INSTRUCTION MANUAL

Auto-setting Fiber Sensor

FX-A1 Series

Thank you very much for using SUNX products. Please read this Instruction Manual

carefully and thoroughly for the correct and optimum use of this product. Kindly keep

this manual in a convenient place for quick reference.

٨٨Never use this product as a sensing device for personnel protection.

In case of using sensing devices for personnel protection, use

WARNING

1

SPECIFICATIONS

Item

Supply voltage

Current consumption

Sensing output

Output operation

Short-circuit protection

Self-diagnosis output

Output operation

Short-circuit protection

Emission frequency 1

Emission frequency 2

Response

time

Emission frequency 3

Sensitivity setting

Timer function

Interference prevention function

Ambient temperature

Ambient humidity

Emitting element

Material

Cable

Weight

Accessory

Note: For the plug-in connector type, add suffix 'J' at the end of the model No.

Model No.: FX-A1J, FX-A1GJ, FX-A1PJ

For the cable length 5m type, add suffix '-C5' at the end of the model No. (only NPN output type)

Model No.: FX-A1-C5, FX-A1G-C5

2

CAUTIONS

٨

Make sure to carry out the wiring in the power supply off condition.

٨

Verify that the supply voltage variation is within the rating.

In case noise generating equipment (switching regulator, inverter motor, etc.) is used in the vicinity

٨

of this product, connect the frame ground (F.G.) terminal of the equipment to an actual ground.

If power is supplied from a commercial switching regulator, ensure that the frame

٨

ground (F.G.) terminal of the power supply is connected to an actual ground.

Do not use during the initial transient time (0.5 sec.) after the power supply is switched on.

٨

The self-diagnosis output is not incorporated with a short-circuit protection. Do not

٨

connect it directly to a power supply or a capacitive load.

٨

Do not run the wires together with high-voltage lines or power lines or put them in

the same raceway. This can cause malfunction due to induction.

٨

Extension up to total 100m is possible with a 0.3mm

order to reduce noise, make the wiring as short as possible.

This sensor is suitable for indoor use only.

٨

Avoid dust, dirt, and steam.

٨

Take care that the product does not come in direct contact with organic solvents, such as, thinner, etc.

٨

This sensor cannot be used in an environment containing inflammable or explosive gases.

٨

Never disassemble or modify the sensor.

