Super Hot SG-135-E, SG-495-E, MG-50-E, MG-150-E, SG135 Installation And Service Manual

...

r

INSTALLATION AND SERVICE MANUAL

INSTALLATION AND SERVICE MANUAL

SG SERIES BOILERS

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury, or loss of life

additional information, consult a qualified installer, service agency or the gas supplier.

SG SERIES BOILERS

FOR MODELS SG-135-E TO SG-495-E

FOR MODELS SG-135-E TO SG-495-E

SEE REAR COVER FOR INDEX

SEE REAR COVER FOR INDEX

Models SG-135-E to SG-270-E

. Please carefully read this manual. For assistance o

Manufacturers of Gas and Electric Boilers, Stainless Steel Tanks, Heat Exchangers and Electric Boosters.

Manufacturers of Gas and Electric Boilers, Stainless Steel Tanks, Heat Exchangers and Electric Boosters.

94 Riverside Drive, North Vancouver, B.C. V7H 2M6 • Telephone (604) 929-1214 • www.alliedboilers.com

94 Riverside Drive, North Vancouver, B.C. V7H 2M6 • Telephone (604) 929-1214 • www.alliedboilers.com

PN2362763

Manufactured by

Manufactured by

Allied Engineering Company

Allied Engineering Company

Division of E-Z-Rect Manufacturing Ltd.

Division of E-Z-Rect Manufacturing Ltd.

Branches: Calgary • Edmonton • Toronto • Denver

Branches: Calgary • Edmonton • Toronto • Denver

`

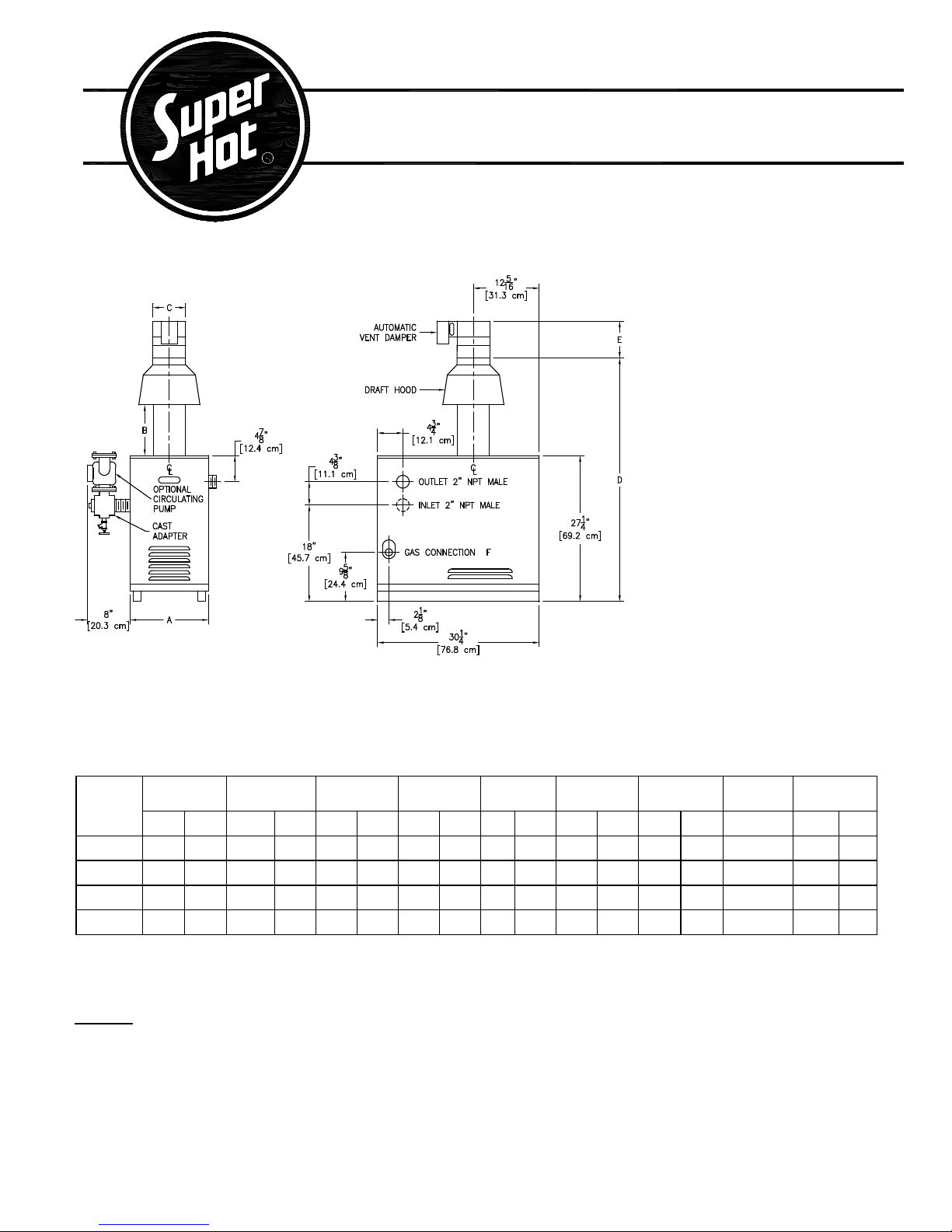

SG SERIES BOILERS

DIMENSIONS AND SPECIFICATIONS

FOR MODELS SG-135 TO SG-270

Standard Model Includes:

• Electronic Ignition

• Zone Control Board with Transformer

• Stainless Steel Burners

• Combination Gas Valve

• High Limit Sensor

• Temperature / Pressure Gauge

• A.S.M.E. Pressure Relief Valve

• Drain Valve

• Draft Hood

• Blocked Vent Safety Switch

• Flame Roll-out Safety Switch

• Automatic Vent Damper

“PS” Packaged Models Include

Standard Model Parts plus:

• Circulating Pump

• Custom Cast Iron Pump Adapter

• Expansion Tank

• Air Purger

• Combination Fill / Regulator Valve

• Automatic Air Vent

Allow 24” (609 mm) minimum in front for servicing.

Minimum clearances to combustible material: Top 24” (610 mm), Sides 2" (51 mm), Rear 2" (51 mm), Flue 6" (153 mm)

APPROVED FOR COMBUSTIBLE FLOORS & CLOSET INSTALLATION.

The Super Hot product improvement program may result in changes to the design and / or specifications being made without notice.

