Page 1

User Manual and Parts List

P/n: 017821

Page 2

General

Safety symbols:

WARNING! If used incorrectly the machine can cause injury.

Please read the Operator’s Manual thoroughly making sure you

understand how to use the machine before use.

Always wear personal protective equipment such as gloves, eye

protection, hearing protection, and a hard hat. Jobsites might require

certain protective equipment be used due to national and local

regulations and insurance policies. Make sure you check with the jobsite

foreman for requirements before work begins.

Dear Customer,

Thank you for choosing a Superior Innovation product. It is our intent to

deliver the best products possible. Delivering innovative, well-built,

ergonomic, efficient products is our goal to help you do the best job

possible. Safety, and innovation are our cornerstone of design.

Page 3

This Operator’s Manual is a valuable document. Make sure it is always

accessible when using the machine. If you lend or sell this machine,

make sure that this document is also transferred, so the new user will

know how to properly use and maintain it.

User Responsibility

It is the owner’s / employer’s responsibility to ensure that the operator is

properly trained and has sufficient knowledge about how to use this

machine safely. Supervisors and operators must read and understand

the Operators Manual. They must be aware of the safety instructions,

limitations, proper use and maintenance. Local and national legislation

may regulate the use of this machine. Find out what legislations are

applicable in your location before use.

Superior Innovations Reservation

All of the information and data in this Operator’s Manual was up to date

at the time the Operator’s Manual was sent to print. Superior

Innovations research and development is continually working on product

development and improvements. Therefore, we reserve the right to

modify the design, appearance and features of the product without prior

notice.

Page 4

Vibration Warning

WARNING! Overexposure to vibration can lead to circulatory damage

and or nerve damage, especially in people who have impaired

circulation. Contact your doctor if you experience symptoms of

overexposure to vibration. Symptoms include: numbness, loss of feeling,

tingling, pricking, pain, loss of strength, and changes in skin color and

condition. These conditions normally occur in the fingers, hands or

wrists and can be further increased in cold temperatures.

Transportation and Storage

After work is completed, remove the MagVibe™ Pro or ProTilt© from the

float and thoroughly wipe down before the concrete has time to setup.

DO NOT USE A PRESSURE WASHER OR SUBMERGE IN WATER! There are

sensitive electronics and not all areas can be water tight.

Secure the equipment during transportation to avoid transport damage

and accidents.

Store in a lockable area so that it is not able to be accessed by children or

unauthorized persons.

Personal Protective Equipment

You must use approved personal protective equipment whenever you

use the machine. Personal protective equipment cannot eliminate

injury, but it will reduce the degree of injury if an accident does happen.

Ask your dealer for help in choosing the right protective equipment.

Page 5

Common Sense

It is not possible to cover every conceivable situation. Exercise care and

use common sense if you get into a situation where you feel unsafe.

Stop and seek expert advice by contacting Superior Innovations, Inc., a

service dealer or an experienced user. Do not attempt any task that you

are unsure of.

Work Area Safety

Observe your surroundings to ensure nothing can affect your control of

the machine.

Observe your surroundings to ensure there is no risk of people or

animals that can come into contact with the machine while in operation.

Do not use machine in bad weather, such as heavy rain, strong winds,

intense cold, or heavy fog. Working in such weather is trying and can

lead to difficult situations.

Ensure that the work area is sufficiently illuminated to create a safe

working environment.

Make sure that there are no electrical cables routed in the working area.

Make sure that the work area is clear, clean and free of obstacles that

can cause trips or spills.

Page 6

Before Starting

Inspect equipment to ensure that there are no loose fasteners, cracks,

leaks, or other obvious damage. If there are do not use until the

problems are corrected.

Make sure that daily maintenance has been completed.

Make sure that the MagVibe™ Pro battery is fully charged.