٨

3

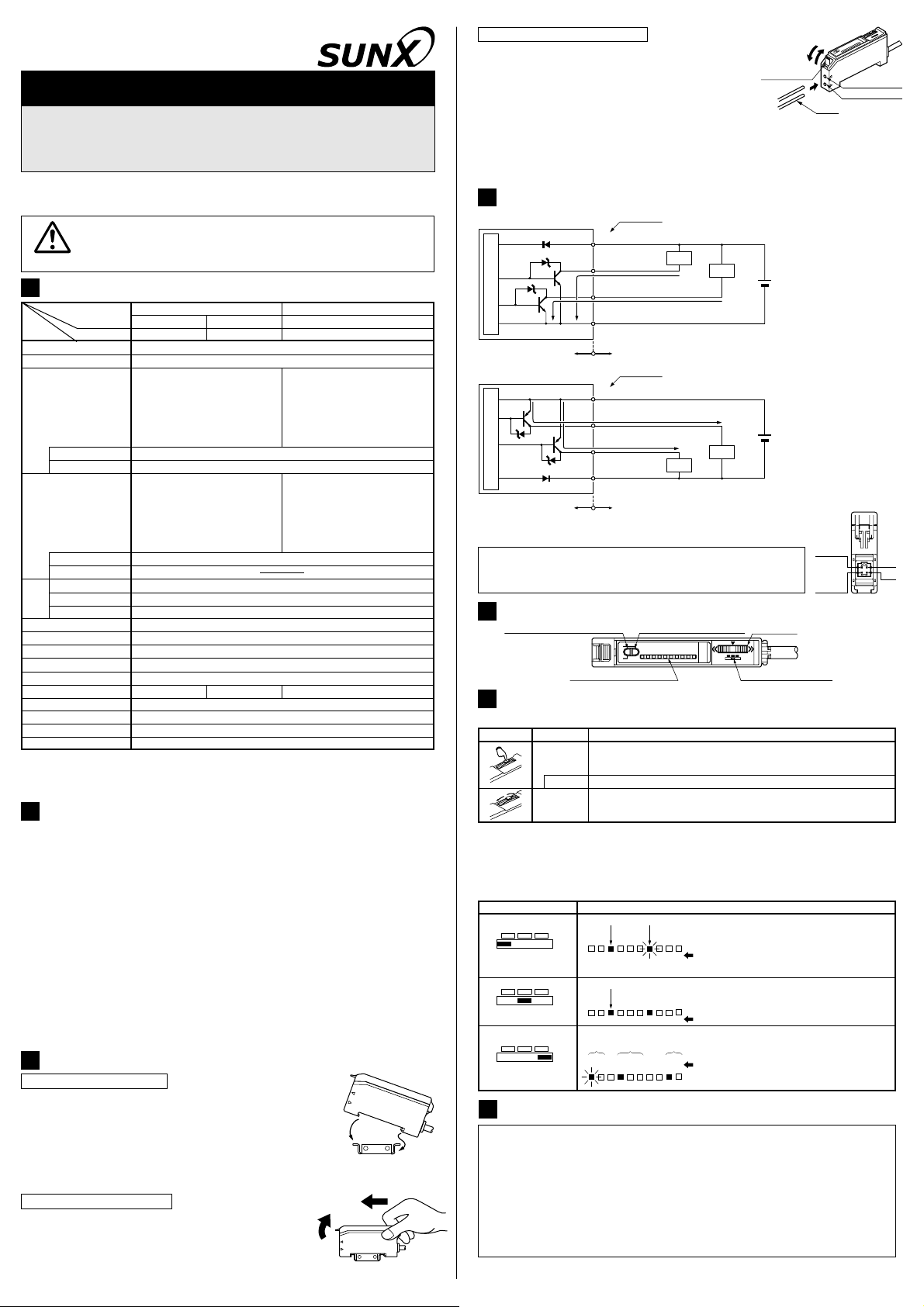

MOUNTING

How to mount the amplifier

ԘԙFit the rear part of the mounting section of the amplifier

on the attached amplifier mounting bracket (MS-DIN-2)

or a 35mm width DIN rail.

Press down the rear part of the mounting section of the

unit on the attached amplifier mounting bracket

(MS-DIN-2) or a 35mm width DIN rail and fit the front

part of the mounting section to the attached amplifier

mounting bracket (MS-DIN-2) or a 35mm width DIN rail.

How to remove the amplifier

ԘԙPush the amplifier forward.

Lift up the front part of the amplifier to remove it.

Take care that if the front part is lifted without pushing the

Note:

amplifier forward, the hook on the rear portion of the mounting

section is likely to break.

products which meet standards, such as OSHA, ANSI or IEC etc.,

for personnel protection applicable in each region or country.

Type

Model No.

NPN output

Red LED type Red LED type

FX-A1

NPN open-collector transistor

Maximum sink current: 100mA

Applied voltage: 30V DC or less

(between sensing output and 0V)

Residual voltage:

1V or less (at 100mA sink current)

0.4V or less (at 16mA sink current)

NPN open-collector transistor

Maximum sink current: 50mA

Applied voltage: 30V DC or less

(between self-diagnosis output and 0V)

Residual voltage:

1V or less (at 50mA sink current)

0.4V or less (at 16mA sink current)

Approx. 40ms fixed OFF-delay timer (switchable, either effective or ineffective)

Incorporated (up to three sets of fibers can be mounted adjacently)

-10 to +50 (No dew condensation or icing allowed), Storage: -20 to +70

Red LED (modulated)

Enclosure: Heat-resistant ABS, Enclosure cover: Polycarbonate

Green LED type

FX-A1G

12 to 24V DCr10%˴Ripple P-P 10% or less

Selectable, either Light-ON or Dark-ON, with jog switch

2-level teaching / Limit teaching / Full auto-teaching

35 to 85% RH, Storage: 35 to 85% RH

0.2mm

MS-DIN-2 (Amplifier mounting bracket): 1 No.

50mA or less

PNP open-collector transistor

Applied voltage: 30V DC or less

Residual voltage:

Incorporated

PNP open-collector transistor

Maximum source current: 50mA

Applied voltage: 30V DC or less

Residual voltage:

ON in unstable sensing condition

0.5ms or less

0.65ms or less

0.75ms or less

Green LED (modulated)

2

4-core cabtyre cable, 2m long

70g approx.