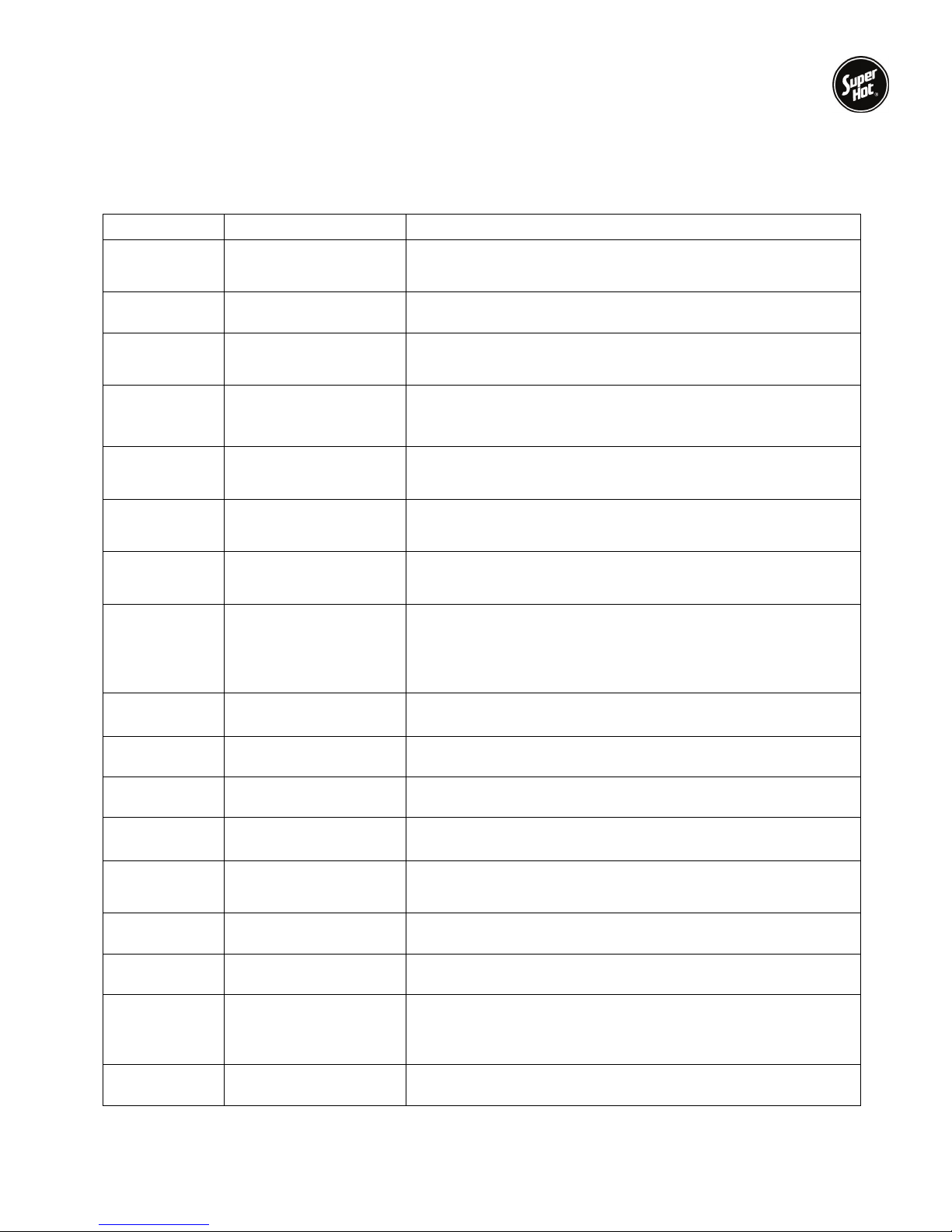

MODEL

NUMBER

SG135 135 39.6 114 33.4 14.7 37.3 9.5 24.1 6.0 15.2 45.3 115 4.5 13.9 0.50” 191 87

SG180 180 52.8 152 44.5 17.7 45.0 9.5 24.1 6.0 15.2 45.3 115 4.5 13.9 0.50” 222 101

SG225 225 65.9 190 55.6 20.7 52.6 9.5 24.1 7.0 17.8 46.5 118 6.5 16.5 0.75” 253 115

SG270 270 79.1 228 66.9 23.7 60.2 9.5 24.1 8.0 20.3 47.6 121 7.5 19.0 0.75” 284 129

* For altitudes above 2,000 feet, refer to Section 3.6 to determine the appropriate Input derate or contact the factory.

** Output based on Natural Gas models

INPUT* OUTPUT** DIM A DIM B DIM C DIM D DIM E

MBH kW MBH kW in cm in cm in cm in cm in cm NPT lb kg

GAS

CONN. F

SHIPPING

WEIGHT

Options:

• Natural Gas add suffix "N" - Propane models add suffix “P”

• Electric Ignition add suffix “E”

• High/Low fire add suffix “M” - Consult Factory for Availability

• Add 45 pounds weight (20 kg) for packaged boilers - add suffix “PS”

2

SG SERIES BOILERS

DIMENSIONS AND SPECIFICATIONS

FOR MODELS SG-315 TO SG-495

Standard Model Includes:

• Electronic Ignition

• Stainless Steel Burners

• Gas Valve

• Redundant Gas Valve

• Operating Aquastat

• High Limit Sensor

• Temperature / Pressure Gauge

• A.S.M.E. Pressure Relief Valve 30 p.s.i.

• Drain Valve

• Draft Hood

• Transformer

• Control Panel Enclosure

Allow 24” (610 mm) minimum in front for servicing.

Minimum clearances to combustible material: Top 24” (610 mm), Sides 2” (51 mm), Rear 2” (51 mm), Flue 6" (153 mm)

APPROVED FOR COMBUSTIBLE FLOORS & CLOSET INSTALLATION, do not install on carpeting.

The Super Hot product improvement program may result in changes to the design and / or specifications being made without notice.

MODEL

NUMBER

SG315 315 92.3 265 77.7 7.9 26.7 67.8 9.5 24.1 8.0 20.3 47.6 121 3/4” 307 140

SG360 360 106 303 88.8 9.0 29.7 75.4 9.5 24.1 9.0 22.9 48.6 124 3/4” 336 153

SG400 400 117 337 98.7 10.0 32.7 83.1 9.5 24.1 9.0 22.9 48.6 124 3/4” 368 167

SG450 450 132 379 111 11.3 35.7 90.7 15.5 39.4 10.0 25.4 55.3 140 1” 395 180

SG495 495 145 416 122 12.4 38.7 98.3 15.5 39.4 10.0 25.4 55.3 140 1” 424 193

INPUT* OUTPUT DIM A** DIM B DIM C DIM D

MBH kW MBH kW H.P. in Cm in cm in cm in cm

GAS

CONN. F

Typical

NPT

SHIPPING

WEIGHT

lb kg

* In Canada: For altitudes above 2,000 feet, contact the factory for the appropriate Input derate.

* In U.S.A.: For altitudes above 2,000 feet, reduce input 4% for each 1000 feet above sea level.

** Add 3” to dimension ‘A’ (1 1/2” to each side of boiler) to allow for 2” NPT water connections.

Options:

• Natural Gas add suffix "N" - Propane models add suffix “P”

• Electric Ignition add suffix “E”

• High/Low fire add suffix “M” - Full Modulation add suffix “MOD”

