Superior DS-36RN, DS-36RP, DSR-HTK, ELB-45, DSR-EXT12 Installation And Operating Instructions Manual

...

Installation

And Operating

Instructions

For Superior's

Discovety Series

Sealed Combustion

WARNING: IMPROPER

INSTALLATION

ADJUSTMENT,

ALTERATION,

SERVICI

OR

MAINTENANCE

CAN

CAUSE

INJURY

OR

PROPERTY

DAMAGE. REFER

TO

THIS

MANUAL.

FOR

ASSISTANCE

OR

AODI.

TIONALINFORMATION

CONSULTAIIUALI-

FIE0

INSTALLER,

SERVICE

AGENCY

OR

THE

GAS

SUPPLIER.

FOR YOUR

SAFETY

Natural Gas Models

DS-36RN

Propane Models

DS-36RP

Decorative Gas

Appliance

And Termination

Components

DSR-EXT12

DSR-EXT6

DSR-HTK

EL

B-45

What to do if you smell gas:

11-

Do not try to light any appliance.

I

Do not touch any electrical

switches. Do not use any phone in

your building.

Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instruc-

tions.

If you cannot reach your gas sup-

plier, call the fire department.

Do notstoreoruse gasoline

orother

flammable vapors or liquids in the

vicinity of this or any other appliance.

PLACES

ARE

VENTED

DECORATIVE

GAS

APPLIANCES.

DO

NOT

BURN

WOOD

OR

Due to high temperatures, the appliance should be located out of

traffic and away from furniture or

drapes. Do not place clothing or

other materials on or near the appliance.

I

PLEASE

RETAIN

THlS MANUAL

FOR

FUTURE

REFERENCE.

I

f i r e - p a r t s . c o m

I

TABLE

0,F

CONTENTS

-

......................................

lntroduct~on page

2

.........................

General information page 2

Location and clearances

..................

page

3

Installation

.....................................

a

3

Framing dimensions

........................

page 3

......................

Appliance dimensions page

5

..................

Outside wall termination page 6

Gas connections

...........................

-...page

8

....................

High elevation derating page

8

....................

Finishing requirements page 10

......................................

Accessories page

11

...........................

Operation and care page 11

Maintenance age 11

Partslcomponents

..........................

page 12

Troubleshooting guide

.....................

page 13

Replacement parts list

.....................

page 14

.......................

Liahtino instructions paqe 16

. .

Warranty.