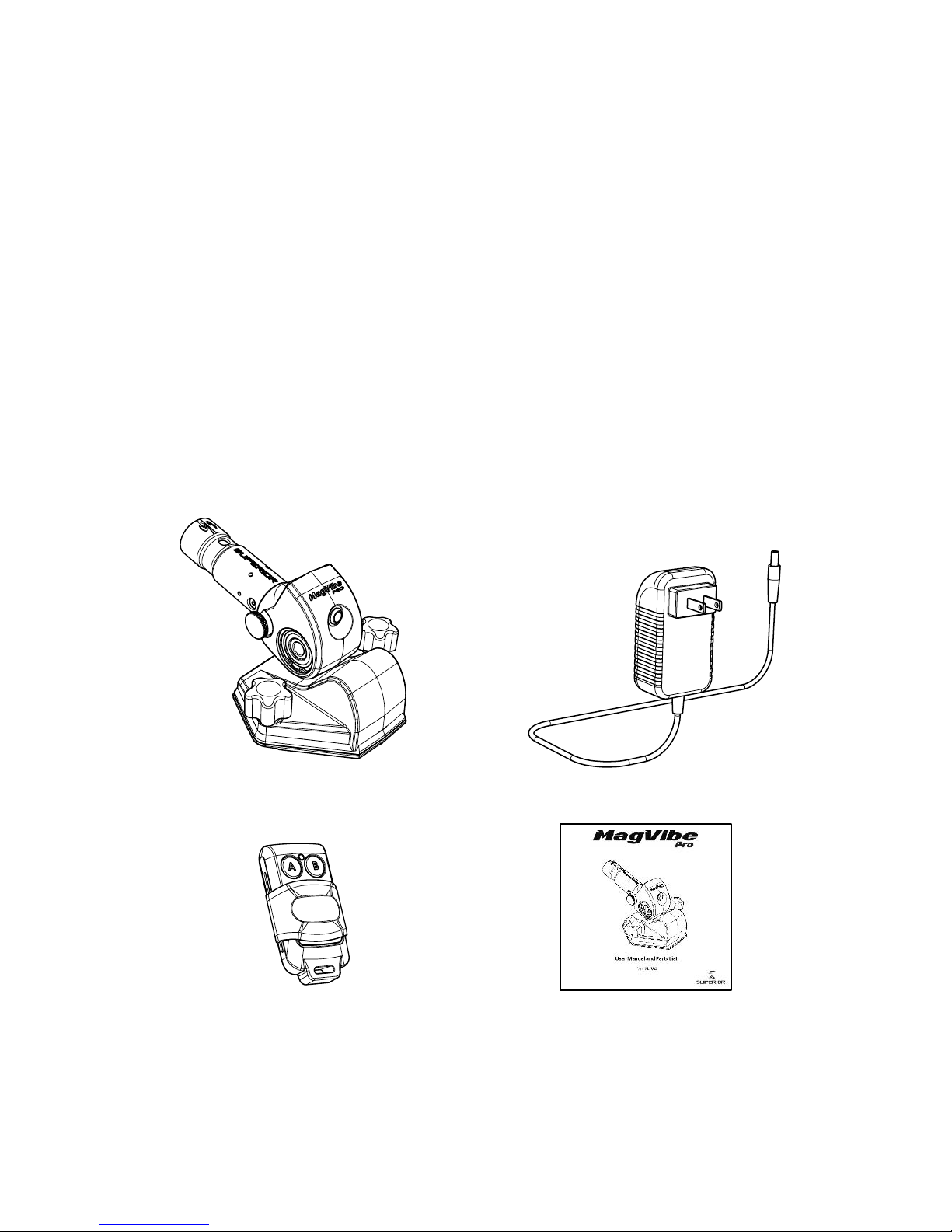

In the Box

Page 7

Warranty

New equipment sold by Superior Innovations is warranted to be free

from manufacturing defects under normal service for a period of one (1)

year from date of purchase by the original consumer. Component

manufacturers offer separate warranties and are covered separately.

These components are the lithium polymer battery, the electric motor,

RF remote control batteries (27A) and the battery indicator. These

components carry a 180-day warranty from the original date of

purchase. For complete information or to request a return goods

authorization number (RGA#) call technical service at (844) 624-8423.

Superior Innovation’s obligation under this warranty is expressly limited

to the replacement or repair at our service facility or one that has been

pre-authorized by Superior Innovations.

This warranty does not apply to defects caused by damage,

unreasonable use, faulty repairs made by others or defects caused by

failure to provide reasonable maintenance, while in the possession of the

consumer. Further, the warranty is void if the product, or any of its

components, is altered or modified by the consumer or if the product is

used in an inappropriate manner not recommended by the

manufacturer.

