Super Hot MG-50-E-MG-150-E, SG-135-E-SG-495-E, AAA-480-E-AAA-3000-E, MG-50-E, MG-150-E User's Information Manual

...

USER'S INFORMATION MANUAL

GAS BOILERS

FOR MODELS: MG-50-E TO MG-150-E

SG-135-E TO SG-495-E

AAA-480-E TO AAA-3000-E

WARNING:

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury

or loss of life.

→ Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

→ WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

→ Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

DATE OF INSTALLATION :

INSTALLED BY :

COMPANY :

ADDRESS :

PHONE :

Manufacturers of Gas and Electric Boilers, Stainless Steel Tanks, Heat Exchangers and Electric Boosters.

94 Riverside Drive, North Vancouver, B.C. V7H 2M6 • Telephone (604) 929-1214 • www.alliedboilers.com

PN2362763

H

Manufactured by

Allied Engineering Company

Division of E-Z-Rect Manufacturing Ltd.

Branches: Calgary • Edmonton • Toronto • Denver

MG, SG & AAA Series Boilers – User’s Information Manual

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, personal injury (exposure to hazardous materials) or loss of life. Installation and

service must be performed by a qualified installer, service agency or the gas supplier (who

must read and follow the supplied instructions before installing, servicing, or removing this

boiler). This product contains materials (Refractory Ceramic Fibers) that have been identified

as carcinogenic, or possibly carcinogenic, to humans. Follow the Refractory Handling

Procedure instructions in the Installation and Service Manual.

WARNING

It is the responsibility of the homeowner to keep the vent terminal and air supply terminal clear

of snow and ice.

Use of Carbon Monoxide Detectors is recommended. Follow building code requirements with

respect to installation and approvals.

IN THE STATE OF MASSACHUSETTS ONLY

For installations in the Commonwealth of Massachusetts, the following local requirements apply

in addition to all other applicable NFPA requirements:

For direct-vent boilers, mechanical-vent heating appliances or domestic hot water equipment, where the bottom of the vent terminal

and the intake is installed below four feet above grade the following requirements must comply:

1. If not present on each floor level where there are bedrooms, a carbon monoxide detector and alarm must be placed in a living

area outside the bedrooms. The carbon monoxide detector and alarm must comply with NFPA 720 (Current Edition).

2. A carbon Monoxide detector and alarm shall be located in the room that houses the appliance and/or equipment and shall:

a) Be powered by the same electrical circuit as the appliance and/or equipment such that only one service switch services

both the appliance and the carbon monoxide detector;

b) Have battery back-up power;

c) Meet ANSI/UL 2034 Standards and comply with NFPA 720 (Current Edition); and

d) Have been approved and listed by a Nationally Recognized Testing Lab as recognized under 527 CMR.

3. A product-approved vent terminal must be used, and if applicable, a product approved air intake must be used. Installation

shall be performed in strict compliance with the manufacturer’s instructions. A copy of the installation instructions shall remain

with the appliance and/or equipment at the completion of the installation.

4. A metal or plastic identification plate shall be mounted at the exterior of the building, four feet directly above the location of vent

terminal. The plate shall be of sufficient size to be easily read from a distance of eight feet away, and read “Gas Vent Directly

Below”.

For direct-vent boilers, mechanical-vent heating boilers or domestic hot water equipment where the bottom of the vent terminal and

the intake is installed higher than four feet above grade the following requirements must comply:

1. If not present on each floor level where there are bedrooms, a carbon monoxide detector and alarm must be placed in a living

area outside the bedrooms. The carbon monoxide detector and alarm must comply with NFPA 720 (Current Edition).

2. A carbon monoxide detector shall:

a) Be located in the room where the boiler and/or equipment is located;

b) Be either hard-wired or battery powered or both; and,

c) Shall comply with NFPA 720 (Current Edition).

3. A product-approved vent terminal must be used, and if applicable, a product approved air intake must be used. Installation

shall be in strict compliance with the manufacturer’s instructions. A copy of the installation instructions shall remain with the

appliance and/or equipment at the completion of the installation.

2

MG, SG & AAA Series Boilers – User’s Information Manual

1 ABOUT OUR MANUALS

Your Super Hot boiler has been provided with two manuals:

• User's Information Manual - This manual is intended for the owner or user of the boiler and provides

information on routine operation and maintenance, and emergency shutdown.

• Installation and Service Manual - This manual must only be used by a qualified heating installer,

service technician or gas supplier. Installation or service by anyone unqualified to do so may

result in severe personal injury, death or substantial property damage.