-I

I

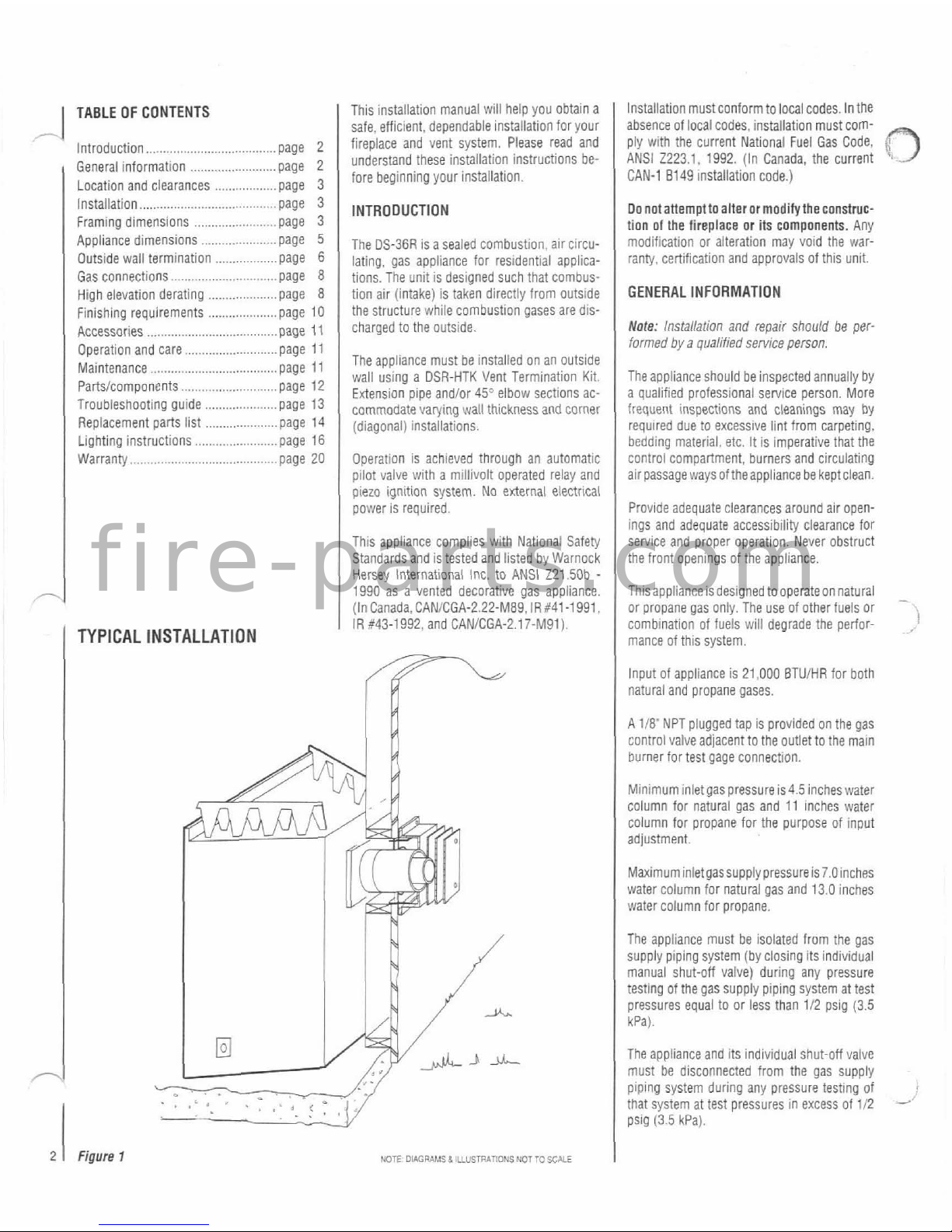

TYPICAL

INSTALLATION

This installation manual will help you obtain a

safe,

efficient,

dependable installation for your

fireplace and vent system. Please read and

understand these installation instructions before beginning your installation.

INTRODUCTION

The DS-36R is a sealed combustion,

alr circu-

lating, gas appliance for residential applica-

tions. The unit is designed such that combus-

tion air (intake) is taken directly from outside

the structure while combustion gases are discharged to the outside.

The appliance must be installed on an

outslde

wall using a DSR-HTK Vent Termination Kit.

Extension pipe

andlor 45Vlbow sections ac-

commodate varying wall thickness

and

corner

1

(diagonal) installations.

Operation is achieved through an automatic

pilot valve with a millivolt operated relay and

piezo ignition system. No external electrical

power is required.

This appliance complies with National Safety

Standards and is tested and listed by Warnock

Hersey International

lnc. to ANSI

Z21.50b

-

1990 as a vented decorative gas appliance.

(In

Canada,CAN/CGA-2.22-M89.lR:41-1991

IR 643-1992, and CANICGA-2.17-M91).

2

1

Figure

1

NOTE DiAcRAMs 8 UusrnArIoUs UoT

To

SCALE

Installation must conform to local codes. In the

absence of local codes, installation must comply with the current National Fuel Gas Code,

3

ANSI 2223.1. 1992. (In Canada, the current

CAN-1

8149 installation code.)

Donotanempttoalterormoditytheconstmc-

tion of the fireplace or its components. Any

modification or aiteration may void the warranty, certification and approvals of this unit.

GENERAL INFORMATION

Note:

Installation

and repair should be

per-

formed

by a qualified sennce person.

The appiiance should be inspected annually by

a oualified orofessionai service oerson. More

frequent

lnipections and cleanings may

by

required due to excessive lint from carpeting,

bedding

material. etc.

It

is imperative that the

control compartment, burners and circulating

air passage ways

oftheappllance be keptclean.

Provide adequate clearances around air openings and adequate accessibility clearance for

service and proper operation. Never obstruct

the front openings of the appliance.

Thlsappliance 1s deslgned tooperateon natural

-

or propane gas only The use of other fuels or

comb~nat~on of fuels

will

degrade the perfor-

.

mance of thls system

Input of appliance is 21,000

BTUiHR for both

natural and propane gases.

A 118' NPT plugged tap is provided on the gas

control valveadjacent to the outlet to the main

burner for test gage connection.

