Superabrasive Lavina 12, Lavina 12E User Manual

LAVINA® 12/12E

User Manual

Tech Support Line: 800-987-8403 | www.superabrasive.com | info@superabrasive.us

1

Superabrasive Owner’s Manual Original Language – Lavina® 12 4/2017

2

CONTENT

1. GENERAL INFORMATION

Manufacturer 3

General Description 3

Machine Characteristics 3

Lavina® 12 Main Design 3

Environmental Conditions 3

Electrical Connection 3

Vacuum Connection 3

Water Connection 3

Technical Data 4

Vibrations 4

Sonorous Emissions 4

Label Data 4

Customer service 4

2. SAFETY INSTRUCTIONS

Recommended Use 4

Prohibited Use 4

Preparation for Work 4

Protection Devices 4

Arrest Functions 4

Safe Use 4

Residual Risks 5

Before You Begin 5

Operating the Machine 5

After Work is completed 5

The Work Area 5

Personal Protective Equipment (PPE) 5

Operator 5

6. EXPLODED VIEW

General exploded view (Fig.6.1) 7

Exploded view of the outside housing (Fig.6.2) 7

Exploded view of the inside housing (Fig.6.3) 8

Exploded view of a pulley (Fig.6.4) 8

Exploded view of the belt driving pulley (Fig.6.5) 8

Exploded view of the belt tensioning device (Fig.6.6) 8

Exploded view of the power tool attachment (Fig.6.7) 8

7. MAINTENANCE AND INSPECTION

Cleaning 9

Check Daily 9

Check Every 200 Working Hours 9

Check Every 500 Working Hours 9

Vacuum 9

Mechanical Parts 9

Dust 9

8. TROUBLESHOOTING

Index of Problems and Solutions

Replacing Power Cord and Plugs 9

Tensioning the Belt 9

3. OPERATION

Before start operation 5

Preliminary Controls 5

Mounting Tools 5

Tool Protecting Guard 6

Setting the Speed 6

Switching On and Off 6

Operating Machine 6

Stopping Machine 6

4. ACCESSORIES

Wrenches 6

Tool holders 6

5. POPULAR TOOLS

Tools 6

9. WARRANTY AND RETURNS

Warranty Policy 10

Return Policy 10

10. DISPOSAL 10

11. MANUFACTURER’S CONTACTS

10

12. SPARE PARTS

Lavina® 12 Assembly and Parts Specification General

(Fig. 12.1) 11

Lavina® 12 Assembly and Parts Specification Housing

(Fig. 12.2) 12

Lavina® 12 Assembly and Parts Specification

Planetary Head (Fig. 12.3) 13

Lavina® 12 Assembly and Parts Specification Pulley

(Fig. 12.4) 13

Lavina® 12 Assembly And Parts Specification Motor

Connection (Fig. 12.5) 14

Superabrasive Owner’s Manual Original Language – Lavina® 12 4/2017

Fig.1.1

1. GENERAL INFORMATION

This owner’s manual is intended for the operator of the Lavina® 12 machine, the servicing technician as well as for

anyone involved with operating or servicing the machine. We recommend that you read the instructions very carefully

and follow them strictly. The manual includes information about assembling, using, handling, adjusting and maintaining

your Lavina® 12 floor grinding and polishing machine.

MANUFACTURER

Superabrasive was founded in 1987, as a manufacturer of high quality diamond tools for the stone and concrete

industry. Today, Superabrasive is one of the world’s leading companies in the production of diamond tools and floor

grinding machinery. At Superabrasive, we strive to deliver the very best solutions to our customers, and enable them to

work more efficiently.

GENERAL DESCRIPTION

The Lavina® 12 machine is a 3-disc machine intended for polishing and buffing concrete, marble, granite, limestone and

terrazzo surfaces with diamond tools. The Lavina® 12 is intended to work on countertops, steps of stairs treads,

bathroom floors, and walls or difficult to reach surfaces. Additionally, the machine could be used for grinding wood floor

surfaces.

For best results, use only tools manufactured or recommended by Superabrasive and its distributors.

WARNING!

