Superior Vantage Engine O-360 SERIES, Vantage Engine IO-360 SERIES Maintenance Manual

O-360 & IO-360 SERIES ENGINES

MAINTENANCE MANUAL

621 South Royal Lane, Suite 100 / Coppell, TX 75019 / 800-277-5168

www.superiorairparts.com

Manual P/N SVMM01, Revision B, February 2007

© February 2007 Superior Air Parts Inc.

i

RW

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

ii

© February 2007 Superior Air Parts Inc.

General Information

Maintenance Manual

O-360 and IO-360 Series Engines

Manual Number SVMM01

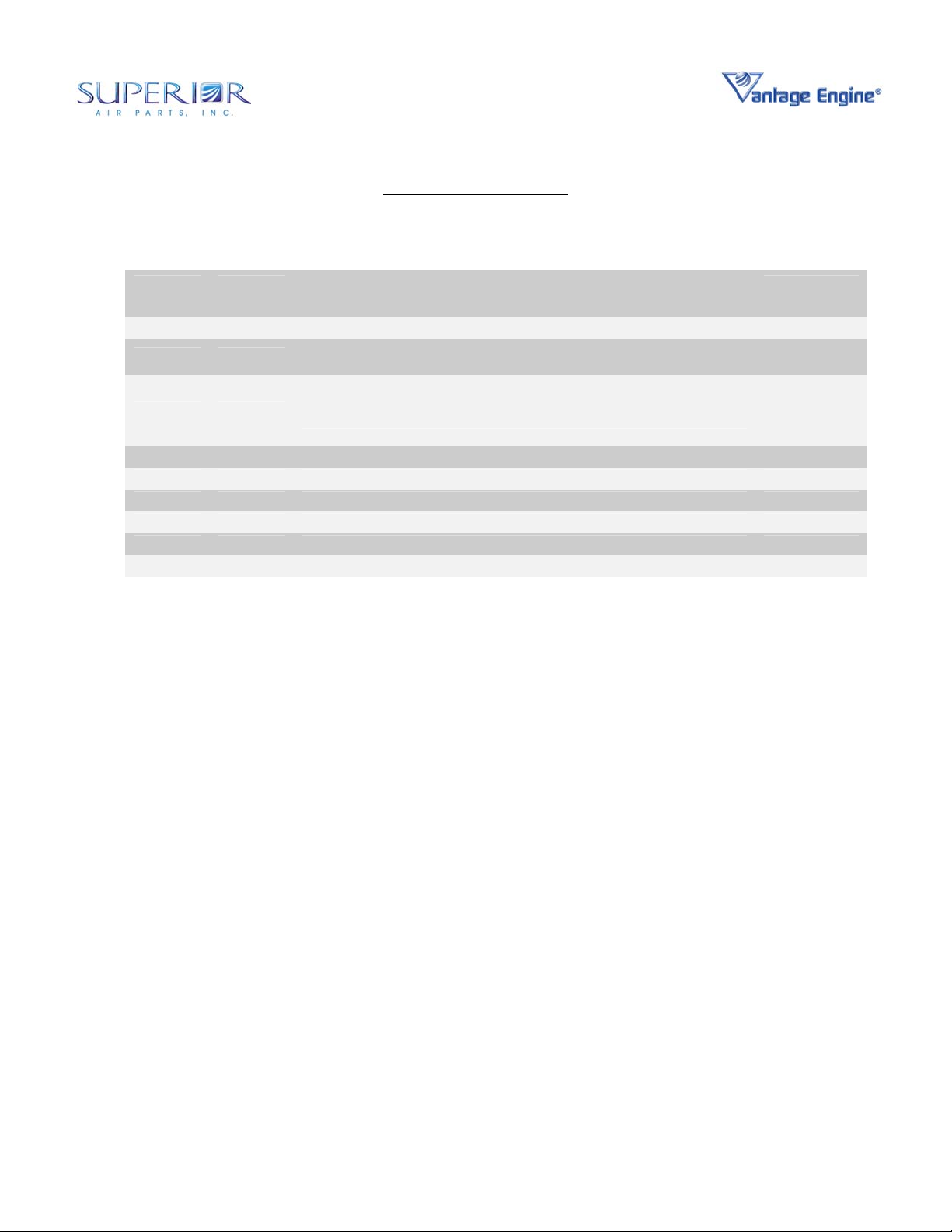

Revision History

Revision

Letter

IR 02/27/06 Initial Release All

A 3/6/06

B 02/28/07

Effective

Date

Description

SAP CR# 8004, del magneto 100 hr insp. from ALS, add “or

annual” to & del mag cap removal from 100 hr insp

Add Celsius Temperature conversions to Fahrenheit

temperatures

Pages

Revised

05-00-00, p1

05-20-00, p3

72-00-10 All

72-00-12 All

72030-00 All

72-50-00 All

iii

© February 2007 Superior Air Parts Inc.

General Information

Maintenance Manual

O-360 and IO-360 Series Engines

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

iv

© February 2007 Superior Air Parts Inc.

General Information

Maintenance Manual

O-360 and IO-360 Series Engines

SAFETY ADVISORY

WARNING: BEFORE MATERIALS CALLED OUT IN THIS PUBLICATION ARE USED, KNOW THE

HANDLING, STORAGE AND DISPOSAL PRECAUTIONS RECOMMENDED BY THE

MANUFACTURER OR SUPPLIER. FAILURE TO COMPLY WITH THE

MANUFACTURER’S OR SUPPLIER’S RECOMMENDATION CAN RESULT IN

PERSONAL INJURY.

CAUTION: INFORMATION IS TO EMPHASIZE INSTRUCTIONS OR PREVENT POSSIBLE

EQUIPMENT DAMAGE.

The user must know the manufacturer or supplier information and obey the procedures,

recommendations, warnings, and cautions set forth for the use, handling, storage, and disposal of

materials.

The WARNINGS used in this manual inform the user about dangerous materials or equipment that can

cause injury. They do not replace the manufacturer's instructions.

This Safety Advisory has all the warnings included in this manual.

WARNING: OPERATION OF A DEFECTIVE ENGINE WITHOUT A PRELIMINARY EXAMINATION

CAN CAUSE FURTHER DAMAGE TO A DISABLED COMPONENT AND POSSIBLE

INJURY TO PERSONNEL. MAKE SURE THOROUGH INSPECTION AND

TROUBLESHOOTING PROCEDURES ARE ACCOMPLISHED. THIS WILL HELP TO

PREVENT INJURIES TO PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT.

WARNING: FUEL IS TOXIC AND FLAMMABLE. DO NOT BREATHE VAPORS. USE IN A WELL-

VENTILATED AREA FREE FROM SPARKS, FLAME, OR HOT SURFACES. PUT ON

SPLASH GOGGLES, SOLVENT-RESISTANT GLOVES, AND OTHER PROTECTIVE

GEAR. IN CASE OF EYE CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND

SEEK MEDICAL ATTENTION. IN CASE OF SKIN CONTACT, WASH WITH SOAP AND

WATER.

WARNING: HOT OIL MAY CAUSE BURNS TO EYES AND SKIN. PUT ON SPLASH GOGGLES,

INSULATED GLOVES, AND OTHER PROTECTIVE GEAR. IN CASE OF EYE

CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL

ATTENTION. IN CASE OF SKIN CONTACT, WASH WITH SOAP AND WATER.

WARNING: DO NOT INSTALL THE IGNITION HARNESS "B" NUTS ON THE SPARK PLUGS UNTIL

THE PROPELLER INSTALLATION IS COMPLETED. FAILURE TO COMPLY COULD

RESULT IN BODILY INJURY WHEN THE PROPELLER IS ROTATED DURING

INSTALLATION.

WARNING: SOLVENT IS TOXIC. USE IN WELL-VENTILATED AREA. PREVENT EYE AND SKIN

CONTACT AND DO NOT BREATHE VAPORS. IN CASE OF EYE CONTACT, FLUSH

WITH WATER. IN CASE OF SKIN CONTACT, WASH WITH SOAP AND WATER.

v

© February 2007 Superior Air Parts Inc.

General Information

Maintenance Manual

O-360 and IO-360 Series Engines

WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT

THE PRESSURE IS NOT MORE THAN 30 PSI. DO NOT DIRECT THE AIRSTREAM AT

PERSONNEL OR LIGHT OBJECTS. PUT ON GOGGLES OR A FACE SHIELD TO

PROTECT YOUR EYES. THIS WILL HELP PREVENT INJURIES TO PERSONNEL OR

DAMAGE TO THE EQUIPMENT. IF YOU HAVE AN EYE INJURY, GET MEDICAL

ATTENTION.

WARNING: USE METHYL ETHYL KETONE (MEK) SOLVENT CORRECTLY. THE SOLVENT IS

FLAMMABLE AND REACTIVE. IT CAN HAVE A BAD EFFECT ON YOUR HEALTH OR

SAFETY. BEFORE YOU USE THE SOLVENT, GET THE MATERIAL SAFETY DATA

SHEET (MSDS) FROM THE MANUFACTURER OR SUPPLIER OF THE MATERIAL

AND READ IT CAREFULLY. BEFORE YOU USE THE SOLVENT, PUT ON SAFETY

SPLASH GOGGLES, SOLVENT-RESISTANT GLOVES (BUTYL RUBBER), RUBBER

APRON, AND CHEMICAL-SAFETY SHOES. MAKE SURE THAT YOU HAVE

SUFFICIENT AIRFLOW TO KEEP THE SOLVENT FUMES BELOW THE MSDS LIMIT.

