or

Emitter

Receiver

Stable incident beam

indicator (Green)

Operation indicator

(Red)

INSTRUCTION MANUAL

Sensor protection

bracket (MS-NA3-3)

(Optional)

NA1-PK3 Series

Thank you very much for using SUNX products.

Please read this Instruction Manual carefully and

thoroughly for the correct and optimum use of

this product. Kindly keep this manual in a convenient place for quick reference.

If this product is used as a sensing de-

Ɣ

vice for personnel protection, serious

body injury or death could result.

Never use this product as a sensing device

Ɣ

with any press machine, shearing machine,

roll grinding machine, forming machine, vulcanizer, or robot etc. for protection of a hand

or a part of the body.

This product does not include a self-check-

Ɣ

ing circuit for safety functions necessary

to allow its use as a safety device. Thus, a

system failure or malfunction can result in

either an energized or a de-energized output

condition.

When this product is used as a sensing

Ɣ

device in the following applications and if a

problem relating to “law” or “product liability”

occurs, SUNX shall not be liable for the failure and for the damage or less.

1) Use of this product installed to a machinery or a device as a sensing device to

detect a hand or a part of the operator’s

body entering a dangerous area and stop

the machinery or the device.

2) Installation of this product to a protection

device for preventing to enter a dangerous

area and use of this as a sensing device

which detects a hand or a part of the operator’s body and open / close the door or

window.

3) Use of this product as a sensing device for

personnel protection (including interlock).

For sensing devices to be used as safety

Ɣ

devices for press machines or for personnel protection, use products which meet

standards, such as OSHA, ANSI or IEC etc.,

for personnel protection applicable in each

region or country.

In case of using as a safety device for press

Ɣ

machine, use a product approved by the

Ministry of Health, Labor and Welfare in Japan.