3

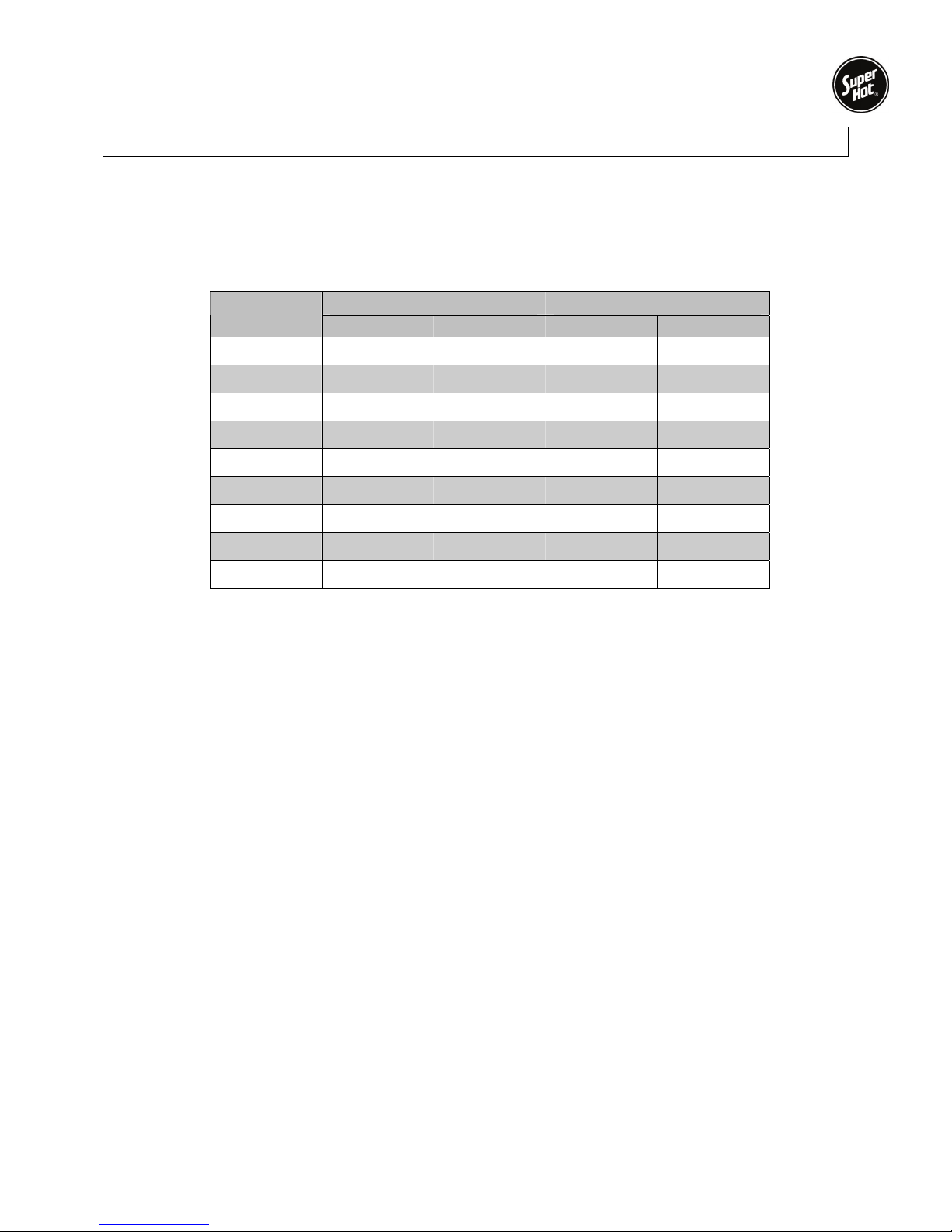

SG Series Boilers – Installation and Service Manual

Boiler Water Flow Data

NOTE: The boiler should be properly sized for its heating application and maintain an adequate water

flow rate during operation. Significantly oversizing the boiler or decreasing boiler water flow

rate will cause excessive stage cycling and may result in premature failure of components.

Typical Water Flow Versus Pressure Drop Across Boiler

Model

Number

U.S. GPM P.D. FT. U.S. GPM P.D. FT.

SG135 11.4 2.8 7.6 1.2

SG180 15.1 2.8 10.1 1.2

SG225 18.9 2.8 12.6 1.2

SG270 22.7 2.8 15.1 1.2

SG315 26.5 3.2 17.7 1.3

SG360 30.3 3.2 20.2 1.4

SG400 33.6 3.3 22.4 1.4

20°F T.D. 30°F T.D.

SG450 37.8 3.8 25.2 1.6

SG495 41.6 4.0 27.7 1.8

4

SG Series Boilers – Installation and Service Manual

ABOUT OUR MANUALS

Your Super Hot boiler has been provided with two manuals:

• User's Information Manual - This manual is intended for the owner or user of the boiler and provides

information on routine operation and maintenance, and emergency shutdown.

• Installation and Service Manual - This manual must only be used by a qualified heating installer,

service technician or gas supplier. Installation or service by anyone unqualified to do so may

result in severe personal injury, death or substantial property damage.

Both manuals should be kept in the envelope provided and affixed adjacent to the boiler so that they are

readily available for future reference.

Lighting Instructions Section 1

1.1 SAFETY INSTRUCTIONS

WARNING

If you do not follow these instructions exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

A. BEFORE LIGHTING smell all around the

boiler area for gas. Be sure to smell next to

the floor because some gas is heavier than

air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier,

call the fire department.

B. Use only your hand to push in or turn the gas

C. Do not use this boiler if any part has been

control knob. Never use tools. If the knob will

not push in or turn by hand, don't try to repair

it, call a qualified service technician. Force or

attempted repair may result in a fire or

explosion.

under water. Immediately call a qualified

service technician to inspect the appliance

and to replace any part of the control system

and any gas control which has been under

water.

1.2 LIGHTING INSTRUCTIONS

Determine the ignition system that applies from the list below and go to the applicable lighting instruction

section.

• Intermittent electronic ignition with combination gas valve (Section 1.3)

• Intermittent electronic ignition with non-combination gas valve (Section 1.4)

Note: A combination gas valve combines the operating and safety shut-off into one valve body. A noncombination gas valve system utilizes separate valve bodies for operating and safety shut-off.

If you are unsure which type of gas valve or ignition system your boiler is equipped with, check the

lighting instructions sticker on the boiler or contact the factory.

5

SG Series Boilers – Installation and Service Manual

1.3 LIGHTING INSTRUCTIONS FOR INTERMITTENT ELECTRONIC IGNITION

WITH COMBINATION GAS VALVE.

1. This boiler is equipped with an ignition device

which automatically lights the pilot. Do not

to light the pilot by hand. Ensure gas supply

to the boiler is turned on.

2. STOP! Read the safety instructions in

Section 1.1.

3. Set the room thermostat to lowest setting.

4. Turn off all electrical power to the appliance.

5. Remove control access panel if necessary.

6. Push in gas control knob slightly and turn

clockwise

to "OFF".

try

NOTE: On some gas valves the knob cannot

7. Wait five (5) minutes to clear out any gas.

8. Turn gas control knob counterclockwise

9. Replace control access panel if necessary.

10. Turn on all electrical power to the boiler.

11. Set room thermostat to desired setting.

12. If the appliance will not operate, follow the

To turn off gas to boiler or emergency shut-off

Follow Section 1.5.

be turned to "OFF" or “ON” position unless

knob is pushed in slightly. Do not force.

Then smell for gas, including near the floor. If

you smell gas, STOP! Follow "A" in the safety

instructions in Section 1.1. If you don't smell

gas, go to the next step.

to "ON".

instructions "To Turn Off Gas To Boiler" in

Section 1.6 and call your service technician or

gas supplier.

1.4 LIGHTING INSTRUCTIONS FOR INTERMITTENT ELECTRONIC IGNITION

WITH NON-COMBINATION GAS VALVE.

This boiler is equipped with an ignition device, which automatically lights the pilot. Do not try to light the

pilot by hand. Before turning on the electrical power switch, be sure all gas supply lines are purged of air

and power supply to control is the correct voltage.

If the pilot or main burners are not lit or the control system is locked-out due to flame failure, close the

main and pilot gas shut-off valves and call your service technician or gas supplier. If you smell gas,

STOP! Follow “A” in the safety instructions in Section 1.1.

Check Control Operation

1. STOP! Read the safety instructions in

Section 1.1.

2. For 100% shut off check, close main and pilot

manual gas shut off valves, turn off all

electric power to the boiler and wait for five

minutes to clear out any gas.

3. Then smell for gas, including near the floor.

If you smell gas, STOP! Follow safety

instructions in Section 1.1. If you don’t smell

gas, go to the next step.

4. Set the thermostat above room temperature

and turn on all electric power to the boiler to

energize the electronic ignition and pilot

valve. After a few seconds, control system

should “lockout” and all functions are off.

5. To take the control system out of “lockout”

either press the reset button or interrupt

power to the boiler, depending on the boiler

controller. Some controllers will retry ignition

automatically after 5 minutes lockout.

