Page 1

UVFC-600

INSTALLATION

INSTRUCTIONS

STANDARD SERIES

36" & 42" Unvented Fireboxes

P/N 700,018M REV. C 12/2003

MODELS

UVFR-500 UVFC-500

UVFR-600 UVFC-600

UVFR-500

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNING: IF THE INFORMATION IN THIS MANUAL

IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

FOR YOUR SAFETY: Do not store or use gasoline

or other flammable vapors or liquids in the vicinity

of this or any other appliance.

FOR YOUR SAFETY: What to do if you smell gas:

• DO NOT light any appliance.

• DO NOT touch any electrical switches.

• DO NOT use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone.

Follow your gas suppliers instructions.

• If your gas supplier cannot be reached, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

FOR USE ONLY WITH DECORATIVE TYPE UNVENTED ROOM

HEATERS.

DO NOT BUILD A WOOD FIRE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE INJURY OR PROPERTY DAMAGE. REFER TO THIS MANUAL.

FOR ASSISTANCE OR ADDITIONAL INFORMATION CONSULT A QUALIFIED INSTALLER, SERVICE AGENCY OR THE

GAS SUPPLIER.

WARNING: DO NOT BURN WOOD OR OTHER MATERIAL IN

THESE APPLIANCES.

CAREFULLY REVIEW THE INSTRUCTIONS SUPPLIED WITH

THE DECORATIVE TYPE UNVENTED ROOM HEATER FOR

THE MINIMUM FIREPLACE SIZE REQUIREMENT.

DO NOT INSTALL THE APPLIANCE IN THIS FIREBOX, UNLESS THIS FIREBOX MEETS THE MINIMUM DIMENSIONS

REQUIRED FOR THE INSTALLATIONS.

This is an unvented gas-fired heater. It uses air

(oxygen) from the room in which it is installed.

Provisions for adequate combustion and ventilation air must be provided. Refer to Combustion

and Ventilation Air Section, Page 3.

Due to high temperatures, the appliance should be located out

of traffic and away from furniture or draperies.

Do not place clothing or other materials on or near this appliance.

IMPORTANT: READ AND UNDERSTAND THESE INSTRUCTIONS

COMPLETELY BEFORE INSTALLING YOUR UNVENTED ROOM

HEATERS.

1

Page 2

TABLE OF CONTENTS

Firebox/Log Set Reference Chart ..... page 2

General Information......................... page 2

Inventory ......................................... page 2

Tools/Building Supplies ................... page 2

Important Safety Information .......... page 2

Codes .............................................. page 3

Combustion and Ventilation Air ....... page 3

Location of firebox........................... page 4

Clearances ....................................... page 4

Assembly Steps ...............................page 5

Gas Line Installation ........................ page 5

Firebox Framing............................... page 6

UVF-500 Specifications ................... page 6

Firebox Installation .......................... page 7

UVF-600 Specifications ................... page 7

Framing Specifications .................... page 8

Canopy Installation .......................... page 9

Optional Equipment ......................... page 9

Firebox finishes ............................... page 10

Replacement Parts .......................... page 10

Accessories/Components ................ page 10

Replacement Parts List.................... page 11

GENERAL INFORMATION

These ventless firebox enclosures are designed

to accept all ANSI Z21.11.2 approved Decorative Type Unvented Gas Log Room Heaters.

For the appropriate Unvented Gas Log Room

Heater model, refer to the chart below. Refer to

the installation instructions provided with the

log sets for detailed instructions.

The UVFC Series are unvented fireboxes. They

feature a self-contained heat-circulating system.

The UVFR Series is a conventional radiantheat unvented firebox.

This installation manual will enable you to

obtain a safe, efficient and dependable installation of your room heater system.

Do not alter or modify the firebox or its components under any circumstances. Any modification or alteration of the firebox system, including but not limited to the firebox and accessories, may void the warranty, listings and

approvals of this system and could result in an

unsafe and potentially dangerous installation.

These Built-In Unvented Fireboxes have been

tested and approved as Ventless Firebox Enclosures for Gas-Fired Decorative Type Ventless

Room Heaters to IAS 2-97.

WARNING: THESE BUILT-IN UNVENTED FIREBOXES HAVE ONLY

BEEN TESTED AND APPROVED FOR

USE WITH ANSI Z21.11.2 UNVENTED GAS LOGS.

Check the inventory list to be sure that you have

all the necessary parts in usable condition. Also

check for concealed damage.