Both manuals should be kept in the envelope provided and affixed adjacent to the boiler so that they are

readily available for future reference.

2 SAFETY INSTRUCTIONS

WARNING

If you do not follow these instructions exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

A. BEFORE LIGHTING smell all around the

boiler area for gas. Be sure to smell next to

the floor because some gas is heavier than

air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier,

call the fire department.

B. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will

not push in or turn by hand, don't try to repair

it, call a qualified service technician. Force or

attempted repair may result in a fire or

explosion.

C. Do not use this boiler if any part has been

under water. Immediately call a qualified

service technician to inspect the appliance

and to replace any part of the control system

and any gas control which has been under

water.

3 LIGHTING INSTRUCTIONS

Your boiler is equipped with one of two optional electronic ignition systems. Determine the ignition

system that applies from the list below and go to the applicable lighting instruction section.

• Intermittent electronic ignition with combination gas valve for MG-50-E to SG-400-E (Section 4)

• Intermittent electronic ignition with non-combination gas valve for SG-450-E to AAA-3000-E

(Section5)

Note: A combination gas valve combines the operating and safety shut-off into one valve body and is

typical in residential installations. A non-combination gas valve system utilizes two separate valve

bodies for operating and safety shut-off and is typical in commercial installations.

If you are unsure which type of gas valve your boiler is equipped with, check the lighting instructions

sticker on the boiler or contact the factory.

3

MG, SG & AAA Series Boilers – User’s Information Manual

4 LIGHTING INSTRUCTIONS FOR INTERMITTENT ELECTRONIC IGNITION

WITH COMBINATION GAS VALVE.

1. This boiler is equipped with an ignition device

which automatically lights the pilot. Do not

to light the pilot by hand. Ensure gas supply

to the boiler is turned on.

2. STOP! Read the safety instructions in

Section 2.

