SuperDroid Robots IG52-DB Assembly And Operation Manual

IG52-DB Heavy Duty Enclosed Robot

Assembly and Operation

The IG52-DB Enclosed is a rugged and powerful robot platform. Make it RC or use it with sensors

and a microcontroller to make it autonomous/semi-autonomous.

Images shown may not be an exact representation of the robot’s features listed in this document

SuperDroid Robots, Inc Contact

224 Technology Park Lane (919) 557-9162

Fuquay Varina, NC 27526 SDR@SDRobots.com

www.SuperDroidRobots.com

Revised: February 8, 2019 Page 2 of 13

Contents

Mechanical Assembly ................................................................................................................................................... 4

Electrical Assembly ..................................................................................................................................................... 10

Operation .................................................................................................................................................................... 12

General Terms............................................................................................................................................................. 13

SuperDroid Robots, Inc Contact

224 Technology Park Lane (919) 557-9162

Fuquay Varina, NC 27526 SDR@SDRobots.com

www.SuperDroidRobots.com

Revised: February 8, 2019 Page 3 of 13

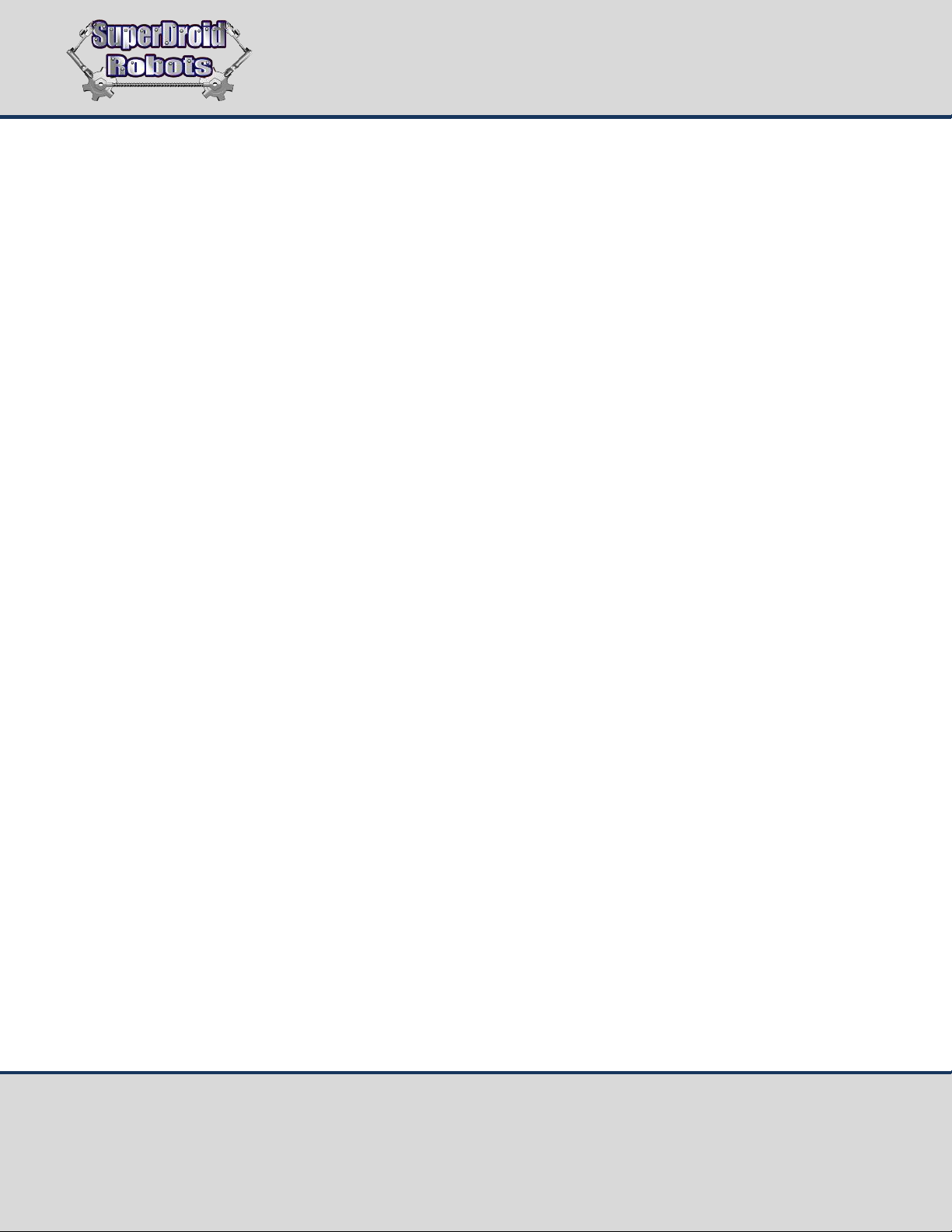

Figure 1: Exploded view sketch

SuperDroid Robots, Inc Contact

224 Technology Park Lane (919) 557-9162

Fuquay Varina, NC 27526 SDR@SDRobots.com

www.SuperDroidRobots.com

Revised: February 8, 2019 Page 4 of 13

Mechanical Assembly

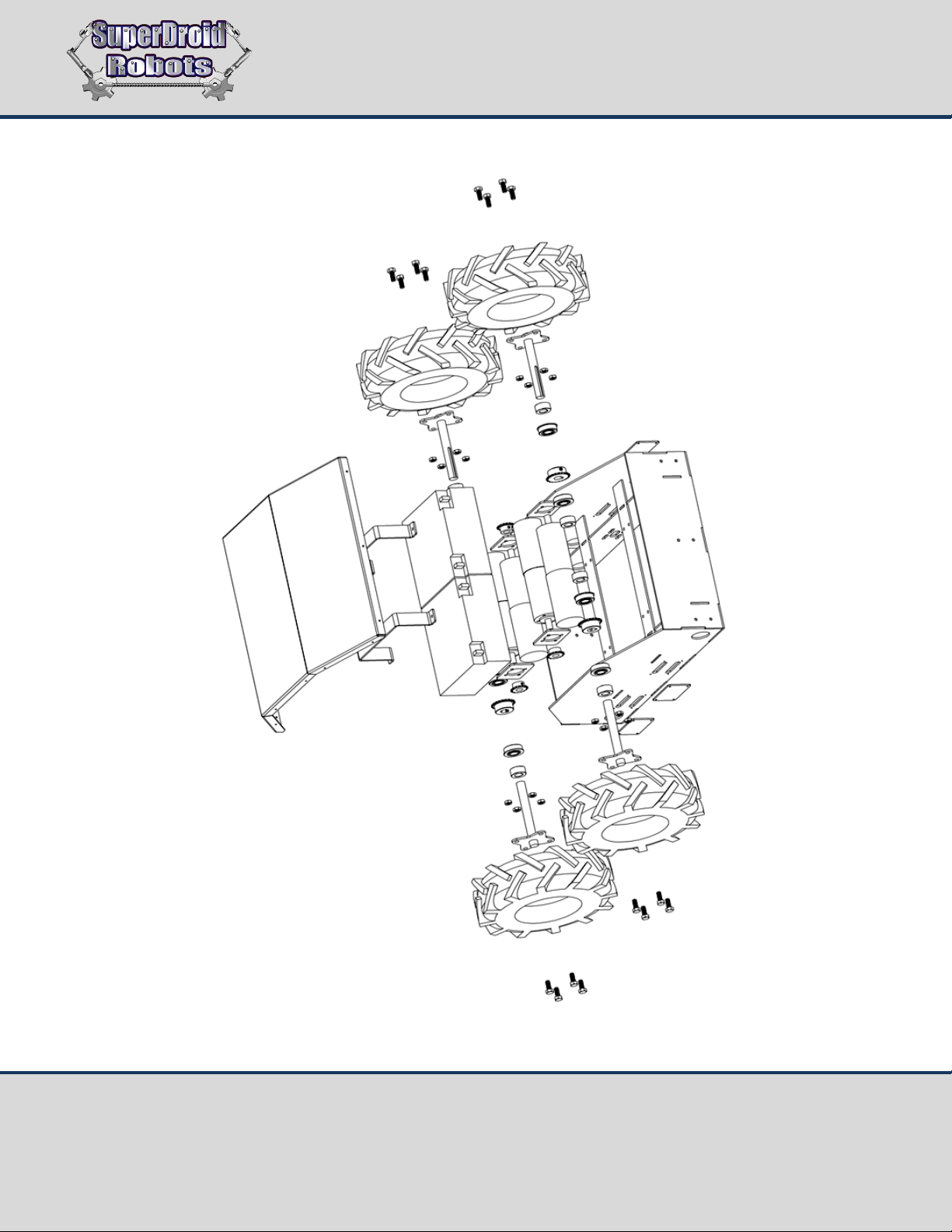

1. Mount the motors as shown in Figure 2, with the motor spacer plate between the motor and the chassis.

Make sure to use Loctite on the screws. Once the motor is mounted, the small sprockets can be mounted

on the motor shaft. The hub should face the motor and they should be pushed all the way against the

inside plate with just a small clearance for rotation.