Mtn~mum inlet gas pressure is4.5 incheswater

column for natural gas and 11

Inches water

column for propane for the purpose of input

adjustment.

Maximum inletgassupply pressure

is7.Oinches

water column for natural gas and 13.0 inches

water column for propane.

The appliance must be isolated from the gas

supply

plping system (by closing its individual

manual shut-off valve) during any pressure

testing of the gas supply

piplng system at test

pressures equal to or less than 112 psig (3.5

kPa).

The appliance and its individual shut-off vaive

must be disconnected from the gas supply

piping system during any pressure testing of

that system at test pressures in excess of 112

-'

psig

(3.5

kPa).

f i r e - p a r t s . c o m

Do not use this appliance if any part has been

-

under water, Immediately call a qualified service technician to inspect the appliance and to

replace any pans of the control system that

have been under water.

ASSEMBLY STEPS

The typical sequence of installation foilows.

however,each installation isunique resultingin

variations to those described.

This appliance must be vented through an

1.

Construct appliance framing

outside wall and must not be connected to a

If the appliance is to be elevated above floor

level, a soiid continuous platform must be

constructed.

chimney or flue

sewing a soiid fuel burning

appliance.

LOCATION AND CLEARANCES

The header may rest on the top metal spacers.

but must not be notched to fit around them.

2.

Routegas supply line toappliance location.

3.

Position appliance and install the vent termination.

On

flatwall installations. two (2) studs (on

16'

centers. as illustrated) should be provided at

the rear structure to accommodate installation

of the vent termination.

In selecting the location, the esthetic and

func-

4.