3. Set the room thermostat to lowest setting.

4. Turn off all electrical power to the appliance.

5. Remove control access panel if necessary.

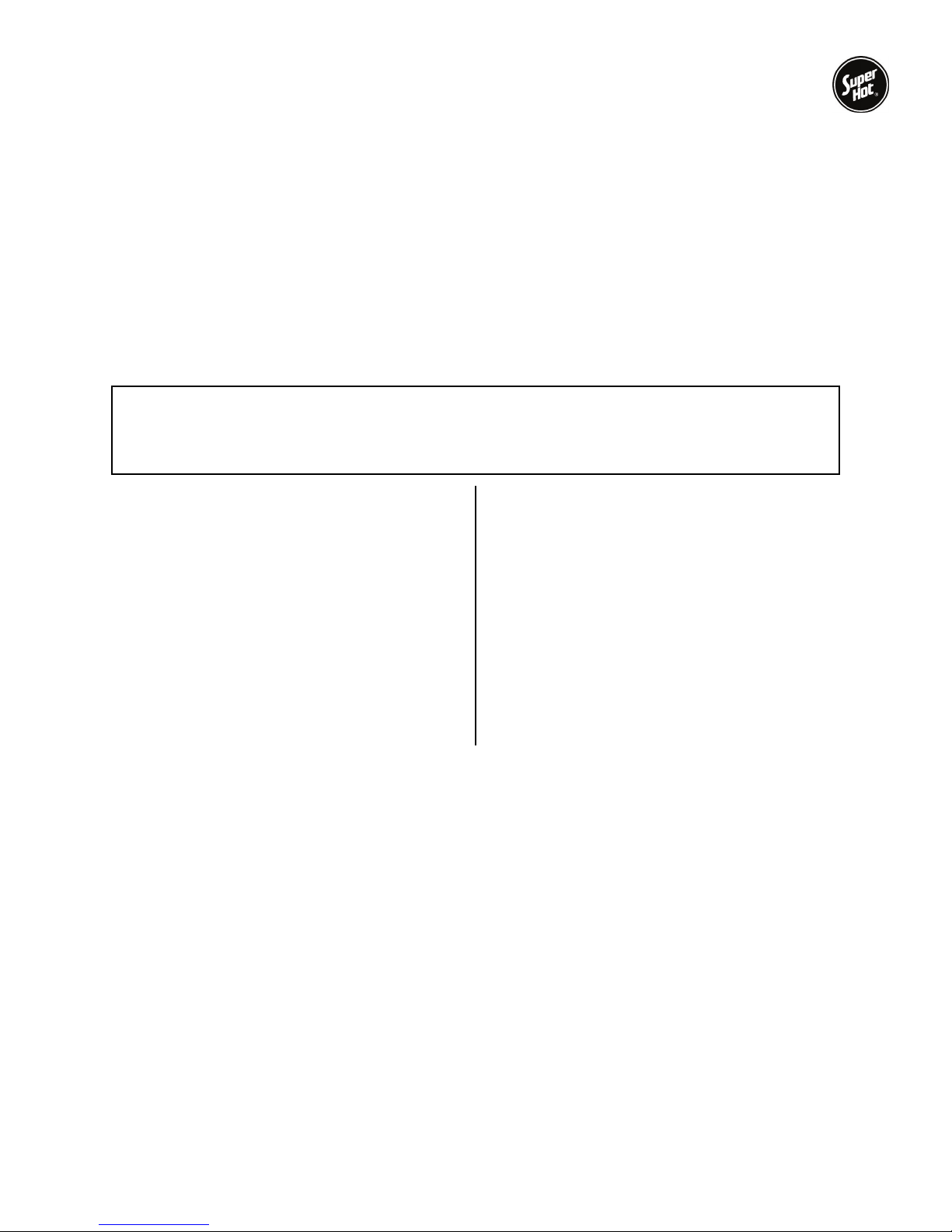

6. Push in gas control knob slightly and turn

clockwise

to "OFF".

try

NOTE: On some gas valves the knob cannot

be turned to "OFF" or “ON” position unless

knob is pushed in slightly. Do not force.

7. Wait five (5) minutes to clear out any gas.

Then smell for gas, including near the floor.

If you smell gas, STOP! Follow "A" in the

safety instructions in Section 2. If you don't

smell gas, go to the next step.

8. Turn gas control knob counterclockwise

to "ON".

9. Replace control access panel if necessary.

10. Turn on all electrical power to the Boiler.

11. Set room thermostat to desired setting.

12. If the appliance will not operate, follow the

instructions "To Turn Off Gas To Boiler" in

Section 7 and call your service technician or

gas supplier.

To turn off gas to boiler or emergency shut-off

Follow Section 6.

5 LIGHTING INSTRUCTIONS FOR INTERMITTENT ELECTRONIC IGNITION

WITH NON-COMBINATION GAS VALVE.

This boiler is equipped with an ignition device, which automatically lights the pilot. Do not try to light the

pilot by hand. Before turning on the electrical power switch, be sure all gas supply lines are purged of air

and power supply to control is the correct voltage.

If the pilot or main burners are not lit or the control system is locked-out due to flame failure, close the

main and pilot gas shut-off valves and call your service technician or gas supplier. If you smell gas,

STOP! Follow “A” in the safety instructions in Section 2.

Check Control Operation

1. STOP! Read the safety instructions in

Section 2.

2. For 100% shut off check, close main and pilot

manual gas shut off valves, turn off all electric

power to the boiler and wait for five minutes to

clear out any gas.

3. Then smell for gas, including near the floor. If

you smell gas, STOP! Follow safety instructions

in Section 2. If you don’t smell gas, go to the

next step.

4. Set the thermostat above room temperature

and turn on all electric power to the boiler to

energize the electronic ignition and pilot valve.

After a few seconds, the control system

should “lockout” and all functions are off.

5. To take the control system out of “lockout”

either press the reset button or interrupt power

to the boiler, depending on the boiler

controller. Some controllers will retry ignition

automatically after 5 minutes lockout.

Start System

1. Turn on the main and pilot manual gas shutoff valves.

2. Set thermostat above room temperature and

turn on all electrical power to the boiler.

3. Once the pilot flame is proven, the controller

opens the main burner gas valves. The pilot

flame will ignite the gas as it exits the main

burner ports.

4. Set thermostat to the desired setting to put

system back in service.

Relight Operation

Five minutes complete shut off period is required

before attempting to relight the boiler. To relight

the boiler, follow the Start System procedure

(above).

To turn off gas to boiler or emergency shut-off

Follow Section 6.

4

MG, SG & AAA Series Boilers – User’s Information Manual

6 TO TURN OFF GAS TO THE BOILER OR EMERGENCY SHUT-OFF.

WARNING

Should boiler overheat, or the gas supply fail to shut off, do not turn off or disconnect the

electrical supply to the circulating pump. Instead, shut off the gas supply at a location external

to the boiler.