Page 8

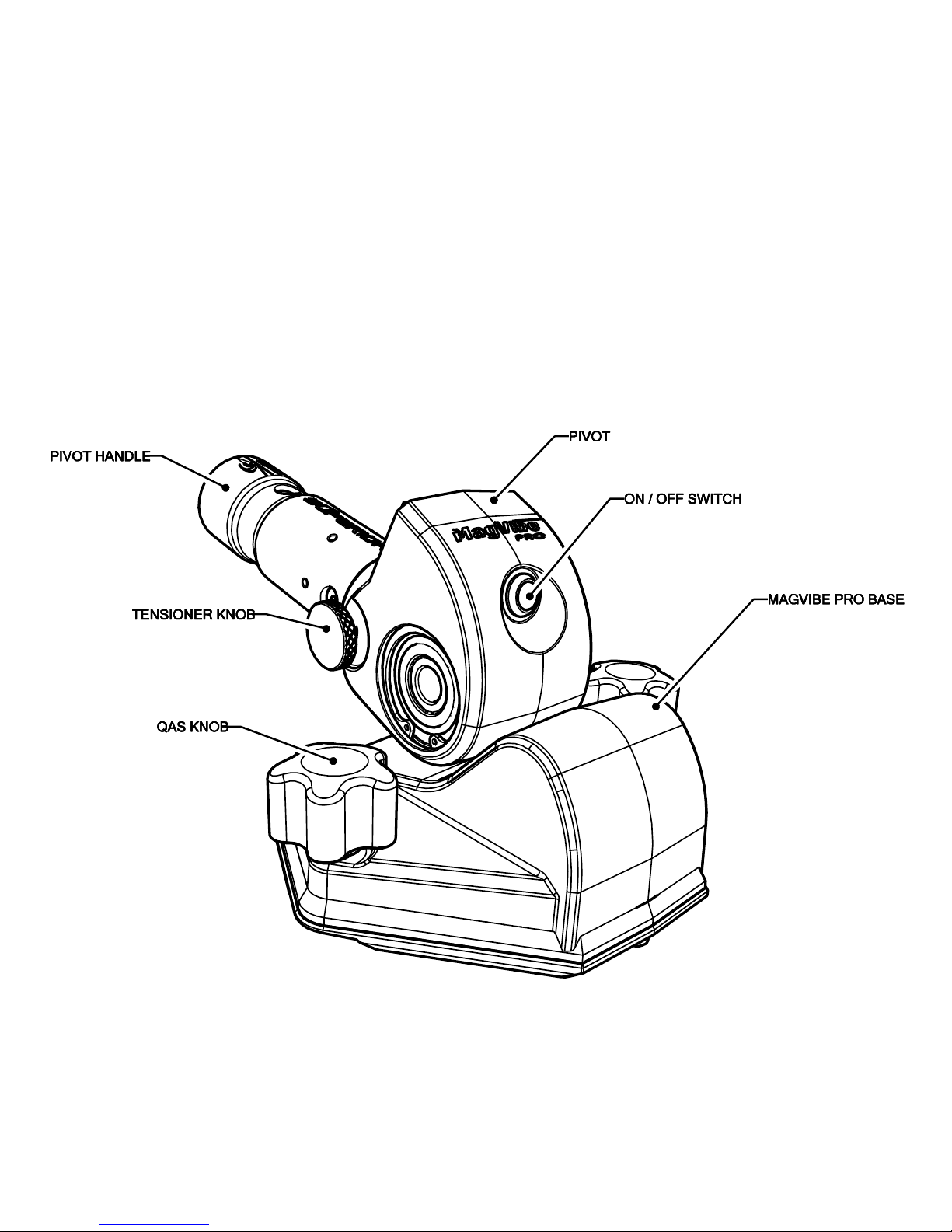

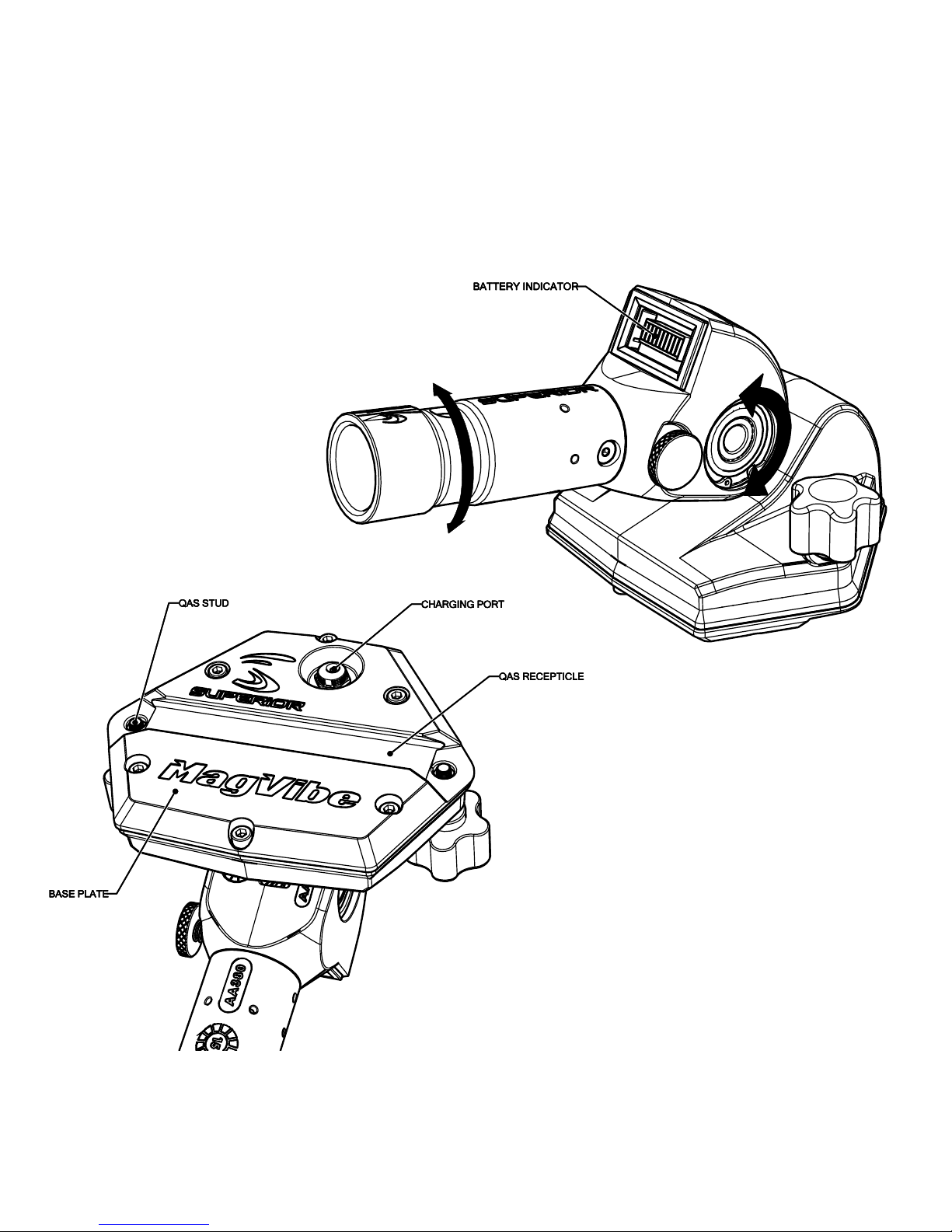

Description / Features / Controls

Page 9

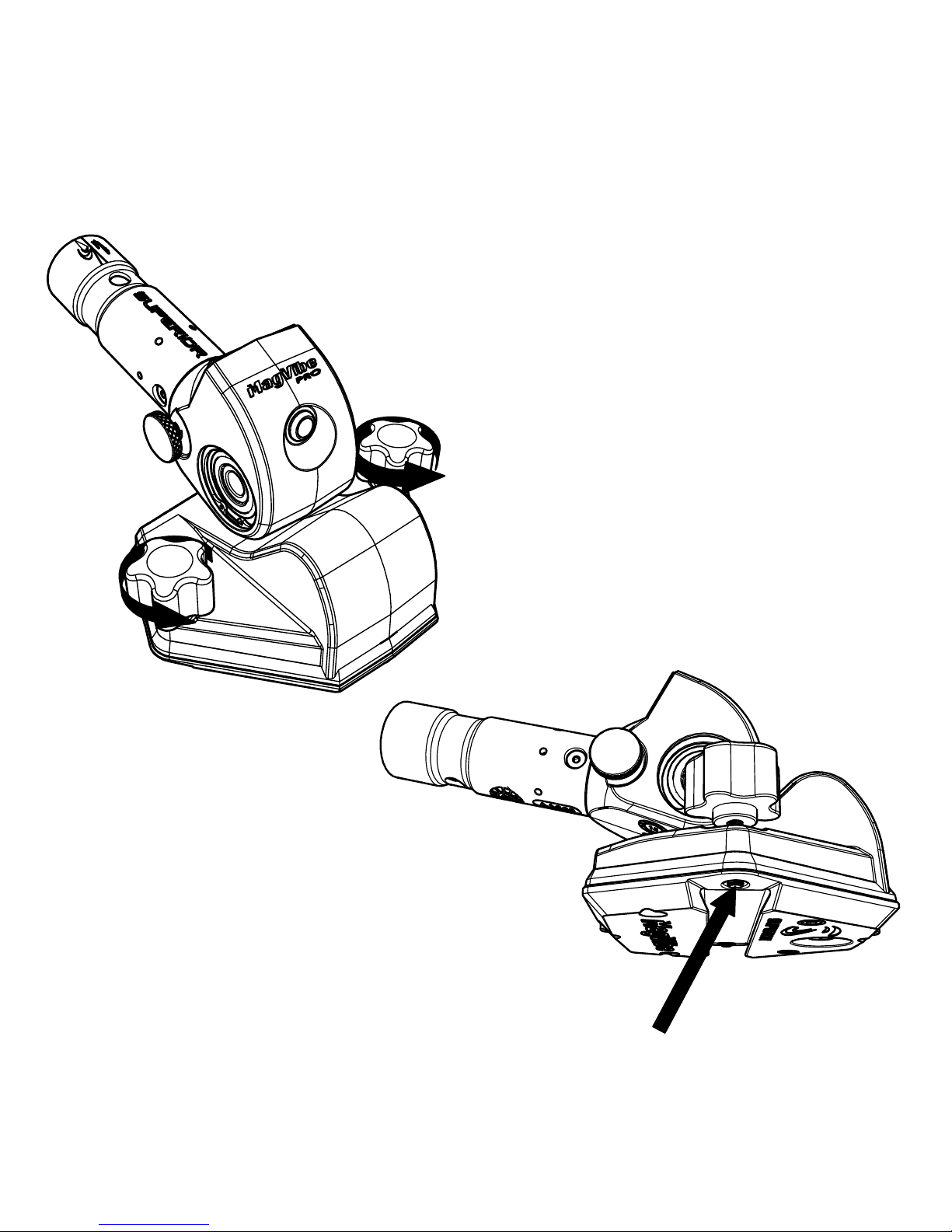

Description / Features / Controls

Rotating the pivot handle will

pivot the MagVibe Pro base.

From stop to stop is 50°.

Page 10

QAS™ is a quick attach system designed to make it quick and easy to attach a Magvibe™

Pro, ProTilt©, or accessories to a ProFloat© or other manufacturers floats. The ability to

quickly Remove the pivot allows for stacking of floats for transportation, easier cleanup

and the ability to switch floats very fast. The Magvibe™ Pro, ProTilt© and ProFloat© have

a built-in QAS™ mounts. For other types of floats there are a variety of QAS™ adapters:

The QAS™-M is a four bolt adapter, the QAS™-W is a t-washer adapter for channel mount

