Page 1

Hardware Manual

Reduced to the max

Smart

Open-Source

Page 2

28. Juni 2012

2

Page 3

28. Juni 2012

3

Copyright reminder

2008 by Supercomputing Systems AG, Switzerland.

This work is licensed under a Creative Commons Attribution-Share Alike 3.0 license.

Versions

Version

Date

Author

Comments

Visa

1.0

13.11.2008

DE/LL

First Release

1.2

01.10.2009

BM

Added monochrome option

1.2.1

06.10.2009

BM

Fixed I/O resistor values in table 3.6.1.

Added comment about which LED is softwarecontrollable (chapter 3.2)

1.2.2

25.11.2009

BM

Added position and dimension of holes of lense holder

1.2.3

24.03.2010

LL

Updated dimension drawing

1.2.4

28.06.2011

SZ

Updated dimension drawing

Page 4

28. Juni 2012

4

Contents

1 leanXcam .................................................................................................................................. 6

1.1 Introduction ................................................................................................................................ 6

1.2 Purpose of this document .......................................................................................................... 6

2 Hardware Overview .................................................................................................................. 8

2.1 Block Diagram ............................................................................................................................ 8

2.2 On-Board Devices ...................................................................................................................... 9

2.3 Interfaces ................................................................................................................................... 9

2.3.1 Digital Inputs, optically isolated ................................................................................................ 10

2.3.2 Digital Outputs, optically isolated ............................................................................................. 11

3 Hardware Components .......................................................................................................... 12

3.1 Main Components .................................................................................................................... 12

3.2 LED Indicators .......................................................................................................................... 13

3.3 Quartz and Clock Oscillators ................................................................................................... 14

3.4 Supply Measurement Points .................................................................................................... 15

3.5 On-Board Headers and Jumpers ............................................................................................. 16

3.5.1 Pinout of the On-Board Headers .............................................................................................. 17

3.6 Interface Connectors ................................................................................................................ 19

3.6.1 Pinout of the I/O Connector ..................................................................................................... 20

4 Mechanical Dimension .......................................................................................................... 21

4.1 Mechanical Dimensions of the PCB ......................................................................................... 21

4.2 Mechanical Dimensions of the enclosure ................................................................................ 22

5 Examples ................................................................................................................................ 23

5.1 External Flash Circuit Example ................................................................................................ 23

5.2 Simple Output Example ........................................................................................................... 24

5.3 Isolated Output Example .......................................................................................................... 25

Page 5

28. Juni 2012

5

Page 6

28. Juni 2012

6

1 leanXcam

1.1 Introduction

leanXcam is an intelligent colour camera with a rich set of features that provides an impressive

performance, in spite of its low production cost. The smart combination of a well-established sensor

chip, a fast digital signal processor, a tailored Linux-based operation system and the image processing

framework from SCS-Vision makes the leanXcam an incomparable achievement in the field of Vision.

Communication is ensured by Ethernet connection and digital I/Os.

1.2 Purpose of this document

This document gives an overview of the leanXcam HW and provides information about the used

devices, interfaces and some examples. This document should be used by readers who are interested

in the physical blocks contained in the leanXcam or by readers who want to use more debug features

like RS232 and JTAG, when designing with the leanXcam.

