Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

OME Series

Explosion-Proof

Quarter-Turn

Electric Valve Actuator

Operation Manual

SY07-C001A-EN

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

Contents

1 General Information ..................................................................................................................................1

1.1 Safety Instructions .......................................................................................................................... 1

1.2 Installation Notices ......................................................................................................................... 1

1.3 Working Conditions ........................................................................................................................ 3

1.4 Standards ........................................................................................................................................ 3

1.5 Inspection, Storage, Transport ........................................................................................................ 5

2 Product Overview ......................................................................................................................................6

2.1 Features........................................................................................................................................... 7

3 Product Mechanical Data ..........................................................................................................................7

3.1 Parts Identification.......................................................................................................................... 7

3.2 Technical Information .................................................................................................................... 8

3.3 Mounting Base Details ................................................................................................................... 8

3.4 Actuator Selection .......................................................................................................................... 9

3.5 Sizing .............................................................................................................................................. 9

3.6 Duty Cycle .................................................................................................................................... 10

3.7 Flamepath Joint ............................................................................................................................ 11

3.8 Nameplate Details ........................................................................................................................ 12

4 Mounting And Setup ...............................................................................................................................13

4.1 Handwheel Installation ................................................................................................................. 13

4.2 Value Mounting Instructions ........................................................................................................ 14

4.3 Wiring Instructions ....................................................................................................................... 15

4.4 Actuator Setup .............................................................................................................................. 16

4.5 Adjustment Steps .......................................................................................................................... 16

5 Modulating Control Board Adjustment ...................................................................................................21

5.1 Modulating Control Board Surface .............................................................................................. 21

5.2 Procedure ...................................................................................................................................... 21

5.3 Dip Switch Setting (SW1) ............................................................................................................ 22

5.4 Sensitivity Switch Setting (SW2) ................................................................................................. 25

5.5 Settings for OPEN and CLOSE .................................................................................................... 25

6 Troubleshooting .......................................................................................................................................30

7 Warranty ..................................................................................................................................................32

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

1

1 General Information

Failure to follow safety instructions may cause serious injury, equipment damage, or voided

warranty.

1.1 Safety Instructions

Installation, maintenance and repair works must be performed by trained personnel.

The handling shall follow the safety and warning instruction contained in this manual.

The user should read and follow instructions contained in this operation manual included with

the product. Failure to do this may result in damages and void warranty. Sun Yeh will not be

liable for damages due to operator negligence or misuse.

Local health and safety legislation shall be complied with.

In a few cases, the surface temperature may exceed 60°C (140 ℉). Please check the surface

temperature before operation, using an appropriate thermometer and wearing protective gloves

before operation.

1.2 Installation Notices

All setting of opening the cover must be made in the safe place, prevent the spark from

making the possibility of explosion.

Operating by handwheel: Do not use excessive force when operating the handwheel as this

can damage the actuator or valve.

1.2.1 General

DO NOT install in ambient temperatures that exceed 70 °C (158 °F).

DO NOT, under any circumstances, remove the cover of the actuator while in a hazardous

location when the power is still live inside the actuator. This could cause ignition of a

hazardous atmosphere.

DO NOT, under any circumstances, use an explosion-proof electric actuator in a hazardous

location that does not meet the specification which the actuator was designed for.

Mount, test, and calibrate actuators in non-hazardous location.

When removing the actuator, care must be taken not to scratch, scar or deform the flame

path of the cover or base of the actuator. That will negate the protection rating of the

enclosure in a hazardous location.

The explosion proof electric actuator is shipped with mating surfces of the cover and base.

When assembling them, pay attention to the mating number (QA code) to assure the

protection rating in a hazardous location.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

2

Please read operation manual and wiring diagram carefully before installation.

Verify that supply voltage is in accordance with the data on nameplate to prevent short

circuit or electrical/electronic parts damage caused by incorrect power input.

Turn power off before wiring or maintenance.

There are grounding devices both inside and outside of the actuator and the ground wires

should be connected properly.

The metal plugs in conduit entries are for transit only. For long term protection fit suitable

flameproof cable gland and power cable should be with a minimum withstand

temperature105 °C (221°F). Please refer to 1.2.3 (P.3).

To avoid functional failure caused by static, do not touch any components on the PCB with

metal tools or bare hands.

Do not parallel wire multiple actuators together without using an extra relay.

Use proper techniques when installing conduit and properly seal the connection. Do not

mount the actuator with conduit entries in upright position to prevent condensation from

entering the unit.

Actuator should be installed in an upright or horizontal position. Do not mount upside

down or below a horizontal position.

Periodically inspect actuator enclosure to prevent dust from accumulating.

Perform below inspections prior to installation. Not allowed to adopt if any item is

unqualified.

Check the marking and certificate number to see if it conforms to the indicated

application.

All the parts of the housing are assembled in the right manner and fastened.

USE FASTENERS WITH YIELD STRESS ≥ 700MPa.

All the explosion-proof parts should be made without cracks or functional defects.

1.2.2 CSA Certification Considerations

KEEP COVER TIGHT WHILE CIRCUITS ARE ALIVE.

AFTER DE-ENERGIZING, DELAY 10 MINUTES BEFORE

OPENING THE COVER.

SEAL REQUIRED WITHIN 18 INCHES (450 mm) OF ENCLOSURE (for Divisions

only).

SEAL REQUIRED WITHIN 2 INCHES (50 mm) OF ENCLOSURE (for Zones only).

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

3

1.2.3 Cable Glands

Please select the relatively explosion-proof cable connector according to the

product specifications.

ATEX / IECEx / TS Certification:

The actuator is delivered with two conduit entries plugged by metal plugs. Use cable

glands with ATEX / IECEx / TS certification and in accordance with the technical

characteristics required by Ex db IIB Gb, Ex tb IIIC Db. The electrical supply cable

must be suitable for power rating and with a minimum withstand temperature 105 °C

(221 °F).

CNEx Certification:

The actuator is delivered with two conduit entries plugged by metal plugs. Use cable

glands with CNEx certification and in accordance with the technical characteristics

required by CNEx Ex db IIB Gb, Ex tD A21 IP68. The electrical supply cable must be

suitable for power rating and with a minimum withstand temperature 105 °C (221 °F).

CSA Certification:

The actuator is delivered with two conduit entries plugged by metal plugs. Use cable

glands with CSA certification. The electrical supply cable must be suitable for power

rating and with a minimum withstand temperature 105 °C (221 °F).

1.3 Working Conditions

ATEX / IECEx / CNEx / TS Certification:

Atmospheric pressure:80 - 110 kPa.

Ambient temperature:- 30 °C to + 70 °C (- 22 °F to + 158 °F).

