Page 1

Installation and Operation Instructions

Superior® Unvented (Vent-Free) Gas Log Heaters

P/N 126818-01 REV. C 08/2016

P126818-01

PFS

Report No. F11-017

®

US

Models

TF18NE TF18PE TF2430NE TF2430PE

For use with log sets

LTF18MM LTF18RS LTF18WT

LTF24MM LTF24RS LTF24WT

LTF30MM LTF30RS LTF30WT

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

This appliance may be installed in an aftermarket permanently located, manufactured (mobile) home,

where not prohibited by local codes. This appliance is only for use with the type of gas indicated on the

rating plate. This appliance is not convertible for use with other gases.

WARNING: This appliance is for installation only in a solid-fuel burning masonry or UL127 factory-built

fi replace or in a listed ventless fi rebox enclosure. It is design-certifi ed for these installations in accordance

with ANSI Z21.11.2. Exception: DO NOT install this appliance in a factory-built fi replace that includes

instructions stating it has not been tested or should not be used with unvented gas logs.

This is an unvented gas-fi red heater. It uses air (oxygen) from the room in which it is installed. Provisions

for adequate combustion and ventilation air must be provided. Refer to Air for Combustion and Ventilation

section on Page 6 of this manual.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death, or property damage.

- Do not store or use gasoline or other fl ammable vapors and liquids in the vicinity of this or any other

appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fi re department.

- Installation and service must be performed by a qualifi ed installer, service agency or the gas supplier.

Page 2

TABLE OF CONTENTS

Safety .................................................................. 2

Product Identifi cation ........................................... 5

Local Codes......................................................... 5

Unpacking............................................................ 5

Product Features ................................................. 6

Air For Combustion and Ventilation ..................... 6

Installation ........................................................... 8

Operation ........................................................... 24

Inspecting Burners............................................. 30

Cleaning and Maintenance ................................ 31

SAFETY

WARNING: Improper

installation, adjustment,

alteration, service or maintenance can cause injury

or property damage. Refer

to this manual for correct

installation and operational

procedures. For assistance

or additional information

consult a qualifi ed installer,

service agency or the gas

supplier.

Wiring Diagram .................................................. 32

Specifi cations .................................................... 32

Troubleshooting ................................................. 33

Parts .................................................................. 40

Replacement Parts ............................................ 45

Service Hints ..................................................... 45

Technical Service............................................... 45

Accessories ....................................................... 46

Warranty ............................................................ 47

WARNING: This is an

unvented gas-fi red heater.

It uses air (oxygen) from

the room in which it is

installed. Provisions for

adequate combustion and

ventilation air must be

provided. Refer to Air for

Combustion and Ventilation section on Page 6 of

this manual.

WARNING: This appliance is for installation

only in a solid-fuel-burning

masonry or UL127 factorybuilt fi replace or in a listed

ventless fi rebox enclosure.

It is design-certified for

these installations in accordance with ANSI Z21.11.2.

Exception: DO NOT install

this appliance in a factorybuilt fi replace that includes

instructions stating it has

not been tested or should

not be used with unvented

gas logs.

This appliance may be

installed in an aftermarket,* permanently located,

manufactured (mobile)

home, where not prohibited by local codes.

This appliance is only for

use with the type of gas

indicated on the rating

plate. This appliance is not

convertible for use with

other gases.

* Aftermarket: Completion of sale, not for

purpose of resale, from the manufacturer

www.SuperiorFireplaces.US.com

126818-01C2

Page 3

SAFETY

Continued

WARNING: This product contains and/or generates chemicals

known to the state of California

to cause cancer or birth defects

or other reproductive harm.

IMPORT ANT: Read this owner’s

manual carefully and completely

before trying to assemble, operate or service this appliance.

Improper use of this appliance

can cause serious injury or

death from burns, fi re, explo-

sion, electrical shock and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs of

carbon monoxide poisoning resemble the fl u,

with headaches, dizziness or nausea. If you

have these signs, the fi replace may not be

working properly. Get fresh air at once! Have

fi replace serviced. Some people are more affected by carbon monoxide than others. These

include pregnant women, people with heart

or lung disease or anemia, those under the

infl uence of alcohol and those at high altitudes.

Natural and Propane/LP

odor-making agent is added to these gases.

The odor helps you detect a gas leak. However, the odor added to the gas can fade. Gas

may be present even though no odor exists.

Make certain you read and understand all

warnings. Keep this manual for reference. It

is your guide to safe and proper operation of

this appliance.

gases are odorless. An

WARNING: Any change to

this heater or its controls can

be dangerous.

WARNING: Do not allow fans

to blow directly into the fi replace.

Avoid any drafts that alter burner

fl ame patterns. Ceiling fans can

create drafts that alter burner fl ame

patterns. Altered burner patterns

can cause sooting.

Due to high temperatures, the appliance should be located out of

traffi c and away from furniture and

draperies.

Do not place clothing or other

fl ammable material on or near the

appliance. Never place any objects

on the appliance.

Appliance base assembly becomes

very hot when running appliance.

Keep children and adults away from

hot surface to avoid burns or clothing ignition. Appliance will remain

hot for a time after shutdown. Allow

surface to cool before touching.

Carefully supervise young children

when they are in the room with appliance. When using the hand-held

remote accessory, keep selector

switch in the OFF position to prevent

children from turning on burners

with remote.

You must operate this appliance

with the fi replace screen and hood

in place. Make sure fi replace screen

and hood are in place before running

appliance. The fi replace screen shall

have openings for introduction of

combustion air.

WARNING: Do not use a

blower insert, heat exchanger

insert or other accessory not approved for use with this heater .

126818-01C 3

www.SuperiorFireplaces.US.com

Keep the appliance area clear and

free from combustible materials,

gasoline and other fl ammable

vapors and liquids.

Page 4

SAFETY

Continued

1. This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases.

2. Do not place propane/LP supply tank(s)

inside any structure. Locate propane/LP

supply tank(s) outdoors (propane/LP units

only).

3. If you smell gas

• shut off gas supply

• do not try to light any appliance

• do not touch any electrical switch; do not

use any phone in your building

• immediately call your gas supplier from

a neighbor’s phone. Follow the gas supplier’s instructions

• if you cannot reach your gas supplier,

call the fi re department

4. This heater shall not be installed in a

bedroom or bathroom.

5. Before installing in a solid fuel-burning fi re-

place, the chimney fl ue and fi rebox must

be cleaned of soot, creosote, ashes and

loose paint by a qualifi ed chimney cleaner.

Creosote will ignite if highly heated. A dirty

chimney fl ue may create and distribute

soot within the house. Inspect chimney

fl ue for damage. If damaged, repair fl ue

and fi rebox before operating appliance.

6. Do not burn solid-fuel in a fi replace in

which a vent-free room appliance is installed.

7. If fi replace has glass doors, never operate

this appliance with glass doors closed.

Any glass doors shall be fully opened

when the appliance in operation. If you

operate appliance with doors closed, heat

buildup inside fi replace will cause glass to

burst. Make sure there are no obstructions

across openings of fi replace.

8. To prevent the creation of soot, follow the

instructions in Cleaning and Maintenance,

Page 31.

9. Before using furniture polish, wax, carpet

cleaner or similar products, turn appliance

off. If heated, the vapors from these products may create a white powder residue

within burner box or on adjacent walls and

furniture.

10. This appliance needs fresh, outside air

ventilation to run properly. This appliance

has an Oxygen Depletion Sensing (ODS)

safety shutoff system. The ODS shuts

down the appliance if enough fresh air is

not available. See Air for Combustion and

Ventilation, Page 6. If appliance keeps

shutting off, see Troubleshooting, Page

33.

11. Do not run appliance

• where fl ammable liquids or vapors are

used or stored

• under dusty conditions

12. Do not use this appliance to cook food or

burn paper or other objects.

13. Do not use this room heater if any part

has been under water. Immediately call

a qualifi ed service technician to inspect

the room heater and to replace any part

of the control system and any gas control

which has been under water.

14. Do not operate appliance if any log is

broken. Do not operate appliance if a log

is chipped (dime-sized or larger).

15. Turn appliance off and let cool before

servicing, installing or repairing. Only a

qualifi ed service person should install,

service or repair appliance.

16. Make sure the remote is set to the OFF

position when you are away from home

for long periods of time.

17. Operating appliance above elevations of

4,500 feet may cause pilot outage.

18. To prevent performance problems, do

not use propane/LP fuel tank of less than

100 lb. capacity (propane/LP units only).

19. Provide adequate clearances around air

openings.

Y oung children should be carefully supervised when they are in the same room

as the appliance. Toddlers, young children and others may be susceptible

to accidental burns. A physical barrier is recommended if there are at-risk

individuals in the house. To restrict access to a fi replace or stove, install

an adjustable safety gate to keep toddlers, young children and other at-risk

individuals out of the room and away from hot surfaces.

SuperiorFireplaces.US.com

126818-01C4

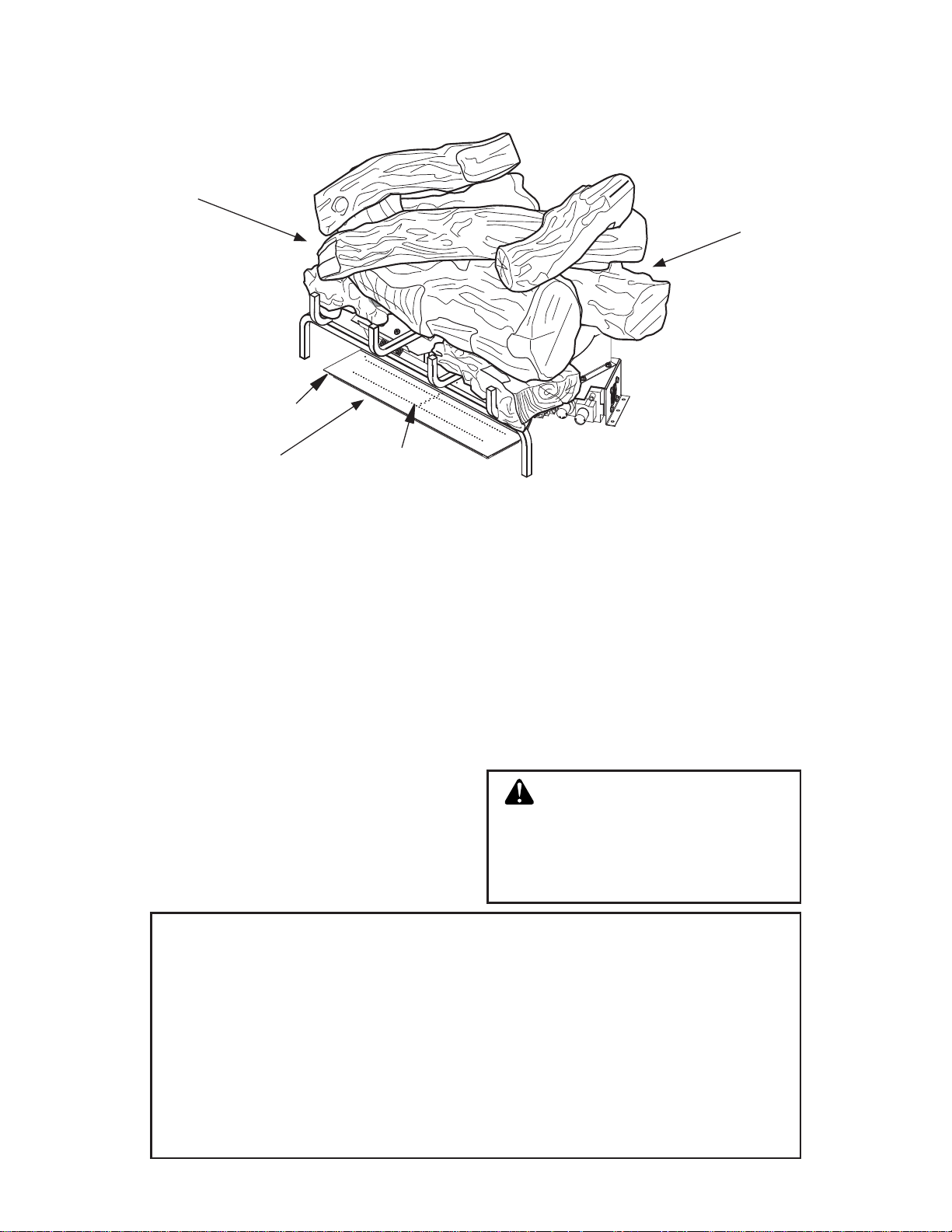

Page 5

Left

Side

PRODUCT IDENTIFICATION

Right

Side

Chassis

Front

Glowing

Embers

Figure 1 - Product Identifi cation

LOCAL CODES

Install and use appliance with care. Follow all

local codes. In the absence of local codes, use

the latest edition of The National Fuel Gas

Code, ANSI Z223.1/NFPA 54*.