floats. There is also a QAS™-F adapter that converts a standard pivot to have a quick

attach system so you can attach to a ProFloat©.

QAS™-M Adapter

QAS™-F Adapter

QAS™-W Adapter

Page 11

ProFloat© Attachment

Loosen both QAS™ knobs by turning them

counter-clockwise.

Make sure that the threaded

studs are retracted enough to

clear the QAS™ dovetail.

Page 12

Align the QAS™

receptacle with the

QAS™ dovetail and

slide over to engage.

Center the

MagVibe Pro™

over the QAS™

dovetail and

tighten both QAS™

knobs by turning

them clockwise.

Page 13

Four Fastener Float Attachment (QAS™-M)

Place QAS™-M adapter

onto four fastener

float and tighten (4)

3/8”-16 x ½” Low head

socket head cap

screws (supplied with

adapter). You will

need a 3/16” Allen tool

for this operation.

Loosen both QAS™

knobs by turning

them

counterclockwise.

Make sure that the

threaded studs are

retracted enough to

clear the dovetail.

Page 14

Align and slide the dovetail

over the QAS™ receptacle

located on the bottom of

the Magvibe™, Protilt© or

accessory.

Tighten both

QAS™ knobs

by turning

them

clockwise.

Page 15

QAS™-W

Slide (2) QAS™-W T-washers into the channel of the float. Place the dovetail mount onto

the float and tighten (4) M6 x 10mm socket head cap screws (supplied with adapter).

You will need a 4mm Allen tool for this operation.

Page 16

Loosen both QAS™ knobs

by turning them

counterclockwise. Make

sure that the threaded

studs are retracted

enough to clear the

dovetail.

Align and slide the

Magvibe™ Pro QAS™

receptacle over the

dovetail on the QAS™W adapter.

