine for Service 1

Installation of Engine 1

ix

General Information

Page 10

Section

Chapter

72 00 11 Fits and Clearances

Sub-Section

General 1

Service Limits 1

Overhaul Manual

O-360 and IO-360 Series Engines

TABLE OF CONTENTS (cont’d)

Page Number

12 Preservation and Storage

13 Repair

Repair 1 – Threaded Area Repair and Stud Replacement

Repair 2 – Nick and Scratch Repair

Repair 3 – Crankshaft or Crankpin Repair

Repair 4 – Painted Parts

Repair 5 – Crankshaft Oil Seal Surface

Repair 6 – Cylinder Interior Surface

Repair 7 – Cylinder Head Cooling Fins

Repair 8 – Valve, Valve Seat, and Valve Guide

Repair 9 – Spark Plug Threaded Insert

Repair 10 – Rocker Bushing Replacement

Repair 11 – Connecting Rod Bushing Replacement

14 Testing

Appendix A Assembly In Process Quality Inspections

General 1

Temporary Storage 2

Indefinite Storage 3

Returning an Engine to Service After Storage 3

General 1

Repair Procedures 1

General 1

Special Tools and Equipment 1

Engine Installation and Testing Procedures 1

Engine Storage After Testing 1

5

7

9

11

13

15

17

19

27

29

31

© March 2005 Superior Air Parts Inc.