*Available from:

American National Standards Institute, Inc.

25 West 43rd Street, 4th fl oor

New York, NY 10036

National Fire Protection Association, Inc.

1 Batterymarch Park

Quincy, MA 02169-7471

Quincy, MA 02269

UNPACKING

1. Remove logs and appliance base assembly from carton(s).

NOTE: Do not pick up appliance base as-

sembly by burners. This could damage the

appliance. Always handle base assembly

by grate.

2. Remove all protective packaging applied

to logs and appliance for shipment.

3. Check appliance for any shipping damage. If appliance is damaged, promptly

inform dealer where you purchased the

appliance.

CAUTION: Do not remove

the data plates from the grate

assembly. The data plates

contain important warranty

and safety information.

COMMONWEALTH OF MASSACHUSETTS REQUIREMENTS

These appliances are approved for installation in the US state of Massachusetts if the following additional requirements are met:

• Un-vented Room Heaters shall be installed in accordance with 527 CMR 30.

• Installation and repair must be done by a plumber or gas fi tter licensed in the Common-

wealth of Massachusetts.

• The fl exible gas line connector used shall not exceed 36 inches (92 centimeters) in length.

• The individual manual shut-off must be a T-handle type valve.

• Unvented appliances may NOT be installed in bedrooms or bathrooms.

• A working smoke detector must be installed in the area where vent-free appliances are

installed.

Seller of unvented propane or natural gas-fi red supplemental room heaters shall provide

to each purchaser a copy of 527 CMR 30 upon sale of the unit.

126818-01C 5

SuperiorFireplaces.US.com

Page 6

PRODUCT FEATURES

OPERATION

This appliance is clean burning. It requires

no outside venting. There is no heat loss out

a vent or up a chimney. Heat is generated by

both realistic fl ames and glowing coals. This

appliance is designed for vent-free operation

with fl ue damper closed. It has been tested

and approved to the ANSI Z21.11.2 standard

for unvented appliances. State and local codes

in some areas prohibit the use of vent-free

appliances.

AIR FOR COMBUSTION AND VENTILATION

WARNING: This heater shall

not be installed in a room or space

unless the required volume of

indoor combustion air is provided

by the method described in the

National Fuel Gas Code, ANSI

Z223.1/NFP A 54, the International

Fuel Gas Code, or applicable local

codes. Read the following instructions to ensure proper fresh air

for this and other fuel-burning

appliances in your home.

Today’s homes are built more energy effi cient

than ever. New materials, increased insulation

and new construction methods help reduce

heat loss in homes. Homeowners apply

weather strip and caulk around windows and

doors to keep the cold air out and the warm air

in. During heating months, homeowners want

their homes as airtight as possible.

While it is good to make your home energy

effi cient, your home needs to breathe. Fresh

air must enter your home. All fuel-burning appliances need fresh air for proper combustion

and ventilation.

Exhaust fans, some fi replaces, clothes dryers

and some fuel-burning appliances draw air

from the house to operate. You must provide

adequate fresh air for these appliances. That

will ensure proper venting of vented fuel-burning

appliances.

PROVIDING ADEQUA TE

VENTILATION

The following are excerpts from National Fuel

Gas Code, ANSI Z223.1/NFPA 54, Air for

Combustion and Ventilation.

All spaces in homes fall into one of the three

following ventilation classifi cations:

SuperiorFireplaces.US.com

SAFETY DEVICE

This appliance has a pilot with an Oxygen

Depletion Sensing (ODS) safety shutoff

system. The ODS/pilot is a required feature

for vent-free room appliances. The ODS/pilot

shuts off the appliance if there is not enough

fresh air.

ELECTRONIC IGNITION SYSTEM

This appliance has an electronic Igniter to light

appliance fuel supply.

1. Unusually Tight Construction

2. Unconfi ned Space

3. Confi ned Space

The information on Pages 6-8 will help you

classify your space and provide adequate

ventilation.

Unusually Tight Construction

The air that leaks around doors and windows

may provide enough fresh air for combustion

and ventilation. However, in buildings of unusually tight construction, you must provide

additional fresh air.

Unusually tight construction is defi ned as

construction where:

a. walls and ceilings exposed to the out-

side atmosphere have a continuous

water vapor retarder with a rating of

one perm (6 x 10

less with openings gasketed or sealed

and

b. weather stripping has been added on

openable windows and doors and

c. caulking or sealants are applied to

areas such as joints around window

and door frames, between sole plates

and fl oors, between wall-ceiling joints,

between wall panels, at penetrations

for plumbing, electrical and gas lines

and at other openings.

If your home meets all three criteria above,

you must provide additional fresh air. See

Ventilation Air From Outdoors, page 8.

If your home does not meet all three criteria

above, proceed to Determining Fresh-Air Flow

For Heater Location, Page 7.

Confi ned and Unconfi ned Space

The National Fuel Gas Code, ANSI Z223.1/

NFPA54 allows two methods for determining

whether the space in which the heater is being

installed is confi ned or unconfi ned space. The

-11

kg per pa-sec-m2) or

126818-01C6

Page 7

AIR FOR COMBUSTION AND VENTILATION

Continued

standard method defi nes a confi ned space as

a space whose volume is less than 50 cubic

feet per 1,000 Btu/hr (4.8 m

3

per kw) of the aggregate input rating of all appliances installed

in that space and an unconfi ned space as

a space whose volume is not less than 50

3

cubic feet per 1,000 Btu/hr (4.8 m

per kw) of

the aggregate input rating of all appliances

installed in that space. Rooms communicating

directly with the space in which the appliances

are installed*, through openings not furnished

with doors, are considered a part of the unconfi ned space.

Where the air infi ltration rate of a structure is

known, the Known Air Infi ltration Rate Method

may be used. Follow The National Fuel Gas

Code, ANSI Z223.1/NFPA 54 to use this

method to determine if the space is confi ned

or unconfi ned.

* Adjoining rooms are communicating only if

there are doorless passageways or ventilation

grills between them.

DETERMINING FRESH-AIR FLOW

FOR HEATER LOCATION

Determining if You Have a Confi ned or

Unconfi ned Space Using the Standard

Method

Use this work sheet to determine if you have

a confi ned or unconfi ned space.

Space: Includes the room in which you will install

fi replace plus any adjoining rooms with doorless passageways or ventilation grills between

the rooms.

1. Determine the volume of the space (length

x width x height).

Length x Width x Height =__________cu. ft.

(volume of space)

Example: Space size 20 ft. (length) x 16 ft.

(width) x 8 ft. (ceiling height) = 2560 cu. ft.

(volume of space)

If additional ventilation to adjoining room

is supplied with grills or openings, add the

volume of these rooms to the total volume

of the space.

2. Multiply the space volume by 20 to determine

the maximum Btu/Hr the space can support.

________ (volume of space) x 20 = (Maxi-

mum Btu/Hr the space can support)

Example: 2560 cu. ft. (volume of space) x 20

= 51,200 (maximum Btu/Hr the space can

support)

3. Add the Btu/Hr of all fuel-burning appliances

in the space.

Vent-free fi replace __________ Btu/Hr

Gas water heater* __________Btu/Hr

Gas furnace __________ Btu/Hr

Vented gas heater __________ Btu/Hr

Gas fi replace logs __________ Btu/Hr

Other gas appliances* + _________ Btu/Hr

Total = _________ Btu/Hr

* Do not include direct-vent gas appliances.

Direct-vent draws combustion air from the

outdoors and vents to the outdoors.

Example:

Gas water heater __________ Btu/Hr

Vent-free fi replace + _________ Btu/Hr

Total = _________ Btu/Hr

4. Compare the maximum Btu/Hr the space

can support with the actual amount of Btu/

Hr used.

______Btu/Hr (maximum the space can

support)

______Btu/Hr (actual amount used)

Example: 51,200 Btu/Hr (maximum the

space can support)

73,000 Btu/Hr (actual amount of

Btu/Hr used)

The space in the above example is a confi ned

space because the actual Btu/Hr used is more

than the maximum Btu/Hr the space can support. You must provide additional fresh air. Your

options are as follows:

A. Rework worksheet, adding the space of an

adjoining room. If the extra space provides

an unconfi ned space, remove door to adjoin-

ing room or add ventilation grills between

rooms. See Ventilation Air From Inside

Building, Page 8.

B. Vent room directly to the outdoors. See

Ventilation Air From Outdoors, Page 8.

C. Install a lower Btu/Hr heater, if lower Btu/Hr

size makes room unconfi ned.

If the actual Btu/Hr used is less than the maxi-

mum Btu/Hr the space can support, the space is

an unconfi ned space. You will need no additional

fresh air ventilation.

40,000

33,000

73,000

WARNING: If the area in which

the heater may be operated does

not meet the required volume for

indoor combustion air, combustion

and ventilation air shall be provided

by one of the methods described in

the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, the International

Fuel Gas Code, or applicable local

codes.