PNP output

FX-A1P

Maximum source current: 100mA

(between sensing output and +V)

1V or less (at 100mA source current)

0.4V or less (at 16mA source current)

(between self-diagnosis output and +V)

1V or less (at 50mA source current)

0.4V or less (at 16mA source current)

Red LED (modulated)

2

, or more, cable. However, in

ԙ

Attached amplifier mounting

bracket or 35mm width DIN rail

Ԙ

ԙ

Ԙ

How to connect the fiber cables

Ԙ

Snap the fiber lock lever down.

ԙ

Insert the fiber cables slowly into the inlets until

they stop. (Note 1)

Ԛ

Return the fiber lock lever to the original position,

Fiber lock

lever

till it stops.

Notes: 1)2)In case the fiber cables are not inserted to a position where they stop, the sensing range reduces.

However, in case of a flexible fiber, take care that it may bend inside the amplifier, during insertion.

With the coaxial reflective type fiber, such as, FD-G4 or FD-FM2, insert the single-core

fiber cable into the beam-emitting inlet and the multi-core fiber cable into the beam-receiving inlet. If they are inserted in reverse, the sensing accuracy will deteriorate.

4

I/O CIRCUIT DIAGRAMS

٨ NPN output type

D

1

Z

D1

T

Z

D2

Sensor circuit

r1

T

r2

PNP output type٨

T

r3

T

r4

Z

D3

Sensor circuit

Z

D4

D

2

Note: Use the optional cable with a connector for the plug-in connector type.

Model No.: CN-54-C2 (cable length 2m), CN-54-C5 (cable length 5m)

Symbols... D1, D2

5

PART DESCRIPTION

Operation indicator (Orange)

6

JOG SWITCH & LEVEL INDICATOR FUNCTION

: Reverse supply polarity protection diode

ZD1, ZD2, ZD3, ZD4: Surge absorption zener diode

: NPN output transistor

1, Tr2

Tr

: PNP output transistor

Tr 3, Tr4

Level indicators (Green)

Color code

(Brown) +V

(Black)

Sensing output

(Orange) Self-diagnosis output

(Blue) 0V

Users' circuitInternal circuit

Color code

(Brown) +V

(Black)

(Orange)

Self-diagnosis output

(Blue) 0V

Users' circuitInternal circuit

Load

100mA max.

50mA max.

100mA max.

Sensing output

50mA max.

Load

Stability indicator (Green)

Load

+

-

+

-

Load

Jog switch

Mode selection switch

12 to 24V DC

r10%

12 to 24V DC

r10%

Ԛ

Ԙ

Beam-emitting part

Beam-receiving part

ԙ

Fiber

Connector pin

position

Sensing

output

Selfdiagnosis

output

+V

0V

٨ Functions of jog switch

Jog switch Operation

Press

3 sec. or more

㧙

㧗

Tu rn

In 2-level teaching, it sets the sensitivity.

In limit teaching, it stores the incident light intensity in the object absent condition.

Each item is selected and the item or the contents of each item to be set is decided.

In full auto-teaching, it sets the sensitivity.

In limit teaching, it determines the direction of shift of the sensitivity.

It does fine adjustment of the set sensitivity.

The contents of each item are selected.

Function

٨Functions of level indicators

If the mode selection switch is set to 'SET' or 'RUN', the level indicators show the

position of the set sensitivity level. However, if the mode selection switch is set to

'MODE', the level indicators show the output operation/emission frequency/timer

settings.

Mode selection switch

SET MODE

RUN

SET MODE

RUN

SET MODE

RUN

7

SENSITIVITY SETTING

٨

When the mode selection switch is set to 'SET' or 'MODE', the sensor is

Hundreds position

L-ON

987654321

*: The sensitivity level is changed in the range 0 to 999 within the sensor.

Hundreds position

L-ON

987654321

Output

operation

L-ON

987654321

D-ON

D-ON

D-ON

Tens position

FR1

FR2

FR3

FR1

FR2

FR3

Emission

frequency

FR1

FR2

FR3

NON

NON

Timer

operation

NON

OFD

0

Set sensitivity

OFD

0

Set sensitivity

Each mode

OFD

0

Function

Sensitivity level is displayed.

Hundreds position: lights up continuously

Tens position: blinks

Units position: not shown

Sensitivity level is displayed.

