Superior DRL3042TEN, DRL3054TEN, DRL3054TEP, DRL3042TEP Installation And Operation Instructions Manual

Installation and Operation Instructions

PFS

USC

P900079-02

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

P/N 900079-02 Rev. B 05/2015

Ce manuel est disponible en francais, simplement

en faire la demande. Numéro de la pièce 900079-03.

®

Models

DRL3042TEN DRL3042TEP DRL3054TEN DRL3054TEP

Report No. F14-108

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Installateur : Laissez cette notice avec l’appareil.

Consommateur : Conservez cette notice pour

consultation ultérieure.

A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this appliance

and shall be installed for the protection of children

and other at-risk individuals.

This appliance may be installed in an aftermarket permanently located, manufactured home (USA only) or mobile

home, where not prohibited by local codes. This appliance is only for use with the type of gas indicated on the

rating plate. This appliance is not convertible for use with other gases, unless a certified kit is used.

Cet appareil peut installé dans une maison préfabriquée (mobile) déjà installée à demeure, si les réglements

locaux le permettent. Ce appareil doit être utilisé uniquement avec le type de gaz indiqué sure la plaque

signalétique. Cet appareil ne peut être converti à d’autres gaz, sauf si une trousse de conversion est utilsée.

L’écran pare-étincelles fourni avec ce foyer réduit le

risque de brûlure en cas de contact accidentel avec

la vitre chaude et doit être installé pour la protection

Des enfants et Des personnes à risques.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result

in serious injury, death, or property damage.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

AVERTISSEMENT:

RISQUED’INDENDIE OU D’EXPLOSION

Le non-respect Des avertissements de sécurité

pourrait d’entraîner des blessures graves, la mort

ou des dommages matériels.

— Ne pas entreposer ni utilizer d’essence ni d’autres

vapeurs ou liquides inflammables dans le voisinage de cet appareil ou de tout autre appareil.

— QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucan interrupteur. Ne pas vous

servir des téléphones se trouvant dans le bâtiment où vous trouvez.

• Sortez immédiatement de bâtiment.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions du

fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le service des incindies.

— L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié

ou par le fournisseur de gaz.

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

A barrier designed to reduce the risk of burns from the hot viewing glass

is provided with this appliance and shall be installed for the protection of

children and other at-risk individuals.

See attached color flyer for proper color representation

General Information

900079-02 05/2015

DANGER

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

DANGER

VITRE CHAUDE

RISQUE DE BRÛLURES.

NE TOUCHEZ PAS UNE VITRE

NON REFROIDIE.

NE LAISSEZ JAMAIS UN ENFANT

DE TOUCHER LA VITRE.

L’écran pare-étincelles fourni avec ce foyer réduit le risque de brûlure en

cas de contact accidentel avec la vitre chaude et doit être installé pour la

protection Des enfants et Des personnes à risques.

Voir ci-joint tract pour une bonne représentation de la couleur

PELIGRO

EL VIDRIO CALIENTE

CAUSARÁ QUEMADURAS.

USTED DEBE NUNCA

TOCAR EL VIDRIO CALIENTE.

LOS NIÑOS DEBEN NUNCA

TOCAR EL VIDRIO.

Una barrera diseñada para reducir el riesgo de quemaduras desde la mirilla (vidrio) caliente es proveida con este aparato y deberá instalarse para

la protección de los niños y otros individuos en riesgo.

2

Vea el volante adjunto para la representación de color adecuado

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

General Information

900079-02 05/2015

Safety and Your

Fireplace

All parts of your

IHP fireplace get

EXTREMELY HOT!

To prevent severe

burns and injuries,

install a screen or

physical barrier to

prevent direct contact

with the glass.

Follow the safety instructions

below and be sure everyone in

your household understands this

burn hazard:

• The surfaces on your fireplace get

EXTREMELY HOT!

• The glass on the front of the

fireplace reaches EXTREMELY

HIGH temperatures and can cause

severe burns if touched.

• Keep children away from an

operating fireplace. Closely

supervise children in any room

where a fireplace is operating to

prevent contact with glass.

• Keep clothing, furniture,

gasoline, and other flammable

liquids away from the fireplace.

• Even after the gas is turned

off, fireplace surfaces remain

extremely hot.

Be sure to attach the enclosed

Safety-in-Operation Warnings where

you turn on your fireplace, to help

remind everyone of the dangers

associated with high temperatures

(Page 45).

Read Important Safety Information

(Page 5)

3

EXTRÊMEMENT CHAUDES !

La sécurité et

votre foyer

Toutes les parties de votre

foyer IHP deviennent

Afin d'éviter de vous

brûler gravement ou de

vous blesser, installez

une grille ou une barrière

physique pour empêcher

tout contact direct avec la vitre.

Suivez les instructions de sécurité

ci-dessous et veillez à ce que tous les

membres de votre famille soient conscients

du danger de brûlure encouru :

• Les surfaces de votre foyer deviennent

EXTRÊMEMENT CHAUDES !

• La vitre située à l'avant du

foyer atteint des températures

EXTRÊMEMENT ÉLEVÉES et peut

causer de graves blessures en

cas de contact.

• Tenez les enfants à l'écart

du foyer lorsqu'il fonctionne.

Surveillez attentivement les

enfants dans les pièces où un

foyer est utilisé afin d'éviter qu'ils

ne soient en contact avec la vitre.

• Tenez tous les vêtements, les

meubles, l'essence et tout autre liquide

inflammable à l'écart du foyer.

• Même après fermeture du gaz,

les surfaces du foyer restent

extrêmement chaudes.

Veillez à coller les Étiquettes de mise

en garde relatives à la sécurité

d'utilisation à l'endroit où vous

utilisez le foyer, pour rappeler à tous

les utilisateurs les dangers liés aux

températures élevées (Page 45).

Lisez L’information de sûreté

importante (Page 5).

[FRENCH][ENGLISH]

Seguridad y su

chimenea

¡Todas las partes de la

chimenea IHP se ponen

MUY CALIENTES!

Instale una malla o barrera física para evitar

el contacto directo con el vidrio y prevenir

las quemaduras y lesiones graves.

Siga las instrucciones de seguridad

a continuación y asegúrese de que

todos en su hogar sepan acerca de

este peligro de quemadura:

• ¡Las superficies de la chimenea

se ponen MUY CALIENTES!

• El vidrio delante de la

chimenea alcanza temperaturas

EXTREMADAMENTE ALTAS

y puede causar quemaduras

graves si se toca.

• Mantenga a los niños alejados de

la chimenea en funcionamiento.

Supervise en forma cercana a los

niños en cualquier cuarto donde haya

una chimenea funcionando para

impedir el contacto con el vidrio.

• Mantenga la ropa, mobiliario,

gasolina y otros líquidos

inflamables alejados de la

chimenea.

• Aún después de haber apagado

el gas, las superficies de

la chimenea permanecen

extremadamente calientes.

Asegúrese de colocar las Etiquetas

de advertencia de seguridad

de operación en el lugar donde

enciende la chimenea, para que todos

recuerden los peligros asociados con

las altas temperaturas (Página 45).

Lea Información importante de

seguridad (Página 5).

[SPANISH]

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

THANK YOU FOR YOUR PURCHASE. WE APPRECIATE YOUR BUSINESS!

Please carefully read and follow all instructions in this manual. Pay special attention to all warnings and safety

information. Following these safety, care, and operation instructions will help ensure many years of dependable and

enjoyable service from your fireplace.

General Information

900079-02 05/2015

Look for the EnerGuide

Gas Fireplace Energy

Efficiency Rating in this manual.

Based on CSA P.4.1-02

Please read and understand these instructions before installing,

operating, or servicing this product.

General Information

Important Safety Information ............................................................5

Fireplace Installation, Operation, and Maintenance Notices ............... 6

Packaging .......................................................................................... 8

Introduction ....................................................................................... 8

Installation

Requirements for the Commonwealth of Massachusetts ................11

Cold Climate Insulation .................................................................... 11

Manufactured Home Requirements ................................................. 12

Location ...........................................................................................12

Vent Termination Clearances ...........................................................13

Minimum Clearances to Combustibles ............................................15

Wall Finishes / Surrounds / Mantels ................................................16

Installation Preparation ....................................................................16

Installation Sequence ......................................................................17

Construct the Fireplace Framing ...................................................... 17

Route the Gas Supply Line into the Fireplace ..................................19

Install the Vent System ....................................................................24

Complete the Field Wiring ................................................................35

Connect the Gas Line ....................................................................... 37

Verify Proper Fireplace Operation ....................................................38

We recommend that our

gas hearth products be

installed and serviced by

professionals who are

certied in the U.S. by the

National Fireplace Institute®

(NFI) as NFI Gas Specialists.

If necessary, Install the Firebox Floors.............................................38

If necessary, Install the Firebox Liners.............................................38

Install the Glass Media ....................................................................39

Install the Baffle ............................................................................... 39

Install the Glass Door ......................................................................39

Adjust the Air Shutter to Ensure Proper Flame Appearance ............. 39

Install the Finishing Materials .......................................................... 41

Install the Wall Switch Receiver .......................................................44

Initialize the Remote Control System ............................................... 44

Attach the Safety-in-Operation Warnings.........................................45

Installation Accessories ................................................................... 46

Gas Conversion Kits ........................................................................48

Operation

Maintenance .................................................................................... 59

Optional Accessory Components ..................................................... 62

Lighting Instructions .......................................................................63

Troubleshooting ...............................................................................65

Replacement Parts ..........................................................................66

Warranty ..........................................................................................69

4

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

General Information

900079-02 05/2015

GENERAL INFORMATION

IMPORTANT SAFETY INFORMATION L’information de sûreté importante Información importante de seguridad

WARNING AVERTISSEMENT ADVERTENCIA

Do not operate appliance with the

glass front removed, cracked or

broken.

Do not use this fireplace if any part has

been under water. Immediately call a

qualified service technician to inspect the

fireplace and to replace any part of the

control system and any gas control which

has been under water.

Due to high temperatures, the fireplace

should be located out of traffic and away

from furniture and draperies.

Children and adults should be alerted to

the hazards of high surface temperature

and should stay away to avoid burns or

clothing ignition.

Clothing or other flammable material

should not be placed on or near the

fireplace.

Young children should be carefully

supervised when they are in the same

room as the fireplace. Toddlers, young

children, and others may be susceptible

to accidental contact burns. A physical

barrier is recommended if there are

at-risk individuals in the house. To

restrict access to a fireplace or stove,

install an adjustable safety gate to keep

toddlers, young children, and other atrisk individuals out of the room and away

from hot surfaces.

Any safety screen or guard removed for

servicing a fireplace must be replaced

prior to operating the fireplace.