x

General Information

Page 11

Overhaul Manual

O-360 and IO-360 Series Engines

LIST OF FIGURES

Figure

02-00-00.1 Engine Model Number Designation 02 00 00 1

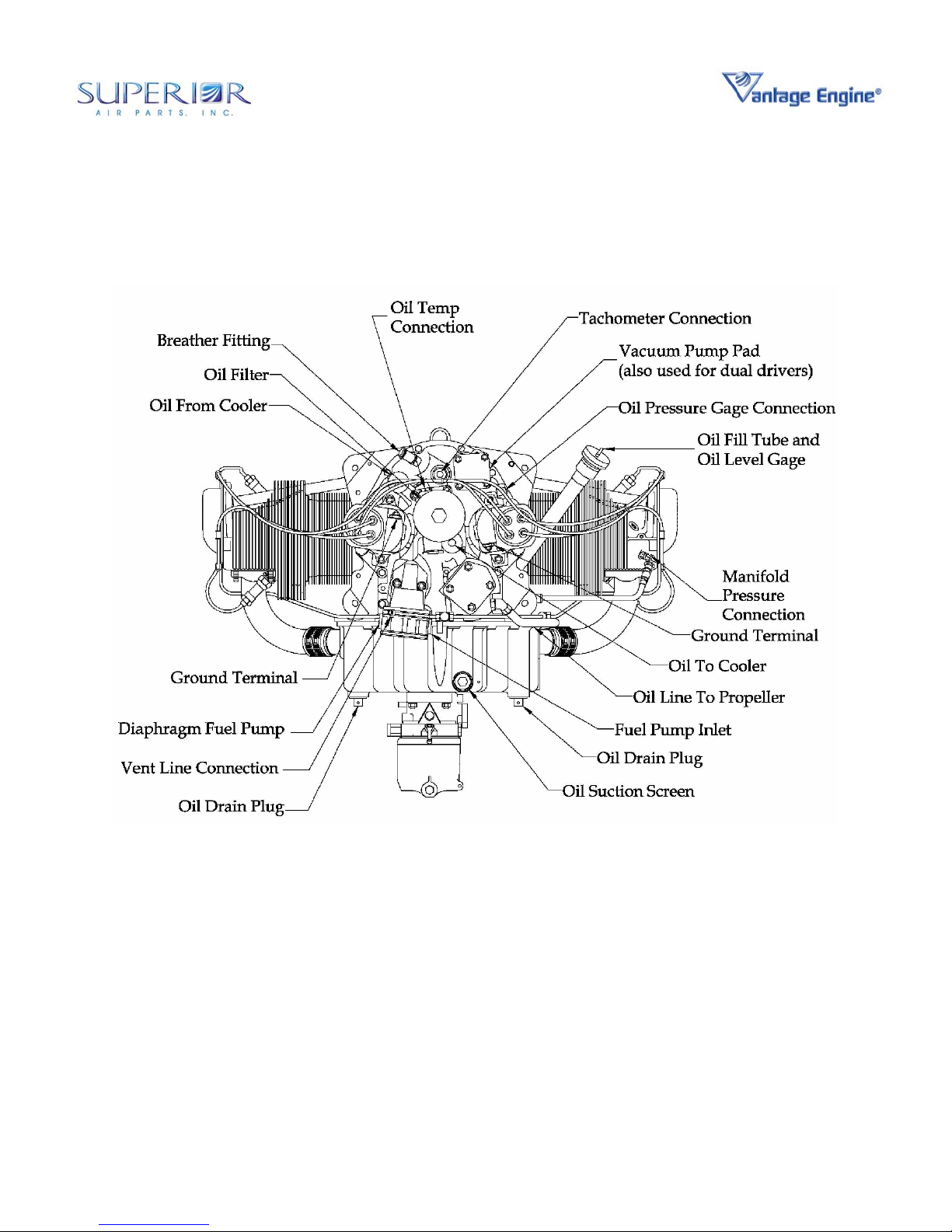

02-00-00.2 O-360 Engine Front View 6

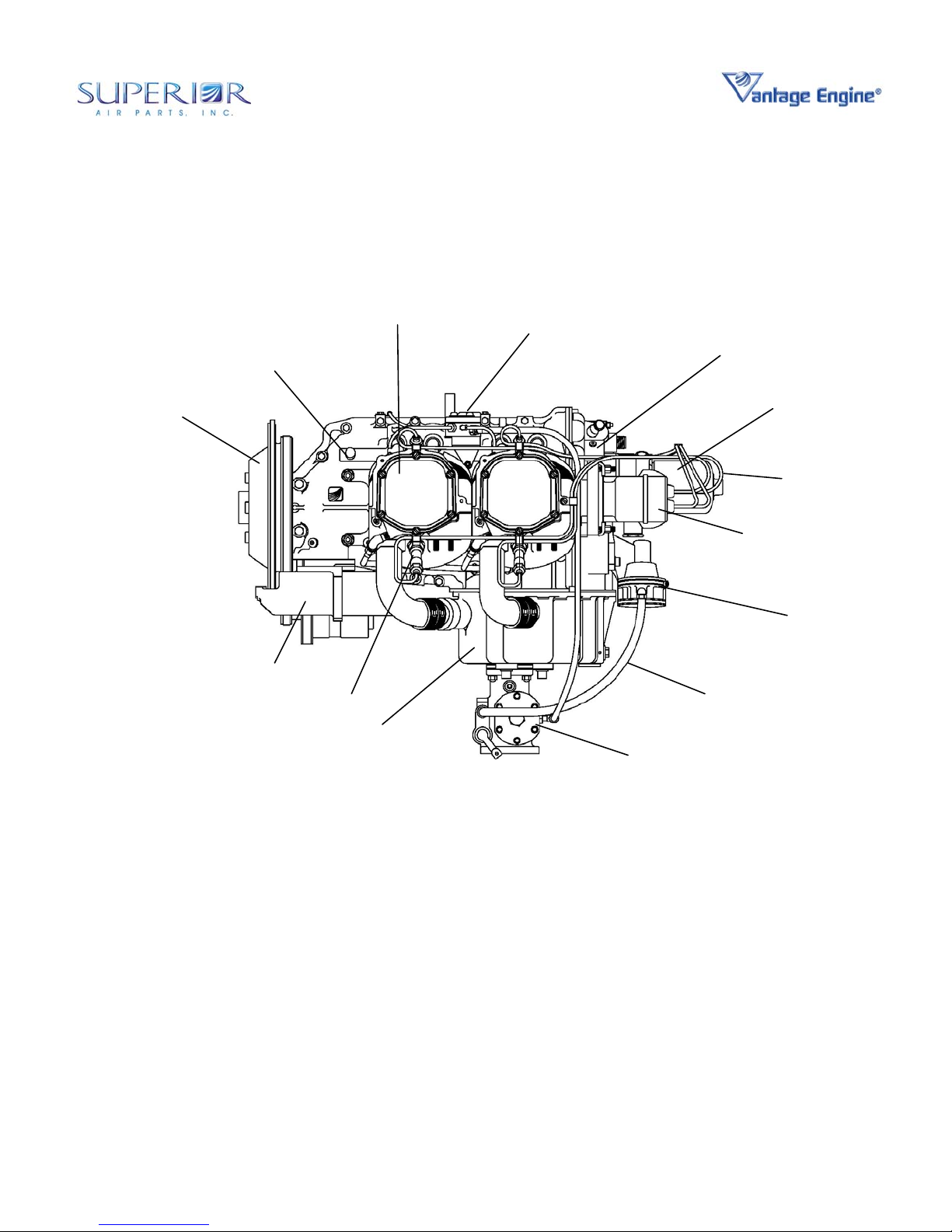

02-00-00.3 O-360 Engine Left Side View 7

02-00-00.4 O-360 Engine Top View 8

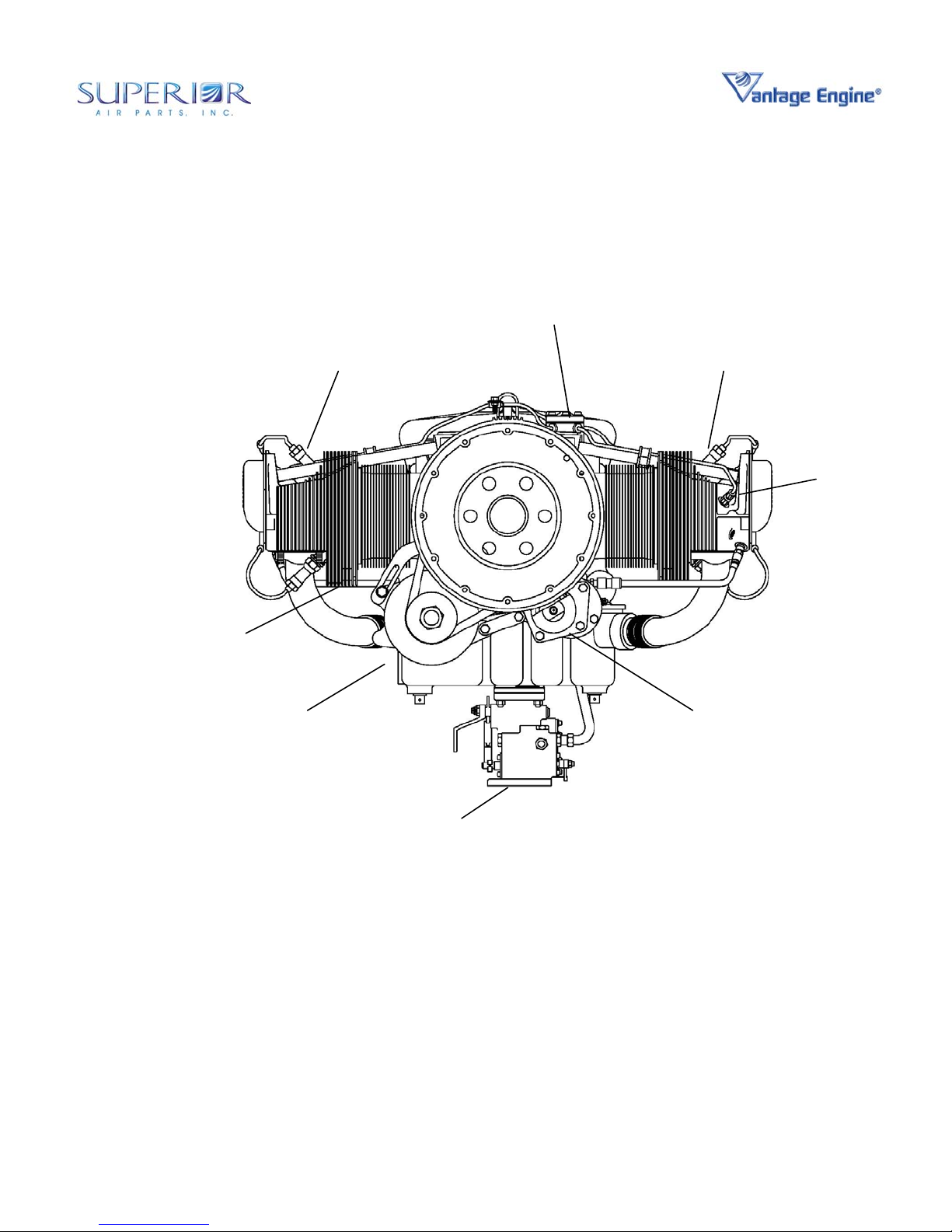

02-00-00.5 O-360 Engine Rear View 9

02-00-00.6 IO-360 Engine Front View 10

02-00-00.7 IO-360 Engine Left Side View 11

02-00-00.8 IO-360 Engine Top View 12

02-00-00.9 IO-360 Engine Rear View 13

02-00-00.10 Ignition Wiring Diagram 14

02-00-00.11 Oil System Schematic 15

72-00-08.1 Reserved 08 -

72-00-08.2 Accessory Housing 4

72-00-08.3 Crankcase Bearing and Flange Surfaces 5

72-00-08.4 Cylinder Assembly 8

72-00-08.5 Piston Assembly 9

72-00-08.6 Piston Rings and Lands 10

72-00-08.7 Valve Train 12

72-00-08.8 Camshaft Assembly 15

Chapter

Section

Page

Sub-Section

72-00-09.1 Crankcase Bearing Retention Dowel 09 4

72-00-09.2 Crankshaft Bearing and Oil Pressure Relief Valve 5

72-00-09.3 Crankshaft Assembly 6

72-00-09.4 Crankshaft Thrust and Slinger Clearance 7

72-00-09.5 Crankcase Assembly 8

72-00-09.6 Connecting Rod and Piston Assembly 12

72-00-09.7 Connecting Rod Installation 13

72-00-09.8 Camshaft Assembly 14

72-00-09.9 Main Bearing Reference Marks 15

72-00-09.10 Main Bearing Installation 16

72-00-09.11 Crankcase Attaching Hardware 17

72-00-09.12 Crankcase Attaching Hardware (cont’d.) 18

72-00-09.13 Sealant Compound and Silk Thread Application 19

72-00-09.14 Crankcase Halves Assembly 20

xi

© March 2005 Superior Air Parts Inc.

General Information

Page 12

Overhaul Manual

O-360 and IO-360 Series Engines

LIST OF FIGURES (cont’d.)

Figure

72-00-09.15 Cylinder Valve Train and Spring Assembly 72 00 09 22

72-00-09.16 Piston Assembly to Connecting Rod 23

72-00-09.17 Cylinder Assembly and Head Oil Drain Line 25

72-00-09.18 Piston Assembly with Ring Compressor Tool 26

72-00-09.19 Cylinder Base Nuts Sequence of Tightening 27

72-00-09.20 Idler Gear and Tachometer Shaft Assemblies 30

72-00-09.21 Idler Gear and Tachometer Shaft Assemblies (cont’d.) 31

72-00-09.22 Accessory Drive Gear Arrangement 32

72-00-09.23 Accessory Housing 35

72-00-09.24 Oil Pump Assembly 36

72-00-09.25 Accessory Housing Gasket Trimming 37

72-00-09.26 Inner Cylinder Cooling Baffle 39

72-00-09.27 Oil Sump and Induction System 40

72-00-09.28 Oil Level Gage 41

72-00-09.29 Induction System 42

72-00-09.30 Intake Tube Assembly 43

72-00-09.31 Vacuum Pump Drive 45

72-00-09.32 Fuel Pump 47

72-00-09.33 Propeller Governor Adapter 49

72-00-09.34 Propeller Governor Oil Line 50

72-00-09.35 Oil Filter Assembly 51

72-00-09.36 Fuel Priming System 53

72-00-09.37 Carburetor Installation 54

72-00-09.38 Fuel Injection Servo Installation 55

72-00-09.39 Fuel Injection Manifold Installation 56

72-00-09.40 Magneto and Adapter Installation 59

72-00-09.41 Starter Ring Gear Alignment 60

72-00-09.43 Alternator Installation 61

Chapter

Section

Page

Sub-Section

72-00-13.1 Cylinder Interior Resurface Crosshatch 15 16

72-00-13.2 Cooling Fin Removal Maximum 18

72-00-13.3 Valve Seat Dimensions 23

72-00-13.4 Valve Guide Dimensions 24

72-00-13.5 Valve to Seat Fit Acceptable Criteria 25

© March 2005 Superior Air Parts Inc.

xii

General Information

Page 13

Overhaul Manual

O-360 and IO-360 Series Engines

LIST OF TABLES

Table

Section

Chapter

01-00-00.1 Abbreviations 01 00 00 2

01-00-00.2 Consumable Materials 3

02-00-00.1 Manufacturer’s General Specifications 02 00 00 3

02-00-00.2 Accessory Drive Specifications 4

02-00-00.3 Manufacturer’s Physical Specifications 4

02-00-00.4 Engine Accessories 4

02-00-00.5 Illustrated Views of the Engine 5

72-00-03.1 Special Tools and Equipment 72 00 03 1

72-00-03.2 Abnormal Operating Procedures 1

72-00-03.3 Engine Will Not Start 2

72-00-03.4 Rough Idling 2

72-00-03.5 Engine Not Able To Develop Full Power 2

72-00-03.6 Rough Engine Operation 3

72-00-03.7 Low Power & Engine Runs Rough 3

72-00-03.8 Low Oil Pressure On Engine Gage 3

72-00-03.9 High Oil Temperature 4

72-00-03.10 Excessive Oil Consumption 4

Page

Sub-Section

72-00-05.1 Equipment and Materials List 05 1

72-00-06.1 Disassembly Materials 06 1

72-00-06.2 Discard Parts 1

72-00-06.3 Special Tools and Equipment 3

72-00-07.1 Equipment Required for Cleaning 07 1

72-00-07.2 Materials Required for Cleaning 1

72-00-08.1 Inspection Materials 08 1

72-00-08.2 Special Tools and Equipment 1

72-00-09.1 Assembly Materials 09 1

72-00-09.2 Special Tools and Equipment 2

72-00-10.1 Equipment and Materials List 10 1

xiii

© March 2005 Superior Air Parts Inc.

General Information

Page 14

Overhaul Manual

O-360 and IO-360 Series Engines

LIST OF TABLES (cont’d)

Table

Section

Chapter

72-00-11.1 Dimensional Limits 72 00 11 1

72-00-11.2 Torque Limits 3

72-00-11.3 Backlash and End Clearance Limits 4

72-00-11.4 Valve Spring Dimensional Limits 4

72-00-11.5 Crush Type Gasket Tightening Angles 4

72-00-12.1 Storage Materials 14 1

72-00-13.1 List of Repairs 13 2

72-00-13.2 List of Materials 2

72-00-13.3 List of Equipment 3

72-00-13.4 List of Repair Codes 3

72-00-13.5 Reserved -

72-00-13.6 Consumable Materials for Paint Procedures 11

72-00-13.7 Exhaust Valve Seat Standard and Oversize Dimensions 20

72-00-13.8 Intake Valve Seat Standard and Oversize Dimensions 20

72-00-13.9 Exhaust Valve Guide Standard and Oversize Dimensions 21

72-00-13.10 Intake Valve Guide Standard and Oversize Dimensions 21

Page

Sub-Section

© March 2005 Superior Air Parts Inc.

xiv

General Information

Page 15

Overhaul Manual

O-360 and IO-360 Series Engines

INTRODUCTION

About This Manual

The purpose of this Overhaul Manual is to

provide the necessary instructions for major

repair and replacement of Superior Vantage

O-360 and IO-360 series engines. Maintenance

information may be found in the Maintenance

Manual, SVMM01.

The information in this publication is based on

data available at the time of publication and is

updated, supplemented, and automatically

amended by Service Bulletins and Publication

Revisions that are issued by Superior Air Parts

Inc.

This manual is divided into separate sections

relating to the general and specific overhaul

instructions required for the engine. These

general and specific instructions are generally

organized and numbered per the

recommendations of the General Aviation

Manufacturers Association (GAMA). In this way,

information may be located in a conventional

manner to aid in both accuracy and timeliness.

Page numbering is organized within each

section. The section number (e.g., 72-00-01) is

displayed in the right hand section of the footer

on each page. The page number is displayed in

the center of the footer on each page.

Superior Air Parts has made clear and accurate

information available for those who maintain,

own and repair the Vantage O-360 and IO-360

Series Engines. Superior Air Parts values your

input regarding revisions and additional

information for our manuals. Please forward

your comments and input to:

Superior Air Parts

Attn: Engineering Department

621 South Royal Lane Suite 100

Coppell, Texas 75019

Related Publications

The following are related engine and accessory

publications.

O & IO-360 Installation and Operation Manual,

SVIOM01

O & IO-360 Maintenance Manual, SVMM01

O & O-360 Illustrated Parts Catalog, SVIPC01

Unison Master Service Manual, F-1100

Unison Autolite Manual, L-1710A

Precision RSA-5 Service Manual, 15-338

Precision MA-4-5 Manual, MSAHBK-1

Champion Aerospace Service Manual, AV-6R

Kelly Aerospace Service Manual, OE-A2

Obtaining Service Information

All Vantage Series Engine manuals and service

information may be downloaded at:

www.superiorairparts.com

All Vantage Series Engine manuals and service

information may be purchased by contacting:

Superior Air Parts

621 South Royal Lane, Suite 100

Coppell, Texas 75019

or call: 972-829-4600

Accessory Information may be obtained at:

www.championaerospace.com

www.unisonindustries.com

www.skytecair.com

www.precisionairmotive.com

www.aeroaccessories.com

www.kellyaerospace.com

Abbreviations

A list of abbreviations used in this manual is

shown in Table 01-00-00.1 below.

© March 2005 Superior Air Parts Inc.

1

01-00-00

Introduction

Page 16

Overhaul Manual

O-360 and IO-360 Series Engines

Table 01-00-00.1 • Abbreviations

Abbreviation Definition

AMS Aerospace Material Standard

Assy Assembly

BTC / BTDC Before Top Center / Before Top Dead Center

CHT Cylinder Head Temperature

DIA Diameter

F Fahrenheit

Fig. Figure

Ft-Lb Foot-Pounds

IAW In Accordance With

I.D. Inside Diameter

In-Lb Inch-Pounds

Lb Pounds

No. Number

NPT National Pipe Thread

O.D. Outside Diameter

Oz. Ounce

P/N Part Number

Prop Propeller

PSI Pounds per Square Inch

RPM Revolutio ns Per Minute

SAE Society of Automotive Engineers

TIR Total Indicator Reading

UNF Unified National Fine

° Degree

© March 2005 Superior Air Parts Inc.

2

01-00-00

Introduction

Page 17

Overhaul Manual

O-360 and IO-360 Series Engines

Consumable Materials List

Refer to Table 01-00-00.2 below for consumable

materials used during repair of the Vantage O360 and IO-360 series engines.

Table 01-00-00.2 • Consumable Materials

Material Source

Acetone or Methyl Ethyl Ketone (MEK) Commercially Available

Assembly Grease – Lubriplate No. 105 Commercially Available

Cleaning Solvent Comm ercially Available

Copper Based Anti-seize, Fel-ProTM C5-A Commercially Available

Fuelube

Isopropyl alcohol Commercially Available

LoctiteTM 271, P/N 27183 Commercially Available

LoctiteTM No. 2 Gasket Sealant P/N 30514 Commercially Available

Lubricating Oil, SAE 10 Commercially Available

Lubricating Oil, SAE 50 Commercially Available

Mineral Oil (MIL-L-6082), SAE 50 weight Commercially Available

PermatexTM, P/N 27100 Commercially Available

PliobondTM #20 Commercially Available

Pre-Lube Mixture – approx. 15% pre-lubricant

(STPTM brand or equivalent) plus 85% SAE 50

straight weight mineral oil

Preservative oil mix (MIL-C-6529, type 1 plus

MIL-L-6082)

RTVTM 102 Silicon Sealant General Electric

Safety Wire (0.032) Type 304 Stainless Steel,

P/N MS20995 C32

Safety Wire (0.041) Type 304 Stainless Steel,

P/N MS20995 C41

SilasticTM 140 Sealant Commercially Available

Silk thread, size 00 (100% Silk) Commercially Available

STPTM High Viscosity Oil Treatment Commercially Available

TitesealTM No. 2 Gasket and Joint Compound

P/N T2-01

Phthalate resin-type enamel AMS3125C or

equivalent MIL-E-7729 Randolph Black (#303)

Toluene or equivalent AMS3180 (or equivalent

Federal Spec TT-T-548)

Zinc Chromate Primer Commercially Available

TM

NOTE:

Equivalent substitutes may be used.