126818-01C 7

SuperiorFireplaces.US.com

Page 8

AIR FOR COMBUSTION AND VENTILATION

A

Or

Remove

Door into

Adjoining

Room,

Option

3

Ventilation Grills

Into Adjoining Room,

Option 2

Ventilation

Grills Into

Adjoining

Room,

Option 1

12"

12"

Continued

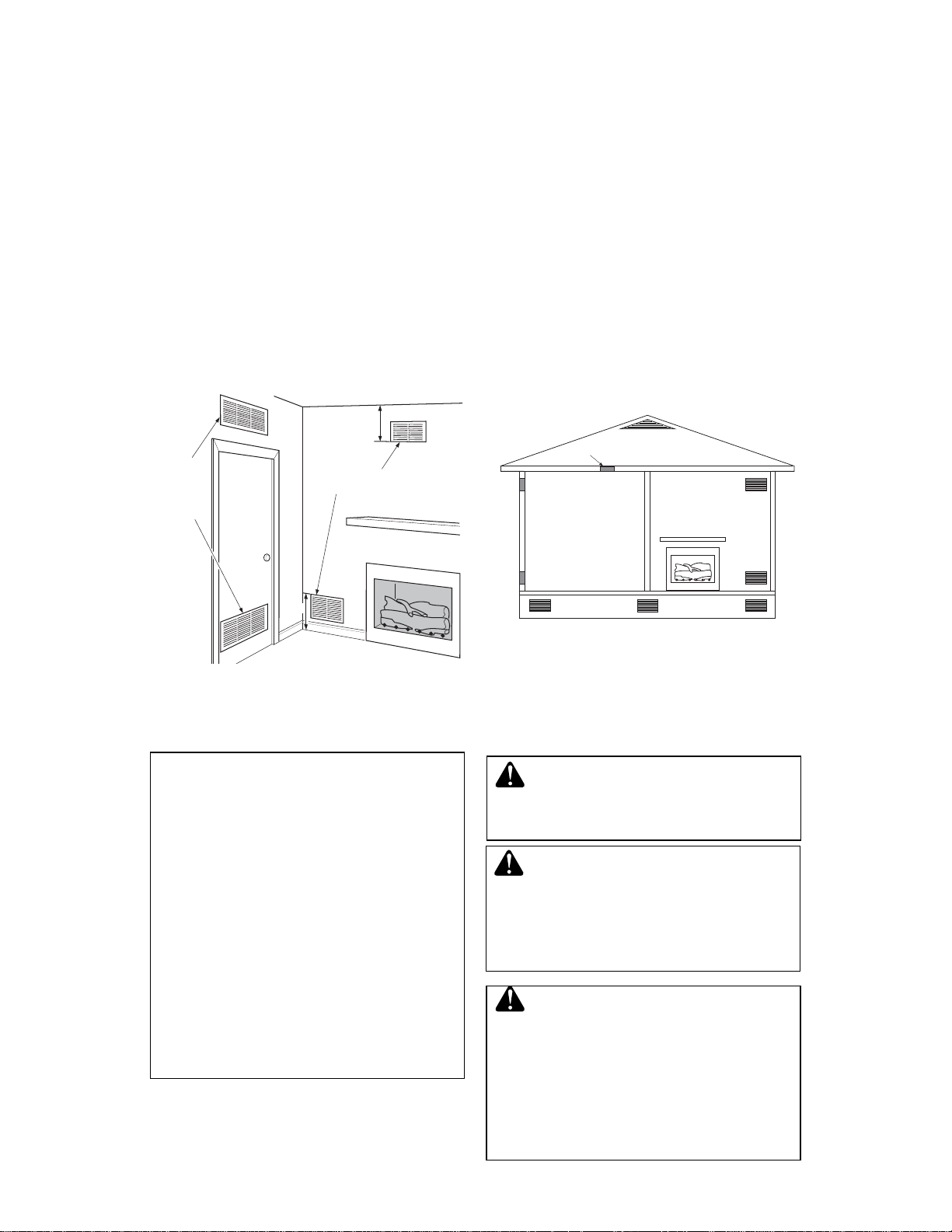

VENTILA TION AIR

Ventilation Air From Inside Building

This fresh air would come from an adjoining

unconfi ned space. When ventilating to an

adjoining unconfi ned space, you must provide

two permanent openings: one within 12" of the

ceiling and one within 12" of the fl oor on the

wall connecting the two spaces (see options

1 and 2, Figure 2). You can also remove door

into adjoining room (see option 3, Figure 2).

Follow the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, Air for Combustion and

Ventilation for required size of ventilation

grills or ducts.

Ventilation Air From Outdoors

Provide extra fresh air by using ventilation

grills or ducts. You must provide two permanent openings: one within 12" of the ceiling

and one within 12" of the fl oor. Connect these

items directly to the outdoors or spaces open

to the outdoors. These spaces include attics

and crawl spaces. Follow the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, Air for

Combustion and Ventilation for required size

of ventilation grills or ducts.

IMPORTANT: Do not provide openings

for inlet or outlet air into attic if attic has a

thermostat-controlled power vent. Heated air

entering the attic will activate the power vent.

Ventilated

Attic

Ventilated

Crawl Space

To Attic

To

Crawl

Space

Outlet

ir

Inlet

Air

Outlet

Air

Inlet Air

Figure 2 - Ventilation Air from Inside

Building

INSTALLATION

NOTICE: This appliance is intended for use as supplemental

heat. Use this appliance along

with your primary heating system. Do not install this appliance

as your primary heat source. If

you have a central heating system, you may run system’s circulating blower while using appliance. This will help circulate

the heat throughout the house.

In the event of a power outage,

you can use this appliance as

your primary heat source.

Figure 3 - Ventilation Air from Outdoors

WARNING: A qualifi ed ser-

vice person must install appliance. Follow all local codes.

WARNING: Any outside air

ducts and/or ash dumps in the

fi replace shall be permanently

closed at time of appliance installation.

WARNING: Seal any fresh

air vents or ash clean-out doors

located on fl oor or wall of fi re-

place. If not, drafting may cause

pilot outage or sooting. Use a

heat-resistant sealant. Do not

seal chimney fl ue damper.

SuperiorFireplaces.US.com

126818-01C8

Page 9

INSTALLATION

Continued

W ARNING: Before installing

in a solid fuel-burning fi replace,

the chimney fl ue and fi rebox

must be cleaned of soot, creosote, ashes and loose paint by

a qualified chimney cleaner.

Creosote will ignite if highly

heated. A dirty chimney fl ue may

create and distribute soot within

the house. Inspect chimney and

fi rebox fl ue for damage. If dam-

aged, repair fl ue and fi rebox

before operating appliance.

CHECK GAS TYPE

Use the correct type of gas (natural or propane/

LP). If your gas supply is not the correct gas

type, do not install appliance. Call dealer

where you purchased the appliance for proper

type appliance.

WARNING: This appliance is

equipped for either natural gas

or propane/LP gas but not both.

Gas type is indicated on the rating plate. Field conversion is not

permitted.

INST ALLATION AND CLEARANCES

FOR VENT-FREE OPERATION

W ARNING: Never install the

appliance

• in a bedroom or bathroom

• in a recreational vehicle

where curtains, furniture, cloth-

•

ing or other fl ammable objects

are less than 36" from front, 42"

from top of appliance; for side

clearances see Figure 4, Page 10

• in high traffi c areas

• in windy or drafty areas

CAUTION: This appliance

creates warm air currents. These

currents move heat to wall surfaces next to appliance. Installing

appliance next to vinyl or cloth

wall coverings or operating appliance where impurities (such as,

but not limited to, tobacco smoke,

aromatic candles, cleaning fl uids,

oil or kerosene lamps, etc.) in the

air exist, may discolor walls or

cause odors.

IMPORTANT: Vent-free appliances add

moisture to the air. Although this is benefi cial,

installing appliance in rooms without enough

ventilation air may cause mildew to form from

too much moisture. See Air for Combustion

and Ventilation, Page 6.

WARNING: Maintain the

minimum clearances. If you can,

provide greater clearances from

fl oor, ceiling and adjoining wall.

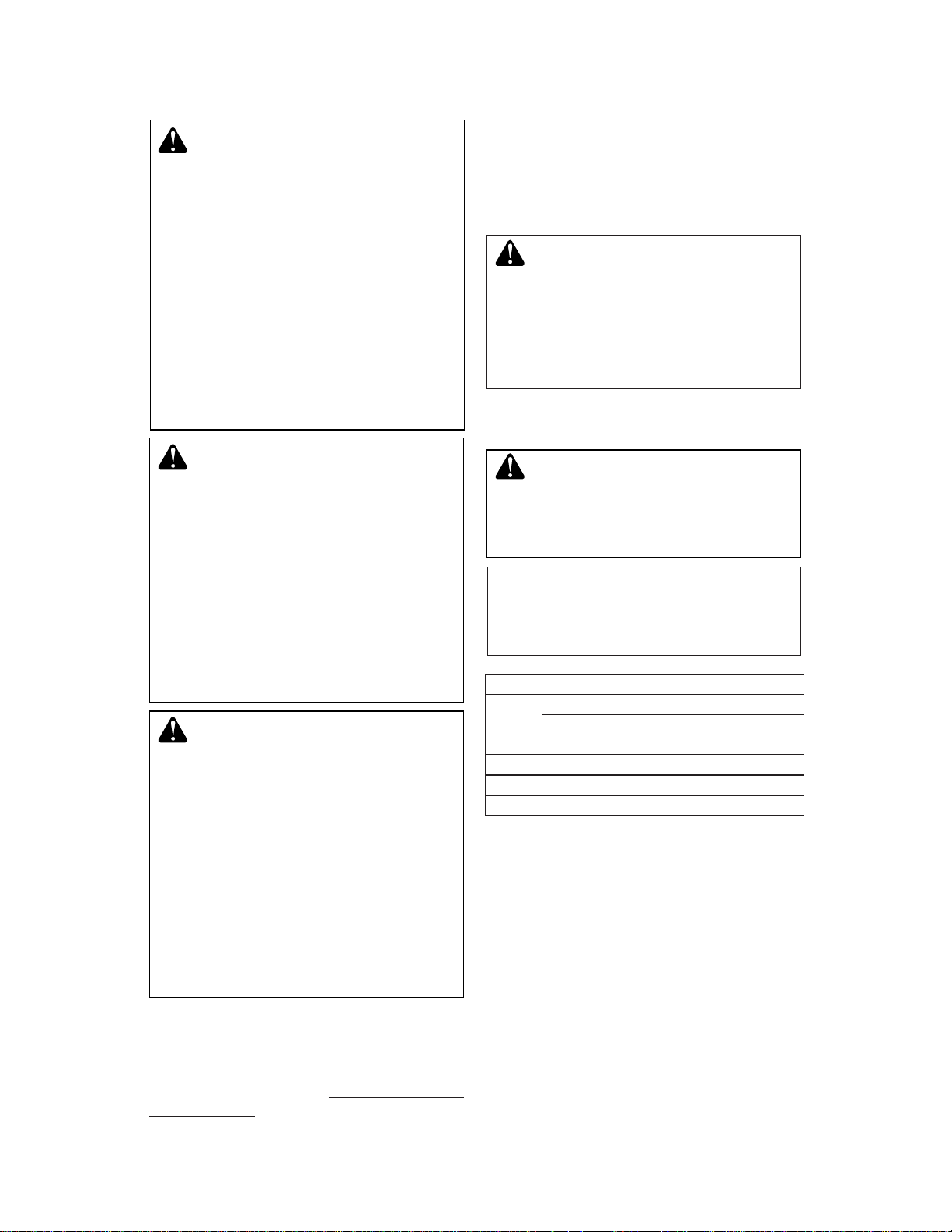

MINIMUM FIREPLACE CLEARANCE TO

COMBUSTIBLE MATERIALS

Side Wall 16", Ceiling 42"

Floor 5", Front: 36"