Make connection

gas Supply and install

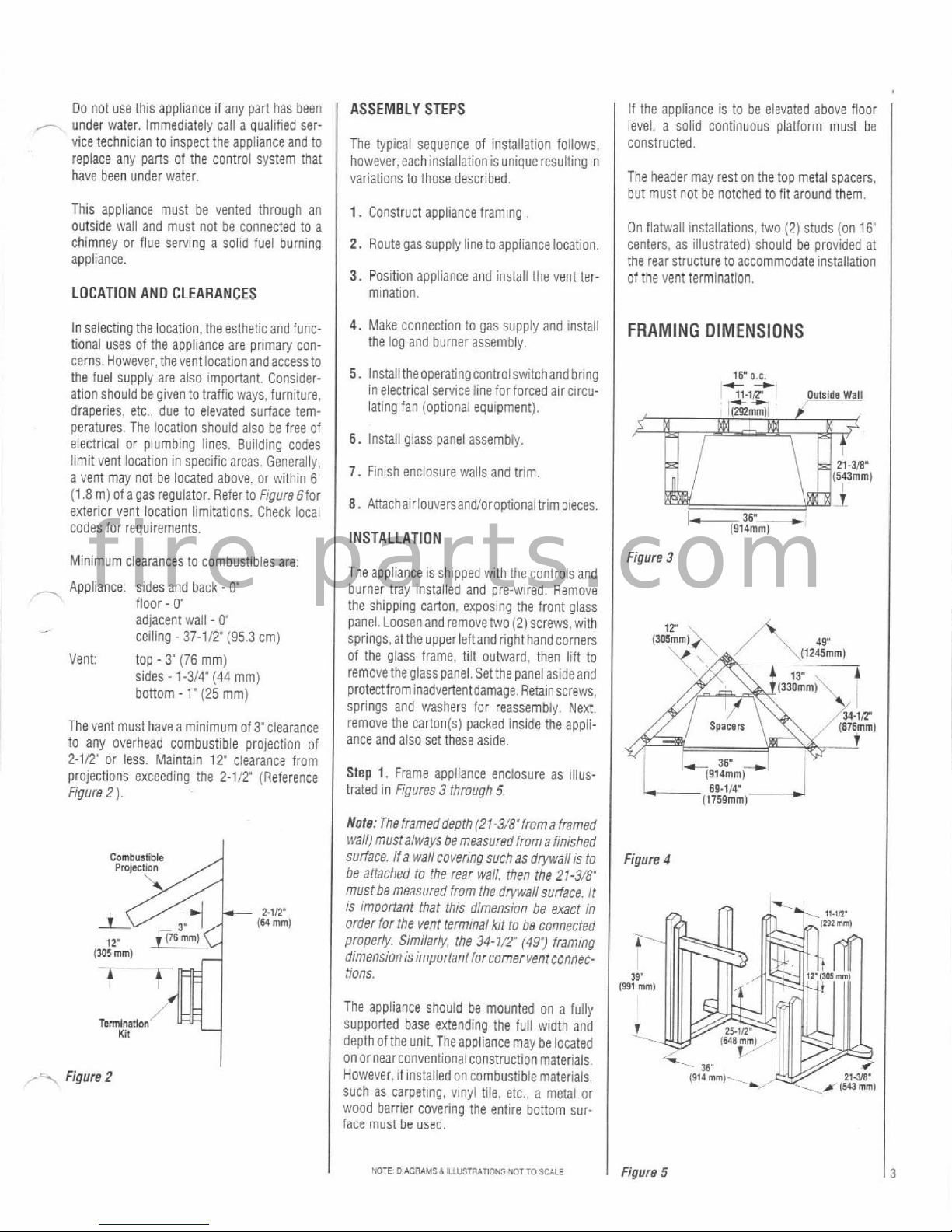

FRAMING DIMENSIONS

tional uses of the aonliance are orimaw con-

the log and burner assembly.

,

.

,

~~

cerns. However, thevent location and access to

the fuel supply are also important. Consideration should be given to

traffic ways, furniture.

draperies, etc., due to elevated surface temperatures. The location should also be free of

electrical or plumbing lines. Building codes

limit vent location in specific areas. Generally,

a Vent may not be located above. or within

6'

(1.8 m) of a gas regulator. Refer to

FigureGfor

exterior vent location limitations. Check local

codes for requirements.

Minimum clearances lo combustibles are:

,-

Appliance sides and back - 0"

floor - 0"

adjacent wall - 0'

celiing - 37-112'

(95

3

cm)

Vent

top

-

3'

(76

mm)

sides

-

1-314"

(44

mm)

bottom

-

1'

(25

mm)

The vent must have a minimum

Of3"Clearance

to any overhead combustible projection of

2-112" or less. Maintain

12'

clearance from

projections exceeding the

2-112" (Reference

Figure 2

)

.

+-.

Figure

2

5.

Install theoperating controlswitchand bring

in electrical service line for forced air circulating fan (optional equipment).

6.

install giass panel assembly.

7.

Finish enclosure walls and trim.

8.

Anachairlouversandioroptionaltrimpieces.

INSTALLATION

The appliance is shlpped with the controis and

burner tray instailed and pre-wired. Remove

the shipping carton. exposing the front glass

panel. Loosen and remove two (2) screws. with

springs,atthe

upperieftandrighthandcorners

of the glass frame, tiit outward. then lilt to

removethe glass panel.

Setthe panel asideand

protectfrom inadvertentdamage. Retainscrews.

springs and washers for

reassembly. Next.

remove the

carton(s) packed inside the appii-

ance and also set these aside.

Step

1.

Frame appliance enclosure as illus-

trated in

Figures 3 through

5,

Note: The frameddeprh (21-3i8"froma framed

wall) mustalways be measured from a finished

surface. If a wall covering such as

drywall is to

be

attached to the rear wall, then the 21-3/8~

must be measured from the drywall surface. It

is important that this dimension be exact in

order far the vent

term~nal kit to be connected

properly.

Similarly. the 34-71.?

(491

framing

dimension is important forcorner

ventconnec-

t10ns.

The appliance should be mounted on a fully

supported base extending the full width and

depth

ofthe unit. Theappliance may be located

on or nearconventional construction materials.

However, if installed on combustible materials,

Such as carpeting, vinyl tile, etc.. a metal or

wood barrier covering the entire bottom sur-

face

must

be

used.

15.

O.C.

l%.,i?

