Page 1

Installation and Operation Instructions

PFS

Superior® Clean-Face Round Back Fireplace

with Bi-Fold Doors and Combustion Air Kit

P/N 127312-01 Rev. D 10/2025

®

P127312-01

USC

Models

MHW36R

SAVE THIS BOOK

This book is valuable. In addition to instructing you on how to install and maintain your appliance, it also

contains information that will enable you to obtain replacement parts or accessory items when needed. Keep

it with your other important papers.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Installateur : Laissez cette notice avec l’appareil.

Consommateur : Conservez cette notice pour consultation ultérieure.

This wood burning fireplace complies with UL127

CAN/ULC-S610-M87 standard as a FACTORY

BUILT FIREPLACE.

This fireplace is approved for use as a wood burning fireplace or for use with a vented gas log approved to

ANSI Z21.60 or Z21.84 standards or for use with a vent-free gas log heater approved to ANSI Z21.11.2 standard

An IHP hood must be installed when using a vent-free log heater (see Accessories, page 19).

FOR CANADA: The authority having jurisdiction

(such as the municipal building department, fire

department, etc.) should be contacted before

installation to determine the need to obtain a permit.

This installation manual will enable you to obtain a safe, efficient and dependable installation of your fireplace

system. Please read and understand these instructions before beginning your installation.

Do not alter or modify the fireplace or its components under any circumstances. Any modification or alteration of

the fireplace system, including but not limited to the fireplace, chimney components and accessories, may void the

warranty, listings and approvals of this system and could result in an unsafe and potentially dangerous installation.

IMPORTANT! TO ASSURE PROPER ALIGNMENT OF GLASS DOORS: INSTALL THIS FIREPLACE IN A SQUARE

AND PLUMB CONDITION, USING SHIMS AS NECESSARY AT SIDES AND/OR BOTTOM.

Ce foyer au bois est conforme aux UL 127 CAN/ULCS610-M87 norme comme une USINE CONSTRUITE

CHEMINÉE.

.

POUR LE CANADA: L’autorité compétente (comme le

service municipal du bâtiment, les pompiers, etc.) doit

être contacté avant l’installation afin de déterminer la

nécessité d’obtenir un permis.

Page 2

TABLE OF CONTENTS

Safety ................................................................................................... 2

Fireplace Installation ............................................................................ 2

Venting Installation .............................................................................. 6

Optional Gas Line Installation ............................................................ 13

Finishing Fireplace ............................................................................. 15

Operation and Maintenance Guidelines .............................................. 15

Technical Service ...............................................................................17

Replacement Parts ............................................................................. 17

Accessories ........................................................................................ 18

Important Notices .............................................................................. 21

Warranty ............................................................................................ 23

CAUTION

Thestructural integrityof the mobilehome oor

and ceiling/roof must be maintained.

WARNING

Do not install a fireplace insert in this box unless

the manufacturer's instructions with the insert

specifically state this fireplace has been tested for

use with the insert.

FOR YOUR SAFETY

SAFETY

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause injury, property

damage or loss of life. Refer to this manual for

assistance or additional information. Consult a

qualified installer or local distributor.

IMPORTANT: Check HUD requirements before installing this

fireplace.

These units are intended for installation in manufactured (mobile) homes.

These units may also be installed in buildings of conventional construction

including modular housing, providing all instructions provided herein

are strictly adhered to. These fireplaces include a combustion air kit and

bi-fold doors.

Before beginning the installation of the fireplace, read these instructions

through completely.

• ThisIHPreplaceanditscomponentsaresafewheninstalledaccord-

ingtothisinstallationmanual.UnlessyouuseINNOVATIVEHEARTH

PRODUCTS(IHP)approvedcomponents,whichhavebeendesigned

and tested for the fireplace system, you may cause a fire hazard.

• TheIHPwarrantywillbevoidedbyandIHPdisclaimsanyresponsibility for the following actions.

a. Modification of the fireplace, components, doors, air inlet system and

damper control.

b. UseofanycomponentpartnotmanufacturedorapprovedbyIHP

incombinationwithanIHPreplacesystem.

• Donotstoreorusegasolineoranyotherammablevapors

or liquids in the vicinity of this or any other appliance.

• Duetohightemperatures,theapplianceshouldbelocated

out of traffic and away from furniture and draperies.

• Donotplaceclothingorotherammablematerialsonor

near the appliance.

• Neverleavechildrenunattendedwhenareisburningin

the fireplace.

This fireplace is not intended to be used as a substitute for a

furnace to heat an entire home. Use for supplemental heat only.

This wood burning fireplace complies with the UL 127 standard

as a FACTORY BUILT FIREPLACE and is listed and tested by the

PFS Corporation.

FIREPLACE INSTALLATION

SELECTING LOCATION

To determine the safest and most efficient location for the fireplace, you

must take into consideration the following guidelines:

1. The location must allow for proper clearances (see Figures 2 and 3,

page 4).

2. Consider a location where the heat output will not be affected by

drafts, air conditioning ducts, windows or doors.

3. A location that avoids the cutting of joists or roof rafters will make

installation easier.

4. An outside air kit is included with this fireplace (see Outside Air Kit on

page 6)

WARNING

Proper installation is the most important step in ensuring safe and continuous operation of the fireplace. Consult the local building codes as to

the particular requirements concerned with the installation of all factory

built fireplaces.

SuperiorFireplaces.US.com 127312-01D2

Do not install this appliance in a bedroom.

Page 3

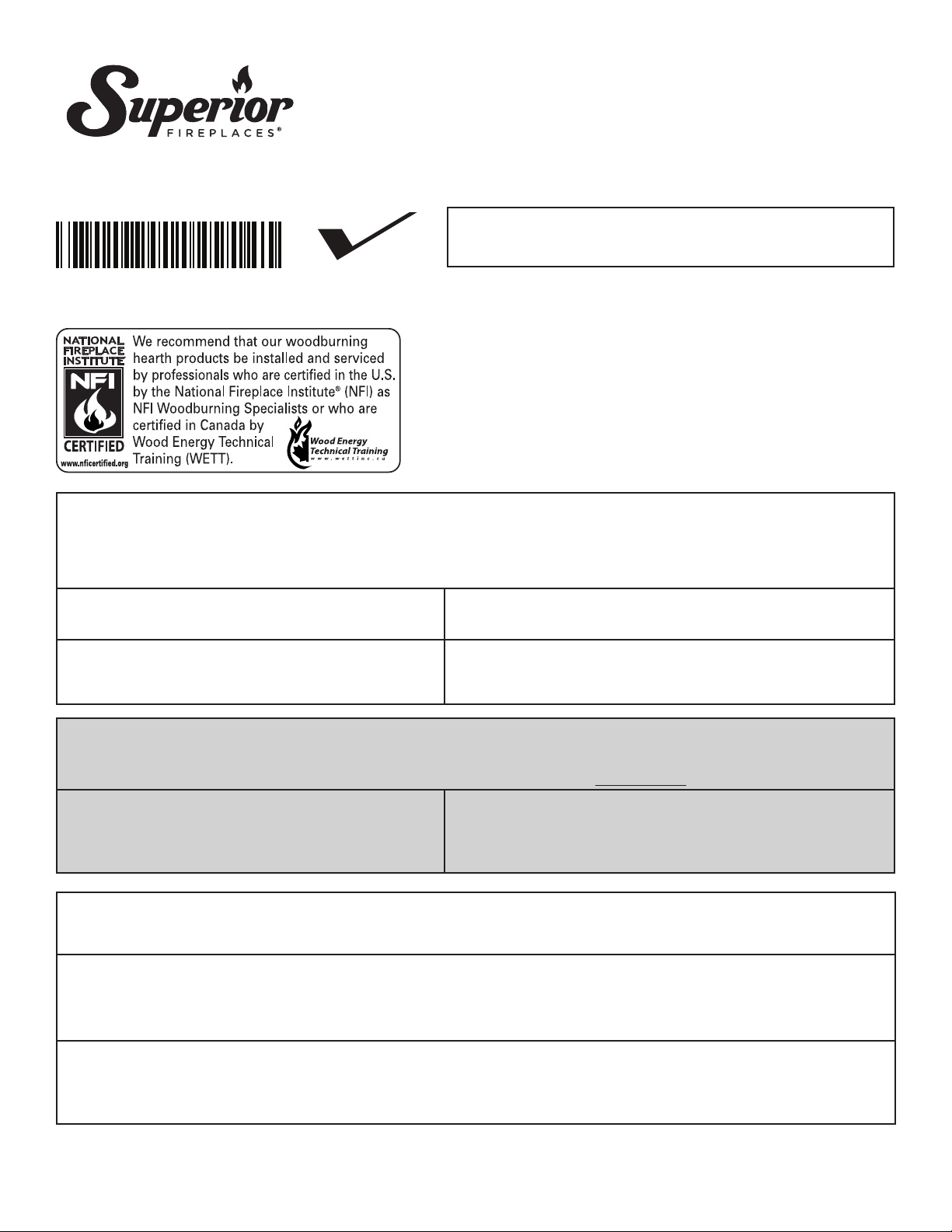

SPECIFICATIONS

Round Top Termination

Storm Collar

Flashing

42"

1

/4"

36

J-Box

Access

RH SIDE VIEW

3

7

/4"

36"

1"

41"

Gas Line Conduit

Sleeve (Both Sides)

22

3

6

3"

0" To Top

1/2" Air Space

Back and Sides

0" To

Bottom

1

/8"

/4"

Spacer

Firestop

Thimble

221/16"

13"

Firestop

5/8"

1" Airspace

To Combustible

Materials

Combustible

Wall Board

No Combustible

Material On Face

Not Less Than 14"

To Perpendicular

Sidewall

3

9

LH SIDE VIEW

Figure 1 - Specifications

127312-01D

/8"

Rear View

of Fireplace

91/2"

8" Each

Side

14"

14"

SuperiorFireplaces.US.com

Hearth Extension

52" x 16"