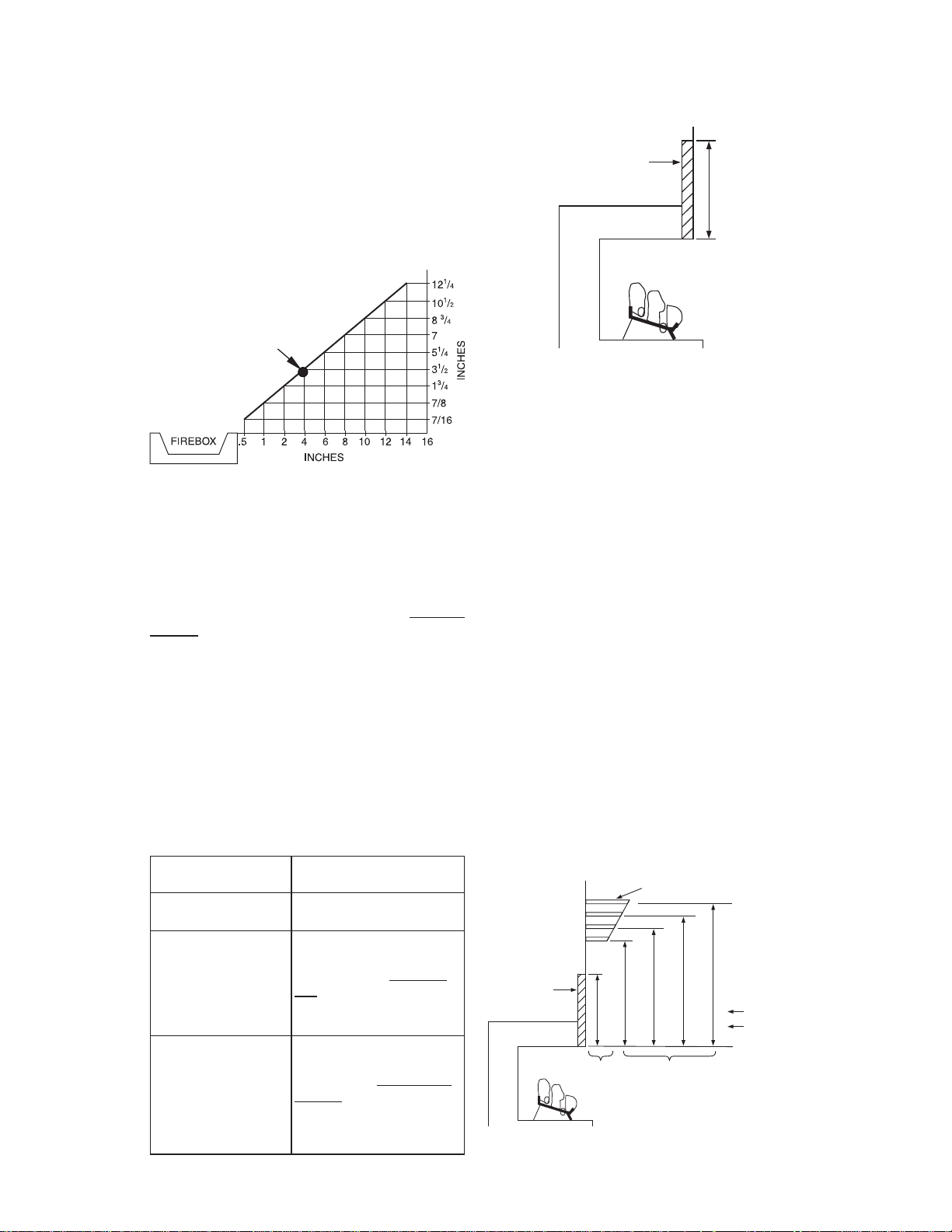

LOG SIZING REQUIREMENTS

Log

Size

18" 19" 14" 28" 20"

24" 19" 14" 32" 22"

30" 19" 14" 40" 30"

Carefully follow the instructions below. This

will ensure safe installation into a masonry,

UL127-listed manufactured fi replace or listed

vent-free fi rebox.

Minimum Clearances For Side Combustible

Material, Side Wall and Ceiling

A. Clearances from the side of the fi replace

cabinet to any combustible material and

wall should follow diagram in Figure 4,

Page 10.

Example: The face of a mantel, bookshelf,

etc. is made of combustible material

and protrudes 3-1/2" from the wall. This

combustible material must be 4" from the

side of the fi replace cabinet (see Figure

4, Page 10).

Minimum Firebox Size

Height Depth

Front

Width

Rear*

Width

126818-01C 9

SuperiorFireplaces.US.com

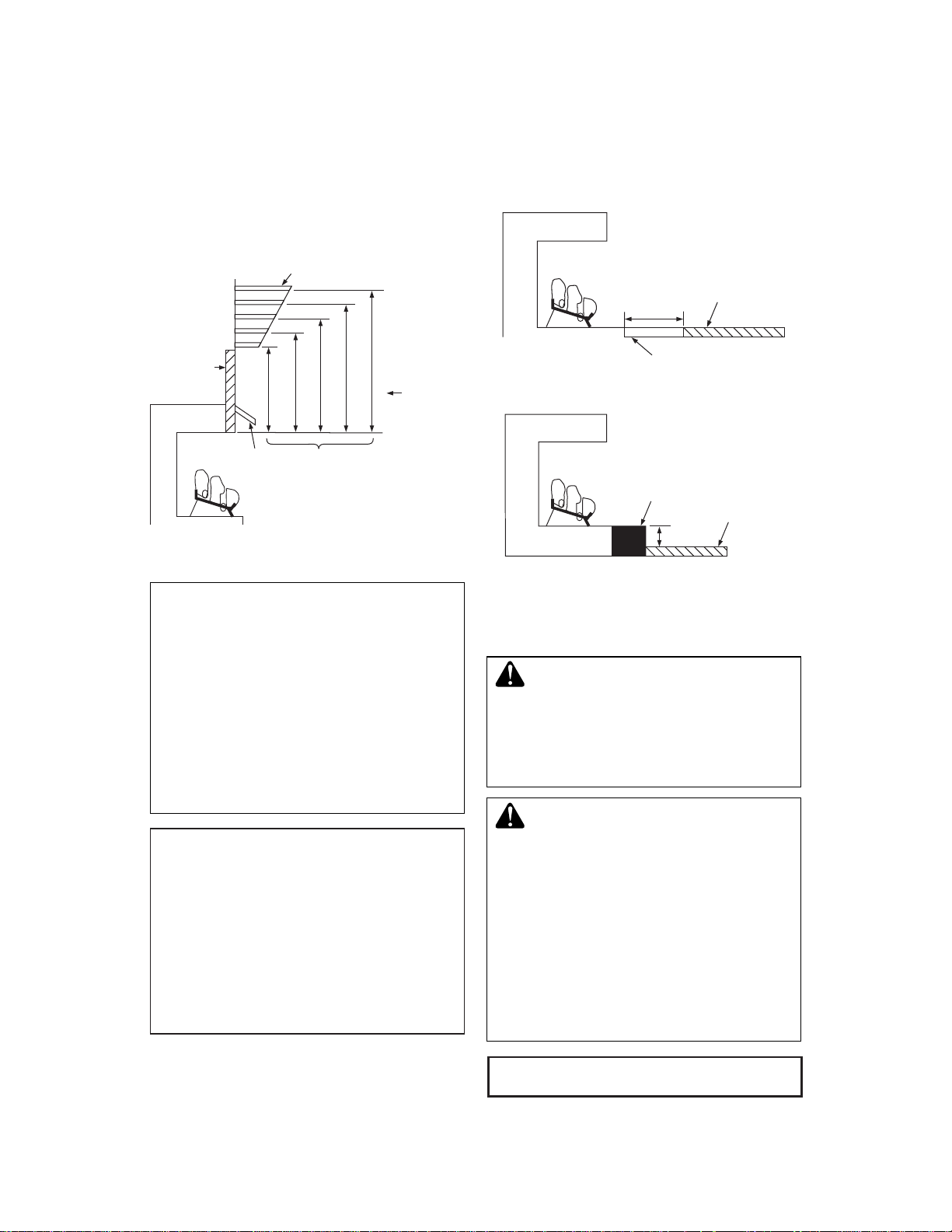

Page 10

Minimum NonCombustible

Material

Minimum NonCombustible

Material Height

Distances to

Underside of

Mantel

Top of Fireplace

Opening

Underside of

Mantel Shelf

12"

8"

(A)

18"

14"

20"

17"

22"

19"

24"

20"

All minimum

distances are

in inches

Log Set

24"/30" Models

18" Model

2

1

/2

"

6"

8"

10"

Mantel Shelf

Heat Resistant

Material

(A)

INSTALLATION

Continued

NOTE: When installing your gas logs into

a manufactured fi rebox, follow fi rebox

manufacturer’s instructions for minimum

clearances to combustible materials.

B. Clearances from the top of the fi replace

opening to the ceiling should not be less

than 42".

Example

*

*Minimum 16" from Side Wall

Figure 4 - Minimum Clearance for

Combustible to Wall

Minimum Noncombustible Material

Clearances

If Not Using Mantel

NOTE: If using a mantel proceed to If Using

Mantel. If not using a mantel, follow these

instructions.

You must have noncombustible material(s)

above the fi replace opening. Noncombustible

materials (such as slate, marble, tile, etc.) must

be at least 1/2" thick. With sheet metal, you

must have noncombustible material behind

it. Noncombustible material must extend at

least 8" up (for all models). If noncombustible

material is less than 12", you must install the

fi replace hood accessory (24" and 30" Models

Only). See Figure 5 for minimum clearances.

Noncombustible

Material Distance (A)

1

2" or more Noncombustible material

Between 8" and 12"

Less than 8"

Requirements for Safe

Installation

OK.

24" or 30" Models: Install

fi replace hood accessory

(GA6050 - see Accessories, Page 46).

18" Model: Noncombustible material OK.

Noncombustible material

must be extended to at

least 8". See Between 8"

and 12", above. If you can-

not extend material, you

must operate appliance

with fl ue damper open.

SuperiorFireplaces.US.com

Figure 5 - Heat Resistant Material (Slate,

Marble, Tile, etc.) Above Fireplace

If Using Mantel

You must have noncombustible material(s)

above the fi replace opening. Noncombus-

tible materials (such as slate, marble, tile,

etc.) must be at least 1/2" thick. With sheet

metal, you must have noncombustible material behind it. Noncombustible material

must extend at least 8" up (for all models). If

noncombustible material is less than 12", you

must install the fi replace hood accessory (24"

and 30" Models Only). Even if noncombustible

material is more than 12", you may need the

hood accessory to defl ect heat away from

your mantel shelf. See Figures 5 and 6 and

Figure 7, Page 11, for minimum clearances.

MANTEL CLEARANCES

In addition to meeting noncombustible material clearances, you must also meet required

clearances between fi replace opening and

mantel shelf. If you do not meet the clearances

listed below, you will need a hood.

Determining Minimum Mantel Clearance

If you meet minimum clearance between

mantel shelf and top of fi replace opening, a

hood is not required (see Figure 6).

Figure 6 - Minimum Mantel Clearances

Without Using Hood

126818-01C10

Page 11

INSTALLATION

Minimum

Noncombustible

Material

8"

Min.