Inventory

Unvented Gas Firebox

Canopy

Gas Connector Fittings

Installation and Operating Instructions

Tools and Building Supplies

Normally Required

Tools Should Include:

Phillips screwdriver

Hammer

Saw and/or sabersaw

Level

Measuring tape

Electric drill and bits

Pliers

Square

Piping complying with local codes

Pipe wrench

Tee joint

Pipe compound

Building Supplies Should Include:

Framing materials

Wall finishing materials

Caulking materials (noncombustible)

Fireplace surround materials

(noncombustible)

IMPORTANT SAFETY INFORMATION

INSTALLER: PLEASE LEAVE THESE INSTRUCTIONS WITH THE OWNER.

DO NOT ATTEMPT TO BURN SOLID

WOOD FUELS, OTHER GAS LOG SETS

OR ANY OTHER COMBUSTIBLE MATERIALS IN THIS UNVENTED FIREBOX.

Log Set Sizing Reference Chart

Unvented Firebox Unvented Room Heater Log Set

Model Natural Propane (L.P.G)

UVFC-500 VFGL-18/24MN/VN-3 VFGL-18/24MP/VP-3

PVFGL-18MN/VN PVFGL-18MP/VP

OWNER: PLEASE RETAIN THESE INSTRUCTION FOR FUTURE REFERENCE

IMPORTANT: BEFORE STARTING YOUR FIREBOX INSTALLATION, READ THESE INSTALLATION INSTRUCTIONS CAREFULLY TO BE SURE

YOU UNDERSTAND THEM COMPLETELY AND

IN ENTIRETY. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD CAUSE A HEATER

MALFUNCTION RESULTING IN SERIOUS INJURY AND/OR PROPERTY DAMAGE.

WARNING: ANY CHANGE TO THIS UNVENTED ROOM HEATER CAN BE DAN-

UVFC-600 VFGL-24/28MN/VN-3 VFGL-24/28MP/VP-3

PVFGL-24MN/VN PVFGL-24MP/VP

UVFR-500 VFGL-18/24MN/VN-3 VFGL-18/24MP/VP-3

PVFGL-18MN/VN PVFGL-18MP/VP

UVFR-600 VFGL-24/28MN/VN-3 VFGL-24/28MP/VP-3

PVFGL-24MN/VN PVFGL-24MP/VP

2

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

GEROUS. IMPROPER INSTALLATION OR

USE OF THIS HEATER CAN CAUSE SERIOUS INJURY OR DEATH FROM FIRE,

BURNS, EXPLOSION OR CARBON MONOXIDE POISONING.

Page 3

Carbon Monoxide Poisoning: Early signs of

carbon monoxide poisoning are similar to the

flu with headaches, dizziness and/or nausea.

If you have these signs, obtain fresh air immediately. Have the Unvented Gas Heater

serviced as it may not be operating correctly.

• Due to high temperatures, the firebox should

be located out of traffic and away from furniture

and draperies.

• Children and adults should be alerted to the

hazard of high surface temperature and should

stay away to avoid burns or clothing ignition.

• Young children should be carefully supervised when they are in the same room with the

heater.

• Do not place clothing or other flammable

material on or near the heater.

• Any safety screen or guard removed for

servicing the firebox must be replaced and/or

closed prior to operating the heater.

• Installation and repair should be done by a

qualified service person. The heater should be

inspected before use and at least annually by

a professional service person. More frequent

cleaning may be required due to excessive lint

from carpeting, bedding material, etc. It is

important that control compartments, burners

and circulating air passageways of the heater

be kept clean.

• Allow the heater to cool before servicing.

Always shut off any electricity or gas to the

heater while performing service work.

• Do not install the firebox in a sleeping room

or bathroom.

• The appliance and its individual shut-off valve

must be disconnected from the gas supply

piping system while performing any tests of the

gas supply piping system at pressures in excess of ¹⁄₂ psig.

• The heater must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ¹⁄₂ psig.

• Keep heater area clear and free from combustible materials, gasoline and other flammable vapors and liquids.

• Do not use this heater if any part has been

under water. Immediately call a qualified service technician to inspect the heater and to

replace any part of the control system and any

gas control which has been under water.

• Ensure that the heater is clean when operating. Excessive dust accumulation on the burner

and logs will increase the amount of carbon

monoxide formation and could lead to carbon

monoxide poisoning and death.

CODES

Adhere to all local codes or in their absence the

latest edition of The National Fuel Gas Code

ANSI Z223.1 or NFPA54 which can be obtained

from The American National Standards Institute, Inc. (1430 Broadway, New York, NY,

10018) or National Fire Protection Association,

Inc. (Batterymarch Park, Quincy, MA, 02269).