Installation and repair should be done

by a qualified service person. The

fireplace should be inspected before use

and at least annually by a professional

service person. More frequent cleaning

may be required due to excessive lint

from carpeting, bedding material, et

cetera. It is imperative that control

compartments, burners, and circulating

air passageways of the fireplace be kept

clean (Maintenance on Page 59).

[English] [French] [Spanish]

Ne pas utiliser l’appareil si le

panneau frontal en verre n’est pas

en place, est craqué ou brisé.

Ne pas utiliser cet appareil s’il a été

plongé, même partiellement, dans l’eau.

Appeler un technicien qualifié pour

inspecter l’appareil et remplacer toute

partie du système de commande et toute

commande qui a été plongée dans l’eau.

En raison des températures élevées,

l’appareil devrait être installé dans un

endroit où il y a peu de circulation et loin

du mobilier et des tentures.

Les enfants et les adultes devraient être

informés des dangers que posent les

températures de surface élevées et se

tenir à distance afin d’éviter des brûlures

ou que leurs vêtements ne s’enflamment.

On ne devrait pas placer de vêtements

ni d’autres matières inflammables sur

l’appareil ni à proximité.

Les jeunes enfants devraient être

surveillés étroitement lorsqu’ils se

trouvent dans la même pièce que

l’appareil. Les tout petits, les jeunes

enfants ou les adultes peuvent subir des

brûlures s’ils viennent en contact avec

la surface chaude. Il est recommandé

d’installer une barrière physique si des

personnes à risques habitent la maison.

Pour empêcher l’accès à un foyer ou à un

poêle, installez une barrière de sécurité

; cette mesure empêchera les tout petits,

les jeunes enfants et toute autre personne

à risque d’avoir accès à la pièce et aux

surfaces chaudes.

Tout écran ou protecteur retiré pour

permettre l’entretien de l’appareil doit

être remis en place avant de mettre

l’appareil en marche.

L’installation et la réparation devrait

être confiées à un technicien qualifié.

L’appareil devrait faire l’objet

d’une inspection par un technicien

professionnel avant d’être utilisé et au

moins une fois l’an par la suite. Des

nettoyages plus fréquents peuvent être

nécessaires si les tapis, la literie, et

cetera produisent une quantité importante

de poussière. Il est essentiel que les

compartiments abritant les commandes,

les brûleurs et les conduits de circulation

d’air de l’appareil soient tenus propres

(Page 59).

No opere el artefacto con el frente

de vidrio quitado, agrietado o roto.

No use este artefacto si alguna de sus

partes ha estado bajo agua. Llame

de inmediato a un técnico de servicio

calificado para que inspeccione el

artefacto y reemplace cualquier parte del

sistema de control y cualquier control de

gas que haya estado bajo agua.

Debido a las altas temperaturas, el

artefacto debe situarse fuera de las

áreas de tráfico y lejos del mobiliario y

cortinas.

Se debe alertar a los niños y adultos

sobre los peligros de las altas

temperaturas en la superficie y que

se mantengan alejados para evitar

quemaduras o ignición de la ropa.

No debe colocarse ropa u otros

materiales inflamables sobre y cerca del

artefacto.

Se debe supervisar de cerca a los niños

cuando estén en el mismo cuarto que

el artefacto. Los niños pequeños, los

jóvenes y otras personas pueden ser

susceptibles a quemaduras por contacto

accidental. Se recomienda instalar

una barrera física si hay personas en

riesgo en la casa. Para restringir el

acceso a una chimenea o estufa, instale

una puerta de seguridad ajustable

para mantener a los niños pequeños,

jóvenes y otras personas en riesgo fuera

del cuarto y lejos de las superficies

calientes.

Cualquier malla o resguardo de seguridad

quitado para dar servicio a un artefacto,

debe reinstalarse antes de operar

el artefacto.

Una persona de servicio competente

debe realizar la instalación y reparación.

Una persona de servicio profesional

debe inspeccionar el artefacto antes

de usar al menos una vez por año. Se

puede requerir limpieza más frecuente

debido a la pelusa excesiva del

alfombrado, del material de cobijas,

etc. Es imprescindible mantener limpios

los compartimientos de control, los

quemadores y los pasajes de circulación

del aire del artefacto (Página 59).

5

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

FIREPLACE INSTALLATION, OPERATION, AND MAINTENANCE NOTICES

DO NOT ATTEMPT TO ALTER OR MODIFY THE CONSTRUCTION OF THE APPLIANCE OR ITS COMPONENTS. ANY

MODIFICATION OR ALTERATION MAY VOID THE WARRANTY, CERTIFICATION, AND LISTINGS OF THIS UNIT.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or

property damage. Refer to this manual. For assistance or additional information consult a

qualified installer, service agency or the gas supplier.

AVERTISSEMENT

Une installation, un réglage,une modification, une réparation ou un entretien mal effectué

peut causer des dommages matériels ou des blessures. Voir la notice de l’utilisateur qui

accompagne l’appareil. Pour de l’aide ou des renseignements supplémentaires, consultez

un installateur, un technicien agréé ou le fournisseur de gaz.

WARNING

General Information

900079-02 05/2015

Failure to comply with these installation instructions will result in an improperly installed

and operating appliance, voiding its warranty. Any change to this appliance and/or its

operating controls is dangerous.

6

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

Clothing or other flammable material should not be placed on or near the appliance.

On ne devrait pas placer de vêtements ni d’autres matières inflammables sur l’appareil ni à proximité.

Improper installation or use of this appliance can cause serious injury or death from fire, burns,

explosion or carbon monoxide poisoning.

Hot while in operation. Do not touch. Severe Burns may result. Keep children, clothing

furniture, gasoline and other liquids having flammable vapors away.

General Information

900079-02 05/2015

WARNING

AVERTISSEMENT

WARNING

CAUTION

ATTENTION

L’appareil est chaud lorsqu’il fonctionne. Ne pas toucher l’appareil. Risque de brûlures

graves. Surveiller les enfants. Garder les vêtements, les meubles, l’essence ou autres

liquides produisant des vapeur inflammables loin de l’appareil.

NOTE:

• If the barrier becomes damaged, the barrier shall be replaced with the manufacturer’s barrier for this

appliance.

• For use with barrier(s) Part No(s). J7427 (42” Models) and J7426 (54” Models).

• These fireplaces are designed as supplemental heaters, and are not to be used as the primary heat source when

installed in a dwelling.

• Provide adequate clearances around air openings and adequate accessibility clearance for service and proper

operation. Never obstruct the front or back openings of the fireplace.

• These fireplaces are designed to operate on natural or propane gas only. The use of other fuels or combination of

fuels will degrade the performance of this system and may be dangerous.

• These fireplaces must not be connected to a chimney or flue serving a separate solid fuel burning fireplace.

• These fireplaces are vented gas appliances. Do not burn wood or other material in these appliances.

• Only trim kit(s) supplied by the manufacturer shall be used in the installation of this fireplace.

Remarqué :

• Seules les trousses de garniture fournies par le fabricant doivent être utilisées pour l’installation de cet appareil.

7

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

INSTALLATION

PACKAGING

All models include

The assembled vented gas fireplace heater is packaged with:

• Literature Kit (Installation and Operation Instructions (this manual), and Safety-In-Operation Warning Labels)

• Vent restrictor assembly

• (1) Non-combustible fiber board

• Handheld remote control (transmitter) with (3) AAA batteries

• Remote control receiver (wall switch) assembly with (4) AA batteries

• Glass media kit, black

• Barrier

Optional accessories

• Surround kit

• Gas conversion kit

INTRODUCTION

These vented gas fireplace heaters are direct-vent (top vent only), sealed combustion, air-circulating gas fireplaces

designed for residential applications. Direct-vent appliances operate with the combustion chamber isolated from the

indoor environment. All air for combustion is brought in from the outside, and exhaust gases are vented through the

same direct-vent, coaxial (intake/exhaust) vent system.

These appliances are designed to operate on natural or propane gas only. The use of other fuels or fuel combinations

will degrade the performance of this system, may be dangerous, and may void the warranty.

Electronic fireplaces are designed with an electronic intermittent pilot ignition system. Electrical power (110 Vac line

voltage) is recommended to operate the fireplace; however, AA batteries (not provided) can be used for full-time

operation or as a backup in case of a power outage.

Batteries will operate the flame ON/OFF function only. Electrical power is required to operate the optional blower.

A remote control system is included with all models and provides remote ON/OFF flame control (manual adjustment

of the gas valve settings is not possible).

Installation

900079-02 05/2015

NOTE: Installation and repair should be done by a qualified service person. The fireplace should be inspected before

use and at least annually by a professional service person. More frequent cleaning may be required due to excessive

lint from carpeting, bedding material, etcetera. It is imperative that control compartments, burners and circulating air

passageways of the fireplace be kept clean.

Remarqué : L’installation et la réparation devrait être confiées à un technicien qualifié. L’appareil devrait faire

l’objet d’une inspection par un technicien professionnel avant d’être utilisé et au moins une fois l’an par la suite.

Des nettoyages plus fréquents peuvent être nécessaires si les tapis, la literie, et cetera produisent une quantité

importante de pous-sière. Il est essentiel que les compartiments abritant les commandes, les brûleurs et les

conduits de circulation d’air de l’appareil soient tenus propres.

NOTE: Diagrams and illustrations are not necessarily shown to scale.

8

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

Approved Vent Components

These fireplaces are designed, tested and listed for operation and installation with the following vent

components only:

• Secure Vent® Direct-Vent System Components,

• Secure Flex® Flexible Vent Components, and

• Z-FLEX® Model GA Venting Systems listed to UL1777 and ULCS635 manufactured by Flexmaster

Canada Limited.

Use only the correct size venting (4 1/2” inner and 7 1/2” outer).

These approved vent system components are labeled for identification. DO NOT use any other manufacturer’s vent

components with these fireplaces.

Codes and Standards

These fireplaces comply with National Safety Standards and are tested and listed by PFS (Report No. F14-108) to

ANSI Z21.88 (in Canada, CSA-2.33), and CAN/CGA-2.17-M91 (CSA P4.1) in both USA and Canada, as vented gas

fireplace heaters.

These fireplaces are listed for installation in bedrooms, aftermarket mobile homes, and manufactured homes.

The installation must conform to local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54—latest edition (In Canada, the current CAN/CGA-B149.1 installation code).

The fireplace, when installed, must be electrically grounded and wired in accordance with local codes or, in the

absence of local codes, with the National Electrical Code, ANSI/NFPA 70—latest edition, or the Canadian Electrical

Code, CSA C22.1—latest edition.

