INSTRUCTION MANUAL

20mm Beam Pitch · General Purpose Area Sensor

SF1-N Series

Thank you very much for using SUNX products. Please read this

Instruction Manual carefully and thoroughly for the correct and optimum

use of this product. Kindly keep this manual in a convenient place for

quick reference.

If this product is used as a sensing device for personnel

protection, serious body injury or death could result.

Never use this product as a sensing device with any press

machine, shearing machine, roll grinding machine, forming

machine, vulcanizer, or robot etc. for protection of a hand or a

part of the body.

This product does not include a self-checking circuit for safety

functions necessary to allow its use as a sefety device. Thus,

a system failure or malfunction can result in either an

energized or a de-energized output condition.

When this product is used as a sensing device in the

following applications and if a problem relating to ‘law’ or

‘product liability’ occurs, SUNX shall not be liable for the

failure and for the damage or less.

Use of this product installed to a machinery or a device as

1)

a sensing device to detect a hand or a part of the

WARNING

operator’s body entering a dangerous area and stop the

machinery or the device.

Installation of this product to a protection device for

2)

preventing to enter a dangerous area and use of this as a

sensing device which detectes a hand or a part of the

operator’s body and open/close the door or window.

Use of this product as a sensing device for personnel

3)

protection (including interlock).

For sensing devices to be used as safety devices for press

machines or for personnel protection, use products which

meet standards, such as OSHA, ANSI or IEC etc., for

personnel protection applicable in each region or country.

In case of using as a safety device for press machine, use a

product approved by the Ministry of Labor in Japan.

1

SPECIFICATIONS

Number of beam channels

Model No.

Item

With spatter protection hood

Sensing height

SF1-N8

SF1-N8-H

140mm

Sensing range

Beam pitch

Sensing object

Supply voltage

Current consumption

Emitter: 55mA or less, Receiver: 60mA or less Emitter: 70mA or less, Receiver: 75mA or less Emitter: 85mA or less, Receiver: 90mA or less

Output

Output operation

Short-circuit protection

Response time

Emitter

Receiver

Indicators

Emitting indicator: Green LED

Operation indicator: Red LED (lights up when one or more beams are interrupted, and blinks when extraneous light is received)

Stable incident beam indicator: Green LED (lights up when all beams are received stably)

Unstable incident beam indicator: Yellow LED (lights up when one or more beams are received unstably)

The three color indicators blink in rotation when the receiving circuit fails, and blink simultaneously when the output circuit fails.

The operation indicator and the unstable incident beam indicator blink alternately when the emitting circuit fails or the synchronization wire breaks.

Test input function

Interference prevention function

Protection

Ambient temperature

Ambient humidity

Ambient illuminance

Emitting element

Material

Cable

Weight (total of the emitter and the receiver)

With spatter protection hood

500g approx.

630g approx.

Accessory

Notes: 1)

Output OFF condition

•

One or more beam are interrupted.

• Other components that the output transistor or the parts relevant to the output fail. (Note 2) • Some intense ambient light is received.

2)

The output transistor can be checked by the test cantrol function.

8

16

SF1-N16

SF1-N16-H

300mm

24

SF1-N24

SF1-N24-H

460mm

32

SF1-N32

SF1-N32-H

620mm

40

SF1-N40

SF1-N40-H

780mm

48

SF1-N48

SF1-N48-H

940mm

56

SF1-N56

SF1-N56-H

1,100mm

7m

20mm

ø30mm or more opaque object (ø35mm or more opaque object if the setting distance is 0.5m or less.)

12 to 24V DC±10% Ripple P-P 10% or less

Emitter: 100mA or less, Receiver: 105mA or less

NPN open-collector transistor

• Maximum sink current: 100mA

• Applied voltage: 30V DC or less (between output and 0V)

• Residual voltage: 1.6V or less (at 100mA sink current)

ON when all beams are received/OFF when one or more beams are interrupted (OFF, also, when the sensor fails.) (Note 1)

Incorporated

12ms or less

lights up under normal emission, blinks under emitting circuit failure or on cable break between the synchronization and the external input

terminals when interference prevention function is used (only the emitting indicator of the Sensor B blinks), and lights off under no emission

Incorporated

Incorporated

IP65 (IEC)

–10 to +55°C (No dew condensation or icing allowed), Storage: –10 to +60°C

35 to 85% RH, Storage: 35 to 85% RH

Sunlight: 20,000 x at the light-receiving face, Incandescent light: 3,500 x at the light-receiving face

Infrared LED (modulated)

Protection enclosure: Aluminum, Unit case: ABS, Front cover: Acrylic, Lens: Acrylic

840g approx.