COMBUSTION AND VENTILATION AIR

Heaters installed in these appliances shall not

be installed in a confined space. Heaters

installed in these appliances may be located

in unusually tight construction provided the

space is unconfined, or if confined, is provided with two permanent openings communicating directly with an additional room(s)

of sufficient volume so that the combined

volume of all connected spaces meets the

criteria for an unconfined space, (National

Fuel Gas Code ANSI Z223.1 1992, Section

5.3). Generally 50 ft3 per 1,000 BTU input of

all operating appliances in the space.

The National Fuel Gas Code defines a confined

space as a space whose volume is less than

50 ft3 per 1,000 BTU/Hr (4.8 m3 per kw) of the

aggregate input rating of all appliances installed in that space and an unconfined space

as a space whose volume is not less than 50 ft

per 1,000 BTU/Hr (4.8 m3 per kw) of the aggregate input rating of all appliances installed in

that space. Rooms communicating directly with

the space in which the appliances are installed,

through openings not furnished with doors, are

considered a part of the unconfined space.

Unusually tight construction is defined as construction where:

a. wall and ceilings exposed to the outside

atmosphere have a continuous water vapor

retarder with a rating or one perm or less with

openings gasketed or sealed, and

b. weather stripping has been added on operable windows and doors, and

c. caulking or sealants are applied to areas such

as joints around window and door frames,

between sole plates and floors, between wallceiling joints, between wall panels, at penetrations for plumbing, electrical, and gas lines,

and at other openings.

Use the following equations to determine if

you have a confined or unconfined space.

1.Determine the volume of space — ft

Length x Width x Height = _____ ft

(Include adjoining rooms with doorless passageways or ventilation grills between

rooms.)

Example: 24' (L) x 16' (W) x 8' (H) = 3072

3

ft

2.Divide the volume of space by 50 ft3 to

determine the maximum BTU/Hr the space

can support.

______ (volume of space – ft

(Maximum BTU/Hr the space can support)

Example: 3072 ft

3

/ 50 ft3 = 61.44

or 61,440 BTU/Hr the space can support.

3.Add the BTU/Hr of all the fuel burning appli-

ances in the space.

Vent-Free heater _______ BTU/Hr

Gas appliance #1* _______ BTU/Hr

Gas appliance #2 + _______ BTU/Hr

Total = _______ BTU/Hr

Example:

Vent-free heater 26,000 BTU/Hr

Gas appliance #1 40,000 BTU/Hr

(water heater)

Total = 66,000 BTU/Hr

3

* Do not include direct-vent gas appliances.

Direct-vent is sealed combustion and draws

combustion air from the outdoors.

4. Compare the maximum BTU/Hr the space

can support with the actual amount of BTU/

Hr used.

_________ BTU/Hr

(max. the space can support)

_________ BTU/Hr

(actual amount of BTU/Hr used)

Example:

61,440 BTU/Hr

(max. the space can support)

66,000 BTU/Hr

(actual amount of BTU/Hr used)

The space in the above example is a confined

space because the actual BTU/Hr used is more

than the maximum BTU/Hr the space can support. You must provide additional fresh air.

3

.

3

)/ 50 ft3 =

3

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

3

Page 4

WARNING: IF THE AREA IN WHICH THE

HEATER MAY BE OPERATED IS SMALLER

THAN THAT DEFINED AS AN UNCONFINED SPACE, PROVIDE ADEQUATE

COMBUSTION AND VENTILATION AIR BY

ONE OF THE METHODS DESCRIBED IN

THE NATIONAL FUEL GAS CODE, ANSI

Z223.1 1992, SECTION 5.3 OR APPLICABLE LOCAL CODES.

Your options are:

a. Rework equations adding the space of ad-

joining room(s). If the extra volume provides

an unconfined space, then remove door or

add ventilation grills between rooms. Refer

to National Fuel Gas Code, ANSI Z223.1

1992, Section 5.3.

b. Vent room directly to the outdoors. Refer to

National Fuel Gas Code, ANSI Z223.1 1992,

Section 5.3.

c. Install a lower BTU/Hr heater, such as a

21,000 BTU/Hr, to make the area an unconfined space.

If the actual BTU/Hr used is less than the

maximum BTU/Hr the space can support, then

the space is an unconfined space. You will need

no additional fresh air ventilation for an unconfined space.

• Never obstruct the front opening of the unvented firebox or restrict the flow of combustion and ventilation air.

