Superior O-360 SERIES, IO-360 SERIES, Vantage Engine O-360 SERIES, Vantage Engine IO-360 SERIES Installation & Operation Manual

Page 1

O-360 & IO-360 SERIES ENGINES

INSTALLATION & OPERATION MANUAL

621 South Royal Lane, Suite 100 / Coppell, TX 75019 / 800-277-5168

P/N SVIOM01 Revision A, March, 2004

www.superior-air-parts.com

FAA Approved

Page 2

Installation & Operation Manual

O-360 and IO-360 Series Engines

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY

SUPERIOR'S EXPRESS WARRANTIES AND THE REMEDIES THEREUNDER ARE EXCLUSIVE AND

GIVEN IN PLACE OF (A) ALL OTHER WARRANTIES, EXPRESS, IMPLIED, OR STATUTORY,

WHETHER WRITTEN OR ORAL, INCLUDING, BUT NOT LIMITED TO, ANY WARRANTY OF

MERCHANTABILITY, FITNESS OR PARTICULAR PURPOSE, OR IMPLIED WARRANTY ARISING

FROM PERFORMANCE, COURSE OF DEALING OR USAGE OF TRADE AND (B) ALL OTHER

OBLIGATIONS, LIABILITIES, RIGHTS, CLAIMS OR REMEDIES, EXPRESS OR IMPLIED, ARISING BY

LAW OR OTHERWISE, INCLUDING BUT NOT LIMITED TO ANY RIGHT OR REMEDIES IN

CONTRACT, TORT, STRICT LIABILITY OR ARISING FROM SUPERIOR'S NEGLIGENCE, ACTUAL OR

IMPUTED.

SUPERIOR'S OBLIGATIONS AND PURCHASER'S REMEDIES UNDER SUPERIOR'S EXPRESS

WARRANTIES ARE LIMITED TO SUPERIOR'S CHOICE OF REFUND, REPAIR OR REPLACEMENT

ON AN EXCHANGE BASIS AND EXCLUDE LIABILITY FOR INCIDENTAL, SPECIAL,

CONSEQUENTIAL OR ANY OTHER DAMAGES, INCLUDING WITHOUT LIMITATION, ANY LIABILITY

OF CUSTOMER TO A THIRD PARTY OR FOR ECONOMIC LOSS, REPLACEMENT COST, COST OF

CAPITAL, LOST REVENUE, LOST PROFITS, OR LOSS OF USE OF OR DAMAGE TO AN AIRCRAFT,

ENGINE, COMPONENT OR OTHER PROPERTY AND IN NO EVENT WILL SUPERIOR'S LIABILITY

EXCEED THE ORIGINAL COST OF THE ENGINE OR ACCESSORY.

Written notice of any warranty claim must be submitted to Superior within thirty (30) days of a suspected

defect in material or workmanship and the engine, accessory or part must be made available for

Superior's inspection within thirty (30) days after the claim has been made. Superior reserves the right to

deny any claim not submitted in accordance with these requirements.

These LIMITED WARRANTIES are the only warranties offered by Superior. No agreement varying these

warranties or Superior's obligations under them will be binding on Superior unless made in writing by a

duly authorized representative of Superior.

Superior will not process or honor warranty claims on delinquent accounts.

© March 2004 Superior Air Parts Inc.

Page 3

Installation & Operation Manual

O-360 and IO-360 Series Engines

Table Of Contents

Chapter 1 Engine Description

Chapter 2 Airworthiness Limitations

Chapter 3 Aircraft / Engine Integration Considerations

Revision History

List Of Figures

List Of Tables

Introduction

About This Manual

Related Publications

Installation Approval Requirements

Obtaining Service Information

1. General Description

2. Continued Airworthiness

3. Model Designations

4. Engine Components General Description

5. Features And Operating Mechanisms

1. General

2. Induction System

3. Fuel System

4. Engine Cooling

5. Exhaust

6. Lubrication System

7. Propeller Attachment

8. Electrical System

9. Engine Controls

10. Engine Accessories

11. Engine Mounting

Page Number

i

ii

iii

iv

iv

iv

iv

v

1

1

1

3

13

1

1

4

7

9

12

15

16

18

20

22

Chapter 4 Engine Installation

1. General Instructions

2. Preparing Engine For Service

3. Installation of Engine

4. Instrumentation Connections

Chapter 5 Special Procedures

1. General Break In Procedures

2. Special Tools And Equipment

3. Break In Procedures

4. General Inspection Check

5. Daily Pre Flight Inspection

Chapter 6 Normal Operating Procedures

1. General

2. Engine Operation And Limits

3. Operation Instructions

© March 2004 Superior Air Parts Inc.

1

1

2

2

1

1

1

3

3

1

1

1

Page 4

Installation & Operation Manual

O-360 and IO-360 Series Engines

Table Of Contents (continued)

Chapter 7 Abnormal Operating Procedures

1. General

2. Engine Will Not Start

3. Rough Idling

4. Engine Not Able to Develop Full Power

5. Rough Engine Operation

6. Low Power and Engine Runs Rough

7. Low Oil Pressure On Engine Gage

8. High Oil Temperature

9. Excessive Oil Consumption

Chapter 8 Servicing Requirements

1. General

2. Lubricants

3. Fuels

4. Consumables

Chapter 9 Engine Preservation And Storage

1. Temporary Storage

2. Indefinite Storage

3. Inspection Procedures

4. Returning An Engine To Service After Storage

Appendix A O-360 Model Specification Data

Appendix B IO-360 Model Specification Data

1

2

2

3

3

3

4

4

4

1

1

2

2

1

2

2

3

© March 2004 Superior Air Parts Inc.

Page 5

Installation & Operation Manual

O-360 and IO-360 Series Engines

Manual Number SVIOM01

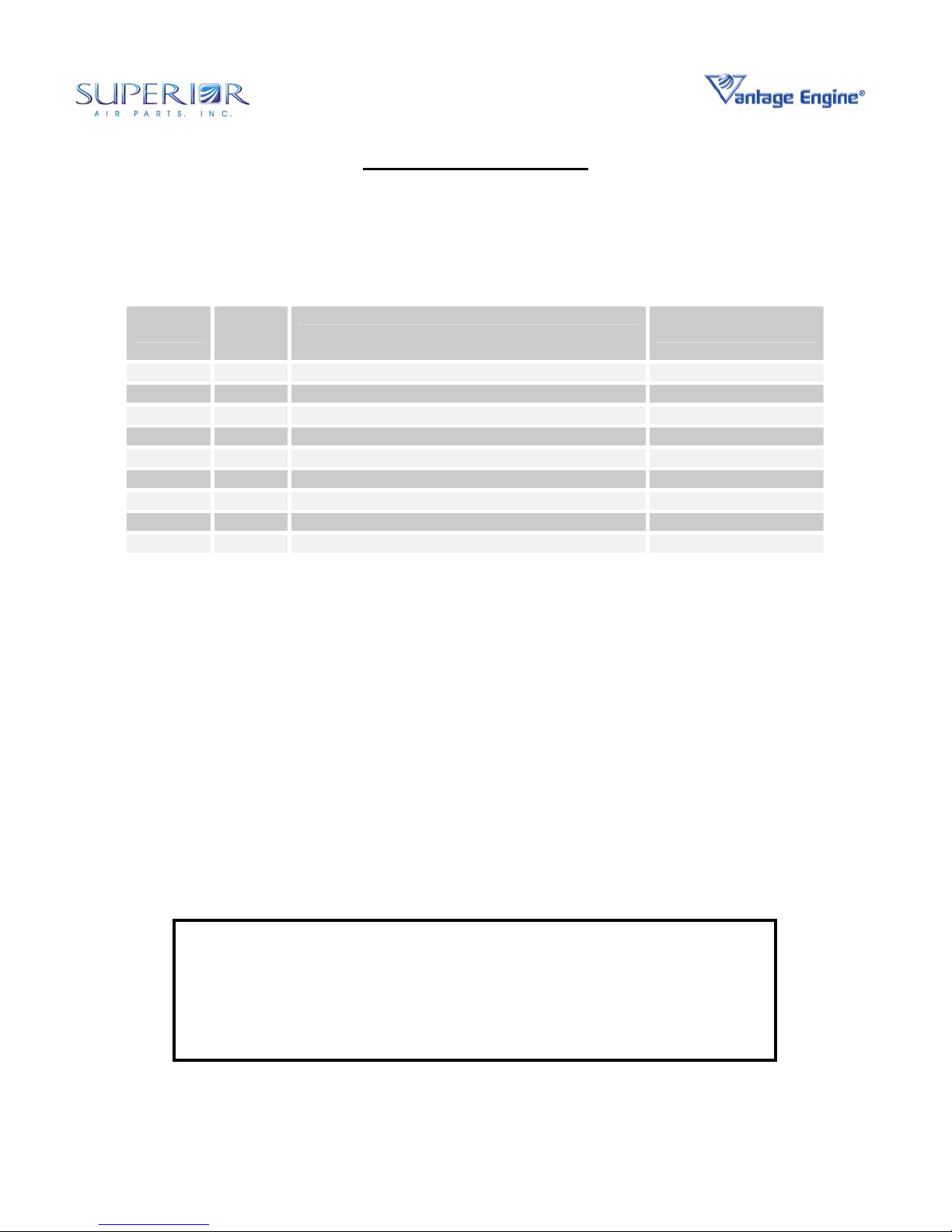

Revision History

Revision

Letter

A 03/29/04 Initial Release All

Effectiv

e

Date

Description Pages

Revised

It is the users responsibility to insure that this is the current revision of

this manual. Do not perform any operation, installation, maintenance,

or other procedure until confirming this manual is current.

© March 2004 Superior Air Parts Inc.

WARNING

i

Page 6

Installation & Operation Manual

O-360 and IO-360 Series Engines

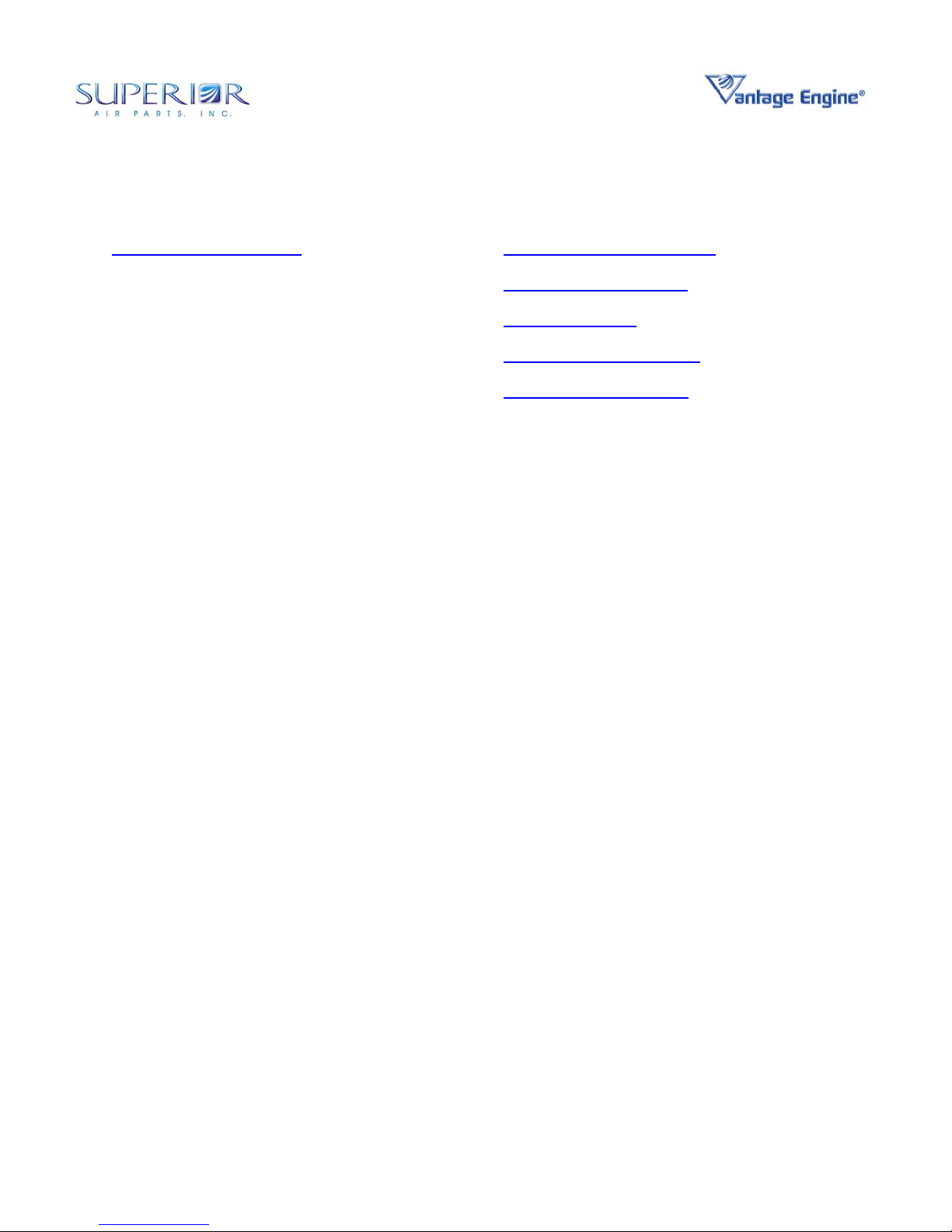

List Of Figures

Figure

Number

1-1 Model Number Designation 1 1

1-2 O-360 Engine Front View 1 5

1-3 O-360 Engine Left Side View 1 6

1-4 O-360 Engine Top View 1 7

1-5 O-360 Engine Rear View 1 8

1-6 IO-360 Engine Front View 1 9

1-7 IO-360 Engine Left Side View 1 10

1-8 IO-360 Engine Top View 1 11

1-9 IO-360 Engine Rear View 1 12

3-1 Oil System Schematic 3 14

3-2 Ignition Wiring Diagram 3 17

3-3 Alternator Mounting Pad 3 21

3-4 #1 Dynafocal Mount Dimensions 3 23

3-5 #2 Dynafocal Mount Dimensions 3 23

3-6 Conical Mount Dimensions 3 24

3-7 Limit and Ultimate Engine Forces 3 26

3-8 Engine Mount Forcing Function for Engine Startup and Shutdown 3 27

3-9 Engine Mount Forcing Function for Steady State Conditions 3 27

Figure Description Chapter Page

© March 2004 Superior Air Parts Inc.