Relative humidity:Not more than 95 % (+ 25 °C / 77 °F).

The actuator can operate normally within tolerated variation of ± 10% of rated supply.

voltage or ± 1% of rated frequency.

CSA Certification:

Atmospheric pressure:80 - 106 kPa.

Ambient temperature:-30 °C to +70 °C (-22 °F to +158 °F).

Air with normal oxygen content:21 % (Volume).

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

4

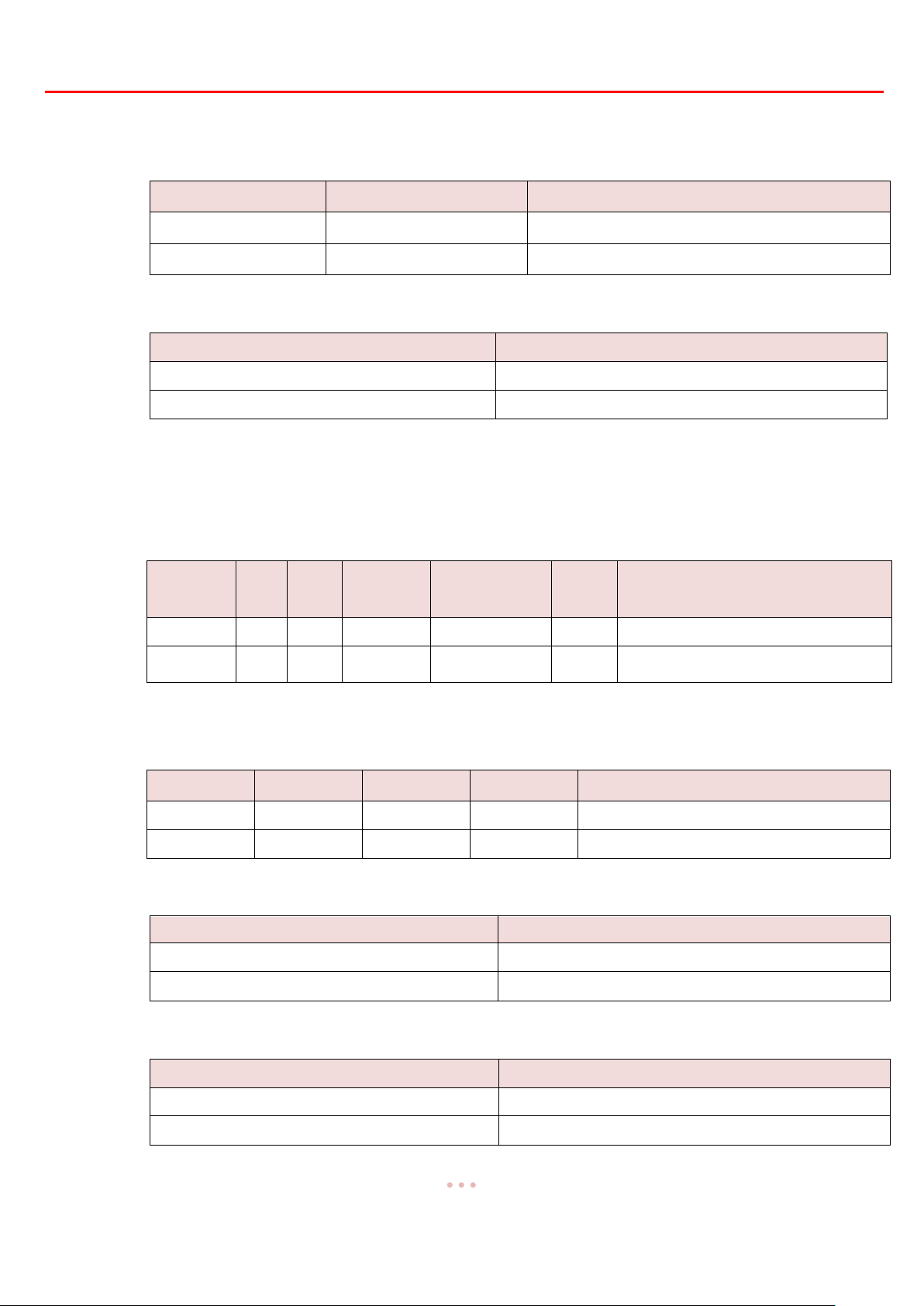

Directive

Group

Ambient Temperature

ATEX II 2 GD

Ex db IIB T4 Gb

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

ATEX II 2 GD

Ex tb IIIC T130 °C Db

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

Group

Ambient Temperature

Ex db IIB T4 Gb

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

Ex tb IIIC T130 °C Db

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

National

Conformity

Class

Zone

Protection

Method

Groups

T-Code

Ambient Temperature

AEx / Ex

I 1 db

IIB, IIA

T4

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

AEx / Ex

II

21

tb

IIIC, IIIB, IIIA

T130°C

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

Class

Division

Groups

T-Code

Ambient Temperature

I 1 C,D

T4

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

II 1 E,F,G

T130°C

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

Group

Ambient Temperature

Ex db IIB T4 Gb

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

Ex tD A21 IP68 T130°C

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

Group

Ambient Temperature

Ex db IIB T4 Gb

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

Ex tb IIIC T130°C Db

- 30 °C to + 70 °C ( - 22 °F to + 158 °F )

1.4 Standards

ATEX European Hazardous Area: EN60079-0, EN60079-1, EN60079-31

IECEx International Hazardous Area:IEC 60079-0, IEC 60079-1, IEC60079-31

North American Hazardous Area:

Zone System:

CAN/CSA-C22.2 No. 0-10, CAN/CSA-C22.2 No. 60079-0, CAN/CSA-C22.2 No. 60079-1,

CAN/CSA-C22.2 No. 60079-31, UL 60079-0, UL 60079-1, UL 60079-31

Division System:

CAN/CSA-C22.2 No. 0-10, CSA C22.2 No. 30-M1986, CSA C22.2 No. 25-17,

FM 3600, FM 3615, FM 3616

CNEx Certification:GB3836.1, GB3836.2, GB12476.1, GB12476.5

TS Certification:CNS3376-0, CNS3376-1, IEC60079-31

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

5

1.5 Inspection, Storage, Transport

1.5.1 Receiving / Inspection

Carefully inspect the package for any damages resulting from shipping and report all

damages to the freight carrier and seller.

After unpacking the product and information packet, please keep the cartons and any

packing materials in case of product return or replacement. Verify that the items listed in

packing slip or in bill of lading are the same as what were ordered. If there is any

discrepancy, please contact the seller.

Verify that the technical data on nameplate is in accordance with what was ordered.