1. Set the thermostat to the lowest setting.

2. Turn all electrical power to the boiler off unless boiler is overheating (see "WARNING" above).

3. Remove control access panel on the boiler if necessary.

4. For combination valve: Push in gas control knob slightly and turn clockwise

force it.

For non-combination valve: Close the main and pilot manual gas shut off valves. The valve is "OFF"

when handle is perpendicular to the direction of gas flow.

5. Replace control access panel if necessary.

If the boiler does not operate properly, immediately contact a qualified service agency for

adjustment or corrective measures.

to "OFF". Do not

7 AREA AROUND BOILER

WARNING

Do not use this boiler if any part has been under water. Immediately call a qualified service

technician to inspect the boiler and to replace any part of the control system and any gas control

which has been under water.

Keep boiler area clear and free from combustible materials, gasoline and other flammable vapors and

liquids.

Do not store anything against the boiler or allow dirt or debris to accumulate in the area immediately

surrounding the boiler. It is unsafe for the flow of supply and exhaust air to be obstructed in any way.

Should your boiler be subjected to fire, flood or some other unusual condition, turn off all gas and

electrical supply. If you are unable to turn off the gas, call your gas company or gas supplier at once. Do

not put the boiler in operation again until it has been ascertained by a qualified agency that the controls

are functioning correctly. The installer should always clearly identify the emergency shut-off devices and

make the owner aware of their location and method of operation.

8 CHECK FOR GAS LEAKS

To identify gas leaks, smell for gas around boiler area and gas piping connections. To check a specific

area for leakage, spray a mixture of soap and water onto the suspected area – active bubbling indicates a

gas leak. DO NOT TEST FOR LEAKS WITH AN OPEN FLAME.

Propane or liquefied petroleum (LP) is heavier than air may collect or "pool" in a low area in the event of a

leak from defective equipment. This gas may then ignite resulting in a fire or explosion. Smell near to the

ground and low points when checking for propane gas leaks.

If you smell gas, STOP! Follow "A" in the safety instructions in Section 2.

5

MG, SG & AAA Series Boilers – User’s Information Manual

9 CORROSIVE ATMOSPHERES

If a gas boiler is to be installed near a corrosive or potentially corrosive air supply, the boiler should be

isolated from it and outside air should be supplied.

Chemical vapors from products containing chlorine or fluorine must be avoided. Even though these

chemicals may be safe to breathe, corrosive substances can become liberated when passed through a

gas flame. Even at low concentrations, these chemicals can significantly contaminate the air supply and

shorten the life of any gas burning appliance. The following is a list of some of the products which should

be avoided:

• bleaches and chlorinated cleaning products

• paints and sprays

• water softeners (calcium or sodium chloride)

• leaking refrigeration equipment

• freon from common aerosol dispensers

These chemicals are especially commons near swimming pools, beauty shops, dry cleaning

establishments, laundry areas, workshops, and garages. The warranty is void when failure is due to

corrosion.

10 AIR SUPPLY FOR COMBUSTION AND VENTILATION

A sufficient air supply MUST be provided to this boiler. Air openings to the boiler room provide the air for

combustion, flue gas dilution and ventilation and are always required, regardless whether the air is taken

from inside or outside. The air opening size and location, as well as exhaust venting considerations must

conform to the applicable codes. If any alteration of the air supply and venting system is required, contact

a qualified service agency.

The boiler room must never be under a negative pressure. Air openings should be sized by your installer

not only to the dimensions required for the total input of all fuel-fired appliances in the boiler space, but

also to handle the air movement rate of any exhaust fans or air movers using air from the building or

space.

Make sure the venting terminations are always kept clear of obstructions (i.e. snow, ice, etc.). Louvers

and grilles used in your air supply and ventilation system should be checked regularly and cleaned of any

dust, dirt, or debris which will block proper airflow.

11 CHECK FOR DRAFT HOOD SPILLAGE

WARNING

Continuous spillage at the draft hood relief opening may result in severe personal injury, death

or substantial property damage.

After the main burners have operated for 5 minutes, check to see that combustion products are going up

the chimney or gas vent properly by passing a lighted match (or smoke from a cigar, cigarette, or pipe)

around the edge of the relief opening of the draft hood. If the chimney or gas vent is drawing properly,

the match flame or smoke will be drawn into the draft hood. If not, the combustion products will tend to

extinguish this flame.

If the combustion products are escaping from the relief opening of the draft hood, IMMEDIATELY

shutdown the boiler and contact a qualified service agency to make proper adjustments or repairs.