1

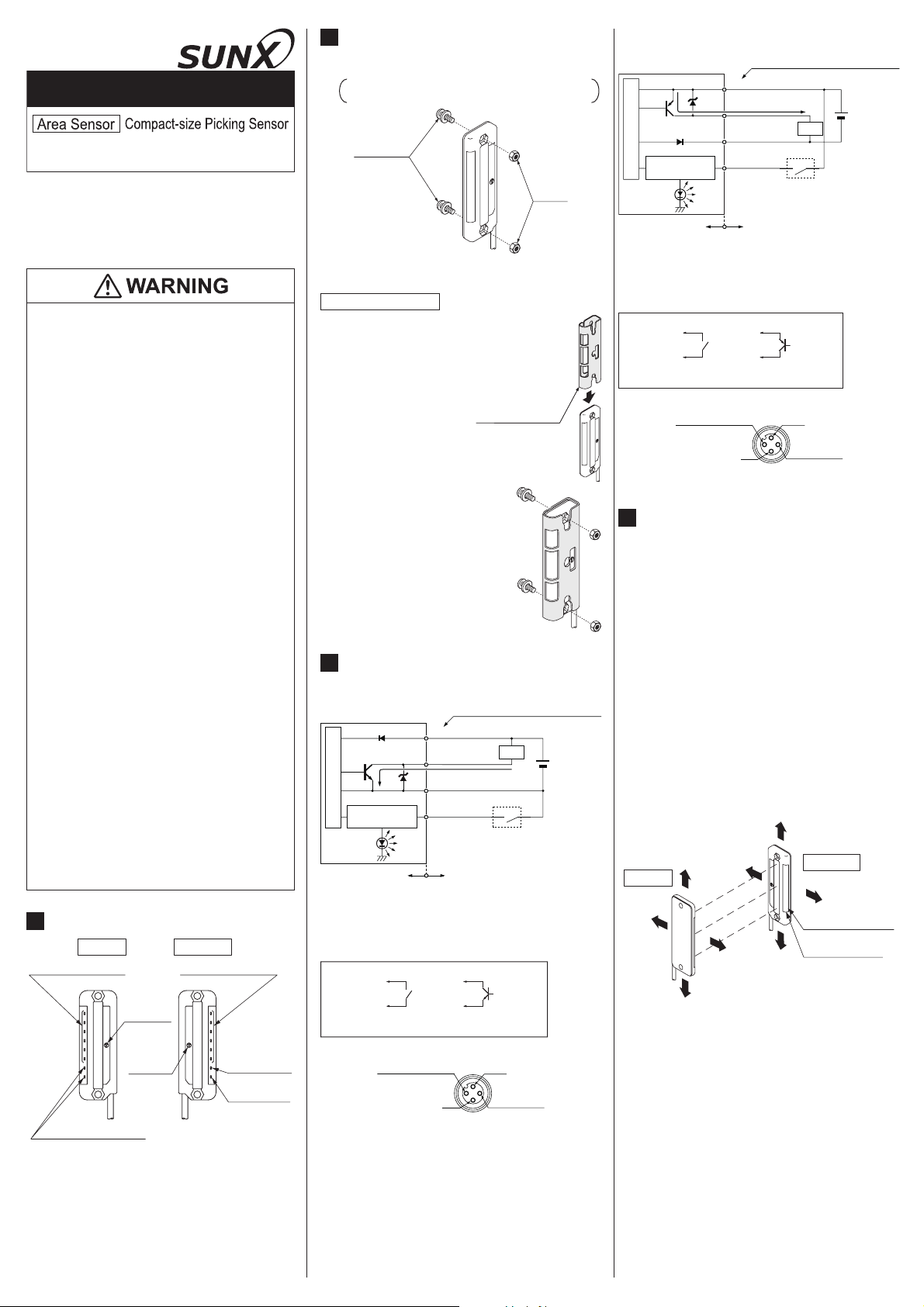

PART DESCRIPTION

Emitter Receiver

Job indicators (Orange)

Power indicator (Green)

Frequency

selection

switch

Operation /

frequency

selection

switch

Job indicators (Orange)

Stable incident

beam indicator

(Green)

Operation

indicator (Red)

2

MOUNTING

Use M4 screws with washers and M4 nuts. The

Ɣ

tightening torque should be 0.5N·m or less.

Please arrange the screws and the nuts

separately.

M4 screws

with washers

M4 nuts

The sensor protection bracket (MS-NA3-3) (op-

Ɣ

tional) is also available.

Mounting method

Insert the sensor protec-

1.

tion bracket (MS-NA3-3)

from upwards of the sensor body, and match the

position of the mounting

holes of the sensor body

and the sensor protection bracket (MS-NA3-3).

2.

Mount with the M4

screws with washers and

the M4 nuts enclosed

with the sensor protection bracket (MS-NA3-3).

The tightening torque

should be 0.5N·m or

less.

3

I/O CIRCUIT DIAGRAMS

<NPN output type>

Color code /

Connector pin No. of the pigtailed type

(Brown / 1) +V

(Black / 4) Output

(Note 1)

Main circuit

Job indicator

lighting circuit

Internal circuit Users' circuit

Notes: 1) The output is not incorporated in the emitter.

2) When the job indicator is used as a large size op-

*1

eration indicator, connect the job indicator input wire

(pink) of the emitter and receiver to the output wire

(black) of the receiver.

Non-voltage contact or NPN open-collector transistor

Low (0 to 2V DC): Lights up

High (5 to 30V DC or Open): Lights off

(Blue / 3) 0V

(Pink / 2) Job

indicator input

(Note 2)

or

100mA max.

1

Load

+

-

12 to 24V DC

±10%

Connector-pin position (Pigtailed type)Ɣ

2

Job indicator input

3

0V

Note: No connection is required for the emitter.

1

+V

4

Output (Note)

<PNP output type>

Color code /

Connector pin No. of the pigtailed type

(Brown / 1) +V

100mA max.

(Black / 4) Output (Note 1)

Main circuit

Job indicator

lighting circuit

Internal circuit Users' circuit

Notes: 1) The output is not incorporated in the emitter.

2) When the job indicator is used as a large size op-

*1

eration indicator, connect the job indicator input wire

(pink) of the emitter and receiver to the output wire

(black) of the receiver.

Non-voltage contact or PNP open-collector transistor

High (4 to 30V DC): Lights up

Low (0 to 0.6V DC or Open): Lights off

(Blue / 3) 0V

(Pink / 2) Job

indicator input

(Note 2)

+

12 to 24V DC

±10%

-

Load

1

Connector-pin position (Pigtailed type)Ɣ

2

Job indicator input

3

0V

Note: No connection is required for the emitter.

4

BEAM ALIGNMENT

1

+V

4

Output (Note)

1. Place the emitter and the receiver face to face

along a straight line.

2. After the cables have been correctly connected,

switch the power ON.

3. Move the emitter in the up, down, left and right

directions, in order to determine the range of

the beam received condition with the help of the

operation indicator (red) on the receiver. Then,

set the emitter at the center of this range.