1,080g approx.

2

4-core cabtyre cable, 0.5m long, with a round connector at the end

0.5mm

Use together with the optional mating cable

1,170g approx.

1,530g approx.

1,500g approx.

1,990g approx.

1,830g approx.

2,440g approx.

2,170g approx.

2,900g approx.

2,500g approx.

3,350g approx.

MS-SF1-1 (Sensor mounting bracket): 1 set

•

Either the emitting element, the emitting circuit, the receiving element, or the receiving circuit breaks.

•

Either +V wire, 0V wire, output wire, or synchronization wire breaks.

64

SF1-N64

SF1-N64-H

1,260mm

2,830g approx.

3,800g approx.

2

CAUTIONS

Make sure to carry out the wiring in the power supply off condition.

Take care that wrong wiring will damage the sensor.

Verify that the supply voltage variation is within the rating.

If power is supplied from a commercial switching regulator, ensure that

the frame ground (F.G.) terminal of the power supply is connected to an

actual ground.

Do not run the wires together with high-voltage lines or power lines or

put them in the same raceway. This can cause malfunction due to

induction.

Do not use during the initial transient time (1.5 sec.) after the power

supply is switched on.

Do not use the sensor without the front cover or the enclosure. IP

protection cannot be maintained and a contact failure may occur

between modular units.

Avoid dust, dirt, and steam.

Take care that the product does not come in direct contact with organic

solvents, such as, thinner, etc.

Take care that the sensor is not directly exposed to fluorescent light from a

rapid-starter lamp or a high frequency lighting device, as it may affect the

sensing performance

This sensor is suitable for indoor use only.

Extension up to total 20m is possible with 0.5mm2, or

.

Sensing

object

Emitter

Receiver

more, cable for both emitter and receiver.

Install the sensor where it cannot be affected by a

beam reflected from a machinery frame or a

workpiece. If the reflected beam is received, beam

interruption is not achieved.

The emitter and the receiver must face

each other corrctly. If they are set

upside down, the sensor does not work.

Cable

Make sure that stress is not applied

directly to the sensor cable joint.

When mounting the sensor, the tightening torque should be 2N·m or less.