6

MG, SG & AAA Series Boilers – User’s Information Manual

12 BURNER SYSTEM

To maintain safe and efficient operation, examine the burner system regularly through the inspection hole

near the pilot tube.

Check condition of burner system

Over time, it is possible for parts of the burners

system to become plugged, cracked, eroded

and/or dislodged resulting in unsafe operation.

Pilot Flame

The pilot flame

should be adjusted

to the point where

the sensor rod is

completely

enveloped by the

flame (Figure 1), but

not necessarily

glowing red.

Check for lifting

FIGURE 1 - PILOT FLAME

Flames should not lift excessively from the

burner ports. The flames may lift slightly during

ADJUSTMENT

Check ignition and extinction

Ignition should flow quickly and smoothly across

all the burners. Popping noises or explosions

from the burners during ignition, extinction or

normal burner operation indicate the need for

service.

Check flame color

An extremely yellow flame, as seen on a burning

candle or match, is an indication of incomplete

combustion and is usually accompanied by the

formation of soot and carbon monoxide (carbon

monoxide is a lethal, colorless and odorless

gas). If soot is allowed to accumulate, it will

partially restrict free passage of products of

combustion to the flue. Under typically

operating conditions, the flame should have a

distinct bright blue inner cone and a blue/orange

outer cone.

ignition or when the burners are cold.

If any of the above problems are observed or the burner system does not operate properly,

immediately contact a qualified service agency for adjustment or corrective measures.

13 BOILER WATER

Avoid unnecessary replenishment of system water. It can allow oxygen to enter the system and cause

serious corrosion problems. As well, minerals dissolved in the water supply will precipitate when heated;

minerals preferentially deposit in the heat exchanger. Do not draw water from the heating system for

cleaning, flushing, etc.

Any audible sounds in the boiler system may be indications of scaling or lack of sufficient water flow and

the system should be checked without delay. Scaling is due to improper maintenance. It is not the fault

of the boiler. Scale damage is not covered by warranty.

In cold weather conditions, take precautionary measures to ensure the system will maintain a minimum

return temperature of 138°F. Lower return temperatures will cause condensation on the heat exchanger

or in the venting system and reduce draft suction. In addition, low temperatures in the system may result

in extensive damage due to freezing if the system should shutdown, possibly due to a safety switch

shutdown, for any length of time.

If freeze protection is required, use an inhibited propylene glycol solution which is specifically designed

for hydronic heating systems and always maintained at a neutral pH (e.g. Fernox Alphi-11 or equivalent).

Follow the supplier’s instructions for proper use and maintenance. Do not use automotive antifreeze.

Some types of chemical additives can cause problems such as accelerated corrosion and result in

premature failure of the boiler heat exchanger and/or system components, especially when not properly

used or maintained. Corrosion is a preventable condition and is not covered by warranty.

7

MG, SG & AAA Series Boilers – User’s Information Manual

14 PRESSURE RELIEF VALVE

A pressure relief valve is supplied as standard equipment. The pressure relief valve provides extra

protection against damage that could be caused by malfunctioning controls or excessive water pressure.

If a pressure relief valve is not used, the warranty is void.

The pressure relief valve must be installed by a qualified installer in accordance with local codes and

should not be tampered with in any way. The outlet of the pressure relief valve should be positioned over

a suitable drain. The drain pipe must pitch down from the pressure relief valve and should be no smaller

than the outlet of the pressure relief valve. The end of the drain line should not be concealed or threaded

and should be protected from freezing. No valve of any type should be installed between the pressure

relief valve and unit or in the drain line. Extensive runs, traps or bends reduce the capacity of the

pressure relief valve. The pressure relief valve is a code requirement.

If discharge occurs during normal operation, call a qualified service agency immediately. Discharge

indicates an unsafe pressure condition or a malfunctioning pressure relief valve. Avoid contact with the

hot water or steam discharged to prevent personal injury.

15 BLOCKED VENT AND FLAME ROLL-OUT SAFETY SWITCHES

Applicable to all boilers with an input rating less than 300,000 BTU/HR

• This boiler is equipped with a "Blocked Vent" shut-off system. The safety switch will shut down the

boiler should the vent or flue become partially or completely blocked. Should this occur do not attempt

to re-light the burner. Contact a qualified service agency to ensure it is safe to re-light the boiler.