1.5.2 Storage

The actuator should be stored in a dry area with relative humidity of less than 90 %(20 ± 5

°C)and at temperature between -20 °C to + 40 °C (-4 °F to + 104 °F).

The product shall be stored with suitable protection from corrosive substance that can

damage the metal and insulating parts.

The metal plugs for temporary protection should not be removed until the actuator is ready

to be cabled. Use suitable flameproof cable glands to ensure IP rated protection when

installing. Please refer to 1.2.3 (P.3).

1.5.3 Transport

Attach ropes or hooks for the purpose of lifting by hoist only to housing and not to

handwheel.

Actuators packaged in cartons can stand up to land, sea, or air transportation.

Packaged actuators shall avoid of violent impact and strong vibrations and be protected

from rain or snow.

1.5.4 Lubrication

The gear train has been sufficiently lubricated at the factory. No additional lubrication is

required.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

6

2 Product Overview

OME series explosion-proof quarter-turn electric actuators offer torque ranges from 35Nm to

1,500Nm ( 310 in.lb to 13,280 in.lb ). Product design is based on a self-locking worm drive principal,

which provides for a smooth running, dependable, robust drive system. All models are ISO 5211 compliant,

have a visual position indicator on top of actuator cover and manual override except OME-A. The manual

operation is non-clutch design that can be operated without any lever, clutch or brake upon power outage.

ATEX / IECEx / CNEx / TS Explosion-proof instructions:

OME series Explosion-proof Quarter-turn Electric Valve Actuator (referred as "actuator") is a

control device for valves and can be used in the places, where is classified as Zone 1 or Zone 2,

contained GroupⅡA and GroupⅡB gases, Zone 21 or Zone 22, contained the combustible dust

atmosphere or the mixture circumstance with the explosive gas atmospheres and the combustible

dust atmospheres. Temperature group T1-T4.

Certificate Number:

Sira17ATEX1243X

IECEx SIR17.0062X

CNEx17.2492X

(ITIR) 2018 No.07-00013

CSA explosion-proof instructions:

Division System where is classified as North American Division 1 or Division 2 of hazardous

location, contains Group C and Group D gases and temperature group T1 - T4; or contains one

or several flammable dusts with minimum flaming point over 130 °C; or include both above

flammable gases and dusts.

Zone System where is classified as North American Zone 1 or Zone 2 of hazardous location,

contains Group ⅡA and Group ⅡB gases and temperature group T1 - T4; or in Zone 21 or

Zone 22, contained one or several flammable dusts with the minimum flaming point over 130

°C; or include both above flammable gases and dusts.

Certificate Number:

70156877

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

7

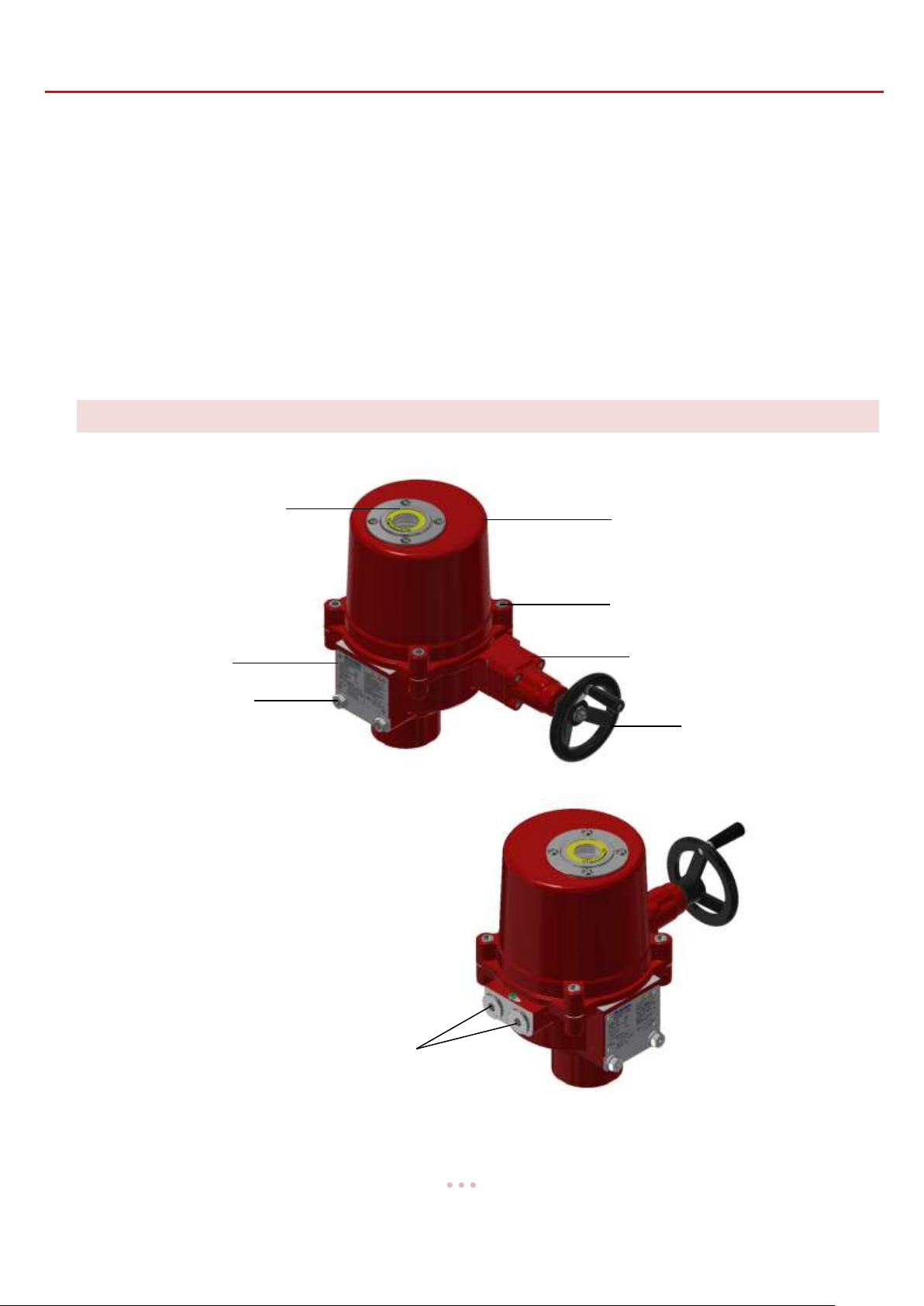

Actuator Top Cover

Top Cover Screw

Position Indicator

Casting End Cap

Handwheel

Nameplate

Mechanical End Stops

Conduit Entries Flamepath Joint

2.1 Features

Enclosure conforms to IP68 (7 m / 72 hrs).