Cable Cable

3

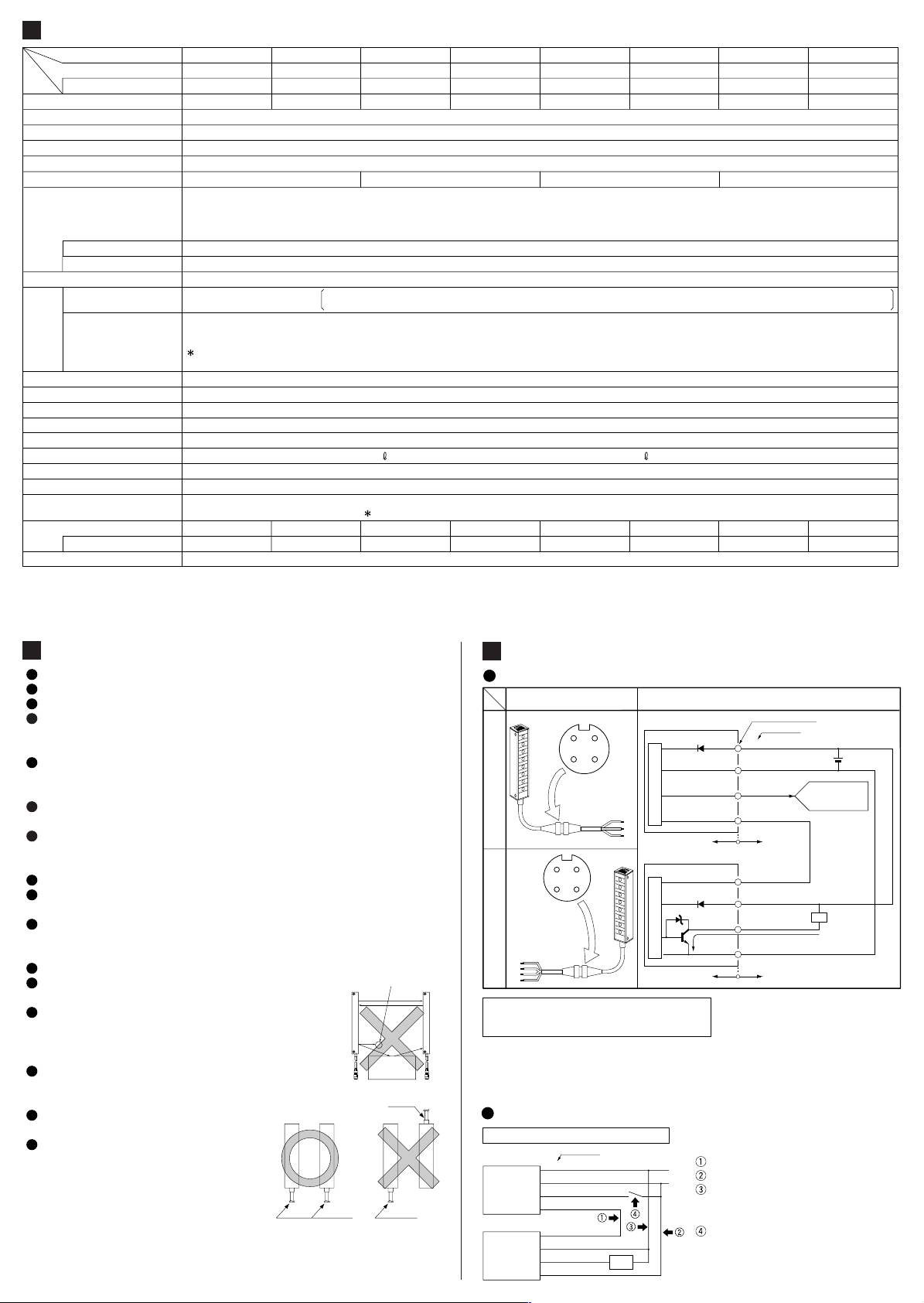

CONNECTIONS

I/O circuit diagram

Connector pin positions I/O circuit diagram

+VSync.

EmitterReceiver

Symbols···

Notes: 1)

21

34

+VSync.

Output

External

input

0V

21

34

0V

D

: Reverse supply polarity protection diode

Z

D

: Surge absorption zener diode

:

Tr

NPN output transister

Do not connect the synchronization wire to the ES terminal (external input) of

NPS or PS-930 sensor controller.

To supply power to the emitter and the receiver from separate power

2)

supplies, be sure to connect both 0V (blue) wires in common and adjust both

the power supplies to the same voltage.

Sensor circuitSensor circuit

Internal circuit

Z

D

Tr

Internal circuit

D

D

(Brown) +V

1

(Blue) 0V

3

(Pink) External input

4

(Orange/Violet)

Synchronization (Note 1)

2

(Orange/Violet)

Synchronization

(Note 1)

2

(Brown) +V

1

(Black) Output

4

(Blue) 0V

3

Wiring diagrams

When using one set of sensor

Emitter

Receiver

Color code

(Brown) +V

(Blue) 0V

(Pink) External input wire

(Orange/Violet) Synchronization wire

(Orange/Violet)

Synchronization wire

(Brown) +V

(Black) Output

(Blue) 0V

Load

Connect both the synchronization wires.

+V

Connect both the 0V wires in common.

0V

Although both the +V wires need not be

connected in common, they must be at

the same voltage.

To use the test input function, connect a

switch between the external input wire

and 0V. If this function is not used, insulate the external input wire.

Connector pin No.