Installation

900079-02 05/2015

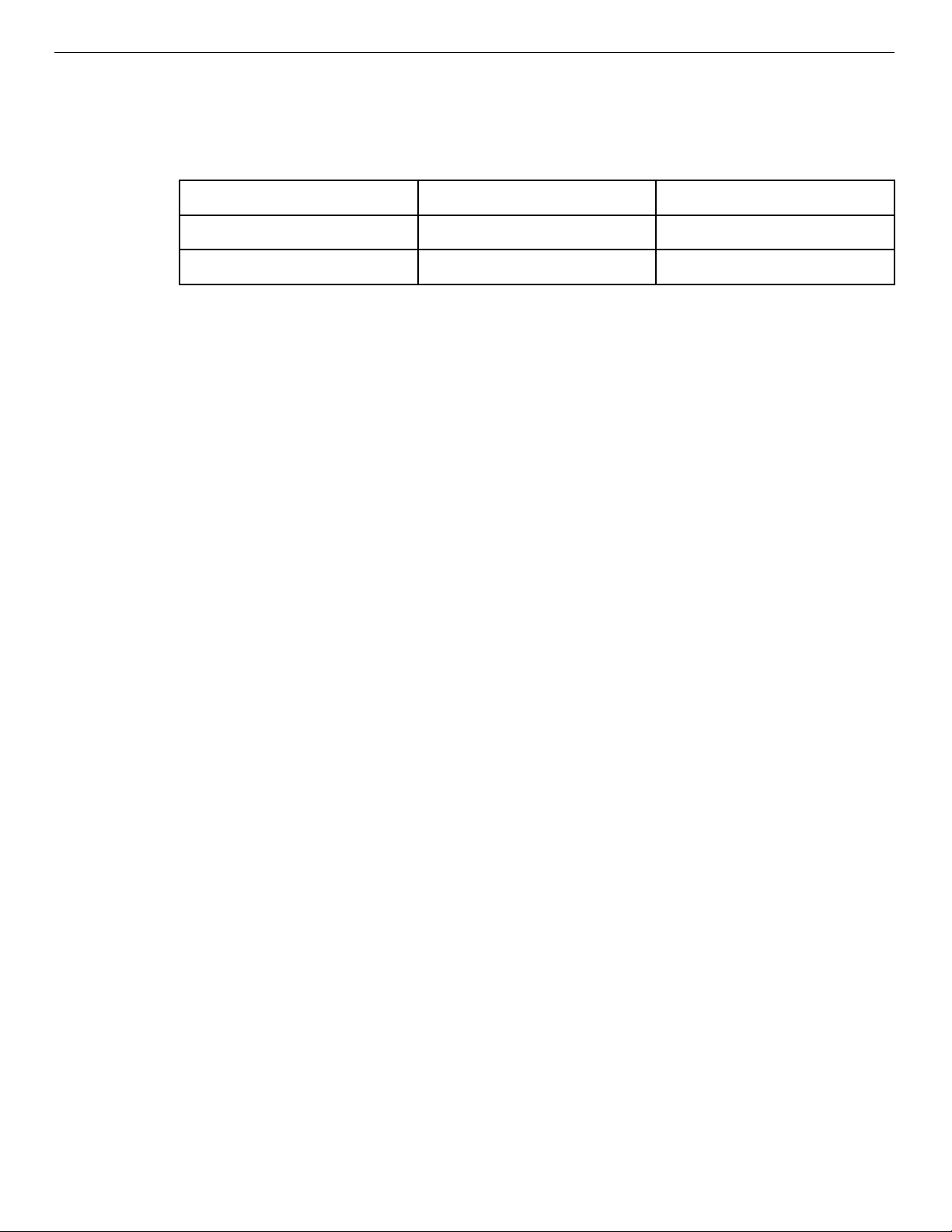

BTU Input

Gas Pressure

Table 1: Input Rate, Gas Valves

Models

42” 22,000 20,000

54” 30,000 30,000

Natural Gas Propane (field converted)

Input Rate (BTU/HR)

Table 2: Thermal Efficiency (%)

Model

42” 66.7 54.2 69.6 59.4

54” 71.9 63.2 72.1 65.5

* AFUE is a measurement of the US Department of Energy

** P4 (EnerGuide) is a measurement of the Canadian Office of Energy Efficiency.

AFUE * P4 ** AFUE * P4 **

Natural Gas Propane

Table 3: Inlet Gas Supply Pressure

Fuel Minimum Maximum

Natural Gas 5” WC / (1.25 kPa) 10.5” WC / (2.61 kPa)

Propane 11.0” WC / (2.74 kPa) 13.0” WC / (3.23 kPa)

Table 4: Manifold Gas Supply Pressure

Natural Gas 3.5” WC / (0.87 kPa)

Propane 10.0” WC / (2.49 kPa)

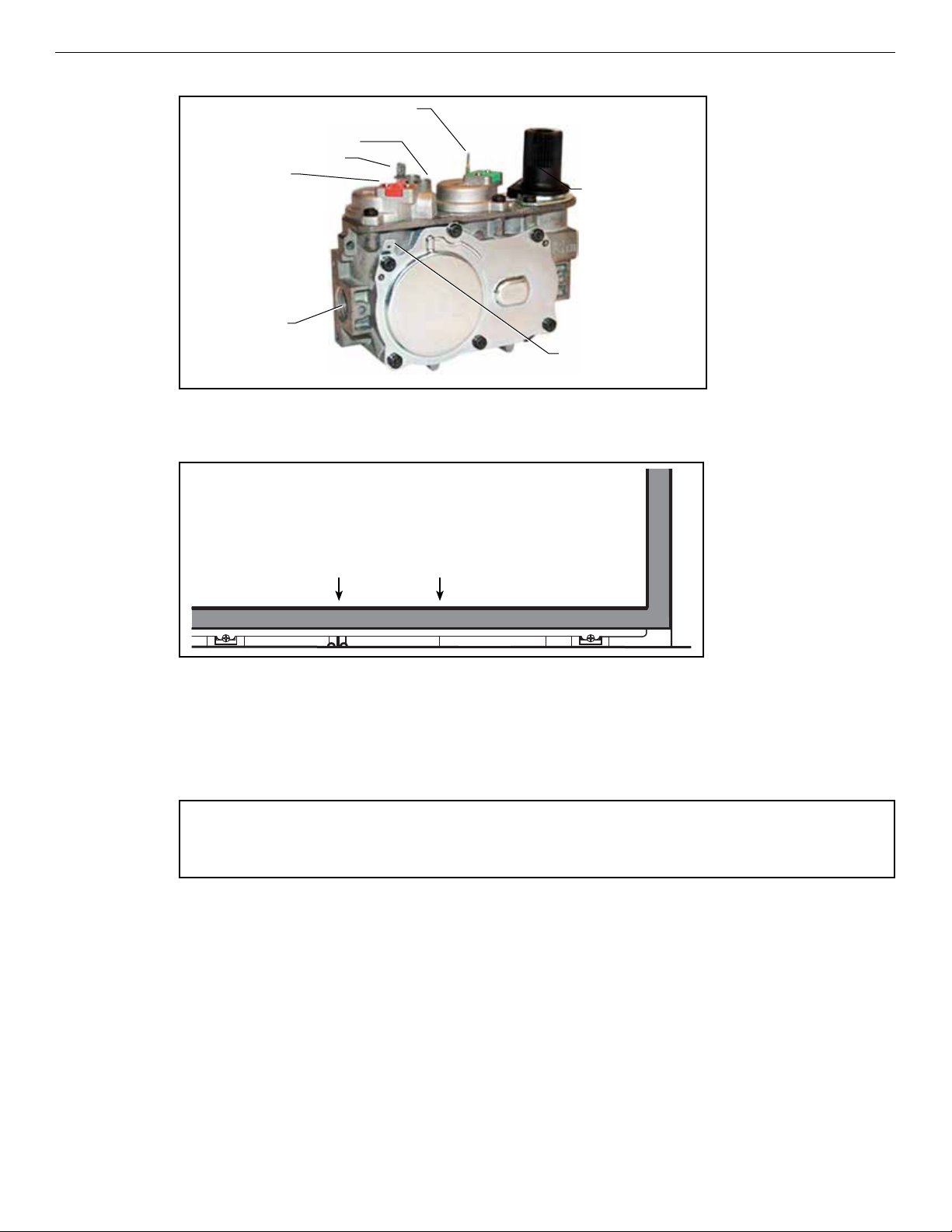

The control valves have a 3/8” (10 mm) NPT thread inlet and outlet side of the valve (Figure 1).

9

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

Figure 1: Electronic Gas Valve

(from DFC Wire Harness)

Line (IN) Test Port

Manifold (OUT) Test Port

Orange Wire

(from DFC Wire

Harness)

Main Gas Inlet

3/8" NPT

The SIT gas valve in this fireplace has a 3/8” NPT thread main gas inlet and outlet. Test gauge connections are

provided on the front of the electronic gas control valve (identified IN for the inlet and OUT for the manifold side).

Figure 2: Accessing the gas valve

Installation

900079-02 05/2015

Green Wire

Pressure

Regulator

Tower

Yellow Ground Wire

(from DFC Wire Harness)

Glass Door Assembly

(Lower Right Corner)

Air Shutter

Adjustment Lever

Battery Backup Holder

(attached to bracket with cable)

Propane tanks are at pressures that will cause damage to valve components. Verify that the tanks have step down

regulators to reduce the pressure to safe levels.

Using a propane tank smaller than 100 lbs may create pressure loss and insufficient fuel delivery, which can cause

sooting, severe delayed ignition, or other malfunctions (see NPFA 58).

Any damage as a result of insufficient tank size or other improper installation is NOT covered under the

limited warranty.

The appliance and its appliance main gas valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply piping system by closing its equipment shutoff valve during

any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5 kPa).

10

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

Orifice Sizes—Sea Level to High Altitude

These fireplaces are tested and approved for installation at elevations of 0–4500 ft (0–1372 m) above sea level

using the standard burner orifice sizes (Table 5). For elevations above 4500 ft, contact your gas supplier or qualified

service technician.

Table 5: Burner Orifice Sizes, Elevation 0–4500 ft ( 0–1372 m)

Model

42”

54”

* Standard size installed at factory

Deration

At elevations above 4500 ft, the amount of BTU fuel value delivered must be reduced by either:

• Using gas that has been derated by the gas company.

• Changing the burner orifice to a smaller size as regulated by the local authorities having jurisdiction and by the

(USA) National Fuel Gas Code NFPA 54/ANSI Z223.1—latest edition or, in Canada, the CAN/CGA-B149.1 codes—

latest edition.

NOTE: Flame breadth, height and width will diminish 4% for every 1,000 ft of altitude.

IN CANADA—CAN/CGA-2.17-M91 (HIGH ALTITUDE):

THE CONVERSION SHALL BE CARRIED OUT BY A MANUFACTURER’S AUTHORIZED REPRESENTATIVE,

IN ACCORDANCE WITH THE REQUIREMENTS OF THE MANUFACTURER, PROVINCIAL OR TERRITORIAL

AUTHORITIES HAVING JURISDICTION AND IN ACCORDANCE WITH THE REQUIREMENTS OF THE CAN/

CGA-B149.1 OR CAN/CGA-B149.2 INSTALLATION CODES.