Opening for

Outside Air

3

Page 4

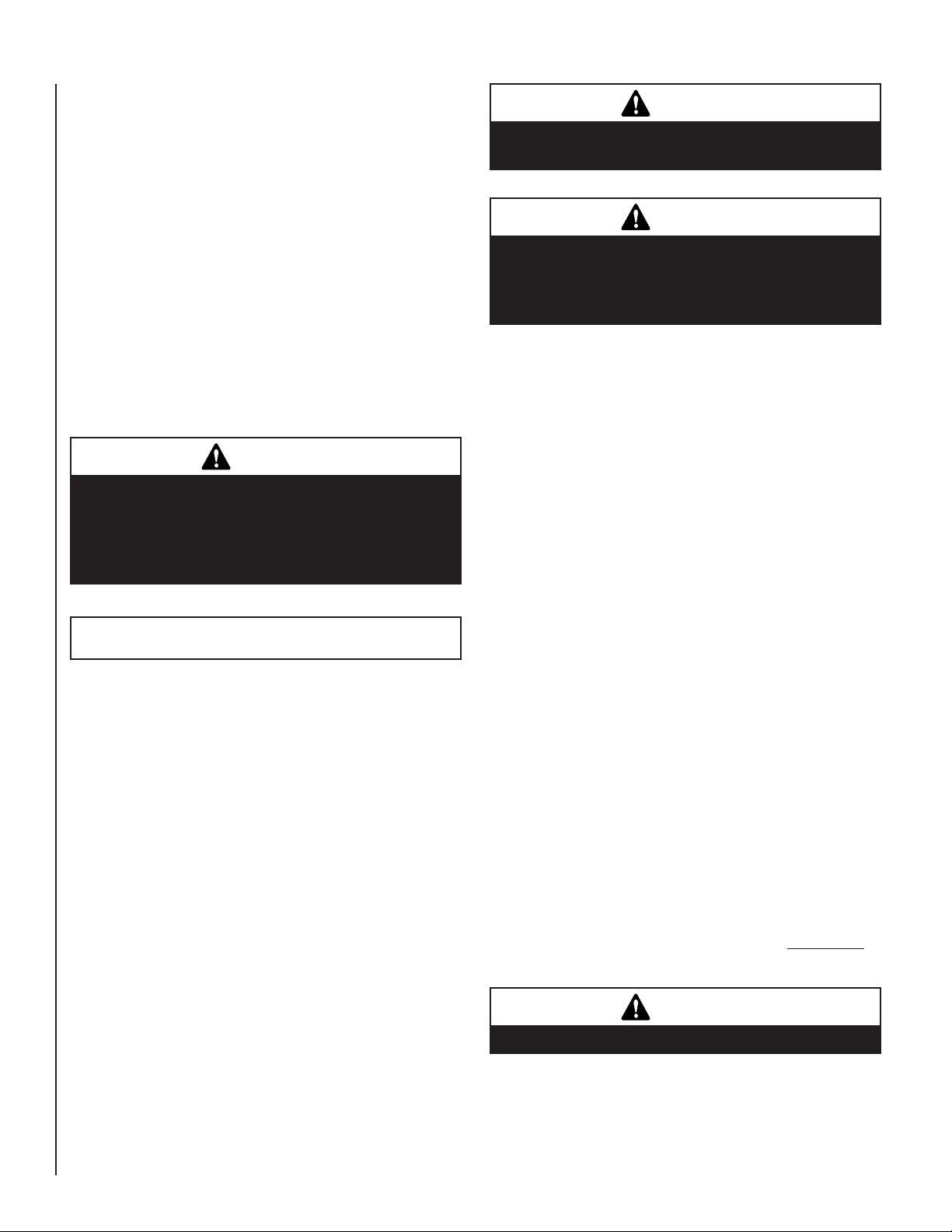

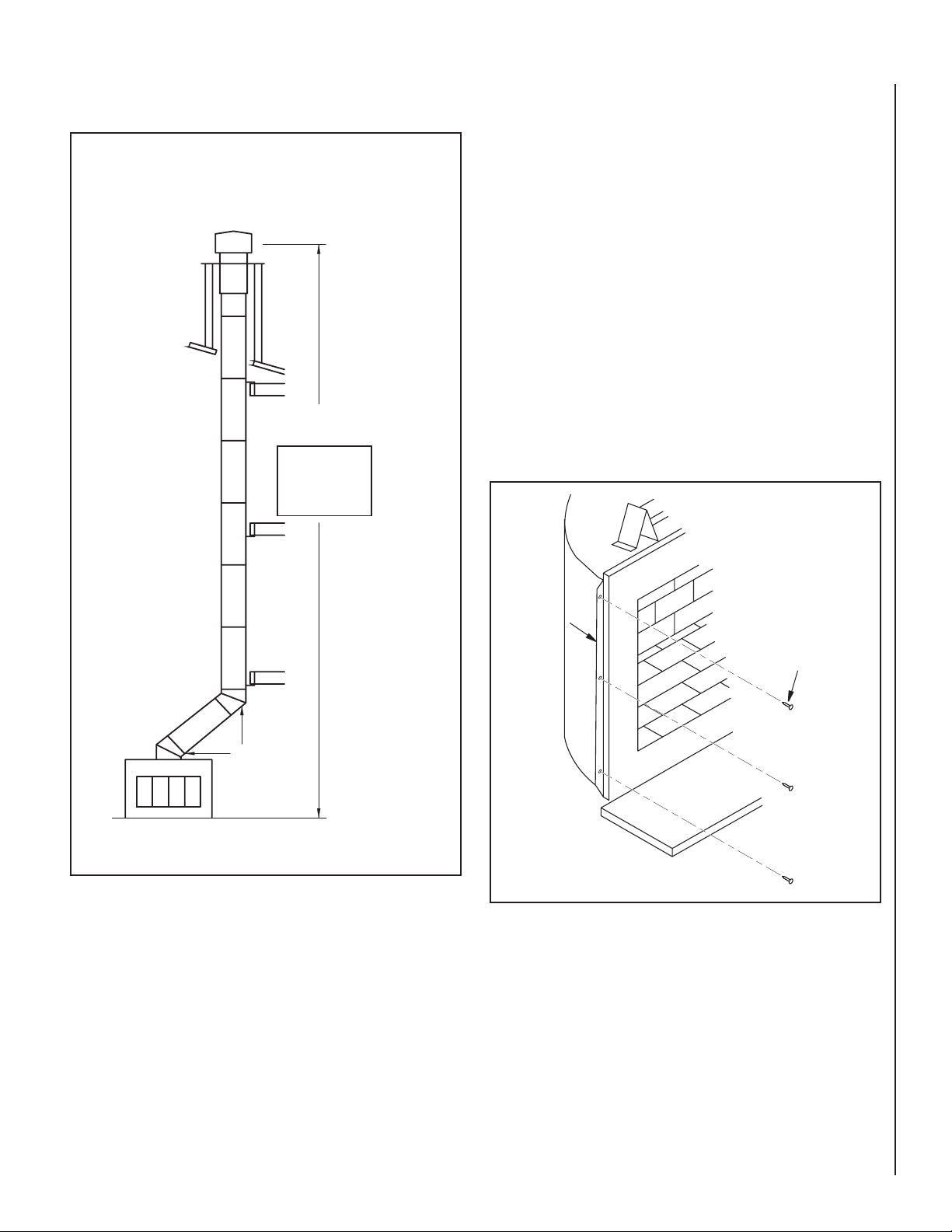

FIREPLACE INSTALLATION

Effective Height of

Termination Cap

RT-8DM

30E-8DM

40' Max.

Height

20' for

Manufactured

Home

Application

Continued

WARNING

42 1/4"

3

41

/4"

Figure 2 - Framing Dimensions

Maintain 1/2" Air Space

between surface of

Maintain 1/2" Air Space

framing, insulation, and

Between Framing

drywall.

and Fireplace

13" Min.

43

22

Min.

5

/8"

10"

Do not pack required air spaces with insulation or

other materials.

MINIMUM/MAXIMUM CHIMNEY HEIGHT

Minimum height of the chimney, measured from base of fireplace to flue

gas outlet of termination, is 14 feet* for straight flue or a flue with one

elbow set. Maximum distance between elbows is 2 feet.

Maximum height of any system is 40 feet.* This measurement includes

fireplace, chimney sections and height of termination assembly at level

of flue gas outlet (see Figure 5).

Effective Height of

Termination Cap

5

/8"

14' Min.

Height

11' for

Manufactured

Home

Application

RT-8DM

Effective Height of

Termination Cap

14' Min.

Height

11' for

Manufactured

Home

Application

RT-8DM

41 3/4" Min.

61

11/16" Min.

Figure 3 - Corner Installation

MINIMUM CLEARANCE TO COMBUSTIBLES

Back and sides of fireplace 1/2" minimum*

Floor under fireplace** 0" minimum

Wall to front of fireplace 36" minimum

Perpendicular wall to opening 14" minimum

Top spacers 0" minimum

Mantel clearances see Mantels, page 15

Chimney outer pipe surfaces 1" minimum

* Not required at nailing flanges

** See step 2 of Framing, page 5

2' Max

Pipe Length

Figure 4

*For manufactured home application, minimum height is 11' for straight

flue or flue with one elbow set. Maximum height of any system is 20'.