Hundreds position: lights up continuously

Tens position: not shown

Units position: not shown

Each mode is displayed.

Item being set: blinks

Remaining 2 items: light up

continuously

more susceptible to extraneous light. Hence, when sensing objects, ensure to set

the mode selection switch to 'RUN'.

٨

When the mode selection switch is changed from 'SET' to 'RUN' or from 'MODE'

to 'RUN', the set sensitivity or the contents of each mode setting are stored in an

EEPROM. Since the EEPROM has a life time, the sensitivity setting cannot be

done for more than 100,000 times.

Do not move or bend the fiber cable after the sensitivity setting. Detection may

٨

become unstable.

In case of 2-level teaching

٨

This is the method of setting the sensitivity by teaching two levels, corresponding to the

object present and object absent conditions. Normally, setting is done as given below.

Level indicators OperationStep

Ԙ

ԙ

987654321

987654321

Ԛ

987654321

ԛ

Ԝ

987654321

ԝ

Note: If the jog switch is pressed continuously for 3 sec., or more, full auto-teaching is done.

Also, if the mode selection switch is changed to 'RUN' while level indicators '4' and '5' are

blinking, the incident light intensity taught at Step Ԛ is not recorded.

Set the fiber within the sensing range.

Set the mode selection switch to 'SET'.

0

The present sensitivity setting is displayed.

Press the jog switch in the object present condition. The level indicators

0

'3' and '6' blink.

Release the jog switch within 3 sec. The level indicators '4' and '5' blink and

the incident light intensity in the object present condition is read. (Note)

0

The jog switch is pressed in the object absent condition.

The stability indicator (green) lights up and the sensitivity level is set at the

middle value of the incident light intensity levels in the object present and object

absent conditions. The sensitivity level is then displayed on the level indicators.

Hundreds position: lights up continuously, Tens position: blinks,

0

Units position: not shown

Example: The level indicators in the figure on the left show that the

sensitivity level is in the range 720 to 729.

Set the mode selection switch to 'RUN'.

The sensitivity level does not change even if the jog switch is operated.

<Procedure for maximum sensitivity setting>

Set the mode selection switch to 'SET'.

Ԙ

Press the jog switch in the condition when there is no object or background body.

ԙ

The level indicators '4' and '5' blink after receiving the teaching.

Ԛ

ԛ

Once again, press the jog switch in the condition when there is no object or background body.

Ԝ

The level indicator '9' blinks.

ԝ

Set the mode selection switch to 'RUN'.

Note: Please take care that, if the sensor is set to max. sensitivity, it becomes weak against

extraneous light, noise and optical interference.

In case of fine adjustment

Ԙ

ԙ

Ԛ

Level indicators OperationStep

987654321

987654321

987654321

987654321

987654321

Set the mode selection switch to 'SET'.

0

The present sensitivity setting is displayed.

0

In case the sensitivity is to be increased, turn the jog switch a little to

the '+' side to increase the sensitivity slowly. If the jog switch is turned

0

or

fully to the '+' side, the sensitivity increases rapidly.

In case the sensitivity is to be decreased, turn the jog switch a little to

-

' side to decrease the sensitivity slowly. If the jog switch is turned

the '

0

fully to the '

0

Set the mode selection switch to 'RUN'.

The sensitivity level does not change even if the jog switch is operated.

-

' side, the sensitivity decreases rapidly.

In case of limit teaching

٨ This is the method of setting the sensitivity by teaching only the object absent

condition (incident light stable condition). This is used for detection in presence of a

background body or for detection of small objects.

Level indicatorsStep

Ԙ

ԙ

987654321

987654321

Ԛ

987654321

ԛ

987654321

Ԝ

Note: If the jog switch is pressed continuously for 3 sec., or more, full auto-teaching is done.

Also, if the mode selection switch is changed to 'RUN' while level indicators '4' and '5' are

blinking, the incident light intensity taught at Step Ԛ is not recorded.

Set the fiber within the sensing range.

Set the mode selection switch to 'SET'.

0

The present sensitivity setting is displayed.

Press the jog switch in the object absent condition. The level indicators

0

'3' and '6' blink.

Release the jog switch within 3 sec. The level indicators '4' and '5' blink and

the incident light intensity in the object present condition is read. (Note)

0

Turn the jog switch to either the '+' or the '-' side.