Page 7

28. Juni 2012

7

Page 8

28. Juni 2012

8

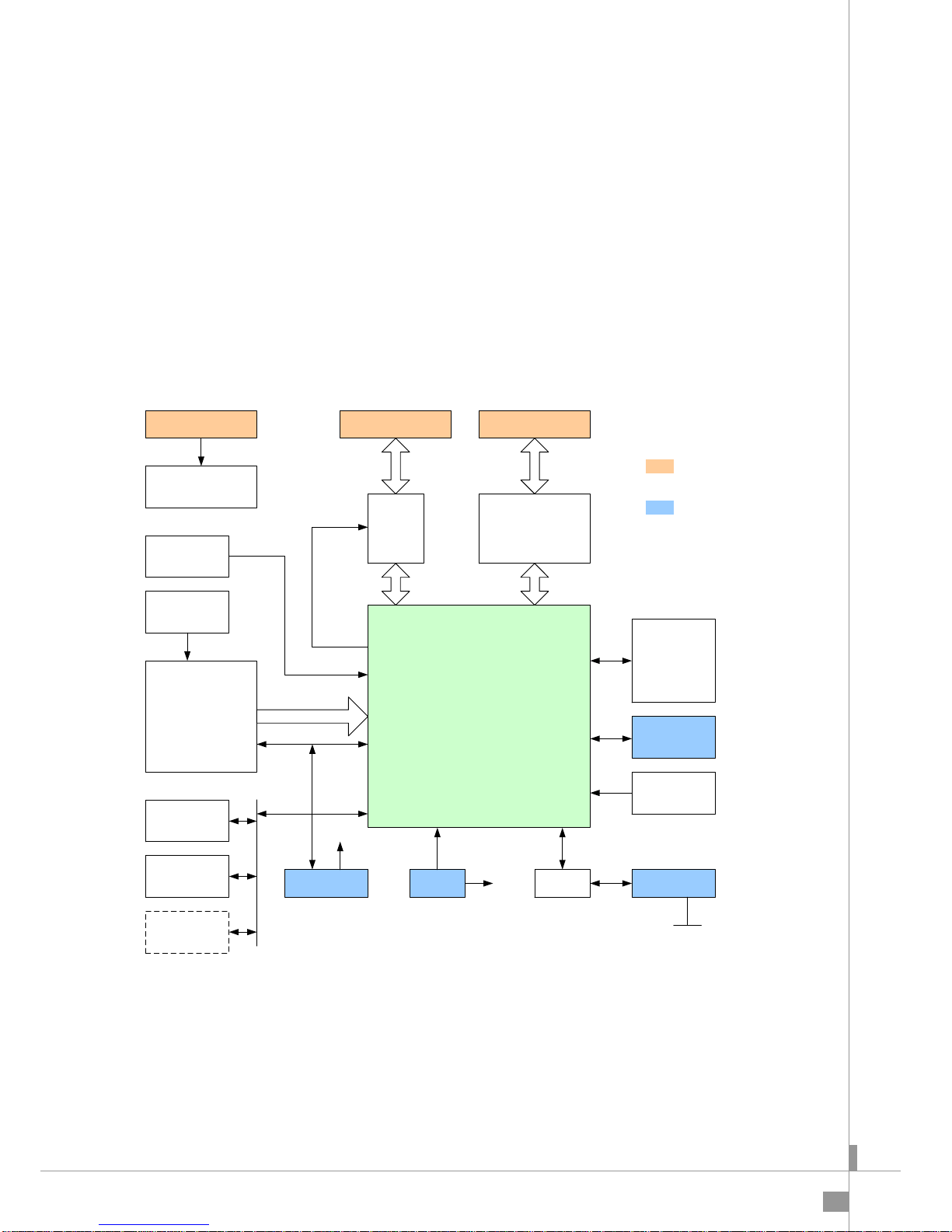

2 Hardware Overview

This section gives an overview of the main components/devices and interfaces available on the

leanXcam board.

2.1 Block Diagram

In Figure 1 the block diagram of the leanXcam HW is shown.

CMOS Image

Sensor

Micron MT9V032

DSP

BlackFin ADSP-BF537

PPI

4 MByte

FLASH

4 MByte

FLASH

SPI

Systemclock

25MHz

Ethernet

PHY

EMAC

Clock_Out

Reset

I2C

sync.