ii

Page 7

Installation & Operation Manual

O-360 and IO-360 Series Engines

List Of Tables

Table

Number

1-1 Manufacturer’s General Specifications 1 3

1-2 Manufacturer’s Physical Specifications 1 4

1-3 Views of the Engine 1 4

3-1 Accessory Drive Data 3 20

3-2 Lord Engine Mounts for Superior Vantage Engines 3 21

3-3 Limit and Ultimate Engine Mount Loads 3 25

4-1 Instrumentation Connections 4 2

6-1 Normal Starting Procedures 6 3

6-2 Starting A Flooded Engine 6 4

6-3 Ground Running / Fixed Wing Warm-Up 6 5

6-4 Ground Running / Rotorcraft Warm-Up 6 5

6-5 Fixed Wing - Pre-Takeoff Ground Check 6 6

6-6 Rotorcraft - Pre-Takeoff Ground Check 6 7

6-7 Fuel Mixture Leaning General Rules 6 8

6-8 Leaning with Exhaust Gas Temperature Gage 7 9

6-9 Leaning with Flowmeter 6 9

6-10 Leaning with Manual Mixture Control 6 9

6-11 Shut Down Procedure 6 9

7-1 Abnormal Operating Procedures 7 1

7-2 Engine Will Not Start 7 2

7-3 Rough Idling 7 2

7-4 Engine Not Able To Develop Full Power 7 3

7-5 Rough Engine Operation 7 3

7-6 Low Power & Engine Runs Rough 7 3

7-7 Low Oil Pressure On Engine Gage 7 4

7-8 High Oil Temperature 7 4

7-9 Excessive Oil Consumption 7 4

8-1 Oil Grades 8 1

8-2 Oil Sump Capacity 8 1

8-3 Minimum Octane Fuels 8 2

8-4 Consumables 8 2

Table Description Chapter Page

© March 2004 Superior Air Parts Inc.

iii

Page 8

Installation & Operation Manual

O-360 and IO-360 Series Engines

Introduction

About This Manual

This engine installation and operation manual is

provided as guidance for the installation and

installation design of a Superior Vantage Engine

to an airframe and to describe its’ operational

characteristics. Its purpose is to provide

technical information to aid in designing and

operating an effective engine installation so as

to achieve maximum performance while

providing for maximum service life.

Superior Air Parts has made clear and accurate

information available for those who maintain,

own and repair the Vantage O-360 and IO-360

Series Engines. Superior Air Parts values your

input regarding revisions and additional

information for our manuals. Please forward

your comments and input to:

Superior Air Parts

Attn. Engineering Department

621 South Royal Lane Suite 100

Coppell, Texas 75019

Related Publications

The following are related engine and accessory

publications.

O & IO-360 Maintenance Manual SVMM01

O & IO-360 Overhaul Manual SVOM01

O & O-360 Illustrated Parts Cat. SVIPC01

Unison Master Service Manual, F-1100

Precision RSA-5 Service Manual, 15-338

Precision MA-4-5 Manual, MSAHBK-1

Champion Aerospace Service Manual,

AV-6R

Installation Approval Requirements

The engine warranty for a Vantage Engine

installation is subject to the technical approval of

Superior. Upon approval of an installation

design, Superior will provide a letter that states

in part that the installation design is acceptable

and does not adversely effect the function of the

engine with respect to engine longevity while the

engine is operated in accordance with

recommended procedures.

Superior requires certain technical data

regarding the installation in order to determine

its acceptability for warranty purposes. This

data may include, but is not limited to drawings,

photographs and test data. Approval of the

installation for these purposes is limited to the

installation design furnished by the airframe

manufacturer to Superior. Modifications or

changes to the installation design requires a

new or amended letter of approval prior to the

warranty becoming effective for that design.

Approval of the installation by Superior as

described above is limited to engine warranty

issues only. It does not in any way indicate

approval of other aspects of the installation

design such as structural integrity and

manufacturability.

Superior Vantage Engines discussed in this

document must be installed and operated in

accordance with the limitations, conditions and

operating procedures described in this

document, the Model Specification Data and the

Installation and Operation Manual. They must

also be maintained in accordance with the

applicable Overhaul Manual and other

Instructions for Continued Airworthiness.

Superior accepts no responsibility for

airworthiness of any aircraft resulting from the

installation of the engine or associated

equipment.

© March 2004 Superior Air Parts Inc.

iv

Page 9

Installation & Operation Manual

O-360 and IO-360 Series Engines

Obtaining Service Information

All Vantage Series Engine manuals and service

information may be downloaded at:

www.superior-air-parts.com

All Vantage Series Engine manuals and service

information may also be purchased by

contacting:

Superior Air Parts

621 South Royal Lane, Suite 100

Coppell, Texas 75019

or call: 972-829-4600

Accessory Information may be obtained at:

www.championaerospace.com

www.unisonindustries.com

www.skytecair.com

www.precisionairmotive.com

www.aeroaccessories.com

© March 2004 Superior Air Parts Inc.

v

Page 10

Installation & Operation Manual

O-360 and IO-360 Series Engines

CHAPTER 1

Engine Description

1. GENERAL DESCRIPTION

Superior Vantage Engines are four-cylinder,

horizontally opposed, air-cooled, direct drive

powerplants incorporating a wet sump, bottom

mounted induction, bottom exhaust with either

carbureted or port injected fuel systems.

Provisions exist for both front and rear mounted

accessories. All engine components will be

referenced as they are installed in the airframe.

Therefore, the “front” of the engine is the

propeller end and the “rear” of the engine is the

accessory mounting drive area. The oil sump is

on the “bottom” of the engine and the cylinder

shroud tubes are on the “top”. The terms “left”

and “right” are defined as being viewed from the

rear of the engine looking toward the front.

Cylinder numbering is from the front to the rear

with odd numbered cylinders on the right side of

the engine. The direction of crankshaft rotation

is clockwise as viewed from the rear of the

engine looking forward unless otherwise

specified. Accessory drive rotation direction is

defined as viewed from the rear of the engine

looking forward.

2. CONTINUED AIRWORTHINESS

Vantage Engines discussed in this document

must be installed and operated in accordance

with the limitations, conditions and operating

procedures described in this document. They

must also be maintained in accordance with the

applicable Overhaul Manual and other

Instructions for Continued Airworthiness. The

engine’s time between overhaul (TBO) period is

initially defined as 1000 hours. A TBO extension

program is in process.

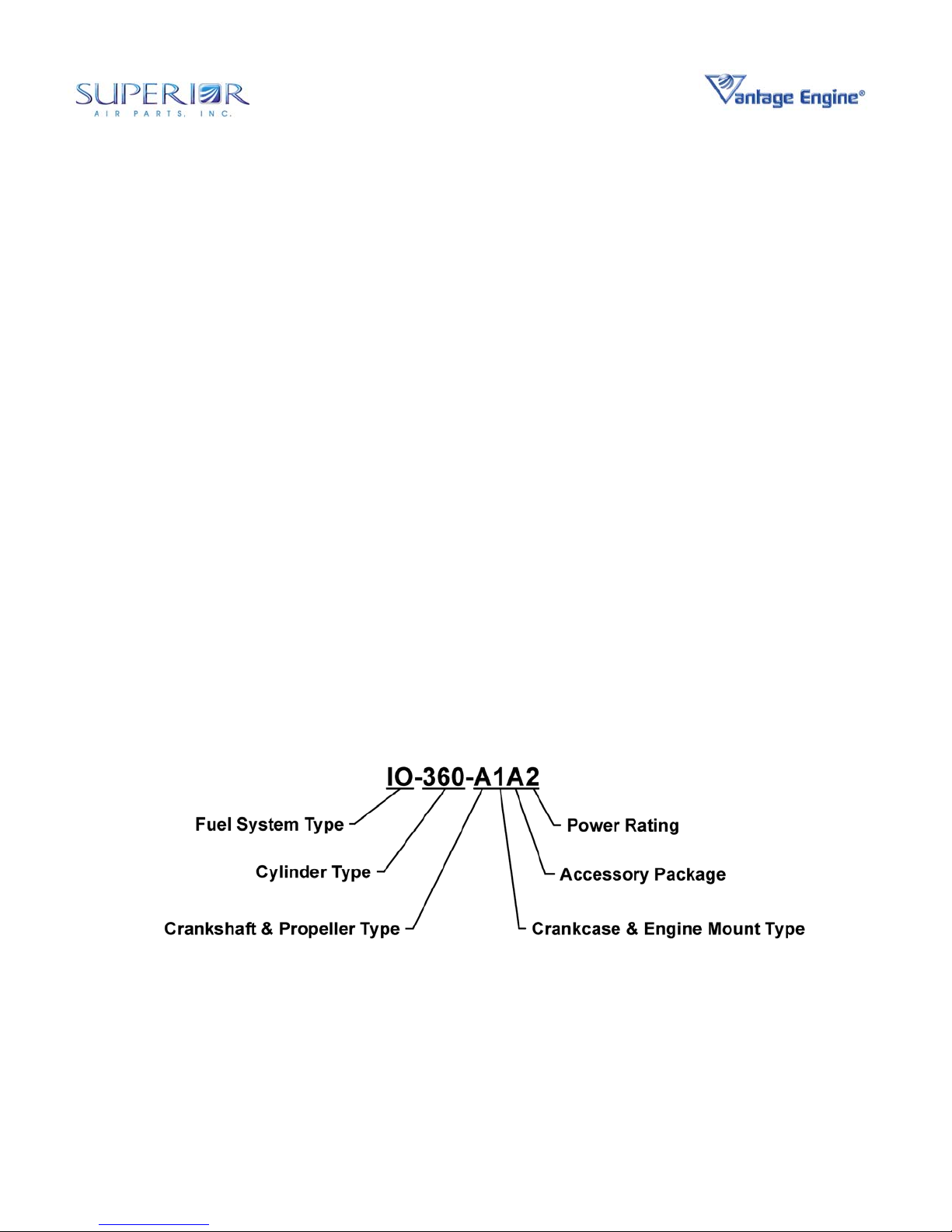

3. MODEL DESIGNATIONS

The model number designation is defined in a

way that the digits of the model number can

easily identify the basic configuration of the

engine as described in Figure 1-1.

Figure 1-1 • Model Number Designation

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

1

Page 11

Installation & Operation Manual

O-360 and IO-360 Series Engines

Fuel System Type

IO Denotes Port Fuel Injection System and “opposed cylinder” arrangement.

O Denotes a carbureted system and “opposed cylinder” arrangement.

Cylinder Type

360 Parallel valve cylinder, 361 cubic inches.

Model Suffix

1

A Fixed-Pitch, Thin-wall front main

B Constant-Speed, Thin-wall front main

2

4

Denotes detail engine configuration

st

Digit Crankshaft & Propeller Type

nd

Digit Crankcase & Engine Mount Type

1 #1 Dynafocal Mount

2 #2 Dynafocal Mount

3 Conical Mount

rd

3

Digit Accessory Package

Fuel System Ignition System

Carbureted Fuel Injected

A Unison Magnetos Precision Carburetor Precision Fuel Injection

th

Digit Power Rating: Piston Compression Ratio

1* - 2 8.5:1 180

*For Future Use

Cylinder Type

360

CR HP

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

2

Page 12

Installation & Operation Manual

O-360 and IO-360 Series Engines

4. ENGINE COMPONENTS GENERAL

DESCRIPTION

The O-360 and IO-360 series engines are air-cooled,

four cylinder, horizontally opposed, direct drive

engines. See Table 1-1 for Manufacturer’s General

Specifications.

A. The complete engine includes the following

components and assemblies:

1. Crankcase Assembly

2. Crankshaft Assembly

3. Camshaft Assembly

4. Valve Train Assembly

5. Cylinder Assemblies

6. Connecting Rod Assemblies

7. Oil Sump Assembly

8. Inter Cylinder Baffles

9. Starter

10. Lubrication System (includes oil filter)

11. Accessory Drive

12. Ignition System (includes spark plugs)

13. Fuel System

14. Starter Support Assembly

15. Oil Gage

16. Induction System

17. Accessories

Note:

Complete engine does not include

outer cylinder baffles, propeller governor,

and airframe to engine control cables,

attaching hardware, hose clamps, vacuum

pump, exhaust system, fittings or alternator.