12" 15" 18"

All minimum

distances are

in inches

Log Sets

18", 24",

30" & 36"

Models

20"

2

1

/2

"

6"

8"

10"

12"

Distances to

Underside of

Mantel

Hood

(GA6050 or

GA6053)

Top of

Fireplace

Opening

Underside of

Mantel Shelf

Mantel Shelf

Continued

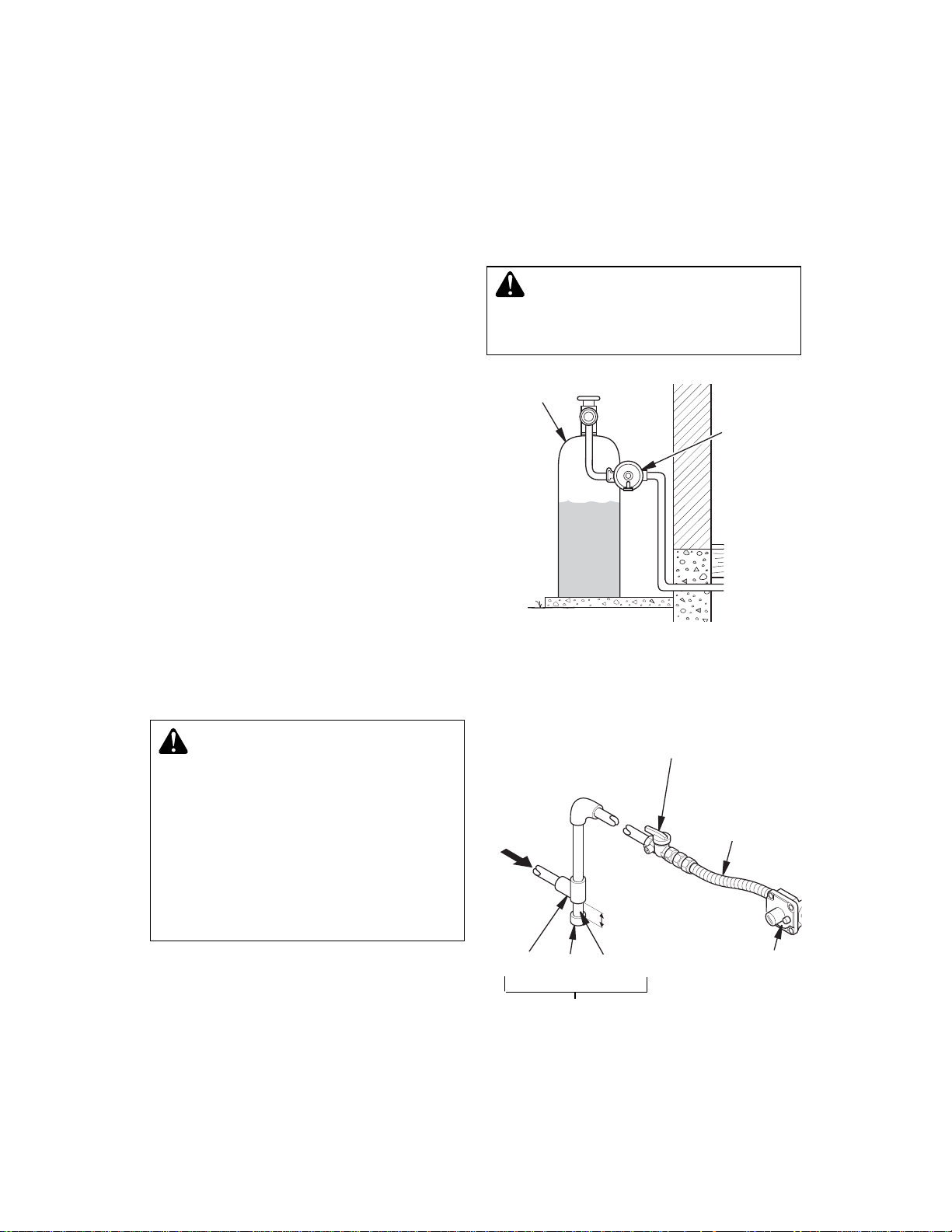

Determining Minimum Mantel Clearance

When Using a Hood

If minimum clearances in Figure 6, are not

met, you must have a hood. When using a

14" to the fi replace, you must install ap-

pliance at least 5" above the top surface

of combustible fl ooring including tile and

carpet (see Figure 9).

hood there are still certain minimum mantel

clearances required. Follow minimum clear-

ances shown in Figure 7, when using hood.

Combustible

14"

Min.

Noncombustible Material

Material

Figure 8 - Minimum Fireplace Clearances

If Installed at Floor Level

Hearth

Figure 7 - Minimum Mantel Clearances

5"

Min.

Combustible

Material

When Using Hood

Figure 9 - Minimum Fireplace Clearances

NOTICE: Surface temperatures

of adjacent walls and mantels become hot during operation. Walls

INST ALLING APPLIANCE BASE

ASSEMBLY

Above Combustible Flooring

and mantels above the fi rebox

may become hot to the touch.

If installed properly, these temperatures meet the requirement

of the national product standard.

Follow all minimum clearances

W ARNING: Y ou must secure

this appliance to fi replace fl oor.

If not, appliance will move when

you adjust controls. Moving appliance may cause a gas leak.

shown in this manual.

WARNING: If installing in a

NOTICE: If your installation does

not meet the minimum clearances shown, you must do one

of the following:

• operate the logs only with the

fl ue damper open

• raise the mantel to an acceptable height

• remove the mantel

FLOOR CLEARANCES

A. If installing appliance on the fl oor level,

you must maintain the minimum distance

of 14" to combustibles (see Figure 8).

B. If combustible materials are less than

126818-01C 11

SuperiorFireplaces.US.com

sunken fi replace, special care

is needed. You must raise the

fi replace fl oor to allow access

to appliance control panel. This

will ensure adequate air fl ow

and guard against sooting and

controls being damaged. Raise

fi replace fl oor with noncombus-

tible material. Make sure material

Minimum clearance requirements include any projections such

as shelves, window sills, mantels, etc. above the appliance.

Page 12

INSTALLATION

Continued

CAUTION: Do not pick up

appliance base assembly by

burners. This could damage

appliance. Only handle base

assembly by grates.

is secure.

IMPORTANT: Make sure the appliance burn-

ers are level.

Installation Items Needed

• hardware package (provided with appliance)

• approved fl exible gas hose and fi ttings (only

provided with TF burner system series) (if

allowed by local codes)

• sealant (resistant to propane/LP gas, not

provided)

• electric drill with 3/16” masonry drill bit

1. Apply pipe joint sealant lightly to male

threads of the 3/8 NPT side of gas fi tting

and connect to inlet side of gas control.

Remove gas fi tting from fl exible gas hose

(provided) before connecting to elbow

(see Figure 10).

2. Position appliance base assembly in

fi replace.

3. Mark screw locations through holes in

front panel of base (see Figure 11). If

installing in a brick-bottom fi replace, mark

screw locations in mortar joint of bricks.

4. Remove appliance base from fi replace.

5. Drill holes at marked locations using 3/16"

drill bit.

6. Attach base, through holes in back side pan-

els of base, to fi replace fl oor using masonry

screws provided in hardware package (see

Figure 1 1).

7. Connect to gas supply. See Connecting

To Gas Supply.

Appliance Gas

Regulator

Masonry Screw

Figure 11 - Attaching Base to Fireplace

Floor

CONNECTING TO GAS SUPPLY

WARNING: This appliance

requires a 3/8" NPT (National

Pipe Thread) inlet connection to

the pressure regulator.

WARNING: A qualifi ed ser-

vice person must connect appliance to gas supply . Follow all

local codes.

CAUTION: Never connect

propane/LP appliance directly

to the propane/LP supply. This

appliance requires an external

regulator (not supplied). Install

the external regulator between the

appliance and propane/LP supply.

WARNING: Never connect

natural gas appliance to private

(non-utility) gas wells. This

gas is commonly known as

wellhead gas.

Flexible Gas Hose (if

allowed by local codes)

Figure 10 - Attaching Flexible Gas Hose

to Appliance Gas Regulator

SuperiorFireplaces.US.com

126818-01C12

Page 13

INSTALLATION

Continued

Installation Items Needed

Before installing appliance, make sure you

have the items listed below.

• external regulator (supplied by installer)

• piping (check local codes)

• sealant (resistant to propane/LP gas)

• equipment shutoff valve *

• test gauge connection *

• sediment trap

• tee joint

• pipe wrench

• approved fl exible gas line with gas con-

nector (if allowed by local codes) (not

provided)

* An equipment shutoff valve with 1/8" NPT

tap is an acceptable alternative to test gauge

connection. Purchase the optional equipment

shutoff valve from your dealer.

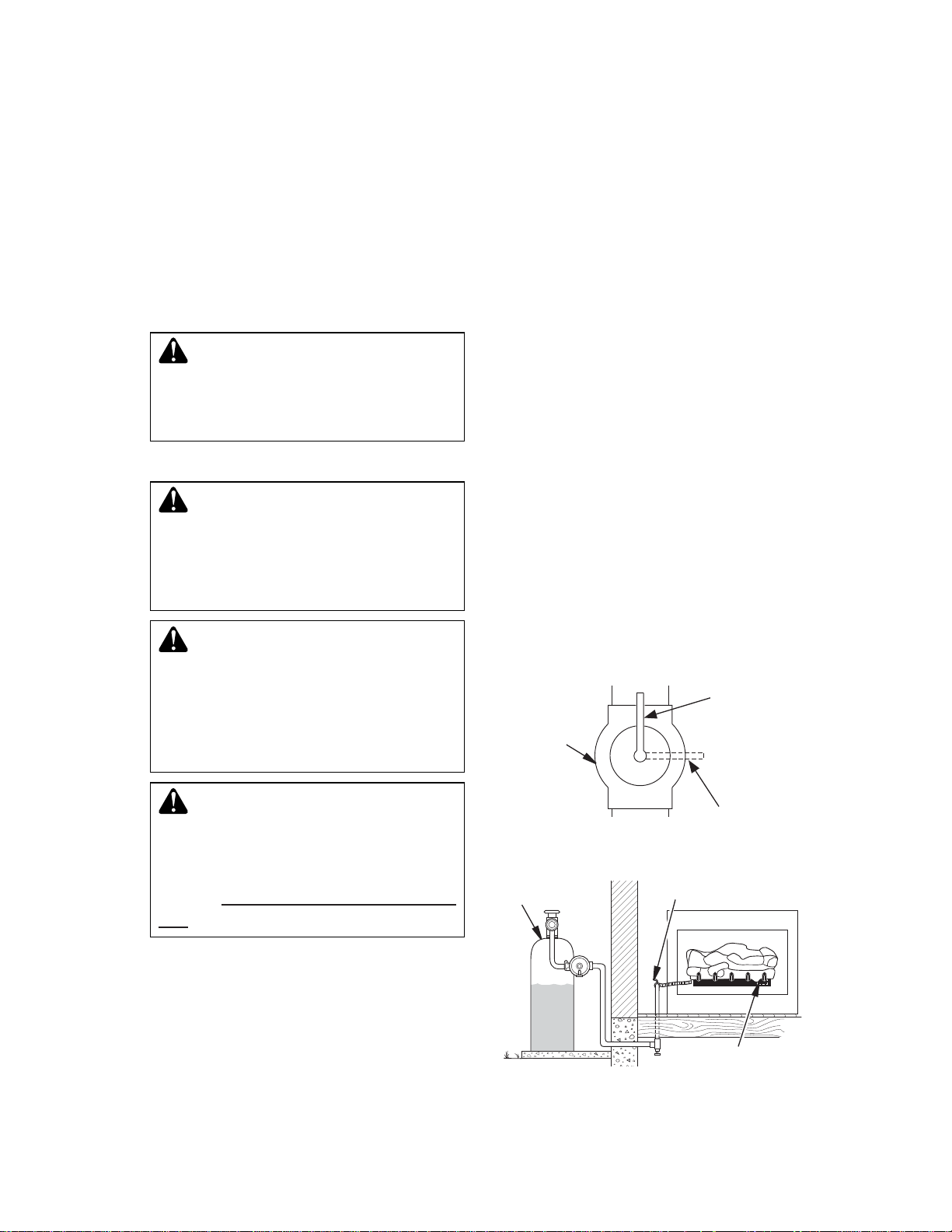

For propane/LP units, the installer must

supply an external regulator. The external

regulator will reduce incoming gas pressure.

You must reduce incoming gas pressure to

between 11" and 14" of water. If you do not

reduce incoming gas pressure, appliance

regulator damage could occur. Install external regulator with the vent pointing down as

shown in Figure 12. Pointing the vent down

protects it from freezing rain or sleet.

CAUTION: Use only new,

black iron or steel pipe. Internally-tinned copper tubing

may be used in certain areas.

Check your local codes. Use

pipe of 1/2" diameter or greater

to allow proper gas volume to

appliance. If pipe is too small,

undue loss of volume will occur.

Check your building codes for any special

requirements for locating equipment shutoff

valve to appliances.

Apply pipe joint sealant lightly to male NPT

threads. This will prevent excess sealant from

going into pipe. Excess sealant in pipe could

result in clogged appliance valves.

WARNING: Use pipe joint

sealant that is resistant to liquid

petroleum (LP) gas.