WARNING: ENGINE OIL IS HAZARDOUS AND MAY CAUSE INJURY TO SKIN AND EYES. PUT

ON RUBBER GLOVES AND GOGGLES.

WARNING: PLACE A SUITABLE STAND UNDER THE AIRCRAFT TAILCONE IF NEEDED BEFORE

REMOVING THE ENGINE. THE LOSS OF WEIGHT MAY CAUSE THE AIRCRAFT TAIL

TO DROP.

WARNING: USE THE CORRECT PERSONAL PROTECTION. SOME CHEMICAL SOLUTIONS CAN

CAUSE SKIN, EYE AND LUNG DAMAGE. FOLLOW THE MANUFACTURER'S

INSTRUCTIONS FOR EACH CLEANING SOLUTION.

WARNING: TO PREVENT THE POSSIBILITY OF SERIOUS BODILY INJURY OR DEATH, BEFORE

MOVING THE PROPELLER DO THE FOLLOWING:

• DO NOT STAND WITHIN THE ARC OF THE PROPELLER BLADES WHILE

TURNING THE PROPELLER.

• VERIFY ALL SPARK PLUG LEADS ARE DISCONNECTED.

• VERIFY MAGNETO SWITCHES ARE CONNECTED TO MAGNETOS AND THAT

THEY ARE IN THE “OFF” POSITION AND P-LEADS ARE GROUNDED.

• THROTTLE POSITION “CLOSED”.

• MIXTURE CONTROL POSITION “IDLE-CUT OFF”.

• SET BRAKES AND BLOCK AIRCRAFT WHEELS. ENSURE THAT AIRCRAFT

• TIE DOWNS ARE INSTALLED AND VERIFY THAT THE CABIN DOOR LATCH IS

OPEN.

vi

© February 2007 Superior Air Parts Inc.

General Information

Section

Chapter

General Information

Sub-Section

Revision History iii

Safety Advisory v

Table of Contents vii

List of Figures xi

List of Tables xiii

Maintenance Manual

O-360 and IO-360 Series Engines

TABLE OF CONTENTS

Page Number

01 00 00 Introduction

02 00 00 Description and Operation

04 00 00 Airworthiness Limitations Section

05 00 00 Scheduled Inspection and Maintenance

20 00

50 00

About This Manual 1

Related Publications 1

Obtaining Revisions to Instructions for Continued

Airworthiness

General Description 1

Continued Airworthiness 1

Model Designations 1

Engine Components General Description 3

Specifications 3

Features and Operating Mechanisms 5

Mandatory Replacement Time 1

Mandatory Inspection Intervals 1

General 1

25 Hour Inspection 1

50 Hour Inspection 1

100 Hour or Annual Inspection 3

500 Hour Inspection 6

1000 Hour Inspection 6

Recommended TBO 6

Recommended Accessory Replacement 6

Unscheduled Inspection and Maintenance 1

1

vii

© February 2007 Superior Air Parts Inc.

General Information

Section

Chapter

72 00 00 Engine Section

Sub-Section

General 1

Maintenance Manual

O-360 and IO-360 Series Engines

TABLE OF CONTENTS (cont’d)

Page Number

01 Testing a nd Fault Isolation

05 Engine Removal

06 Engine Disassembly

07 Cleaning

General 1

Troubleshooting 1

General 1

Removal 1

Preservation 1

General 1

General 1

Cleaning Instructions 1

Overall Engine Cleaning 1

Spark Plugs and Electrical Components 1

Oil System Components 2

Degreasing 2

Decarbonizing 2

Corrosion Removal 3

Parts Preservation and Corrosion Prevention 3

09 Engine Assembly

10 Engine Installation

11 Torque s, Fits, and Clearances

© February 2007 Superior Air Parts Inc.

General 1

General 1

Preparing Engine for Service 1

Installation of Engine 1

General 1

Service Limits 1

viii

General Information

Maintenance Manual

O-360 and IO-360 Series Engines

Section

Chapter

72 00 12 Preservation and Storage

Sub-Section

General 1

Temporary Storage 2

Indefinite Storage 3

Returning an Engine To Service After Storage 3

TABLE OF CONTENTS (cont’d)

Page Number

00 13 Repair Procedures

15 Servicing

10 00 Front Section

30 00 Cylinder Section

50 00 Lubrication Section

General 1

General 1

Fuels 1

Lubricants 1

Consumables 2

General 1

Starter 1

Alternator 3

Propeller Governor System 6

General 1

Cylinder Replacement 1

Cylinder Break-in Procedures 10

General 1

Oil Pressure Adjustment 1

Oil Filter Adapter and Vernatherm Valve 1

Oil Sump Suction Screen 2

© February 2007 Superior Air Parts Inc.

ix

General Information

Section

Chapter

73 00 00 Engine Fuel System

Sub-Section

General 1

Fuel System Leaks 1

Fuel Pump Replacement 3

Fuel Screen 3

Maintenance Manual

O-360 and IO-360 Series Engines

TABLE OF CONTENTS (cont’d)

Page Number

10 00 Fuel Injection System

20 00 Carburetion System

74 00 00 Ignition Section

Fuel Injector Nozzle Cleaning 1

Idle Speed and Mixture Adjustment 1

Primer Nozzle Cleaning 1

General 1

Magneto Replacement 1

Ignition Harness Replacement 2

Appendix 1

Unison Industries L-1363B, 4300/6300 Series Magneto

Maintenance and Overhaul Manual

x

© February 2007 Superior Air Parts Inc.