The Lavina® 12 machine is manufactured and fitted for the above-mentioned applications only! Every other use may

possess risks to the persons involved. Each hour of operation, stop the machine for 15 minutes to allow the drive

system to cool.

MACHINE CHARACTERISTICS

The Lavina® 12 is made to easily grind/polish working surfaces. It runs 3 heads to increase grinding capacity.

LAVINA® 12 MAIN DESIGN

The handles provide the operator maximum of comfort and control. They

allow the operator to work safely. (Fig.1.1-1)

The controls are positioned on top of the power tool. (Fig.1.1.2-3)

The power tool is mounted on top of the planetary head and the gears are

driving a clutch. The clutch is driving the belt of the planetary movement and

the movement the toothed gear which is driving over pignons the three

grinding heads. (Fig.1.1-4)

The planetary head with a lightweight aluminum top plate covers the

working tools. (Fig.1.1-5)

The protective skirt mounted with Velcro® protects the operator from dust

and debris. (Fig.1.1-6)

The hour meter shows total hours of operation. (Fig.1.1-7)

ENVIRONMENTAL CONDITIONS

The temperature range for operating the Lavina® 12 outdoors is between 41°F and 86°F or 5°C and 30°C. Never use

the Lavina® 12 during rain or snow when working outdoors. When working indoors, always operate the machine in wellventilated areas.

ELECTRICAL CONNECTION

The voltage (Volt) and power (Ampere) are displayed on a label on the of the power tools to avoid any incorrect

connection. Refer to these before connecting the power. To avoid electrical shocks, make sure the ground power

supply is functioning properly.

VACUUM CONNECTION

A connection for a vacuum dust extractor is located on the power tool. The Lavina® 12 does not include a vacuum dust

extractor. The customer must purchase the vacuum dust extractor separately. The hose of the vacuum extractor must

be Ø 1”1/2 or 38 mm and can be fitted over the pipe. The vacuum dust extractor must be adapted for grinders and have

a minimum air displacement of 220m3/h or 130 CFM with a negative vacuum of 21 kPa.

WATER CONNECTION

A quick connection for a water tube of diameter ¼” with ball valve is placed under the power tool.