Propane/LP

Supply Tank

Figure 12 - External Regulator With Vent

Pointing Down

PROPANE/LP From

External Regulator

(11" W.C.** to 14"

W.C. Pressure)

NATURAL From

Gas Meter (5" W.C.**

to 10.5" W.C.

Pressure)

Equipment Shutoff Valve

With 1/8" NPT Tap*

3" Minimum

External

Regulator

with Vent

Pointing

Down

Approved

Flexible Gas

Hose (if allowed

by local codes)

Installation must include an equipment shutoff

valve, union and plugged 1/8" NPT tap. Locate

NPT tap within reach for test gauge hook up.

NPT tap must be upstream from appliance

(see Figure 13).

IMPORTANT: Install equipment shutoff valve

in an accessible location. The equipment

shutoff valve is for turning on or shutting off

the gas to the appliance.

126818-01C 13

SuperiorFireplaces.US.com

Tee Cap Pipe

Joint Nipple

Sediment Trap

Figure 13 - Gas Connection

* Purchase the optional equipment shutoff

valve from your dealer.

**Minimum inlet pressure for purpose of input

adjustment.

Gas

Regulator

Page 14

INSTALLATION

Continued

We recommend that you install a sediment

trap in supply line as shown in Figure 13,

Page 13. Locate sediment trap where it is

within reach for cleaning. Install in piping

system between fuel supply and appliance.

Locate sediment trap where trapped matter

is not likely to freeze. A sediment trap traps

moisture and contaminants. This keeps them

from going into appliance controls. If sediment

trap is not installed or is installed wrong, appliance may not run properly.

CAUTION: A void damage to

gas control. Hold gas control

with wrench when connecting it

to gas piping and/or fi ttings.

CHECKING GAS CONNECTIONS

WARNING: Test all gas piping

and connections, internal and

external to unit, for leaks after

installing or servicing. Correct

all leaks at once.

WARNING: Never use an

open fl ame to check for a leak.

Apply a noncorrosive leak detection fl uid to all joints. Bubbles

forming show a leak. Correct all

leaks at once.

3. Pressurize supply piping system by either

opening propane/LP supply tank valve

for propane/LP gas or opening main gas

valve located on or near gas meter for

natural gas or using compressed air.

4. Check all joints of gas supply piping system.

Apply noncorrosive leak detection fl uid to

all joints. Bubbles forming show a leak.

5. Correct all leaks at once.

6. Reconnect appliance and equipment

shutoff valve to gas supply. Check reconnected fi ttings for leaks.

Test Pressures Equal To or Less Than 1/2

PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Fig-

ure 14).

2. Pressurize supply piping system by either

opening propane/LP supply tank valve

for propane/LP gas or opening main gas

valve located on or near gas meter for

natural gas or using compressed air.

3. Check all joints from gas meter to equipment shutoff valve for natural gas or

propane/LP supply to equipment shutoff

valve for propane/LP (see Figure 15 or

Figure 16, Pages 14-15). Apply noncor-

rosive leak detection fl uid to all joints.

Bubbles forming show a leak.

4. Correct all leaks at once.

Open

Equipment

Shutoff

Valve

CAUTION: Make sure external regulator has been installed

between propane/LP supply

and appliance. See guidelines

under Connecting to Gas Sup-

ply, Page 12.

PRESSURE TESTING GAS SUPPLY

PIPING SYSTEM

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1. Disconnect appliance with its appliance

main gas valve (control valve) and equipment shutoff valve from gas supply piping

system. Pressures in excess of 1/2 psig

(3.5 kPa) will damage appliance regulator.

2. Cap off open end of gas pipe where equipment shutoff valve was connected.

SuperiorFireplaces.US.com

Closed

Figure 14 - Equipment Shutoff Valve

Propane/LP

Supply Tank

Figure 15 - Checking Gas Joints

(Propane/LP Only)

Equipment

Shutoff Valve

Control Valve

Location

126818-01C14

Page 15

INSTALLATION

Gas Meter

S1 Button

Continued

Equipment Shutoff Valve

Control Valve

Location

Figure 16 - Checking Gas Joints (Natural

Gas Only)

PRESSURE TESTING APPLIANCE GAS

CONNECTIONS

1.

Open equipment shutoff valve (see Figure

14, Page 14).

2. Open main gas valve located on or near

gas meter for natural gas or open propane/

LP supply tank valve.

3. Make sure control knob of appliance is in

the OFF position.

4. Check all joints from gas meter to equipment

shutoff valve for natural gas or propane/

LP supply to equipment shutoff valve for

propane/LP (see Figure 15, Page 14 or

Figure 16, Page 15). Apply noncorrosive

leak detection fl uid to all joints. Bubbles

forming show a leak.

5. Correct all leaks at once.

6. Light appliance (see Operation, Page 24).

Check all other internal joints for leaks.

7.

Turn off appliance (see To Turn Off Gas to

Appliance, Page 24.

Connect Battery Plug Here

Figure 17 - Control Module

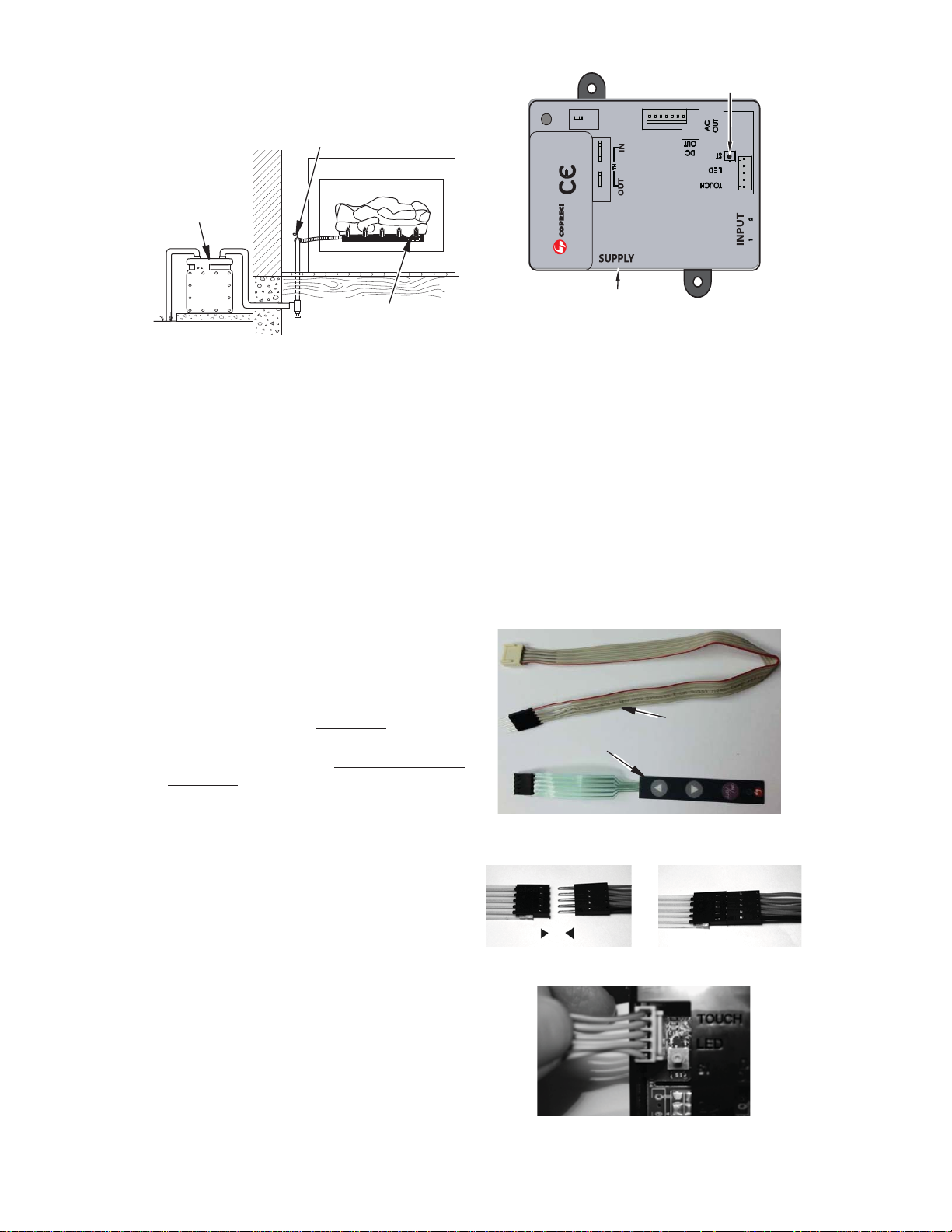

TOUCH PAD INSTALLATION

Locate the touch pad wire harness and the

touch pad control (see Figure 18). They are

shipped from the factory in the clear plastic

bag with your owner’s manual. Connect the

black plastic connectors together as shown

in Figure 19. Connect the remaining end

with the white plastic connector to the control

module in the socket marked TOUCH LED

(see Figure 20).

NOTE: The touch pad includes a red LED

display light. If the LED remains on, the black

plug is connected upside down. You must

unplug the touch pad control from the touch

pad wire harness, turn over, and reconnect.

Touch Pad Wire

Touch Pad Control

Harness

POWER SUPPLY AND BATTERY

INSTALLATION

It is helpful to have a fl ashlight so you can

see the connections as described below. Locate the battery power supply. It is the black

box with the red and black wires. Locate the

control module (see Figure 17). Connect the

battery power supply to the control module

by plugging the battery power supply to the

mating receptacle on the control module. The

receptacle is located on the side of the black

control module next to the word “SUPPLY”

which is molded in the control module’s black

housing (see Figure 17). Be certain to push

the plug fully into the receptacle. Install batteries in the battery power supply and hand

held remote control.

126818-01C 15

SuperiorFireplaces.US.com

Figure 18 - Touch Pad Wire Harness and

Touch Pad Control

Figure 19 - Touch Pad Control Cable

Figure 20 - Connecting end of Touch Pad

Cable

Page 16

INSTALLATION

Continued

INSTALLING LOGS, EMBERS AND

VOLCANIC STONE

WARNING: Failure to position the parts in accordance

with these diagrams or failure

to use only parts specifi cally

approved with this appliance

may result in property damage

or personal injury.

CAUTION: After installation and periodically thereafter ,

check to ensure that no fl ame

comes in contact with any log.

With appliance set to Hi, check

to see if fl ames contact any log.

If so, reposition logs according

to log installation instructions in

this manual. Flames contacting

logs will create soot.

TF Series Burner System - Log

Compatibility Chart

Burner System

Models

Fiber Log

Models

Concrete Log

Models

LTF(18,24,30)-MM LOG PLACEMENT

It is very important to install the logs exactly

as instructed. Do not modify logs. Only use

logs supplied with appliance or as identifi ed

for use with the appliance as shown in Figure

21, Page 16. Each log includes reference

numbers formed in the bottom or back of the

log. The circled number indicates the order it

is placed on the burner system. The remaining

numbers indicate the size burner system the

logs are designed to fi t. For example, the fi rst

log for a 24 inch burner system will include

a circled 1 and also a 24. The circled 1 indicates this is the fi rst log to be installed. The

24 indicates this log belongs to a 24 inch log

set. See Page 42 for reference numbers detail.

1. Place the rear log (#1) on base assembly

as shown in Figure 22. Log will fi t over

right end of burner and rest in middle of

U-burner.