Ohio Industrial Lubricants

Locally Prepared Mixture

Locally Prepared Mixture

Commercially Available

Commercially Available

Commercially Available

Commercially Available

Commercially Available

© March 2005 Superior Air Parts Inc.

3

01-00-00

Introduction

Page 18

Overhaul Manual

O-360 and IO-360 Series Engines

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

© March 2005 Superior Air Parts Inc.

4

01-00-00

Introduction

Page 19

Overhaul Manual

O-360 and IO-360 Series Engines

DESCRIPTION AND OPERATION

General Description

Superior Vantage Engines are four-cylinder,

horizontally opposed, air-cooled, direct drive

powerplants incorporating a wet sump, bottom

mounted induction, bottom exhaust with either

carbureted or port injected fuel systems.

Provisions exist for both front and rear mounted

accessories. All engine components will be

referenced as they are installed in the airframe.

Therefore, the “front” of the engine is the

propeller end and the “rear” of the engine is the

accessory mounting drive area. The oil sump is

on the “bottom” of the engine and the cylinder

shroud tubes are on the “top”. The terms “left”

and “right” are defined as being viewed from the

rear of the engine looking toward the front.

Cylinder numbering is from the front to the rear

with odd numbered cylinders on the right side of

the engine. The direction of crankshaft rotation

is clockwise as viewed from the rear of the

engine looking forward unless otherwise

specified. Accessory drive rotation direction is

defined as viewed from the rear of the engine

looking forward.

Continued Airworthiness

Vantage Engines discussed in this document

must be installed and operated in accordance

with the limitations, conditions and operating

procedures described in the Installation and

Operation Manual (SVIOM01). They must also

be maintained in accordance with this manual

and the applicable Overhaul Manual

(SVOHM01) and other Instructions for

Continued Airworthiness. The engine’s time

between overhaul (TBO) period is initially

defined as 1000 hours. A TBO extension

program is in process.

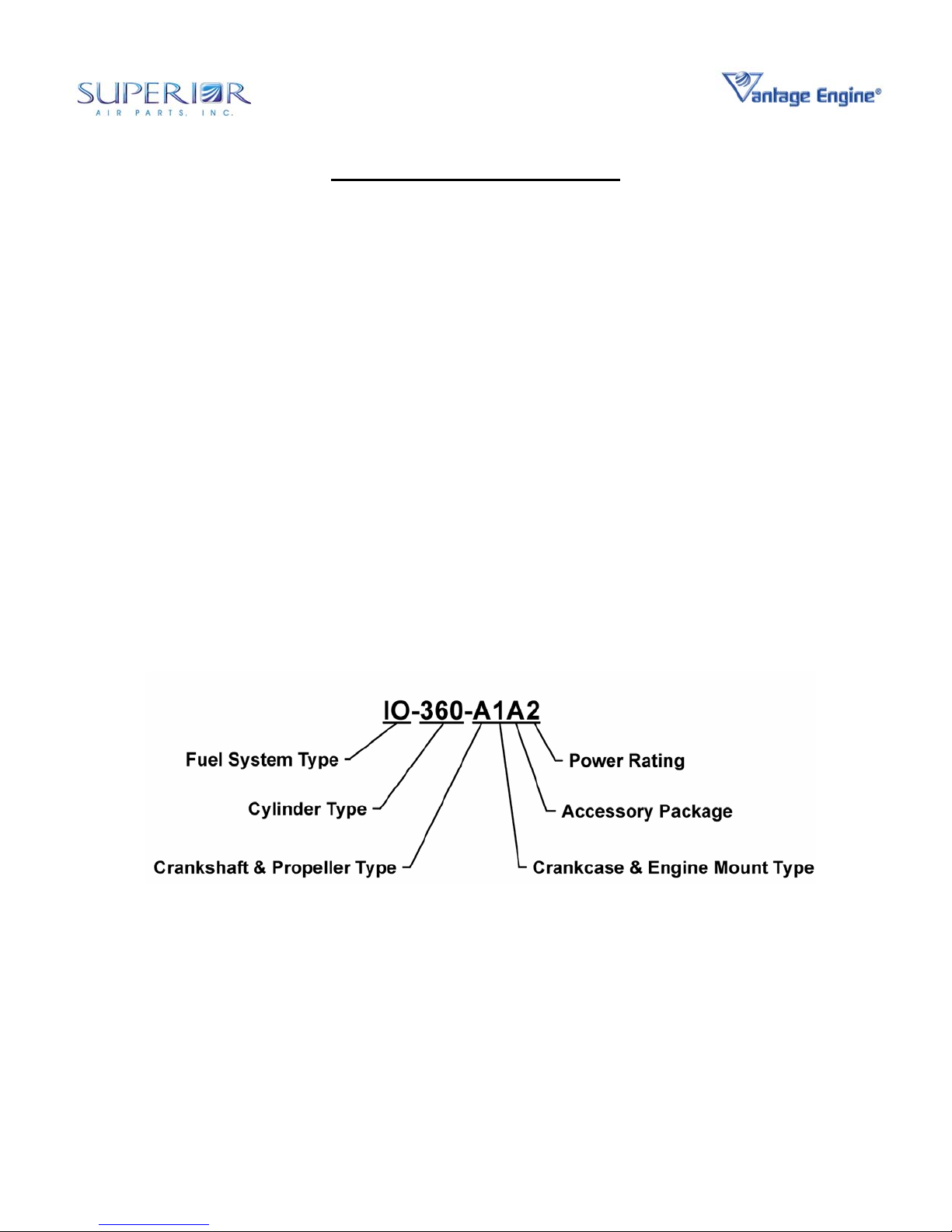

Model Designations

The model number designation is defined in a

way that the digits of the model number can

easily identify the basic configuration of the

engine as described in Figure 02-00-00.1.

Figure 02-00-00.1 • Engine Model Number Designation

© March 2005 Superior Air Parts Inc.

1

02-00-00

Description and Operation

Page 20

Overhaul Manual

O-360 and IO-360 Series Engines

Fuel System Type

IO Denotes Port Fuel Injection System and “opposed cylinder” arrangement.

O Denotes a carbureted system and “opposed cylinder” arrangement.

Cylinder Type

360 Parallel valve cylinder, 361 cubic inches.

Model Suffix

1st Digit Crankshaft & Propeller Type

A Fixed-Pitch, Thin-wall front main

B Constant-Speed, Thin-wall front main

D Constant-Speed, Heavy-wall front main

E Fixed-Pitch, Solid front main

2nd Digit Crankcase & Engine Mount Type

3rd Digit Accessory Package

4th Digit Power Rating: Piston Compression Ratio

Denotes detail engine configuration

C Fixed-Pitch, Heavy-wall front main

1 #1 Dynafocal Mount

2 #2 Dynafocal Mount

3 Conical Mount

Fuel System Ignition System

Carbureted (O-360) Fuel Injected (IO-360)

A Unison Magnetos Precision Carburetor Precision Fuel Injection

1* - 2 8.5:1 180

* For Future Use

Cylinder Type

360

CR HP

© March 2005 Superior Air Parts Inc.

2

02-00-00

Description and Operation

Page 21

Overhaul Manual

O-360 and IO-360 Series Engines

Engine Components General Description

The O-360 and IO-360 series engines are aircooled, four cylinder, horizontally opposed,

direct drive engines. See Table 02-00-00.1 for

Manufacturer’s General Specifications.

The complete engine includes the following

components and assemblies:

Crankcase Assembly

Crankshaft Assembly

Camshaft Assembly

Valve Train Assembly

Cylinder Assemblies

Connecting Rod Assemblies

Oil Sump Assembly

Intercylinder Baffles

Starter

Lubrication System (Includes Oil Filter)

Accessory Drive

Ignition System (Includes Spark Plugs)

Fuel System

Starter Support Assembly

Oil Gage

Induction System

Accessories

NOTE: Complete engine does not include outer

cylinder baffles, propeller governor, and airframe

to engine control cables, attaching hardware,

hose clamps, vacuum pump, exhaust system, or

fittings. Fuel pump is included, unless otherwise

specified, on carbureted engines. Alternator

may be included, if specified.

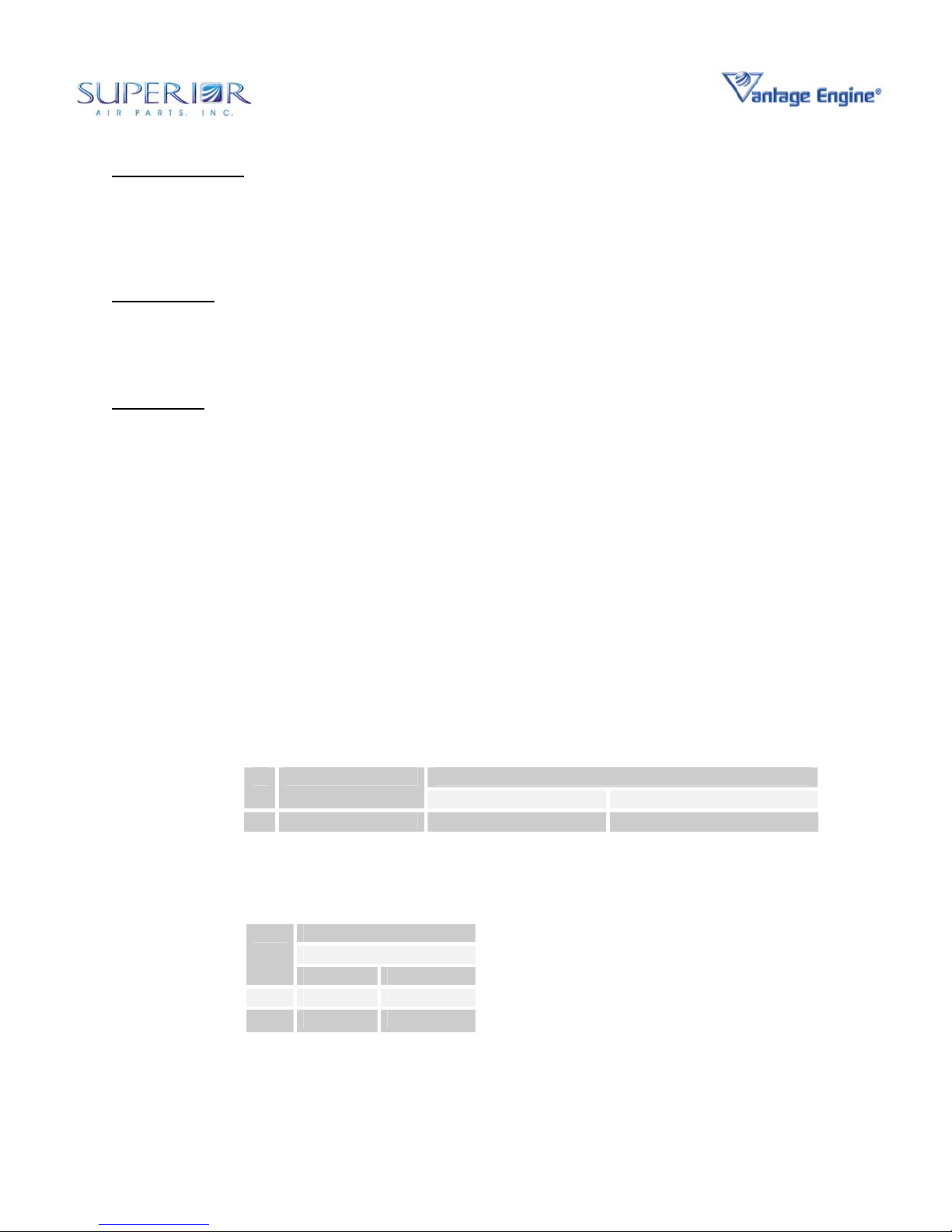

Specifications

The manufacturer’s physical specifications are

listed in Table 02-00-00.2 and are applicable to

the O-360 and IO-360 series engines.

Accessory Drive Specifications are provided in

Table 02-00-00.2 and is also applicable for both

O-360 and IO-360 models. Table 02-00-00.3

lists Physical Specifications for the engines and

Accessories are provided in Table 02-00-00.4.

The Model Specification Data (MSD) provides

more specific information by engine type and is

available from Superior Air Parts, Inc.

Illustrated views of the O-360 and IO-360

engines identifying key components and subassemblies are provided in Figures 02-00-00.1

thru 02-00-00.9 of this section and are listed

Table 02-00-00.5 for convenience. Figure 0200-00.10 illustrates the engine wiring diagram

and Figure 02-00-00.11 illustrates the oil system

schematic.