B. Specifications

The manufacturer’s physical specifications

are listed in Table 1-2 are applicable to the

O-360 and IO-360 series engines. See

Model Specification Data (MSD) for more

specific information.

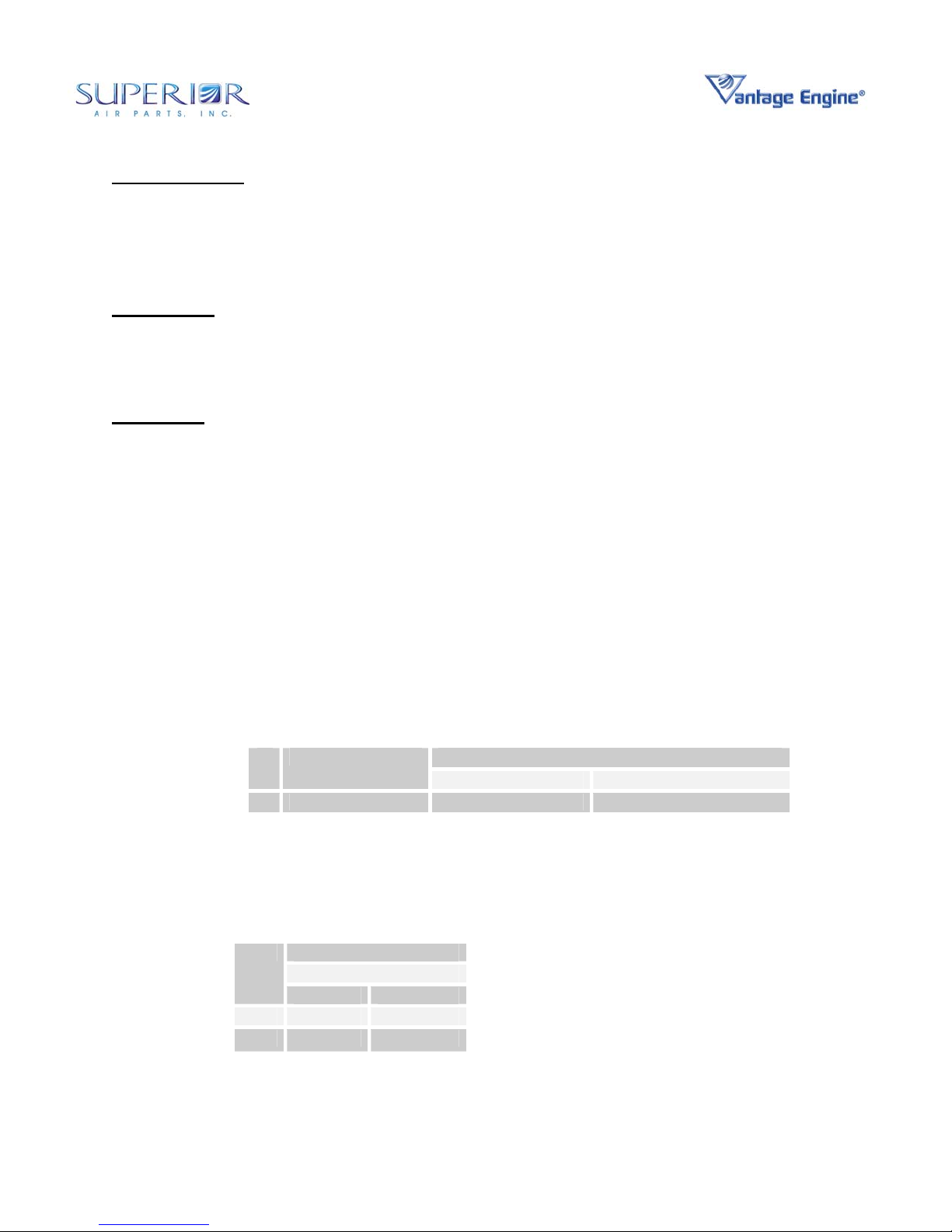

Table 1-1 • Manufacturer’s General Specifications

Model O-360 and IO-360

Rated Power Hp 180

Rated Speed, RPM RPM 2700

Bore, inches In 5.125

Stroke, inches In 4.375

Displacement cubic inches In3 361.0

Compression Ratio 8.5:1

Firing Order 1-3-2-4

Spark timing °BTDC 25

Propeller drive ratio 1:1

Propeller drive rotation

(viewed from rear)

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

Clockwise

3

Page 13

Installation & Operation Manual

O-360 and IO-360 Series Engines

Table 1-2 • Manufacturer’s Physical Specifications

Model

O-360 24.6 33.4 32.8 See MSD

IO-360 24.0 33.4 32.8 See MSD

Height

(In)

Width

(In)

Length

(In)