1

Base

assembly

''U'' Burner

TF18NE

TF18PE

TF2430NE

TF2430PE

Figure 21 - TF Series Burner System-

Log Compatibility Chart

LTF18MM

LTF24MM

LTF30MM

LTF18-RS

LTF18WT

LTF24-RS

LTF30-RS

LTF24WT

LTF30WT

SuperiorFireplaces.US.com

Figure 22 - Installing Log # 1

126818-01C16

Page 17

INSTALLATION

Continued

2. Place the middle log (#2) in front of the Uburner and against the edges of the plate

as shown in Figure 23.

2

Figure 23 - Installing Log # 2

3. Place the front left log (#3) onto the base

assembly between the middle log (#2) and

the grate fi ngers. The back of the front left

log (#3) will rest against the front of the

middle log (#2). The notch at the end of

the front left log (#3) will fi t around the grate

bar. See Figure 24.

pin on the top of the rear log (#1) with the

round hole in the bottom of the left back top

log (#5). See Figure 26.

4

Figure 25 - Installing Log # 4

5

Rectangular

Peg

Metal

Pin

3

Figure 24 - Installing Log # 3

4. Place the front right log (#4) onto the base

assembly between the middle log (#2) and

the grate. The back of the front right log

(#4) will rest against the front of the middle

log (#2). The notch in the end of the front

right log (#4) will fi t around the grate bar.

See Figure 25.

5. Place the left back top log (#5) on top of

the rear log (#1). Match the rectangular peg

on top of the left side of the rear log (#1)

with the rectangular hole on the bottom of

the left back top log (#5). Match the metal

Figure 26 - Installing Log # 5

6. Place the left top forked log (#6) on the top

of the middle log (#2). Match the rectangular projection on top of the middle log (#2)

with the rectangular hole on the bottom of

the left top forked log (#6). Match the metal

pin on the top of the middle log (#2) with

the round hold in the bottom of the left top

forked log (#6). See Figure 27, Page 18.

7. Place the right rear chunk log (#7) on top

of the middle log (#2) and rear log (#1) as

shown in Figure 28, Page 18. Match the

round peg on the top of the rear log (#1)

with the round hole on the bottom of the

right rear chunk (#7) log and square peg

on the top of the middle log (#2) with the

square hole on the bottom of the right rear

chunk log (#7).

126818-01C 17

SuperiorFireplaces.US.com

Page 18

INSTALLATION

Continued

6

Rectangular

Peg

Figure 27 - Installing Log # 6

Metal Pin

7

Round

Peg

Metal Pin

Figure 29 - Installing Log # 8

Round

Peg

8

9

Square Peg

Figure 28 - Installing Log # 7

8. Place the front right mid log (#8) on top of

the front right log (#4) as shown in Figure

29. Match the round metal pin on the top of

the front right log (#4) with the round hole

on the bottom of the front right mid log (#8).

9. Place the top right log (#9) on top of the

right rear chunk log (#7) and front right mid

log (#8) as shown in Figure 30. Match the

round peg on the top of the right rear chunk

log (#7) with the round hole on the bottom

of the top right log (#9) and square peg on

the top of the front right mid log (#8) with

the square hole on the bottom of the top

right log (#9).

SuperiorFireplaces.US.com

Square Peg

Figure 30 - Installing Log # 9

10. Place the right rear top log (#10) on top

of the right rear chunk log (#7) as shown in

Figure 31, Page 19. Match the rectangular

peg on the top of the right rear chunk log

(#7) with the rectangular hole on the bottom

of the right rear top log (#10).

11. Place the left top log (#11) on top of the left

back top log (#5) and left top forked log (#6)

as shown in Figure 32, Page 19. Match the

round peg on the top of the left top forked

log (#6) with the round hole on the bottom

of the top left log (#11) and rectangular peg

on the top of the left back top log (#5) with

the rectangular hole on the bottom of the

top left log (#11).

126818-01C18

Page 19

INSTALLATION

Continued

LTF(18,24,30)-RS LOG PLACEMENT

10

It is very important to install the logs exactly

as instructed. Do not modify logs. Only use

logs supplied with appliance or as identifi ed

for use with the appliance as shown.

1. Place bottom ember log on base as-

sembly as shown in Figure 34. The log

should fi t over the left side of the burner

and rest in the middle of the U-burner.

Bottom Ember Log

Figure 31 - Installing Log # 10

11

Round

Peg

Figure 32 - Installing Log # 11

Burner

Tube

Square Peg

Base Assembly

Figure 34 - Installing Bottom Ember Log

2. Place the rear log on the base assembly

as shown in Figure 35. The rear log has

grooves in the bottom which will allow

the log to sit on the burner and behind

the bottom ember log

Rear Log

Burner Tube

Figure 33 - Final Assembly

126818-01C 19

SuperiorFireplaces.US.com

Figure 35 - Installing Rear Log

Page 20

INSTALLATION

Continued

3. Place the right front log onto the base

and grate assembly as shown in Figure

36. The log has notches in the bottom

for the grate.

Right Front Log

Grate

Assembly

5. Place the right crossover log onto the

rear log and the right front log as shown

in Figure 38. The right crossover log

has notches in the bottom that will line

up with the projections on the rear log

and the right front log.

Right Crossover Log

Projections for

Sitting Log

Figure 36 - Installing Right Front Log

4. Place the left front log onto the base and

the right front log as shown in Figure

37. The left front log has a notch on the

bottom that will line up with the projection

on the right front log.

Left Front Log

Rectangular

Projection

Base

Assembly

Figure 38 - Installing Right Crossover

Log

6. Place the left crossover log onto the

rear log and the left front log as shown

in Figure 39. The left crossover log has

notches in the bottom that will line up

with the projections on the rear log and

the left front log.

Left Crossover Log

Projection for

Sitting Log

Figure 37 - Installing Left Front Log

SuperiorFireplaces.US.com

Projection for

Sitting Log

Figure 39 - Installing Left Crossover Log

126818-01C20

Page 21

INSTALLATION

Continued

LTF(18,24,30)-WT LOG PLACEMENT

It is very important to install the logs exactly

as instructed. Do not modify logs. Only use

logs supplied with appliance or as identifi ed

for use with the appliance as shown.

1. Place the rear log (#1) on base assembly

as shown in Figure 41. Log will fi t over

right end of burner and rest in middle of

U-burner (see Figure 41).

Figure 40 - Burner Assembly

Rear

Log

1

3. Place the front left log (#3) onto the base

assembly between the middle log and the

grate. The back of the front left log will rest

against the front of the middle log. The

notch in the end of the front left log will fi t

around the grate bar. See Figure 43.

Front Left Log

3

Figure 43 - Installing Log #3

4. Place the front right log (#4) onto the base

assembly between the middle log and the

grate. The back of the front right log will

rest against the front of the middle log. The

notch in the end of the front right log will fi t

around the grate bar. See Figure 44.

Figure 41 - Installing Log #1

2. Place the middle log (#2) in front of ''U''burner and against the edges of plate as

shown in Figure 42.

Middle Log

2

Front Right Log

4

Figure 44 - Installing Log #4

126818-01C 21

SuperiorFireplaces.US.com

Page 22

INSTALLATION

Continued

5. Place the left top back log (#5) on top of the

rear log. Match the rectangular projection

on top of the left side of the rear log with

the rectangular hole on the bottom of the

left top back log. Match the metal pin on

the top of the rear log with the round hole

in the bottom of the left top back log. See

Figure 45.

Left Top Back Log

5

Figure 45 - Installing Log # 5

6. Place the left top front log (#6) on the top

of the middle log and the left top back log.

Match the rectangular projection on top of

the middle log with the rectangular hole on

the bottom of the left top front log. The left

top front log will rest on the fl at part of the

left top back log. See Figure 46.

Right Crossover Log

7

Figure 47 - Installing Log # 7

8. Match the round hole on the bottom of the

center crossover log (#8) with the metal pin

on the top of the right crossover log. Rest

the front of the center crossover log on top

of the front right log and against the grate.

See Figure 48 for fi nal assembly.

Center Crossover Log

8

Left Top Front Log

6

Figure 46 - Installing Log # 6

7. Place the right crossover log (#7) on top

of the middle log and rear log as shown

in Figure 47. Match the round peg on the

top of the rear log with the round hole on

the bottom of the right crossover log and

square peg on the top of the middle log

with the square hole on the bottom of the

right crossover log.

Figure 48 - Installing Log # 8

Figure 49 - Final Assembly

(top view)

SuperiorFireplaces.US.com

126818-01C22

Page 23

INSTALLATION

Continued

EMBER PLACEMENT

WARNING: Do not operate unit

without ember material correctly

in place as shown in Figures 50

& 51. Do NOT place ember material anywhere else on the unit.

Use only ember material supplied

with unit. Excessive or incorrectly

placed ember material may produce carbon monoxide or soot. If

replacement embers are needed,

the replacement embers must be

purchased from IHP. See Page 41

for part numbers.

WARNING: All previously applied loose material must be removed prior to reapplication.

1. Two ember materials are supplied with

this log set. Platinum Bright Embers give

a bright glow appearing as hot coals.

Should embers need replacing, see Parts,

Page 41.

Platinum Bright Ember placement. Add

embers to front, fl at burner. Gently remove

embers from bag. Separate pieces of

ember material and place on surface of

fl at burner just behind horizontal ports as

shown in Figure 50.

Glowing Embers placement. Place

Glowing Embers material on front fl at

burner in areas away from ports as shown

in Figure 51.

2. Add Volcanic Stone and small decorative

logs around base of appliance if desired.

DO NOT place rock or additional logs

on front burner or on logs. Placing any

material on unit other than ember material

on front burner may result in production

of carbon monoxide or soot.

Ember Material

Figure 50 - Platinum Bright Embers

Glowing Embers

Figure 51 - Placement of Glowing Embers (shown with Platinum Bright Embers)

126818-01C 23

SuperiorFireplaces.US.com

Flat Front Burner

Page 24

OPERATION

NOTICE: During initial operation of

new appliance, burning logs will give

off a paper-burning smell. Orange

fl ame will also be present. Open

damper or window to vent smell. This

will only last a few hours.

WARNING:

• If fi replace has glass doors, never

operate this appliance with glass

doors closed. If you operate appliance with doors closed, heat

buildup inside fi replace will cause

glass to burst. Make sure there are

no obstructions across openings of

fi replace.

• You must operate this appliance

with a fi replace screen in place.

Make sure fi replace screen is closed

before running appliance.

WARNING: Damper handle will

be hot if appliance has been running.

CAUTION: Do not try to adjust

heating levels by using the equipment

shutoff valve.

FOR YOUR SAFETY

READ BEFORE LIGHTING

W ARNING: If you do not follow these instructions exactly,

a fi re or explosion may result

causing property damage, personal injury or loss of life.

A. This appliance is equipped with an igni-

tion device which automatically lights

the pilot. Do not light pilot by hand.

B. BEFORE LIGHTING smell all around

the appliance area for gas. Be sure to

smell next to the fl oor because some

gas is heavier than air and will settle

on the fl oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fi re department.

C. Do not use this room heater if any part

has been under water. Immediately call

a qualifi ed service technician to inspect

the room heater and to replace any part

of the control system and any gas control which has been under water.

LIGHTING

INSTRUCTIONS

1. STOP! Read the safety information.

2. Make sure equipment shutoff valve is

fully open.

3. Press any button on the remote to power

the remote on. Press the MODE zone or

the MODE/SET Button to start the unit.

You will hear a beep from the control

module and the pilot will start to light the

unit.

NOTE: Y ou may be running this appliance for

the fi rst time after hooking up to gas sup-

ply . If so, you may have to restart the unit

several of times to allow the air to bleed

from the system.

TO TURN OFF GAS

TO APPLIANCE

1. Once you have activated the screen press

the MODE Zone or MODE/SET Button

until you see OFF.

2. Close equipment shutoff valve.

REMOTE CONTROL OPERATION

BASIC CONSTRUCTION

• Touch-Screen LCD and three push but-

tons will allow input from users.