SuperiorFireplaces.US.com 127312-01D4

Page 5

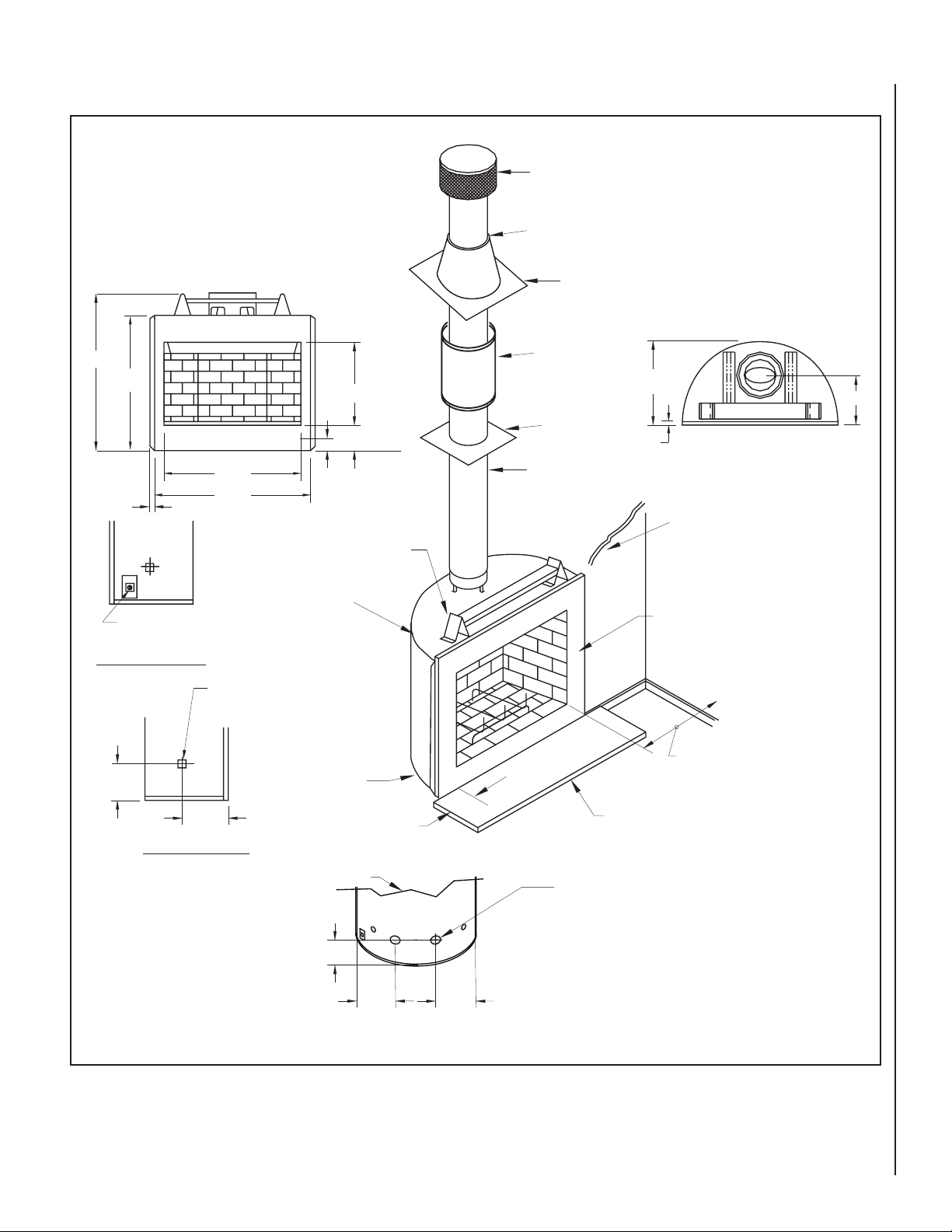

FIREPLACE INSTALLATION

Continued

Standard

Installation

RT-8DM

Alternate

Installation

Effective Height of

Termination Cap

40' Max.

Height

20' for

Manufactured

Home

Application

FRAMING

1. Frame opening for fireplace using dimensions shown in Figures 2

and 3.

2. The fireplace may not be installed on carpeting, tile or any combustible

material other than wood flooring, fireplace must be installed on a

metal or wood panel extending full width and depth of fireplace. (It is

acceptable to cover two outside ends or columns of top louver panel

leaving four center columns open).

3. Set fireplace directly in front of this opening and slide unit back until

nailing flanges touch side framing.

4. Check level of fireplace and shim with sheet metal if necessary.

5. Before securing fireplace to prepared framing, metal ember protector

(provided) must be placed between hearth extension (not supplied)

and under bottom front edge of fireplace to protect against glowing

embers falling through. If fireplace is to be installed on a raised platform, a Z-type ember protector (not supplied) must be fabricated to fit

your required platform height. Ember protector should extend under

fireplace a minimum of 1-1/2". The ember protector should be made

of metal material.

6. Using screws or nails, secure fireplace to framing through flanges

located on sides of fireplace (see Figure 6).

Alternate

30E-8DM

Installation

Figure 5 - Standard and Alternate Venting Installation

Nailing

Flange

Screw or

Nail

Figure 6 - Nailing Flanges

127312-01D

SuperiorFireplaces.US.com

5

Page 6

FIREPLACE INSTALLATION

Continued

HEARTH EXTENSION

A hearth extension projecting a minimum of 16" in front of and a minimum

of 8" beyond each side of the fireplace opening is required to protect

combustible floor construction in front of the fireplace. Use an equal material which meets the following specifications: a layer of noncombustible,

inorganic material having a thermal conductivity of k = .84 BTU IN/FT2

HR°F(orless)at1"thick.Forexample,ifthematerialselectedhasak

factor of 0.25, such as glass fiber, the following formula would apply:

0.25 x 1.0" = 0.30" thickness required

0.84

Thermal conductivity "k" of materials can be obtained from the manufacturer or supplier of the noncombustible material. If the hearth extension

is to be covered, use noncombustible material such as tile, slate, brick,

concrete, metal, glass, marble, stone, etc. Provide a means to prevent

hearth extension from shifting and seal gap between fireplace frame and

hearth extension with a noncombustible material (see Figure 7).

Fireplace

Front

Ember

Protector

Fireplace Front

Elevated

Seal Gap

Seal Gap

Ember

Protector

Hearth

Extension

WARNING

Hearth extension is to be installed only as shown

in Figure 7.

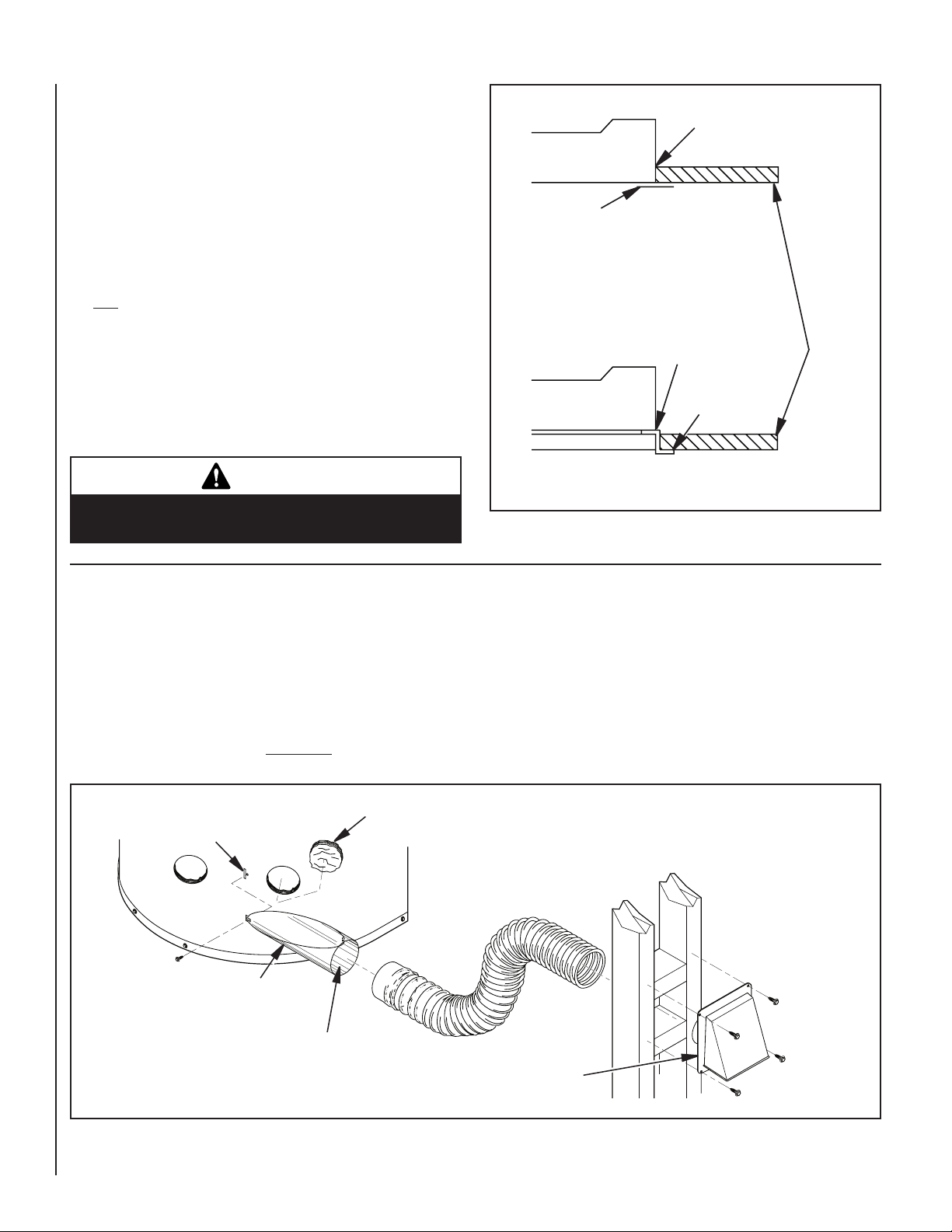

VENTING INSTALLATION

OUTSIDE AIR KIT

Installation of an outside air kit should be completed during the rough

framing of fireplace due to nature of its location. The supplied flex duct

measures approximately 10" compressed and up to approximately 36"

extended. Outside combustion air is accessed through mobile home floor

using air kit model AK6E, included with the fireplace, or a side wall using

optional air kit model AK6-WE (see Accessories on page 19).

Insert Inner Tab of Inlet Tube into

Slot on Outer Surround

Insulation

Figure 7 - Hearth Extension

Installer may choose either left or right side mounting to allow for

proper wall/rafter clearances.

For AK6-WE Only: Construct a 4-1/2" x 4-1/2" framing or opening on

exterior wall (see Figure 8, page 6).

For AK6E Only: The outside air vent is installed through a ventilated crawl

space (see Figure 9, page 7).

Air Vent Location Must

Allow for Bushes, Snow

and Other Possible

Obstructions

Left Side

Mounting Shown

Secure to Collar with Metal

Tape, Screws or Tie Straps

Figure 8 - Outside Air Kit AK6-WE Installation

Outside Air Vent

Termination

SuperiorFireplaces.US.com 127312-01D6

Page 7

VENTING INSTALLATION

Continued

1. Locate and remove air inlet cover plate on fireplace‘s outer surround.

Save screws.

2. Cut out any visible insulation that may obstruct airflow.

3. Extend flex duct to attach air inlet tube.

4. Insert inner tab of inlet tube into mating slot next to opening.

5. Place outer tab of inlet tube over mating hole next to opening

and secure with screws removed from cover plate in step 1.

6. Install outside air vent termination in a location that will not be

obstructed by bushes, snow, etc. Locate vent near the fireplace

to make flex duct installation easier.