Weight

Table 1-3 • Views of the Engine

Engine View Figure Number Location

O-360 Engine Front View Figure 1-2 p. 5

O-360 Engine Left Side View Figure 1-3 p. 6

O-360 Engine Top View Figure 1-4 p. 7

O-360 Engine Rear View Figure 1-5 p. 8

IO-360 Engine Front View Figure 1-6 p. 9

IO-360 Engine Left Side View Figure 1-7 p. 10

IO-360 Engine Top View Figure 1-8 p. 11

IO-360 Engine Rear View Figure 1-9 p. 12

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

4

Page 14

Installation & Operation Manual

O-360 and IO-360 Series Engines

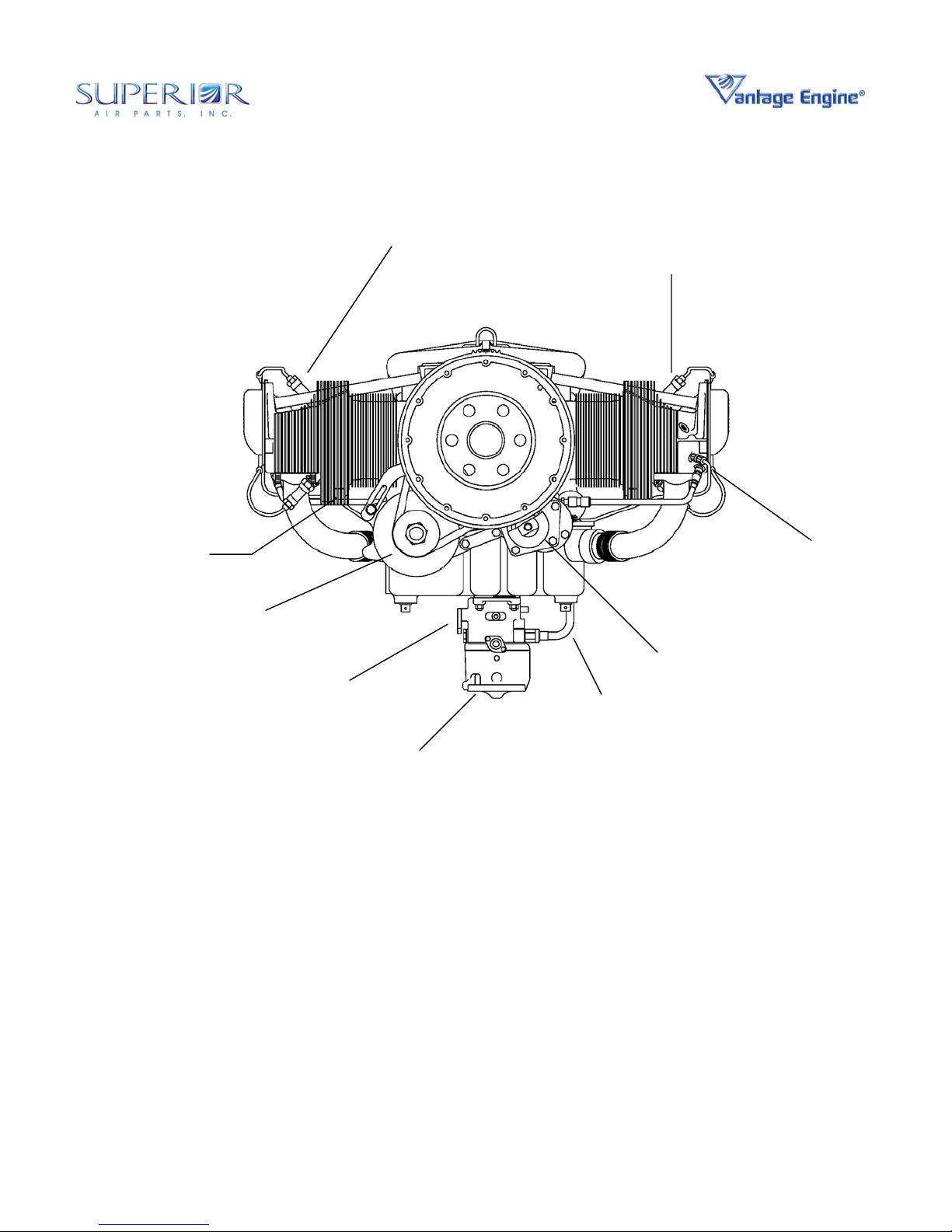

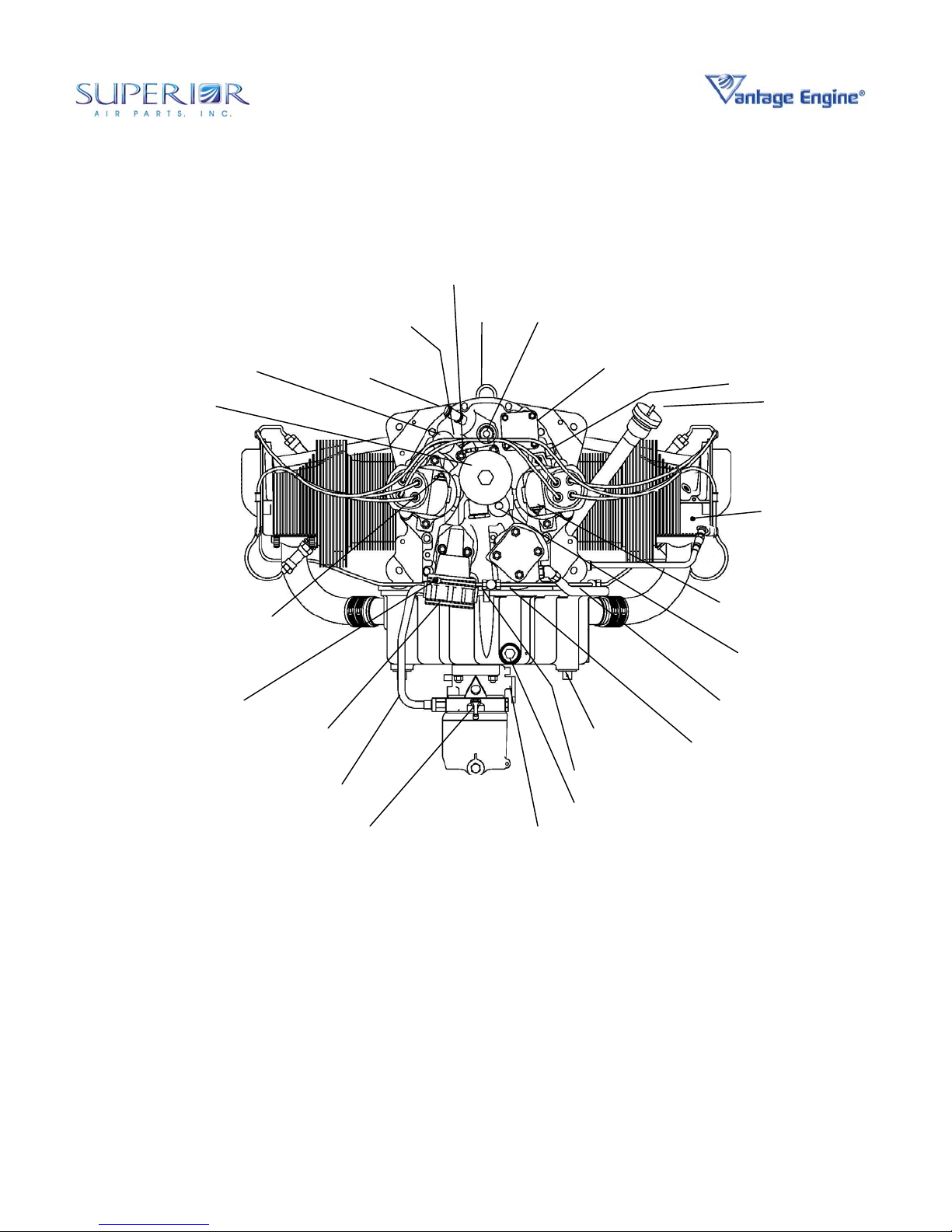

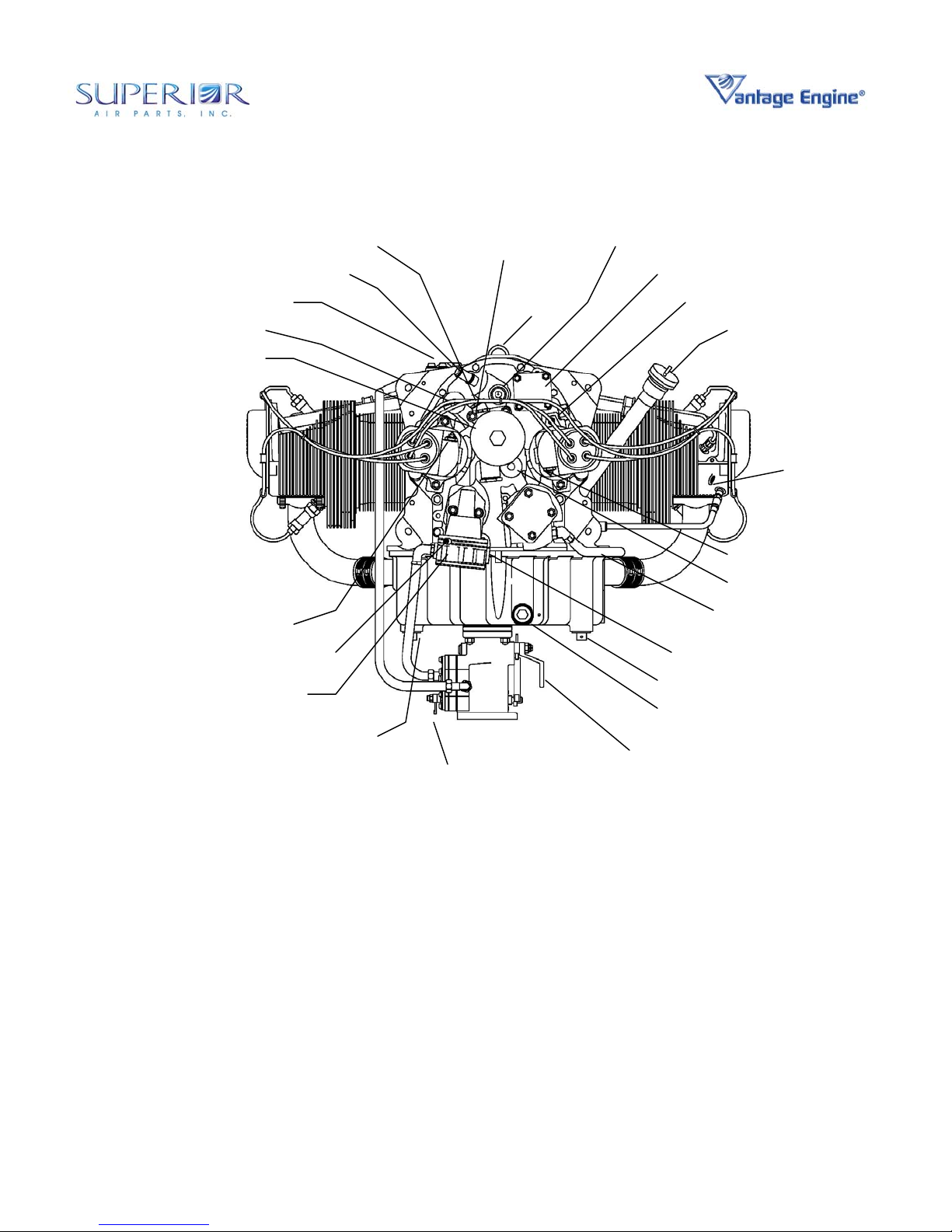

SPARK PLUG

SPARK PLUG

CHT PROBE LOCATION

(TYPICAL EACH HEAD)