3

Superabrasive Owner’s Manual Original Language – Lavina® 12 4/2017

4

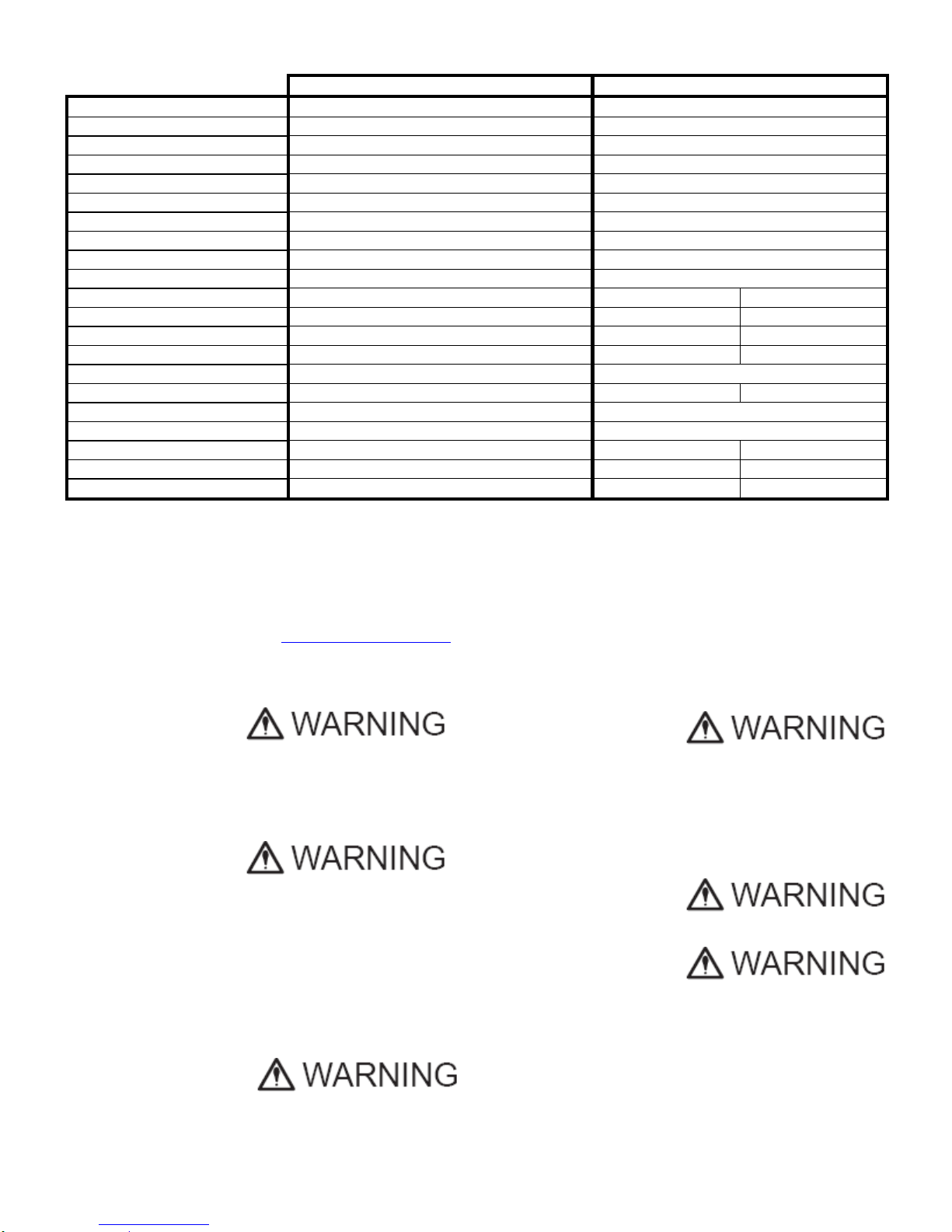

Lavina® 12 110 Volt

Lavina® 12E 220 Volt

Angle grinder

FEIN WPO 14-25E

FEIN WPO 14-25E

Voltage/Hz

1 ph x 110 V 50/60Hz

1 ph x 220 V 50/60Hz

Amperage

Max 10.9 Amps

Max 6 Amps

Breaker requirement

15 Amps

15 Amps

Power

1.2 kW

1.2 kW

Driver Speed

900-2500 rpm

900-2500 rpm

Platen Speed

820-2240

820-2240

Platform Speed

160-440

160-440

Platen Driving Direction

counterclockwise

counterclockwise

Platform Driving Direction

clockwise

clockwise

Working width

307 mm

12”

307 mm

12”

Tool holder diameter

3x 127 mm

3x 5”

3x 127 mm

3x 5”

Tool diameter

3x 127 mm

3x 5”

3x 127 mm

3x 5”

Weight

15 kg

33 lbs

15 kg

33 lbs

Application

Dry/wet

Dry/wet

Vacuum connection

38 mm

1”1/2

38 mm

1”1/2

Water Feeding

Central

Central

Water connection

Hose ¼”

Hose ¼”

Cable length

4 m

12.8 ft

4 m

12.8 ft

Machine LxWxH

430x315x216 mm

16.9”x12.4”x8.5”

430x315x216 mm

16.9”x12.4”x8.5”

Packing LxWxH

450x351x249 mm

17.7”x13.8”x9.8”

450x351x249 mm

17.7”x13.8”x9.8”

TECHNICAL DATA

LABEL DATA

The data on the label provides the correct voltage and kW (needed for operational purposes);

Weight (needed for transportation purposes); production year and serial number (needed for maintenance purposes).

CUSTOMER SERVICE

For customer assistance and technical support call your local distributor or call Superabrasive Inc. at

1-800-987-8403 or visit us at: www.superabrasive.com , where you can download a copy of this manual.

The protection devices are working properly.

2. SAFETY INSTRUCTIONS

RECOMMENDED USE

The Lavina

grind and polish concrete, terrazzo, natural stone and

hardwoods. It can be used for renovations as well as for

polishing. The machine is also designed for dry use. Use a

vacuum of appropriate size. For more information, please

refer to the chapter on handling the vacuum connection.

PROHIBITED USE

The machine MUST NOT be used:

For applications different from the ones stated in the

General Description chapter.

For not-suitable materials.