• This boiler is equipped with a "Flame Roll-out" shut-off system. The safety switch will shut down the

boiler should flames roll-out of the combustion chamber. Should this occur do not attempt to re-light

the burner. Contact a qualified service agency to ensure it is safe to re-light the boiler.

16 INSPECTION & MAINTENANCE SCHEDULE

This boiler has been designed to provide years of trouble-free performance in normal installations. The

owner or user should conduct a general external examination covering all items on the "User Checklist" at

the beginning of each heating season and in mid-heating season to assure continued good

performance.

In addition, have the boiler inspected by qualified service technician or gas supplier’s service person

annually at the beginning of the heating season for continued safe operation.

Note that some operating conditions may require more frequent inspections.

8

MG, SG & AAA Series Boilers – User’s Information Manual

17 USER CHECKLIST

Check air openings are not restricted and will not be blocked off. Adequate supply air is

ο

necessary for combustion, flue gas dilution and ventilation.

When the boiler has operated for several minutes, check for spillage at draft hood, venting

ο

ducts, and other areas susceptible to spillage.

Check externally the draft hood and vent system for soot, rust scale or corrosion. Check for

ο

dislodged venting or possible leaks in venting ducts.

Visually inspect main burners and pilot to ensure proper flame operating characteristics and

ο

ignition/extinction is ok.

Visually check burners to see that they are not cracked or dislodged.

ο

Check that gas piping is secured. Smell for gas leaks around boiler and gas piping

connections. Gas leaks can also be checked for using a soap solution; do not use an open

ο

flame to check for leaks. Note: Propane is heavier than air and pools in low areas in the event

of a leak.

Visually inspect for leaks in the water piping and at water piping connections.

ο

Circulating pumps used with hot water heating systems should be inspected for water leaks.

ο

Check for weeping at pressure relief valve outlet during normal operation.

ο

Listen for unusual audible sounds in the boiler.

ο

Read temperature and pressure gauge. Check with qualified installer or service agency to

determine acceptable temperature and pressure range for your heating system.

ο

Combustible materials, gasoline and other flammable vapors and liquids should not be stored

ο

in the area of the boiler.

If any problems are identified during your inspection, contact a qualified service agency for

corrective measures.

Once every year at the beginning of the heating season:

Have a qualified service technician remove the draft hood from the boiler and inspect the

flueways for the presence of soot or rust scale. The draft hood and smoke pipe connecting the

ο

draft hood to the flue must be inspected for rust or corrosion before replacing the draft hood. The

presence of soot, rust scale or corrosion indicates misadjustment.

Have a qualified service technician inspect the pilot burner and main burner.

ο

The qualified service technician should follow the "Maintenance Checklist" and other applicable

ο

safety information found in the Installation and Service Manual.

9

MG, SG & AAA Series Boilers – User’s Information Manual

18 TYPICAL RESIDENTIAL BOILER COMPONENT LOCATIONS

10

MG, SG & AAA Series Boilers – User’s Information Manual

19 TYPICAL COMMERCIAL BOILER COMPONENT LOCATIONS

11

MG, SG & AAA Series Boilers – User’s Information Manual

20 INDEX

Section Page

General Warnings…………………………………………………………………………………….. ................... 2

1 About Our Manual .................................................................................................................................. 3

2 Safety Instructions .................................................................................................................................. 3

3 Lighting Instructions................................................................................................................................ 3

4 Lighting Instructions for Intermittent Electronic Ignition with Combination Gas Valve........................... 4

5 Lighting Instructions for Intermittent Electronic Ignition with Non-Combination Gas Valve................... 4

6 To Turn off Gas to the Boiler or Emergency Shut-Off ........................................................................... 5

7 Area around Boiler.................................................................................................................................. 5

8 Check for Gas Leaks .............................................................................................................................. 5

9 Corrosive Atmospheres.......................................................................................................................... 6

10 Air Supply for Combustion and Ventilation............................................................................................. 6

11 Check for Draft Hood Spillage................................................................................................................ 6

12 Burner System........................................................................................................................................ 7

13 Boiler Water............................................................................................................................................ 7

14 Pressure Relief Valve ............................................................................................................................. 8

15 Blocked Vent and Flame Roll-Out Safety Switches ............................................................................... 8

16 Inspection & Maintenance Schedule ...................................................................................................... 8

17 User Checklist ........................................................................................................................................ 9

18 Typical Residential Boiler Component Locations.................................................................................10

19 Typical Commercial Boiler Component Locations ............................................................................... 11

20 Index ..................................................................................................................................................... 12

12

Loading...

Loading...