Start System

1. Turn on the main and pilot manual gas shutoff valves.

2. Set thermostat above room temperature and

turn on all electrical power to the boiler.

3. Once the pilot flame is proven, the controller

opens the main burner gas valves. The pilot

flame will ignite the gas as it exits the main

burner ports.

4. Set thermostat to the desired setting to put

system back in service.

Relight Operation

Five minutes complete shut off period is required

before attempting to relight the boiler. To relight

the boiler, follow the Start System procedure

(above).

To turn off gas to boiler or emergency shutoff

Follow Section 1.5

6

SG Series Boilers – Installation and Service Manual

y

1.5 TO TURN OFF GAS TO THE BOILER OR EMERGENCY SHUT-OFF

WARNING

Should boiler overheat, or the gas supply fail to shut off, do not turn off or disconnect the

electrical supply to the circulating pump. Instead, shut off the gas supply at a location external

to the boiler.

1. Set the thermostat to the lowest setting.

2. Turn all electrical power to the boiler off.

3. Remove control access panel on the boiler if necessary.

4. For combination valve: Push in gas control knob slightly and turn clockwise

force it.

For non-combination valve: Close the main and pilot manual gas shut off valves. The valve is "OFF"

when handle is perpendicular to the direction of gas flow.

5. Replace control access panel if necessary.

to "OFF". Do not

1.6 CONTROLLER PROGRAMMING AND SERVICE CODES

2012 NRCan and DOE Compliance and Operation

Operation of this control may delay the burner operation while the residual heat is circulated

out of boiler.

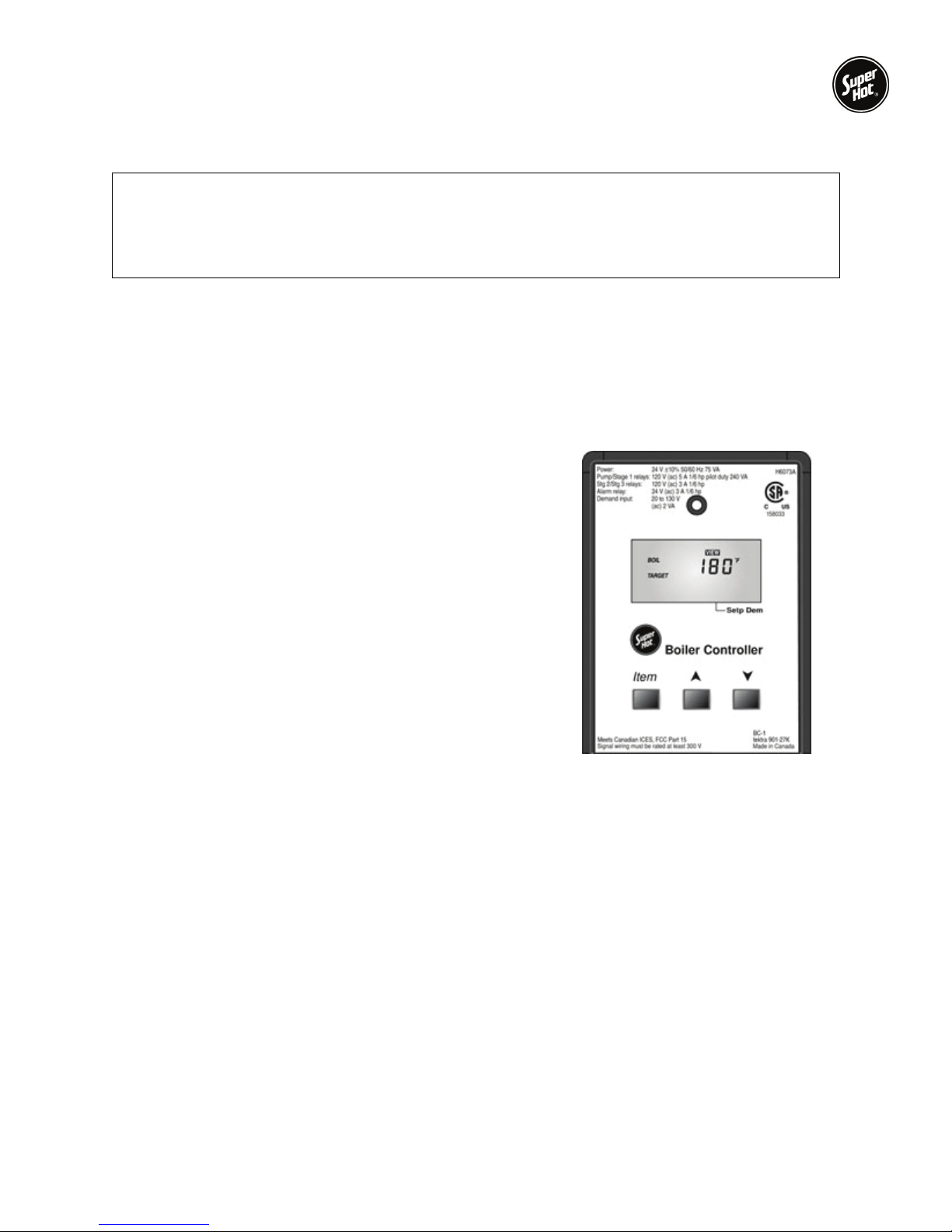

The integrated boiler control module provides ignition

sequence, flame monitoring and safety shutoff for intermittent

pilot spark ignition. It also provides limit rated water

temperature control for with two separate sensors in one

casing (3-wire).

The control is located on the front panel inside the boiler.