High alloy-steel gear trains with elf-locking prevent back-drive.

Clutch-less manual override.

ISO 5211 mounting flange.

Mechanical end stops.

Flatted position indicator.

Built-in motor thermal protection.

3 Product Mechanical Data

3.1 Parts Identification

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

8

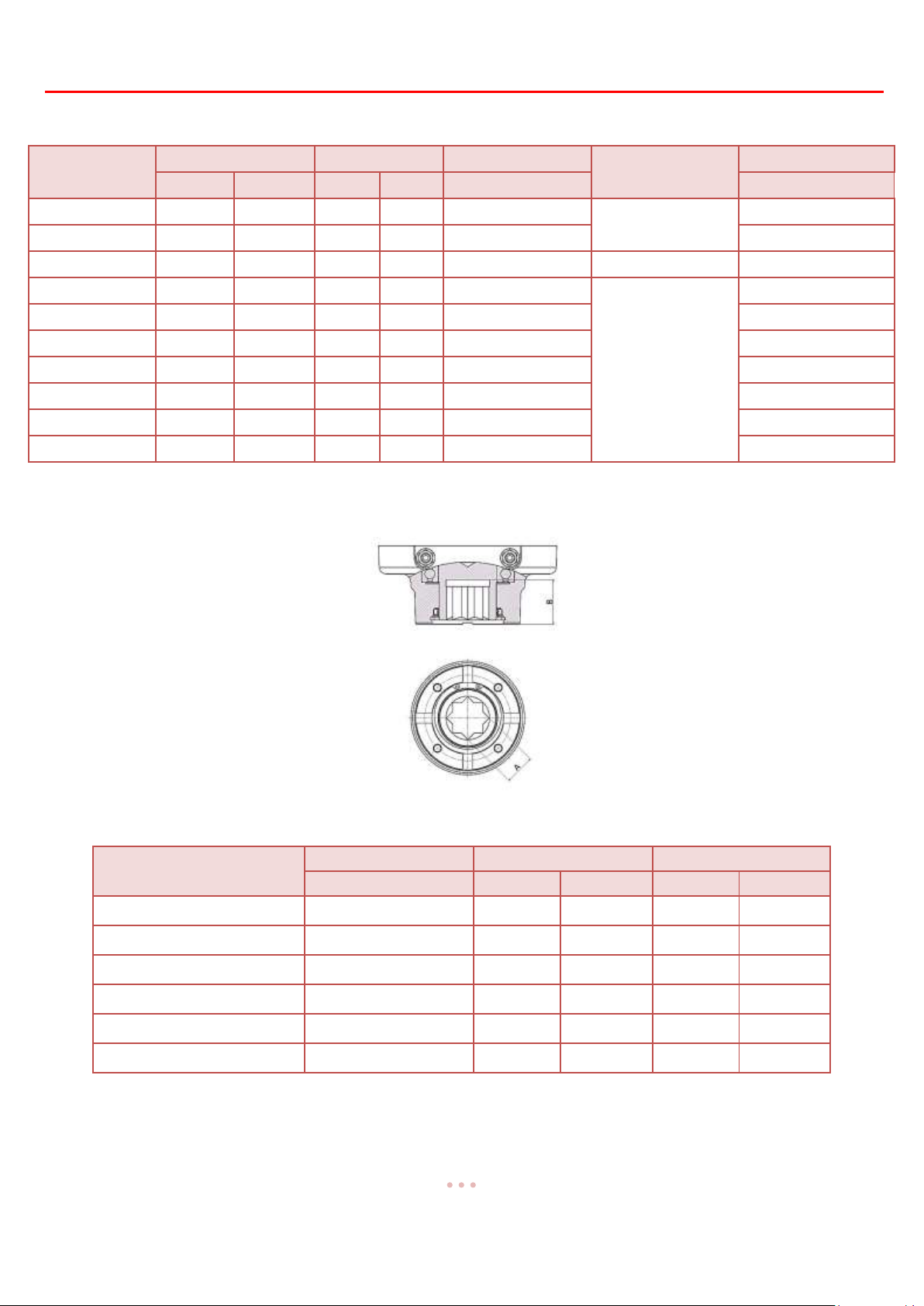

Model

Torque

Weight

Moto Power

Manual Override

Mounting Flange

Nm

inlb

kg

lb

Watt

ISO 5211

OME-1

35

310

2 4 10

Lever

F03 / F05

OME-AM

50

445

3 7 10

F07

OME-A

50

445

3 7 10

N/A

F07

OME-2

90

800

18

40

40

Handwheel

F07

OME-3

150

1330

18

40

40

F07

OME-4

400

3540

32

71

80

F10

OME-5

500

4430

32

71

80

F10

OME-6

650

5755

32

71

80

F10

OME-7

1000

8855

46

101

120

F12 or F14

OME-8

1500

13280

46

101

120

F12 or F14

Model

Mounting Flange

Shaft (A)

Depth of Shaft (B)

ISO 5211

mm

inch

mm

inch

OME-1

F03 / F05

14

0.551

17

0.669

OME-A

F07

17

0.669

20

0.787

OME-AM

F07

17

0.669

20

0.787

OME-2 to OME-3

F07

22

0.866

30

1.181

OME-4 to OME-6

F10

36

1.417

48

1.889

OME-7 to OME-8

F12 or F14

36

1.417

50

1.968

3.2 Technical Information

3.3 Mounting Base Details

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

9

OME- ❶-❷-❸-❹

❶Type

A

AM

1

2

3

4

5

6

7

8

❷Voltage

24 : 24 VAC

D24 : 24 VDC

110 : 110 VAC 1PH

120 : 120 VAC 1PH

220 : 220 VAC 1PH

240 : 240 VAC 1PH

❸Control Mode

F:Floating

M:Modulating

❹Duty cycle

30:30 %

75:75 %

3.4 Actuator Selection

3.5 Sizing

The actuator shall be sized to ensure that its torque output meets the load requirements of valve

and its ability to overcome the required duty cycle of application (As a MINIMUM, a 30% safety

factor is suggested for the calculation of torque requirement).

a.

If the maximum torque of 5” valve is 80 Nm 80 × 1.3 (safety factor) = 104 Nm

104 Nm < 150 Nm (OME-3) OK!

104 Nm > 90 Nm (OME-2) Not OK!

b. In cases where the actuator does not fit directly onto the valve, a mounting kit is required. Please

ensure the bracket and coupling are properly designed and manufactured to withstand the torque

output of the actuator.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

10

Running Time (Sec)

Running Time (Sec) + Rest Time (Sec)

Running Time (Sec) x (1- Duty Cycle)

Duty Cycle

3.6 Duty Cycle

The duty cycle is the relationship between the running time and resting time. It is calculated as

below:

Duty Cycle = x100 %

Rest Time (Sec)=

If the running time for OME-2 is 15 sec, 30% duty cycle, the rest (off) time shall be

calculated as below:

15 × [ ( 1–30%) / 30% ] = 35 The rest time will be 35 sec.