Natural Gas

drill size

#43 (0.089”)*

Cat. No. 99K7501

#37 (0.104”)*

Cat. No. 24M10

Installation

900079-02 05/2015

Propane

drill size

#55 (0.052”)*

Cat. No. 19L52

0.063”*

Cat. No. LB-37G00

REQUIREMENTS FOR THE COMMONWEALTH OF MASSACHUSETTS

These appliances are approved for installation in the U.S. state of Massachusetts if the following additional

requirements are met:

• Install this appliance in accordance with Massachusetts Rules and Regulations 248 C.M.R. Sections 4.00

through 8.00.

• Installation and repair must be done by a plumber or gas fitter licensed in the Commonwealth of Massachusetts.

• The flexible gas line connector used shall not exceed 36” (914 mm) in length.

• The individual manual shutoff must be a T-handle type valve.

Massachusetts Horizontal Vent Requirements

In the Commonwealth of Massachusetts, horizontal terminations installed less than seven (7) ft above the finished

grade must comply with the following additional requirements:

• A hard wired carbon monoxide detector with an alarm and battery back-up must be installed on the floor level

where the gas fireplace is installed. The carbon monoxide detector must comply with NFPA 720, be ANSI/UL

2034 listed and be ISA certified.

• A metal or plastic identification plate must be permanently mounted to the exterior of the building at a minimum height

of eight (8) ft above grade and be directly in line with the horizontal termination. The sign must read, in print size no

less than one-half (1/2) inch in size, GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS.

COLD CLIMATE INSULATION

For cold climate installations, seal all cracks around your fireplace with noncombustible material and wherever cold

air could enter the room. It is especially important to insulate outside chase cavity between studs and under floor on

which fireplace rests, if floor is above ground level. Gas line holes and other openings should be caulked or stuffed

with unfaced fiberglass insulation. Caulk the firestop only where the pipe penetrates an outside wall, attic, or other

unconditioned space.

NOTE: Do not use loose, or blown-in insulation in the cavity surrounding the fireplace.

If the fireplace is being installed on a cement slab in cold climates, a sheet of plywood or other raised platform can

be placed underneath to prevent conduction of cold transferring to the fireplace and into the room. It also helps to

sheetrock inside surfaces and tape for maximum air tightness and caulk firestops.

11

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

MANUFACTURED HOME REQUIREMENTS

This appliance may be installed in an aftermarket, permanently located, manufactured home (USA only) or mobile

home, where not prohibited by local codes.

Cet appareil peut être installé dans une maison préfabriquée (mobile) déjà installée à demeure si les règlements

locaux le permettent.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for

use with other gases, unless a certified kit is used.

Cet appareil doit être utilisé uniquement avec le type de gaz indiqué sur la plaque signalétique. Cet appareil ne

peut être converti à d’autres gaz, sauf si une trousse de conversion est utilisée.

Ensure that the cross members are not cut or weakened during installation. The structural

integrity of the manufactured home floor, wall, and ceiling / roof must be maintained.

This appliance must be grounded to the chassis of the manufactured home in accordance

with local codes or in the absence of local codes, with the National Electrical Code ANSI /

NFPA 70—latest edition or the Canadian Electrical Code CSA C22.1—latest edition.

Installation

900079-02 05/2015

CAUTION

CAUTION

LOCATION

In selecting the location, the aesthetic and functional use of the fireplace are primary concerns. However, vent

system routing to the exterior and access to the fuel supply are also important. The fireplace may be located on or

near conventional construction materials. See Construct the Fireplace Framing on Page 17 for more information.

Due to high temperatures, the fireplace should be located out of traffic and away from furniture and draperies.

En raison des températures élevées, l’appareil devrait être installé dans un endroit où il y a peu de

circulation et loin du mobilier et des tentures.

The location should also be free of electrical, plumbing or other heating/air conditioning ducting.

Be aware that this is a heat producing fireplace. Objects placed above the unit are exposed to elevated temperatures.

Do not insulate the space between the fireplace and the area above it.

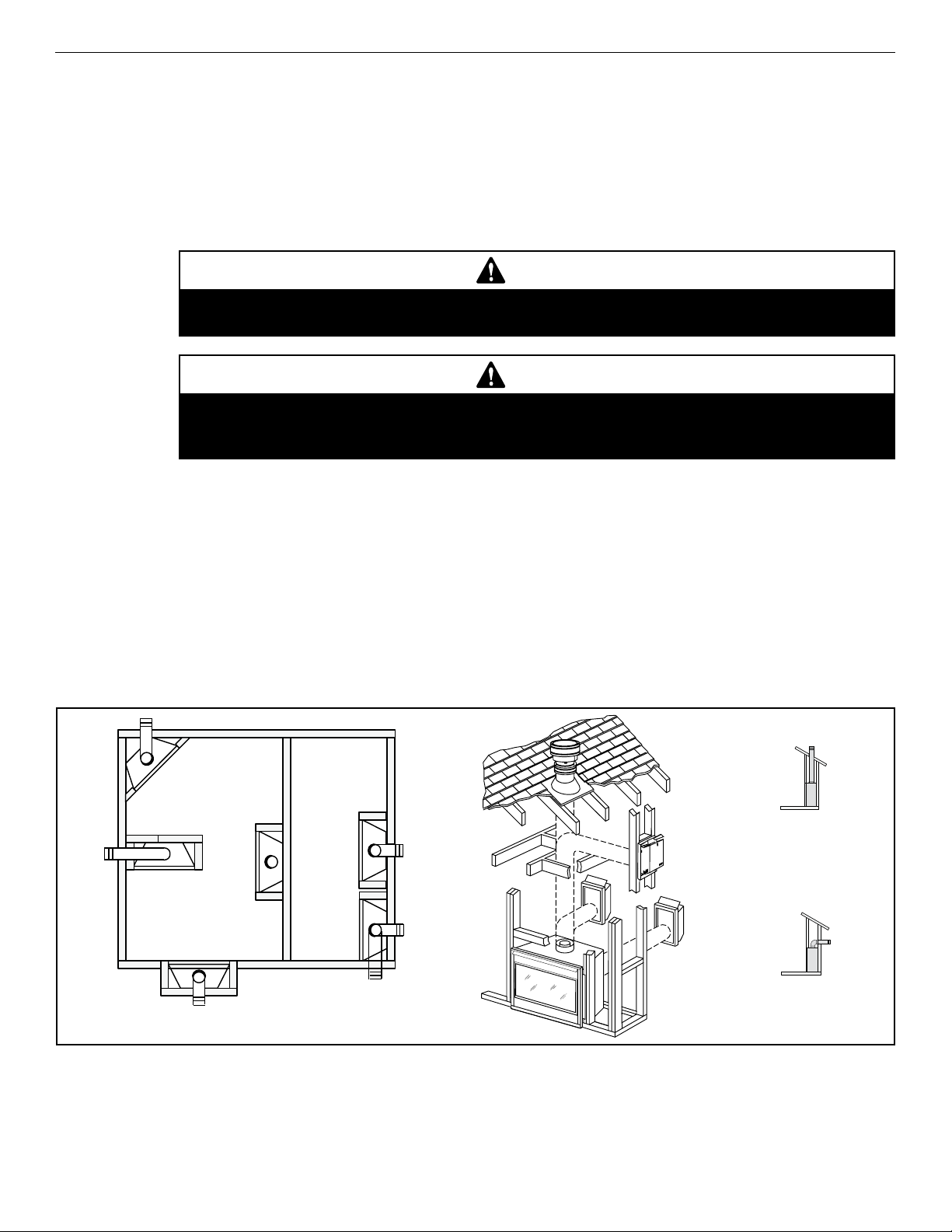

Figure 3: Typical Locations and Venting

Top Vent

Top Vent

Recessed

Installation

Top Vent

Vertical Vent

(Top Vent)

Top Vent Top Vent

12

Top Vent

Horizontal Vent

(Top Vent)

Innovative Hearth Products

12

X

Roof pitch is X/12

2 ft

minimum

2 ft minimum

Lowest

discharge

opening

H*

*H = minimum height from roof to

lowest discharge opening of vent

Horizontal overhang

Vertical

wall

Vent

termination

Storm collar

Concentric

vent pipe

Flashing

1” (25.4 mm) minimum

clearance to combustibles

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

VENT TERMINATION CLEARANCES

The following vent termination figures and charts should be used. Install venting according to local codes, these

instructions, the current National Fuel Gas Code (ANSI Z223.1/NFPA 54) in the USA or the current standards of CAN/

CGA-B149.1 in Canada.

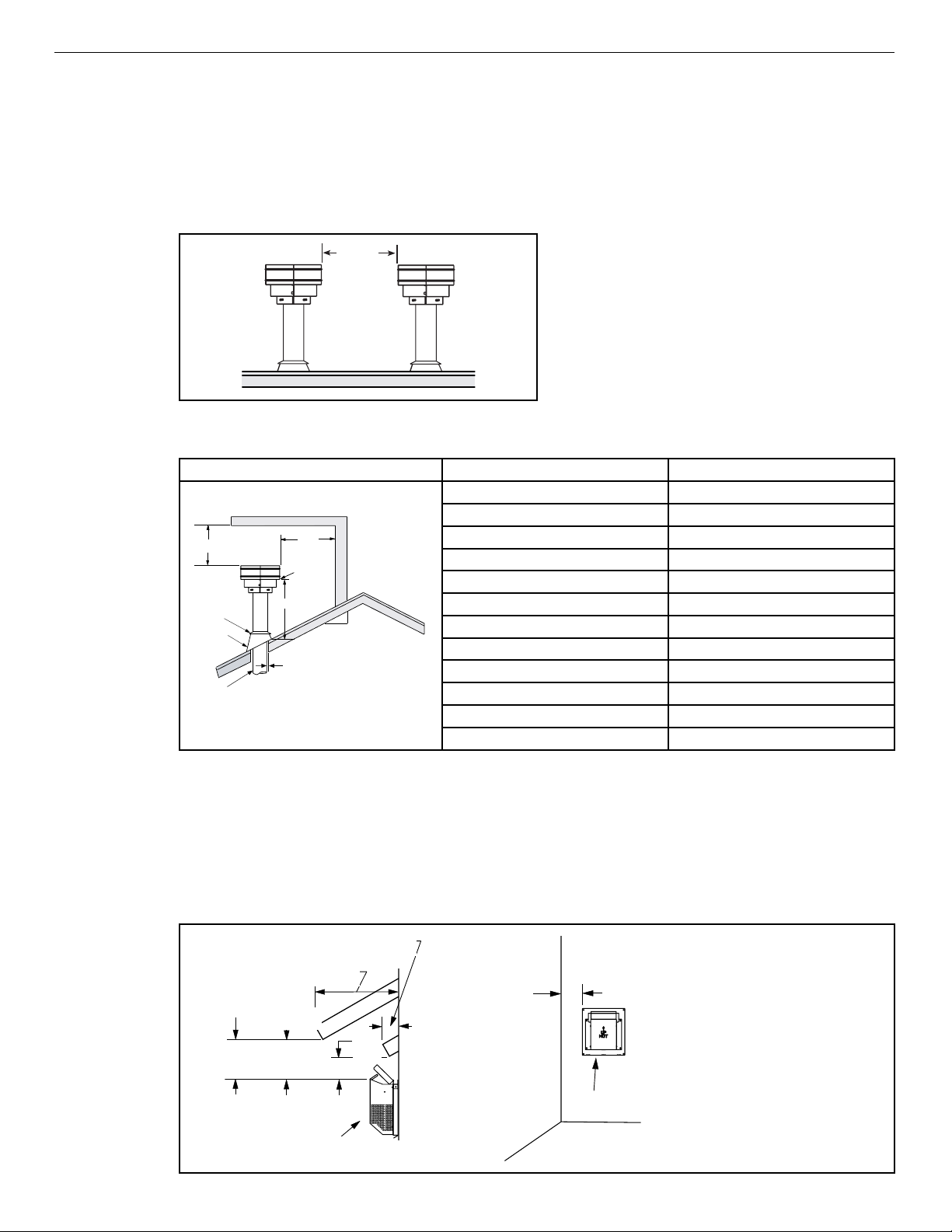

Vertical Vent Termination Clearances

Terminate multiple vent terminations according to the installation codes listed above and Figure 4.