Insert Inner Tab of Inlet Tube

into Slot on Outer Surround

Left Side

Mounting Shown

Insulation

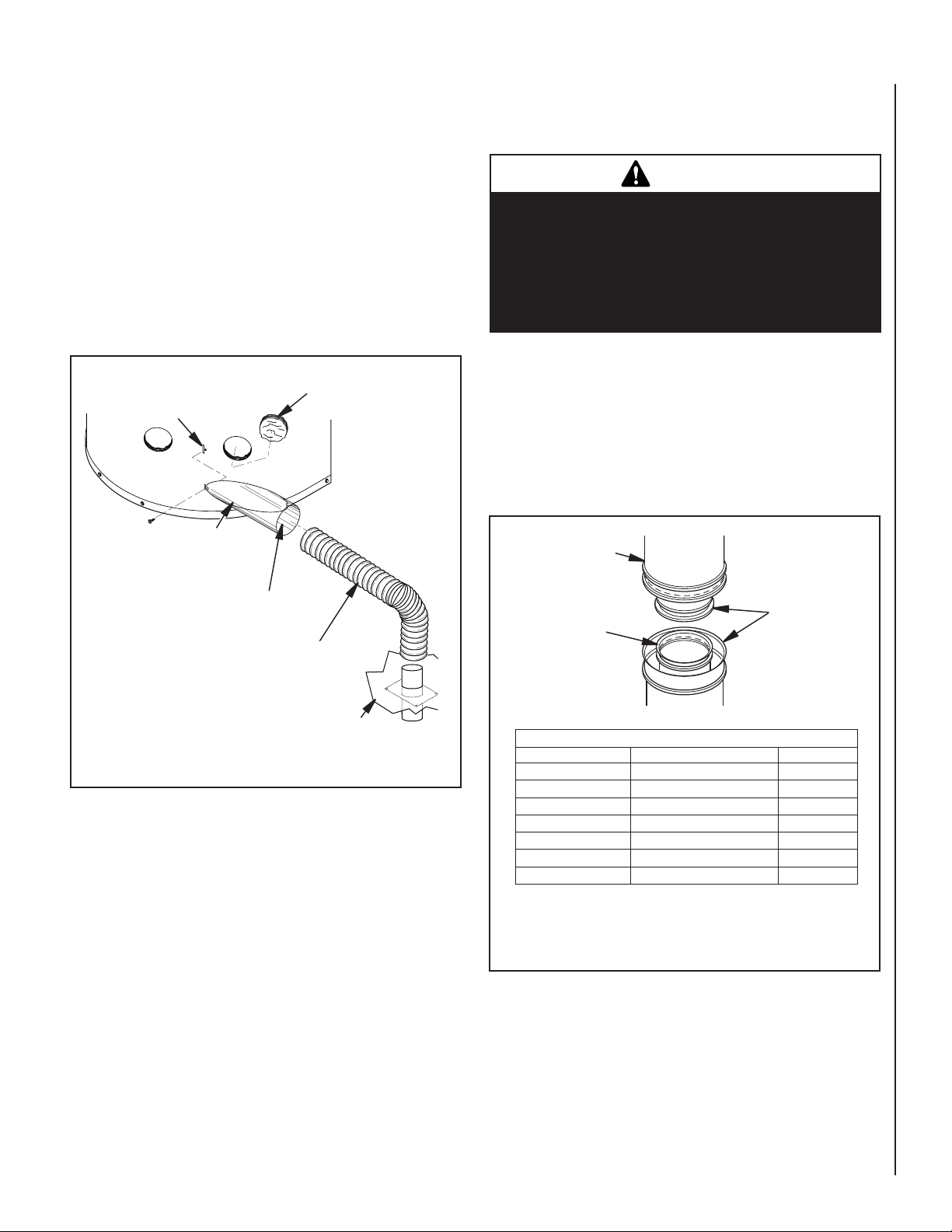

CHIMNEY PIPE

WARNING

Label part number 900599-01 must be applied

by the installer to all chimney pipe sections but

is not required on sections that will be visible

after the installation is complete. Label must

wrap around the circumference of the pipe. See

accessories, page 19 for Kit F2659.

The chimney system approved for this fireplace consists of 12", 18", 24",

36" and 48" snap-lock, double-wall pipe segments, planned for maximum

adaptability to individual site requirements. Actual lengths gained after

fitting overlaps must be taken into consideration (lineal gain) and are

given in the lineal gain chart (see Figure 10). Lineal Gain is the actual

measurable length of a part after two or more parts are connected.

12-3/8" Galvanized

Outer Pipe

Secure to Collar with Metal

Tape, Screws or Tie Straps

Flex Duct Extends

Up to 36"

Figure 9 - Outside Air Kit AK6E Installation

Floor

Hemmed End

8" Stainless

Inner Pipe

LINEAL GAIN

PART NO. DESCRIPTION GAIN

MHW36R Fireplace 42

12-8DM Pipe Section 10-5/8

18-8DM Pipe Section 16-5/8

24-8DM Pipe Section 23-5/8

36-8DM Pipe Section 34-5/8

48-8DM Pipe Section 46-5/8

RTL-8DM Round Termination 7-3/4

* The lineal gain for the terminations is measured to the flue gas

outlet height.

Figure 10 - Lineal Gain

"

"

"

"

"

"

*

"

127312-01D

SuperiorFireplaces.US.com

7

Page 8

VENTING INSTALLATION

Continued

There are three vent kits available which have been specially designed

for common installations in manufactured (mobile) homes: MW8K (8'

ventkit),MW9K(9'ventkit)andMW8K-HT(8'HTventkit).Contentsof

these kits are listed under Accessories on page 20. IMPORTANT: If height

of chimney assembly exceeds requirements for transportation of home,

chimney installation may be completed after home is sited.

NOTE: Termination must always be installed after the home is sited.

ASSEMBLY AND INSTALLATION OF DOUBLE WALL CHIMNEY

SYSTEM

Each double wall chimney section consists of a galvanized outer pipe, a

stainless steel inner flue pipe and a wire spacer. Pipe sections must be assembled independently as chimney is installed. When connecting chimney

directly to fireplace, inner flue pipe section must be installed first with lanced

side up. Outer pipe section can then be installed over flue pipe section with

hemmed end up. Press down on each pipe section until lances securely

engage hem on fireplace starter. The wire spacer will assure proper spacing

between inner and outer pipe sections.

WARNING

The opening in the collar around the chimney at the

top of the fireplace must not be obstructed. Never

use blown insulation to fill the chimney enclosure.

Flange

End of

Tube

Open End

of Tube

Thimble

Base

Figure 11 - Attaching Adjustable Thimble

Placement

Holes

Continue to assemble chimney sections as outlined above, making sure

that both inner and outer pipe sections are locked together. When installing double wall snap-lock chimney together, it is important to assure that

the joint between chimney sections is locked. Check by pulling chimney

upward after locking. Chimney will not come apart if properly locked. It

is not necessary to add screws to keep chimney together (exception, see

Figure 16, page 11).

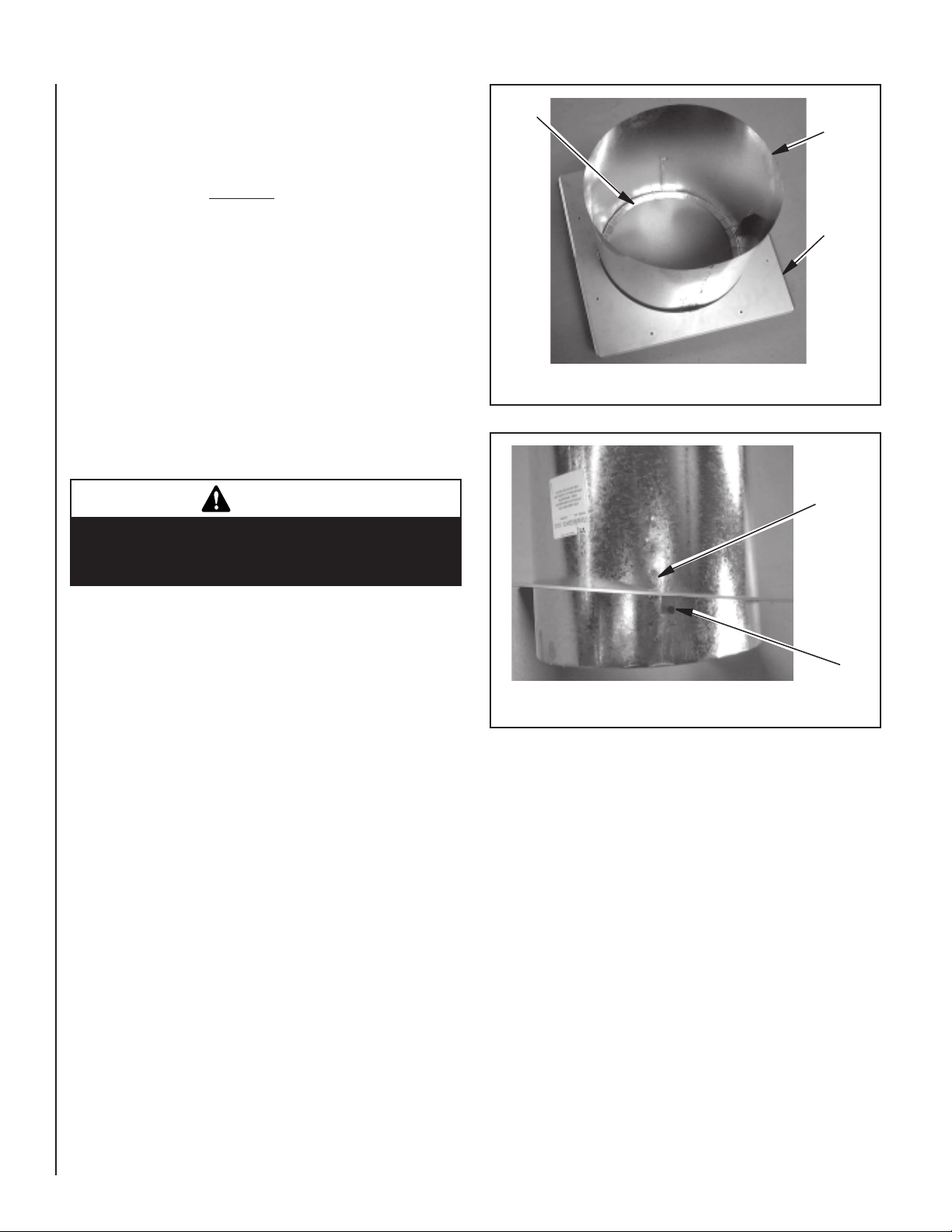

ADJUSTABLE FIRESTOP THIMBLE

This adjustable thimble adjusts to the most commonly used ceiling

pitches automatically. Refer to the following procedure for installing the

adjustable thimble:

The adjustable thimble may be installed around the chimney components

at assembly or the chimney components may be inserted though the

installed thimble.