m*

+

Outside

Wall

Figure

3

Figure

4

I

NOTE

OWGRAMSb

ILIU5TR*mONS

WTTO

SCALE

I

Figure

5

f i r e - p a r t s . c o m

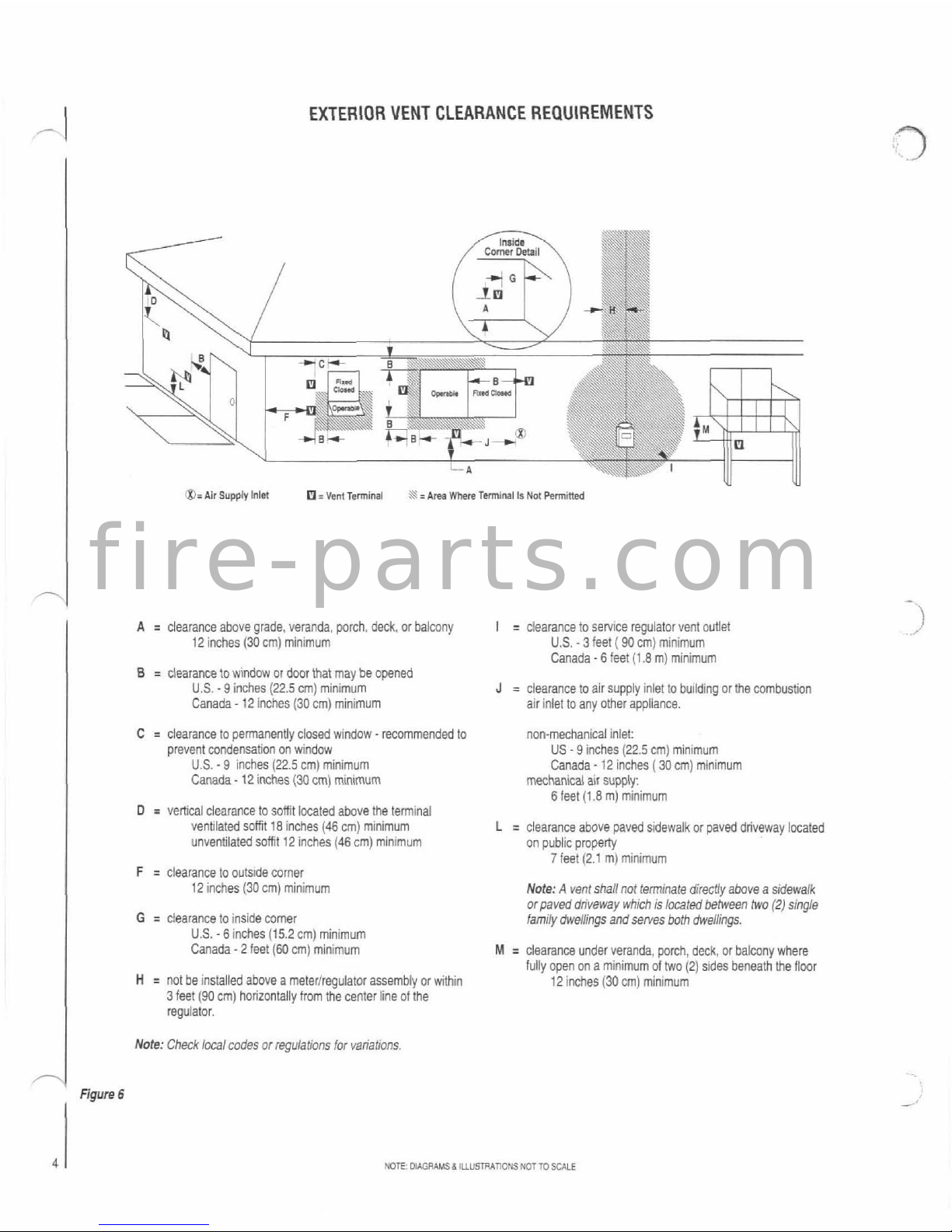

EXTERIOR VENT CLEARANCE REQUIREMENTS

a=

Air

Supply Inlet

Cl=

Vent

Terminal

A

r

Area

W)ma

Tminal Is

Not

Pennmed

I

A = clearance above grade, veranda, porch, deck, or balcony

12 inches (30 cm) minimum

B

=

clearance to window or door that may be opened

U.S.

-

9 inches

(22.5

cm) minimum

Canada

-

12 inches

(30

cm) minimum

C

=

clearance to permanently closed window - recommended to

prevent condensation on window

U.S.

-

9

inches (22.5 cm) minimum

Canada

-

12

inches (30 cm) m!nlmum

D

=

vertical ciearance to soffit located above the terminal

verlaled sorl

18

rcnes 146

CT)

ntnlmm

~nvent ate0

SOY

'2

ncpes

(46 cn, T n

~1-n

F

=

clearance to outside comer

12 inches (30

cm) minimum

G

=

clearance to inside comer

U.S.

-

6

inches (15.2 cm) minimum

Canada

-

2 feet

(60

cm) minimum

H

=

not be installed above a metedregulator assembly or within

3 feet (90 cm) horizontally from the center line of the

regulator.