Figure 4: Multiple Terminations

Terminate single vent caps relative to building components according to Table 6 and Figure 4.

Table 6: Termination Heights for Vents above Flat or Sloped Roofs (NFPA 54 / ANSI Z223.1)—Gas Vent Rule

Installation

900079-02 05/2015

12”

(305 mm)

minimum

Roof Pitch Termination Height *

Flat to 6/12 1.0 ft (0.3 m)

6/12 to 7/12 1.25 ft (0.38 m)

7/12 to 8/12 1.5 ft (0.46 m)

8/12 to 9/12 2.0 ft (0.61 m)

9/12 to 10/12 2.5 ft (0.76 m)

10/12 to 11/12 3.25 ft (0.99 m)

11/12 to 12/12 4.0 ft (1.22 m)

12/12 to 14/12 5.0 ft (1.52 m)

14/12 to 16/12 6.0 ft (1.83 m)

16/12 to 18/12 7.0 ft (2.13 m)

18/12 to 20/12 7.5 ft (2.29 m)

20/12 to 21/12 8.0 ft (2.44 m)

Horizontal Vent Termination Clearances

The horizontal vent termination must have a minimum of 6” (152 mm) clearance to any overhead combustible

projection of 2 1/2” (64 mm) or less (Figure 5). For projections exceeding 2 1/2” (64 mm) (Figure 5). For additional

vent location restrictions refer to Table 7.

All horizontal terminations may be located as close as 6” (152mm) to any (non-combustible and combustible)

exterior sidewall. This distance may be decreased to 2” (51mm) for noncombustible exterior sidewalls with

SV4.5HT-2 termination (Table 21).

Figure 5: Horizontal Vent Termination Clearances

Combustible projection

2 1/2” or less in length

Combustible projection

greater than 2 1/2” in length

Ventilated

soffit

Unventilated

soffit

18”

(457 mm)

12”

(305 mm)

Termination kit

6

(152)

6”

Termination kit

NOTE: See Figure 27

on Page 31 for

exterior wall recess

allowances for the

SV4.5HT-2 termination.

13

(TERMINATION PROHIBITED)

Inside Corner

Balcony with No Side

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

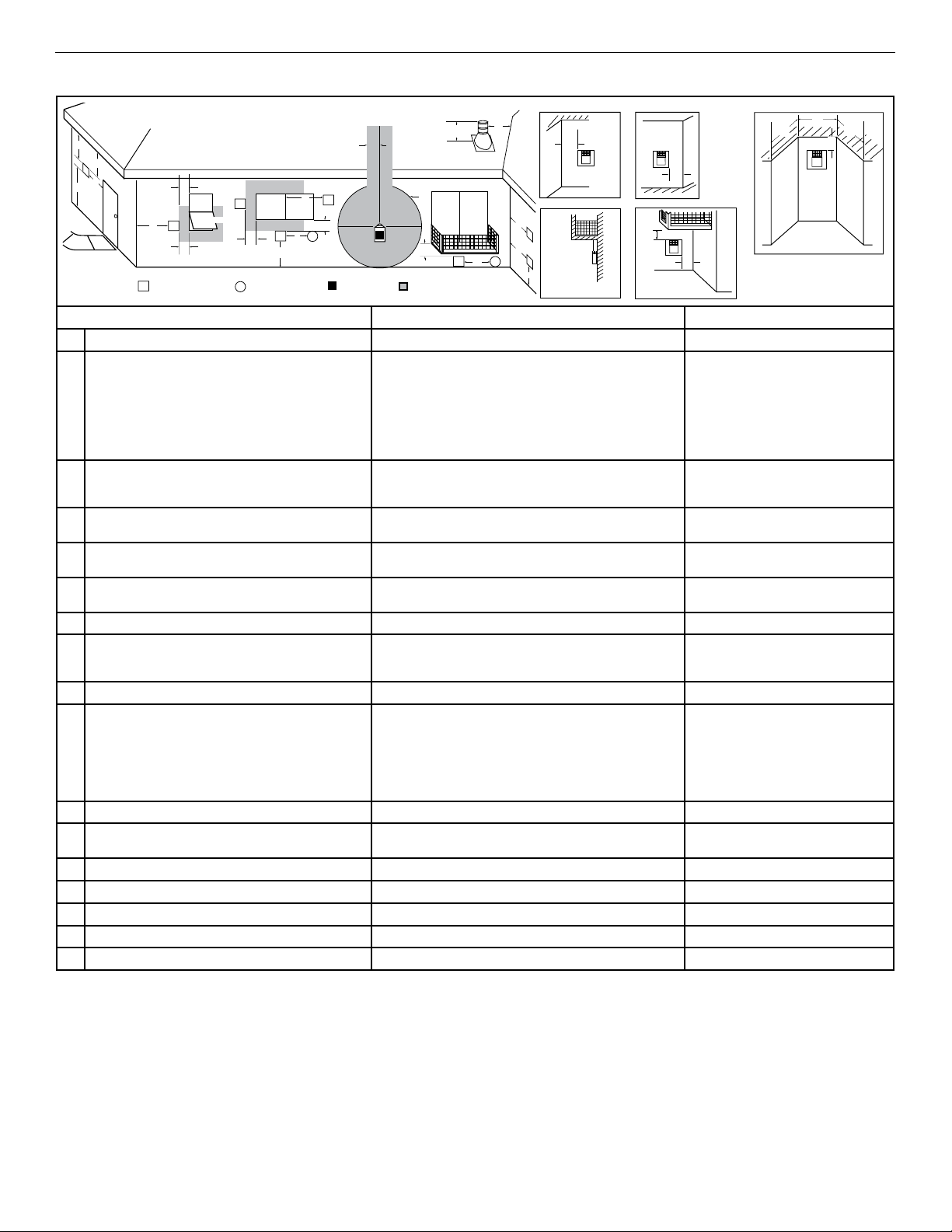

Table 7: Horizontal vent termination clearances for buildings with combustible and noncumbustible exteriors

Outside Corner Recessed Location

D

E

V

B

L

C

F

V

B

TERMINATION CAP

V

Fixed

Closed

Openable

V

Openable

V

B

A

AIR SUPPLY INLET

X

Fixed

Closed

J

B

V

B

X

G

GAS METER RESTRICTED AREA

A Clearance above grade, veranda, porch, desk, or balcony 12” (300 mm) ** 12” (300 mm) *

B Clearance to window or door that may be opened 6” (150 mm)

C Clearance to permanently closed window 9” (229 mm)

D Vertical clearance to ventilated soffit located above the

termination within a horizontal distance of 18” (458 mm)

E Clearance to unventilated soffit 12” (305 mm)

F Clearance to outside corner 5” (127 mm)

G Clearance to inside corner 2” (51 mm) minimum 2” (51 mm) minimum

H Clearance to each inside of center line extended above

meter / regulator assembly

I Clearance to service regulator vent outlet 36” (910 mm)** 36” (910 mm)*

J Clearance to nonmechanical air supply inlet to building or

the combustion air inlet to any other fireplace

K Clearance to a mechanical air supply inlet 36” (910 mm) above if within 10 ft (3 m) horizontally ** 72” (1830 mm) *

L Clearance above paved sidewalk or paved diveway located

on public property

M Clearance under veranda, porch, deck or balcony 12” (300 mm) *‡ 12” (300 mm) *‡

N Depth of alcove (maximum) 72” (1830 mm) ** 72” (1830 mm) *

O Clearance to termination (alcove) 6” (15.2 mm) ** 6” (15.2 mm)*

P Width of alcove (minimum) 36” (910 mm) ** 36” (910 mm) *

Q Clearance to combustible above (alcove) 18” (457 mm) ** 18” (457 mm) *

*

In accordance with the current CSA-B149.1 National Gas And Propane Installation Code

**

In accordance with the curent ANSI Z223.1/NFPA 54 National Fuel Gas Codes

‡

A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and serves both dwellings

*‡

Only permitted if veranda, porch, deck, or balcony is fully-open on a minimum two sides beneath the floor

See Table 6

H

G

V

V

F

I

G

G

M

V

K

V

G

V

X

A

WallVBalcony with Perpendicular Side Wall

M

M

V

U.S. Installation ** Canadian Installation *

6” (150 mm)

for fireplaces < 10,000 Btu/h (3 kW),

9” (230 mm)

for fireplaces > 10,000 Btu/h (3 kW), and < 50,000 Btu/h

for fireplaces < 10,000 Btu/h (3 kW),

12” (300 mm)

for fireplaces > 10,000 Btu/h (3 kW)

(15 kW),

12” (300 mm)

for fireplaces > 50,000 Btu/h (15 kW) **

12” (305 mm)

recommended to prevent window condensation

recommended to prevent

window condensation

18” (458 mm) 18” (458 mm)

12” (305 mm)

30” (760 mm) to vinyl soffit

30” (760 mm) to vinyl soffit

5” (127 mm)

minimum

36” (910 mm)

within a height of 15 ft above the meter / regulator assembly **

minimum

36” (910 mm)

within a height of 15 ft above the meter /

regulator assembly *

6” (150 mm)

for fireplaces < 10,000 Btu/h (3 kW),

9” (230 mm)

for fireplaces > 10,000 Btu/h (3 kW) and < 50,000 Btu/h (15 kW),

6” (150 mm)

for fireplaces < 10,000 Btu/h (3 kW),

12” (300 mm)

for fireplaces > 10,000 Btu/h (3 kW)

12” (300 mm)

for fireplaces > 50,000 Btu/h (15 kW)**

84” (2130 mm) ‡ 84” (2130 mm) ‡

Installation

900079-02 05/2015

P

N

O

Q

V

14

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

MINIMUM CLEARANCES TO COMBUSTIBLES

Fireplace And Vent Clearances

The fireplace is approved with zero clearance to combustible materials on all sides (Table 8), with the

following exceptions:

• When unit is recessed, the side walls surrounding the unit must not extend beyond unit front edge (Figure 6).