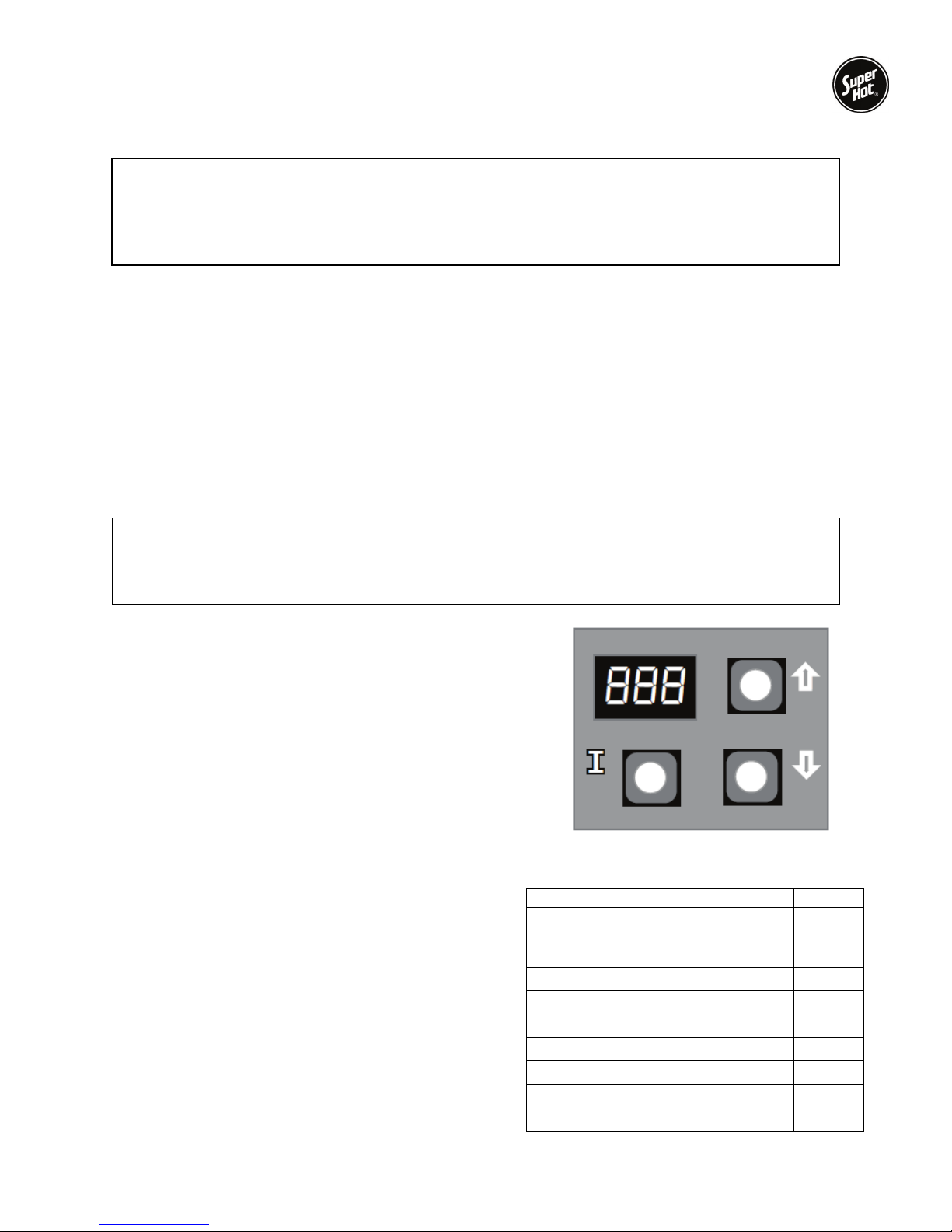

The control display, along with Up ▲, Down ▼, and “I” keys

may be used to view boiler operating status and program

parameters (Figure 1).

1.6.1 RUN MODE

In the RUN mode, status items and parameters are

viewable.

To read settings, press and release the “I” key to find the

parameter of interest. Each setting will alternately flash

between the relevant display code listed in the Table 1

and its corresponding value. For example, press and

release “I” key until “HL_” setpoint is displayed, it will then

flash a three-digit number, i.e., 220, followed by ˚F (or ˚C).

This indicates that the boiler water temperature of 220 ˚F

is set. Other operating parameters display the settings in

a similar fashion.

7

Figure 1 Control Displa

Table 1 Run Mode Parameters

Text Description Display

STA Status (see status

numbers)

BT Boiler temperature

SP Operating setpoint

HL High limit setpoint

HDF Differential set-point

FLA Flame current

RUN Run time hours

CYC Boiler cycles

ERR Error (see error numbers)

StA

bt

SP

HL

HdF

FLA

run

CYC

Err

SG Series Boilers – Installation and Service Manual

p

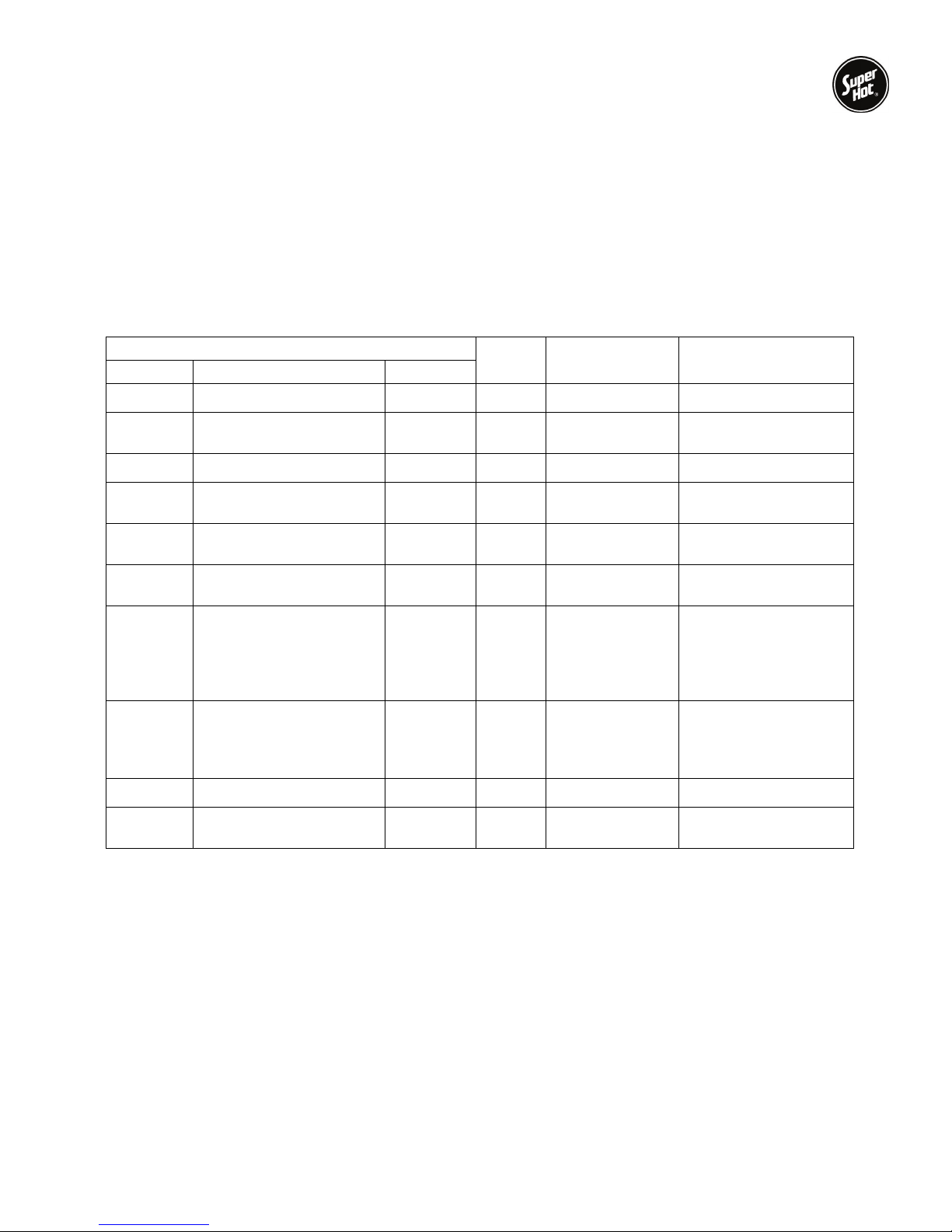

1.6.2 INSTALLER MODE

To enter the adjustment mode:

1. Press with Up ▲, Down ▼, and “I” keys (see Figure 1) simultaneously for three seconds.

2. Press and release the “I” key until the parameter (listed in the Table 2) requiring adjustment is

displayed.