In environments which: Possess risks of explosion

Possess high concentration of powders or oil substances

in the air

Possess risks of fire

Feature inclement conditions.

PREPARATION FOR

WORK

Make sure that:

You have closed the work area, so that no person

unfamiliar with operating the machine can enter the area.

The tool plate and tools are adjusted to the machine

properly

There are no missing parts of the machine

®

12 machine is designed and manufactured to

The electrical cable is free to move and follow the

machine easily.

PROTECTION DEVICES

The machine is equipped with several protection devices

including the following:

A protection skirt and a hood for protecting the tool

plates.

These devices protect the operator and/or others

persons from potential injuries. Do not remove them. On

contrary, before using the machine, please ensure that

all protection devices are mounted and function properly.

ARREST FUNCTIONS

Functions of arresting of the machine are following:

Button to stop the motor (category 1)

SAFE USE

The Lavina

correlated with its use. However, it is not possible to

eliminate the risks of an eventual accident with the

machine. Unskilled or uninstructed operator may cause

correlated residual risks. Such risks are:

Position Risks due to operator’s incorrect working

Entanglement Risks due to wearing

Training Risks due to lack of operational training

®

12 is designed to eliminate all risks

position

inappropriate working clothes

Superabrasive Owner’s Manual Original Language – Lavina® 12 4/2017

5

NOTE: In order to reduce all consequences of the above-

mentioned risks, we advise that machine operators will follow

the instructions in the manual at all time.

RESIDUAL RISKS

During the normal operating and maintenance cycles, the

operator is exposed to few residual risks, which cannot

be eliminated due to the nature of the operations.

BEFORE YOU BEGIN

Working area must be clear from any debris or objects.

A first-time operator must always read the manual and

pay attention to all safety instructions.

All electric connections and cables must be inspected for

potential damages.

Ground wire system of the power supply must be also

inspected.

Perform general daily inspections of the machine and

inspect the machine before each use.

Always inspect the safety devices:

The tool protector must be working

The machine must be clean

Confirm that there are no missing parts especially after

transportation, repair or maintenance.

OPERATING MACHINE

When operating the Lavina

is no one, but you around the machine.

Never leave the machine unattended while working.

The electrical cable must move freely and must be

damage-free.

Check if the surface, you work on, is not too uneven. If

this is the case, it may damage the machine.

AFTER WORK IS COMPLETED

®

12, make certain that there

THE WORK AREA

Make certain that people do not enter the work area.

Avoid cables and hoses being in the way.

Always check the surface for debris

PERSONAL PROTECTIVE EQUIPMENT (PPE)

Always wear safety shoes when working with the

machine.

Always wear ear protectors when working with the

machine.

All personnel in the immediate work area must wear

goggles eye protectors with side shields.

Always wear safety gloves when changing the tools.

Always wear clothes suitable for the work environment.

OPERATOR

The operator must know the machine’s work

environment.

Only one operator at a time can work with the machine.

The operator must be properly trained and well instructed

prior operating the machine.

The operator must understand all the instructions in this

manual.

The operator must understand and interpret all the

drawings and designs in manual.

The operator must know all sanitation and safety

regulations pertaining to the operation of the machine.

The operator must have grinding experience.

The operator must know what to do in case of

emergency.

The operator must have an adequate technical

knowledge and preparation.