• When the unit is installed with one side flush with a wall, the wall on the other side of the unit must not extend

beyond the front edge of the unit (Figure 6).

Table 8: Minimum Clearances *

From Bottom of Unit to Ceiling 65” (1651 mm)

Front Service Clearance—

clearance immediately in front of viewing area(s)

* 3” (76 mm) above any horizontal/inclined vent component.

** See Page 20 for clearance requirements to the nailing flange located at each side of the unit and any screw heads adjacent to it.

Back

Sides

Top Spacers 0” (0 mm)

Floor 0” (0 mm)

Vent

1/2” (13 mm) to wrapper

0” (0 mm) to Spacers

1/2” (13 mm) to wrapper

0” (0 mm) to Spacers **

3” (76 mm)—Top *

1” (25.4 mm)—Sides and Bottom

36” (914 mm)

Installation

900079-02 05/2015

Hearth Extension

A hearth extension is not required with this fireplace. If a hearth extension is used, do not block the lower control

compartment door. Any hearth extension used is for appearance only and does not have to conform to standard

hearth extension installation requirements.

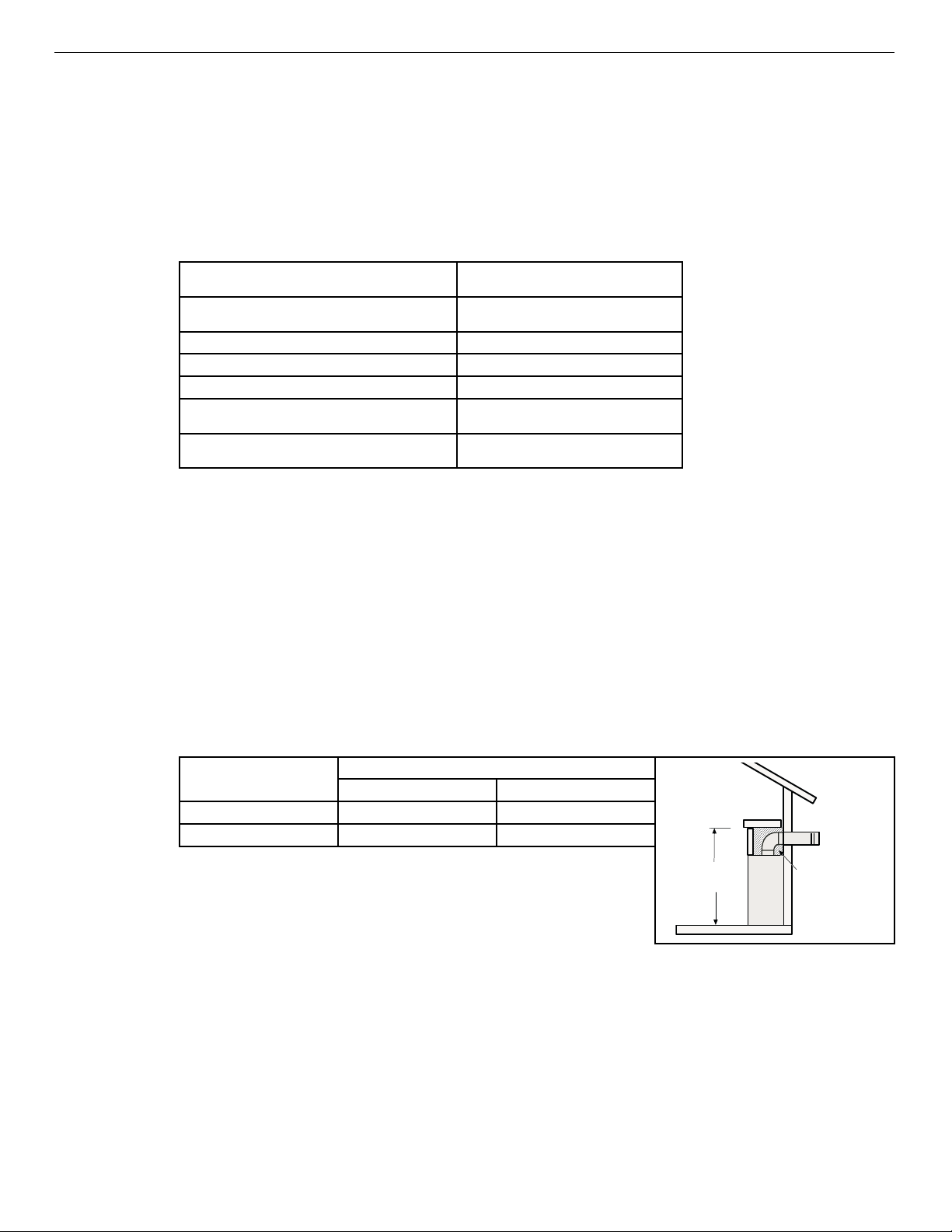

Shelf Height

The venting attached to the top vent should be routed in a way to minimize obstructions to the space above the

fireplace. Do not insulate the space between the fireplace and the area above it (Table 9). The minimum height from

the base of the fireplace to the underside of combustible materials used to construct a utility shelf in this fashion is

shown in Table 9.

NOTE: This is a heat-producing appliance. Objects placed above the unit are exposed to elevated temperatures.

Table 9: Combustible Shelf Height—Top Vent

Model

42” * 51 1/4” (1299 mm) 53” (1345 mm)

54” * 55” (1400 mm)** 56 3/4” (1441 mm)**

* 6” straight vent section required before 90° elbow

** Includes 3” clearance to combustibles required above vent components

Top Vent with one 90° Elbow

Secure Vent

®

Secure Flex® (flex elbow)

Shelf Height

(see table)

No combustibles

or insulation

in the shaded

area between

the appliance

and the shelf

above it.

15

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

Wall Finishes / Surrounds / Mantels

Clearances to combustible mantels vary according to mantel depth (Figure 6).

Mantels constructed of non-combustible material may be installed at any height above the appliance opening; however, do

NOT allow anything to hang below the top edge of the fireplace door.

Minimum clearance requirements include any projections such as shelves, window sills, mantels, etc. above

the fireplace.

NOTE: To avoid heat-related finish damage, use finish materials rated 175 °F, or higher, on the underside of the mantel.

NOTE: The factory-supplied non-combustible fiber board MUST be installed above the fireplace opening.

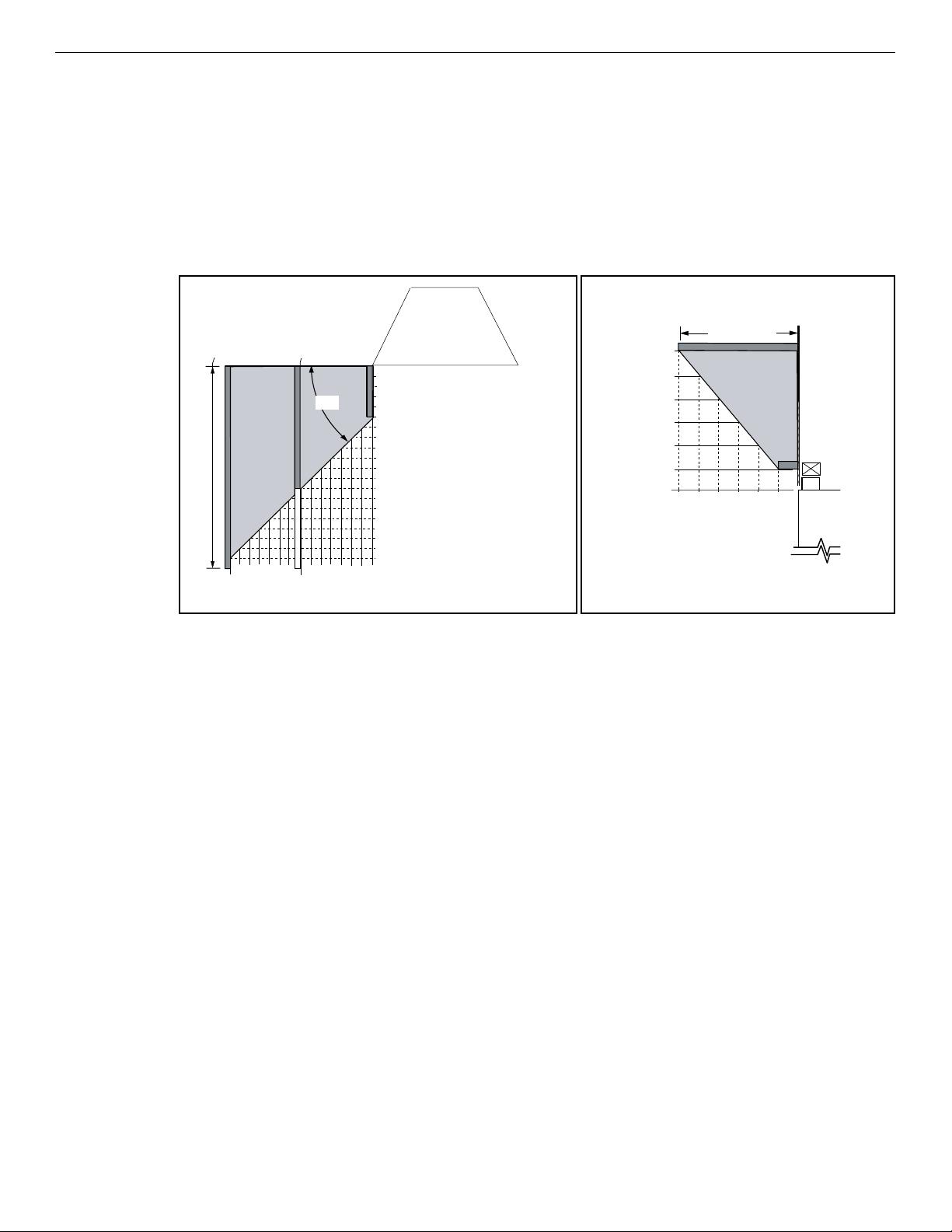

Figure 6: Combustible Side Clearances Figure 7: Mantel Height

At 14” minimum

side wall

clearance, a

combustible wall

can project to

any length.