Figure 2: Exploded view sketch of motor mounting

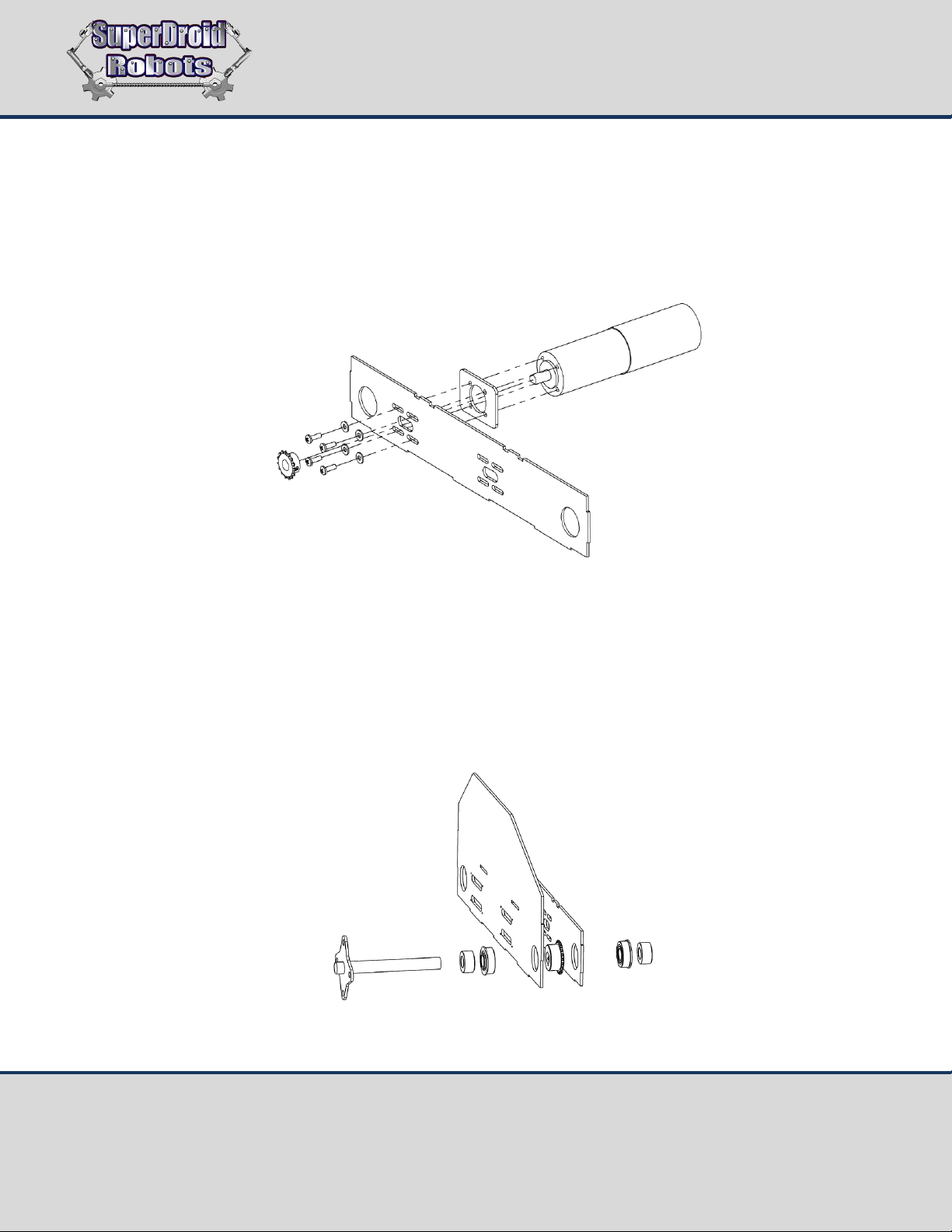

2. Slide all 8 bearings into place through the bearing holes in the chassis. Slide a lock collar onto the axle,

then slide the axle through the first bearing. At this point, put the key in the shaft and slide on the wheel

sprocket. Finally slide the shaft through the second bearing. Slide another lock collar on to secure the

inside bearing and slide the outside lock collar over to secure the outside bearing. Use Loctite on all set

screws.

Figure 3: Axle assembly

Loading...

Loading...