I

Note:

Check

local codes or regulations for variations.

I

=

clearance to service regulator vent outlet

U.S.

-

3

feet ( 90 cm) minimum

Canada

-

6

feet (1.8 m) minimum

J

=

clearance to air supply inlet to building or Vle combustion

air inlet to any other appliance.

non-mechanical inlet:

US

-

9

inches (22.5 cm) minimum

Canada - 12 inches ( 30 cm) minimum

mechanical air supply:

6

feet (1.8 m) minimum

L

=

clearance above paved sidewalk or paved driveway located

on public

propeq

7

feet (2.1 m) minimum

Note:

A

vent shall

not

terminate directly above a sidewalk

or paved dnveway which is located between two

(2)

single

tami/y dwellings andserves

both

dwellings.

M = clearance under veranda, parch, deck, or balcony where

fully open on a minimum of two (2) s~des beneath the floor

12 inches (30

cm) minimum

-1

Figure

6

NOE.

OIAGRkLISd

IUUSTUATIOIIS

NOTTO

SCALE

f i r e - p a r t s . c o m

-

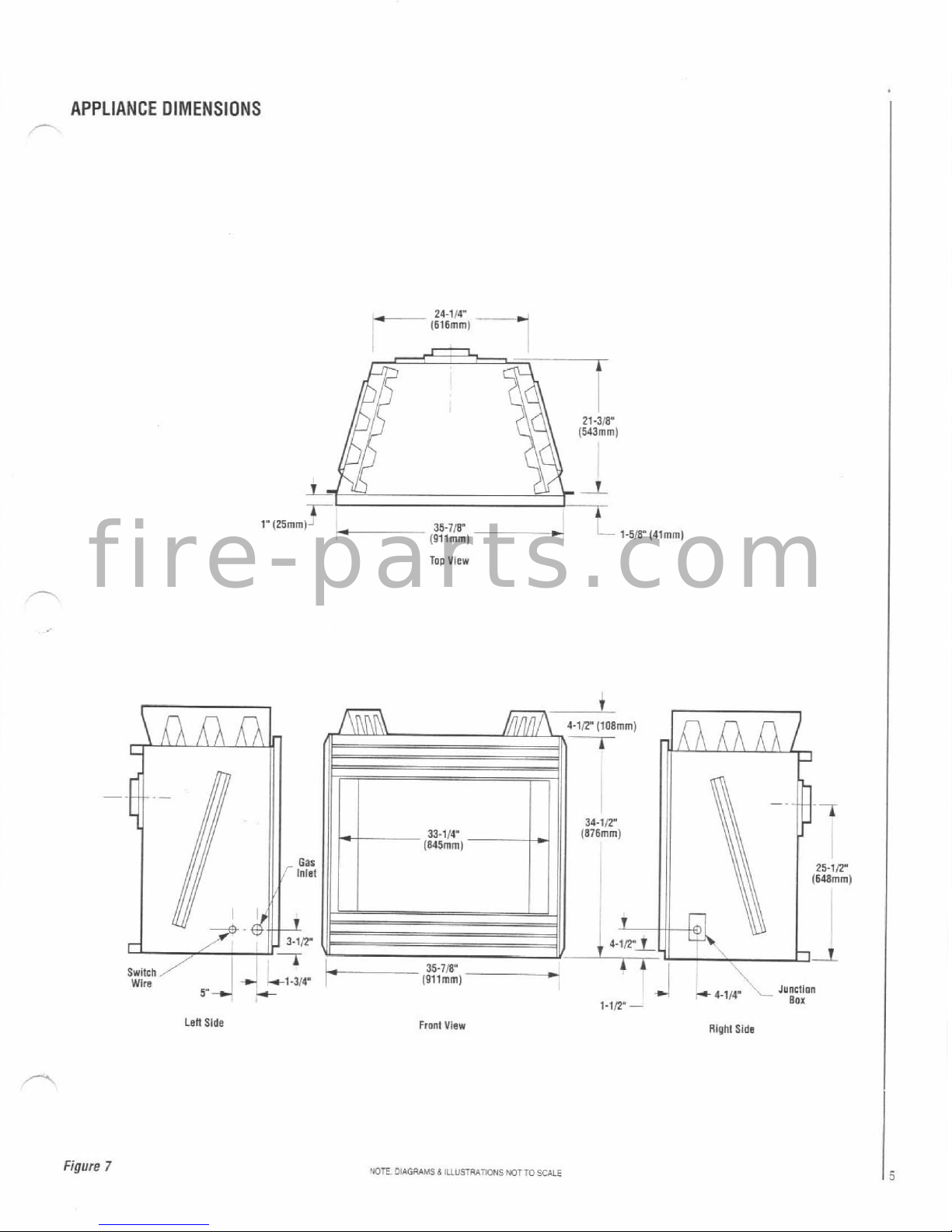

APPLIANCE DIMENSIONS

Too

View

,

4.1,4'

,--

Junction

1-l,Y

-

BOX

Len

Side

FmnI

View

Rlphl

Side

Figure

7

NOTE

OlAGRAMS

&

ILLUSBATIONS

NOTTO

SCALE

f i r e - p a r t s . c o m

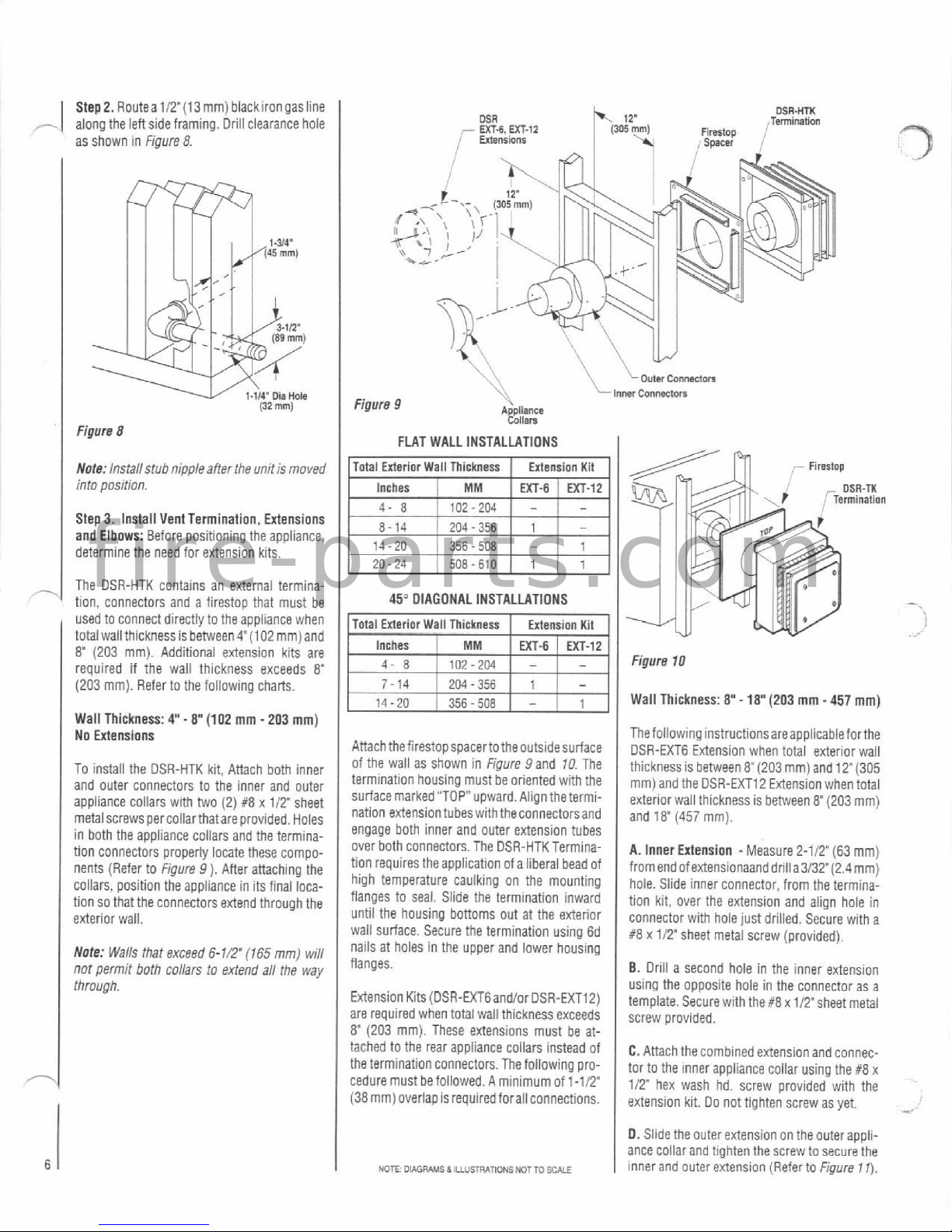

Step2. Routea112'(13mm) blackirongasline

-

along the leftsideframing. Driii clearance hole

as shown in

Figure

8.