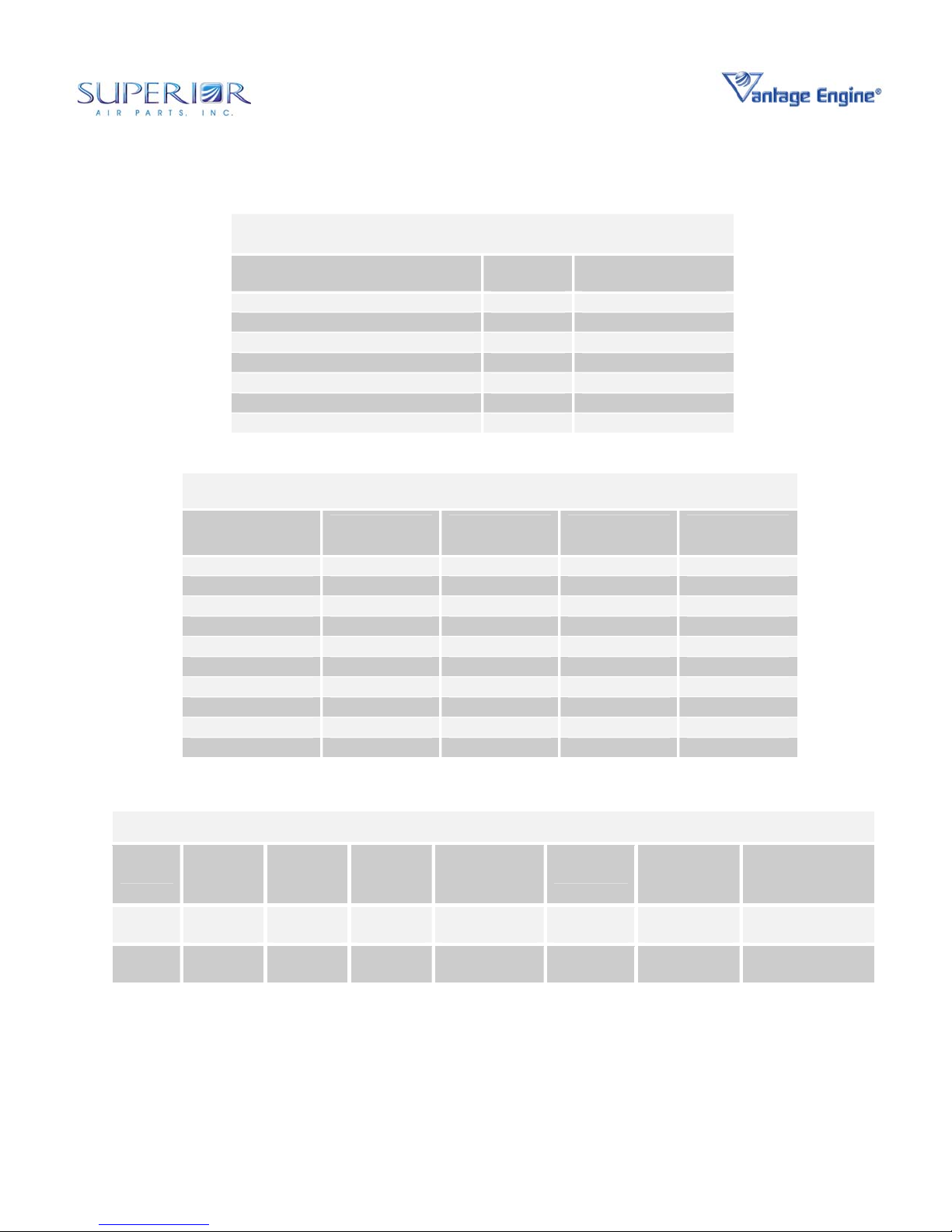

Table 02-00-00.1 • Manufacturer’s General Specifications

Model O-360 and IO-360

Rated Power Hp 180

Rated Speed, RPM RPM 2700

Bore, inches In 5.125

Stroke, inches In 4.375

Displacement cubic inches In

Compression Ratio 8.5:1

Firing Order 1-3-2-4

Spark timing °BTDC 25

Propeller drive ratio 1:1

Propeller drive rotation

(viewed from rear)

© March 2005 Superior Air Parts Inc.

3

3

361.0

Clockwise

02-00-00

Description and Operation

Page 22

Overhaul Manual

O-360 and IO-360 Series Engines

Table 02-00-00.2 • Accessory Drive Specifications

Accessory

Starter 16.556:1 Counter-Clockwise

Alternator (not included) 3.250:1 Clockwise

Tachometer 0.500:1 Clockwise

Magneto 1.000:1 Clockwise

Vacuum Pump (not included) 1.300:1 Counter-Clockwise

Propeller Governor (not included) 0.866:1 Clockwise

Fuel Pump (if furnished) 0.500:1 Plunger Operated

Table 02-00-00.3 • Manufacturer’s Physical Specifications

Model

O-360-Axxx 24.6 33.4 32.8 288

O-360-Bxxx 24.6 33.4 32.8 291

O-360-Cxxx 24.6 33.4 32.8 291

O-360-Dxxx 24.6 33.4 32.8 294

O-360-Exxx 24.6 33.4 32.8 295

IO-360-Axxx 24.0 33.4 32.8 290

IO-360-Bxxx 24.0 33.4 32.8 293

IO-360-Cxxx 24.0 33.4 32.8

IO-360-Dxxx 24.0 33.4 32.8 296

IO-360-Exxx 24.0 33.4 32.8 297

Height

(In)

Table 02-00-00.4 • Approved Engine Accessories

Drive

Ratio

Width

(In)

Direction of

Rotation

Length

(In)

Weight

(Lb)

293

Model

O-360

IO-360

© March 2005 Superior Air Parts Inc.

Left

Magneto

Unison

4371

Unison

4371

Right

Magneto

Unison

4371

Unison

4371

Fuel

System

Precision

MA-4-5

Precision

RSA-5

Fuel Pump

(if furnished)

Aero Acc.

AF15472

Aero Acc.

AF15473

4

Starter

SkyTec

149-12LS

SkyTec

149-12LS

Spark Plug

Harness

Unison

M4001

Unison

M4001

Alternator

(if furnished)

Kelly Aerospace

ALY8520LS

Kelly Aerospace

ALY8520LS

02-00-00

Description and Operation

Page 23

Overhaul Manual

O-360 and IO-360 Series Engines

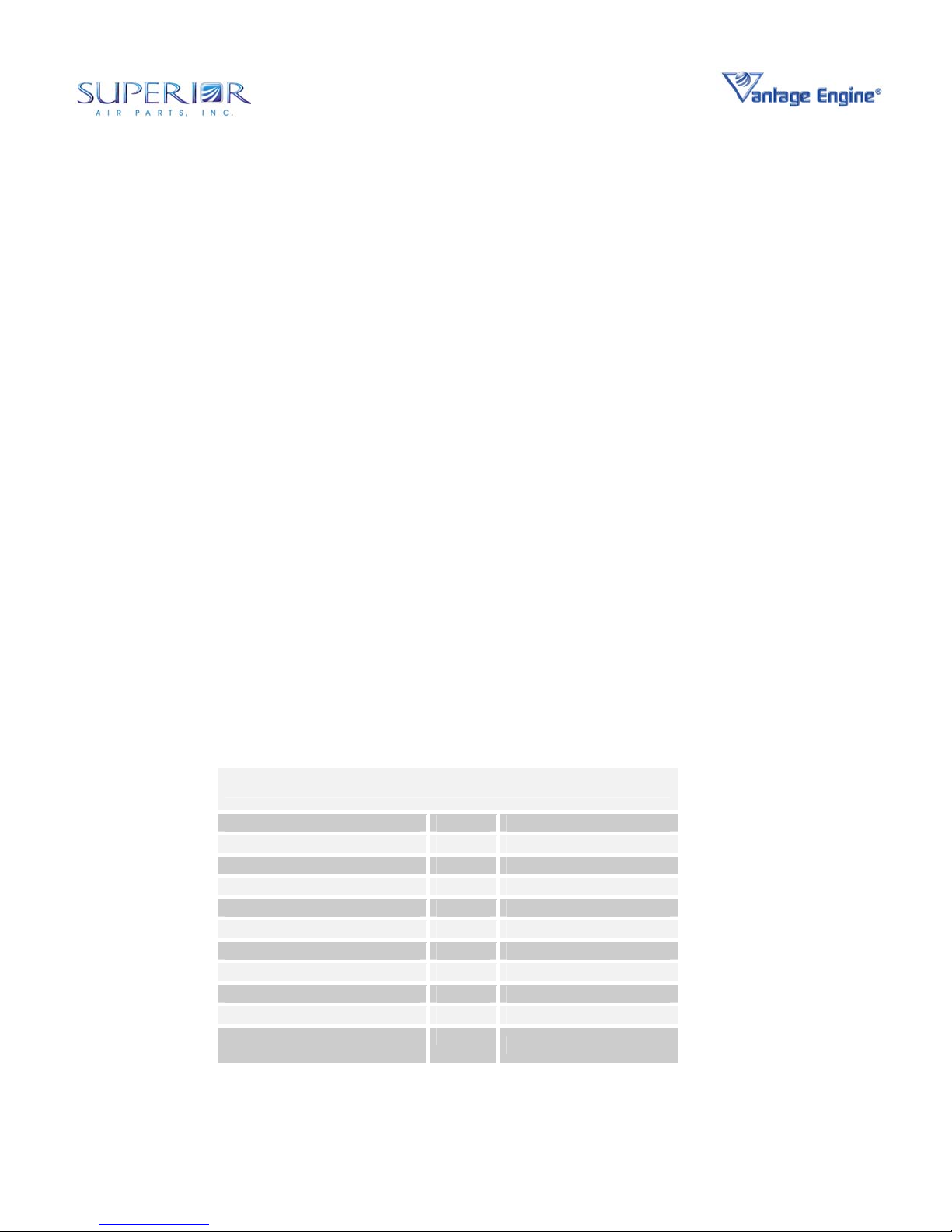

Table 02-00-00.5 • Illustrated Views of the Engine

Engine View Figure Number Location

O-360 Engine Front View Figure 02-00-00.2 p. 7

O-360 Engine Left Side View Figure 02-00-00.3 p. 8

O-360 Engine Top View Figure 02-00-00.4 p. 9

O-360 Engine Rear View Figure 02-00-00.5 p. 10

IO-360 Engine Front View Figure 02-00-00.6 p. 11

IO-360 Engine Left Side View Figure 02-00-00.7 p. 12

IO-360 Engine Top View Figure 02-00-00.8 p. 13

IO-360 Engine Rear View Figure 02-00-00.9 p. 14

Ignition Wiring Diagram Figure 02-00-00.10 p. 15

Oil System Schematic Figure 02-00-00.11 p. 16

© March 2005 Superior Air Parts Inc.