14

14”

(356)

(356 mm)

At 8 1/4” side

wall clearance, a

combustible wall

can project 12”

8 1/4”

8-1/4

(209 mm)

(209)

Installation

900079-02 05/2015

Top View of

Fireplace

o

45

5 (127)

(127 mm)

12 (305)

(305 mm)

17 (431)

(431 mm)

Combustible materials

allowed in shaded area

5”

“Safe Zone”.

Combustible walls

shown in dark gray

12”

Combustible mantel

legs may project

beyond either side of

the fireplace opening

as long as they are kept

within the shaded area

17”

illustrated here.

28 (711)

26 (660)

24 (610)

22 (559)

20 (508)

18 (457)

in. (mm)

12

(305)

Mantel depth

(203)

10

(254)

8

6

(152)

4

(102)

(51)

2

Fireplace

INSTALLATION PREPARATION

The fireplace is shipped with all gas controls and components installed and pre-wired. Before installing the fireplace,

follow these steps:

1. Remove and retain the shipping carton.

2. Confirm receipt of required items listed in Packaging on Page 8.

3. Retrieve the non-combustible fiber board from behind the fireplace, and set aside in a safe location for

later installation.

4. If not already done, remove the glass door (Page 57), and set aside in a secure location for later reinstallation.

NOTE: Place the glass door on the shipping carton to protect its surface.

5. Remove the modesty panel. Set aside in a secure location for later installation.

16

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

INSTALLATION SEQUENCE

The typical sequence of installation is outlined below; however, each installation is unique and may result in

variations to the steps described.

See the pages referenced in the following steps for detailed instructions.

Framing

1. Construct the Fireplace Framing (Page 17).

2. Prepare the Fireplace Top Spacers (Page 19).

3. Route the Gas Supply Line into the Fireplace (Page 19).

4. Rough in the Electrical Supply, if Needed (Page 20).

5. Prepare the Fireplace Nailing Flanges (Page 20).

6. Place the Fireplace in the Framing and Secure (Page 20).

Venting

7. Select a Horizontal or Vertical Vent System (Page 20).

8. Install the Vent Restrictor (if necessary) (Page 20).

9. Install the Vent System (Page 24).

Electrical Connection

10. Complete the Field Wiring (Page 35).

Gas Connection

11. Connect the Gas Line (Page 37).

12. Install the Wall Switch Receiver (Page 44).

13. Initialize the Remote Control System (Page 44).

14. Verify Proper Fireplace Operation (Page 38).

Finishing

15. Install the Glass Media (Page 55).

16. Install the Baffle (Page 39).

17. Install the Glass Door and Barrier (Page 57).

18. Adjust the Air Shutter to Ensure Proper Flame Appearance (Page 39).

19. Install the Finishing Materials (Page 41).

20. Attach the Safety-in-Operation Warning Labels (Page 44).

Installation

900079-02 05/2015

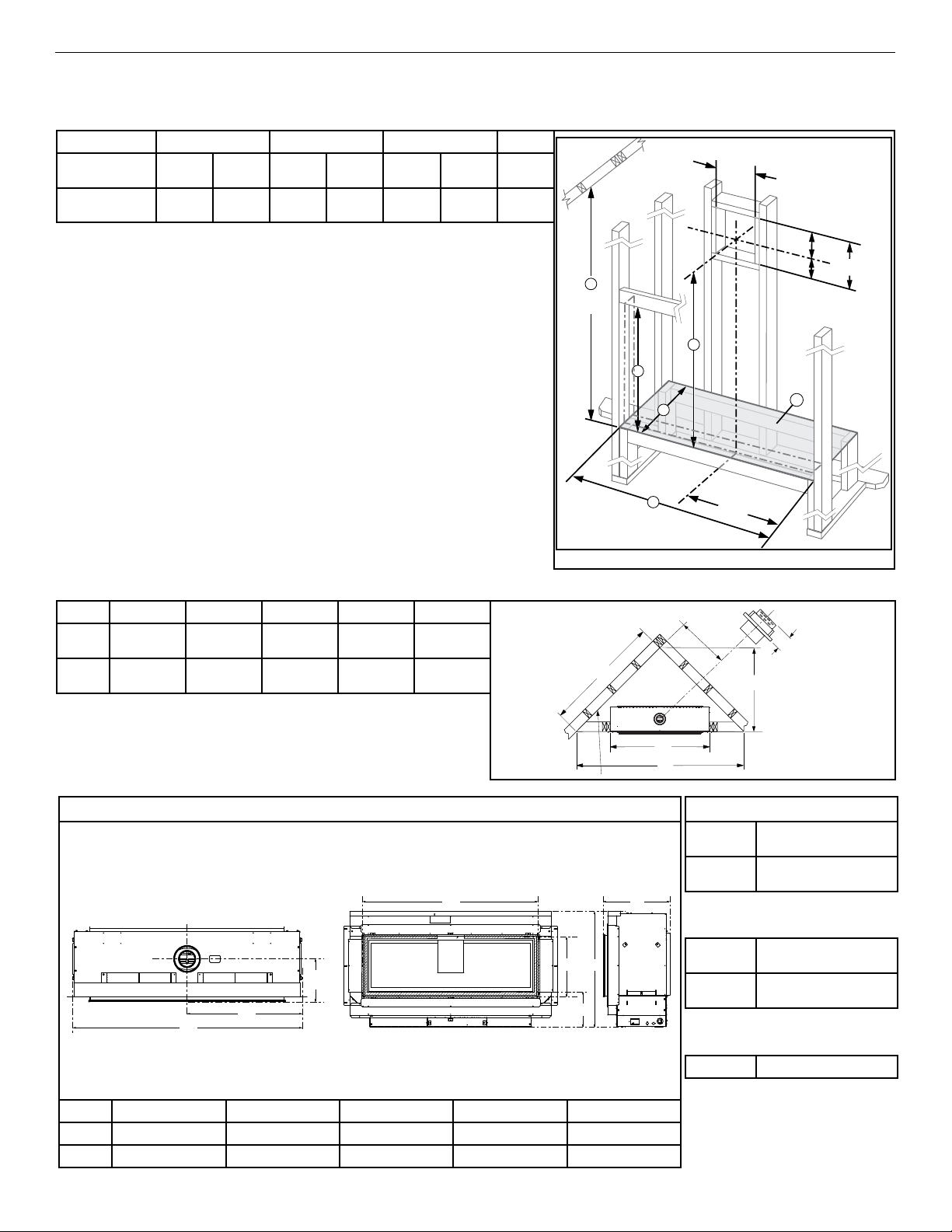

1. Construct the Fireplace Framing

1. Frame the fireplace as illustrated in Table 10. All framing details must allow for a minimum clearance to combustible

framing members as shown in Table 8. Steel studs are strongly recommended where exposed to heat.

2. Mount the fireplace on a fully supported base extending the full width and depth of the unit. If installed on

combustible materials, such as carpeting, vinyl tile, or combustible material other than wood flooring, the

appliance shall be installed on a metal or wood panel extending the full width and depth of the fireplace.

NOTE: Headers may be in direct contact with the fireplace top standoff spacers when they are bent up vertically,

maintaining the 4 3/8” clearance to the fireplace top, but must not be supported by them or notched to fit around

them. All construction above the fireplace must be self-supporting. DO NOT use the fireplace for structural support.

17

Innovative Hearth Products

20 1/2

(521)

9 7/8

(251)

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

Installation

900079-02 05/2015

NOTE: Fireplace is designed for 1” thickness of non comustible board on the face of the unit. If the finished surface is to match a thinner finish material the unit must

be recessed up to 1/2” to allow non-combustible to be flush with surrounding finish material (see * for dimensions).

Table 10: Fireplace Framing Dimensions

Model a b c d

42”

54”

*with 1/2” recess for flush framing

NOTE:

54 3/4

1366

65 3/4

1670

NOTE: Illustration provided for dimensions. Fireplace must be adequately framed and supported

with 2 x 4, or larger building materials.

a. Required frame opening width (1/2 of a = horizontal centerline of fireplace and vent

framing opening)

58 3/4*

1492*

69 3/4*

1772*

20 1/2

521

20 1/2

521

21*

533*

21*

533*

37

940

41 3/4

1061

38 1/2*

978*

43 1/4*

1099*

44 3/8

1127

48 1/4

1226

e

65

(1651)

CEILING

10-1/2

(267)

(178)

5-1/8

(130)

7

12-1/8

(308)

b. Required frame opening depth with 1/2” (13mm) thick wall finish material (for other wall

finish thicknesses, adjust frame opening depth and nailing flanges accordingly)

c. Minimum frame opening height (from base of appliance to header)

d. Minimum height from appliance base to vertical centerline of horizontal termination vent

pipe (with 6” straight vent section and 90° elbow off appliance vent collar)

NOTE: The vertical centerline of the horizontal termination vent pipe is NOT the same as the vertical centerline

of the vent frame opening because of firestop/spacer offset.

e. Minimum height from appliance base front to ceiling

f. Mounting platform

NOTE: Mount on a fully supported platform extending full width and depth of unit.

Table 11: Fireplace Framing Specifications—Corner Installation with Horizontal Termination

Model A B C D E

42”

54”

53 3/4”

(1365 mm)

65 3/4”

(1670 mm)

NOTE: Back wall of chase/enclosure (including finishing materials) shown.

94 3/4

(2407 mm)

106 3/4”

(2711 mm)

67”

(1702 mm)

75 1/2”

(1917 mm)

47 3/8”

(1203 mm)

53 3/8”

(1356 mm)

25 1/8”

(638 mm)

29 3/8”

(745mm)

C

d

c

b

a

1/2 of A

f

~

*

inches

(millimeters)

E

7 (178)

D

A

B

Table 12: Fireplace Dimensions Table 13: Viewable Glass

42” models

54” models

D

20 1/2

(521)

Table 14: Surround Dimensions

42” models

54” models

Table 15: Vent Collar

All models 4 1/2” inner x 7 1/2” outer

NOTE: Before installing fireplace,

nailing flanges MUST be adjusted

according to finish (cleanface or

surround) and wall finish material

thickness. This is critical to ensure

proper fireplace location, especially if

installing optional surround and bezel.

A

B

Top View

Model A B C D E

42” 26 7/8” (683 mm) 53 3/4” (1366 mm) 32 1/2” (826 mm) 44 1/8” (1121 mm) 15 11/16” (398 mm)

54” 32 1/2” (826 mm) 65 3/4” (1670 mm) 36 3/8” (924 mm) 56 1/8” (1426 mm) 19 5/8” (498 mm)

18

NOTE: Assemble top standoffs before installing fireplace.

11 7/8

(302)

Front View

C

E

9 7/8

(251)

Right Side View

40” W x 10 1/2” H

1016 mm x 267 mm

51” W x 14 3/4” H

1295 mm x 375 mm

56 1/2” W x 23 3/4” H

1435 mm x 603 mm

68” W x 27 1/2” H

1727 mm x 699 mm

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

Prepare the Fireplace Top Spacers

2.