If the running time for OME-2 is 15 sec, 75% duty cycle, the rest (off) time shall be

calculated as below:

15 × [ ( 1–75%) / 75% ] = 5 The rest time will be 5 sec.

Note: For higher duty cycles, choose the 75% duty cycle.

One cycle consists of open-rest-close-rest.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

11

Model

Screw

Allen Key

Torque

mm

Nm

OME-A, OME-AM & OME-1

M6

5

8

OME-2 to OME-3

M10

8

43

OME-4 to OME-8

M12

10

75

Top Cover

Main Housing

Flamepath Joints

Conduit Entries

Flamepath Joint

O-ring

Explosion-proof

Metal Plug

Top Cover Screw

3.7 Flamepath Joint

During cover removal and conduit entry removal, ensure that surfaces are free from

scratches or scrapes.

Actuator installation and maintenance must be performed by trained personnel.

Flamepath Joint

Cover Romoval

Remove the conduit entry metal plugs to relieve the pressure inside the actuator for the ease of

the top cover removal and gently remove the cover. DO NOT attempt to remove the top cover with a

screwdriver as it will damage the surfaces.

Cover Installation

Please ensure that the O-ring seal is in good condition prior to cover installation. Slowly

re-install the cover while being careful not to pinch the O-ring seal.

The explosion-proof enclosures are labeled with a QA code on both of the middle plate and

the cover, please verify the QA code inside the cover is the same as the one on middle plate

when installation. The cover is not interchangeable.

Please follow this table to tighten the cover screw:

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

12

❶ Model No.

❷ Running Time

❸ Torque

❹ Enclosure Rating

❺ Motor Power

❻ Supply Voltage

❶

❷

❸

❹

❺

❻

❼

❽

❾

❼ Rated Current

❽ Serial No.

❾ Date of Manufacture

❿ Ambient Temp.

⓫ Waring

ATEX, IECEx and CNEx

TS

❶

❷

❸

❹

❺

❻

❼

❽

❾

⓫

⓫

CSA

❶

❷

❸

❹

❺

❻

❼

❿

❽

❾

⓫

Nameplate indication

3.8 Nameplate Details

Please make sure the explosion-proof specification for the product is consistent with

nameplate and instruction.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

13

Min. 2mm

4 Mounting And Setup

4.1 Handwheel Installation

a. Pass the screw through the handle and tighten the nut onto handwheel.

Do not overtighten.

b. Secure the handle to the wheel with the slotted screw and tighten the locknut all the way down to

the wheel. Ensure that the locknut is locked between the wheel and the handle.

Leave a 2mm gap between the locknut and the handle as the figure below to allow the

handle free to rotate and then to have a smooth manual operation.

c. Slide fixing screw through washers and handwheel and secure them to override shaft as shown in

the figure below.

Turn off power when installing

handwheel.

d. Assembly completed as shown in the

figure below.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

14

Handwheel

Actuator Driver

4.2 Valve Mounting Instructions

a. Make sure both the valve and actuator are in the same position before mounting, either

fully-open or fully-closed. If not, use the manual override to correct this.

b. Once mounted together, either directly or with a mounting kit, ensure that they are properly

secured together and all fasteners are tightened.

Remove all of valve handle parts, for example, the handle or open/close mechanical

stops so as to not interfere with the actuator.

c. Check again that the valve and actuator are in the same position.

d. Remove the conduit entry plug to relieve the pressure inside the actuator for the ease of the top

cover removal and gently remove the cover, please refer to 3.7 (P.11) for cover installation.

The power must be off before removing the cover.

AFTER DE-ENERGIZING, DELAY 10 MINUTES BEFORE OPENING THE

COVER.

e. Refer to section 4.3 (P.15) for wiring notices and connect the wires according to the wiring

diagram labeled inside the cover of actuator.

f. Supply power to actuator.

Care must be taken at all times as there are live

circuits present that may cause electrical shock.

g. Re-calibration may be required for the end positions, refer to

4.4 (P. 16) for further instructions.

h. For modulating units, refer to 5 (P.21 - P.27) setting

instructions.

Use the insulated wires and length should be less than 30 m.

A minimum of 18 AWG wire is recommended for all field wiring.

Turn power off before changing any settings.

i. Assemble the cover and secure cover screws firmly after setting.

Refer to 3.7 (P.11) for installation and check if there is any foreign object between top

cover flamepath joint and base.

Please ensure that the O-ring seal is in good condition prior to cover installation.

The explosion-proof enclosures are labeled with a QA code on both of the middle plate

and the cover, please verify the QA code inside the cover is the same as the one on

middle plate when installation. The cover is not interchangeable.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

15

4.3 Wiring Instructions

Turn power off before making the electrical connecrion!

There are grounding devices both inside and outside of the actuator (green screw) and the ground

wires should be connected properly.

The conduit entries are attached two conduit entries plugged by metal plugs, and the specification

as below. Each actuator is attached with two metal plugs to conduit entries.

OME-A, OME-AM and OME-1: 1/2” NPT, M20.

OME-2 to OME-8: 3/4” NPT, 1/2” NPT, M20, M25.

Use correct size of fittings so as to not damage the threads.

Verify the supply power is in accordance with the data on the nameplate to prevent a short circuit

and an electrical shock.

Do not apply power to actuator before wiring, otherwise it can cause an electrical

shock or damage components of the actuator.

After wiring, please tighten the conduit entries with suitable cable glands and cover properly.

Unused conduit entries have to be sealed with metal plugs to reach explosion- proof function.

Please refer to 1.2.3 (P.3).

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

16

【Close】

【Open】

Mechanical End Stop

4.4 Actuator Set-up

The power must be off during this procedure so as to avoid damage to the actuator.

Do not make adjustments to the mechanical end stops when actuator is in motion.

All steps below must be completed before normal operation.

The actuators have been set and calibrated at the factory. Most of products will not require

recalibration of these settings. However these are general settings. After valve and actuator are

bolted together, apply power to verify the end positions are correct. If an adjustment is required,

please follow steps below:

4.4.1 Instructions

The travel cams are set to control the open and closed position of the valve. See

below procedure for corresponding actuator model:

OME-1, OME-A and OME-AM:The position is set to stop the travel of the actuator

when the travel cams activate the limit switch.