Install the thimble from below a finished roof and ceiling assembly. Push

the thimble assembly (tube section first) up into an already prepared opening and secure open end of the thimble base to the finished underside of

the roof and ceiling assembly (Figure 11).

Note: The two screws on which the thimble base pivots may be removed

and reinstalled into any of the series of placement holes provided for the

adjustment of the adjustable thimble's point of rotation (Figure 11A).

Adjust the pivot screens to locate the open end of the tube section as

required for the roof line. Additional screws may be placed at the high

and low points of the thimble base in the tabs provided.

Place the thimble base against the finished roof and ceiling assembly and

secure it to the framing with screws or nails. The thimble is self-adjusting

around inserted chimney components. Thimble extensions are available

and may be installed into the adjustable thimble's tube section as needed

to extend the thimble through the roof-line. Secure the thimble extension

to the tube section with screws no more than 1/2" in length.

Pivot

Screw

Figure 11A - Attaching Adjustable Thimble

Position appropriate thimble/firestop spacer combination at ceiling and

nail temporarily with two (2) 8d nails or equivalent fasteners (see Figures

12A, 12B and 12C). Use one fastener on opposite sides to hold thimble/

firestop spacercombination in position. Nail permanently, using at least

two (2) more fasteners, after chimney sections have been assembled

through the thimble/firestop spacer combination and after any necessary adjustments

have been made. Firestop spacer must be secured by at least four (4)

fasteners when completely installed.

Note: If there is a room above ceiling level, firestop spacer must be

installed on the bottom side of the ceiling. If an attic is above ceiling

level, firestop thimble must be installed on the bottom side of ceiling

joist (Figure 12).

Note: The installation of the thimble extension is not required in manufactured homes having ventilated attic spaces, when the chimney height

is equal to or greater than 12 feet.

Ensure the thimble penetrates the roof opening. The thimble must extend

completely through the ceiling or roof cavity to the outermost plane of

the roof. Note: Thimble extensions are available from your dealer for

constructions in which the distance between the outside of the roof and

the inside of the ceiling exceeds 13". The thimbles and their extensions

provide for zero clearances to combustibles and must be used at the

ceiling/roof in manufactured homes (see Figures 12B and 12C, page 9).

SuperiorFireplaces.US.com 127312-01D8

Page 9

"

VENTING INSTALLATION

Continued

Room Above

WARNING

Do not allow insulating materials to be blown into

the space inside the thimble and the chimney. To

do so could result in a fire hazard.

Attic Above

14" Min.

Note: Trim Thimble/

Extension To Desired Length

And Pitch At The Rood Line

Figure 12

Figure 12A

Thimble

Extension

Pitched Roof

Firestop Spacer

Firestop Thimble

Outer Pipe Of

Chimney

Thimble

FM8-AT1

Pitched Roof

14" Min.

Thimble

1" Clearance

Minimum

Outer Pipe Of

Chimney

Outer Pipe Of

Chimney

14" Min.

Thimble Cathedral

Ceiling

Figure 12C

PENETRATING ROOF

To maintain a 1" clearance to pipe on a roof with a pitch, a rectangular

opening must be cut.

1. Determine center point through which pipe will penetrate the roof.

2. Determine center point of the roof. Pitch is the distance the roof drops

over a given span, usually 12". A 6/12 pitch means that the roof drops

6" for each 12" measured horizontally down from roof rafters.

3. Use roof opening chart (Figure 13) to determine correct opening

length and flashing required.

4. Remove shingles around opening measured. Cut out this section.

5. Add next sections of pipe until end penetrates roof line. Check to see

that proper clearances are maintained. Extend chimney by adding

sections of double wall pipe until pipe is minimum of 30" above

highest point of roof cutout. Termination and chimney must extend

a minimum of 36" above highest point where it passes through roof.

Minimum Measurements

14 3/8"

(36.5 cm)

1"

(2.5

cm)

13

30"

(76.2 cm)

1"

(2.5 cm)

1"

(2.5

cm)

127312-01D

14" Min.

Outer Pipe Of

Chimney

Thimble

Bow Roof

Figure 12B

SuperiorFireplaces.US.com

Opening "A"

PITCH SLOPE OPENING "A" MAX FLASHING MODE NO.

Flat 0° 15" 6F-8

0-6/12 26.6° 16-1/8" 6F-8

6/12 - 12/12 45° 20-3/8" 12F-8

Figure 13 - Determine Roof Opening

9

Page 10

VENTING INSTALLATION

Continued

USING ELBOW OFFSETS (30E-8DM)

1.

To achieve desired offset, you may install combinations of 12", 18",

24", 36" and 48" length of double wall pipe (see offset chart and

Figure 14).

OFFSET RISE CHIMNEY LENGTH

A B 48" 36" 24" 18" 12"

4 3/8" 16 3/8"

ELBOW SET ONLY

9" 25 3/4" 1

11 7/8" 31" 1

15" 37 3/8" 1

16 3/4" 40 1/2" 1 1

20" 47 1/8" 1

22 5/8" 52 1/8" 1 1

25 1/2" 57 7/8" 1

27 5/8" 62" 1 1

30 3/8" 67 1/4" 1 1

33" 72 5/8" 1 1

35 3/4" 78" 2

37 7/8" 82" 1 1 1

41 1/4" 88 5/8" 1 1

43 3/8" 92 3/4" 2 1

46 5/8" 99 3/8" 2

48 3/4" 103 1/2" 1 1 1

51 1/2" 108 7/8" 2 1

54 1/4" 114 1/8" 2 1

57" 119 1/2" 1 2

59" 123 5/8" 2 1 1

61 3/4" 129" 1 2 1

64 1/2" 134 3/8" 1 2 1

67 1/4" 139 5/8" 4

2. Chimney weight above offset rests on return elbow. Straps must be

securely nailed to rafters or joists (see Figure 15, details A and B).

3. Maximum length of pipe between supports (return elbow or 12S-8DM)

is 6' of angle run. Maximum of two 6' angle run sections per chimney

system (see Figure 14).

4. All pipe connections between offset and return must be secured with

two screws on outer pipe only (see Figure 16). Do not penetrate inner

stainless.

See Detail A

Straps

Straps

Detail B

Angle Firestop

Straps

Detail A

Return Elbow

Figure 15 - Ceiling Support Pipe 12S-8DM

Straps

See Detail B

OFFSET CHART (22-50 FT. SYSTEM HEIGHT)

Screws

Figure 14 - Elbow Offset

B

A

SuperiorFireplaces.US.com 127312-01D10

Page 11

VENTING INSTALLATION

Continued

Return

Elbow

Offset Elbow

6' Max.

Return

Elbow

6' Max.

Offset Elbow

Offset Elbow

A

Offset Elbow

Return

Elbow

6' Max.

Offset Elbow

6' Max.

B

Figure 16 - Typical Offset Terminations (For Systems with 2 Elbow Sets, Maximum Height is 20')

FIRESTOP SPACERS (3600FS-8DM-1)

Firestop spacers are required at each point where the chimney penetrates a

floor space. Their purpose is to establish and maintain the required clearance

Storm Collar

Flashing

Cone

between the chimney and the combustible materials. When the pipe passes

through a framed opening into a living space above, the firestop must be

placed onto the ceiling from below as shown in Figure 17.

Nail Only Outer

Perimeter of

Flashing

Return

Elbow

Ceiling Support Pipe

12S-8DM

Return

Elbow

6' Max.

6' Max.

C

Overlap Shingles Top

and Sides Only

Existing

Ceiling Frame

Firestop

Spacer

Screws or Staples

(Min. of 8)

Figure 17 - Firestop Spacer with Living Space Above Ceiling

FLASHING INSTALLATION (V6F-8DM OR V12F-8DM)

Determine the flashing to be used with the roof opening chart. Slide

flashing over pipe until base is flat against roof. Replace as many shingles

as needed to cover exposed area and flashing base. Secure in position

by nailing through shingles (see Figure 18). DONOTNAILTHROUGH

FLASHINGCONE.

127312-01D

SuperiorFireplaces.US.com

Underlap Shingles

at Bottom

Figure 18 - Flashing Installation

Installing Flashing on a Metal Roof

When installing flashing on a metal roof, it is required that putty tape be

used between flashing and roof. Flashing must be secured to roof using

#8 x 3/4" screws and then sealed with roof coating to prevent leakage

through screw holes. A roof coating must also be applied around the

perimeter of flashing to provide a proper seal.

11

Page 12

VENTING INSTALLATION

Continued

RTL-8DM

Storm Collar Installation (SC1)

Place storm collar over pipe and slide down until it is snug against the

open edge of flashing (see Figure 19). Use SC1 for all round terminations.

NOTE: Storm collar is required but can be installed after the home is sited.

Chimney

Pipe

Storm

Collar

Waterproof

Caulk

Flashing

Figure 19 - Storm Collar

Terminations/Spark Arrestor

Fireplace system must be terminated with listed round top termination. In any case,

refer to installation instructions supplied with termination. Terminations approved

for this fireplace are RT-8DM and RTL-8DM. Figure 20 shows an RTL-8DM round

top termination.

IMPORTANT: Terminations are required but can be installed once the manufactured

house is sited.