General Information

Maintenance Manual

O-360 and IO-360 Series Engines

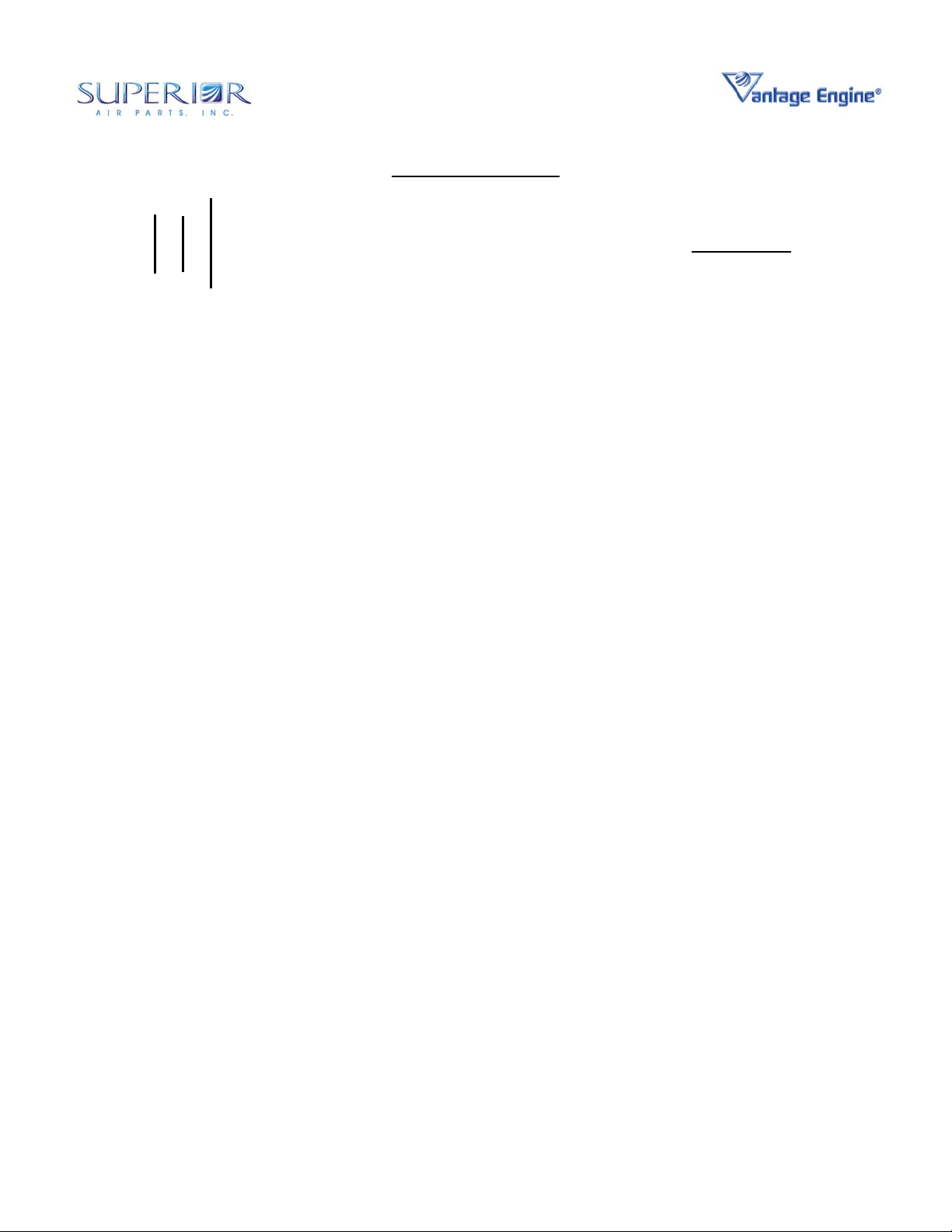

LIST OF FIGURES

Figure

02-00-00.1 Engine Model Number Designation 02 00 00 2

02-00-00.2 O-360 Engine Front View 7

02-00-00.3 O-360 Engine Left Side View 8

02-00-00.4 O-360 Engine Top View 9

02-00-00.5 O-360 Engine Rear View 10

02-00-00.6 IO-360 Engine Front View 11

02-00-00.7 IO-360 Engine Left Side View 12

02-00-00.8 IO-360 Engine Top View 13

02-00-00.9 IO-360 Engine Rear View 14

72-10-00.1 Starter Installation 72 10 00 2

72-10-00.2 Alternator Installation 3

72-10-00.3 Alternator and Mounting Hardware Detail 5

72-10-00.4 Propeller Governor Oil Line 7

72-30-00.1 Assembled Cylinders 30 00 3

72-30-00.2 Piston Pin and Piston Assembly 4

72-30-00.3 Piston Ring Compressor 5

72-30-00.4 Cylinder Base Nut Tightening Sequence 6

72-30-00.5 Installation of Pushrods 7

72-30-00.6 Rocker Arm and Pushrod Assembly 8

72-30-00.5 Intercylinder Baffle Assembly 9

Section

Chapter

Page

Sub-Section

72-50-00.1 Oil System Schematic 50 00 2

72-50-00.2 Oil Filter and Adapter Assembly 3

72-50-00.3 Oil Sump Assembly 5

72-50-00.4 Oil Pressure Relief Valve 6

73-00-00.1 Engine Fuel Pump Assembly 73 00 00 2

74-00-00.1 Magneto Components 74 00 00 3

74-00-00.2 Timing Diagram 4

74-00-00.3 Ignition Wiring Diagram 5

xi

© February 2007 Superior Air Parts Inc.

General Information

Maintenance Manual

O-360 and IO-360 Series Engines

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

xii

© February 2007 Superior Air Parts Inc.

General Information

Maintenance Manual

O-360 and IO-360 Series Engines

LIST OF TABLES

Table

Section

Chapter

01-00-00.1 Special Tools and Equipment 01 00 00 1

02-00-00.1 General Specifications 02 00 00 3

02-00-00.2 Accessory Drive Specifications 3

02-00-00.3 Manufacturer’s Physical Specifications 4

02-00-00.4 Primary Engine Accessories 4

02-00-00.5 Illustrated Views of the Engine 5

02-00-00.6 Secondary Engine Accessories 5

05-00-00.1 Scheduled Inspection and Maintenance Intervals 05 00 00 1

72-00-01.1 Abnormal Operation Troubleshooting Procedures 72 00 01 1

72-00-01.2 Engine Will Not Start 2

72-00-01.3 Rough Idling 2

72-00-01.4 Engine Not Able To Develop Full Power 2

72-00-01.5 Rough Engine Operation 3

72-00-01.6 Low Power & Engine Runs Rough 3

72-00-01.7 Low Oil Pressure On Engine Gage 3

72-00-01.8 High Oil Temperature 4

72-00-01.9 Excessive Oil Consumption 4

Page

Sub-Section

72-00-05.1 Equipment and Materials List 05 1

72-00-07.1 Equipment Required for Cleaning 07 1

72-00-07.2 Materials Required for Cleaning 1

72-00-10.1 Equipment and Materials List 10 1

72-00-11.1 Dimensional Limits 11 2

72-00-11.2 Backlash and End Clearance Limits 2

72-00-11.3 Torque Limits 3

72-00-11.4 Valve Spring Dimensional Limits 4

72-00-11.5 Crush Type Gasket Tightening Angles 4

72-00-12.1 Preservation and Storage Materials 12 1

xiii

© February 2007 Superior Air Parts Inc.

General Information

Maintenance Manual

O-360 and IO-360 Series Engines

LIST OF TABLES (cont’d)

Table

Section

Chapter

Sub-Section

72-00-15.1 Oil Grades 72 00 15 1

72-00-15.2 Oil Sump Capacity 1

72-00-15.3 Minimum Octane Fuels 2

72-00-15.4 Consumables 2

72-00-15.4 Hoses 2

72-10-00.1 Alternator Belt Tension Requirements 10 00 4

72-30-00.1 Equipment and Material List 30 00 1

72-50-00.1 Oil Pressure Springs 50 00 1

73-00-00.1 List of Materials 73 00 00 1

74-00-00.1 List of Equipment 74 00 00 1

Page

xiv

© February 2007 Superior Air Parts Inc.

General Information

Maintenance Manual

O-360 and IO-360 Series Engines

INTRODUCTION

About This Manual

Information contained in this Engine

Maintenance Manual fulfills the content

requirements of FAR 33.4 Appendix A33.3(a)

and has been found acceptable to the Federal

Aviation Administration (FAA). The purpose of

this Maintenance Manual is to provide the

necessary instructions for performing

maintenance on the Superior Vantage Engine.

Repair and replacement information may be

found in the overhaul manual.

The information in this publication is based on

data available at the time of publication and is

updated, supplemented, and automatically

amended by Publication Revisions and Service

Bulletins that are issued by Superior Air Parts.

This manual is divided into separate sections

relating to the general and specific maintenance

instructions required for the engine. These

general and specific instructions are organized

and numbered per the recommendations of the

General Aviation Manufacturers Association

(GAMA). In this way, information may be

located in a conventional manner to aid in both

accuracy and timeliness.

Page numbering is organized within each

section. The section number (e.g., 72-00-01) is

displayed in the right hand section of the footer

on each page. The page number is displayed in

the center of the footer on each page.

All measurements are noted in English (U.S.)

units. Conventional unit abbreviations are used.

Be sure to ground magneto P-leads prior to any

maintenance and perform normal pre-run

checks and inspections upon completion any

maintenance.

Superior Air Parts has made clear and accurate

information available for those who maintain,

own and repair the Vantage O-360 and IO-360

Series Engines. Superior Air Parts values your

input regarding revisions and additional

information for our manuals. Please forward

your comments and input to:

Superior Air Parts

Attn: Engineering Department

621 South Royal Lane Suite 100

Coppell, Texas 75019

Table 01-00-00.1 • Special Tools and Equipment

Item Vendor

Electrical Tester Commercially Available

Related Publications

The following are related engine publications.

• SVIOM01, O-360 & IO-360 Installation and

Operation Manual

• SVOHM01, O-360 & IO-360 Overhaul

Manual

Obtaining Revisions to Instructions for

Continued Airworthiness

All Vantage Engine manuals and service

information may be downloaded at

www.superiorairparts.com

Or may be purchased by contacting:

Superior Air Parts

621 South Royal Lane, Suite 100

Coppell, Texas 75019

or call: 972-829-4600

1

© March 2006 Superior Air Parts Inc.

01-00-00

Introduction

Maintenance Manual

O-360 and IO-360 Series Engines

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

2

© March 2006 Superior Air Parts Inc.

01-00-00

Introduction

Maintenance Manual

O-360 and IO-360 Series Engines

DESCRIPTION AND OPERATION

General Description

Superior Vantage Engines are four-cylinder,

horizontally opposed, air-cooled, direct drive

powerplants incorporating a wet sump, bottom

mounted induction, bottom exhaust with either

carbureted or port injected fuel systems.

Provisions exist for both front and rear mounted

accessories. All engine components will be

referenced as they are installed in the airframe.

Therefore, the “front” of the engine is the

propeller end and the “rear” of the engine is the

accessory mounting drive area. The oil sump is

on the “bottom” of the engine and the cylinder

shroud tubes are on the “top”. The terms “left”

and “right” are defined as being viewed from the

rear of the engine looking toward the front.

Cylinder numbering is from the front to the rear

with odd numbered cylinders on the right side of

the engine. The direction of crankshaft rotation

is clockwise as viewed from the rear of the

engine looking forward unless otherwise

specified. Accessory drive rotation direction is

defined as viewed from the rear of the engine

looking forward.

Continued Airworthiness

Vantage Engines discussed in this document

must be installed and operated in accordance

with the limitations, conditions and operating

procedures described in the Installation and

Operation Manual (SVIOM01). They must also

be maintained and repaired in accordance with

this manual and the Overhaul Manual

(SVOHM01).