Tighten both

QAS™ knobs by

turning them

clockwise.

Page 17

Attaching the Pole Extension

Press and hold the pins in pole extension, then align and insert into Magvibe™ Pro pivot

handle. Push into bore and make sure that the pins snap through the two holes in the

pivot handle to engage.

Same procedure for an

outside pole extension; except you will

slide the pole extension over the pivot handle. The

Magvibe™ Pro pivot handle will accommodate Ø1-3/8”

internal and Ø1-3/4” external poles.

Page 18

Turning Magvibe™ Pro On / Off

There are two ways to turn the Magvibe™ Pro on and off. The first method is to use the

pre-programmed RF remote control (supplied) and the second is to depress the latching

on / off switch.

To use the RF remote control, slide the protective button

cover downward to expose the buttons. There are two

buttons: Button A turns the Magvibe™ Pro on and off,

and Button B is an auxiliary RF control for powered

accessories from Superior Innovations.

To turn the Magvibe™ Pro on, simply press

button A and the vibration will start. When you

want to turn it off, press button A again. The

range will depend on surroundings, however, it

should have a forty-foot line of sight range.

Page 19

If you lose your RF remote control you can

still turn the Magvibe™ Pro on and off by

pressing the latching on / off switch.

NOTE: This switch is very compact and was

designed to be used as a failsafe if the RF

remote was lost.

Adjusting the Pivot Tensioner

The pivot tension can be adjusted by the

user to add pressure to the gear-set which

creates friction to help hold the float at an

angle. The end result is a fatigue

reduction in the operator’s wrist and

hands.

To adjust; turn the

tensioner knob

clockwise. The

more it is turned

the more friction

is applied to the

gear-set. When

you want less of

an aid, turn the

tensioner knob

counterclockwise

to reduce friction.

Page 20

Battery Indicator

The battery indicator is positioned so the

operator can see the status of the battery when

the Magvibe™ Pro is in operation. There are 10

LED’s: 5 Green, 3 Amber and 2 Red. Every LED

represents approximately 10% of battery life.

For instance, if 6 LED’S are lit, you have

approximately 60% of battery life remaining.

Charging the Battery

The 18VDC Lithium

Polymer battery is built in

to the Magvibe™ Pro. It

has 3000mAh capacity

which should yield ~18hrs

on a single charge. To

charge it, plug the charger

(supplied) into a 120 VAC

wall outlet, and the 5mm

charging plug into the

charging port of the

Magvibe™ Pro. The

charging port is located

underneath the QAS™ base plate and must be removed from the float to charge.