CAUTION

Attach Bracket Tabs

to Outer Pipe (3

Places) Secure with

Screws

Overlap Shingles

Top and Sides

Level of Flue Gas

Outlet

Caulk

Storm

Collar

Flashing

Underlap Shingles

Bottom Only

Figure 20 - Termination

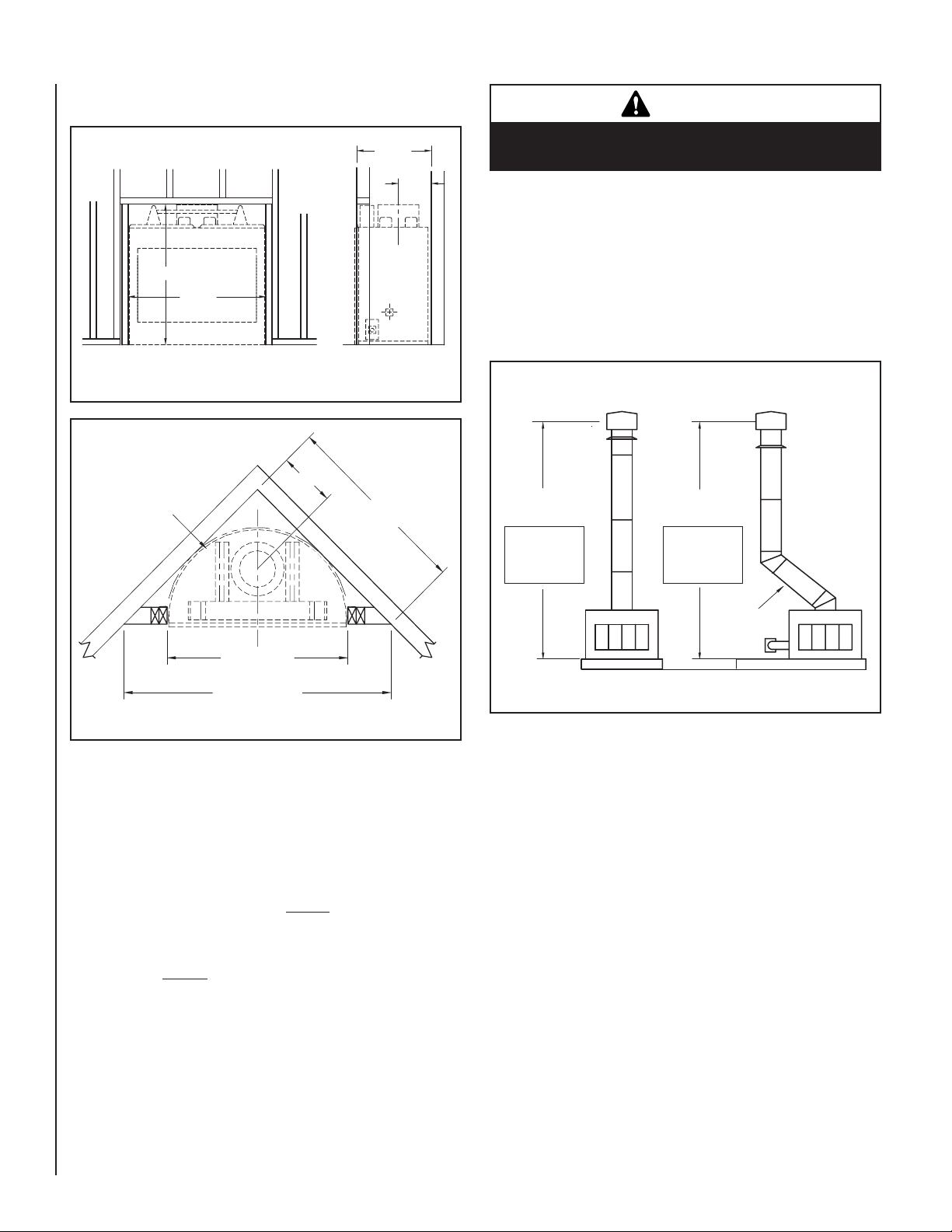

CHASE INSTALLATIONS

Instructions for chase installations are included with chase style termination

chosen. In a multiple chase installation, be sure to provide adequate distance

between terminations to prevent smoke spillage from one termination to another.

We suggest that terminations be separated at least 24", center to center and stacked

at a vertical height difference of 18" (see Figure 21).

Donotsealopeningsontherooftopashing.Follow

the installation instructions provided with the termination being used.

Terminations with 16" slip pipe sections are available. The RTT-8DM and

RTTL-8DM are approved for flashing installations. When needed, these

adjustable terminations may be used in combination with the pipe assembly

to achieve correct chimney height.

NOTE: In the rare instance there is a problem with side driven rain or wind,

or the chimney is not drafting properly, an ADS-8DM Anti Draft Shield can

be used with round terminations.

18"

Min.

Typ.

24" Min.

24" Min.

Figure 21 - Multiple Chase Installation

SuperiorFireplaces.US.com 127312-01D12

Page 13

VENTING INSTALLATION

Continued

10 FOOT RULE

All flue gas outlet chimney terminations must extend a minimum of 3 feet

in height above the highest point where it passes through the roof and

must be at least 2 feet above the highest point of the roof that is within

a horizontal distance of 10 feet (see Figure 22).

Self Drilling

Screws

Chimney Support

Bracket

18"

10'

Level of Flue

Gas Outlet

10'

2' Min.

3' Min.

2' Min.

3' Min.

Figure 22 - 10 Foot Rule

CHIMNEY SUPPORT BRACKET KIT: CSK-8DM

If exposed portion of chimney is greater than five feet above roofline,

support wires are recommended to keep chimney secured. Support

wires must be attached to chimney support brackets. Chimney support

brackets must be attached to outer pipe of chimney with self-drilling

screws provided in kit (screws must not penetrate inner flue pipe). The

angle of support wires should not be more than 45°from horizontal

when fastened to roof. Place chimney support brackets approximately

18"belowreplaceterminationandspacebracketsapproximately120°

apart (see Figure 23) Follow instructions included in kit.

Support Wire

Cable

Ferrule

120°

Top View of

Chimney

120°

Figure 23 - Support Wires

120°

Eye

Bolt

Angle of Support Wire

Should Not Be More Than

45° From Horizontal

OPTIONAL GAS LINE INSTALLATION

Permanently Located (Sited) Homes Only

Gas line hook up should be done by your supplier or a qualified service

person.

NOTE: Before you proceed, make sure your gas supply is turned off.

A gas line may be installed for the purpose of installing a vented or vent

free appliance available through your local distributor. Use only a 1/2"

black iron pipe and appropriate fittings. When installing a gas line, a

shutoff valve designed for installation outside appliance is recommended.

1. Remove knockout indentation on refractory or firebrick wall located

above the refractory hearth floor. Knockout indentation must be firmly

tapped with any solid object such as a 1/2" dowel until it is released.

Remove fragmented portions of refractory (see Figure 24).

2. Remove gas line cover plate located on either side of fireplace and

pull out insulation from gas line conduit sleeve. Save insulation for

reuse. Replace screws.

127312-01D

SuperiorFireplaces.US.com

Outside of

Fireplace

Gas Line

Conduit

Insulation

Gas Conduit

Cover

Knockout

Figure 24 - Gas Line Knockout

Side Firebrick

Finished Side

1/2" Dowel

Refractory

Knockout Plug

13

Page 14

OPTIONAL GAS LINE INSTALLATION

Continued

NOTE: Secure incoming gas line to wood framing to provide rigidity for

threaded end.

3. Run a 1/2" black iron gas line into fireplace through rear at gas

line conduit sleeve (if using a raised platform, add height). Provide

sufficient gas line into fireplace chamber for fitting connection (see

Figure 25, page 14).

NOTE: Secure incoming gas line to wood framing to provide rigidity for

threaded end.

4. Repack insulation around gas line and into sleeve opening. Seal any

gaps between gas line and refractory knockout hole with refractory

cement or commercial furnace cement, Install gas appliance or cap

off gas line if desired.

CAUTION

All gas piping and connections must be tested

for leaks after the installation is completed. After

ensuring that the gas valve is on, apply soap and

water solution to all connections and joints. Bubbles

forming show a leak. Correct all leaks at once. DO

NOT USE AN OPEN FLAME FOR LEAK TESTING AND

DO NOT OPERATE ANY APPLIANCE IF A LEAK IS

DETECTED. LEAK TESTING SHOULD BE DONE BY

A QUALIFIED SERVICE PERSON.

If you wish to install an unvented (vent-free) gas log set, ONLY UNVENTED

GAS LOG SETSWHICH HAVE BEEN FOUND TO COMPLYWITH THE

STANDARDFORUNVENTEDROOMHEATERS,ANSIZ21.11.2,ARETO

BEINSTALLEDINTHISFIREPLACE.

A vent-free log may be installed in an aftermarket,* permanently located,

manufactured (mobile) home, where not prohibited by locator.

*Aftermarket: Completion of sale, not for purpose of resale, from the

manufacturer.

NOTE: A hood must be installed when using an vent-free gas log set (see

Accessories, page 19).

If you install a decorative gas appliance (vented gas log), the decorative

gas appliance must comply with the Standard for Decorative Gas Appliance

for Installation in Solid Fuel Burning Fireplaces, ANSI Z21.60/CSA 2.26 or

Z21.84 and shall also be installed in accordance with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 National Fuel Gas Codes (USA) and CAN/CGAB149.1 National Gas And Propane Installation Code (Canada) - latest edition.

WARNING

Do not operate an unvented gas log set in this

fireplace with the chimney removed.

Outside of

Fireplace

Gas Line

Conduit

Repack

Insulation

Figure 25 - Gas Line Installation

Incoming 1/2"

Black Iron Pipe

Seal Opening

with Refractory

Cement

Side Firebrick

Finished Side

Provide Enough Threaded

End for Fitting Connection

WARNING

If the fireplace has been used for wood burning,

the firebox and chimney must be cleaned of soot,

creosote and ashes be a qualified chimney cleaner.

Creosote will ignite if heavily heated.

WARNING

When using a decorative vented gas log, the damper

must be removed or permanently locked in the fully

open position and the glass doors must be in the

fully open position.

SuperiorFireplaces.US.com 127312-01D14

Page 15

FINISHING FIREPLACE

Combustible materials, such as wallboard, gypsum board, sheet rock, drywall, plywood, etc. may make direct contact with sides and top around the

fireplace face. It is important that combustible materials do not overlap the

face itself. Brick, glass, tile or other noncombustible materials may overlap

the front face provided they do not obstruct essential openings like louvered

slots or any other opening. When overlapping with a noncombustible facing

material, use only noncombustible mortar or adhesive.

IMPORTANT: Glass must be allowed to warm slowly and evenly. Tempered

glasswillwithstandagradualtemperatureriseto550°Fahrenheit,which

is more than a normal fire will generate.

Such materials as pitch/wax laden logs, very dry mill end lumber, and

large amounts of paper or cardboard boxes can create an excessively

hot fire and should not be burned in this fireplace. Always keep fire back

from doors and never allow flames to contact glass.

MANTELS

A mantel may be installed if desired (see Figure 26). Woodwork such

as wood trims, mantels or any other combustible material projecting

from the front face must not be placed within 9" of the fireplace opening.