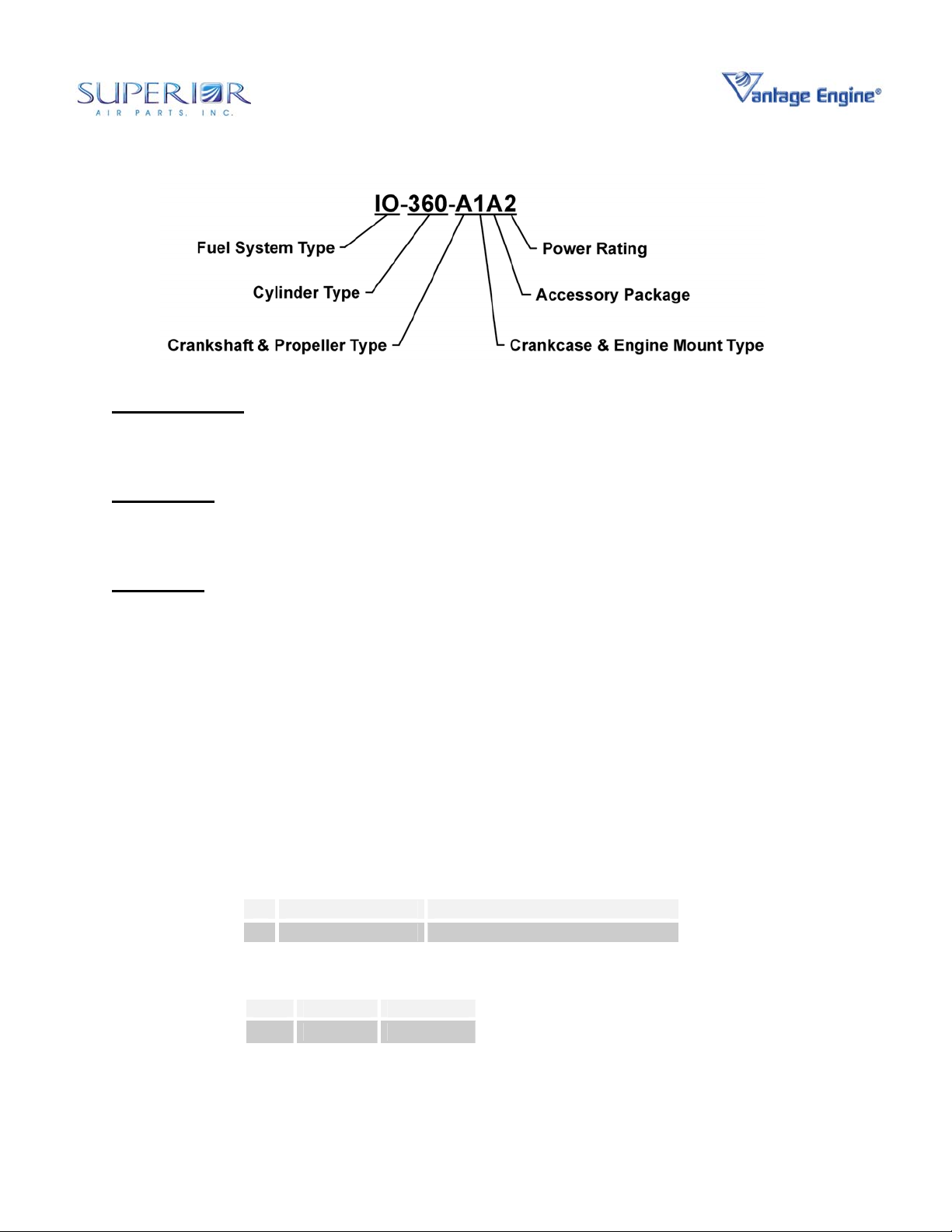

Model Designations

The model number designation is defined in a

way that the digits of the model number can

easily identify the basic configuration of the

engine as described in Figure 02-00-00.1.

Engine Components General Description

The Vantage Engine O-360 and IO-360 series

engines are air-cooled, four cylinder, horizontally

opposed, direct drive engines. See Table 0200-00.1 for General Specifications.

The complete engine includes the following

components and assemblies:

Crankcase Assembly

Crankshaft Assembly

Camshaft Assembly

Valve Train Assembly

Cylinder Assemblies

Connecting Rod Assemblies

Oil Sump Assembly

Intercylinder Baffles

Starter

Lubrication System (Includes Oil Filter)

Accessory Drive

Ignition System (Includes Spark Plugs)

Fuel System

Starter Support Assembly

Oil Level Gage

Induction System

NOTE: Complete engine does not include outer

cylinder baffles, airframe to engine control

cables, attaching hardware, hose clamps,

vacuum pump, exhaust system, or fittings.

Unless otherwise specified, the fuel pump is

included on carbureted engines. Alternator or

propeller governor systems may be included, if

specified the Model Specification Data (MSD) .

1

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

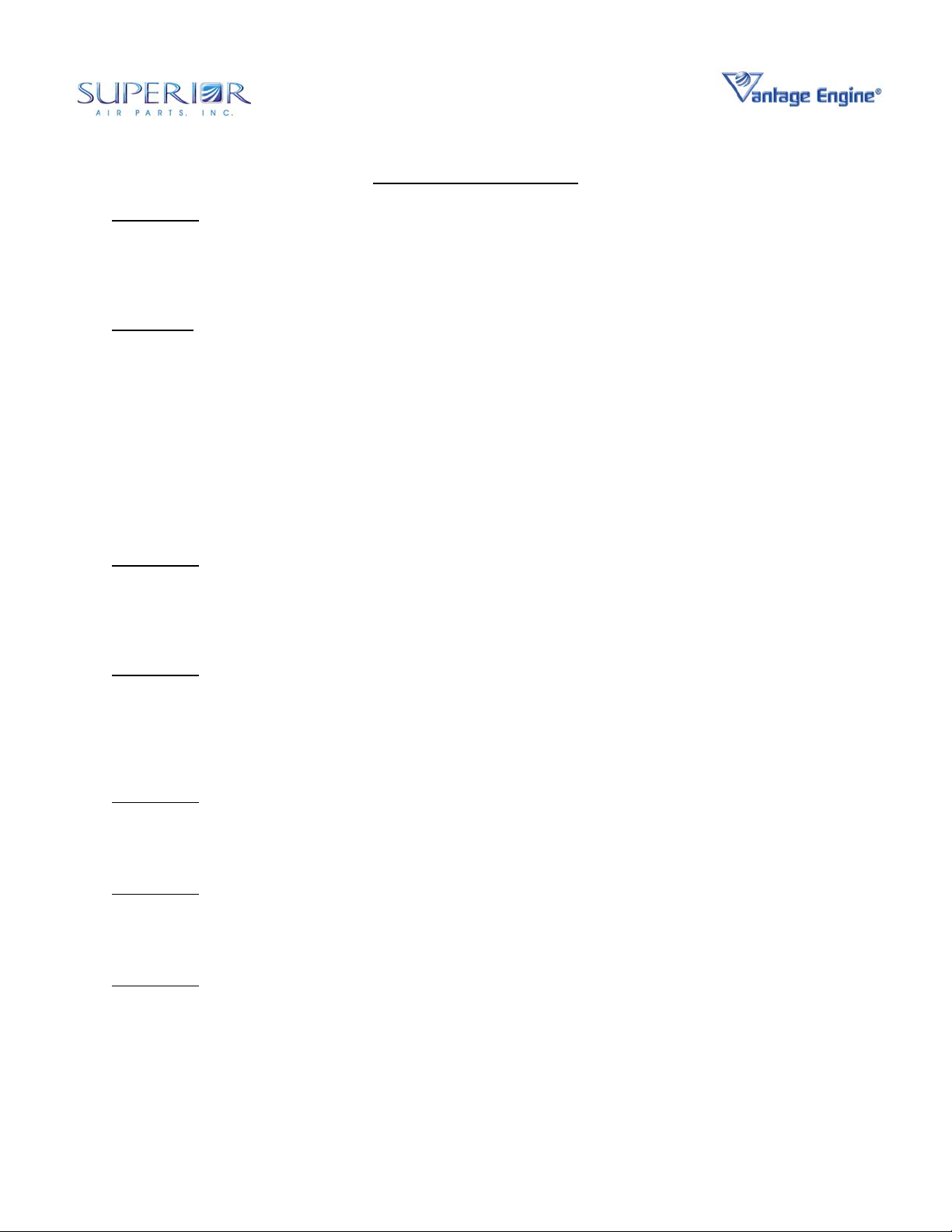

Fuel System Type

O Denotes a Carbureted system and “opposed cylinder” arrangemen t.

IO Denotes a Fuel Injection system and “opposed cylinder” arrangement.

Cylinder Type

360 Parallel valve cylinder, 361 cubic inches.

Model Suffix

1st Digit Crankshaft & Propeller Type

A Fixed-Pitch, Thin-wall front main

B Constant-Speed, Thin-wall front main

C Fixed-Pitch, Heavy-wall front main

D Constant-Speed, Heavy-wall front main

E Fixed-Pitch, Solid front main

2nd Digit Crankcase & Engine Mount Type

3rd Digit Accessory Package

4th Digit Power Rating: Piston Compression Ratio

Denotes detail engine configuration

1 #1 Dynafocal Mount

2 #2 Dynafocal Mount

3 Conical Mount

4 #1 Dynafocal Mount, Front Propeller Governor

5 #2 Dynafocal Mount, Front Propeller Governor

6 Conical Mount, Front Propeller Governor

Ignition System Fuel System

A Unison Magnetos Precision Fuel System

CR HP

2 8.5:1 180

Figure 02-00-00.1 • Engine Model Number Designation

2

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

Specifications

The physical specifications of the O-360 and IO360 series engines are listed in Table 02-00-

00.3. Accessory Drive Specifications are

provided in Table 02-00-00.2. Information on

Primary Accessories, fuel and ignition systems,

are provided in Table 02-00-00.4. The Model

Specification Data (MSD) in the Installation and

Operation Manual may provide more specific

information, such as secondary engine

accessories provided.

Table 02-00-00.1 • General Specifications

Model O-360 and IO-360 series

Rated Power Hp 180

Rated Speed, RPM RPM 2700

Bore, inches In 5.125

Stroke, inches In 4.375

Displacement cubic inches In3 361.0

Compression Ratio 8.5:1

Firing Order 1-3-2-4

Spark timing °BTDC 25

Propeller drive ratio 1:1

Propeller drive rotation

(viewed from rear)

Illustrated views of the O-360 and IO-360

engines identifying key components and subassemblies are provided in Figures 02-00-00.1

thru 02-00-00.9 of this section and are listed in

Table 02-00-00.5 for convenience.