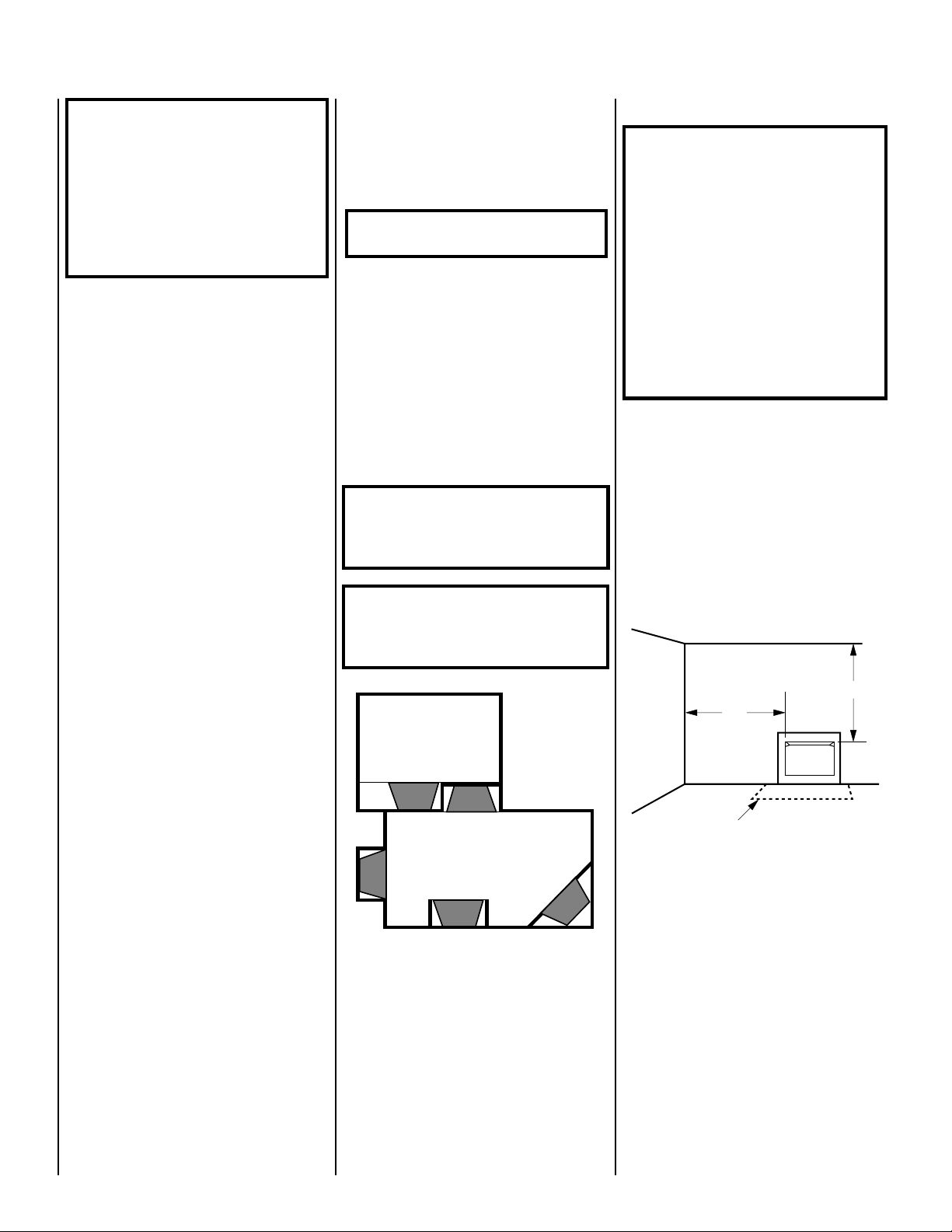

• Minimize modifications to existing construction. See

Figure 1

for location suggestions.

WARNING: MAINTAIN MINIMUM

CLEARANCES.

Do not install in the vicinity where gasoline or

other flammable liquids may be stored. The

unvented firebox must be kept clear and free

from these combustible materials.

CAUTION: HEATERS CREATE WARM AIR CURRENTS. THESE CURRENTS MOVE HEAT TO

WALL SURFACES NEXT TO HEATER. INSTALLING HEATER NEXT TO VINYL OR CLOTH WALL

COVERINGS OR OPERATING HEATER WHERE

IMPURITIES IN THE AIR (SUCH AS TOBACCO

SMOKE) EXISTS, MAY DISCOLOR WALLS.

WARNING: DO NOT ALLOW FANS TO

BLOW DIRECTLY INTO THE FIREPLACE.

AVOID ANY DRAFTS THAT ALTER

BURNER FLAME PATTERNS.