Combustible materials above 9" and projecting more than 1-1/2" from

the fireplace must not be placed less than 12" from the top opening of

the fireplace (NFPA 211, Section - Clearance from Combustible Material).

NOTE: HUD requirements may supersede these minimum dimensions.

Combustible Material

Safe Zone for

Projection of

Combustible

Materials

6"

Ref.

12" Min.

12-1/4" Ref.

33°

3" Nom.

1-1/2" Max.

WARNING

Fireplaces equipped with glass doors should be

operated only with doors fully opened or fully closed.

Doors,ifleftpartlyopen,maydrawgasandame

out of the fireplace opening creating risks of both

fire and smoke.

Doors Fully Closed

Fireplace Front

9" Min.

Fireplace Opening

Upper Section

of Fireplace

Figure 26 - Mantel Clearances to Combustible Material

OPERATION AND MAINTENANCE GUIDELINES

GLASS DOORS

Glass doors are standard with fireplace. When fireplace is in operation,

doors must be FULLY OPENED or FULLY CLOSED position only or a fire

hazard may be created (see Figure 27).

A fireplace equipped glass doors operates much differently than a fireplace

with an open front. A fireplace with glass doors has a limited amount of

air for combustion. Excessive heat within fireplace can result if too large a

fire is built or if combustion air gate is not completely open. The following

tips should be followed to assure that both fireplace and glass door retain

their beauty and function properly. Both flue damper and glass doors

must be fully opened before starting the fire. This will provide sufficient

combustion air and maintain safe temperatures in firebox.

Doors

Fully Opened

Fireplace Front

Figure 27 - Bi-Fold Glass Doors

127312-01D

SuperiorFireplaces.US.com

15

Page 16

OPERATION AND MAINTENANCE GUIDELINES

Continued

Door Removal

1. Fold doors (fully open) and press up on upper door spring clip until

top pin is free of the spring clip (see Figure 28). Tip door toward

middle of fireplace opening and lift door out of the lower pivot hole.

2. Repeat step 1 for remaining door.

Fold Door and

Slide Top Pins

Into Track

Figure 28 - Removing / Installing Bi-Fold Doors

Installing Glass Doors

1. With bi-fold doors completely folded, insert bottom pivot pin into pivot

hole located near bottom corner of front face opening and swing door

to vertical position making sure top pins slide into door track. Door is

installed when top door pin snaps into spring clip (see Figure 28).

2. Repeat step 1 for remaining door.

Spring Clip

Insert Pin into

Spring Clip

Insert Bottom

Pivot Pin into

Hole

Pivot Hole

Figure 29 - Adjusting Bi-Fold Doors

CLEANING GLASS

Clean the glass with any commercial glass cleaner or soap and water.

Do not use any abrasive material to clean glass. Do not clean glass with

any cool water if glass is still hot from fire and smoke.

DAMPER OPERATION

The damper handle, which opens and closes damper blade, is located

inside firebox at center towards back wall. Pushing handle back in keyway

slot will free damper blade to automatically open. To close, reach in and

push handle back into keyhole slot then pull down and forward to lock it

in place (see Figure 30). Damper is not designed to be airtight. A small

gap around damper blade is normal.

Damper

Weight

If you find the doors do not close properly or do not appear level or

straight, proceed with section on door adjustment.

Door Adjustment

Remove doors and slightly loosen lower pivot clips and upper spring

clips. Replace doors and fully close them. Use 1/8" shims (any material)

to level doors. Once proper setting is achieved, carefully open doors

enough so that you can access spring clips with a phillips screwdriver.

Tighten screws. See Figure 29.

SuperiorFireplaces.US.com 127312-01D16

Damper

Handle

Closed Damper

Figure 30 - Damper Operation

Open Damper

WARNING

Risk of fire! Always replace grate with IHP part

number 11116 grate only. This grate has been

designed to keep the operation of your fireplace

safe and efficient.

Page 17

OPERATION AND MAINTENANCE GUIDELINES

Continued

LOCATING ACCESS COVER PLATE

Sheet metal cover plates located underneath front hearth refractory may have

shifted or moved out of place while fireplace was in transit. These cover plates

must be kept in the proper location prior to using the fireplace (See Figure 31).

For further operating guidelines, instructions and warranty information,

please refer to your homeowner's guide or contact your authorized dealer.

TECHNICAL SERVICE

You may have further questions about installation, operation, or

troubleshooting. If so, visit SuperiorFireplaces.US.com.

Haveyourmodelandserialnumbersofyourreplaceready.

Model and serial number information are in the fireplace's rating plate

located underneath the front brick liner.

YoucanalsovisitIHP'swebsiteatIHP.US.com.

REPLACEMENT PARTS

If this product is missing a part or has a broken component, please do

not return it to the store. Visit IHP.US.com for more information.

NOTE: Use only original replacement parts. This will protect your warranty

coverage for parts replaced under warranty.

Whencontacting IHP,please haveyour model andserial numbers of

your fireplace ready.

Access Panel

Figure 31 - Locating Access Cover Plate

Model and serial number information are in the fireplace's rating plate

located on the smoke shelf on the top right side of the fireplace opening.

127312-01D

SuperiorFireplaces.US.com

17

Page 18

FIREPLACE ACCESSORIES

CAT NO. MODEL DESCRIPTION

BI-FOLD GLASS DOORS

J2724 VDG36E 36" Glass Door - Brushed finish

J0468 DP36E 36" Glass Door - Platinum finish

J2709 VDBP36E 36" Glass Door - Black finish

EMBER PROTECTOR

J6906 Ember Protector

GRATE

J4515 Grate 36"

BRICK LINER

J6897 Refractory Rear

J6898 Refractory Side L/R

J6938 Refractory Bottom Rear

J6939 Refractory Bottom Front

OUTSIDE AIR KIT FOR FLOOR INSTALLATION (INCLUDED)

J7317 AK6E Outside Air Kit

INSTALLATION ACCESSORIES

DOUBLE WALL PIPE

F0895 12-8DM 12" Section Double Wall Pipe Snap Lock

F0896 18-8DM 18" Section Double Wall Pipe Snap Lock

F0897 24-8DM 24" Section Double Wall Pipe Snap Lock

F0898 36-8DM 36" Section Double Wall Pipe Snap Lock

F0899 48-8DM 48" Section Double Wall Pipe Snap Lock

CHIMNEY SUPPORT BRACKET KIT

J0380 CSK-8DM Kit Chimney Support Bracket

FIRESTOP SPACER

Support Bracket

Self Drilling Screws

Cable Ferrule

Eye Bolt Screw

Strand Wire (50 ft)

F0907 3600FS-8DM-1 1" Clearance Firestop Spacer ( 1ea.)

ROOF FLASHING

F0910 V12F-8DM Roof Flashing 6/12 to12/12 Pitch

F0909 V6F-8DM Roof Flashing 0 to 6/12 Pitch (30" Base)

SuperiorFireplaces.US.com 127312-01D18

Page 19

INSTALLATION ACCESSORIES Continued

ANTI-DRAFT SHIELD

(Round Top Termination Only)

F0927 ADS-8DM Anti-Draft Shield for Round Top Only

MESH ROUND TOP TERMINATIONS

J6280 RTL-8DM Round Top Termination

SQUARE TOP TERMINATION WITH LOUVERS

F0921 ETL-8DM Square Top with Slip Section

ADJUSTABLE HOOD

Required when installing a vent-free gas log in this fireplace.

F1764 GA6050 BlackFireplaceHood

HEARTH EXTENSION

J1462 HE-36 HearthExtension-36IN

OPTIONAL OUTSIDE AIR KIT FOR SIDE WALL INSTALLATION

J0010 A-K6WE Outside Air Kit

LABEL-UL127-50PK

F2659

LABEL-UL127-

50PK

UL127 Venting Label - 50 PK

STORM COLLAR

F0946 SC2-1 Storm Collar

30° OFFSET AND RETURN

F0900 30E-8DM 30 Degree Offset and Return

ADJUSTABLE FIRESTOP THIMBLE

LB-97008A Adjustable Firestop Thimble

WARNING

HOT

•Fire Risk

•Insulation and combustibles must not touch

pipe

•Consult manual for clearance requirements

•Ensure proper connection

WARNING

HOT

•Fire Risk

•Insulation and combustibles must not touch

pipe

•Consult manual for clearance requirements

•Ensure proper connection

Not shown

WARNING

HOT

•Fire Risk

•Insulation and combustibles must not touch

pipe

•Consult manual for clearance requirements

•Ensure proper connection

900599-01

AIR INLET HOOD

J0019 AK6-WI Termination Outside Air Vent

127312-01D

SuperiorFireplaces.US.com

19

Page 20

INSTALLATION ACCESSORIES Continued

THIMBLE EXTENSIONS

99L69 8" Thimble Extension

91L46 26" Thimble Extension

FLEX DUCT (3 PACK)

J1936 MP6-75 Duct Outside Air 6" x 75'

AIR INLET HOOD (6 PACK)

MK6-WI AirInletHood

FACE EXTENSION

Front face extension would add 6” to the width and 6” to the height of the fireplace face.

J0918 FE-36R Face Extension (C36EMW-R)

VENT KIT* DESCRIPTION

36-8DM 36" Double Wall Pipe 2 2 0

24-8DM 24" Double Wall Pipe 1 0 0

18-8DM 18" Double Wall Pipe 0 2 0

LB97008A Adjustable Firestop Thimble 1 1 1

V6F-8DM Roof Flashing 1 1 1

SC1-1 Storm Collar 1 1 1

RTL-8DM Round Cap Termination 1 1 0

RLT-8HT Round Louvered Termination 0 0 1

36-8HT 36"Flue,8"HT. 0 0 2

24-8HT 24"Flue,8"HT. 0 0 1

*UseforMostCommonManufactured(Mobile)HomeInstallations

J1948

MW8K

(8' Vent Kit)

J1952

MW9K

(9' Vent Kit)

F2122

MW8K-HT

(8' HT Vent Kit)

SuperiorFireplaces.US.com 127312-01D20

Page 21

IMPORTANT NOTICES

CANADA

Canadian code CAN/ULC-S610-M87 and other pertinent

codes require stainless steel chimney for the installation

of this fireplace. A Cold Air Climate Kit is also required

in Canada and is recommended for cooler regions in the

United States. Below, find a list of approved stainless

steel parts.

Chimney Parts List for Canada

Catalog

No.