Clockwise

Table 02-00-00.2 • Accessory Drive Specifications

Accessory

Starter 16.556:1 CounterAlternator 3.250:1 Clockwise

Tachometer 0.500:1 Clockwise

Magneto 1.000:1 Clockwise

Vacuum Pump 1.300:1

Propeller Governor 0.866:1 Clockwise

Fuel Pump 0.500:1 Plunger Operated

© March 2006 Superior Air Parts Inc.

Drive

Ratio

3

Direction of

Rotation

Counter-

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

Table 02-00-00.3 • Physical Specifications

Model

O-360-Axxx 24.6 33.4 32.8 288

O-360-Bxxx 24.6 33.4 32.8 291

O-360-Cxxx 24.6 33.4 32.8 291

O-360-Dxxx 24.6 33.4 32.8 294

O-360-Exxx 24.6 33.4 32.8 295

IO-360-Axxx 24.0 33.4 32.8 290

IO-360-Bxxx 24.0 33.4 32.8 293

IO-360-Cxxx 24.0 33.4 32.8

IO-360-Dxxx 24.0 33.4 32.8 296

IO-360-Exxx 24.0 33.4 32.8 297

*Base engine weight with accessories listed in Table 02-00-00.4 below and a 7.8 lb.

starter, the front propeller governor crankcase option adds 7 lb. to the engine weight.

Model

O-360

IO-360

* See Table 72-00-15.4 for approved consumables (spark plugs, oil filters, belts, hoses)

and Table 02-09-00.6 below for approved secondary engine accessories.

Left

Magneto

Unison

4371

Unison

4371

Height

(In)

Table 02-00-00.4 • Primary Engine Accessories*

Right

Magneto

Unison

4371

Unison

4371

Width

(In)

Ignition

Harness

Unison

M4001

Unison

M4001

Length

(In)

Fuel System

Precision

MA-4-5

Precision

RSA-5-AD1

Weight*

(Lb)

293

Fuel Pump

(if furnished)

Aero Accessories

AF15472

Aero Accessories

AF15473

4

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

Table 02-00-00.5 • Illustrated Views of the Engine

Engine View Figure Number

O-360 Engine Front View Figure 02-00-00.2

O-360 Engine Left Side View Figure 02-00-00.3

O-360 Engine Top View Figure 02-00-00.4

O-360 Engine Rear View Figure 02-00-00.5

IO-360 Engine Front View Figure 02-00-00.6

IO-360 Engine Left Side View Figure 02-00-00.7

IO-360 Engine Top View Figure 02-00-00.8

IO-360 Engine Rear View Figure 02-00-00.9

Table 02-00-00.6 • Secondary Engine Accessories (if provided)

Accessory &

Manufacturer

Starters

Sky-Tec 149-12LS 12 n/a 7.8 pounds

Sky-Tec 149-24LS 24 n/a 7.8 pounds

Sky-Tec 149-NL 12 or 24 n/a 9.4 pounds

Alternators

Kelly Aerospace ALY8520LS 12 60 10.9 pounds

Plane-Power AL12-F60 12 70 9.8 pounds

Plane-Power AL24-F60 24 70 9.8 pounds

Features and Operating Mechanisms

Crankshaft - The crankshaft is made from high

quality, aerospace grade steel. All bearing

journal surfaces are nitrided to surface harden.

There are 3 kinds of crankshafts: thin-wall, thickwall, and solid front mains which can be

identified by looking at the center of the front of

the crankshaft or prop oil cavity. The thin-wall

and thick-wall crankshafts are each available as

fixed-pitch or constant-speed. Fixed-pitch

models have a plug installed in front of the inner

diameter of the front main bearing cavity.

Constant speed models have a plug installed at

the rear of the front main bearing cavity.

Model Voltage Amperage Weight

Connecting Rods - The connecting rods are

made from aerospace grade, high quality steel.

They have replaceable bearing inserts in the

crankshaft ends and bronze bushings in the

piston ends. The bearing caps on the

crankshaft ends are retained by two bolts with

self locking nuts. Caps are tongue and groove

type for improved alignment and rigidity.

Camshaft and Valve Operating Mechanism The camshaft is located above and parallel to

the crankshaft. The camshaft actuates hydraulic

lifters that operate the valves through push rods

and valve rockers.

5

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

Crankcase - The crankcase is made from

aerospace grade, stabilized structural aluminum

alloy. The assembly consists of two reinforced

aluminum alloy castings fastened together by

means of studs, bolts, and nuts. The main

bearing bores are machined for use with

precision type main bearing inserts.

Accessory Housing - The accessory housing is

made from an aluminum casting and is fastened

to the rear of the crankcase and the top rear of

the sump.

Oil Sump - The sump incorporates an oil drain

plug, oil suction screen, mounting pad for

carburetor or fuel injector, the intake riser, and

intake pipe connections.

Cylinders - Millennium

exclusively. These air-cooled cylinders are

manufactured by screwing and shrinking the two

major parts, head and barrel, together. The cast

heads are made from a special aluminum alloy.

All barrels are made from forgings produced to

aerospace specifications. They are internally

choked and honed to allow optimal operating

conditions for the rings and pistons at operating

temperatures.

Pistons - The pistons are made from an

aluminum alloy. The piston pin is a full floating

type with a plug located in each end of the pin.

The piston is a 3-ring type with 2 compression

rings and 1 oil control ring.

Cooling System – Superior Vantage Engines

are designed to be air-cooled. Baffles are

provided to build up air pressure and force the

air between the cylinder fins. The air is

exhausted to the atmosphere through the rear of

the cowling.

Induction System - The distribution of the air to

each cylinder is through the center zone of the

induction system. This is integral with the oil

sump.

®

Cylinders are used

Lubrication System - The full pressure wet

sump lubrication system is supplied by a gear

type pump. It is contained within the accessory

housing.

Priming System - A manual primer system is

provided on all engines using a carburetor. Fuel

injected engines do not require a manual

priming system, relying instead on the fuel

injectors for priming.

Ignition System - Dual ignition is furnished by

two Unison magnetos with two spark plugs per

cylinder.

Electrical System – Engines may be furnished

with an alternator, if provided for in the model

specification. If an alternator is furnished,

installation brackets, hardware and belt are

provided. Alternators are available in either 12

or 24 volt systems and a range of amperages

Fuel Systems

Carbureted

are equipped with a float type carburetor The

MA-4-5 carburetors are of the single barrel float

type equipped with a manual mixture control and

an idle cut-off.

Fuel Injected

equipped with a direct cylinder injected RSA-5AD1 fuel injection system. The fuel injection

system schedules fuel flow in proportion to

airflow. Fuel vaporization takes place at the

intake ports. The RSA fuel injection system is

based on the principle of measuring airflow and

converting the air pressure into a fuel pressure.

The fuel pressure, when applied across the fuel

metering section, makes fuel flow proportional to

airflow.

- Superior Air Parts O-360 engines

- IO-360 series engines are

6

© February 2007 Superior Air Parts Inc.