WARNING: DO NOT USE A BLOWER INSERT, HEAT EXCHANGER INSERT OR

OTHER ACCESSORY NOT APPROVED

FOR USE WITH THIS FIREPLACE.

Clearances

WARNING: DO NOT INSTALL THESE

BUILT-IN UNVENTED FIREBOXES IN

SLEEPING QUARTERS, OR IN RECREATIONAL VEHICLES.

WARNING: DO NOT INSTALL THESE

APPLIANCES:

• WHERE CURTAINS, FURNITURE,

CLOTHING OR OTHER FLAMMABLE

OBJECTS ARE LESS THAN 42" FROM

THE FRONT OF THE UNVENTED ROOM

HEATER.

• IN HIGH TRAFFIC AREAS.

• IN WINDY OR DRAFTY AREAS.

Ensure the minimum clearances shown in

ures 2 and 3

clearances are determined when facing the

front of the firebox.

Follow these instructions carefully to ensure

safe installation. Failure to follow these requirements may create a fire hazard.

Sidewall clearances: The sides of the firebox

opening must be at least 16" from any combustible wall (

are maintained. Left and right

Figure 2

).

Fig-

LOCATION OF FIREBOX

Carefully select the best location for installation

of your built-in unvented firebox. The following

factors should be taken into consideration:

• Clearance to side wall, ceiling, woodwork

and windows.

• Location must not be affected by drafts

caused by kitchen exhaust fans, return air registers for forced air furnaces/air conditioners,

windows or doors.

• Installation must provide adequate ventilation and combustion air.

• Do not install this firebox in a sleeping room

or bathroom.

• Location should be out of high traffic areas

and away from furniture and draperies due to

heat from firebox.

Figure 1

Not to Scale

40"

16"

Optional

Hearth Extension

Figure 2

Ceiling clearance: The ceiling must be at

least 40" from the top of the firebox opening

(

Figure 2

Noncombustible material: Noncombustible

materials, such as slate and marble, must be at

least ¹⁄₂" thick and may be used without restric-

tion above the firebox opening, to the sides or

as a hearth extension, so long as they do not

obstruct vent openings for heat circulating

models.

).

4

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Page 5

Safe

Combustible

Mantel

and Trim

Zone

18"

Min.

Canopy

8"

Max.

9"

Min.

Fireplace

Opening

Finished

Wall

3"

Header

Spacer

Figure 3

Noncombustible material (minimum requirements) with wood mantel or other

combustible projections: To install the fire-

box with a wood mantel, shelf or other combustible projection above firebox opening.

Refer to

Figure 3

.

WARNING: THE CANOPY HOOD MUST

BE IN PLACE TO BE IN COMPLIANCE

WITH THE CLEARANCES SPECIFIED IN

FIGURE 3

. DO NOT REMOVE OR REPLACE CANOPY, ONLY USE CANOPY

SUPPLIED WITH THE FIREBOX. DO

NOT USE ANY CANOPY WHICH MAY BE

PROVIDED WITH THE DECORATIVE TYPE

UNVENTED ROOM HEATER.

If your mantel profile is unsafe, you may either:

• Raise the mantel to an acceptable height, or

• Remove the mantel.

Floor clearance: These fireplaces may sit

directly on a combustible surface.

ASSEMBLY STEPS

Note: Illustrations shown in this manual re-

flect “typical” installations with nominal dimensions and are for design and framing

reference only. Actual installations may vary

due to individual design preferences. However, always maintain minimum clearances to

combustible materials and do not violate any

specific installation requirements. Refer to the

Framing Specifications Figures on page 8.

Note: The following steps represent the normal sequence of installation. Each installation

is unique, however, and might require a different sequence.

Step 1. Position firebox prior to framing or

into prepared framing.

Step 2. Field wire main power supply to circulating models for fan kit. (Electrical connections should only be performed by an experienced, licensed/certified tradesman.)

Step 3. Plumb gas line. (Gas connections

should only be performed by an experienced,

licensed/certified tradesman.)

Step 4. Install decorative type unvented room

heater per the instructions provided with the

unvented room heater.

Step 5. Complete finish wall material, surround and optional hearth extension to your

individual taste.

INSTALLATION

Gas Line Installation

CAUTION: PLUMBING CONNECTIONS SHOULD

ONLY BE PERFORMED BY A QUALIFIED, LICENSED PLUMBER. MAIN GAS SUPPLY MUST

BE OFF WHEN PLUMBING GAS LINE TO FIREPLACE OR PERFORMING SERVICE.

Consult all local codes.