MR

OSR-HTK

Termlnahon

-

UT4.

UT-12

Firertop

I

,'

Enensloor

r

Spacer

(32

mm)

Figure

8

Note:

Installstub nipple affer the unit is moved

into position.

Step3. Install Vent Termination, Extensions

and Elbows: Before positioning the appliance,

determine the need for extension kits.

The DSR-HTK contains an external termination, connectors and a

firestop that must be

-sed to clnnec: a~recrly :o 1-15 applarc? Nhen

I

lural wall thlcrtness s oerween @ 102

nrr,

ano

8'

(203 mm). Additional extension kits are

required if the wall thickness exceeds

8"

(203 mm). Refer to the following charts.

Walt Thickness:

4'-

8'

(102

mm

-

203

mm)

No Extensions

To install the DSR-HTK kit, Attach both inner

and outer connectors to the inner and outer

appliance collars with two

(2)

#8

x

112'

sheet

metal screws per collarthatare provided. Holes

in both the appliance collars and the termination connectors properly

locate these compo-

nents (Refer to

Figure 9 ).

After attaching the

collars, position the appliance in its final loca-

tion so that the connectors extend through the

exterior wall.

Note:

Walls that exceed

6-I/.

(765

mm) will

not permit

both

collars to extend aN the way

through.

\\

Louts

ConMdor.

Figure

9

'+\

lmr

~onnecmn

A

pllance

!011am

FLAT WALL INSTALLATIONS

Total Exterior Wall Thickness Extension Kit

Inches

EXT-6

EXT-12

204

-

356

14-20

356-

508

-

20-24 508 - 610

45"

DIAGONAL INSTALLATIONS

1

Inches

1

MM

I

MT-fi

EXT-12

4

8

1

in?-7M

I

-

I

-

Attach thefirestopspacerto theoutsidesurface

of the wail as shown in

Figure

9

and 10 The

termination housing must

be

oriented with the

surfacemarked "TOP" upward. Align

thetermi-

nation

extensiontubeswiththeconnectorsand

engage both inner and outer extension tubes

over both connectors. The

DSR-HTKTermination requires the application of a liberal bead of

high temperature caulking on the mounting

flanges to seal. Slide the termination inward

until the housing bottoms out at the exterior

wall surface. Secure the termination using 6d

nails at holes in the upper and lower housing

flanges.

Extension Kits

(DSR-EXTGandlor DSR-EXT12)

are required when total wall thickness exceeds

8"

(203 mm). These extensions must be at-

Figure

10

Wall Thickness:

8"

-

18"

(203

mm

-

457

mm)

1

Thefoliowing

instructionsareapplicableforthe

DSR-EXT6 Extension when total exterior wall

tached to the rear appliance collars instead of

the termination connectors. The following procedure must befollowed. A minimumof

1-11?

(38 mm) overlap is requiredforall connections.

Ihll:klless s o:?Neen 8'(203 mm! ano

12'(305

mm an0 !he DSZ-EX72 Extels on wnen tnra

.

exterlorwall thlcknessis between 8"(203 mm)

and

18'

(457

mm).

A.

Inner Extension -Measure 2-112" (63 rnm)

from endof

extensionaanddriIia3/32"(2.4mm)

hole. Slide inner connector, from the termination kit, over the extension and align hole in

connector with hole just drilled. Secure with a

R8 x 112' sheet metal screw (provided).

B.

Drill a second hole in the inner extension

using the opposite hole in the connector as a

template. Secure with

the#8xtITsheet metal

screw provided.

C.

Attach the combined extensionand connec-

tor to the inner appliance collar using the

#8

x

112' hex wash hd. screw provided with the

extension kit. Do not tighten screw as yet.

*

D. Slide the outer extension on the outerappliance collar and tighten the screw to secure the

inner and outer extension (Referta

Figure

11).

f i r e - p a r t s . c o m

Loading...

Loading...