4. Similarly, adjust for up, down, left and right angular movement of the emitter.

5. Further, perform the angular adjustment for the

receiver also.

6. Check that the stable incident beam indicator

(green) lights up.

7. Interrupt each beam channel with the actual

VHQVLQJREMHFWDQGFRQ¿UPWKDWWKHVHQVRURSerates correctly.

Note: The stable incident beam indicator (green) lights up

when all the three beams are stably received by the

receiver.

5

PRINTED IN JAPAN

Overseas Sales Dept. (Head Office)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

Europe Headquarter: Panasonic Electric Works Europe AG

Rudolf-Diesel-Ring 2, D-83607 Holzkirchen, Germany

Phone: +49-8024-648-0

US Headquarter: Panasonic Electric Works Corporation of America

629 Central Avenue New Providence, New Jersey 07974 USA

Phone: +1-908-464-3550

URL : sunx.jp

SUNX Limited

SELECTION OF OUTPUT OPERATION

The output operation can be selected by the

Ɣ

7

operation / frequency selection switch on the

receiver. (Make sure to set the switch in the

power supply off condition.)

State of operation / frequency selection switch

3

FREQ.

L-ON

D-ON

Notes: 1) Selection of the output operation and the frequency

2) In case the operation / frequency selection switch is

6

INTERFERENCE PREVENTION FUNCTION

By setting different emission frequencies, three

Ɣ

2

1

D-ON

3

FREQ.

2

1

D-ON

for the receiver is carried out with the same switch.

When the output operation is set, be sure to select

the same frequency No. of the emitter and the receiver.

set to the position other than 1, 2 or 3, the state of

the receiver is in D-ON / frequency 1.

3

2

1

3

2

1

FREQ.

L-ON

FREQ.

L-ON

Output operation

OFF when

one or more

beams are

interrupted.

ON when

one or more

beams are

interrupted.