ALTERNATOR & BELT NOT

PROVIDED WITH ENGINE

THROTTLE LEVER

FUEL LINE

CARBURETOR

Figure 1-2 • O-360 Engine Front View

STARTER

PRIMING

SYSTEM

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

5

Page 15

Installation & Operation Manual

O-360 and IO-360 Series Engines

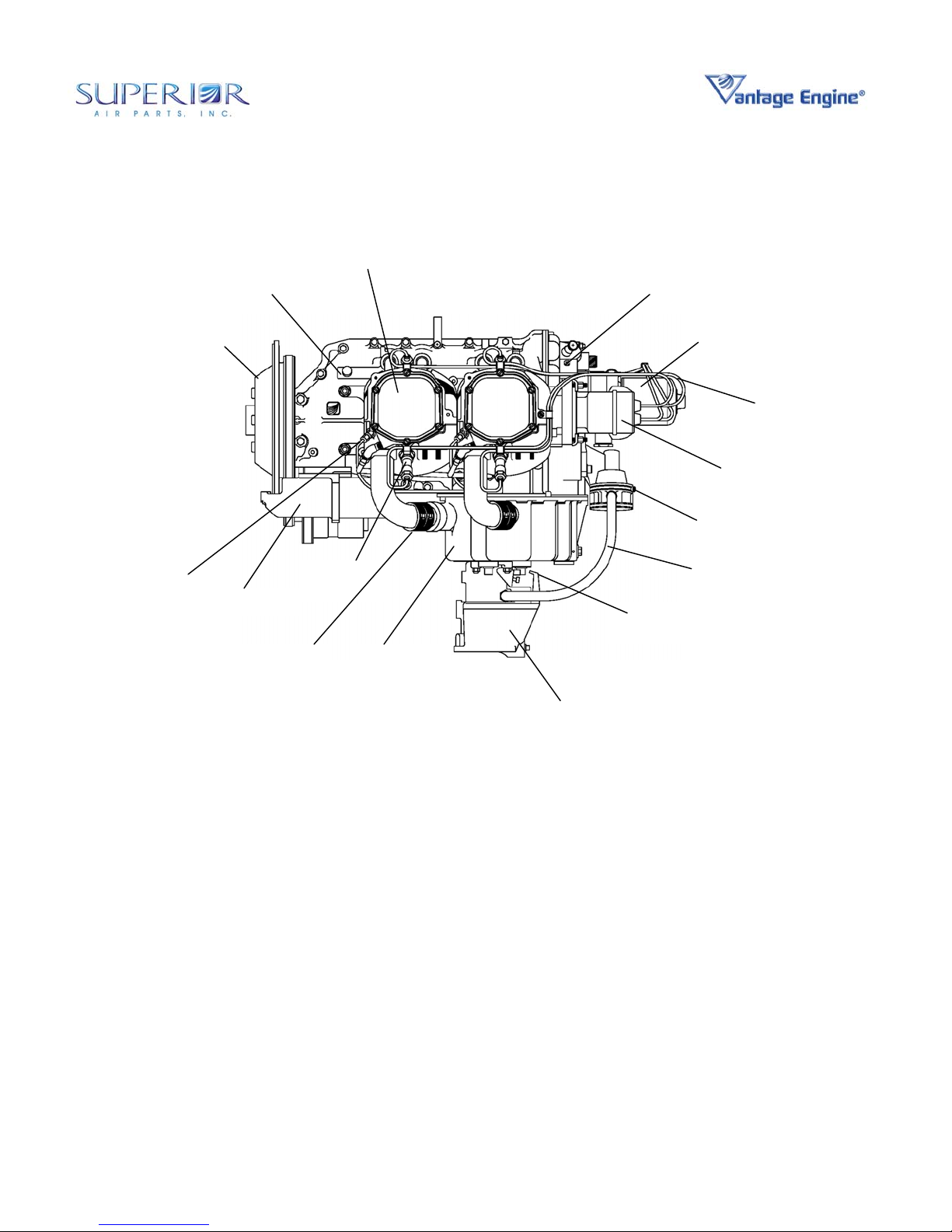

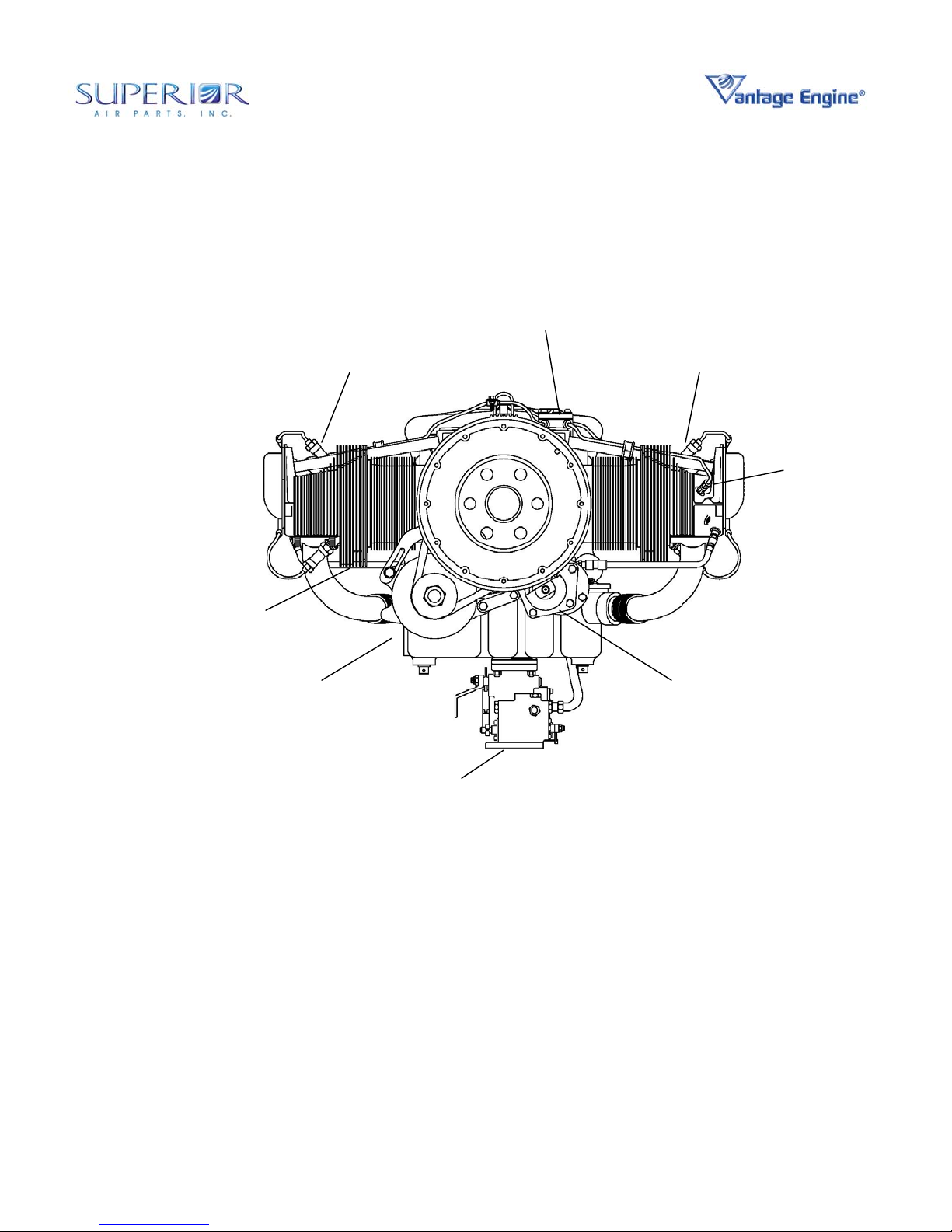

CYLINDER

CRANKCASE

ASSEMBLY

ASSEMBLY

ACCESSORY

HOUSING

STARTER SUPPORT

ASSEMBLY

PRIMING

SYSTEM

STARTER

INDUCTION

SYSTEM

SPARK PLUG

OIL SUMP

ASSEMBLY

CARBURETOR

MIXTURE

LEVER

OIL FILTER

FUEL

PUMP

FUEL

LINE

HARNESS

MAGNETO

Figure 1-3 • O-360 Engine Left Side View

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

6

Page 16

Installation & Operation Manual

O-360 and IO-360 Series Engines

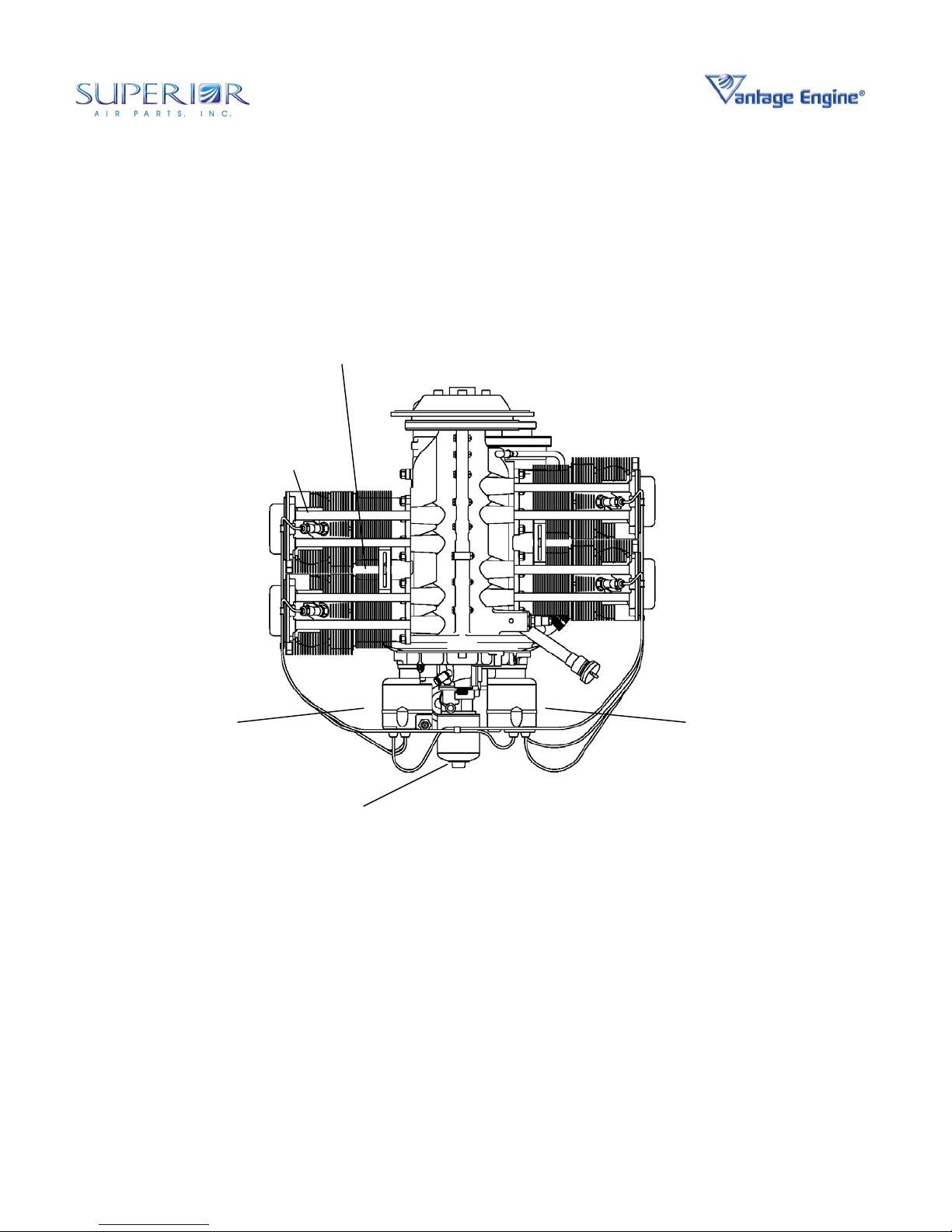

INTER-CYLINDER BAFFLE

SPARK PLUG

MAGNETO

MAGNETO

OIL FILTER

Figure 1-4 • O-360 Engine Top View

7

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

Page 17

Installation & Operation Manual

O-360 and IO-360 Series Engines

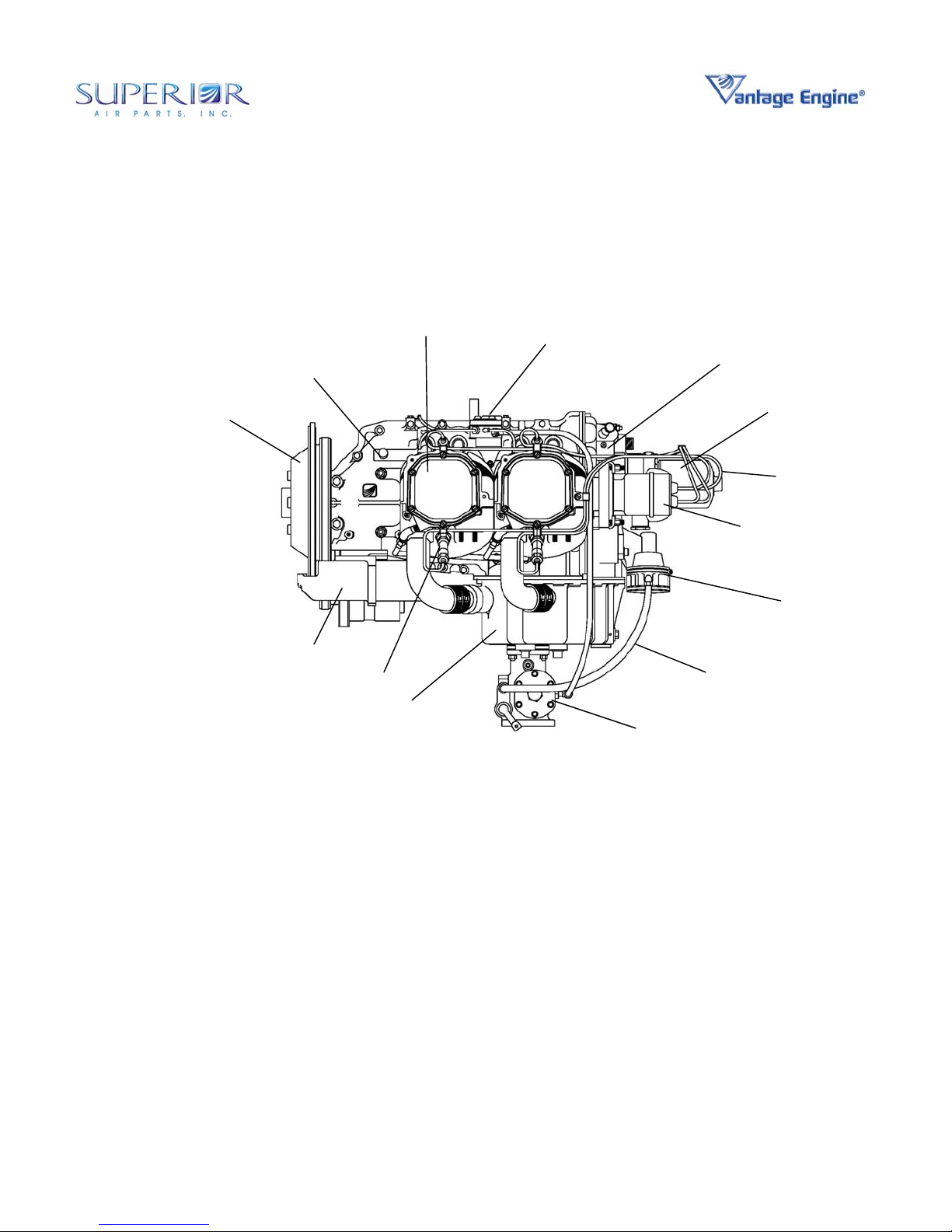

OIL TEMP

CONNECTION

OIL RETURN FROM COOLER

OIL FILTER

GROUND OR “P-LEAD” TERMINAL

VENT LINE

CONNECTION

ALTERNATE OIL TO COOLER

BREATHER

FITTING

DIAPHRAGM

FUEL PUMP

FUEL LINE

FUEL MIXTURE

LEVER

EYE

BRACKET

TACHOMETER CONNECTION

VACUUM PUMP / ACCESSORY PAD

OIL DRAIN

PLUG

FUEL PUMP INLET

OIL SUCTION

SCREEN

THROTTLE

LEVER

OIL PRESSURE GAGE CONNECTION

OIL LEVEL TUBE & GAGE

MANIFOLD

PRESSURE

CONNECTION

GROUND OR “P-LEAD” TERMINAL

OIL SUPPLY TO COOLER

OIL LINE TO

PROPELLER

COMMON PRIMER

LINE SOURCE

Figure 1-5 • O-360 Engine Rear View

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

8

Page 18

Installation & Operation Manual

O-360 and IO-360 Series Engines

FUEL INJECTION

MANIFOLD

CHT PROBE LOCATION

(TYPICAL EACH HEAD)

NOT PROVIDED WITH ENGINE

SPARK PLUG

ALTERNATOR & BELT

FUEL INJECTION

SERVO

STARTER

SPARK PLUG

FUEL

INJECTOR

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

Figure 1-6 • IO-360 Engine Front View

9

Page 19

Installation & Operation Manual

O-360 and IO-360 Series Engines

STARTER SUPPORT

ASSEMBLY

CRANKCASE

ASSEMBLY

STARTER

SPARK PLUG

OIL SUMP

CYLINDER

ASSEMBLY

FUEL INJECTION

MANIFOLD

ACCESSORY

HOUSING

FUEL INJECTION

SERVO

MAGNETO

FUEL LINE

OIL FILTER

WIRING

HARNESS

FUEL PUMP

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

Figure 1- 7 • IO-360 Engine Left Side View

10

Page 20

Installation & Operation Manual

O-360 and IO-360 Series Engines

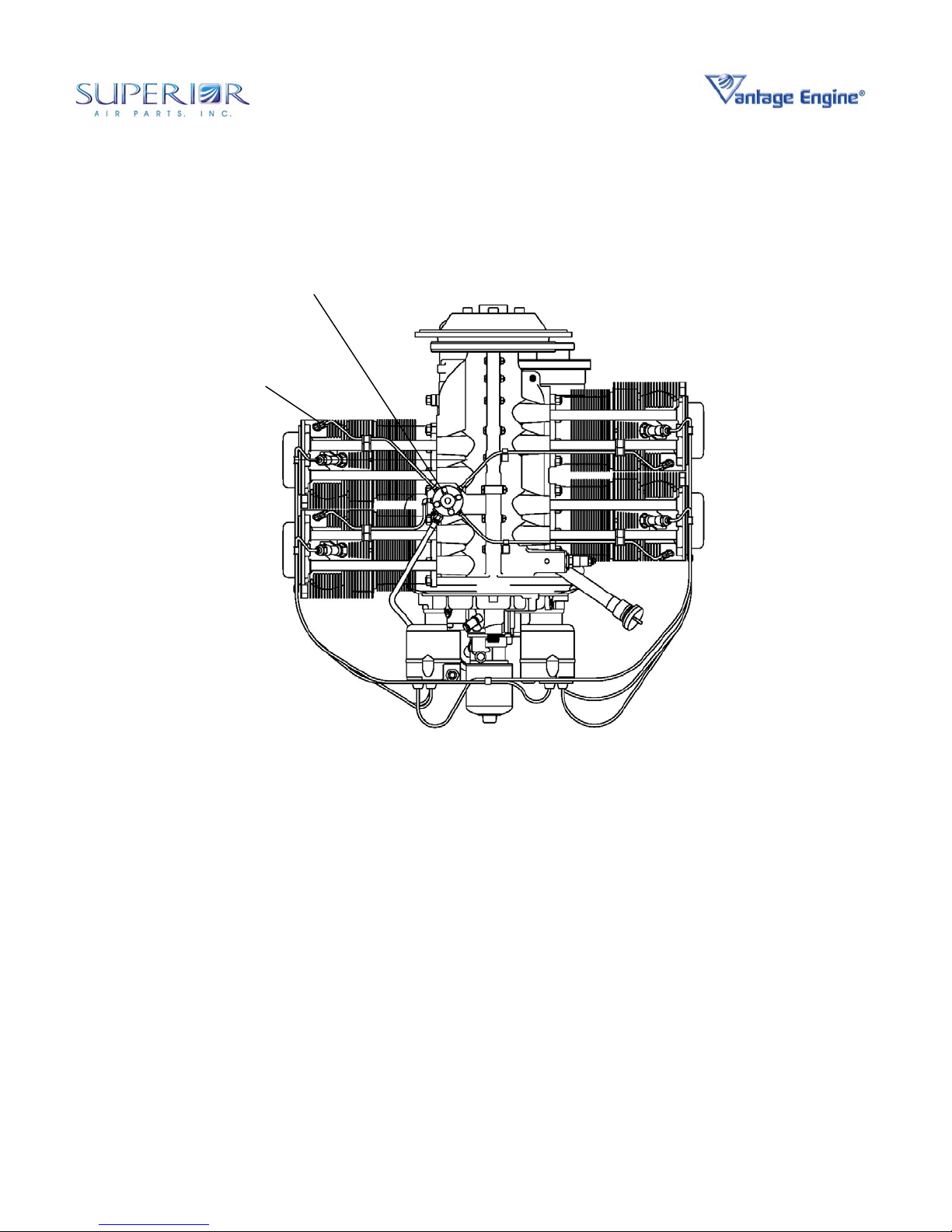

FUEL INJECTION

MANIFOLD

FUEL INJECTIOR

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

Figure 1- 8 • IO-360 Engine Top View

11

Page 21

Installation & Operation Manual

O-360 and IO-360 Series Engines

BREATHER FITTING

FUEL INJECTION MANIFOLD

OIL RETURN FROM COOLER

OIL FILTER

GROUND OR “P-LEAD” TERMINAL

VENT LINE CONNECTION

ALTERNATE OIL

TO COOLER

OIL TEMP

CONNECTION

EYE

BRACKET

TACHOMETER CONNECTION

VACCUM PUMP / ACCESSORY PAD

FUEL PUMP INLET

OIL PRESSURE GAGE CONNECTION

OIL LEVEL TUBE & GAGE

MANIFOLD

PRESSURE

CONNECTION

GROUND OR “P-LEAD” TERMINAL

OIL SUPPLY TO COOLER

OIL LINE TO

PROPELLER

DIAPHRAGM FUEL

PUMP

OIL DRAIN PLUG

MIXTURE CONTROL

LEVER

THROTTLE CONTROL

OIL DRAIN PLUG

OIL SUCTION

SCREEN

LEVER

Figure 1- 9 • IO-360 Engine Rear View

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

12

Page 22

Installation & Operation Manual

O-360 and IO-360 Series Engines

5. FEATURES AND OPERATING

MECHANISMS

Crankshaft - The crankshaft is made from

aerospace grade SAE 4340 Vacuum-Arc-Remelt

(V.A.R.) steel per AMS 6414. All bearing journal

surfaces are nitrided.

Connecting Rods - The connecting rods are

made from aerospace grade SAE 8740 forgings

per AMS 6325. They have replaceable bearing

inserts in the crankshaft ends and bronze

bushings in the piston ends. The bearing caps

on the crankshaft ends are retained by two bolts

with self locking nuts per cap. Caps are tongue

and groove type for improved alignment and

rigidity.