Page 21

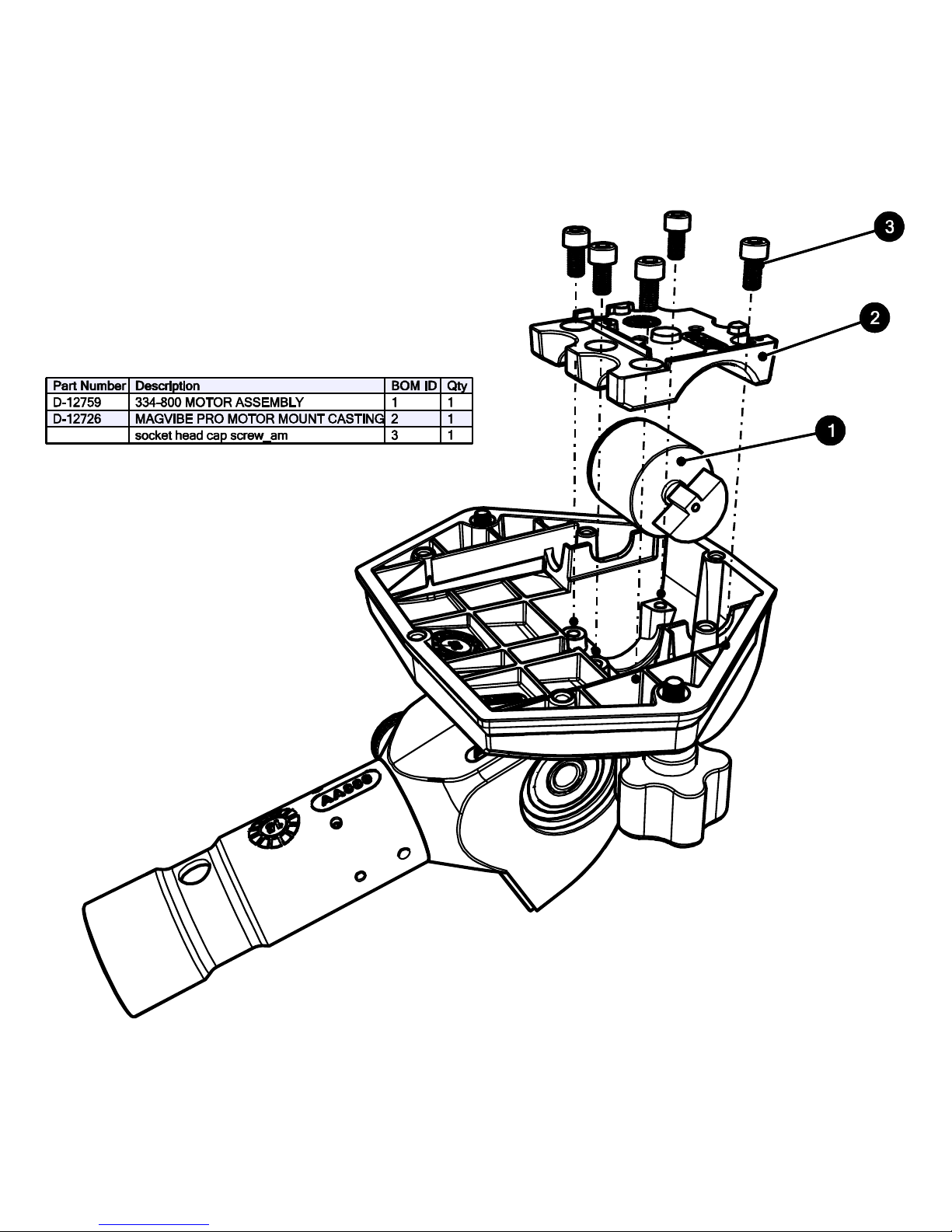

Programming a Replacement Remote

If you lost your remote and need to program a replacement, you can do it yourself. You

will need to order part number D-13535. Once you receive your replacement

remote, use a 4mm Allen key to remove (6) M5 socket

head cap screws on the bottom plate as shown. Lift

off the bottom plate to access the internal cavity of

the Magvibe™ Pro. The plate may resist a bit

due to the gasket sealer.

Once you are inside

of the cavity,

locate the RF /

Motor controller

board. The

button indicated

by the red arrow is

P1 and it will be used

for the programming of

channel 1. Press and hold P1 for at least

1 second; the LED on the board will light for 1 second, go

off for 1 second, and then light again.

Press and hold the A button on the remote control. If the code is

successfully received; the LED will blink, and you can release the A

button. If the code is unsuccessful; the LED will light for 10

seconds as it finishes the learning cycle.

Page 22

Once programming is successful, apply silicon sealer between the Magvibe™ Pro main

body and baseplate. Then reassemble in reverse order.

Maintenance Statement

The owner is responsible for the performance of all required maintenance, as described

in the Operator’s Manual.