It is recommended that the ¹⁄₂" gas line enter

the side of the firebox. Connect the gas line

before the firebox is enclosed in the finished

wall. The gas knockout is determined by an

indentation located at the bottom and slightly

off center in the side refractories. THE KNOCK-

OUT IS ALWAYS REMOVED FROM INSIDE

THE FIREBOX. If removal is attempted from

the outer wrapper, side-refractory damage

may occur. With a medium-sized hammer,

lightly tap the surface of the indentation. The

refractory material is very thin in this area and

is easily removed. Once a small hole has been

made, continue tapping until you have reached

sufficient diameter for the gas line to fit

through. The entire knockout does not have

to be removed.

Install only a ¹⁄₂" (1 ¹⁄₂" max.) inside diameter

approved gas line through the firebox wall for

connection to the unvented room heater inside

the firebox.

Ensure that a sediment trap is installed in the

existing gas line, if not, install a sediment trap

upstream of the heater to prevent moisture and

contaminants from passing through trap to the

heater controls and burners. Failure to do so

could prevent the heater from operating reliably.

An external regulator must be used on all propane (L.P.G.) heaters, in addition to the regulator fitted to the heater, to reduce the supply tank

pressure to 13" w.c. (maximum). Any copper

tubing used to supply propane (L.P.G.) from

the tank must be internally tinned.

IMPORTANT: HOLD HEATER REGULATOR

WITH A WRENCH TO PREVENT MOVEMENT

WHEN CONNECTING TO INLET PIPING.

Check Gas Type: The gas supply must be the

same as stated on the heater’s rating plate. If

the gas supply is different, DO NOT INSTALL

the heater. Contact your dealer for the correct

model.

WARNING: CONNECTING DIRECTLY TO

AN UNREGULATED PROPANE (L.P.G.)

TANK CAN CAUSE AN EXPLOSION.

IMPORTANT: RE-PACK INSULATION MATERIAL IN SQUARE HOLE AROUND GAS LINE,

INTERIOR AND EXTERIOR, TO SEAL.

Consult installation and operating instructions

for the model of unvented room heater to be

installed.

Checking Gas Connections: Test all gas joints

from the gas meter to the gas heater regulator

for leaks using soap and water solution after

completing connection. DO NOT USE AN OPEN

FLAME.

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

5

Page 6

Firebox Framing

UVF-500 SPECIFICATIONS

Construct firebox framing following

through 8

and the chart on page 8 for your

Figures 6

specific installation requirements. Refer to

Figures 4 and 5

on pages 6 and 7 for firebox

dimensions.

The firebox may be installed directly on a combustible floor or raised on a platform of an

appropriate height. Do not place firebox on

carpeting, vinyl or other soft floor coverings. It

may, however, be placed on flat wood, plywood, particle board, metal or other hard surfaces which extend the full width and depth of

the enclosure. Be sure firebox rests on a solid

continuous floor or platform with appropriate

framing for support and so that no cold air can

enter room from under the firebox.

The firebox may be positioned and then the

framing built around it, or the framing may be

constructed and the firebox positioned into the

opening.

Usually, no special floor support is needed for

the firebox, however, to be certain:

1. Estimate the total weight of the firebox

system and surround materials such as marble,

brick, stone, etc., to be installed.

2. Measure the square footage of the floor

space to be occupied by the system and surrounds.

7 ¹⁄₂"

(191 mm)

27 ⁷⁄₈"

(708 mm)

Gas Line

Access

20 ³⁄₁₆"

(513 mm)

(940 mm)

42"

(1067 mm)

Front

Gas Line

Access

37"

36"

(914 mm)

40"

(1016 mm)

2"

(51 mm)

Fireplace Top Spacer

9 ³⁄₁₆"

(233 mm)

9 ¹⁄₁₆"

(230 mm)

9 ⁵⁄₈"

(244 mm)

7 ³⁄₁₆"

(183 mm)

(813 mm)

37"

(940 mm)

32"

(940 mm)

37"

3. Note the floor construction, i.e. 2 x 6’s, 2 x

8’s or 2 x 10’s, single or double joists, type and

thickness of floor boards.

4. Use this information and consult your local

building code to determine if you need additional support.

CAUTION: DO NOT BLOCK THE HEAT-CIRCULATING AIR INLETS AND OUTLETS ON THE

VFC AND VFCE MODELS. DOING SO MAY

CREATE A POTENTIAL FIRE HAZARD.

If you plan to raise the firebox, build the platform assembly then position firebox on top.

Secure the platform to the floor to prevent

possible shifting.