3. Press with Up ▲ or Down ▼ key until the parameter has reached the desired value.

4. After 60 seconds without any key inputs, the control will automatically return to the RUN Mode.

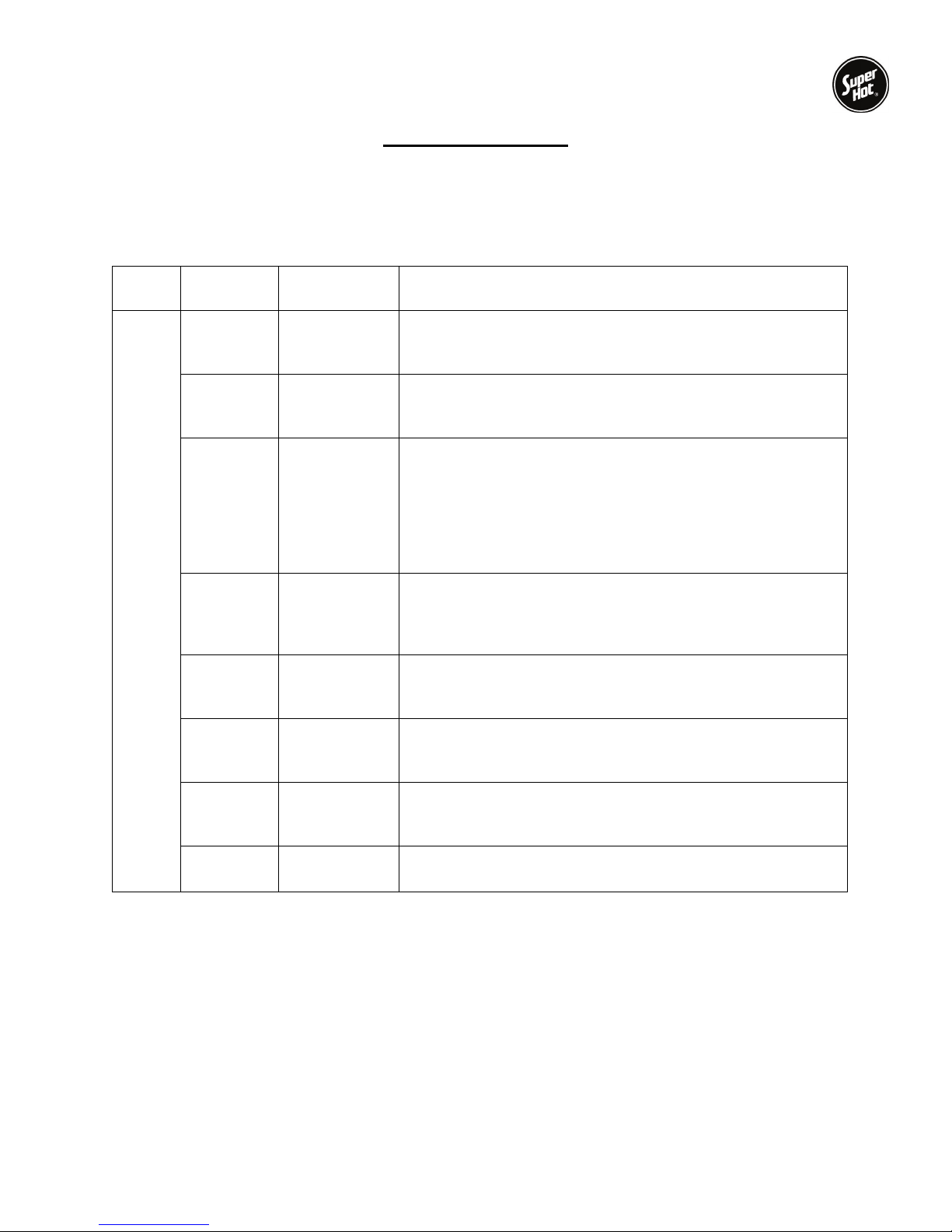

Table 2 Installer Mode O

3-Digit 7-Segment Display

1st Screen 2nd Screen (setting value) 3rd Screen

HL_

HdF

Or_

otH

otL

btL

tPL

tPt

rSt

F-C

<high limit> ˚F or ˚C 180 ˚F 130 to 220 ˚F Adjust high limit setting

<high limit differential> ˚F or ˚C 15 ˚F 10 to 30 ˚F

<pump overrun time> Sec 60 sec 0 to 120 seconds Pump post-purge time

<ODR maximal temp.> ˚F or ˚C 55 ˚F 40 to 70 ˚F

<ODR minimal temp.> ˚F or ˚C 0 ˚F -40 to 40 ˚F

<minimal water temp.> ˚F or ˚C 140 ˚F 130 to 150 ˚F

<minimal boiler temp.> ˚F or ˚C 140 ˚F

<maximal delay> Min 2 1 to 10 minutes

On or OFF N/A N/A Reset lockout

˚F or ˚C

tions

Default Range

˚F ˚F or ˚C

OFF,

120 to 160 ˚F

Description

Adjust high limit

differential

Maximal outdoor

temperature

Minimal outdoor

temperature

Minimal boiler

temperature

Thermal purging

minimal temperature

(parameter is available

only if outdoor

temperature is invalid)

Maximal thermal purge

time (parameter is

available only if outdoor

temperature is invalid)

Select degrees ˚F or ˚C

mode

8

SG Series Boilers – Installation and Service Manual

1.6.3 OPERATING CHECKOUT

After adjusting parameters, put the boiler into operation and observe operation through at least one

complete cycle to make sure that the controller operates properly. See controller troubleshooting section

to assist in determining boiler operation.

The sensor should fit snugly and should touch the bottom of the well for best temperature response. The

sensor is held inside the well using the well clip.

1.6.4 THERMAL PURGE

The intent of thermal purge is to ensure usable residual heat in the boiler is circulated until it is sufficiently

depleted from the system before the burner is allowed to fire. To that end, on a call for heat, the burner

remains off while the circulator runs until the boiler temperature drops to the thermal purge temperature

limit or the time delay is exceeded. Both of these parameters are adjustable. When the boiler temperature

falls below the thermal purge temperature limit or the time delay expires, the burner is allowed to fire.

In addition to the thermal purge temperature and thermal purge time delay parameters, two other

conditions release the integrated boiler controller from thermal purge and allow the burner to run in order

to maintain comfort in the space:

• The boiler temperature has dropped 10 °F from the boiler water temperature measured at the

beginning of the call for heat.

• Boiler temperature is cooling at a rate greater than 5 °F/minute while the circulator is running.

1.6.5 OPERATING STATE CODES AND TROUBLESHOOTING

When there is a problem during a call for heat or boiler operation, the controller provides specific

information to help resolve the issue quickly. If the controller is displaying “StA” by a number, use the

state code definitions in the Table 3 to determine the problem and possible causes.