Description and Operation

02-00-00

Maintenance Manual

O-360 and IO-360 Series Engines

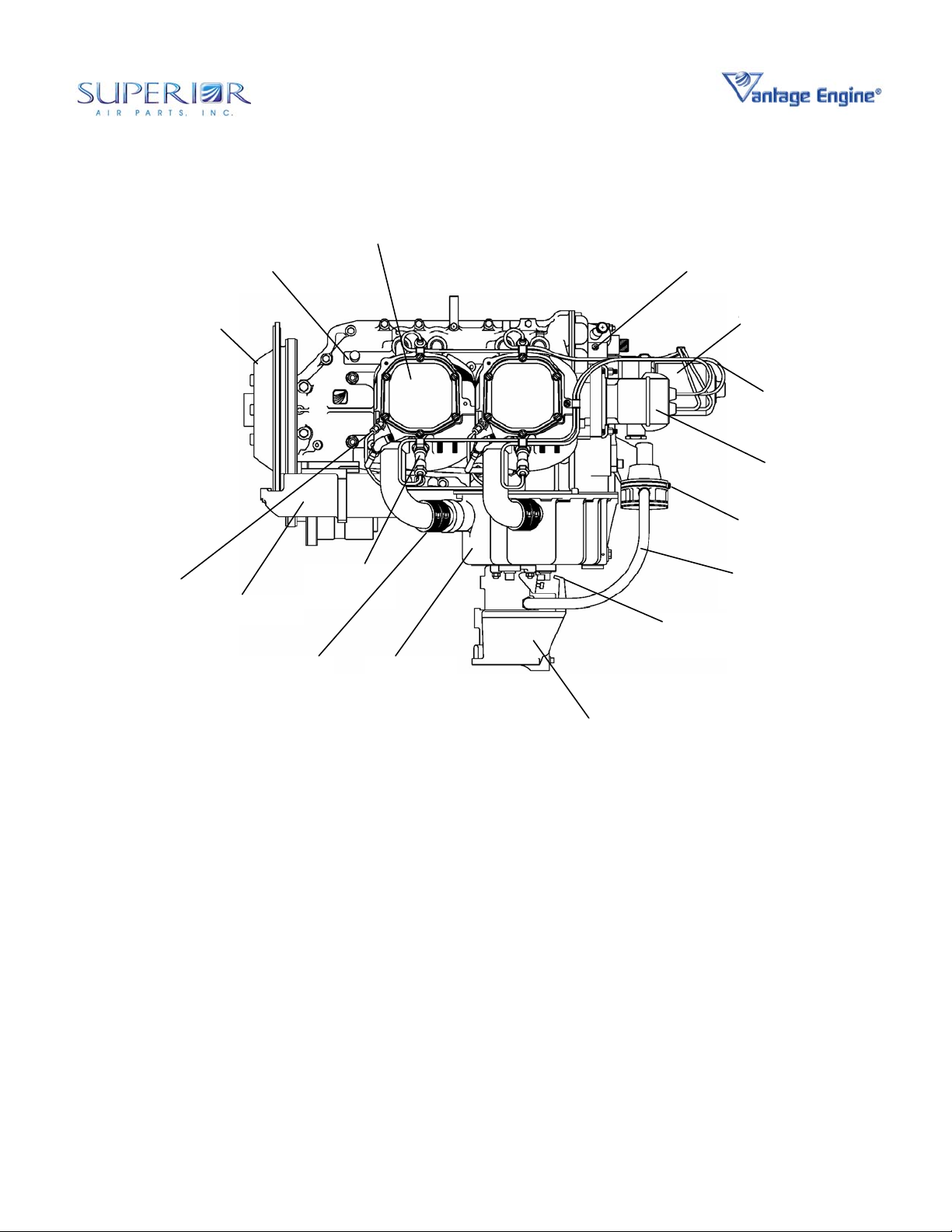

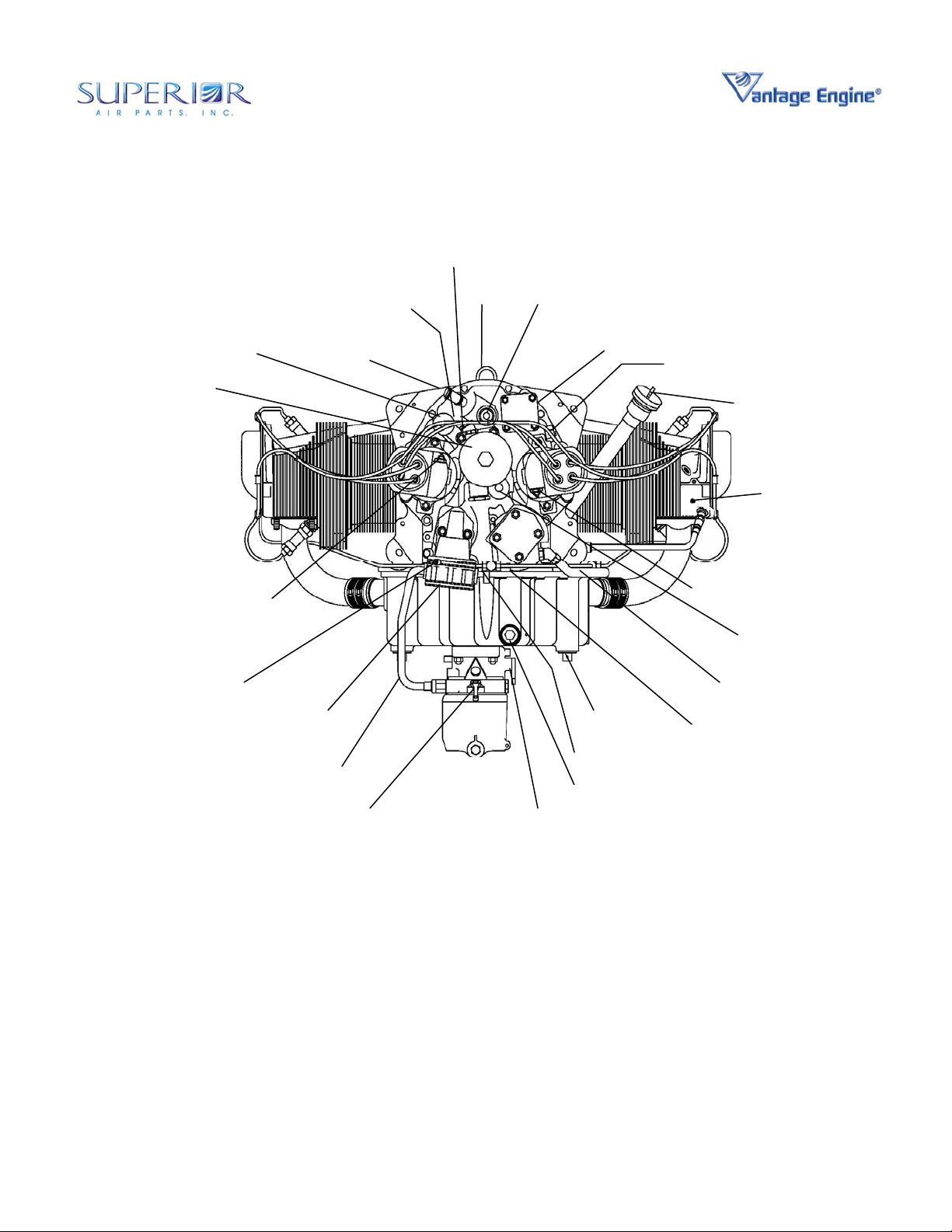

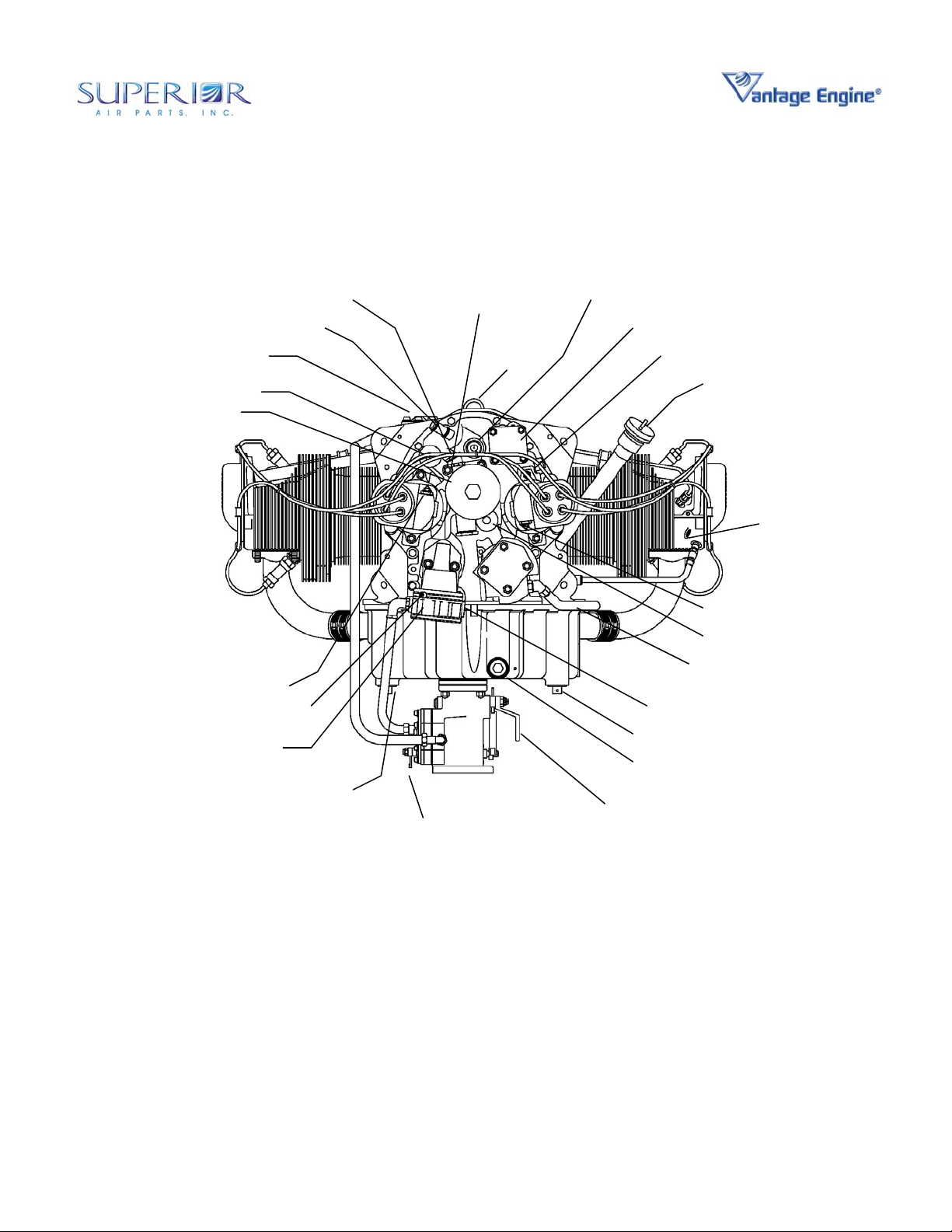

CHT PROBE LOCATION

(TYPICAL EACH HEAD)

ALTERNATOR & BELT

(IF PROVIDED WITH ENGINE)

SPARK PLUG

SPARK PLUG

PRIMING

SYSTEM

STARTER

THROTTLE LEVER

CARBURETOR

FUEL LINE

Figure 02-00-00.2 • O-360 Engine Front View

7

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

STARTER SUPPORT

ASSEMBLY

PRIMING

SYSTEM

CRANKCASE

ASSEMBLY

STARTER

INDUCTION

SYSTEM

CYLINDER

ASSEMBLY

SPARK PLUG

OIL SUMP

ASSEMBLY

ACCESSORY

HOUSING

MIXTURE

LEVER

OIL FILTER

FUEL

PUMP

FUEL

LINE

HARNESS

MAGNETO

CARBURETOR

Figure 02-00-00.3 • O-360 Engine Left Side View

8

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

INTER-CYLINDER BAFFLE

SPARK P L U G

MAGNETO

OIL FILTER

Figure 02-00-00.4 • O-360 Engine Top View

© March 2006 Superior Air Parts Inc.