Bus

SDRAM

64 MByte

Digital I/O

2 opt.inputs

2 opt. outputs

RS232

Reset UART0

Power Supply

5V -> 3.3V

JTAG

Real Time

Clock

Sensor Clock

26.6MHz

Eth_Clock

Clock_In

JTAG

Connector

3-pin header

GPIO

RJ45 Connector I/O Connector

3-pin header

I

2

C

optional

microSD slot

Vcc3.3

Legend:

Main Interfaces

User accessible through

socket connectors or

jumpers

Power Connector

Figure 1: Block Diagram

Page 9

28. Juni 2012

9

2.2 On-Board Devices

The leanXcam board offers the following devices:

- 500 MHz Digital Signal Processor Blackfin ADSP-BF537

- CMOS Sensor Micron MT9V032C12STC (color) or MT9V032C12STM (monochrome), Wide-

VGA 752H x 480V, 10Bit

- 64 MByte RAM Memory

- 4 MByte Flash for Boot program

- 4 MB Flash Memory for Algorithm Software

- microSD Card holder for optional Flash Memory expansion

- Voltage Regulator (LDO) for clean and stable 3.3V Supply Voltage

- Lens holder for standard M12x0.5 mount Lenses

2.3 Interfaces

The leanXcam Board supports the following interfaces:

- Fast-Ethernet 100Mb (10/100Mb) (RJ-45 Connector)

- RS232C Interface for first-time configuration during manufacturing (on-board header)

- I2C Interface to connect additional serial devices (on-board header)

- JTAG for Debugging DSP (on-board 14-pin 2-row header)

- 5V Power Input (6.5mm round connector Lumberg 1613 14)

- 2 optical isolated inputs and 2 optical isolated outputs (isolation can be jumpered, 1 input can

be used as external exposure, 1 output can be used for external flash triggering) with a 6-pin

Phoenix direct-PCB connector. Also see Figure 2 and Figure 3 for details

- Power-ON LED (on-board)

- Link speed und Link activity LED (in RJ45 connector, external view)

- Bi-color status LED (external view)

Page 10

28. Juni 2012

10

2.3.1 Digital Inputs, optically isolated

68R

to DSP

Input 145

68R

to DSP

Input 2 6

1

VIN

external Supply

I/O GND

Jumper J602

Fairchild

MOCD207R2M

Fairchild

MOCD207R2M

Figure 2: Digital Inputs

Jumper 602 can be used to connect the Ground to the I/O GND, if isolation is not required.

Page 11

28. Juni 2012

11

2.3.2 Digital Outputs, optically isolated

Output 1from DSP

from DSP Output 2

Jumper J602

I/O GND

2

3

4

1 external Supply

VIN

Fairchild

MOCD207R2M

Fairchild

MOCD207R2M

33R

33R

Figure 3: Digital Outputs

Jumper 602 can be used to connect the Ground to the I/O GND, if isolation is not required.

Page 12

28. Juni 2012

12

3 Hardware Components

3.1 Main Components

The main components of the leanXcam are as follows:

Data Flash CMOS Sensor Optocoupler I/O Connector

Program Flash Blackfin DSP RS232 Driver LDO Power Connector

SDRAM FET (VR) for DSP Ethernet Physical Ethernet Connector

Page 13

28. Juni 2012

13

3.2 LED Indicators

The leanXcam has two LED indicators, one power LED and one bi-color status LED:

Power LED (3.3V)

Status LED (red / green), software-controllable

Page 14

28. Juni 2012

14

3.3 Quartz and Clock Oscillators

The leanXcam has two clock oscillators and one Quartz:

26.66 MHz Oscillator for CMOS sensor (arrow points to clock pin)

32.768 kHz Quartz for RTC

25 MHz Main clock oscillator for DSP and Ethernet (arrow points to clock pin)

Page 15

28. Juni 2012

15

3.4 Supply Measurement Points

There are on-board voltages which can be measured at the following points:

3.3 Volt VIN (5 Volt)

Ground

Page 16

28. Juni 2012

16

3.5 On-Board Headers and Jumpers

The leanXcam has the following headers and jumpers:

Boot Jumper Factory Reset Jumper RS232C Interface Header I/O GND to GND Jumper

JTAG Connector (not populated) I2C Interface Header

Note: Arrows point to Pin 1 of the headers

Page 17

28. Juni 2012

17

3.5.1 Pinout of the On-Board Headers

Boot Jumper J202

Selection

Description

No Jumper

DSP boots from on-board Flash chip (default)

Jumper inserted

DSP boots from RS232C interface

I/O GND to GND Jumper J602

Selection

Description

No Jumper

inputs and outputs of connector J601 are isolated

Jumper inserted

I/O GND of J601 is connected to System GND (inputs and outputs are

NOT isolated)

Factory Reset Jumper J302

Selection

Description

No Jumper

normal operation (default)

Jumper inserted

Resets the factory default IP address 192.168.1.1 on power-up,

remove this jumper when the leanXcam is accessible afterwards

RS232C Header J702

Pin Number

I/O

Description

1

Input

UART Receive input pin, RS232 level (input to leanXcam)

2

Output

UART Transmit output pin, RS232 level (output from leanXcam)

3

Power

System Ground

Page 18

28. Juni 2012

18

I2C Header J401

Pin Number

I/O

Description

1

Power

3.3V Supply (without fuse !)

2

I/O

SCL Signal (I2C Clock)

3

I/O

SDA Signal (I2C Data)

Page 19

28. Juni 2012

19

3.6 Interface Connectors

The external connectors of the leanXcam are as follows:

5V Power Input Connector (+ at Center) I/O Connector

optional microSD Card connector (backside) Pin 1 Pin 6

Ethernet Connector (RJ45)

Page 20

28. Juni 2012

20

3.6.1 Pinout of the I/O Connector

Connector J601 (Phoenix Contact No: ZEC1,0/6-ST-3,5C1R1)

Pin Number

I/O

Description

1

Power

VIN 5 Volt (connected to the power connector without fuse)

default: leave unconnected or use as power for external devices

(max. 100mA)

2

Output

Output 1 (connected through a 33R current-limit-resistor to the

collector of the opto-coupler output transistor)

3

Output

Output 2 (connected through a 33R current-limit-resistor to the

collector of the opto-coupler output transistor)

This output can be used as a trigger for an external flash

4

Power

I/O Ground (can be connected to System Ground with the Jumper

J602

5

Input

Input 1 (connected through a 68R current-limit-resistor to the anode of

the opto-coupler LED)

6

Input

Input 2 (connected through a 68R current-limit-resistor to the anode of

the opto-coupler LED)

This input can be used as an external exposure trigger

Page 21

28. Juni 2012

21

4 Mechanical Dimension

4.1 Mechanical Dimensions of the PCB

Figure 4: PCB dimensions

Page 22

28. Juni 2012

22

4.2 Mechanical Dimensions of the enclosure

Figure 5: enclosure dimensions

Page 23

28. Juni 2012

23

5 Examples

In this section some examples of typical digital IO Interface connections are shown. Connect the

external devices and logic like shown in these examples, if this is appropriate for the current design

and use.

5.1 External Flash Circuit Example

1k

4k7

Flash Trigger

Signal (3.3V)

NPN Transistor

for ex. 12V

LED Array

Figure 6:LED Flash Example

Page 24

28. Juni 2012

24

5.2 Simple Output Example

from DSP

from DSP

Jumper J602

2

3

4

1

VIN

Fairchild

MOCD207R2M

Fairchild

MOCD207R2M

33R

33R 220R

220R

Figure 7: Non-isolated Output

Page 25

28. Juni 2012

25

5.3 Isolated Output Example

from DSP

from DSP

Jumper J602

2

3

4

1

VIN

Fairchild

MOCD207R2M

Fairchild

MOCD207R2M

33R

33R

1k1k

12 Volt

Figure 8: Isolated output example

Loading...

Loading...