OME-2 to OME-8:The position is set to stop the travel of the actuator when the

travel cams don’t activate the limit switch.

The standard is with two limit switches (LS1 & LS2).

LS1 & LS2:LS1is for open and LS2 is for close. They limit the fully-open and

fully-closed travel range by disabling the electric motor.

LS3 & LS4 are optional. They allow external equipment to confirm that the valve has

reached the fully-open and fully-closed positions.

4.4.2 Adjustment Steps

a. Turn power off.

b. Loosen the locknut and unwind the mechanical end

stops open and closed screws per below instruction.

OME-2 to OME-6: 25 turns

OME-7 to OME-8: Remove the mechanical

end stop screws completely.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

17

Sector Gear

Set Screw M5

Set Screw M5

【OME-1, OME-A and OME-AM】

【OME-2 to OME-8】

c. For modulating units, loosen the M5 set screw on the sector gear or round gear first.

Round Gear

d. Adjust the fully-open position

OME-A is not available for the manual device setting.

1. Use the manual override to turn the valve to the fully-open position.

2. Remove the cover.

OME-1, OME-A and OME-AM: Loosen the M5 set screw of cam TC1 with a 4 mm

Allen Key.

OME-2 to OME-8: Loosen the M3 set screw of cam TC1 with a 2.5 mm Allen Key.

3. Adjust the travel cam based on the corresponding actuator model below:

OME-A and OME-AM

Rotate the cam TC1 clockwise to contact the switch arm.

Slowly rotate the cam TC1 clockwise until a light click is heard.

OME-1

Rotate the cam TC1 counter-clockwise to contact the switch arm.

Slowly rotate the cam TC1 counter-clockwise until a light click is heard.

OME-2 to OME-8

Rotate the cam TC1 counter-clockwise to contact the switch arm.

Slowly rotate the cam TC1 counter-clockwise until a light click is heard.

4. Securely tighten the M5 set screw and apply power to check if the fully-open position is

correct. If it is not correct, please repeat steps 1 to 3.

5. Use the same method to reset the cam TC3.

Adjust cam TC3 so it trips just before cam TC1 does.

6. After the adjustment is completed, check again that the M5 set screw is securely

tightened.

e. Adjust the fully-closed position

1. Use the manual override to turn the valve to the fully-closed position.

2. OME-A, OME-AM and OME-1: Loosen the M5 set screw on switch TC2 with a 4 mm

Allen key.

OME-2 to OME-8: Loosen the M3 set screw of cam TC2 with a 2.5 mm Allen Key.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

18

OME-A and OME-AM

TC4 (Optional Item)

TC3 (Optional Item)

Counter-clockwise: decrease closing degree.

Counter-clockwise: increase opening

3. Adjust the travel cam based on the corresponding actuator model below:

OME-A and OME-AM

Rotate the cam TC2 counter-clockwise to contact the switch arm.

Slowly rotate the cam TC2 counter-clockwise until a light click is heard.

OME-1

Rotate the cam TC2 clockwise to contact the switch arm.

Slowly rotate the cam TC2 clockwise until a light click is heard.

OME-2 to OME-13

Rotate the cam TC2 clockwise to contact the switch arm.

Slowly rotate the cam TC2 clockwise until a light click is heard.

4. Securely tighten the M5 set screw and apply power to check if the fully-closed position

is correct. If it is not correct, please repeat steps 1 to 3.

5. Use the same method to reset the cam TC4.

Adjust cam TC4 so it trips just before cam TC2 does.

6. After the adjustment is completed, check again that the M5 set screw is securely

tightened.

TC2 “CLOSE”

Clockwise: increase closing degree.

TC1 “ OPEN”

Clockwise: decrease opening degree.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

19

OME-1

OME-2 to OME-8

TC4 (Optional Item)

TC3 (Optional Item)

Counter-clockwise: increase closing degree.

Counter-clockwise: decrease opening

TC4 (Optional Item)

TC3 (Optional Item)

Counter-clockwise: increase closing degree.

Counter-clockwise: decrease opening

TC2 “CLOSE”

TC1 “ OPEN”

Clockwise: decrease closing degree.

Clockwise: increase opening degree.

TC2 “CLOSE”

TC1 “ OPEN”

Clockwise: decrease closing degree.

Clockwise: increase opening degree.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

20

OME-A and OME-AM

Rotate the round gear counter-clockwise to

the end and tighten the M5 set screw.

OME-1

Rotate the round gear clockwise to the end

and tighten the M5 set screw.

OME-2 to OME-8

Rotate the sector gear clockwise to the end

and tighten the M5 set screw.

Round Gear

M5 Set Screw

Sector Gear

【OME-1, OME-A and OME-AM】

【OME-2 to OME-8】

f. Supply the power and unwind the mechanical end stop screws to the fully-open position

based on the actuator model listed below:

Do not remove the cover to supply power if the actuator is located in a hazardous

environment. If so, for the following steps, operate the unit manually.

OME-2 to OME-3:1 turn.

OME-4 to OME-8:1/2 turn.

g. Tighten the locknut.

h. Supply the power and unwind the mechanical end stop screws to the fully-closed position

based on the actuator model listed below:

OME2 to OME-3:1 turn.

OME4 to OME-8:1/2 turn.

i. Tighten the locknut of mechanical end stops.

j. Confirm that the limit switches achieve the full open-close stroke.

k. Modulating units:

After completing the fully-open and fully-closed calibration, run the actuator to the

fully-closed position, and then adjust the gear and the set screws as the steps below

according to the corresponding actuator model.

M5 Set Screw

l. The setting procedure is now completed.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

21

Σ

Controller

Motor

Driver

Feedback

Signal

Motor

Gear Box

-

e

+

Input Signal

Output

Signal

OME-1, OME-A and OME-AM

OME-2 to OME-8

1 2 4 5 6 7

11 12

A

B

1

2

3

6

7

8

9

10

11

12

5 Modulating Control Board Adjustment

5.1 Modulating Control Board Surface

The layout is based on 110/220VAC voltage.

5.2 Procedure

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

22

Input Signal

State of Switches

4 - 20 mA

1 at ON, 2 at OFF

1 - 5 V

1 at OFF, 2 at OFF

2 - 10 V

1 at OFF, 2 at ON

1 2 3 4 5 6 7

8

Factory Setting

ON

OFF

OFF

ON

OFF

OFF

OFF

ON

4 - 20 mA input

ON

OFF

1 - 5 V input

OFF

OFF

2 - 10 V input

OFF

ON

4 - 20 mA output

OFF

ON

OFF

2 - 10 V output

ON

OFF

ON

Input 20 mA / 5 V / 10 V to operate valve to fully-open position

OFF

Input 20 mA / 5 V / 10 V to operate valve to fully-closed position

ON

When signal input failed, driving valve to fully-open (when S6 sets at “ ON”).