5

02-00-00

Description and Operation

Page 24

Overhaul Manual

O-360 and IO-360 Series Engines

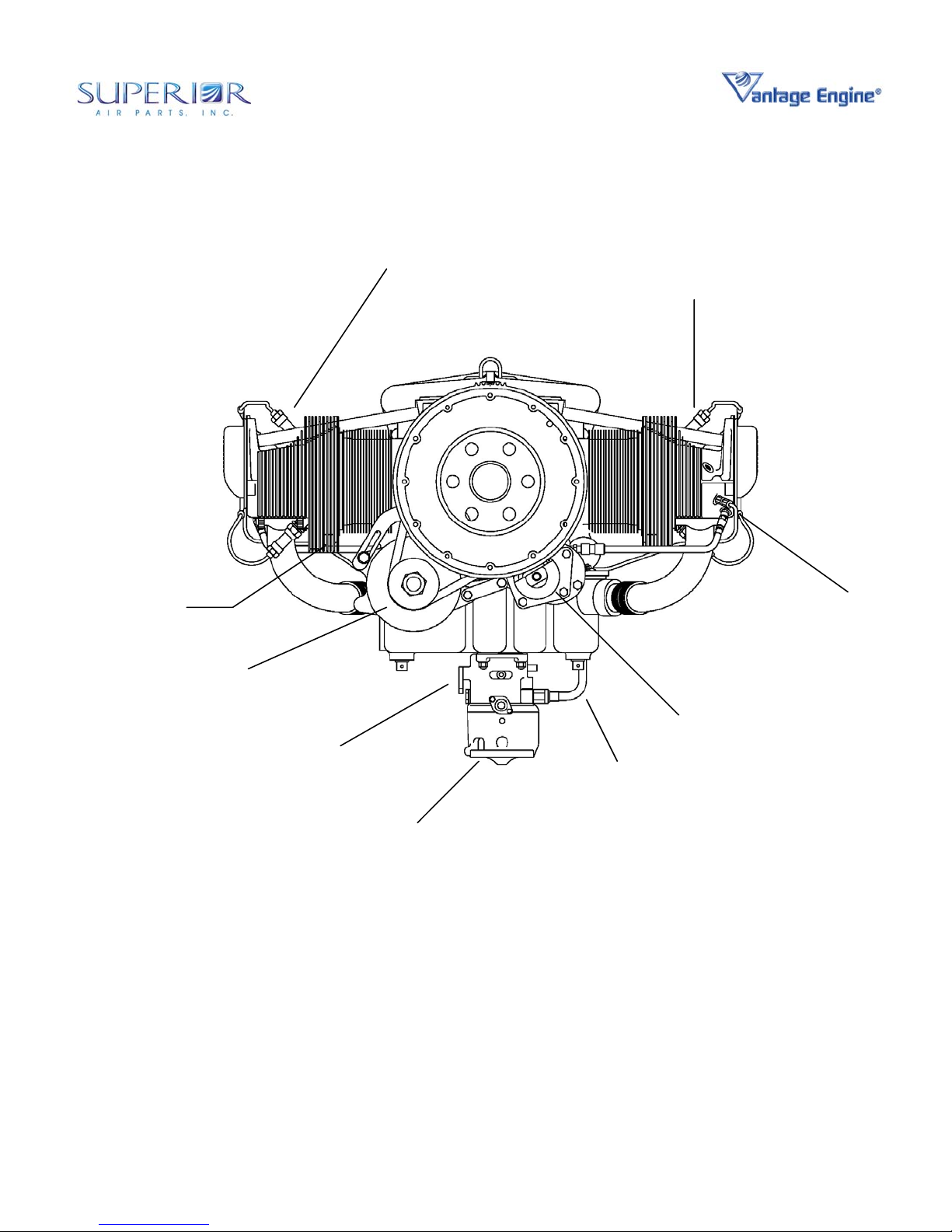

SPARK P LUG

SPARK PLUG

CHT PROBE LOCATION

(TYPICAL EACH HEAD)

ALTERNATOR & BELT NOT

PROVIDED WITH ENGINE

THROTTLE LEVER

FUEL LINE

CARBURETOR

Figure 02-00-00.2 • O-360 Engine Front View

STARTER

PRIMING

SYSTEM

© March 2005 Superior Air Parts Inc.

6

02-00-00

Description and Operation

Page 25

Overhaul Manual

O-360 and IO-360 Series Engines

CYLINDER

CRANKCASE

ASSEMBLY

ASSEMBLY

ACCESSORY

HOUSING

STARTER SUPPORT

ASSEMBLY

PRIMING

SYSTEM

STARTER

INDUCTION

SYSTEM

SPARK P L U G

OIL SUMP

ASSEMBLY

CARBURETOR

MIXTURE

LEVER

OIL FILTER

FUEL

PUMP

FUEL

LINE

HARNESS

MAGNETO

Figure 02-00-00.3 • O-360 Engine Side View

© March 2005 Superior Air Parts Inc.

7

02-00-00

Description and Operation

Page 26

Overhaul Manual

O-360 and IO-360 Series Engines

INTER-CYLINDER BAFFLE

SPARK P L U G

MAGNETO

OIL FILTER

Figure 02-00-00.4 • O-360 Engine Top View

8

© March 2005 Superior Air Parts Inc.

MAGNETO

02-00-00

Description and Operation

Page 27

Overhaul Manual

O-360 and IO-360 Series Engines

Figure 02-00-00.5 • O-360 Engine Rear View

© March 2005 Superior Air Parts Inc.

9

02-00-00

Description and Operation

Page 28

Overhaul Manual

O-360 and IO-360 Series Engines

FUEL INJECTION

MANIFOLD

CHT PROBE LOCATION

(TYP ICAL EAC H H EAD)

NOT PROVIDED WITH ENGINE

SPARK PLUG

ALTERNATOR & BELT

STARTER

SPARK PLUG

FUEL

INJECTOR

Figure 02-00-00.6 • IO-360 Engine Front View

© March 2005 Superior Air Parts Inc.

FUEL INJECTION

SERVO

10

02-00-00

Description and Operation

Page 29

Overhaul Manual

O-360 and IO-360 Series Engines

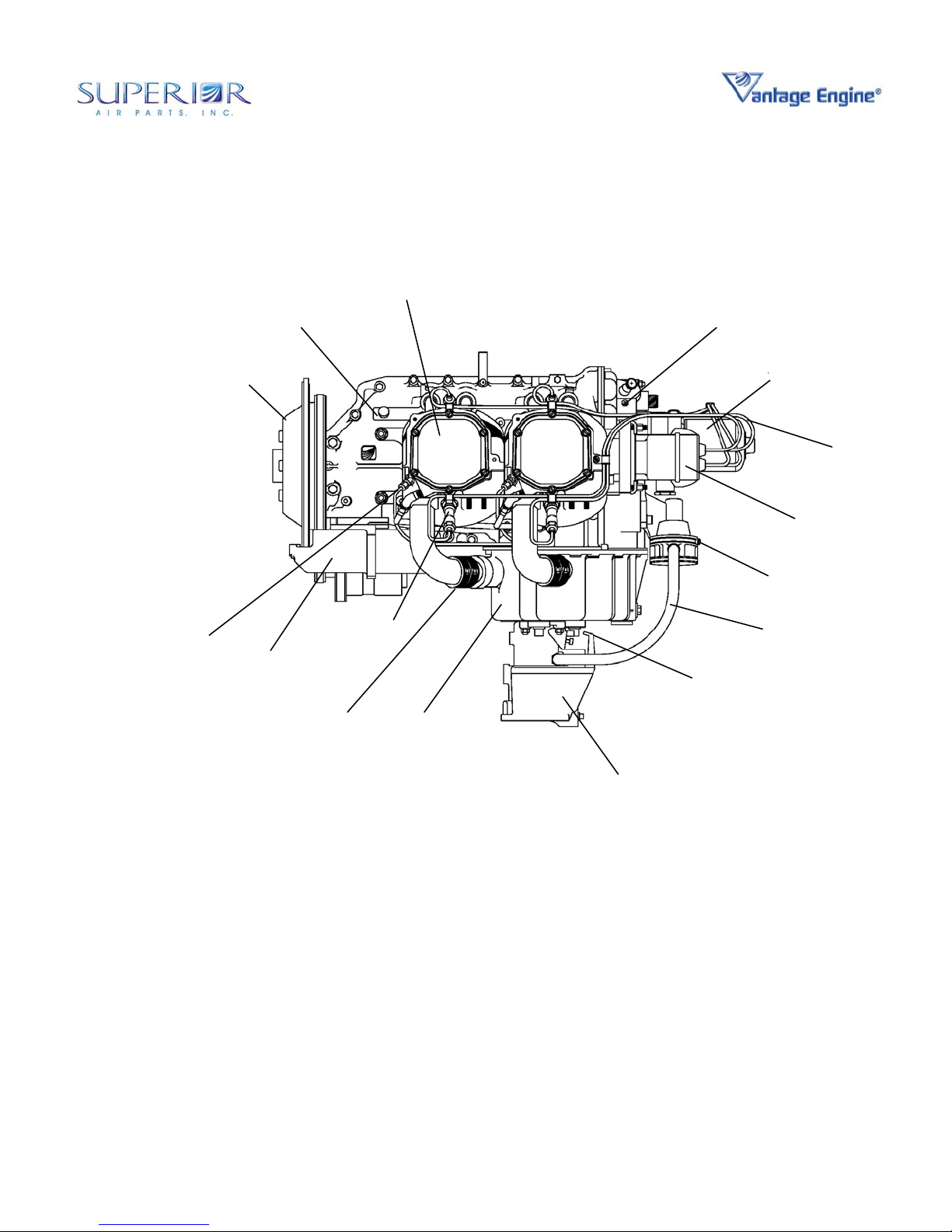

STARTER SUPPORT

ASSEMBLY

CRANKCASE

ASSEMBLY

STARTER

SPARK PLUG

OIL SUMP

CYLINDER

ASSEMBLY

FUEL INJECTION

MANIFOLD

ACCESSORY

FUEL INJECTION

SERVO

HOUSING

FUEL LINE

OIL FILTER

WIRING

HARNESS

MAGNETO

FUEL PUMP

Figure 02-00-00.7 • IO-360 Engine Left Side View

© March 2005 Superior Air Parts Inc.

11

02-00-00

Description and Operation

Page 30

Overhaul Manual

O-360 and IO-360 Series Engines

FUEL INJECTION

MANIFOLD

FUEL INJ ECTIOR

Figure 02-00-00.8 • IO-360 Engine Top View

© March 2005 Superior Air Parts Inc.

12

02-00-00

Description and Operation

Page 31

Overhaul Manual

O-360 and IO-360 Series Engines

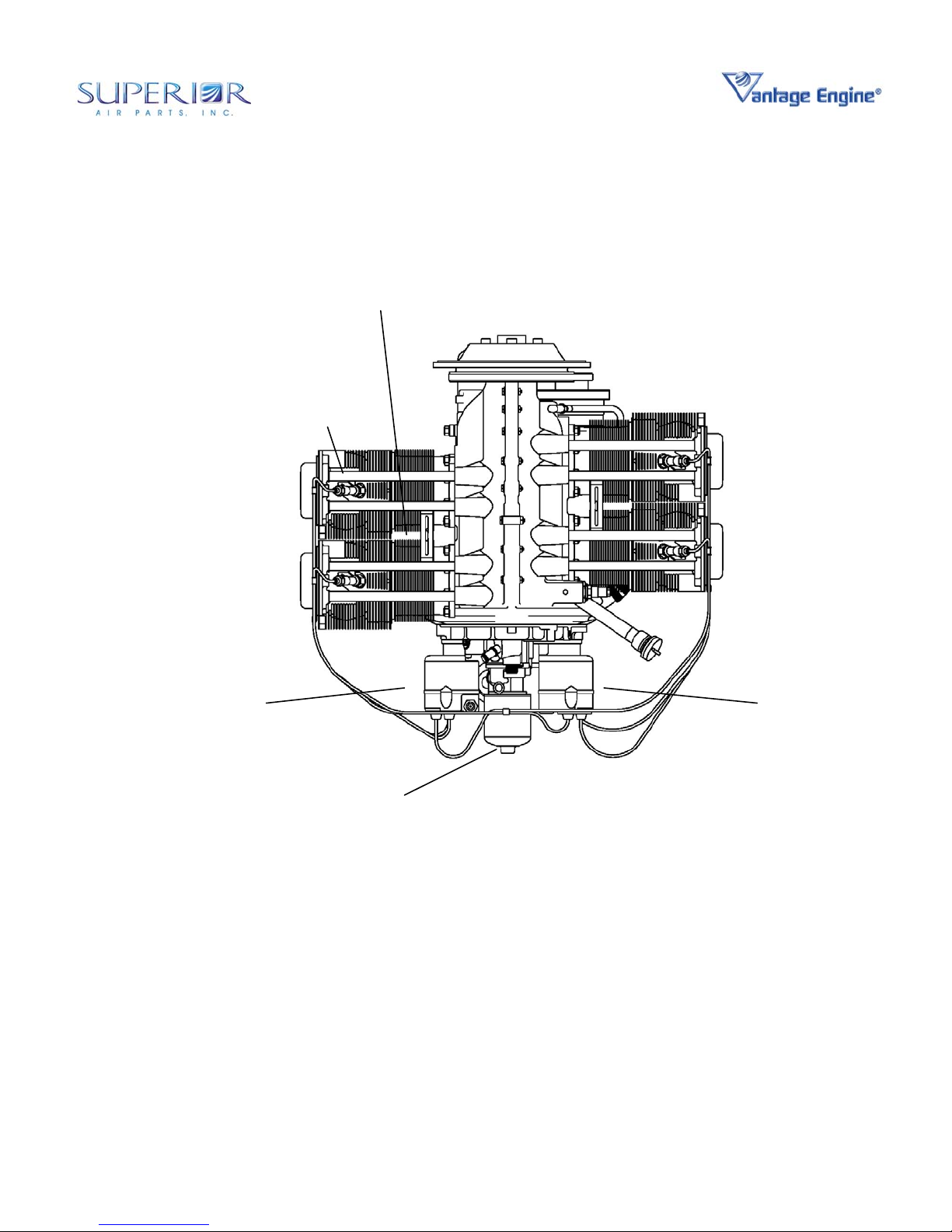

Figure 02-00-00.9 • IO-

© March 2005 Superior Air Parts Inc.