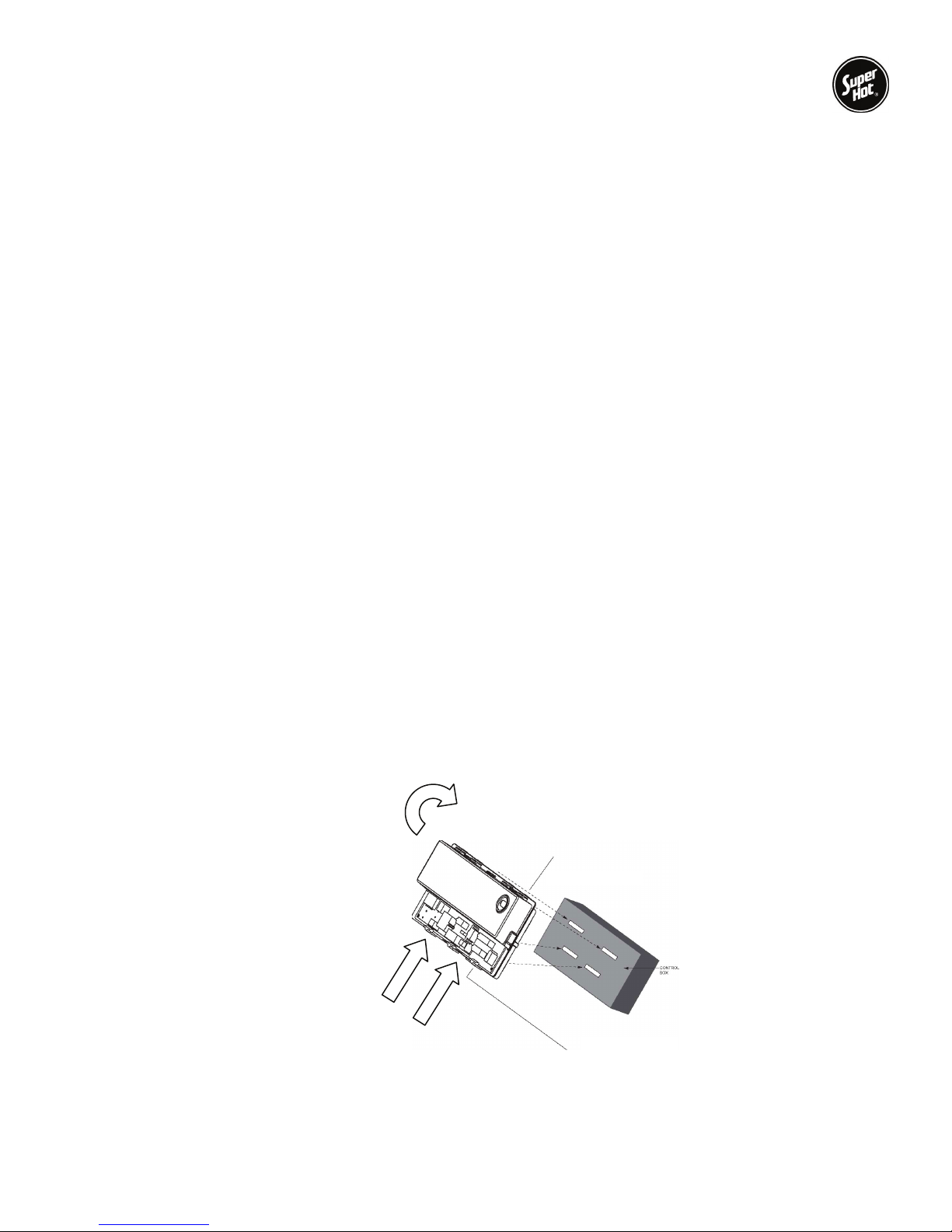

1.6.6 CONTROLLER MOUNTING

The controller has four tabs which align with four slots in the control panel. To remove the controller,

press and hold in the bottom two tabs while simultaneously rotating the controller about 45 degrees to

unhook the top two tabs.

Rotate 45°

PRESS and HOLD

both tabs while

rotating controller

9

SG Series Boilers – Installation and Service Manual

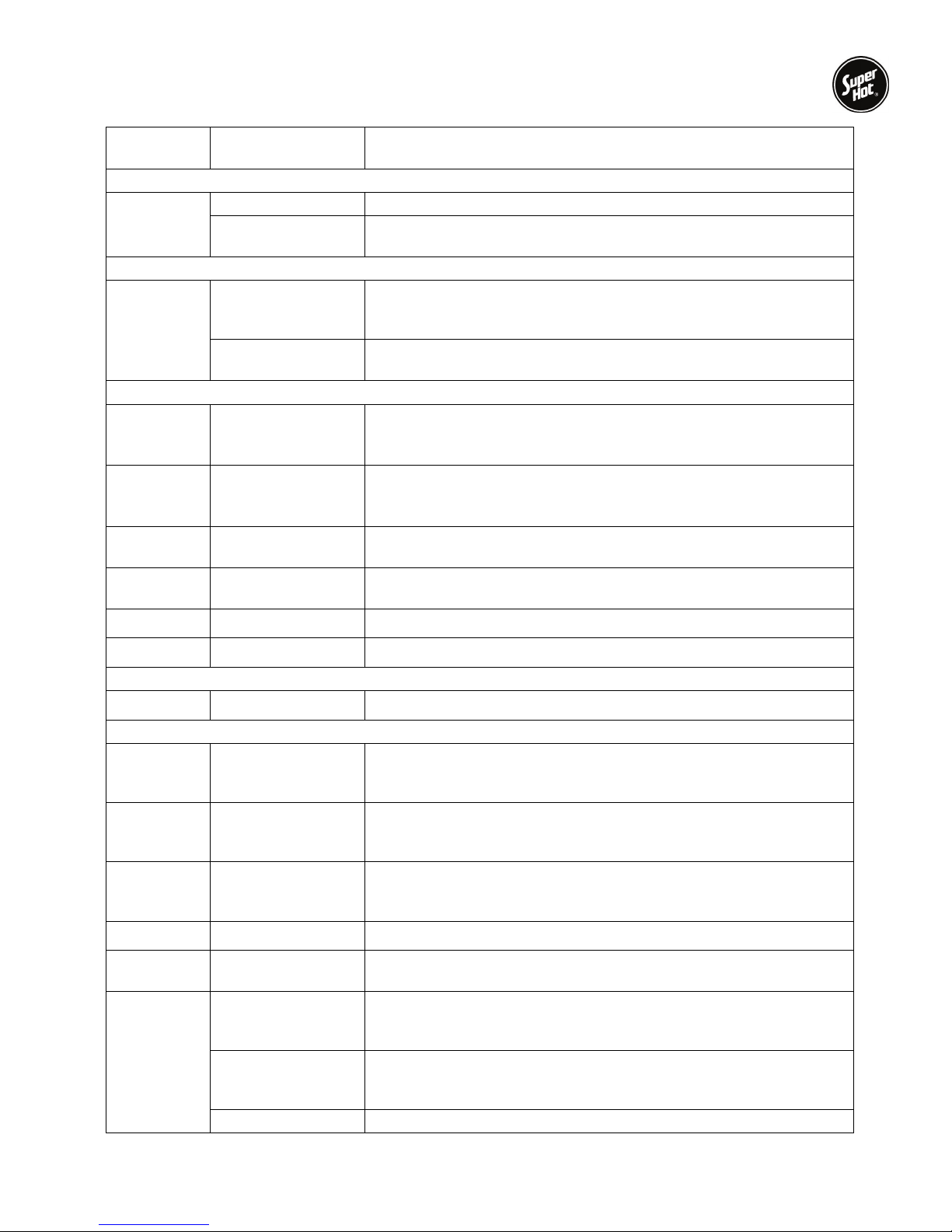

Display

Code

Operation Sequence

StA ↔1

Thermostat Calls For Heat

StA ↔17

Circulator output energizes

StA ↔ 2

StA ↔ 3

StA ↔ 4

StA ↔ 6

StA ↔ 7

StA ↔ 8

Call For Heat Ends

StA ↔ 9

Troubleshooting/Diagnostics

StA ↔10

Err ↔ 2

Err ↔ 29

Err ↔ 62

StA ↔15

StA ↔16

State Specific Description

Idle/Standby The boiler is in standby - no call for heat

Run circulator Heat request present but boiler water temperature sufficiently high to

run circulator pump only (no ignition sequence)

Self Test Hardware self check, check of connected periphery, it is performed

at start up, in the beginning of the heat cycle and in the “Wait For

recovery” state

Wait for recovery There is an external error and the control is waiting to recover, no

lockout

Wait for end switch

to open

Wait for end switch

to close

Pump pre-purge/

thermal purge

Spark, ignition

activation

Prove flame System is proving flame signal, typically 2 seconds

Running System is in running mode, flame signal must be present

Pump post-purge System is purging at the end of a call for heat

Inter-purge

(retry/recycle delay)

Wait for end switch

to open – failed

closed

Wait for end switch

to close – failed

open

Soft lockout System is shutdown and will re-start following an enforced delay

Wait for limit to close

Flame out of

sequence – before

trial

Flame out of

sequence – after

trial

Wait for flame loss Flame signal still present when not expected.