OFF

ON

When signal input failed, driving valve to fully-closed (when S6 sets at “ ON”).

ON

OFF

When signal input failed, driving valve to fully-closed (when S6 sets at “ OFF”).

OFF

ON

When signal input failed, driving valve to fully-open (when S6 sets at “ OFF”).

ON

OFF

When signal input failed, valve stays at the last position.

ON

ON

Please follow steps below if an adjustment of these settings are required. Please restart

the actuator after adjusting.

5.3 Dip Switch Setting (SW1)

The Dip Switch SW1 is a combination of 8 switches and equally divided in two rows. It is

utilized to select signal type of input as well as output and fail positioning when the signal input fails.

The sliders can be placed at either ON (upper) or OFF (lower) state position. Factory settings are

switches 1, 4, 8 at ON state and switches 2, 3, 5, 6, 7 at OFF state.

a. Input Signal Setting (1 - 2)

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

23

Output Signal

State of Switches

4 - 20 mA

3 at OFF, 4 at ON, 5 at OFF

2 - 10V

3 at ON, 4 at OFF, 5 at ON

Input Signal

Fully-Open ( 90°)

Fully-Closed ( 0° )

4 - 20 mA

4 mA

20 mA

1 - 5 V

1 V

5 V

2 - 10 V

2 V

10 V

b. Output Signal Setting (3 - 5)

c. Setting of fail position when signal input failed (Switches 6 - 8)

The input signal type is set by switches 1 and 2. And switch 6 is used to set the

corresponding relationship between value of signal input and operation direction of

actuator.

When S6 is set to ON:

The program defines 20 mA or 5 V or 10 V as a command for fully-closed positioning. The

line graph below shows the signal level and the corresponding position of actuator.

When a low signal value is received, the actuator operates toward fully-open position and

when a high signal value is received, the actuator operates toward fully-closed position.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

24

Fail Position

State of Switch

Fully-Open ( 90°)

7 at OFF, 8 at ON

Fully-Closed ( 0° )

7 at ON, 8 at OFF

The Last Position

7 at ON, 8 at ON

Input Signal

Fully-Open ( 90°)

Fully-Closed ( 0°)

4 - 20 mA

20 mA

4 mA

1 - 5 V

5V

1V

2 - 10 V

10V

2V

Signal Failed Position

Setting of Switch

Fully-Open ( 90°)

7 at ON, 8 at OFF

Fully-Closed ( 0°)

7 at OFF, 8 at ON.

The Last Position

7 at ON, 8 at ON.

The selection of the fail position while the input signal failed, please follow table below:

When S6 is set to OFF

The program defines 20 mA / 5 V /10 V as a command for fully-open positioning. The line

graph below shows the signal level and the corresponding position of the actuator.

When a high signal value received, the actuator operates toward fully-open position and when

a low signal value received, the actuator operates toward fully-closed position.

he selection of the fail position while the input signal failed, please follow table below:

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

25

Variable Resistor

Signal type to be adjusted

Position to be adjusted

VR1

To adjust 10 V, 20 mA signal input

Fully-Open

VR51

To adjust 10 V, 20 mA signal output

Fully-Open

VR2

To adjust 2 V, 4 mA signal input

Fully-Closed

VR52

To adjust 2 V, 4 mA signal output

Fully-Closed

VR51

VR52

VR1

VR2

LDR

LDG

7 1 2 4 5 6 11

12

5.4 Sensitivity Switch Setting (SW2)

Original factory setting is “3”.

When switched to “1”: The Highest Sensitivity and the 0 - 90 degree travel is divided up to

around 50 movements.

When switched to “0”: The Lowest Sensitivity and the 0 - 90 degree travel is divided up to around

10 movements.

5.5 Settings for OPEN and CLOSE

These settings are set and calibrated at the factory. Mostly, they do not need to be

recalibrated. Please follow steps below to set when required.

OME-1, OME-A and OME-AM

Use a multimeter to measure the output signal in accordance with the selected signal type.

VR1, VR51, VR2 and VR52 are used to adjust signal input as well as output.l.

If VR51 and VR52 are adjusted, VR1 and VR2 must be adjusted accordingly.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

26

LD1

Fully-closed

LD6

Motor thermal protector started

LD2

Fully-open

LD7

Output signal short circuit

LD3

Power

LD8

Overcurrent in motor

LD4

Abnormal voltage input

LD9

Local setting mode

LD5

Wrong Input Signal

LD1~9

MODE

SET

DN

UP

VR2

1

2

3

4

5

6

7

8

9

10

11

12

VR51

Clockwise: decreasing signal value.

Counter-clockwise: increasing signal value.

VR52

Clockwise: decreasing signal value.

Counter-clockwise: increasing signal value.

Fully-OPEN setting

Rotate VR1 counter-clockwise until a light click is heard, then apply 10V or 20mA to the

modulating board. After that, slightly rotate VR1 clockwise until the LDR goes on and then

adjust VR51 to complete the setting. When adjusting VR51, if the green light is off, keep

rotating VR1 clockwise until the green light goes on.

Fully-CLOSE setting

Rotate VR2 clockwise until a light click is heard, then apply 2 V or 4 mA to the modulating

board. After that, slightly rotate VR2 counter-clockwise until the LDR goes on and then

adjust VR52 to complete the setting. When adjusting VR52, if the red light is off, keep

rotating VR2 counter-clockwise until the red light goes on.

OME-2 to OME-8

Using UP, DN, MODE, SET buttons to set the open and close position.

Press and hold ”SET” switch for 2 seconds until LD 9 lights to enter local setting mode.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

27

VR2

Clockwise: decreasing signal value.

Counter-clockwise: increasing signal value.

Fully-OPEN setting

a. Press and hold “UP” switch to operate the actuator to open until it has reached

fully-open position and LD2 lights and then input a signal 5 V or 10 V or 20 mA.

b. Press “MODE” switch for 2 seconds to complete the setting of fully-open position.

Fully-CLOSED setting

a. Press and hold “UP” switch to operate the actuator to open until it has reached

fully-closed position and LD2 lights and then input a signal 1 V or 2 V or 4 mA.

b. Press “MODE” switch for 2 seconds to complete the setting of fully-closed position.

See below description for VR2 adjustment:

After completing the above settings, press “SET” switch to quit local setting.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

28

Status of LEDs

Possible problems

Solution

LD3 does not go on

a. No power supplied.

b. Incorrect connection of the

lines #8, #9 of potentiometer.

c. Modulating controller failed.

a. Check the power supply as well as wires

connected to terminals #4 & #5, please

refer to 5 (P.21)

b. Verify the actuator is wired properly as

per wiring diagram.

c. Send back to factory for inspection.