360 Engine Rear View

13

02-00-00

Description and Operation

Page 32

Overhaul Manual

O-360 and IO-360 Series Engines

Figure 02-00-00.10 • Ignition Wiring Diagram

© March 2005 Superior Air Parts Inc.

14

02-00-00

Description and Operation

Page 33

Overhaul Manual

O-360 and IO-360 Series Engines

Figure 02-00-00.11 • Oil System Schematic

© March 2005 Superior Air Parts Inc.

15

02-00-00

Description and Operation

Page 34

Overhaul Manual

O-360 and IO-360 Series Engines

Features and Operating Mechanisms

Crankshaft - The crankshaft is made from high

quality, aerospace grade steel. All bearing

journal surfaces are nitrided. There are 3 kinds

of crankshafts: thin-wall, thick-wall, and solid

front mains which can be identified by looking at

the center of the front of the crankshaft or prop

oil cavity. The thin-wall and thick-wall

crankshafts are each available as fixed-pitch or

constant-speed. Fixed-pitch versions have a

plug installed in the inner diameter of the front

main, or prop oil, cavity which prevents escape

of oil out the front, since there isn’t a prop

governor or constant-speed prop for the oil

pressure to act upon.

Cylinders - Millennium

exclusively. These air-cooled cylinders are

manufactured by screwing and shrinking the two

major parts, head and barrel, together. The cast

heads are made from a special aluminum alloy.

All barrels are made from forgings produced to

aerospace specifications. They are internally

choked and honed to allow optimal operating

conditions for the rings and pistons at operating

temperatures.

Pistons - The pistons are made from an

aluminum alloy. The piston pin is a full floating

type with a plug located in each end of the pin.

The piston is a 3-ring type with 2 compression

rings and 1 oil control ring.

®

Cylinders are used

Connecting Rods - The connecting rods are

made from aerospace grade, high quality steel.

They have replaceable bearing inserts in the

crankshaft ends and bronze bushings in the

piston ends. The bearing caps on the

crankshaft ends are retained by two bolts with

self locking nuts per cap. Caps are tongue and

groove type for improved alignment and rigidity.

Camshaft - Valve Operating Mechanism - The

camshaft is located above and parallel to the

crankshaft. The camshaft actuates hydraulic

lifters that operate the valves through pushrods

and valve rockers.

Crankcase - The crankcase is made from

aerospace grade, stabilized structural aluminum

alloy. The assembly consists of two reinforced

aluminum alloy castings fastened together by

means of studs, bolts, and nuts. The main

bearing bores are machined for use with

precision type main bearing inserts.

Accessory Housing - The accessory housing is

made from an aluminum casting and is fastened

to the rear of the crankcase and the top rear of

the sump.

Oil Sump - The sump incorporates an oil drain

plug, oil suction screen, mounting pad for

carburetor or fuel injector, the intake riser, and

intake pipe connections.

Cooling System – Superior Vantage Engines

are designed to be air-cooled. Baffles are

provided to build up air pressure and force the

air between the cylinder fins. The air is

exhausted to the atmosphere through the rear of

the cowling.

Induction System - The distribution of the air to

each cylinder is through the center zone of the

induction system. This is integral with the oil

sump.

Fuel Systems

Carbureted

are equipped with a float type carburetor The

MA-4-5 carburetors are of the single barrel float

type equipped with a manual mixture control and

an idle cut-off.

Fuel Injected

equipped with a direct cylinder injected RSA-5

fuel injector. The fuel injection system

schedules fuel flow in proportion to airflow. Fuel

vaporization takes place at the intake ports. The

RSA fuel injection system is based on the

principle of measuring airflow and using the air

pressure in a stem type regulator, converting the

air pressure into a fuel pressure. The fuel

pressure (fuel pressure differential), when

applied across the fuel metering section (jetting

system), makes fuel flow proportional to airflow.

- Superior Air Parts O-360 engines

- IO-360 series engines are

© March 2005 Superior Air Parts Inc.

16

02-00-00

Description and Operation

Page 35

Overhaul Manual

O-360 and IO-360 Series Engines

Lubrication System - The full pressure wet

sump lubrication system is supplied by a gear

type pump. It is contained within the accessory

housing.

Priming System - A manual primer system is

provided on all engines using a carburetor. Fuel

injected engines do not require a manual

priming system, relying instead on the fuel

injectors for priming.

Ignition System - Dual ignition is furnished by

two Unison magnetos with two spark plugs per

cylinder.

Electrical System – Engines may be furnished

with an alternator, if provided for in the model

specification. If an alternator is furnished,

installation brackets, hardware and belt are

provided. Alternators are available in either 12

or 24 volt systems and a range of amperages.

© March 2005 Superior Air Parts Inc.

17

02-00-00

Airworthiness Limitations

Page 36

Overhaul Manual

O-360 and IO-360 Series Engines

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

© March 2005 Superior Air Parts Inc.

18

02-00-00

Airworthiness Limitations

Page 37

Overhaul Manual

O-360 and IO-360 Series Engines

AIRWORTHINESS LIMITATIONS

The Airworthiness Limitations Section is FAA

approved and specifies maintenance required

under sections 43.16 and 91.403 of the Federal

Aviation Regulations unless an alternate

program has been FAA approved. This section

is part of the type design of the O-360 and IO360 engine series pursuant to certification

requirements of the Federal Aviation

Regulations.

Mandatory Replacement Time

Subject to additional information contained in

FAA Approved Mandatory Service Bulletins

issued after the date of certification, the O-360

and IO-360 engine series do not contain any

components having mandatory replacement

times required for type certification.

Mandatory Inspection Intervals

Subject to additional information contained in

FAA Approved Mandatory Service Bulletins

issued after the date of certification, the O-360

and IO-360 engine series do not contain any

components having mandatory inspection

intervals other than 100 and 500 hour

inspections of magnetos as required by Unison

Slick Service Bulletin SB2-80C.

Other Mandatory Intervals or Procedures

Subject to additional information contained in

FAA Approved Mandatory Service Bulletins

issued after the date of certification, the O-360

and IO-360 engine series do not have any

inspection-related or replacement time-related

procedures required for type certification.

Distribution of Changes to Airworthiness

Limitations

Changes to this Airworthiness Limitations

Chapter constitute changes to the type design of

the O-360 and IO-360 engine series and require

FAA approval pursuant to Federal Aviation

Regulations. Such changes will be published in

FAA Approved Mandatory Service Bulletins.

Superior Vantage Engine Service Bulletins may

be obtained by writing to:

Superior Air Parts

621 South Royal Lane, Suite 100

Coppell, Texas 75019

or call: 972-829-4600

or on the web at www.superiorairparts.com

© March 2005 Superior Air Parts Inc.

1

04-00-00

Airworthiness Limitations

Page 38

Overhaul Manual

O-360 and IO-360 Series Engines

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

© March 2005 Superior Air Parts Inc.

2

04-00-00

Airworthiness Limitations

Page 39

Overhaul Manual

O-360 and IO-360 Series Engines

TESTING AND FAULT ISOLATION

General

This section provides the Fault Isolation

procedures. Review all probable causes given.

The engine electrical diagram and engine oil

system schematic are provided as an additional

aid in determining probable cause. Testing is

limited to continuity checks of the ignition wiring

harness.

Table 72-00-03.1 • Special Tools and Equipment

Item Vendor

Electrical Tester Commercially Available

Table 72-00-03.2 • Abnormal Operating Procedures

Special tools and equipment are listed in

•

Table 72-00-03.1.

•

The Fault Isolation procedures are listed in

Table 72-00-03.2.

•

The engine ignition diagram is provided in

Figure 02-00-00.10.

•

The engine oil system is provided in Figure

02-00-00-11.

Symptom Table

Engine will not start 72-00-03.3

Rough Idling 72-00-03.4

Engine Not Able to Develop Full Power 72-00-03.5

Rough Engine Operation 72-00-03.6

Low Power and Engine Runs Rough 72-00-03.7

Low Oil Pressure On Engine Gage 72-00-03.8

High Oil Temperature 72-00-03.9

Excessive Oil Consumption 72-00-03.10

Troubleshooting

WARNING

ENGINE WITHOUT A PRELIMINARY

EXAMINATION CAN CAUSE FURTHER

DAMAGE TO A DISABLED COMPONENT

AND POSSIBLE INJURY TO PERSONNEL.

MAKE SURE THOROUGH INSPECTION AND

TROUBLESHOOTING PROCEDURES ARE

ACCOMPLISHED. THIS WILL HELP TO

PREVENT INJURIES TO PERSONNEL

AND/OR DAMAGE TO THE EQUIPMENT.

WARNING

EYES AND SKIN. PUT ON SPLASH

GOGGLES, INSULATED GLOVES, AND

OTHER PROTECTIVE GEAR. IN CASE OF

EYE CONTACT, FLUSH WITH WATER FOR

15 MINUTES AND SEEK MEDICAL

ATTENTION. IN CASE OF SKIN CONTACT,

WASH WITH SOAP AND WATER.

: OPERATION OF A DEFECTIVE

: HOT OIL MAY CAUSE BURNS TO

WARNING

FLAMMABLE. DO NOT BREATHE VAPORS.

USE IN A WELL-VENTILATED AREA FREE

FROM SPARKS, FLAME, OR HOT

SURFACES. PUT ON SPLASH GOGGLES,

SOLVENT-RESISTANT GLOVES, AND

OTHER PROTECTIVE GEAR. IN CASE OF

EYE CONTACT, FLUSH WITH WATER FOR

15 MINUTES AND SEEK MEDICAL

ATTENTION. IN CASE OF SKIN CONTACT,

WASH WITH SOAP AND WATER.

NOTE

: FUEL IS TOXIC AND

: The Fault Isolation sequence is in order of

approximate ease of checking, not

necessarily in order of probability.

© March 2005 Superior Air Parts Inc.

1

72-00-03

Testing and Fault Isolation

Page 40

Overhaul Manual

O-360 and IO-360 Series Engines

Table 72-00-03.3 • Engine Will Not Start

Probable Cause Correction

No Fuel Fill with fuel

Excessive Priming Leave ignition "Off" and mixture control in "Idle

Cut-Off", open throttle and clear cylinders by

cranking a few seconds. Turn ignition switch

"On" and proceed to start.

Defective ignition wire Check with electric tester, and replace any

defective wires.

Dead battery Replace battery.

Malfunction of magneto breaker Clean points. Check internal timing of

magnetos

Lack of sufficient fuel flow Disconnect fuel line and check fuel flow

Water in fuel injector or carburetor Drain fuel injector or carburetor and fuel lines.

Internal failure Check oil screens for metal particles. If found,

complete overhaul of the engine may be

required.

Table 72-00-03.4 • Rough Idling

Probable Cause Correction

Incorrect idle mixture Adjust mixture

Leak in the induction system Tighten all connections in the induction system.

Replace any damaged parts.

Incorrect idle adjustment Adjust throttle stop to obtain correct idle.

Uneven cylinder compression Check condition of piston rings and valve seats

Faulty ignition system Check entire i gnition system

Table 72-00-03.5 • Engine Not Able To Develop Full Power

Probable Cause Correction

Leak in the injection system Tighten all connections and replace damaged

parts.

Throttle lever out of adjustment Adjust throttle lever.

Improper fuel flow Check strainer, gage and flow at the fuel inlet.

Restriction in air scoop Examine air scoop and remove restrictions.

Improper fuel Drain and refill tank with proper fuel

Faulty ignition Tighten all connections. Check system with

tester. Check ignition timing.

Internal Timing Check rocker arm motion as engine is rotated

on nose stand.

© March 2005 Superior Air Parts Inc.

2

72-00-03

Testing and Fault Isolation

Page 41

Overhaul Manual

O-360 and IO-360 Series Engines

Table 72-00-03.6 • Rough Engine Operation

Probable Cause Correction

Broken engine mount Replace or repair mount.

Mounting bushings worn Install new mounting bushings.

Unstable compression Check compression.

Table 72-00-03.7 • Low Power & Engine Runs Rough

Probable Cause Correction

Mixture too rich; indicated by sluggish engine

operation, red exhaust flame at night. Extreme

cases indicated by black smoke from exhaust

Mixture too lean; indicated by overheating or

back firing

Leaks in induction system Tighten all connections. Replace damaged

Defective spark plugs Clean and gap or replace spark plugs.

Improper fuel Drain and refill tank with proper grade.

Magneto breaker points not working properly Clean points. Check internal timing of

Defective ignition wire Check wire with electric tester. Replace

Defective spark plug terminal connectors Replace connectors on spark plug wire.