The control is waiting for the end switch of the vent damper to open

at the beginning of a heat cycle. If the end switch doesn’t open in 60

seconds, the control goes to error code Err 2

The control is waiting for the end switch of venting damper to close at

the beginning of a cycle. If the end switch doesn’t close within 60

seconds, the control goes to error code Err 29

System is purging before ignition trial-safety relay diagnostics

followed safety relay switch-on during last 2 seconds this sate

System is sparking permanently 13 seconds whilst pilot gas valve

relay is turned on

If the control loses flame signal during state code 7 or 8, or flame is

not detected during stat code 6 to 8, it will recycle through the 30

seconds purge time and last 2 seconds part of pre-purge time

The end switch of venting damper has not opened at the beginning

of the heat cycle. The control is not in lockout

Waiting time for pressure switch to close expired. The control is not

in lockout

There may be a call for heat from the thermostat, but the limit switch

is open

Flame signal sensed before trial for ignition.

Flame out of sequence during post-purge.

10

SG Series Boilers – Installation and Service Manual

If the controller is displaying “

determine the problem and possible causes.

Table 4 Error Codes

Display State Solution

Err ↔ 2

End switch of venting

damper failed to open

Err” followed by a number, use the error code definitions in the Table 4 to

The end switch contacts stuck closed. Check the venting

damper and replace it if necessary.

Err ↔ 4

Err ↔ 6

Err ↔18

Err ↔ 23

Err ↔ 24

Err ↔ 29

Err ↔ 32

Err ↔ 57

Err ↔ 58

Low flame current

Flame sensed out of

normal sequence

Gas valve relays

welded 5 consecutive

soft lockouts

Flame sensed during

pre-purge

Flame sensed during

post-purge

End switch of venting

damper failed to close

Sensor error

Flame rod shorted to

burner ground

AC line frequency error

Check pilot assembly and replace it if necessary.

Flame sensed out of normal sequence (before opening gas

valve or after closing gas valve).

A manual reset is required.

Flame sensed during pre-purge (before gas valve signaled

opened)

Flame sensed during post-purge (before gas valve signaled

closed)

The end switch contacts stuck open. Check the venting

damper and replace it if necessary.

Temperature sensor or interface failure (open or short

connection, increased connection resistance, dual sensor

mismatch) or failure of A/D conversion (invalid offset or gain,

too many failures during A/D conversion).

Check and adjust or replace if necessary.

AC signal is too noisy or frequency is incorrect.

Err ↔ 59

Err ↔ 60

Err ↔ 61

Err ↔ 62

Err ↔ 63

Err ↔ 64

Err ↔ 65

Line voltage error

Thermostat input

higher than threshold

Line voltage unstable

Soft lockout

Soft lockout

Soft lockout

Over temperature error

AC voltage out of specification high or low.

Check thermostat wiring and replace it if necessary.

Possibly too many heavy loads switching on and off cause

erratic supply voltage.

Maximum number of retries exceeded.

Maximum number of recycles exceeded.

Internal failure (Electronics failure). Caused by general

electronics failure such as relay open or shorted contacts,

flame sensing circuit error, or A to D error.

Sensor measured temperature in excess of ECO limit.

11

SG Series Boilers – Installation and Service Manual

1.7 BC-1 CONTROLLER (FOR 2 STAGE BOILERS ONLY)

WARNING

For boilers equipped with the BC-1 Controller, read all instructions in this manual and the BC-1

Controller Manual before placing the boiler in operation or making adjustments to the

controller. Adjustments must be made by a qualified heating technician.

The BC-1 controller is supplied as standard option with two stage boilers for models SG-315 and larger.

It is not supplied with boilers equipped with a full modulating gas valve. For convenience, the BC-1

controller is factory wired to terminal block TB4 and ready for field wiring connections. The field wiring to

TB4 is determined based on the operating mode selected (i.e. mode 1 to 6), the heating application and

the piping arrangement (i.e. parallel or primary/secondary). Refer to Figure 2 for the wiring diagram

according to each mode. For important instructions regarding programming and operation of the BC-1

controller, refer to the BC-1 Controller Manual included with your boiler.

Power Outputs from BC-1:

Boiler Stage outputs from 15-STG1 and 17-STG2

terminals from the BC-1 are 24 Vac, 60 Hz (when

factory wired).

Alarm output from 23-ALARM terminal from the BC-1 is

24 Vac, 60 Hz, 0.45 A maximum (when factory wired).

Alarm is wired to terminal block TB4, terminals AL&AL.

Signal Inputs (Do not apply external power):

The following signal inputs are located on terminal block TB4:

HT&R: Room thermostat or zone valve end switch,

24Vac switching input, closed is activation.

ST&R: Setpoint DHW aquastat, 24Vac switching

input, closed is activation.

FS&FS: Flow switch, 24Vac switching input, closed

is activation.

Figure 2 – BC-1 Controller

Thermistor Sensors

BO&CM: Boiler outlet sensor

BI&CM: Boiler inlet sensor

OS&CM: Outdoor sensor

SD&CM: Supply / DHW sensor

BC-1 Controller Mounting

The BC-1 controller mounts on separate bracket on the control panel using a sheet metal screw at the top

center. To remove the controller: 1.) remove the front casing panel, 2.) pull off the black top cover of the

controller, 3.) unscrew the sheet metal screw, 4.) lift the controller slightly out of the rectangular cutout in

the mounting bracket, 5.) pull off the Molex connector while simultaneously holding down the tab on the

left side.

12

SG Series Boilers – Installation and Service Manual

Field wiring to terminal block TB4

Figure 3 – Field wiring to terminal block TB4

13

SG Series Boilers – Installation and Service Manual

Electrical Connections

For all electrical connections: Strip wire ends and insert into the terminal block. Tighten terminal screw

clamps to securely hold the wire.

CAUTION - Risk of damage to the controller - Do not apply power to any connections on terminal

block TB4. 24 Vac has been factory wired to terminals C-1 and HL-15.

Terminal

Block

TB4

Connections Name Description / Comments

BO & CM

Boiler Outlet

Sensor

Connect boiler outlet water temperature sensor to terminals

BO and CM (common). The Boiler Outlet Sensor must be

attached using a cable tie to the boiler outlet pipe.

BI & CM

Boiler Inlet

Sensor

Connect inlet water temperature sensor to terminals BI and

CM (common). The Boiler Inlet Sensor must be attached using

a cable tie to the boiler inlet pipe.

OS & CM

Outdoor

Sensor

Optional Outdoor Sensor (for Mode 4 and 5 only): Connect

Outdoor Sensor 070 to terminals OS and CM (common). The

Outdoor Sensor is installed on an exterior wall, typically facing

North, and above the snow line. It should be shielded from

effects of heat or cold to prevent false outdoor temperature

readings. Avoid direct sunlight, exhaust fans, appliance vents,

and excessive moisture.

SD & CM

Supply/DHW

Sensor

Optional (for Modes 2, 3, and 5 only). Connect a Supply or

DHW Sensor 071 to terminals SD and CM (common). The

Supply/DHW sensor is inserted into a thermowell on the DHW

tank or attached using a cable tie to the supply pipe.

AL & AL

Alarm Optional. The alarm contacts are a powered output, do not

apply power. Connect an alarm (beeper, light, or relay) with a

rating of 24 Vac and maximum 0.45 A to terminals AL and AL.

FS & FS

Flow Switch Not used. Leave Jumper 5-6 on TB4. For convenience, the

Flow Switch terminals have been relocated to terminal block

TB2, poles T1 & S. Do not apply power.

ST & R

Setpoint DHW

Demand

Optional Domestic Hot Water Aquastat (for Modes 4 and 5

only): Connect domestic hot water aquastat to terminals ST

and R. Closed is activation. Do not apply power.

HT & R

Heat Demand Connect Thermostat or Zone Valve End Switch to terminals

HT and R. Closed is activation. Do not apply power.

14

Loading...

Loading...