LD4 goes on

(for 24V units)

The voltage is under 20.4V.

Verify that the input voltage is within the

allowable voltage deviation.

LD5 goes on

a. An incorrect signal type

inputted. For example, preset

with 2-10 V input but input

4-20 mA.

Or preset with 4 - 20 mA

input but input 2 - 10V

signal. In this case, the

actuator still works in 2 - 7V.

When the signal is over 7.2

V, the LD5 lights.

b. Input a voltage exceeding the

rated. For example, preset

with 2-10 V input but input

13.5V.

Verify if the switch 1 is set in accordance

with the type of input signal. Please refer to

5.3 (P.22 - P.24).

LD6 goes on

Motor thermal protector started.

a. The duty cycle exceeded the rated,

please refer to 3.5 (P.9).

b. The contact of motor thermal protector

(MOT) disconnected.

LD7 goes on

a. Signal output short circuits.

b. The input signal type 2 - 10 V

with reversed polarity.

a. Verify if the signal output with reversed

polarity. The negative pole should be

connected to terminal #11 and the

positive pole should be connected to

terminal #12.

b. Verify if the signal input with reversed

polarity when applying 2 - 10V, the

negative pole should be connected to

terminal #6 and the positive pole should

be connected to terminal #7.

5.6 Troubleshooting of modulating controller

In case LD3 does not light or any of LD4 to LD9 lights when the actuator is motorized,

please refer to steps below for basic troubleshooting.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

29

LD8 goes on

Motor over-current.

a. Duty cycle exceeded the rated, please

refer to 3.6 (P.10) and reduce the duty

rating.

b. Check the load.

c. Check if the motor rotor is locked (For

example: Valve is stuck by foreign

objects).

LD9 goes on

Local setting mode - Setting

position for open & close.

After completing setting, press

“SET” button to quit.

After completing the settings, press “SET”

switch to quit.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

30

Possible problems

Solution

a. The limit switch for fully-closed does not

trip.

b. Motor shaft or bearing were stuck.

c. Power applied to terminals #3 and #4

simultaneously (Parallel Connection).

d. Jammed pipe or valve seat stuck.

e. The seating torque of valve increased

caused by oxidized seals and has resulted

in a torque overload on actuator.

a. Operate the actuator manually to

fully-closed position and confirm if the

limit switch trips.

b. Replace them.

c. If the parallel connection is required,

follow the wiring diagram inside the cover

to connect wires or using isolation relays.

d. Check if any blockage or obstacle in pipe

and remove.

e. Manual operate or replace the valve.

Possible problems

Solution

a. The mechanical stop screws ran into the

output drive gearing.

b. A torque overload caused by the valve.

c. Wrong power supply.

d. Supply voltage was too high or too low,

out the tolerance of deviation.

e. Actuator operates too frequently and

exceeded duty cycle rating.

a. Reset the mechanical end stops and travel

cams, please refer to 4.4.2 (P.16 - P.20).

b. This problem happened frequently after

valve operating for a long time. It is

suggested to replace with a new valve.

c. Check the power supply.

d. Check if the operating current values are

higher than the rated values.

e. Adjust the system bandwidth or reduce the

frequency of operation, please refer to 3.6

(P.10).

Possible problems

Solution

Parallel connection.

Check operating current values and install a

relay respectively.

6 Troubleshooting

Floating Controller

Motor does not operate or overheats

The actuator operates but the motor is hot.

To control two or more actuators, sometimes the actuator works abnormally and the motor is

getting hot.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

31

Possible problems

Solution

a. The actuator is not properly installed onto

the valve.

b. The set screw of the cam loosened and

resulted in that the travel end positions

misaligned.

c. The torque of valve is larger than the

torque of actuator.

d. The actuator was mounted to the valve

improperly.

a. Contact technical department to solve the

problem.

b. Readjust the mechanical end stops and

limit switches, please refer to 4.4.2 ( P.16 P.20).

c. Replace with a new valve or a larger size

actuator.

d. Disassemble the actuator from the valve

and reassemble them to verify that they are

installed properly.

Possible problems

Solution

a. Blown fuse.

b. PCB board failed.

c. Wrong supply voltage.

a. Send back to factory for inspection.

b. Send back to factory for inspection.

c. Send back to factory for inspection.

Possible problems

Solution

Worked in an environment out of the

withstandable temperature range.

Please use the capacitor at temperature

between -30 °C to +65 °C (-22 °F to +149 °F).

The valve does not operate no matter under either electrical operation or manual operation.

When power is on, LED indicators did not function.

The capacitor is failed.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

32

Solution

Please refer to 5.6 (P.23 - P.24).

Possible problems

Solution

The input signal with a reversed polarity, it

means a signal failure.

Verify if the negative pole of signal input

connected to terminal #6 and the positive pole

connected to terminal #7.

Possible problems

Solution

a. Potentiometer failed.

b. The sector gear of potentiometer

loosened.

c. Input wrong signal type.

d. Modulating board failed.

a. Replace with a new potentiometer.

b. Remove the input signal wires and operate

the actuator to fully-closed. And then

recalibrate VR, please refer to 4.4.2-k

(P.20).

c. Check if the input signal is correct, please

refer to 5.3 (P.22).

d. Send back to factory for inspection.

Modulating Controller

The LED indicators (LD4 - LD9) flash.

The LED indication functions properly but the actuator could operate to fully-open as well as

fully-closed, modulating control was out of function.

Modulating control was out of function.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

33

7 Warranty

Sun Yeh Ele. Co. Ltd warrants that for a period of twelve months from the date of manufacture it will

either repair or replace, at its option, any of its products which prove to be defective in material or

workmanship. This warranty does not cover damage resulting from causes such as abuse, misuse,

modification or tampering by users. This warranty is extended only to the immediate purchaser of the

Sun Yeh product and is not transferable. To obtain service under this warranty, the purchaser must first

acquire a return authorization from Sun Yeh. Products must be returned to Sun Yeh under freight prepaid.

This warranty is in lieu of all other obligations, liabilities or expressed warranties. Any implied

warranties, including any implied warranty of merchantability are hereby expressly excluded. In no

event shall Sun Yeh be liable for special, incidental or consequential damages arising in connection with

the use of its products, or for any delay in the performance of this warranty due to cause beyond its

control.

Explosion-Proof Quarter-Turn Valve Actuator【OME Series】 Sun Yeh Ele. Ind. Co., Ltd. | 2019.07

34

Loading...

Loading...