SuperiorFireplaces.US.com

126818-01C24

Page 25

OPERATION

Continued

• LCD screen will provide system status & input feedback to user.

• Backlight will illuminate LCD screen for 5 seconds after any user input – the 1st touch

of the LCD screen will only illuminate the backlight (will not respond to associated zone

function). To activate any command, the backlight for the screen must be on and the

command must be touched before the backlight goes off.

• Powered via four AAA sized batteries (6V nominal) with LOW BATTERY INDICATOR

(5.0V).

Touch-Screen LCD and Button Layout (Not to scale)

FUNCTIONAL DESCRIPTION

NOTE: All function adjustments will be automatically accepted 15-seconds after pressing a

given touch zone or button. The user may press the MODE/SET button to immediately accept

the adjustment manually.

SET TEMP Zone

FLAME Zone

CHANNEL UNLOCK Zone

DOWN Button

Figure 52 - Touch-Screen LCD and Button Layout

ON THERMO OFF

Cont.

Pilot

P1

P1

A

°

SET

S M T W T F S

PROGRAM

MODE/SET

u

:

ROOM

°

P2

AM

PM

P2

MODE Zone

ROOM TEMP Zone

TIME/PROG Zone

CHANNEL PROG Zone

MODE/SET Button

UP Button

126818-01C 25

SuperiorFireplaces.US.com

Page 26

OPERATION

Continued

CHANNEL SELECTION

This control may be operated in 3 different

sub-channels for applications where 2.4GHz

interference causes delayed operation of the

remote control. The factory default is Channel

3. To change the channel on the transmitter:

• Touch the CHANNEL PROGRAM and

CHANNEL UNLOCK zones simultaneously and hold for 5-seconds.

• The LCD screen will go blank except

“Ch” will be displayed in the SET TEMP

Zone and either “01”, “02”, or “03” will

be displayed in the ROOM TEMP Zone.

• Press the UP or DOWN buttons to

change the channel number (01-03).

• Press the MODE/SET Button to return

to the normal operating display.

Receiver Operation Notes:

• The receiver manufacturer may refer to

channels 01, 02, or 03.

• Receiver must be paired with transmitter

in the receiver’s factory default channel.

• Once paired, the channel selection may

be changed in the transmitter per the

instructions above.

• Once the channel selection is changed in

the transmitter, the power supply to the

receiver must be removed for at least

30-seconds, then re-applied.

• The receiver will recognize the new

channel selection after about 30-seconds to 1-minute and normal operation

will resume.

MODES OF OPERATION

OPERATION MODES:

• MANUAL OFF

• MANUAL ON

• THERMOSTAT (with optional PROGRAM Mode)

The modes may be cycled in the order above

by touching the MODE Zone or pressing the

MODE/SET Button.

MANUAL OFF MODE:

• Transmits fl ame OFF command.

• Pilot Method: Intermittent Pilot Ignition

(IPI)/Spark-to-Pilot only (continuous/

standing pilot not allowed)

• Pilot fl ame will be turned OFF

• LCD Displays:

• MODE Zone: OFF is displayed

• ROOM TEMP Zone: Measured temperature is displayed

• SET TEMP Zone: Blank

• TIME/PROG Zone: Current day indica-

tor and current time is displayed

• FLAME Zone: Blank

MANUAL ON MODE:

• Transmits fl ame ON command.

• Pilot Method: Intermittent Pilot Ignition

(IPI)/Spark-to-Pilot only (continuous/

standing pilot not allowed)

• Pilot fl ame will be ignited before turn

Main Flame ON.

• LCD Displays:

• MODE Zone: ON is displayed

• ROOM TEMP Zone: Measured temperature is displayed

• SET TEMP Zone: Blank

• TIME/PROG Zone: Current day indicator

and current time is displayed

• FLAME Zone: A Flame Icon and fl ame

setting level number is displayed

THERMOSTAT MODE:

• Will cycle fl ame on and off based on

room and set temperatures. Will transmit

ON command if SET TEMP (+SWING)

is higher than ROOM TEMP and will

transmit OFF command if SET TEMP

(-SWING) is lower than ROOM TEMP.

• Built-in thermostat will measure room

temperature.

• All programming should be written for

deg. F and converted to deg. C when

selected.

• Temperatures may be displayed in

degrees F (factory default) or degrees

C. Press the UP and DOWN Buttons

simultaneously to change between

degrees F and C.

• SET TEMP: While in THERMOSTAT

mode, press the UP or DOWN Button

to change the SET TEMP (45-90 deg. F,

7-32 deg. C); the new set temperature

will automatically be accepted after 2

seconds. The factory default SET TEMP

is 68 deg. F.

SuperiorFireplaces.US.com

126818-01C26

Page 27

OPERATION

Continued

• SWING Temperature: This model does

not allow for SWING temperature adjustment. This model utilizes thermostatic

fl ame modulation that will modulation

the main fl ame based on the difference

between room temperature and set temperature (see example below).

• Important - factory SWING TEMPERATURE setting is 2 degrees. The thermostatic fl ame modulation feature will not

allow this SWING to be changed.

EXAMPLE:

Set Temperature Room Temp. Flame Level

74F OFF

73F Level 1

Set Temperature (72) 72F Level 2

71F (or less) Level 3

• Pilot Method: Continuous/Standing Pilot

only (Intermittent Pilot Ignition (IPI)/

Spark-to-Pilot not allowed).

• Pilot fl ame will remain ON when Main

Flame Cycles ON and OFF.

• Manual Flame Adjustment while in

THERMOSTAT mode: If Flame-A is

manually adjusted while in thermostat

mode, it will override the automatic

fl ame setting until the fl ame cycles off,

then back ON thermostatically; when

the fl ame cycles ON again, automatic

fl ame adjustment will resume. Automatic

fl ame adjustment will also resume if the

operational mode is cycled out of, then

back into THERMOSTAT mode or if the

SET temperature is changed.

• THERMOSTAT OFF LCD Displays:

• MODE Zone: THERMO and OFF is

displayed

• ROOM TEMP Zone: Measured temperature is displayed

• SET TEMP Zone: SET TEMP is displayed

• TIME/PROG Zone: Current day indicator

and current time is displayed

• FLAME Zone: Blank

• THERMOSTAT ON LCD Displays:

• MODE Zone: THERMO and ON are

displayed

• ROOM TEMP Zone: Measured temperature is displayed

• SET TEMP Zone: SET TEMP is displayed

• TIME/PROG Zone: Current day indicator

and current time is displayed

• FLAME Zone: A Flame Icon and fl ame

setting level number is displayed

Thermostat Disable Feature

• The Thermostat Mode (described above)

may be disabled for applications where a

thermostat is not allowed or undesirable.

When Thermostat Mode is Disabled:

• The Modes of operation will cycle between MANUAL ON and MANUAL OFF

(omitting THERMO).

• Program Operation (described below) is

also disabled.

• The SET TEMP zone will be blank.

• The room temperature will still be measured & displayed in the ROOM TEMP

Zone.

• The TIME/PROG zone will continue to

display the Clock and Day of week, but

none of the icons associated with Program Mode will be displayed.

• To disable or re-enable the Thermostat,

the transmitter must be in MANUAL

OFF Mode, then touch and hold the

SET TEMP Zone and the DOWN Button

simultaneously for 10- seconds. The

LCD screen will go blank except either

THERMO and OFF or THERMO and

ON will fl ash 3-times (0.5-seconds OFF,

0.5-seconds ON) to indicate the change

has been made.

DAY AND TIME DISPLAY

• The current day of week and time of

day will be continuously displayed in the

TIME/PROG Zone (except during Setup

operations).

• The day of week will be displayed as

one of the following: S, M, T, W, T, F, S

• The time of day will be in 12-hour AM,

12-hour PM format. Midnight will be

displayed as 12:00am.

• Day/Time Setup:

1. Press and hold the MODE Zone for 5

seconds to enter Day/Time Setup.

2. Touch the UP or DOWN Buttons to adjust

the day of week (press the MODE/SET

Button or wait for 15 seconds for adjustment to be accepted, then enter hour of

day adjustment).

126818-01C 27

SuperiorFireplaces.US.com

Page 28

OPERATION

Continued

3. Press the UP or DOWN Buttons to adjust the hour of the day. The time will

advance in 1-hour increments; AM and

PM will change when the hour advances

to 12:00 midnight and 12:00 noon respectively (press the MODE/SET Button

or wait for 15 seconds for adjustment to

be accepted, then enter minute of hour

adjustment).

4. Press the UP or DOWN Buttons to adjust

the minute of the hour. The time will advance in 1-minute increments (press the

MODE/SET Button or wait for 15 seconds

and the transmitter will exit Day/Time

Setup and return to normal operation).

5. LCD Displays – when in Day/Time Setup:

• MODE Zone: Blank

• ROOM TEMP Zone: Blank

• SET TEMP Zone: Bank

• TIME/PROG Zone: Day of Week, or

Time of Day will Flash

• FLAME Zone: Blank

Program Operation

• Touch the TIME/PROG Zone to activate

or deactivate Program Operation. Touching the MODE Zone or pressing the

MODE/SET Button will also deactivate

Program Operation. When Program Operation is deactivated, the transmitter will

return to MANUAL OFF Mode.

• Program Operation will cycle fi replace

ignition ON and OFF based on time settings (2 weekend periods and 2 weekday

periods) and thermostat settings. Press

the MODE/SET Button or wait for 15

seconds to advance to each subsequent

program setting.

• Pilot Method (same as Thermostat

Mode): Continuous/Standing Pilot

only (Intermittent Pilot Ignition (IPI)/

Spark-to-Pilot not allowed).

• Pilot fl ame will remain ON when Main

Flame Cycles ON and OFF.

• To enter Program Setup, touch and hold

the TIME/PROG Zone for 5 seconds.

• Program OFF LCD Displays:

• MODE Zone: OFF

SuperiorFireplaces.US.com

• ROOM TEMP Zone: Measured temperature is displayed

• SET TEMP Zone: Blank

• TIME/PROG Zone: Current day indicator, current time, and Program status

(P1- OFF or P2-OFF) is displayed

• FLAME Zone: Blank

• Program ON LCD Displays:

• MODE Zone: THERMO and either ON

or OFF is displayed

• ROOM TEMP Zone: Measured temperature is displayed

• SET TEMP Zone: SET TEMP is displayed

• TIME/PROG Zone: Current day indicator, current time, and Program status

(P1- ON or P2-ON) is displayed

• FLAME Zone:

If Thermostat is ON, A Flame Icon and

fl ame setting level number is displayed.

If Thermostat is OFF, display is blank.

Program Disable Feature

• The Program Mode (described above)

may be disabled for applications where

a program operation is not allowed or

undesirable. When Program Mode is

Disabled:

• The user will not be able to activate

Program Mode

• The user will not be able to enter

Program Setup or edit Program Mode

settings.

• The TIME/PROG zone will continue to

display the Clock and Day of week, but

none of the icons associated with Program Mode will be displayed.

• To disable or re-enable the Program

Mode, the transmitter must be in MANUAL OFF Mode, then touch and hold

the TIME/PROG Zone and the DOWN

Button simultaneously for 10-seconds.

The LCD screen will go blank except

either PROGRAM and OFF (OFF display

in MODE Zone) or PROGRAM and ON

(ON display in MODE Zone) will fl ash

3-times (0.5-seconds OFF, 0.5-seconds

ON) to indicate the change has been

made.

Flame-A (or Main) Adjustment

• Transmits a fl ame height setting com-

mand to the control module to adjust the

Flame-A height.

126818-01C28

Page 29

OPERATION