Maintenance Schedule

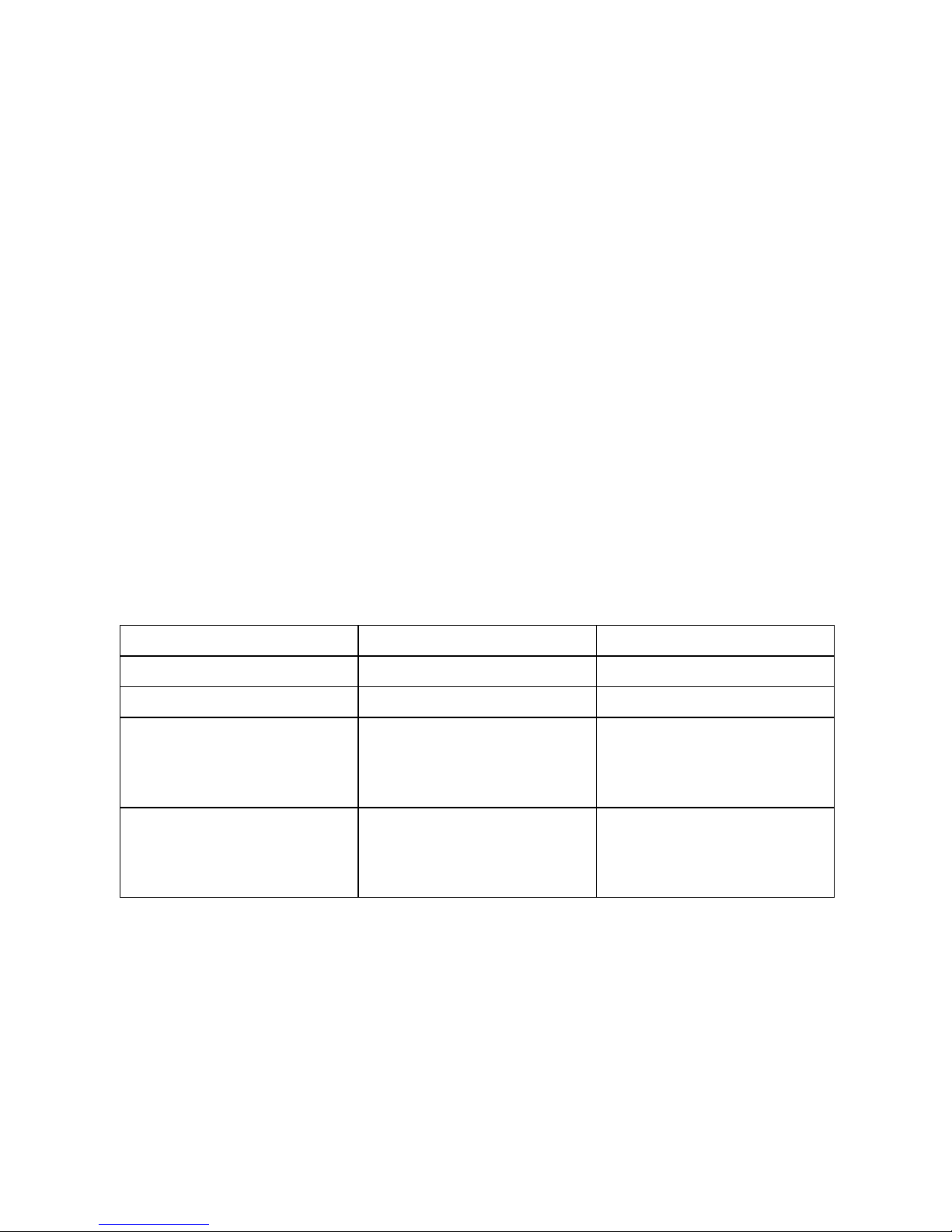

Daily Maintenance

Weekly Maintenance

Monthly Maintenance

Cleaning (external)

Cleaning (external)

Cleaning (external)

Inspection

Inspection

Inspection

loose fasteners,

cracks, leaks, or other

obvious damage

loose fasteners,

cracks, leaks, or other

obvious damage

loose fasteners,

cracks, leaks, or other

obvious damage

Grease gears (see

maintenance in

Operator’s Manual)

Page 23

Maintenance

Remove MagVibe™ Pro from the float and clean after every use. Make sure to pay

special attention to the QAS™ receptacle. If concrete sets-up around the QAS™ it may

become difficult to use. The MagVibe™ Pro has sensitive electronics located inside the

pivot and the main body; DO NOT USE A PRESSURE WASHER.

Tip: Before use apply spray lubricant to the MagVibe™ Pro except to the battery

indicator and the on/off switch. This will make it much easier to clean up after use.

Once a month add

grease to the gears by

injecting it into the

pivot joint as shown.

Page 24

RF Remote Battery Replacement

To replace the battery in the RF remote controller remove

(4) screws on the back side of the RF remote control cover

using a Philips screwdriver.

Remove the RF remote back cover plate.

Make note of the battery polarity.

Remove the RF controller

board.

Remove the 27A battery.

MAKE SURE THAT THE

POLARITY IS CORRECT.

Install a new 27A

battery.

Reinstall the RF controller

board.

Place the RF remote back cover plate making

sure to align the screw holes.

Reinstall the (4) screws and tighten using a Philips

screwdriver. You may need to reprogram

MagVibe Pro RF receiver if the code was lost

during the battery reinstall process. See Programming

a Lost Remote in this manual for instructions.

Page 25

Technical Data

Motor

24V DC, 0.6A

Battery

18V DC, 3000mAh Lithium

Polymer

Weight

Gears

Beveled, 3.17:1 ratio

Dimensional (L x W x H)

10.425” x 6.5” x 3.16”

(264.8mm x 165.1mm x

80.3mm)

Page 26

Page 27

Page 28

Page 29

Page 30

Loading...

Loading...