Readjustment of fuel injector or carburetor may

be required by authorized personnel.

Check fuel lines for dirt or other restrictions.

Readjustment of fuel injector or carburetor may

be required by authorized personnel.

parts.

magnetos.

defective wire.

Table 72-00-03.8 • Low Oil Pressure On Engine Gage

Probable Cause Correction

Lack of oil Add to proper level.

Air lock or dirty relief valve Clean relief valve.

Leak in line Inspect gasket between accessory housing and

crankcase.

High oil temperature See Table 72-00-03.9, “High Oil Temperature”.

Defective pressure gage. Replace defective gage.

Stoppage in oil pump intake passage Check line for obstruction. Clean suction

strainer.

3

© March 2005 Superior Air Parts Inc.

Testing and Fault Isolation

72-00-03

Page 42

Overhaul Manual

O-360 and IO-360 Series Engines

Table 72-00-03.9 • High Oil Temperature

Probable Cause Correction

Insufficient air cooling Che c k air inlet and outlet for deformation or

obstruction.

Insufficient oil supply Fill to proper level with specified oil.

Low grade of oil Replace with oil conforming to specifications.

Clogged oil lines or strainers Remove and clean oil strainers.

Excessive blow-by Check condition of engine rings. Replace if worn

or damaged.

Failing or failed bearing Examine sump for metal particles. If found,

engine overhaul may be required.

Defective temperature gage Replace gage.

Table 72-00-03.10 • Excessive Oil Consumption

Probable Cause Correction

Low grade of oil Fill tank with oil of proper weight and grade.

Failing or failed bearings Check sump oil for metal particles.

Worn piston rings Install new rings.

Incorrect installation of piston rings I nstall new rings.

Failure of rings to seat on new cylinders Use mineral base oil. Climb to cruise altitude at

full power and operate at 75% cruise power

setting until oil consumption stabilizes. See

Break-In Procedures, Special Procedures

Section of this manual.

Oil siphoned from engine in flight Insure that oil filler cap is tight and that o-ring is

in good condition. Insure that breather hose exit

is cut and located to avoid creating a vacuum in

the breather hose.

© March 2005 Superior Air Parts Inc.

4

72-00-03

Testing and Fault Isolation

Page 43

Overhaul Manual

O-360 and IO-360 Series Engines

SPECIAL PROCEDURES

General Break-In Procedures

This section provides the Break-In Procedures

to achieve satisfactory ring seating and long

cylinder life. On all new Vantage engines, after

top overhaul or major engine overhaul, break-in

is critical.

NOTE

: Refer to the engine warranty. Violation

of these procedures will void the

engine's warranty.

Special Tools and Equipment

•

Standard aviation shop tools are required.

•

Engine test stand.

•

The aircraft can be a suitable test stand for

running-in cylinders.

Break-In Procedures

WARNING

ENGINE WITHOUT A PRELIMINARY

EXAMINATION CAN CAUSE FURTHER

DAMAGE TO A DISABLED COMPONENT

AND POSSIBLE INJURY TO PERSONNEL.

MAKE SURE THOROUGH INSPECTION AND

TROUBLESHOOTING PROCEDURES ARE

ACCOMPLISHED. THIS WILL HELP TO

PREVENT INJURIES TO PERSONNEL

AND/OR DAMAGE TO THE EQUIPMENT.

Prior to Break-In Start-Up

•

Engine oil sump should be filled with 100%

straight weight mineral oil. Use MIL-L-6082,

specific grade depending on ambient

temperature. Refer to chapter 72-00-13 for

fluid requirements.

•

Engine must be pre-oiled and oil pressure

obtained prior to start-up.

•

To pre-oil an engine, do the following:

1. Attach pressure-oiling equipment to one

2. Engine baffles and seals must be in

3. Verify accuracy of instruments required

: OPERATION OF A DEFECTIVE

end of the main gallery and force oil

through the galley at 35 psi until oil flows

from the opposite galley with the plug

removed from the front end of the

opposite galley.

good condition and properly installed.

for engine operation.

CAUTION

: BREAK-IN OF AN ENGINE IN

FRIGID CONDITIONS CAN LEAD TO

CYLINDER GLAZING AND FAILED BREAK-IN

DUE TO LOW OIL TEMPERATURE. IT IS

RECOMMENDED THAT OIL TEMPERATURE

BE MAINTAINED BETWEEN 180° AND 190°F.

Break-In Ground Run

Flight propeller may be used if test club is

•

not available.

•

Head aircraft into the wind.

•

Start engine and observe oil pressure. Oil

pressure should be indicated within 30

seconds. If this does not occur, shut down

engine and determine cause.

•

Run engine just long enough to confirm all

components are properly adjusted and

secured. There must be no fuel and/or oil

leaks.

•

Install cowling.

•

Operate engine at 1000 -1200 RPM until oil

has reached minimum operating

temperature 120 °F.

•

Check magneto drop at normal RPM.

•

If engine is equipped with a controllable

pitch propeller, cycle only to a 100 RPM

drop.

•

Shut down engine and check for fuel and/or

oil leaks and repair any discrepancies.

•

At no time should cylinder head temperature

be allowed to exceed recommended

maximum cruise limit of 430°F.

Break-In Flight Operation

•

Perform normal pre-flight and run-up in

accordance with the Installation and

Operation Manual, SVIOM01 (remember:

cycle controllable pitch prop to only a 100

RPM drop). Keep ground runs to a

minimum.

•

Conduct normal take-off at full power, full

rich mixture, to a safe altitude.

NOTE:

In certain geographic locations and

weather conditions (eg; high density

altitudes) “Full Rich” operation may

not be practical. In this event,

substitute the requirement of “Full

Rich” as discussed in this chapter with

the “richest practical setting”.

© March 2005 Superior Air Parts Inc.

1

72-00-04

Special Procedures

Page 44

Overhaul Manual

O-360 and IO-360 Series Engines

NOTE

: Verify the crankcase breather and vent

lines are correctly installed and

positioned. Excessive oil discharge

through the breather can often be

directly related to an improperly installed

or restricted breather line.

•

Maintain shallow climb. Use caution to not

overheat the cylinders. Should overheating

occur, reduce power and adjust mixture

appropriately.

•

Monitor RPM, oil pressure, oil temperature

and cylinder temperature.

•

During the first hour of operation, maintain

level flight at 75% power. Vary the power

setting every 15 minutes during the second

hour between 65-75%.

•

Avoid long descents at cruise RPM and low

manifold pressure (could cause ring flutter).

•

Continue flying at 65-75% power and full

rich mixture on subsequent flights, while

monitoring RPM, Oil Pressure, Oil

Temperature, Cylinder Head Temperature

and oil consumption. Continue until oil

consumption stabilizes and cylinder head

temperatures drop (and stabilize). These

are indications that the piston rings have

seated and the cylinders are broken in.

•

At no time should cylinder head temperature

be allowed to exceed recommended

maximum cruise limit 430°F.

•

After landing, check again for any fuel

and/or oil leaks, or other discrepancies, and

repair as required.

Post Break-In Procedures

•

After break-in, drain all mineral oil. Examine

this oil for foreign matter or metal particle

content.

•

Fill with ashless dispersant of the

appropriate grade for the expected normal

operating conditions and ambient

temperature.

© March 2005 Superior Air Parts Inc.

2

72-00-04

Special Procedures

Page 45

Overhaul Manual

O-360 and IO-360 Series Engines

ENGINE REMOVAL

General

This section contains engine removal

procedures.

Equipment and Materials to accomplish removal

procedures are listed in Table 72-00-05.1.

NOTE:

Removal

• Remove the engine from the airframe as

NOTE:

•

•

•

•

•

•

•

•

•

•

•

•

NOTE: Standard aviation shop tools

are required.

Table 72-00-05.1

Equipment and Materials List

Item Vendor

Engine Stand

Engine Hoist

Protective Covers for

Open Lines or Ports

Commercially

Available

Commercially

Available

Commercially

Available

follows:

Identify each item as the item is

disconnected from the engine to aid in

reinstallation.

Turn all cockpit switches and fuel selector

valves to OFF.

Remove aircraft cowling as required.

Disconnect the battery ground cable.

Disconnect the start cable.

Remove engine baffles as required.

Remove air intake ducting and heat ducting

as required.

Remove engine exhaust system as required.

Disconnect and remove the “B” nuts from

the spark plugs.

Tag and disconnect the engine wiring

bundles from all applicable components.

Remove all clamps attaching engine wire

bundles to engine components and route

bundles clear of the engine.

Drain the engine oil from the sump. Replace

drain plug and tighten.

Remove propeller in accordance with the

airframe manufacturer’s instructions.

•

Consult the airframe manufacturer for

engine to airframe connections.

WARNING

: PLACE A SUITABLE STAND

UNDER THE AIRCRAFT TAILCONE IF

NEEDED BEFORE REMOVING THE ENGINE.

THE LOSS OF WEIGHT MAY CAUSE THE

AIRCRAFT TAIL TO DROP.

•

Attach a hoist to the engine lifting eye

bracket and relieve the weight from the

engine mounts. Only the lifting eye bracket

installed on the backbone of the crankcase

should be used to hoist the engine.

•

Remove the engine mounts and engine as

follows:

1. Loosen and remove the engine mounts

bolts in accordance with manufacturer’s

instructions.

2. Hoist the engine vertically out of the

nacelle and clear of the aircraft.

NOTE:

Hoist the engine slowly and make sure

that all wires, lines, and hoses have

been disconnected.

3. Install the engine onto a transportation

stand, dolly, or an engine shipping

container base.

•

Install protective covers/plugs on any

remaining open fuel, oil/hydraulic lines, and

electrical leads and exhaust ports.

Preservation

•

If the engine is to be stored for longer than

30 days, refer to the Preservation and

Storage section of this manual for

procedures and materials.

© August 2004 Superior Air Parts Inc.

1

72-00-05

Engine Removal

Page 46

Overhaul Manual

O-360 and IO-360 Series Engines

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

© March 2005 Superior Air Parts Inc.

2

72-00-05

Engine Removal

Page 47

Overhaul Manual

O-360 and IO-360 Series Engines

DISASSEMBLY

General

This section contains disassembly procedures.

When necessary, disassembly illustrations are

also provided. All item number references in the

text are specific to this manual and the figures

cited.

Table 72-00-06.1 • Disassembly Materials

Description Source

Penetrating Oil Commercially Available

Parts for Discard

Parts to be discarded are listed in Table 72-00-06.2.

Table 72-00-06.2 • Discard Parts

Disassembly Materials

The materials required for disassembly are listed

in Table 72-00-06.1.

NOTE:

Equivalent substitutes may be used.

Nomenclature

All Engine Oil, Air and Fuel Hoses

Gaskets, Oil Seals, and O-Rings

Bearing Inserts (Connecting Rod and Crankshaft)

Piston Rings and Piston Pins

Stressed Bolts and Fasteners

Intake and Exhaust Valves, Valve Guides and Valve Keepers

Crankshaft Gear Attaching Bolt

Connecting Rod Nuts and Bolts

All Lockwashers, Circlips, Retaining Rings, Locktabs and Locknuts

Counterweight Bushings in Crankshaft and Counterweights (if applicable)

Counterweight Washers (if applicable)

Vermatherm (Oil Temperature Bypass Valve)

Special Tools and Equipment

Special tools and equipment required for

disassembly are listed in Table 72-00-06.3.

NOTE:

Standard reciprocating engine aviation

shop tools and equipment are used

unless otherwise specified.

© March 2005 Superior Air Parts Inc.

1

72-00-06

Engine Disassembly

Page 48

Overhaul Manual

O-360 and IO-360 Series Engines

Table 72-00-06.3 • Special Tools and Equipment

Nomenclature Source

Compressor, Piston Ring Commercially Available

Expander, Piston Ring Commercially Available

Puller, Slide Hammer-Medium Commercially Available

Compressor, Valve Spring Bar Commercially Available

Intercylinder Baffle Tool Commercially Available

Puller, Valve Guide Commercially Available

Puller Set, Oil Seal Commercially Available

Stand, Vertical Nose Support Commercially Available

Tool, Hydraulic Tappet Removal Commercially Available

General Disassembly Procedures

• Place engine in horizontal position on a

transfer cart.

WARNING

: ENGINE OIL IS HAZARDOUS

AND MAY CAUSE INJURY TO SKIN AND

EYES. PUT ON PERSONNEL PROTECTIVE

GEAR.

Remove the oil drain plug and drain the oil

•

from the engine, if not previously drained.