Camshaft - Valve Operating Mechanism - The

camshaft is located above and parallel to the

crankshaft. The camshaft actuates hydraulic

lifters that operate the valves through push rods

and valve rockers.

Crankcase - The crankcase is made from

aerospace grade AA C355-T71 stabilized

structural aluminum alloy per AMS 4214. The

assembly consists of two reinforced aluminum

alloy castings fastened together by means of

studs, bolts, and nuts. The main bearing bores

are machined for use with precision type main

bearing inserts.

Accessory Housing - The accessory housing is

made from an aluminum casting and is fastened

to the rear of the crankcase and the top rear of

the sump.

Oil Sump - The sump incorporates an oil drain

plug, oil suction screen, mounting pad for

carburetor or fuel injector, the intake riser, and

intake pipe connections.

Cylinders - Millennium

exclusively. These air-cooled cylinders are

manufactured by screwing and shrinking the two

major parts, head and barrel, together. The

heads are made from AMS 4220 aluminum alloy

casting material. All barrels are made from

forgings produced to AMS 6382 forging

specifications. They are internally choked and

honed to allow optimal operating conditions for

the rings and pistons at operating temperatures.

© March 2004 Superior Air Parts Inc. Chapter 1 • Engine Description

®

Cylinders are used

Pistons - The pistons are made from an

aluminum alloy. The piston pin is a full floating

type with a plug located in each end of the pin.

The piston is a 3-ring type with 2 compression

rings and 1 oil control ring.

Cooling System – Superior Vantage Engines

are designed to be air-cooled. Baffles are

provided to build up air pressure and force the

air between the cylinder fins. The air is

exhausted to the atmosphere through the rear of

the cowling.

Induction System - The distribution of the air to

each cylinder is through the center zone of the

induction system. This is integral with the oil

sump.

Fuel Systems

Carbureted

are equipped with a float type carburetor The

MA-4-5 carburetors are of the single barrel float

type equipped with a manual mixture control and

an idle cut-off.

Fuel Injected

equipped with a direct cylinder injected RSA-5

fuel injector. The fuel injection system

schedules fuel flow in proportion to airflow. Fuel

vaporization takes place at the intake ports. The

RSA fuel injection system is based on the

principle of measuring airflow and using the air

pressure in a stem type regulator, converting the

air pressure into a fuel pressure. The fuel

pressure (fuel pressure differential), when

applied across the fuel metering section (jetting

system), makes fuel flow proportional to airflow.

Lubrication System - The full pressure wet

sump lubrication system is supplied by a gear

type pump. It is contained within the accessory

housing.

Priming System - A manual primer system is

provided on all engines using a carburetor. Fuel

injected engines do not require a manual

priming system, relying instead on the fuel

injectors for priming.

Ignition System - Dual ignition is furnished by

two Unison magnetos with two spark plugs per

cylinder. Each magneto is equipped with

impulse coupling for improved starting.

13

- Superior Air Parts O-360 engines

- IO-360 series engines are

Page 23

Installation & Operation Manual

O-360 and IO-360 Series Engines

CHAPTER 2

Airworthiness Limitations

The Airworthiness Limitations Section is F.A.A.

approved and specifies maintenance required

under sections 43.16 and 91.403 of the Federal

Aviation Regulations unless an alternate

program has been FAA approved. This section

is part of the type design of the O-360 and IO360 engine series pursuant to certification

requirements of the Federal Aviation

Regulations.

1. MANDATORY REPLACEMENT TIME

Subject to additional information contained in

F.A.A. Approved Mandatory Service Bulletins

issued after the date of certification, the O-360

and IO-360 engine series do not contain any

components having mandatory replacement

times required for type certification.

2. MANDATORY INSPECTION INTERVALS

Subject to additional information contained in

F.A.A. Approved Mandatory Service Bulletins

issued after the date of certification, the O-360

and IO-360 engine series do not contain any

components having mandatory inspection

intervals.

3. OTHER MANDATORY INTERVALS OR

PROCEDURES

Subject to additional information contained in

F.A.A. Approved Mandatory Service Bulletins

issued after the date of certification, the O-360

and IO-360 engine series do not have any

inspection-related or replacement time-related

procedures required for type certification.

4. DISTRIBUTION OF CHANGES TO

AIRWORTHINESS

Changes to this Airworthiness Limitations

Chapter constitute changes to the type design of

the O-360 and IO-360 engine series and require

F.A.A. approval pursuant to Federal Aviation

Regulations. Such changes will be published in

F.A.A. Approved Mandatory Service Bulletins.

Superior Vantage Engine Service Bulletins may

be obtained by writing to:

Superior Air Parts

621 South Royal Lane, Suite 100

Coppell, Texas 75019

or call: 972-829-4600

or on the web at www.superior-air-parts.com

© March 2004 Superior Air Parts Inc. Chapter 2 • Airworthiness Limitations

1

Page 24

Installation & Operation Manual

O-360 and IO-360 Series Engines

CHAPTER 3

Aircraft / Engine Integration Considerations

1. GENERAL

The following sections in this chapter include a

discussion of design practices to be considered

during the integration of a Superior Vantage

engine with an airframe and propeller. These

discussions should be used IN ADDITION TO

the applicable requirements of the FARs.

Superior requires that proper functioning of the

system designs outlined in this chapter be

proven prior to activation of the warranty.

Proper functioning of the installation design shall

be proven by technical data such as test data,

photographs, drawings and engineering

calculations. Superior Air Parts Engineering

Department will provide guidance regarding the

specifics of these requirements as appropriate to

the installation and on a case-by-case basis.

Throughout this chapter reference is made to

data contained in the Model Specification Data.

These documents are engine series specific and

are contained in Appendices of this manual.

Refer to the appropriate Model Specification

Data for your engine model when consulting this

data.

2. INDUCTION SYSTEM

The induction system design can significantly

effect both performance and longevity of an

aircraft engine installation. In addition to more

obvious issues such as air filtration, seemingly

insignificant design features can cause

restrictions or other airflow disturbances

resulting in flow loss or improper function of the

fuel metering system. Induction systems which

yield excessive intake air temperatures can

promote engine detonation.

A. General Induction System Design

It is important that the induction system of

naturally aspirated engines such as the Superior

1 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

Vantage Series be capable of supplying clean,

filtered, cool intake air to the engine at the

maximum required flowrate and with maximum

attainable pressure. The term “maximum

attainable pressure” as used here refers to an

air source that provides maximum intake air

pressure, (including ram air effects) while

minimizing restrictions and flow losses. A

reduction in flowrate or total pressure, or

increased temperature can cause power loss,

reduced service ceiling and increased possibility

of detonation during high power requirements.

Properly engineered intake systems for naturally

aspirated engines should result in total intake air

pressures that are greater than ambient air

pressure. For example, air pressure in the intake

system can be raised by

directing the face of the air pickup into the

relative wind of the aircraft. Further, by locating

the air pickup within the propeller diameter, ram

air effects can be increased. Care should be

taken to position the air pickup as far as possible

away from the propeller axis (but within the

“propeller envelope”) so as to take advantage of

the increased air velocities at the outer areas of

the prop. Care should also be given to prevent

“blanking” of the intake air pickup by the prop

blade. Increasing the size of the air pickup,

particularly in the direction perpendicular to the

blade axis, can help reduce this potential. Care

should also be given to designing an air pickup

that maintains maximum frontal area during

periods of high aircraft angle of attack.

Typically, maximum power is required during

flight conditions having high angle of attack and

reductions in airflow will restrict maximum power

capability.

The intake air system should be designed to

minimize pressure and flow losses. Sharp

elbows and abrupt duct expansions or

contractions all contribute to system losses.

Changes in duct sizing should be accompanied

by tapered transitions to minimize these losses.

Duct losses are a function of air velocity and can

Page 25

Installation & Operation Manual

O-360 and IO-360 Series Engines

be significantly reduced by increasing duct size

and thereby reducing the air velocity.

Utilizing ducts with circular cross-sections or

“square” cross-sections with the highest possible

aspect ratio can also reduce duct losses.

Turning vanes can be used to reduce losses in

sharp corners when necessary.

The state of the airflow as it enters the

carburetor or fuel injector servo body is critical to

effective and efficient fuel mixing. Both

carburetor and fuel injector servo bodies sense

mass airflow and introduce fuel based on that

measurement. If the airflow is turbulent during

this process, inaccurate airflow sensing can

occur resulting in improper fuel flow. Turbulence

of the intake air in a carbureted system will also

promote poor fuel / air mixing and large cylinder

to cylinder mixture variations. The

consequences of these conditions can be as

simple as reduced power or as great as incylinder detonation.

Care should also be given to the placement of

the intake system with respect to hot areas such

as exhaust pipes and other engine components.

Cooler intake air results in better power output

and greater service ceilings. Intake systems

that allow heating of the air reduce available

engine power and can reduce service ceilings.

B. Intake Air Requirements and Filtration

The intake air and filtration system must be

designed for both effective and efficient filtering

with minimal flow loss. Studies have shown that

particulates greater than about 10 microns in

size are particularly harmful to engines;

therefore the filtration system should be selected

accordingly. Filter manufacturers can provide

data regarding effectiveness, efficiency and

capacity of their products including the effect of

particulate size. Guidance regarding overall filter

size, based on filter capacity, can be obtained

from the filter manufacturer.

The size of the air filter must also consider the

total engine airflow requirements and the

maximum air velocity requirements of the filter.

In general, filters are more effective for lower air

velocities but practical considerations must be

made based on space available. Intake air flow

requirements of a Superior Vantage Engine are

defined in Figure 1 of the Model Specification

2 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

Data. It is recommended that the filter be sized

to provide a minimum of 150% of this flow to

minimize pressure drop for both clean and dirty

filters.

C. Carburetor Heat

Due to the cooling effects of both fuel

vaporization and airflow through the venturi,

carburetor ice can form with outdoor air

temperatures as high as 100°F. Therefore, it is

necessary to provide a mechanism to introduce

heat to the intake airstream, downstream of the

air filter, to prevent this condition and to correct it

if icing were to occur. This mechanism also

serves the purpose of an alternate air source

should the filter become unexpectedly blocked

due to ice or debris. The minimum temperature

rise required of the carb heat mechanism is

specified in the FARs.

The design of the carb heat system should, in

general, follow the same guidelines as the

induction air system to minimize pressure loss

and turbulence. For example the flow area

should be as large as possible to reduce air

velocity and therefore flow losses. Relatively

slow-moving air across a heat source will also

experience a higher temperature rise than

faster-moving air over the same heat source.

Good practice suggests that the carb heat duct

should be at least 75% the size of the carburetor

inlet.

The air source for the carb heat mechanism

should be from a source other than the

“standard” filtered intake air. It is common for

the carb heat air to be drawn from within the

lower cowl area. It is also conventional to omit

the use of a traditional air filter at the carb heat

source for several reasons includ ing preventing

the risk of filter blockage for alternate air.

However, it is good practice to include a course

screen to prevent ingestion of “large” foreign

objects.

The carb heat air is normally introduced to the

induction airstream by means of a mixing box.

The mixing box includes a baffle door that is

manually actuated by the pilot and governs the

amount of filtered induction air or carb heat air

that is supplied to the carburetor.

Page 26

Installation & Operation Manual

O-360 and IO-360 Series Engines

It is important that the design of the mixing box

and damper door minimize pressure drop and

turbulence of either filtered intake air or carb

heat air. Some turbulence is unavoidable in this

transition; however it is recommended that a

“straight” section of duct be available after the

transition to smooth the airflow. If possible, this

section should be a length equivalent to 10

diameters. If this length is not possible due to

geometry constraints then appropriate steps

should be taken to straighten the flow. In either

case, thorough testing should be performed to

verify that both intake airflow and carb heat

airflow is free of excessive pressure drop and

turbulence to the extent that they do not degrade

engine performance.

Good practice also dictates that the mixing box

damper door be spring actuated to partially

actuate automatically in the event of unexpected

air filter blockage due to ice or debris. Care

should be taken in the design of this mechanism

to prevent “flutter” of the damper door during

normal operation in either the filtered air or carb

heat mode. The mechanism should also be

designed to prevent unintended use of carb heat

during the filtered air mode, including the effects

of “normal” filter blockage. That is, the automatic

spring mechanism should not be designed to be

so sensitive that normal pressure drop due to

filter use over time would cause carb heat air to

be introduced.

D. Alternate Air Source

Fuel injected engines introduce fuel to the

induction air at the heated cylinder port and do

not present the same concerns regarding

induction icing as the carbureted systems.

However, provisions are required to provide an

alternate induction air source for fuel injected

systems to prevent engine stoppage in the event

of filter blockage due to ice or debris. As with

the design of the carb heat mechanism, this is

conventionally done by drawing air from the

heated lower cowl area and introducing this air

downstream from the intake air filter. Although it

is acceptable to use a mixing box device with

flapper door mechanism as with the carb heat

apparatus, this is not necessary. Where the

carb heat mixing box must be designed so as to

select between the two air sources, the alternate

air source for fuel injected engines is simply the

availability of alternate air. Therefore, it is not

necessary to “block off” the normal filtered air

source.