sets of the sensors can be mounted closely as

VKRZQLQWKH¿JXUHEHORZ

Sensor 1

Sensor 2

Sensor 3

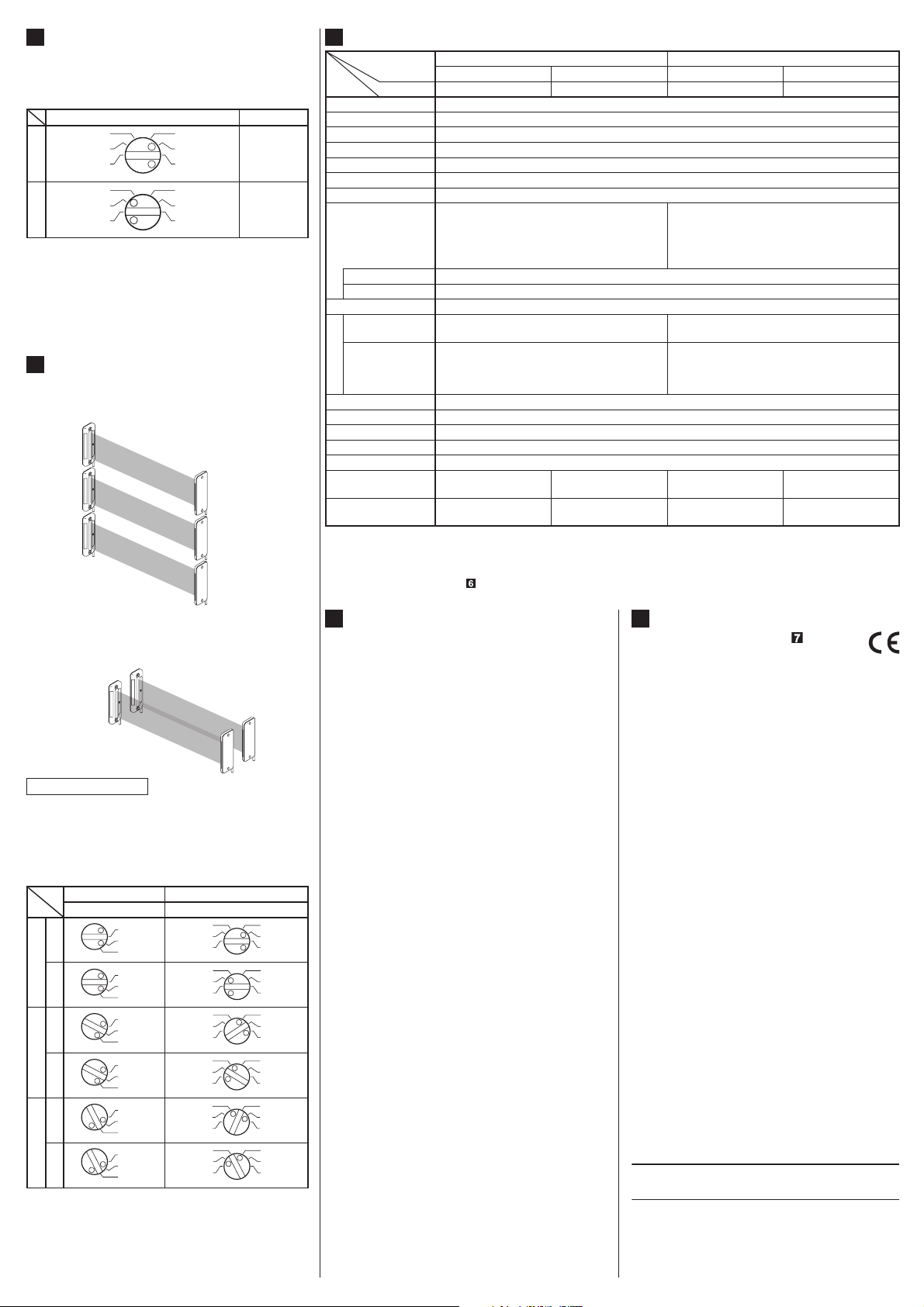

Item

Sensing height 49.2mm

Sensing range 30 to 300mm

Beam pitch 24.6mm

Number of beam channels

Sensing object ø29mm or more opaque object

Supply voltage 12 to 24V DC±10% Ripple P-P10% or less

Current consumption Emitter: 30mA or less, Receiver: 50mA or less

Output

Response time 10ms or less (when interference prevention is used: 30ms or less)

Indicators

Interference prevention function

Ambient temperature –10 to +55°C (No dew condensation or icing allowed), Storage: –20 to +70°C

Ambient humidity 35 to 85% RH, Storage: 35 to 85% RH

Emitting element Infrared LED (synchronized scanning system)

Material Enclosure: Heat-resistant ABS, Lens cover: Acrylic, Display cover: Acrylic

Cable

Weight

1RWHV 7KHPRGHO1RZLWKVXI¿[³-J” is pigtailed type. (cable length: 0.3m)

Model No.: NA1-PK3(-PN)-J

For the cable connected with the pigtailed type, use the connection cable CN-24-C2 (cable length: 2m) (optional) or

2) For details, refer to “

SPECIFICATIONS

Type

Model No. (Note 1)

2m cable length type 5m cable length type 2m cable length type 5m cable length type

NA1-PK3

NPN open-collector transistor

•

Maximum sink current: 100mA

Applied voltage: 30V DC or less (between output and 0V)

•

Residual voltage: 1V or less (at 100mA sink current)

•

Output operation ON or OFF when one or more beam channels are interrupted, selectable by a switch

Short-circuit protection

Emitter

Receiver

CN-24-C5 (cable length: 5m) (optional).

Power indicator: Green LED (lights up when the power is ON)

Job indicator: Orange LED (lights up when the job indicator input is Low)

Operation indicator: Red LED (lights up when the output is ON)

Stable incident beam indicator: Green LED

(lights up when the all beams are stably received)

Job indicator: Orange LED (lights up when the job indicator input is Low)

0.2mm24-core (emitter: 3-core)

oil resistant cabtyre cable, 2m long

Emitter: Approx. 50g

Receiver: Approx. 50g

NPN output PNP output

NA1-PK3-C5 NA1-PK3-PN NA1-PK3-PN-C5

3 beam channels

PNP open-collector transistor

•

Maximum source current: 100mA

Applied voltage: 30V DC or less (between output and +V)

•

Residual voltage: 1V or less (at 100mA source current)

0.4V or less (at 16mA sink current)

•

Incorporated

Power indicator: Green LED (lights up when the power is ON)

Job indicator: Orange LED (lights up when the job indicator input is High)

Operation indicator: Red LED (lights up when the output is ON)

Stable incident beam indicator: Green LED

(lights up when the all beams are stably received)

Job indicator: Orange LED (lights up when the job indicator input is High)

Incorporated (Up to 3 units can be closely mounted) (Note 2)

0.2mm24-core (emitter: 3-core)

oil resistant cabtyre cable, 5m long

Emitter: Approx. 105g

Receiver: 110g

INTERFERENCE PREVENTION FUNCTION.”