900079-02 05/2015

1. The two (2) 4 3/8” standoff spacers on top of the fireplace cabinet are shipped flat (Figure 8).

2. Bend the standoffs as shown (Figure 8):

3. Align the holes in the standoff with the holes in the fireplace top, and secure with the supplied screws (Figure 8).

Figure 8: Standoffs

Positioned flat as

shipped from the

factory

Assembled

standoff

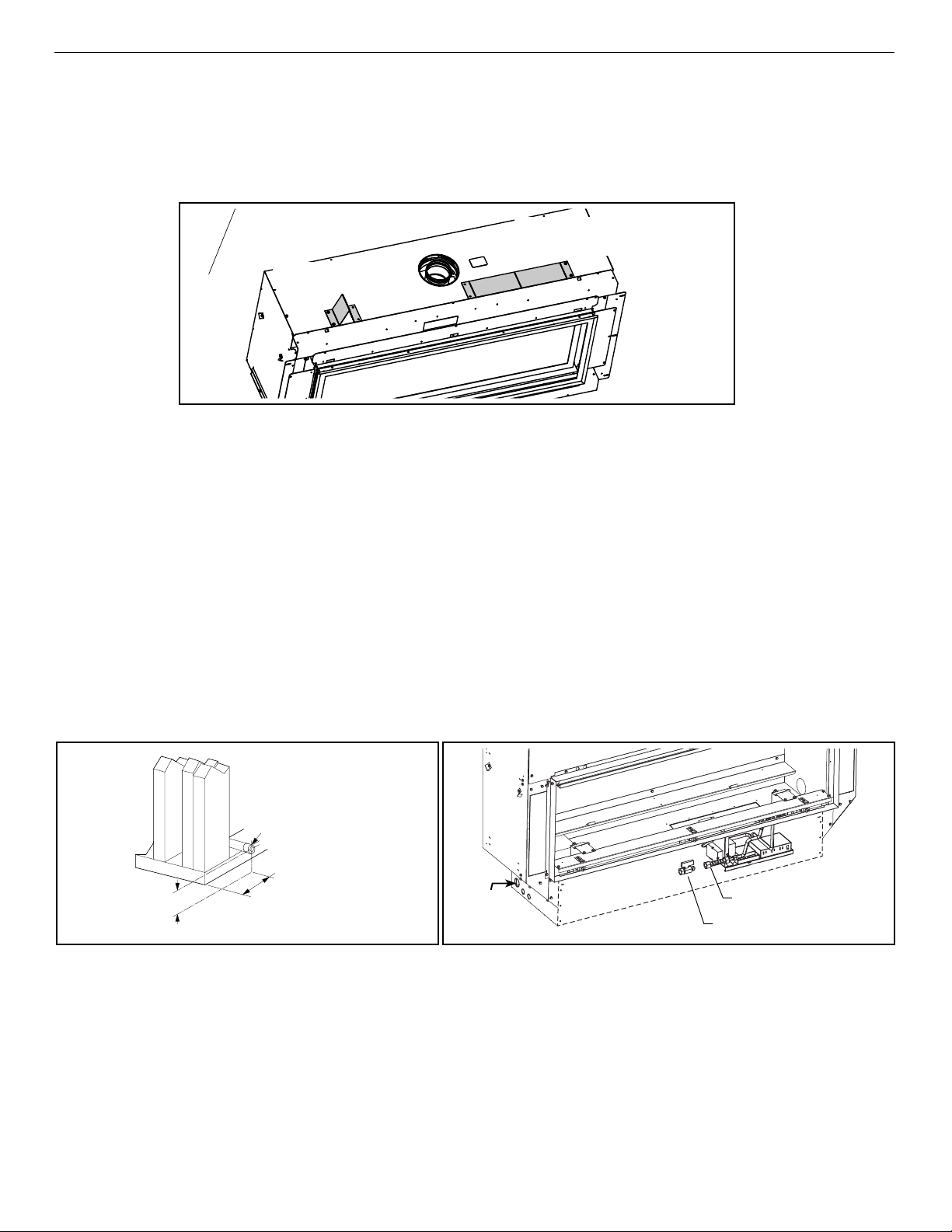

3. Route the Gas Supply Line into the Fireplace

NOTE:

NOTE: If gas shutoff valve on the fireplace is desired, surround kit must be used. Refer the gas line routing included in

the surround instructions.

See Page 53 for more information on Accessing the Control Compartment.

Installation

1. Route a 1/2” (13 mm) gas line to the left side of the fireplace (Figure 9).

2. Route the gas line through the gas supply line access opening (Figure 10).

NOTE: The gas supply line should not be connected to the appliance until step 11. Connect the Gas Line

(Page 37).

NOTE: ONLY a licensed installer should perform these steps—strictly per NFPA guidelines. Installing a gas supply

line from the fuel supply to the appliance involves numerous considerations, including materials, protection, sizing,

location, controls, pressure, sediment, and more.

NOTE: Gas lines must be routed, assembled, and made of materials that are in strict accordance with local codes and

regulations. Never use galvanized or plastic pipe.

Figure 9: Routing the gas line through the framing Figure 10: Routing the gas line into the fireplace

Left side front corner of

fireplace framing shown.

Gas line may also enter on

the right side or bottom.

Pipe coupling

(recommended)

15 3/4”

(400 mm)

1 5/8”

(43 mm)

Gas supply

line access

opening

Gas flex line

Gas line shutoff valve

(disconnected from flex line)

Proper Sizing of Gas Line

Properly size and route the gas supply line from the supply regulator to the area where the appliance is to be installed

per requirements outlined in the National Fuel Gas Code, NFPA 54—latest edition (USA) or CAN/CGA-B149.1—

latest edition (Canada).

NOTE:

• All fireplaces are factory-equipped with a flexible gas line connector and 1/2” shutoff valve (Figure 34).

• See Massachusetts Horizontal Vent Requirements for additional requirements for installations in the state of

Massachusetts in the USA.

• A pipe joint compound rated for gas should be used on the threaded joints. Ensure propane-resistant

compounds are used in propane applications. Be very careful that the pipe compound does not get inside

the pipe.

• A sediment trap in the supply line as close as possible to the fireplace is recommended.

19

Innovative Hearth Products

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

• Check with the local building official for local code requirements (e.g., Are below grade penetrations of the gas

line allowed?, etc).

Installation

900079-02 05/2015

CAUTION

If propane is used, be aware that with a tank that is too small (i.e., under 100 lbs, if this is the only gas

appliance in the dwelling—see NPFA 58), there may be a loss of pressure. This can result in insufficient

fuel delivery that can cause sooting, delayed ignition, or other malfunctions. Any damage resulting from an

improper installation is not covered by the limited warranty.

4. Rough in the Electrical Supply, if Needed

1. As necessary, rough in the fireplace electrical supply per NEC and local codes.

5.

Place the Fireplace in the Framing and Secure

1. Secure the fireplace to the side framing members using the unit’s nailing flanges —one top and bottom on each

side of the fireplace front. Use 8d nails or the equivalent.

NOTE: Nailing flanges, combustible members, and screw heads in areas directly adjacent to the nailing flanges are

EXEMPT from the 1/2” clearance to combustible requirements for the firebox outer wrapper. Combustible framing

may be in direct contact with the nailing flanges and may be located within 1/2” of screw heads and the firebox

wrapper in areas adjacent to the nailing flanges.

VENT SYSTEM PREPARATION

6. Select a Horizontal or Vertical Vent System

1. With the fireplace secured in the framing, determine the vent route and identify the exterior termination location.

The following sections describe vertical (roof) and horizontal (exterior wall) vent applications. Use only approved

vent components (Page 9 and Page 46).

NOTE: This fireplace must be vented directly to the outside.

The vent system may not service multiple appliances, and must never be connected to a

flue serving a separate solid fuel burning appliance.

NOTE: The vent pipe is tested to be run inside an enclosed wall (such as a chase). There is no requirement for

inspection openings in the enclosing wall at any of the joints in the vent pipe.

7. Install the Vent Restrictor (if necessary)

1. Use the vent run descriptions in Figure 14 to determine if a vent restrictor is necessary.

2. If necessary, assemble the vent restrictor and wings as detailed in Figure 14 and Figure 16.

3. If necessary, install the appropriate vent restrictor with the flaps facing up (Figure 15). The vent restrictor is held in

place by friction. The vent restrictor must not be visible inside the firebox.

NOTE: If the baffle and back panel are installed, remove them before installing the vent restrictor.

NOTE: The vent restrictor is shipped in the firebox.

WARNING

20

Innovative Hearth Products

Base

3

5

10

45

6

40

15 ft Maximum

horizontal run

60 ft Maximum vertical run

60

2

15

Horizontal Distance (ft)

Vertical Height (ft)

Vertical Height (ft)

4

6

1

4.5 6

7.5

Position 2Position 1

6 ft Minimum

vertical run

6 ft Minimum

10

9

Superior™ DRL3000 Linear Direct-Vent Gas Fireplaces

Installation

900079-02 05/2015

Figure 11: When to use a vent restrictor Figure 12: Vent restrictor installation, Top vent

*

U-Shaped

Vent

Restrictor

Inner

Fireplace

Collar

Appliance Top Vent Outlet

Vent

Collar

Vent

Restrictor

(held in

place by

friction)

Figure 13: Vent restrictor assembly

Base Vent Restrictor

Vent Restrictor Position 1

*

* For straight runs or runs with elbows as illustrated in Vertical Vent Figures/Tables starting on Page 27.

Vent Restrictor with Vertical Terminations

Vent Restrictor Position 2

When vertically terminating the vent system through the roof and using the vent restrictor, install the vent restrictor

in the top vent of the fireplace outlet.

If installing more than 6 ft of vertical venting, install the restrictor (Figure 15), from inside or outside the unit, in the

inner fireplace collar. The vent restrictor is held in place by friction.

Vent Restrictor with Horizontal Terminations

When horizontally terminating a vent system with a vertical vent run up to 4 ft through an exterior wall, no vent restrictor is required.

If installing more than 4 ft of vertical venting, install the restrictor (Figure 15), from inside or outside the unit, in the

inner fireplace collar. The vent restrictor is held in place by friction.

Table 16: Effective Vent Length

Model Effective Length

SV4.5L6 4 1/2”

SV4.5L12 10 1/2”

SV4.5L24 22 1/2”

SV4.5L36 34 1/2”

SV4.5L48 46 1/2”

Connecting the vent pipe

Secure Vent® SV4.5 direct-vent system components are unitized concentric pipe components featuring positive twist lock connections

(Figure 17 and Figure 18). All of the fireplaces covered in this document are fitted with collars having locking inclined channels. The

dimpled end of the vent components fit over the fireplace/vent collar to create the positive twist lock connection.

21

Loading...

Loading...