Clean the machine and its surroundings properly

Unplug the machine and wind up the electrical cable

Store the machine in a safe place

3. OPERATION

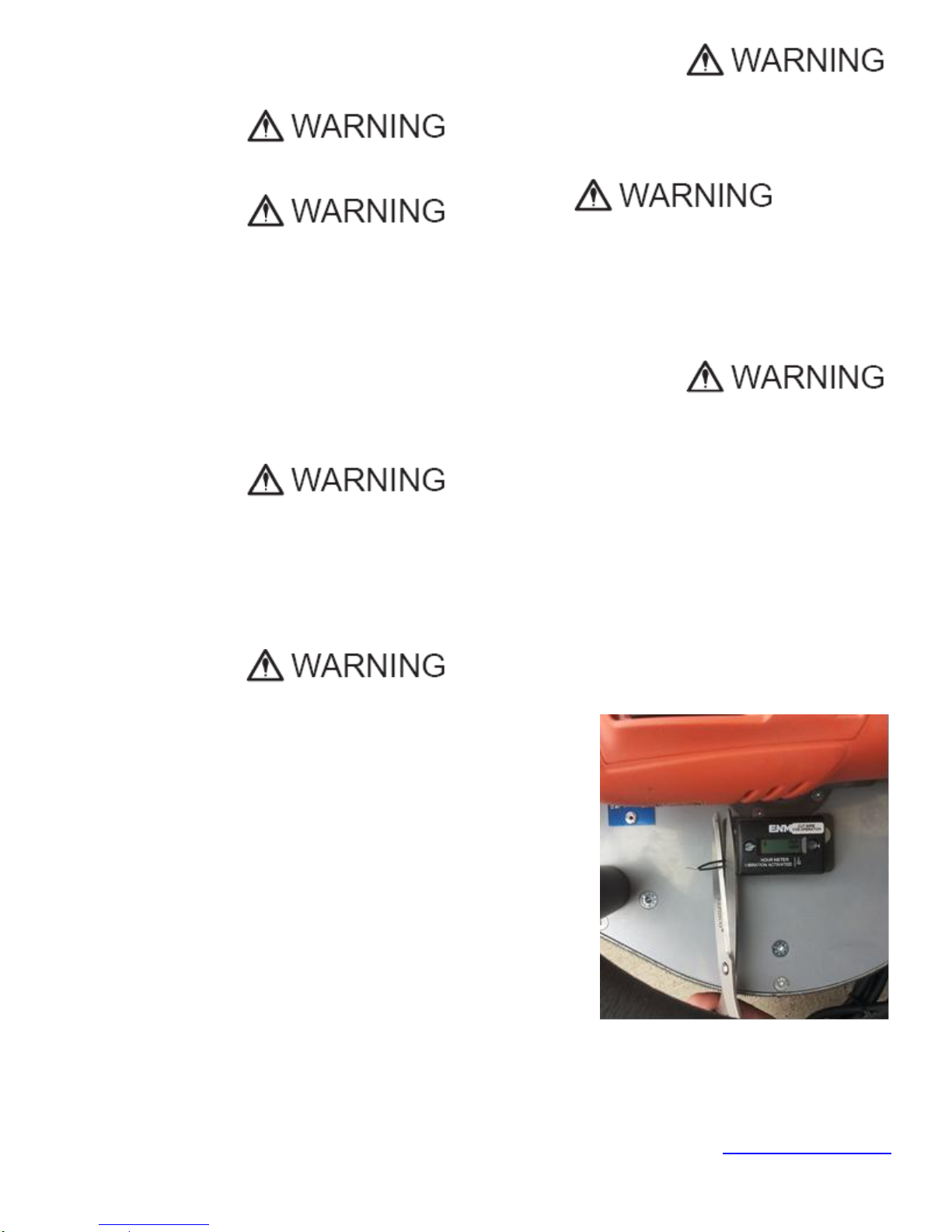

BEFORE START OPERATION CUT THE WIRE OF THE HOUR METER

IF the wire is not cut the hour meter will not start to work. The wires are

not connected to the power supply, they are connected only to the

battery of the hour meter.

PRELIMINARY CONTROLS

Inspect the working area as explained in the safety instructions. For dry

use connect the vacuum extractor and ensure that the vacuum hose is

clear and it will follow the machine easily. Plug in the machine and make

sure that the power cord is free to follow the working direction of the

Lavina® 12. Each hour of operation, stop the machine to make a break of

15 minutes for cooling the drive.

MOUNTING TOOLS

Mount the tools only after ensuring that there is enough diamond bond material left. Be sure that the tool holders are

always clean before mounting. Unplug the machine before dismounting or mounting the tools. The maximum diameter

of the tools is 5” or 127 mm, with thread 5/8”-11-LH UNC. Pay attention the thread is left hand turning or counterclockwise turning also turn opposite as normal. Always use the right wrench to tye the tools. Diamond tools with Velcro

are attached on the tool holders with Velcro. Use only Superabrasive recommended tools see www.superabrasive.com

Loading...

Loading...