0.2mm24-core (emitter: 3-core)

oil resistant cabtyre cable, 2m long

Emitter: Approx. 50g

Receiver: Approx. 50g

0.4V or less (at 16mA source current)

0.2mm24-core (emitter: 3-core)

oil resistant cabtyre cable, 5m long

Emitter: Approx. 105g

Receiver: 110g

However, if the sensors are mounted closely as

Ɣ

VKRZQLQWKH¿JXUHEHORZXS WR VHWVRI VHQ-

sors are possible.

Sensor 2

Sensor 1

Frequency setting

Set the both emitting and receiving frequency

Ɣ

of Sensor 1 to FREQ. 1, the both emitting and

receiving frequency of Sensor 2 to FREQ. 2

and the both emitting and receiving frequency

of Sensor 3 to FREQ. 3. (Make sure to set the

switch in the power supply off condition.)

Emitter Receiver

Frequency selection switch Operation / Frequency selection switch

1

FREQ.

L-ON

Sensor 1

D-ON

L-ON

Sensor 2

D-ON

L-ON

Sensor 3

D-ON

Notes: 1) Take care that selection of the output operation and

2) In case the frequency switch and the operation / fre-

2

3

1

FREQ.

2

3

1

FREQ.

2

3

1

FREQ.

2

3

1

FREQ.

2

3

1

FREQ.

2

3

the frequency for the receiver is carried out with the

same switch.

quency selection switch is set to the position other

than 1, 2 or 3, the state of the emitter is in frequency

1 and that of the receiver is in D-ON / frequency 1.

3

FREQ.

2

1

D-ON

3

FREQ.

2

1

D-ON

3

FREQ.

2

1

D-ON

3

FREQ.

2

1

D-ON

3

FREQ.

2

1

D-ON

3

FREQ.

2

1

D-ON

3

2

1

3

2

1

3

2

1

3

2

1

3

2

1

3

2

1

FREQ.

L-ON

FREQ.

L-ON

FREQ.

L-ON

FREQ.

L-ON

FREQ.

L-ON

FREQ.

L-ON

8

CAUTIONS

This product has been developed / produced for

Ɣ

industrial use only.

Make sure that the power supply is off while wir-

Ɣ

ing and operation of the selection switch.

Take care that wrong wiring may damage the sensor.

Ɣ

Verify that the supply voltage variation is within

Ɣ

the rating.

If power is supplied from a commercial switch-

Ɣ

ing regulator, ensure that the frame ground

(F.G.) terminal of the power supply is connected

to an actual ground.

Do not use during the initial transient time (0.5

Ɣ

sec.) after the power supply is switched on.

In case noise generating equipment (switching

Ɣ

regulator, inverter motor, etc.) is used in the vicinity of the sensor, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

Extension up to total 100m is possible with

Ɣ

2

0.3mm

, or more, cable for both emitter and receiver. However, in order to reduce noise, make

the wiring as short as possible.

Do not run the wires together with high-voltage lines

Ɣ

or power lines or put them in the same raceway.

This can cause malfunction due to induction.

Take care that the sensor is not directly exposed

Ɣ

WRÀXRUHVFHQW ODPSIURPDUDSLGVWDUWHU ODPSD

high frequency lighting device or sunlight etc.,

as it may affect the sensing performance.

Avoid dust, dirt, and steam.

Ɣ

Take care that the product does not come in

Ɣ

contact with water, oil, grease, organic solvents,

such as thinner, etc., strong acid or alkaline.

Make sure to use an isolation transformer for

Ɣ

the DC power supply. If an auto-transformer

(single winding transformer) is used, this product or the power supply may get damaged.

In case a surge is generated in the used power

Ɣ

supply, connect a surge absorber to the supply

and absorb the surge.

The emitter and the receiver must face each

Ɣ

other correctly. If they are set upside down, the

sensor does not work.

,QRUGHUWRWXUQWKHVZLWFKHV DÀDWKHDGVFUHZ-

Ɣ

driver is required. (The blade should be 2.5 ×

0.6mm or less)

This sensor is suitable for indoor use only.

Ɣ

9

INTENDED PRODUCTS FOR CE MARKING

The models listed under “ SPEC-

Ɣ

IFICATIONS” come with CE Marking.

As for all other models, please con-

WDFWRXURI¿FH

Loading...

Loading...