F0881 12-8HT 12"SectionHi-TempDouble

F0882 18-8HT 18"SectionHi-TempDouble

F0883 24-8HT 24"SectionHi-TempDouble

F0884 36-8HT 36"SectionHi-TempDouble

F0885 48-8HT 48"SectionHi-TempDouble

F0886 30E-8HT 30DegreeHi-TempOffset

F0887 12S-8HT Hi-TempChimneySupport

F0888 RT-8HT Hi-TempRoundTopwith

F0889 RTT-8HT Hi-TempRoundTopwith

F0890 RLT-8HT Hi-TempRoundTopwith

F0891 RLTT-8HT Hi-TempRoundTopwith

F0892 ET-8HT Hi-TempPyramidTopwith

F0893 ETL-8HT Hi-TempLargePyramidTop

F0894 AP-8HT Hi-TempAnchorPlate/Col-

F0929 CAK-8 Cold Air Collar Kit - 8"

*When ordered alone, this part cannot ship via parcel

delivery services.

Model No.

8" Hi-Temp

Wood burning Chimney

Wall Pipe Snap Lock

Wall Pipe Snap Lock

Wall Pipe Snap Lock

Wall Pipe Snap Lock

Wall Pipe Snap Lock

and Return

(For Use With Chimney

HeightsInExcessof30')

Mesh Screen

Mesh Screen and Slip Section

Louvered Screen

Louvered Screen and Slip

Section

Slip Section

with Slip Section (use with all

8" systems)

lar Assembly (for masonry

fireplaces)

Chimney

IMPORTANT NOTICE

A manufactured shroud which has

been approved by a national testing agency for use with this fireplace may be used if installed in

accordance with the instructions

by its manufacturer. A locally

fabricated shroud may be used

with IHP Shroud Leg Spacer Kit

(SLK) in accordance with instructions provided with the shroud.

NOTICE: The firebox canopy (hood)

must not be modified or replaced with

a canopy that may be provided with

the unvented decorative room heater.

CAUTION

THE STRUCTURAL INTEGRITY

OF THE MANUFACTURED HOME

FLOOR, WALL, AND CEILING/

ROOF MUST BE MAINTAINED.

WARNING

DO NOT INSTALL IN SLEEPING

ROOM OF MOBILE HOMES.

WARNING

Discontinue use of the appliance immediately if doors are

damaged and contact a qualified

installer for repair. Only doors

certified with the appliance shall

be used.

WARNING

Do not slam or strike doors.

Damage can result in a hazardous condition.

127312-01D

SuperiorFireplaces.US.com

21

Page 22

NOTES

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

SuperiorFireplaces.US.com 127312-01D22

Page 23

Innovative Hearth Products

®

Superior

Brand Wood-Burning Fireplace

20 Year Limited Warranty

THE WARRANTY

Innovative Hearth Products ("IHP") 20 Year Limited Warranty warrants your Superior® Brand wood burning fi replace ("Product") to be free from defects in materials and

workmanship at the time of manufacture. The Product body, fi rebox and ceramic glass carry the 20 Year Limited Warranty. Ceramic glass carries the 20 Year Limited Warranty

against thermal breakage only. After installation, if covered components manufactured by IHP are found to be defective in materials or workmanship during the 20 Year Limited

Warranty period and while the Product remains at the site of the original installation, IHP will, at its option, repair or replace the covered components. If repair or replacement

is not commercially practical, IHP will, at its option, refund the purchase price or wholesale price of the IHP product, whichever is applicable. IHP will also pay IHP prevailing

labor rates, as determined in its sole discretion, incurred in repairing or replacing such components for up to fi ve years. THERE ARE EXCLUSIONS AND LIMITATIONS to this

20 Year Limited Warranty as described herein.

COVERAGE COMMENCEMENT DATE

Warranty coverage begins on the date of purchase. In the case of new home construction, warranty coverage begins on the date of fi rst occupancy of the dwelling or six

months after the sale of the Product by an independent IHP dealer/distributor, whichever occurs earlier. The warranty shall commence no later than 24 months following the

date of product shipment from IHP, regardless of the installation or occupancy date.

EXCLUSIONS AND LIMITATIONS

This 20 Year Limited Warranty applies only if the Product is installed in the United States or Canada and only if operated and maintained in accordance with the printed instructions accompanying the Product and in compliance with all applicable installation and building codes and good trade practices.

This warranty is non-transferable and extends to the original owner only. The Product must be purchased through a listed supplier of IHP and proof of purchase must be

provided. The Product body and fi rebox carry the 20 Year Limited Warranty from the date of installation. Vent components, trim components, paint and applied stains are

excluded from this 20 Year Limited Warranty. The following do not carry a 20 Year Limited Warranty but are warranted as follows:

Air tubes, baffl es and brick retainers – Repair or replacement for one year from the date of installation

Cast iron parts – Replacement for one year from date of installation

Catalyst – Carries a separate warranty. Refer to the warranty certifi cate provided for that part

Electrical components – Repair or replacement for one year from the date of installation

Fireplace screens, refractory and side shields (metal or refractory) – Repair or replacement for two years from date of installation. Excludes hairline cracks.

Fuel grates –These parts are considered consumable accessories and therefore are not warranted, with the exception of defects in material or workmanship which

are covered for 90 days from the date of installation

Gaskets – Replacement for one year from date of installation

Gold & nickel plating – Replacement for two years from date of installation. Excludes tarnishing

Optional glass doors – Repair or replacement for 90 days from the date of installation

Refractory & screens – Replacement for two years from date of installation. Excludes hairline cracks

Removable air tubes – Repair or replacement for seven years from date of installation. IHP prevailing labor rates for years one through fi ve.

Labor coverage – Prevailing IHP labor rates apply for the warranty period of the component.

Parts not otherwise listed carry a 90 day warranty from the date of installation.

Whenever practicable, IHP will provide replacement parts, if available, for a period of 10 years from the last date of manufacture of the Product.

IHP will not be responsible for: (a) damages caused by normal wear and tear, accident, riot, fi re, fl ood or acts of God; (b) damages caused by abuse, negligence, misuse, or

unauthorized alteration or repair of the Product affecting its stability or performance. (The Product must be subject to normal use with approved fuels listed in the Operation

Manual provided with the product. This includes burning such fi replace fuels as wood and natural or propane gas. Fuel products with abnormal burning characteristics,

including but not limited to fuel such as driftwood, coal or plywood and wood products using a binder may burn at excessive temperatures and may cause damage to the

Product or may cause it to function improperly.); (c) damages caused by failing to provide proper maintenance and service in accordance with the instructions provided with

the Product; (d) damages, repairs or ineffi ciency resulting from faulty installation or application of the Product.

Coverage of this 20 Year Limited Warranty is conditional upon use of an adequate fuel grate on factory-built fi replaces only, when applicable.

IHP is not responsible for inadequate fi replace system draft caused by air conditioning and heating systems, mechanical ventilation systems, or general construction conditions which may generate negative air pressure in the room in which the appliance is installed. Additionally IHP assumes no responsibility for smoking conditions caused by

inadequate chimney height, adjoining trees or buildings, adverse wind conditions or unusual environmental factors and conditions. Certain IHP Products are listed for use with

Security Chimneys International, Ltd. or IHP chimney systems only. Use of chimney components other than that specifi ed in the Product manual will void the Product warranty.

This 20 Year Limited Warranty covers only parts and labor as provided herein. In no case shall IHP be responsible for materials, components or construction which are not

manufactured or supplied by IHP or for the labor necessary to install, repair or remove such materials, components or construction. Additional utility bills incurred due to any

malfunction or defect in equipment are not covered by this 20 Year Limited Warranty. All replacement or repair components will be shipped F.O.B. from the nearest stocking

IHP factory.

LIMITATION ON LIABILITY

It is expressly agreed and understood that IHP’s sole obligation and the purchaser’s exclusive remedy under this warranty, under any other warranty, expressed or implied, or

in contract, tort or otherwise, shall be limited to replacement, repair, or refund, as specifi ed herein.

In no event shall IHP be liable for any incidental or consequential damages caused by defects in the Product, whether such damage occurs or is discovered before or after

replacement or repair, and whether such damage is caused by IHP’s negligence. IHP has not made and does not make any representation or warranty of fi tness for a particular

use or purpose, and there is no implied condition of fi tness for a particular use or purpose.

IHP makes no expressed warranties except as stated in this 20 Year Limited Warranty. The duration of any implied warranty is limited to the duration of this expressed warranty.

No one is authorized to change this 20 Year Limited Warranty or to create for IHP any other obligation or liability in connection with the Product. Some states and provinces

do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. The provisions of this 20 Year

Limited Warranty are in addition to and not a modifi cation of or subtraction from any statutory warranties and other rights and remedies provided by law.

INVESTIGATION OF CLAIMS AGAINST WARRANTY

IHP reserves the right to investigate any and all claims against this 20 Year Limited Warranty and to decide, in its sole discretion, upon the method of settlement.

To receive the benefi ts and advantages described in this 20 Year Limited Warranty, the appliance must be installed and repaired by a licensed contractor approved by IHP.

Contact IHP at the address provided herein to obtain a listing of approved dealers/distributors. IHP shall in no event be responsible for any warranty work done by a contrac-

tor that is not approved without fi rst obtaining IHP's prior written consent.

HOW TO REGISTER A CLAIM AGAINST WARRANTY

In order for any claim under this warranty to be valid, you must contact the IHP dealer/distributor from which you purchased the product. If you cannot locate the dealer/

distributor, then you must notify IHP in writing. IHP must be notifi ed of the claimed defect in writing within 90 days of the date of failure. Notices should be directed to the IHP

Warranty Department at 1508 Elm Hill Pike, Suite 108; Nashville, TN 37210 or visit our website at WWW.SUPERIORFIREPLACES.US.COM.

Printed in U.S.A. © 2013 Innovative Hearth Products

P/N 900224-00, Rev. A 10/2015

Innovative Hearth Products

1508 Elm Hill Pike, Suite 108 • Nashville, TN 37210

23

Page 24

WARRANTY

KEEP THIS WARRANTY

Model Number

Serial Number

Date Installed

Dealer's Name

Dealer's Phone Number

Keep receipt for warranty verification

InnovativeHearthProducts reservesthe righttomakechangesatanytime,without notice,in

design, materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local distributor for fireplace code information.

P127312-01

PrintedinU.S.A.©2014IHPLLC

P/N 121312-01 Rev. D 10/2015.

1508ElmHillPike,Suite108•Nashville,TN37210

Loading...

Loading...