Like the carb heat mechanism, the alternate air

source should be designed to minimize both flow

losses and turbulence. An entrance area at

least 75% of the fuel injector servo area is

recommended as well as provisions to

straighten the flow after introduction to the intake

air duct. A screen to prevent ingestion of “large”

foreign objects may be necessary.

The alternate air source mechanism should be

manually controllable by the pilot. As with the

carb heat mechanism, it is advised that the

alternate air source be spring actuated so it will

partially actuate automatically in the event of

unexpected air filter blockage due to ice or

debris. The mechanism should be designed to

preclude flutter and unintended operation during

the filtered air mode, including the effects of

“normal” filter blockage. The automatic spring

mechanism should not be designed to be so

sensitive that normal pressure drop due to filter

use over time would cause carb heat air to be

introduced.

E. Backfire Tolerance

The induction system, carb heat mechanism and

alternate air source must be designed to

withstand “normal” induction backfire events

without structural failure or fire.

3 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

Page 27

Installation & Operation Manual

O-360 and IO-360 Series Engines

3. FUEL SYSTEM

The fuel system design can significantly effect

both performance and longevity of an aircraft

engine installation. In addition to the obvious

performance aspects, fuel systems that limit the

fuel supply can promote engine detonation and

vapor lock. Un-damped and extreme pressure

pulsations can cause malfunction of the fuel

metering systems.

A. Fuel System Requirements and Filtration

Superior Vantage Engines are supplied with

positive displacement fuel pumps that are

directly driven by the engine. These pumps are

designed to provide the appropriate flow and

pressure to the fuel metering devices according

to their requirements. The aircraft fuel system

should be capable of providing at least twice the

maximum engine fuel flow requirements to

minimize the potential for vapor formation. The

fuel flow requirements are defined in Table 1 of

the Model Specification Data.

The flow of fuel must be vapor free, water free

and filtered to be free of foreign objects or

debris. The foreign object filter requirements are

defined in Table 2 of the Model Specification

Data.

B. General Fuel System Design

The aircraft fuel system should be designed so

flow restrictions do not occur in the piping

system. Flow restrictions in this context refer to

system conditions such as sharp radius bends,

abrupt changes in pipe diameter (larger or

smaller), tee and other fittings, valves, etc. In

addition to limiting maximum fuel flow, flow

restrictions increase the potential for vapor

formation. Vapor formation, if extreme can

cause engine stoppage due to lack of fuel.

Vapor formation in a minimal degree can cause

lean operation of the engine that can lead to

improper operation, service ceiling restrictions or

engine detonation under certain conditions.

Note:

unleaded fuel, do not use 90° fittings. Instead,

use large radius bends to reduce the likelihood

of vapor lock. Also, try to locate the fuel boost

pump as close to the fuel tank as possible.

Periodically inspect non-metallic fuel system

components for degradation.

Aircraft boost pumps (non-engine driven) may

be used to supplement fuel flow to the engine

driven fuel pump, prevent vapor lock and aid in

priming of fuel injected systems. The maximum

inlet pressure allowable at the engine driven fuel

pump is defined in Table 3 of the Model

Specification Data. Although the use of aircraft

boost pumps are not required for engine

operation (other than priming of fuel injection

systems), Superior Air Parts recommends their

use as a backup to the engine driven fuel pump

and as an aid in preventing vapor lock,

particularly when using motor gasoline. The fuel

system should be designed such that the

minimum acceptable fuel pressure is available to

the engine driven fuel pump at all times without

the use of an aircraft boost pump. The minimum

acceptable fuel pressure is defined in Table 3 of

the Model Specification Data. In addition, the

fuel system should be capable of providing at

least 150% the maximum required flow of fuel to

the engine driven fuel pump without the need for

an aircraft boost pump. (See Table 1 of the

Model Specification Data.)

Fuel tanks should be vented to the atmosphere

to prevent vacuum formation in the fuel tanks. If

un-vented, the pressure in the fuel tank (as fuel

is consumed) can reduce to the point that the

pressure available at the pump inlet is below the

cavitation limit of the pump. In this case,

cavitation can occur and engine stoppage due to

fuel starvation is possible.

Superior Air Parts recommends the use of fuel

flow meters as an aid to the pilot for proper

engine management. Two types of fuel flow

meters are available for use in such systems;

those that indicate flow based upon sensed

pressure and those that sense flow directly.

When running fuel lines for use with

4 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

Page 28

Installation & Operation Manual

O-360 and IO-360 Series Engines

Fuel flow meters that indicate flows based upon

fuel system pressure can be less accurate than

those that sense flow directly in times when

abnormalities occur. For example, dirty fuel

injectors or carburetor float malfunctions can

cause increases or decreases to system

pressure that would result in improper fuel flow

indications for pressure-based flow meters. For

this reason, Superior Air Parts recommends the

use of direct sensing flow meters such as vane

or turbine styles.

C. Carburetors

Carburetors used on Superior Vantage Engines

are conventional single barrel float type systems

with updraft induction and are equipped with

manual throttle and mixture controls. In the full

lean position, the manual mixture control serves

as an idle cutoff control. The carburetor requires

a low-pressure engine driven fuel pump

(supplied).

Superior Vantage Carbureted Engines require a

priming system. The engines are supplied with

manual primer lines installed to the #1, #2 and

#4 cylinder inlet ports and plumbing to feed from

a common primer source. The aircraft priming

system should be attached to this common

primer source.

The carburetor system is part of the Superior

Vantage Engine and therefore certified as part of

the engine. No one may make significant

changes to either flow settings or mechanical

linkages without prior approval by Superior.

Proper functioning and mixture settings of the

carburetor system must be made in flight and

ground idle tests. These tests should include all

envisioned flight attitudes and conditions as well

as ground idle temperature variations. In

addition to performance characteristics, exhaust

gas and cylinder head temperatures must be

monitored during these tests as a means of

verifying the correctness of the carburetor

system settings.

D. Fuel Injection Systems – Port Type

Fuel injector systems used on Superior Vantage

Engines are direct port injection systems with a

fuel-metering servo at the entrance to the intake

manifold. The fuel-metering servo is equipped

with manual throttle and mixture controls. In the

full lean position, the manual mixture control

serves as an idle cutoff control. The fuel

injection system requires a high-pressure engine

driven fuel pump (supplied).

Superior Vantage Fuel Injected Engines do not

require a separate priming system. Priming is

accomplished by operating an aircraft boost

pump with the manual mixture control in the fullrich position. After priming, the manual mixture

control should be moved to the idle cutoff

position for engine start and then moved back to

full rich after the engine has started.

Proper functioning and mixture settings of the

fuel injection system must be made in flight and

ground idle tests. These tests should include all

envisioned flight attitudes and conditions as well

as ground idle temperature variations. In

addition to performance characteristics, exhaust

gas and cylinder head temperatures must be

monitored during these tests as a means of

verifying the correctness of the fuel injection

system settings.

5 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

Page 29

Installation & Operation Manual

O-360 and IO-360 Series Engines

E. Fuels

Superior Vantage Engines are certified for

100LL Avgas per ASTM D910, 91/98 (lead

optional) Avgas per ASTM D910 and Motor

Gasoline with a minimum antiknock index

(R+M/2 method) of 91 per ASTM D4814. Higher

octane fuel improves the detonation margin

during high power and/or hot operation. When

operating on unleaded fuel, Superior

recommends using fresh, premium auto fuel

available at a major brand, reputable gas

station.

The use of auto fuel blended with alcohol

(ethanol) is forbidden. Winter oxygenated

ethanol fuel blends, or reformulated gasoline are

typically most available during the colder months

for smog reduction. Ethanol (alcohol) mixed

with unleaded fuel can cause vapor lock,

carburetor ice, reduction in range, carburetor

problems, and damage to the fuel system. The

use of an alcohol (and water) tester is

recommended. Acceptable gasoline is specified

per ASTM D-4814 (European EN228), again

without alcohol.

When running fuel lines for an airplane intended

for unleaded auto fuel operation, it is very

important to address issues that can reduce the

likelihood of vapor lock. For example, replace

90° fittings with smooth tubing bent to a larger

radius and do not use expansion or contraction

fittings. Locate the fuel boost pump as close to

the fuel tank as possible. Non-metallic fuel

system components should be manufactured

from materials that are known to be compatible

with auto fuels.

6 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

Page 30

Installation & Operation Manual

O-360 and IO-360 Series Engines

4. ENGINE COOLING

The engine cooling system design can

significantly effect both performance and

longevity of an aircraft engine installation. High

engine temperatures can result in loss of power,

fuel vapor lock, and can promote accelerated

wear and even engine detonation.

A. General Cooling System Design

The Superior Vantage Engine is a horizontally

opposed, air-cooled design. As such, all heat is

removed from the engine either by airflow over

the cylinders and crankcase or through an air-tooil lubricant heat exchanger. The horizontally

opposed cylinder arrangement is a space

efficient design that allows maximum cooling

airflow with minimum drag.

In general, air cooling of the engine heads and

crankcase occurs by directed airflow over those

components. Air is commonly received into the

cowl in a plenum above the engine and directed

downward between the cylinder and barrel fins

to a volume within the lower cowl.

The cooling air normally exits the lower cowl

through the exhaust tailpipe exit area. Airflow

over the engine is governed by the pressure

differential between the upper cowl and lower

cowl areas. In high performance installations

cowl flaps may be added to increase the cooling

airflow.

Superior Vantage Engines are provided with

inter-cylinder metal baffles to aid in the control of

cooling airflow over the cylinders and barrels. In

addition, the installation design must include

baffles that attach to the engine and provide a

seal to the interior of the cowl thus creating a

separation between the upper and lower cowl

volumes. This is typically done primarily with

metal components for stiffness against the ram

air pressure with flexible rubber seals to conform

to the contours of the upper cowl and to allow for

relative movement between the engine and

cowl.

The lubricating oil for Superior Vantage Engines

must be cooled by means of an air-to-fluid heat

exchanger. Typically, this heat exchanger is

mounted to the engine mount structure and

fastened to a rear engine baffle(s), open to the

upper plenum and facing the nose of the cowl.

In this way, ram effect of the cooling air entering

the upper plenum can be utilized to increase the

airflow through the heat exchanger.

B. Airside Heat Rejection

Airside heat rejection, that is heat rejected

through the cylinder heads, barrels and

crankcase, etc., is a primary means for cooling

the engine. The resulting temperature of the

engine is in direct proportion to the amount and

quality of cooling air that passes over the

engine. The engine cowl baffles create an upper

plenum, fed by incoming air from the front of the

cowl that in turn provides cooling air between

and around the barrels and cylinder heads as

controlled by the inter-cylinder baffles. The

amount of airflow over the engine is controlled

by the pressure differential between the upper

and lower cowl volumes. Figure 2 of the Model

Specification Data provides detailed information

concerning the mass airflow as a function of

pressure differential over a Superior Vantage

Engine.

Superior Vantage Engines are tested and

calibrated for airside heat rejection on highly

instrumented test stands. Table 4 of the Model

Specification Data defines cooling airflow

requirements as a function of power output.

7 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

Page 31

Installation & Operation Manual

O-360 and IO-360 Series Engines

C. Oil Heat Rejection

Engine oil is the other primary means of cooling

the engine. Cooling of the engine oil occurs

partly through heat transfer through the walls of

the crankcase and oil sump and partly through a

supplemental oil cooler. Supplemental oil

coolers are oil to air heat exchanger designs and

draw cooling air from the upper cowl plenum

area as discussed previously.

Oil heat rejection requirements for Superior

Vantage Engines are defined in Table 4 of the

Model Specification Data. Superior Air Parts

recommends that the oil cooler be sized to

provide at least 150% of the required maximum

heat transfer to provide an adequate margin of

safety.

The reduction in temperature and density of the

ambient air with increasing altitude can

significantly effect the performance of the oil

cooler and sizing should be chosen accordingly.

Although the reduced temperature of the air can

increase the efficiency of the cooler due to a

larger temperature difference between the hot oil

and the cooling air, the reduced air density is

generally a larger consideration and will result in

an overall reduction in cooler efficiency at higher

altitudes. Therefore, cooler sizing calculations

should be made with the air density appropriate

for the maximum intended altitudes of the

installation.

D. Accessory Cooling

Typically, engine cowl baffles effectively

separate the upper cowl plenum from the lower

cowl plenum through the axes of the cylinders.

However, the rear cowl baffle is typically

attached to the engine crankcase and therefore

most engine accessories are “behind” the rear

cowl baffle or below the cylinder axes and

therefore part of the “lower” cowl plenum.

Unless otherwise provided, these accessories

are located in an area of relatively stagnant air

that has already passed over the engine for

airside cooling or has passed through the oil

cooler. Because of the elevated temperature of

the air surrounding these accessories and the

relative lack of airflow around them, it is often

necessary to add small, supplementary ducts to

provide cooling air. The amount of

supplementary cooling required for these engine

accessories is installation specific and must be

determined by testing. Temperature limits for

these accessories are specified in the Model

Specification Data

8 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

Page 32

Installation & Operation Manual

O-360 and IO-360 Series Engines

5. EXHAUST SYSTEM

The engine exhaust system’s primary role is to

transfer engine exhaust gasses from the cylinder

heads overboard in a safe and efficient manner.

Exhaust systems serve to reduce engine noise,

provide heat sources for carburetor and cabin

heaters and even act to enhance engine

performance in terms of both power and fuel

efficiency. Improperly designed exhaust systems

can create health risks to aircraft occupants and

can be detrimental to engine performance.