Figure 4

20 ¹⁄₄"

(514 mm)

Left Side

Fireplace

Top Spacer

1"

(25 mm)

Junction

27 ¹⁄₄"

(692 mm)

42"

(1067 mm)

Top View

Box

(1016 mm)

40"

19 ⁵⁄₈"

(498 mm)

Right Side

20 ¹⁄₄"

(514 mm)

6

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Page 7

Firebox Installation

UVF-600 SPECIFICATIONS

Note: The firebox must be installed giving full

consideration to the clearance and height requirements identified in this manual.

Step 1. Slide the firebox into prepared framing

or position firebox in its final position and

frame later.

Step 2. Refer to firebox and framing specifications on pages 6, 7and 8

Figures 6 through 10

for framing dimensions and details. Framing

header may be positioned directly on the firebox top spacers.

Note: The framed depth from a framed wall,

must always be measured from a finished

surface. If a wall covering such as drywall is to

be attached to the rear wall, then the depth

must be measured from the drywall surface. It

is important that this dimension be exact.

IMPORTANT: UNDER NO CIRCUMSTANCES

SHALL THE FIREBOX TOP SPACERS BE REMOVED OR MODIFIED. THE HEADER MAY BE

IN DIRECT CONTACT WITH THE TOP SPACERS BUT MUST NOT BE SUPPORTED BY THEM

OR NOTCHED TO FIT AROUND THEM.

Step 3. Level the firebox by checking the top

edge of the firebox. Shim if necessary.

Step 4. Fireplace should be secured to side

framing members using the full length nailing

tabs at the top and bottom of the fireplace front

face. Use 8d nails (

see Figure 9

).

8 ³⁄₈"

(213 mm)

29 ⁵⁄₈"

(752 mm)

Gas Line

Access

22 ⁵⁄₁₆"

(566 mm)

(1143 mm)

45"

38"

(965 mm)

41"

(1041 mm)

(1194 mm)

Front

Gas Line

47"

Access

2"

(51 mm)

13 ³⁄₈"

(340 mm)

43"

(1092 mm)

7 ³⁄₁₆"

(183 mm)

Fireplace Top Spacer

9 ⁷⁄₈"

(251 mm)

10"

(254 mm)

Junction

Box

43"

(1092 mm)

20 ⁵⁄₈"

(524 mm)

Left Side

Fireplace

Top Spacer

1"

(25 mm)

Figure 5

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

31 ⁹⁄₁₆"

(802 mm)

47"

(1194 mm)

Top View

45"

(1143 mm)

21 ¹⁄₄"

(540 mm)

Right Side

(540 mm)

21 ¹⁄₄"

7

Page 8

FRAMING SPECIFICATIONS

B

Header

Framing Dimensions

Opening UVF-500 UVF-600

Figure 6

Figure 7

H

Corner Installation

A

Back Wall Of Chase/Enclosure

Including Finishing Materials

D

C

A

E

If Any

G

Rough

Framing Face

(Unfinished Shown)

A 41 ¹⁄₄" 46 ¹⁄₄"

B 37 ¹⁄₂" 43 ¹⁄₂"

C 27 ¹⁄₂" 31 ³⁄₄"

D 13 ³⁄₄" 15 ⁷⁄₈"

E 66 ³⁄₄" 73"

F 33 ³⁄₈" 36 ¹⁄₂"

G 19 ⁵⁄₈" 20 ⁵⁄₈"

F

H 47 ¹⁄₄" 51 ⁵⁄₈"

Rough Framing Face

(Unfinished Shown)

Figure 8

8

Back Wall Of Chase/Enclosure

Including Finishing Materials

C

A

If Any

G

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Page 9

Step 2. Align the canopy with the holes in the

top frame.

Step 3. Replace the screws previously removed.

Blower Kit Installation

To install the blower kit, follow Steps 1 thru 5

and refer to

Figures 12, 13 and 14

.

8d Nail

Figure 9

Note: The nailing flange and the area directly

behind the nailing flange is exempt from the

clearances described on the firebox clearance

label.

Step 5. To safely operate the heater with consideration of the mantel clearances the canopy

must be installed.

Canopy Installation

The factory-supplied canopy must be installed

on the firebox for safe operation. See

Figure 10

Step 4. Tighten side screws. Make sure the

canopy is level and secure.

OPTIONAL EQUIPMENT

Blower Kit

Circulating Models Only

If you are installing one of the blower kits,

Models FBK-100 or FBK 200, follow Steps 1

through 5, and see the installation instructions

provided with the kit for electrical wiring requirements (

be connected to main power supply at time of

installation if a forced air kit is to be installed

later. The electrical connections must be made

before the firebox is framed and enclosed in the

finished walls.