•

Remove the starter ring gear support.

•

Perform visual inspection during

disassembly and immediately after

disassembly. All individual parts should be

laid out in an orderly manner as they are

removed.

•

All loose studs, cracked baffles, and loose or

damaged fittings should be tagged to

prevent being overlooked during regular

inspection.

•

Tag all components and parts as they are

removed. Bag loose assemblies or attaching

hardware.

•

Prior to starting the component or parts

disassembly phase, engine may be placed

on a vertical nose support stand.

Disassembly

WARNING

: FUEL IS TOXIC AND

FLAMMABLE. DO NOT BREATHE VAPORS.

AVOID EYE AND SKIN CONTACT. USE

PROTECTIVE GEAR. IN CASE OF EYE

CONTACT, FLUSH WITH WATER FOR 15

MINUTES AND SEEK MEDICAL ATTENTION.

IN CASE OF SKIN CONTACT, WASH WITH

SOAP AND WATER.

WARNING

: PUT ON SAFETY GOGGLES

WHEN INSTALLING OR REMOVING SAFETY

WIRE.

Removal of Carburetor and Priming System

(1) Remove engine fuel lines (30, Figure

72-00-09.37) and all attaching

hardware.

(a) Remove engine fuel priming system

attaching hardware clamps, (25, 30,

45 Figure 72-00-09.36) screws (35)

and nuts, (40). Disconnect tube (1,

5, 10, 15) coupling nuts at cylinder

head and attaching tee tubes (20).

(2) Remove the carburetor on O-360 series

engines as follows.

(a) Remove nuts (1, Figure 72-00-

09.37), lockwashers (2) and flat

washers (3) from studs four places.

(b) Remove carburetor (7) from studs

and discard gasket (4).

(c) Remove elbow (5) and discard o-

ring (6).

© March 2005 Superior Air Parts Inc.

2

72-00-06

Engine Disassembly

Page 49

Overhaul Manual

O-360 and IO-360 Series Engines

Fuel injection system removal

(1) Remove engine fuel injection manifold

tubing clamps (70, 75 Figure 72-00-

09.39), nuts (85), and screws (80).

(2) Disconnect injector tubing (55, 60), eight

places at fittings (40), elbow (25), and

injector nozzle assembly (90). Re move

nozzle assemblies (90) four places.

(3) Remove fuel manifold bracket (1)

retaining nuts, washers, (5) and bolts

(10). Remove manifold (15) retaining

bolts (25) and washer (20).

(4) Disconnect and remove fuel hoses (30,

35, Figure 72-00-09.38). Remove nuts,

(25) lockwashers (20), and flat wa shers

(15) from studs. Remove injector se rvo

assembly (10) and remove gasket and

spacer (5).

Magneto and harness removal

(1) Unscrew ignition wiring harness leads

(5, 10, Figure 02-00-00.10) from the top

and bottom spark plugs (50). Remove

harness attaching caps (5), two places,

from the magneto. Remove spark plugs

(50) from cylinder.

(2) Remove magneto (15, Figure 72-00-

09.40) attaching nut (30), washer (25),

and clamp (20). Remove the magneto

(15) and discard gasket (10). Remove

the adapter (5) and gasket (1). Remove

cotter pin (40), nut, and washer.

Remove magneto gear (35) and install

nut back on threads to prevent damage

to drive shaft threads.

Oil level gage housing Removal

(1) Unscrew the oil gage (10, Figure 72-

00-09.28) and remove the oil gage

housing (5). Discard seals (15, 20).

Fuel pump removal (as required)

(1) Remove fuel pump screws (15,

Figure 72-00-09.32) and washers

(10). Remove fuel pump (5) and

gasket (1). Remove elbows (25, 30)

and discard o-rings (20).

Oil filter and Adapter removal

(1) Unscrew the oil filter (40, Figure 72-

00-09.35). Remove the vernatherm

(temperature control valve) (35).

Remove screws (30), washers (15,

20), and nut (25) that secure the oil

filter adapter (10) to the accessory

housing. Discard gasket (5).

Remove cooler bypass plug (55),

and discard gasket (50).

Vacuum pump or cover removal

(1) Remove the vacuum pump (or

cover) attaching nuts (40, Figure 7200-09.31), lockwashers (35) and flat

washers (30). Remove pump (or

cover (20) as appropriate) and

discard gasket (15). Remove

adapter assembly (25). Discard

gasket (10) and remove vacuum

gear (1) and thrust washer (5) from

housing. Remove oil seal (55) and

discard.

Propeller governor removal (as required)

(1) Remove the propeller governor oil line.

Remove any clamps. Remove elbows

(10, 15) and any attaching hardware, as

required, to allow hose removal, discard

o-ring (20).

(2) Remove the cover nuts (30) as required,

(Figure 72-00-09.33), lockwashers (25),

and flat washers (20). Remove cover

(65) and discard gasket (60). Remove

retaining ring (55) and thrust washer (5).

Remove adapter nuts (30), lockwashers

(25), and flat washers (20). Remove

propeller governor adapter (15).

Discard gasket (10). Tag and save

thrust washer (5). Remove gear shaft

(1) from housing.

Accessory Housing Assembly Removal

(1) Remove the accessory housing

assembly by removing the bolts (15,

Figure 72-00-09.23), lockwashers

(10), and flat washers (5). Remove

bolt (20), washer (10), and nut (25)

two places. Remove accessory

housing (40) and gasket (35).

Remove fuel pump plunger (1,

Figure 72-00-09.24).

(a) Remove nuts (90) and washers

(85) to remove oil pump housing

assembly (80). Remove oil

pump drive shaft (115) and

impeller gears (105, 110).

© March 2005 Superior Air Parts Inc.

3

72-00-06

Engine Disassembly

Page 50

Overhaul Manual

O-360 and IO-360 Series Engines

Idler gears and shaft removal

(1) Remove idler gears (15,20, Figure

72-00-09.20). Remove idler shaft

mount screws (5) and nut (10).

Remove idler shafts (1) from

crankcase.

Starter and alternator attaching hardware

removal

(1) Remove starter mount bolt (15,

Figure 72-00-09.42), nuts (20),

lockwashers (10), and flat washers

(5). Remove starter (1) from

crankcase.

(a) Remove alternator mount bolt

(10, Figure 72-00-09.43) and

washer (5) to loosen drive belt.

Remove cotter pin (45), slotted

nut (40), support bolt (25), and

shims (35). Remove cotter pin

(45), slotted nut (40), shims

(35), and support bolt (30).

Remove bolts (20, 90) and flat

washers (15, 85) from strut

bracket (80). Remove strut

support (80) and remove

alternator.

(b) Remove alternator bracket (55)

by removing bolts (60) and lock

plate (50). Remove bolt (75),

flat washer (70), and adjusting

link (65). Visually inspect

hardware and bag for reuse if

not damaged.

Oil sump and induction disassembly

(1) Remove screws (25, Figure 72-00-

09.29), lockwashers (20), and flat

washers (15) from intake pipe flange

(10). Discard gaskets (1).

(2) Remove clamps (35), intake hoses (30),

and intake tubes (5) from oil sump

assembly.

(3) Remove oil screen plug (85, Figure 72-

00-09.27), discard gasket (80), and

remove oil suction screen (75). Inspect

for debris.

(4) Remove bolts (15,20), flat washers (25,

30), lockwashers (25), and nuts (35)

from sump assembly flange. Discard

gasket (11) and remove intake

connection pipes (12) from sump

assembly.

Cylinder drain tubes removal

(1) Loosen hose clamps (85, Figure 72-00-

09.17) on hose (80) at drain nipple (75).

Slide away from drain nipple (75).

Loosen gland nut at cylinder head fitting

and remove tube assembly (90) from

cylinder.

Intercylinder cooling baffle removal

(1) Remove the intercylinder cooling baffles

(1, Figure 72-00-09.26) using

intercylinder baffle tool. Turn the baffle

retaining hook (10) so that it disengages

the retainer (5). Remove the baffle (1)

and hook (10) from between the

cylinders.

Cylinder removal

(1) Remove the valve cover screws (130,

Figure 72-00-09.15) and cover (125)

and discard gasket (120). Rotate the

crankshaft to place the piston of the No.

1 cylinder at top center of the

compression stroke.

NOTE:

CAUTION

SUPPORTED TO PREVENT DAMAGE TO THE

ROD AND CRANKCASE. SUPPORT EACH

With the piston in this position both

valves will be closed and the piston

extended away from the crankcase to

avoid damage when the cylinder is

removed.

(2) Remove the valve rocker shaft caps

(20), the valve rocker shaft (15), valve

rocker arms (5), and the exhaust valve

stem cap (115) from cylinder assembly.

Remove the pushrod (1) by grasping the

rod end and pulling it through the rod

tube (40). Remove nut (60), spring (55),

and lockplate (50). Pull rod tube

through cylinder head and discard tube

seals (35, 45).

(a) Remove cylinder assembly by

: THE CONNECTING ROD MUST BE

removing nuts from cylinder base.

Remove cylinder by pulling straight

away from crankcase. As the

cylinder is being pulled away, hold

the piston to prevent damaged.

Discard cylinder base seal.

© March 2005 Superior Air Parts Inc.

4

72-00-06

Engine Disassembly

Page 51

Overhaul Manual

O-360 and IO-360 Series Engines

CONNECTING ROD WITH HOLD DOWN

PLATES TOOL OR RUBBER BANDS (OR

DISCARDED CYLINDER BASE SEALS)

LOOPED AROUND THE CYLINDER BASE

STUD.

(3) Remove the piston pin (35, Figure 72-

00-09.6) using a piston pin drive tool.

Drive pin (35) from piston to remove

piston (30) from the connecting rod (5).

NOTE:

NOTE:

CAUTION

THROUGH THE GUIDES.

CAUTION

OR SCORE PISTONS WHEN REMOVING THE

RINGS.

Removal of the remaining cylinders

and pistons may be done in any

sequence, but less turning of the

crankshaft is involved if the cylinders

are removed in firing order 1-3-2-4.

(4) Compress valve springs (90, 95, Figure

72-00-09.15) with spring compressor

tool, while supporting cylinder, far

enough to remove the valve cylinder

keys (105, 110).

If the valve keys are stuck in the spring

seat, a light blow with a leather mallet

on top of the compressor tool will

release keys.

: DO NOT DRIVE THE VALVES

(a) Remove upper valve spring seats

(95, 100), inner and outer springs

(85, 90), and lower valve spring

seats (75, 80) from rocker box.

Keep parts for each valve (65, 70)

separate. Hold valves by the stems

to keep them from dropping out of

the cylinder and remove cylinder

from the holding block. Reach

inside and remove valves. If valves

are difficult to remove, push valves

back in and clean carbon from

stems.

: BE CAREFUL NOT TO SCRATCH

(b) Using the piston ring expander tool,

remove the rings (40, 45, Figure 7200-09.6) from all pistons. Remove

the rings in order starting with the

top ring and work down.

(5) Remove and disassemble the hydraulic

lifter assembly.

CAUTION

TAPPET ASSEMBLY TOGETHER DURING

ALL OVERHAUL OPERATIONS. ALL

COMPONENT PARTS ARE TO BE

REASSEMBLED WITH THEIR ORIGINAL

MATING PARTS AND EACH ASSEMBLY

REINSERTED IN ITS ORIGINAL LOCATION.

Crankcase Disassembly

NOTE:

: MAINTAIN THE PARTS OF EACH

(a) Using hydraulic tappet tool, remove

the pushrod socket (30, Figure 7200-09.15) by placing heavy grease

on ball end of the "T". By inserting

the ball end in the tappet and

withdrawing, the socket will adhere

to the grease.

(b) Using the hollow end of the tool,

push it over the plunger and

withdraw the plunger. If the tool is

not available, remove the pushrod

socket with fingers or by using

needle nose pliers. Insert a piece of

wire bent at a right angle into the

plunger between the plunger and

the lifter body. Turn 90 degrees to

engage a coil of spring and draw out

the plunger assembly.

(1) Remove nuts (25, 45, 70, 85, Figure 72-

00-09.11 and 72-00-09.12), bolts (5, 30,

55, 90, 95), and washers (15, 20, 35,

40, 60, 65, 80). Draw or pull the thrubolts (1) from the crankcase using

cylinder base nuts and washers and/or

spacers.

(2) Separate crankcase using care not to

allow camshaft to fall to floor. Caution

should be used to keep the right case

thru-studs from becoming misaligned

when separating the crankcase halves

(60, Figure 72.00-09.5).

Carefully pull crankshaft nose seal