A. Health and Safety Issues

Carbon monoxide is a colorless, odorless gas

that is potentially lethal and a basic by-product

of internal combustion engines. The primary

role of exhaust systems to safely conduct this

gas from the combustion chamber away from

persons on-board the aircraft cannot be

overstated. Exhaust systems must be airtight

with no potential for carbon monoxide leaks and

must exit outside the aircraft in a location where

gases will not be reintroduced to the airframe.

Due to the extreme temperature of exhaust

system components (up to 1600°F), care must

also be taken to isolate combustible materials.

This includes flammable liquids such as fuel, oil

and hydraulic fluid as well as dry combustible

materials.

B. Exhaust System Design and Sizing

Several styles of exhaust systems are

commonly used in piston aircraft engines.

Engines with smaller power ratings sometimes

use “stub” or “direct” exhaust systems. These

systems simply provide a short section of

exhaust pipe to direct the exhaust gas away

from the cylinder head and are not connected

with each other. While these systems are

typically the loudest and least beneficial in terms

of performance enhancement, they can hold the

benefit of being the lightest design. Although it

is possible to use this type of system on

Superior Vantage Engines it is not the

recommended approach.

Another exhaust design style is to connect 2 or 4

of the exhaust tubes together before exiting the

9 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

aircraft. Commonly referred to as 2-into-1 or 4into-1 systems, these designs feature a spaceefficient way to transport the exhaust gas safely

overboard. Although these systems are not

designed to add substantial performance

benefits to the engine, they can rob power and

efficiency if not properly designed. The

intersections of the exhaust pipe segments must

be designed such that pressure pulsations

traveling down a given exhaust pipe do not

adversely effect the operation of cylinders with

intersecting pipes. If pressure pulsations

traveled from one exhaust pipe and back “up”

another, excessive pressure could be present as

the second cylinder’s exhaust valve opened and

cause a disruption to the exhaust gas exit. High

back pressure, whether caused from basic

system flow restrictions or pressure waves of

adjacent cylinders can have significant effects

on volumetric efficiency and thereby on power

output and fuel efficiency.

A third exhaust system style is commonly

referred to as a crossover design. This style

connects the exhaust pipes of two cylinders in

such a manner as to enhance performance. In

an ideal crossover system, as the pressure

wave from one cylinder passes the connection

point of the two exhaust pipes a slight suction is

created in the exhaust pipe of the second

cylinder. When properly tuned, this suction is

caused as the exhaust valve of the second

cylinder opens and aids in the emptying of the

second cylinder. The pressure wave of the

second cylinder then creates a slight suction in

the exhaust pipe of the first cylinder, aiding in its

emptying. This behavior improves the breathing

of the cylinders and can have volumetric

efficiency, power and fuel efficiency benefits.

For Superior Vantage Engines with 4 cylinders,

crossover exhaust systems should couple

cylinder 1 with cylinder 2 and cylinder 3 with

cylinder 4. Crossover exhaust systems are

typically less space efficient and a little heavier

than other styles, but have the unique benefit of

enhancing performance of the engine.

Regardless of the style employed, several

factors should be considered to make an

effective exhaust system.

Page 33

Installation & Operation Manual

O-360 and IO-360 Series Engines

(1.) Exhaust Pipe Exits

Exhaust exits should be positioned such that the

gasses are released clear of the aircraft and not

allowed to reenter the cabin. Also, the exhaust

exits should be located far enough away from

the aircraft structure to prevent corrosive

byproducts of combustion from causing damage.

Enlarged exit pipes can be used to change the

tone and volume of the exhaust sound. Care

should be taken however not to enlarge the exit

pipes so much as to create sound amplification

as with a megaphone.

(2.) Limit Backpressure

As discussed earlier, high exhaust backpressure

can have detrimental effects on engine

performance. Other than acoustic, pressure

wave effects backpressure can be minimized in

the design by good piping design practices to

limit flow losses. For example, exhaust pipe

size should be kept as large as practicable and

never less than the exhaust port size. Exhaust

pipe lengths, other than being equal for tuning

purposes, should be as short as practicable.

Bends should be “large radius”, smooth and as

few as possible. Pipe intersections should be at

acute angles whenever possible and never at

“large” angles where acoustic waves might be

oriented “backward” up an adjoining pipe.

Whenever possible, collector elements should

be avoided due to their potential to reduce

engine performance. If necessary, collectors

should be designed to eliminate the potential for

acoustic pressure waves to be reflected back

through the exhaust system. This may include

features internal to the collector such as

damping plates, perforated pipes, etc. Such

features necessarily increase flow losses

through the system and therefore increase

exhaust backpressure and care should be taken

to minimize this problem. Also abrupt increases

or decreases in piping size, such as in a

collector, can increase flow losses and should

be avoided.

10 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

(3.) Shrouds and Thermal Protection

Exhaust gas temperatures can be as high as

1600°F. Therefore, it is sometimes necessary to

shield thermally sensitive components. Control

cables, hoses, engine isolator components,

nose gear tires, etc should be either located far

enough from the exhaust pipes to not be

damaged by the heat, insulated or shielded.

Fuel lines should be insulated as appropriate to

prevent safety concerns or vaporization of the

fuel within the lines. Similar care should be

given to oil or hydraulic lines. Also, intake air

system components including carburetors and

fuel injector servo bodies should be shielded

either by distance or material from exhaust

system heat.

(4.) Exhaust System Support

The exhaust system should be supported in

such a way as to prevent vibration and thermal

growth from imparting stress on the pipes. The

exhaust system should be “hard mounted” to the

cylinder head using the studs provided at the

exhaust port and should have flexible mounts at

or near the exit. Interim supports, if needed

should be of a flexible style.

(5.) Joint Design

The exhaust system should be designed for

ease of installation and also to provide flexibility

for thermal growth during operation. Multiple

piece exhaust systems are preferable to single

piece designs for both of these reasons. Care

should be given to the location of slip joints in

the exhaust system so that their placement does

not interfere with preferred locations for cabin

heat muffs and also to provide for thermal

growth between hot and cold sections. For

example, large sections that are welded together

without slip joints to allow for thermal variations

can cause stresses in the system that can lead

to early failure. The number of welded and slip

joints should be minimized to limit the potential

for exhaust leaks. Also, welds should be of

superior quality to prevent metallurgical or

fatigue failure and subsequent exhaust leaks.

Page 34

Installation & Operation Manual

O-360 and IO-360 Series Engines

(6.) EGT Probes

Exhaust gas temperature (EGT) probes are

commonly added to engine installations to

provide engine management information to the

pilot. The location of the probes is important to

the accuracy of their information. EGT probes

should be located approximately 6” from the

exhaust port flange and equidistant among all

cylinders.

C. Exhaust System Materials

Exhaust pipes and mounting hardware should

be made of corrosion resistant materials such as

Inconel or 321 or 347 stabilized stainless steel.

Other materials, such as 304 stainless steel are

not stabilized for sustained high temperatures

and may result in carbide precipitation and early

fatigue failure. Wall thickness should be large

enough to provide structural integrity yet thin

enough to maintain reduced weight. Historically,

some exhaust systems have been made with

thicker material to withstand material loss due to

scaling and oxidation. Proper material selection

however has been shown to be a more effective

solution allowing for lighter weight exhaust

systems.

D. Exhaust Gaskets

Superior recommends the use of metal gaskets

in the installation of exhaust systems. Metal

gaskets improve the seal to the exhaust port

reducing the possibility for exhaust gas leakage

as well as noise leaks. Gaskets also improve

the thermal conductivity from the head to the

exhaust pipe that helps to remove heat from the

exhaust area of the head. Exhaust gaskets

should be made of corrosion resistant materials

such as Inconel or stainless steel and should be

designed to withstand the pressure of exhaust

backfire events.

11 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

Page 35

Installation & Operation Manual

O-360 and IO-360 Series Engines

6. LUBRICATION SYSTEM

The engine lubrication system is responsible for

the reduction in friction between components,

removal of combustion by-products and other

contaminants, and the removal of heat from

internal engine components. A continuous

supply of clean, cooled oil of the proper grade

and specification is essential to this process.

Failure to do so can result in a wide variety of

problems ranging from increased wear to engine

stoppage.

A. Lubricating Oil Requirements

Superior recommends the use of high quality

100% mineral oil during the break-in period.

After engine break-in, high quality ashless

dispersant engine oil per MIL-L-22851 or SAE J1899 should be used in Superior Vantage

Engines. Ashless dispersant oils are used to

prevent the formation of sludge, aid in the

neutralization of corrosive acids and prevent ash

deposits on cylinder walls that can become hot

spots and sources for pre-ignition. The grade or

viscosity of oil should be chosen based upon the

climate where the engine will be operated as

shown in Table 8-1.

Superior Vantage Engines are provided with a

suction screen filter, sometimes referred to as a

“finger filter” to prevent large contaminants from

being drawn into the pressurized portion of the

oil system. In addition, Superior Vantage

Engines are provided with a full-flow oil filter to

maintain contaminant free oil and promote long

engine life. Superior recommends changing the

full-flow oil filter, inspecting / cleaning the suction

screen filter and changing the oil in accordance

with published maintenance schedules.

In addition to clean oil of the proper viscosity, it

is important to ensure that the oil is free of

aeration and foam in the pressurized portion of

the oil system. This can become an issue at

high altitudes as the vapor pressure of the oil

exceeds the ambient pressure. Severe aeration

within the anticipated flight altitudes of a

Superior Vantage normally aspirated engine, but

must be verified through flight testing.

12 Chapter 3 • Aircraft / Engine

© March 2004 Superior Air Parts Inc. Integration Considerations

B. Lubricating System Components

The lubricating system of Superior Vantage

Engines is composed in general of an oil sump

or reservoir, an oil cooler circuit, an internal

pressurized circuit and for installations with

constant speed propellers a propeller governor

circuit. A schematic of the lubricating system is

provided in Figure 3-1.

(1.) Oil Sump

Superior Vantage Engines utilize a “wet sump”

design. That is, the engine oil sump is the

primary reservoir for engine oil as opposed to a

remote reservoir as is done in many aerobatic

installations. However, provisions exist to attach

an aerobatic oil system to the Superior Vantage

Engine if desired. For more information

regarding aerobatic installations contact

Superior Air Parts.

The maximum capacity of the oil sump is 8 U.S.

quarts. Oil quantities in excess of this amount

can cause loss of engine efficiency due to

“splashing” and fluid drag of internal

components through the oil and also “pumping”

of the oil out the crankcase breather fitting.

Minimum oil capacity is governed by the ability

of the oil pump to draw full oil (i.e. no entrained

air) from the sump in various flight attitudes.

(2.) Oil Pump and Pressure Control Valve

Superior Vantage Engines employ a high flow,

positive displacement gear pump to provide oil

throughout the engine. The pump is capable of

producing oil flow and pressure values much

higher than those required by the engine as a

safety measure to ensure that the necessary oil

is always available to the engine. Because of

this, a pressure control valve is used to govern

the maximum oil pressure in the system. Oil

pressures that are too high will promote external

leaks that would not otherwise occur.

The oil pressure control valve is adjustable so

that the operator may ensure that the oil

pressure is within specified limits. If oil pressure

under normal operating conditions always

exceeds the maximum or minimum specified

limits as defined in Table 5 of the Model

Page 36

Installation & Operation Manual

O-360 and IO-360 Series Engines

Specification Data, the valve may be adjusted as

follows:

With the engine warmed up and running at 2000

RPM, observe the oil pressure gage reading. If

the pressure is above maximum or below

minimum specified limits, stop the engine and

turn the adjusting screw, with either a flathead

screwdriver or a 9/16 inch box wrench, inward

(clockwise) to increase pressure or outward

(counter-clockwise) to decrease pressure. See

Table 5 of the Model Specification Data for

specific oil pressure data.

(3.) Vernatherm and Oil Cooler

Automatic oil temperature control valves

(Vernatherm valves) are used to govern the flow

of oil through the external oil cooler. These

valves are set at the time of assembly and are

not serviceable by the operator. When the

engine is cool, the vernatherm valve is open and

oil is free to flow directly through the engine

without being routed through the external oil

cooler. As the oil temperature reaches its

desired limits however some or all of the oil is

routed through the oil cooler circuit.

The oil cooler circuit is the only part of the

lubrication circuit that is controlled by the

installation design. It is necessary to maintain

good hydraulic practices in the design of the oil

cooler circuit to minimize flow and pressure

losses. These include using large diameter

hoses and avoiding sharp bends and restrictive

couplings whenever possible. Flow and

pressure losses in the oil system not only cause

inefficiencies in the overall engine system but

also add to the potential for aeration during high

altitude flight.

C. Crankcase Ventilation

Pressure is generated within the crankcase

during normal engine operation primarily as a

result of piston ring blow-by. If the crankcase

pressure were not controlled nose seal and

other seal failures would occur leading to loss of

oil. Superior Vantage Engines utilize crankcase

breather circuits as a means of controlling

crankcase pressure. See Table 4 of the Model

Specification Data for specific measurements

defining crankcase pressures.

The installation design should include provisions

to connect a crankcase ventilation hose to the

engine breather fitting on the rear of the engine.

The purpose of this hose is to direct the

crankcase gas safely overboard. It is

recommended that an air-oil separator be used