This appliance must be electrically grounded in

accordance with local codes or, in the absence

of local codes, the national electrical code,

ANSI/NFPA 70 - (Latest Edition).

CAUTION: ELECTRICAL CONNECTIONS

SHOULD ONLY BE PERFORMED BY A QUALIFIED, LICENSED ELECTRICIAN. MAIN POWER

.

MUST BE OFF WHEN CONNECTING TO MAIN

ELECTRICAL POWER SUPPLY OR PERFORMING SERVICE.

see Figure 11 )

. The firebox must

Step 1. Locate the blower motor shield.

Step 2. Remove the motor shield by bending it

along the perforation until the tabs break away.

Step 3. With the motor shield removed, place

the blower in the unit with the power cord up

and slide to the back of the unit until the motor

is behind the rear support.

Step 4. Rotate the blower 90 degrees, so that

the discharge is up.

Step 5. Move left side of blower around until it

is in the proper position and bend the retaining

tabs in the bottom of the unit up into the slots

on the blower.

Blower Motor

Motor Shield

Figure 12

UVF-500

Shown

UVF-500

Canopies

Attaching

Screws

3 Screws for 500 Models

4 Screws for 600 Models

UVF-600

Canopies

Firebox

Opening

Firebox

Opening

Figure 10

Step 1. Remove the screws from the top front

frame assembly. There are three (3) screws on

the 500 models and four (4) screws on the 600

models.

Blower Motor

Grounded

to Appliance

120V

Appliance Junction Box

NOTE: If any of the original wire as supplied

must be replaced, it must be replaced with type

AWM 105°c – 18Ga. wire

Figure 11

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Perforation

Tabs

Motor Plug

Motor Shield Removed

Receptacle

Figure 13

Rotated Blower In Final Position

Figure 14

9

Page 10

FIREBOX FINISHES

ACCESSORIES AND COMPONENTS

There are a wide variety of “finished looks” for

your built-in unvented firebox from formal wall

decor with elaborate mantels to rustic wood

paneling or warm brick facings.

Only noncombustible materials like marble,

stone, tile, brick, etc. may overlap the black

front facing but be sure not to block the upper

or lower grilles. Seal all joints between the black

facing and wall surrounds to prevent air intrusion. Use noncombustible caulking material

only to seal the black metal facing to the surround material on the finished wall.

REPLACEMENT PARTS

An exploded view of the firebox with numbered parts and a replacement parts list can be

found on page 11. Normally, all parts should

be ordered through your distributor or dealer.

Parts will be shipped at prevailing prices at

time of order.

When ordering repair parts, always give the

following information:

1. The model number of the firebox.

2. The serial number of the firebox.

3. The part number.

4. The description of the part.

5. The quantity required.

6. The installation date of the firebox.

If you encounter any problems or have any

questions concerning the installation of a unvented heater in this system, please contact

your distributor or dealer.

(FBK-200 Models Only)

Blower Kits

-Single Speed 80L84 FBK-100

-Variable Speed 80L85 FBK-200

Blower Kit

The FBK-100 blower provides for a constant

velocity forced air circulation feature for your

appliance. The FBK-200 assembly with variable speed wall switch provides a forced air

circulation feature for your appliance.

Decorative Volcanic Stone 80L42 FDVS

Decorative Volcanic Stone

The decorative volcanic stone, Model FDVS,

can be used to enhance the look of your appliance. Decorative volcanic stone is standard

with this appliance. Order model FDVS for

replacement of stone when needed. Spread the

decorative volcanic stone evenly around the

bottom of the firebox.

10

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Page 11

REPLACEMENT PARTS

3

2

4

1

5

UVFR-600

3

4

6

5

UVFR-500

UVF-500 UVF-600

No. DESCRIPTION Part No. Qty. Part No. Qty.

Gas Fireplace Assembly – – – –

1. Firescreen 36L89 2 36L99 2

2. Rod, Screen 88L95 2 88L96 2

3. Refractory, Side 88L59 2 88L65 2

4. Refractory, Rear 88L58 1 88L64 1

5. Refractory Base 88L57 1 88L63 1

6. Canopy 96L27 1 96L28 1

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

11

Page 12

The manufacturer reserves the right to make changes at any time, without notice, in design, materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local distributor for fireplace code information.

Printed in U.S.A. © 2000 by LHP

P/N 700,018M REV. C 12/2003

Manufactured By LHP

1110 West Taft Avenue • Orange, CA 92865

Loading...

Loading...