9

MAGNETO

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

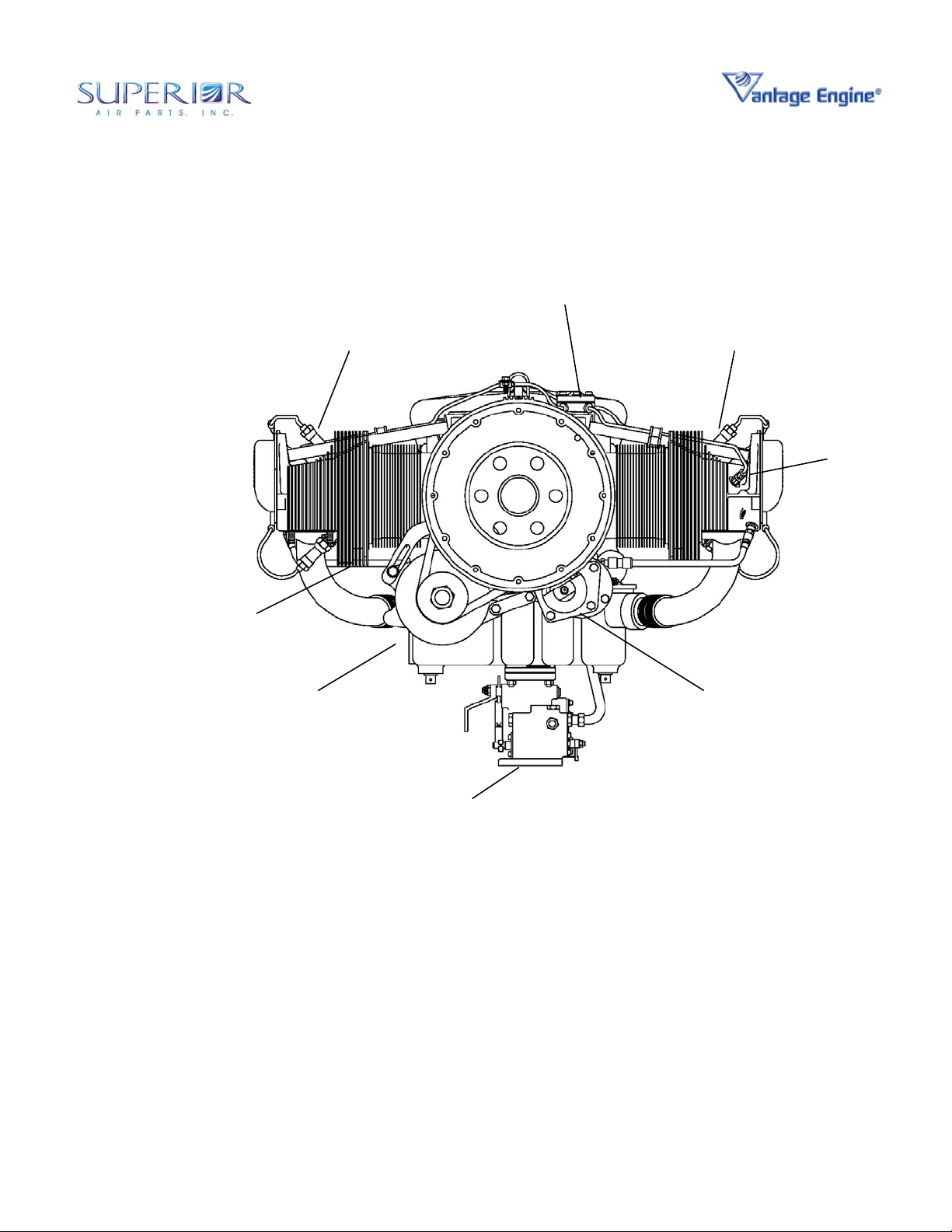

ALTERNATE OIL TO COOLER

OIL TEMP

CONNECTION

BRACKET

EYE

TACHOMETER CONNECTION

OIL RETURN FROM COOLER

OIL FILTER

GROUND OR “P-LEAD” TERMINAL

VENT LINE

CONNECTION

DIAPHRAGM

FUEL PUMP

BREATHER

FUEL LINE

FITTING

FUEL MIXTURE

LEVER

THROTTLE

LEVER

VACUUM PUMP / ACCESSORY PAD

OIL PRESSURE GAGE CONNECTION

OIL DRAIN

PLUG

FUEL PUMP INLET

OIL SUCTION

SCREEN

OIL LEVEL TUBE & GAGE

MANIFOLD

PRESSURE

CONNECTION

GROUND OR “P-LEAD” TERMINAL

OIL SUPPLY TO COOLER

OIL LINE TO

PROPELLER

COMMON PRIMER

LINE SOURCE

Figure 02-00-00.5 • O-360 Engine Rear View

10

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

FUEL INJECTION

MANIFOLD

CHT PROBE LOCATION

(TYPICAL EACH HEAD)

(IF PROVIDED WITH ENGINE)