Color code

Users' circuit

100mA max.

Users' circuit

+

12 to 24V DC

±10%

–

Used for test input

function or interference

prevention function.

Load

(Note 2)

When using two sets of sensors (Using interference prevention function)

Emitter of

Sensor A

Receiver of

Sensor A

Emitter of

Sensor B

Receiver of

Sensor B

Color code

(Brown) +V

(Blue) 0V

(Pink) External input wire

(Orange/Violet) Synchronization wire

(Orange/Violet)

Synchronization wire

(Brown) +V

(Black) Output

(Blue) 0V

(Brown) +V

(Blue) 0V

(Pink) External input wire

(Orange/Violet) Synchronization wire

(Orange/Violet)

Synchronization wire

(Brown) +V

(Black) Output

(Blue) 0V

Load

Load

Connect together the synchronization

+V

wires of both the sensors.

0V

Connect both the 0V wires in common.

Although both the +V wires need not

be connected in common, they must be

at the same voltage.

Connect the external input wire of Sensor B to synchronization wire of Sensor

A to prevent interference between Sensor A and Sensor B.

To use the test input function, connect

a switch between the external input

wire of Sensor A and 0V. If this

function is not used, insulate the

external input wire.

Mating cable

Connecting Disconnecting

Put together the convex and the

concave of respective connectors,

and press them each other.

Hold one ring not to rotate and

turn the other ring clockwise until

they become tight.

Convex

[Sensor side]

Concave

[Mating side]

Turn the ring counterclockwise and pull the

one from the other.

Fixing ring

Fixing ring

If the output follows the change (High and Low) of the external input, the

sensor is normal. If it does not, the sensor is in abnormal condition.

External input

Output

6

CHANGING THE NUMBER OF BEAM CHANNELS

High

Low

ON

OFF

T

T

20ms

Normal Abnormal

T 20ms

Slide the cover stopper in the direction

of the arrow and pull the front cover

upward.

Cover

stopper

Front cover

Remove the four fixing screws on the

rear face.

4

FUNCTIONAL DESCRIPTION

2 4

1

3

Emitter

Description

Emitter indicator

(Green LED)

Stable incident

beam indicator

(Green LED)

Unstable incident

beam indicator

(Yellow LED)

Operation indicator

(Red LED)

5

TEST INPUT FUNCTION

Lights up under normal emission, blinks under emitting circuit failure or

on cable break between the synchronization and the external input

terminals when interference prevention function is used (only the emitting

indicator of the Sensor B blinks), and lights off under no emission

Lights up when all beams

are received stably

Lights up when one or more

beams are received unstably

Lights up when one or more

beams are interrupted, and blinks

when extraneous light is received

Receiver

Function

, and blink in

rotation when the receiving

circuit fails, and blink

simultaneously when the

output circuit fails.

and blink alternately

when the emitting circuit

fails or the synchronization

wire breaks.

Making the external input wire (pink) Low stops the emission and turns

off the emitting indicator. Because this function turns the output on and

off without any object, it is useful for a start-up test.

Signal condition

Non-voltage contact or

NPN open-collector transistor

Pull the modules upward one by one

with your hands.

Arrange the required protection

enclosure and front cover that matches

the required sensing height, and

connect the relay units and the end

cap.

Tighten the four fixing screws and

insert the front cover by pulling the

cover stoppwe back.

(Pink)

External input

or

Low (0 to 1V): emission stopped

(Blue) 0V

Note:

When two sets are used with interference prevention, connect the external input

wire that is not connected to the synchronization wire to 0V (refer to

3

‘ CONNECTIONS’). This stops the emission of both sensors.

High (4.5 to 30V, or open): emission

Notes: 1)

Be sure to turn the power supply off before linking units.

If this is not done, the sensor may get damaged.

Do not apply excess force to the units while linking.

2)

Be sure to put the end cap on the top.

3)

The fixing screws are attached to the protection enclosure.

4)

Head Office

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7211 FAX: +81-(0)568-33-2631

Overseas Sales Dept.

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

http://www.sunx.co.jp/ SUNX Limited

PRINTED IN JAPAN

Loading...

Loading...