SPARK PLUG

ALTERNATOR & BELT

SPARK PLUG

FUEL

INJECTOR

STARTER

FUEL INJECTION

SERVO

Figure 02-00-00.6 • IO-360 Engine Front View

11

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

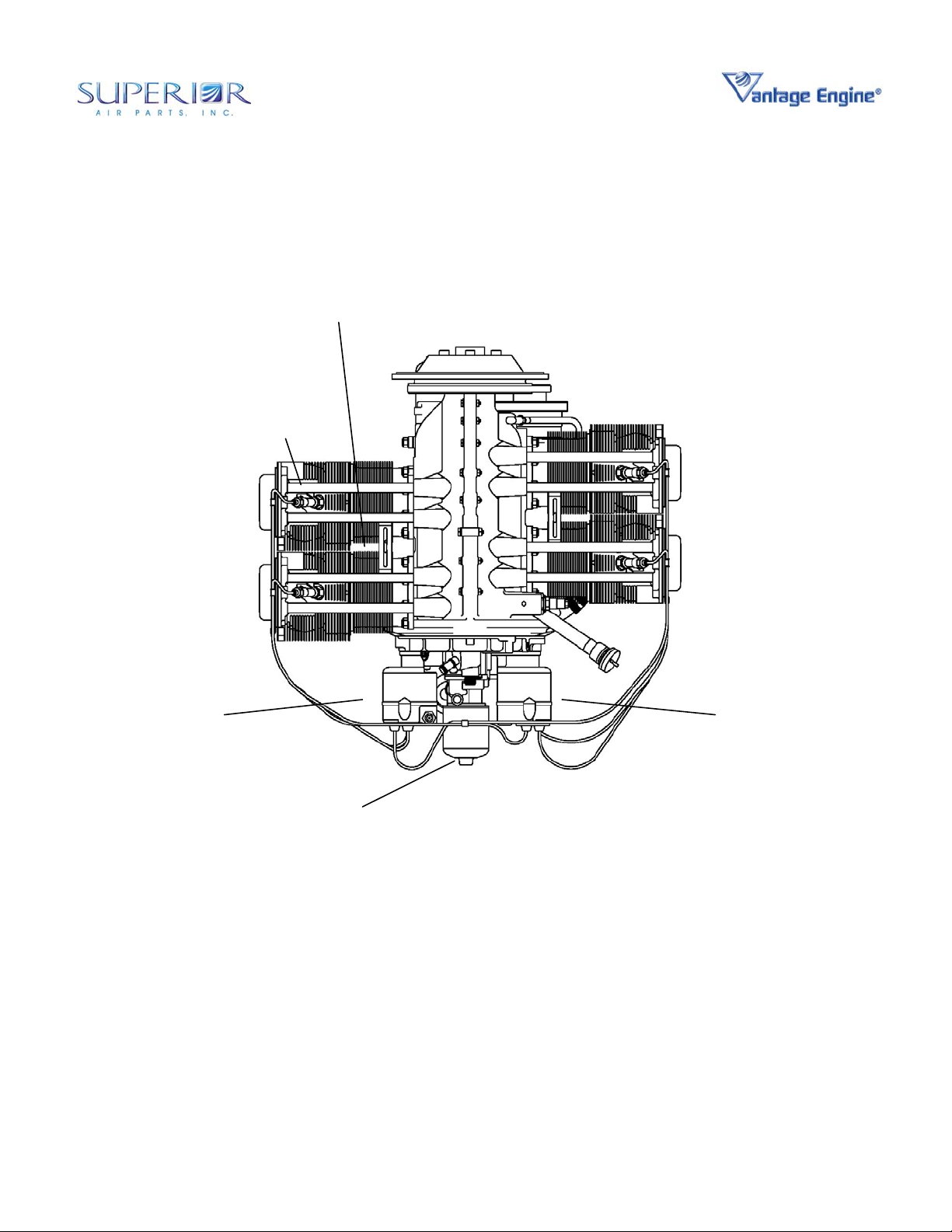

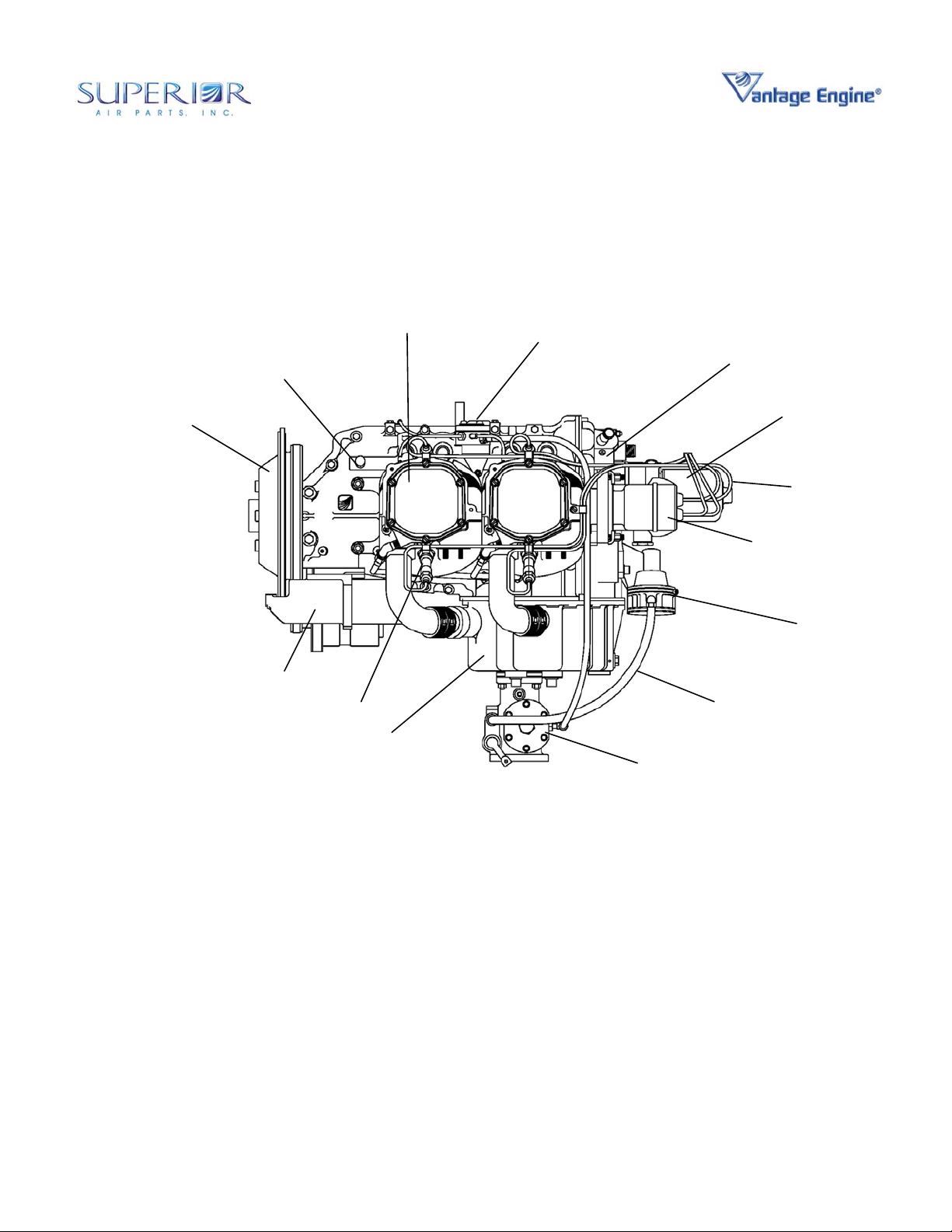

CRANKCASE

ASSEMBLY

CYLINDER

ASSEMBLY

FUEL INJECTION

MANIFOLD

ACCESSORY

HOUSING

STARTER SUPPORT

ASSEMBLY

STARTER

SPARK PLUG

OIL SUMP

FUEL INJECTION

Figure 02-00-00.7 • IO-360 Engine Left Side View

SERVO

MAGNETO

FUEL LINE

OIL FILTER

WIRING

HARNESS

FUEL PUMP

12

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

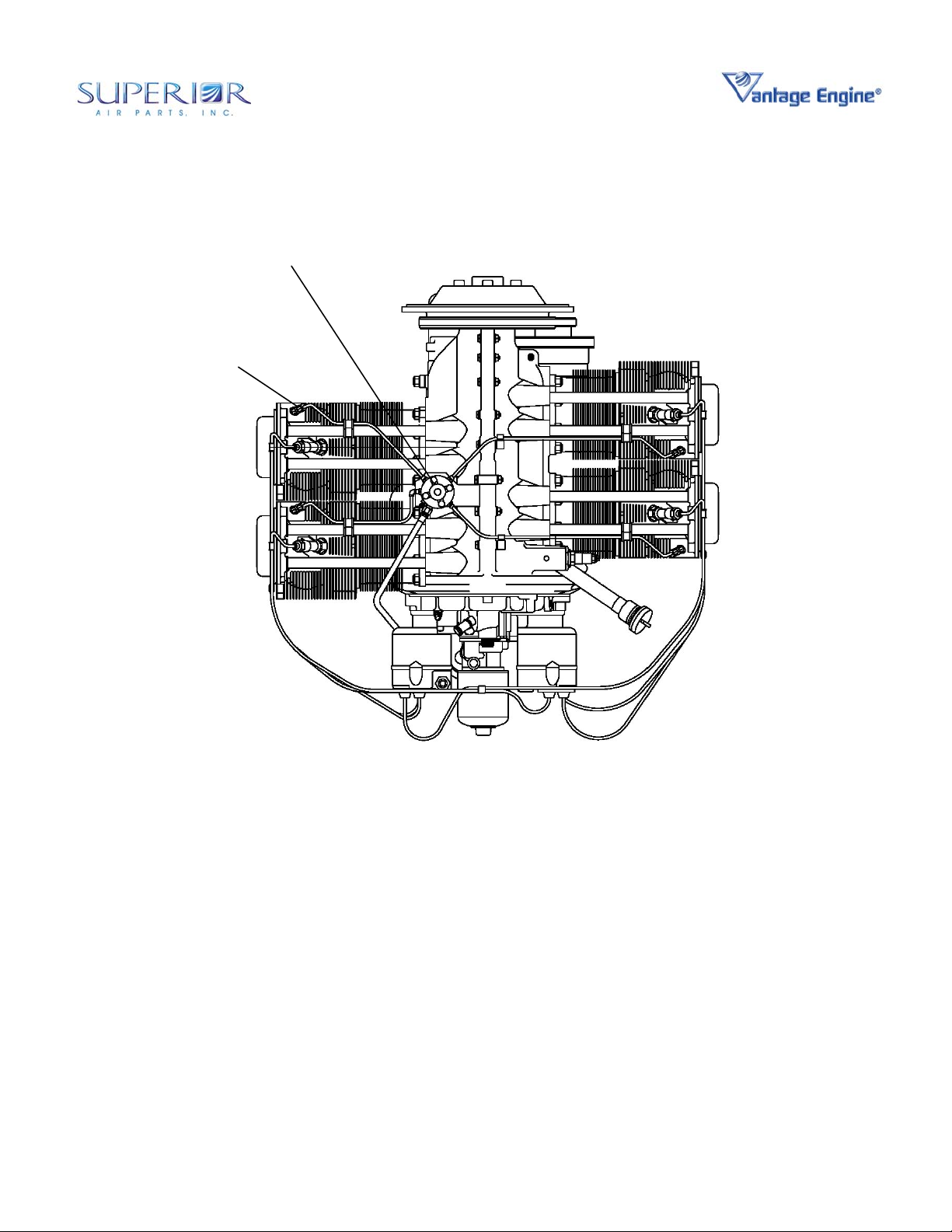

FUEL INJECTI ON

MANIFOLD

FUEL INJ ECTIOR

Figure 02-00-00.8 • IO-360 Engine Top View

13

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Maintenance Manual

O-360 and IO-360 Series Engines

BREATHER FITTING

FUEL INJECTION MANIFOLD

OIL RETURN FROM COOLER

OIL FILTER

GROUND OR “P-LEAD” TERMINAL

VENT LINE CONNECTION

ALTERNATE OIL

TO COOLER

OIL TEMP

CONNECTION

EYE

BRACKET

TACHOMETER CONNECTION

VACCUM PUMP / ACCESSORY PAD

FUEL PUMP INLET

OIL PRESSURE GAGE CONNECTION

OIL LEVEL TUBE & GAGE

MANIFOLD

PRESSURE

CONNECTION

GROUND OR “P-LEAD” TERMINAL

OIL SUPPLY TO COOLER

OIL LINE TO

PROPELLER

DIAPHRAGM FUEL

PUMP

OIL DRAIN PLUG

MIXTURE CONTROL

LEVER

THROTTLE CONTROL

OIL DRAIN PLUG

OIL SUCTION

SCREEN

LEVER

Figure 02-00-00.9 • IO-360 Engine Rear View

14

© March 2006 Superior Air Parts Inc.

02-00-00

Description and Operation

Loading...

Loading...