0

Example: The level indicators in the figure on the left show that the

Set the mode selection switch to 'RUN'.

The sensitivity is increased

'+' side:

by 15% approx. with respect

to that set at Ԛ. Used in

case of thru-beam type fiber.

-

' side:

The sensitivity is decreased

'

by 15% approx. with respect

to that set at Ԛ. Used in

case of reflective type fiber.

sensitivity level is in the range 720 to 729.

The sensitivity level does not change even if the jog switch is operated.

Operation

High

100%

Sensitivity

level

Low

ON

OFF

Turn to '+' side

Sensitivity

level

Sensitivity

level with

object absent

Sensitivity

level

OFF

15%

15%

ON

0

Turn to '-' side

In case of full auto-teaching

٨ Full auto-teaching is used when it is desired to set the sensitivity without stopping

the assembly line, with the object in the moving condition.

Level indicators OperationStep

Ԙ

ԙ

Ԛ

ԛ

Ԝ

987654321

987654321

987654321

Set the fiber within the sensing range.

Set the mode selection switch to 'SET'.

0

The present sensitivity setting is displayed.

Press the jog switch continuously for 3 sec., or more, with the object

moving on the assembly line.

When the jog switch is pressed, the level indicators '3' and '6' blink and

0

when it is pressed continuously for 3 sec., or more, they start blinking

rapidly. Then, release the jog switch when the object has passed.

The stability indicator (green) lights up and the sensitivity level is set at the

middle value of the incident light intensity levels in the object present and object

absent conditions. The sensitivity level is then displayed on the level indicators.

Hundreds position: lights up continuously, Tens position: blinks,

0

Units position: not shown

Example: The level indicators in the figure on the left show that the

sensitivity level is in the range 720 to 729.

Set the mode selection switch to 'RUN'.

The sensitivity level does not change even if the jog switch is operated.

8

SETTING OF EACH MODE

Level indicators DescriptionStep

Ԙ

ԙ

The mode being set blinks.

Ԛ

Output oper-

ation setting

ԛ

Ԝ

Emission fre-

quency setting

ԝ

Ԟ

Timer oper-

ation setting

ԟ

Ԡ

L-ON

L-ON

L-ON

L-ON

D-ON

D-ON

D-ON

D-ON

FR1

FR2

FR1

FR2

FR1

FR2

FR1

FR2

Set the mode selection switch to 'MODE'.

Turn the jog switch to either the '+' or the '-' side.

FR3

NON

OFD

L-ON (Light-ON) D-ON (Dark-ON)

Press the jog switch at the output operation desired to be set.

Turn the jog switch to either the '+' or the '-' side.

FR3

FR1

NON

OFD

(Emission frequency 1)

Press the jog switch at the emission frequency desired to be set.

Turn the jog switch to either the '+' or the '

FR3

FR3

NON

NON

OFD

(without timer)

Press the jog switch at the timer operation desired to be set.

NON

OFD

Back to ԙ.

Set the mode selection switch to 'RUN' after finishing the settings.

+

FR2

(Emission frequency 2)

+

OFD

(approx. 40ms fixed OFF-delay timer)

+

-

FR3

(Emission frequency 3)

+

-

' side.

In case only a part of the settings are to be changed, set the mode selection switch to 'RUN', at

the appropriate time, in the middle of the above procedure to make only the required changes.

9

TIMER FUNCTION

٨

FX-A1 series incorporate an approx. 40ms fixed OFF-delay timer. Since the output is

extended by a fixed period, it is useful when the connected device has a slow response

time or when small objects are being sensed and the output signal width is small.

Please refer to ' SETTING OF EACH MODE' for the setting method.

8

<Time chart>

Timer

operation

Normal

OFF-delay

timer

Output

operation

Light-ON

Dark-ON

Light-ON

Dark-ON

Sensing

condition

TT T

T

Light

Dark

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Timer period: T = 40ms approx.

10

INTERFERENCE PREVENTION FUNCTION

٨

Since the FX-A1 series incorporate an interference prevention function, up to 3 sets of

fibers can be mounted close to each other by setting different emission frequencies.

Further, close mounting is also possible along with

fibers which are fitted to the fiber sensor amplifiers,

FX-D1 series and FX-M1 series.

Please refer to ' SETTING OF EACH MODE' for the

8

setting method.

However, note that the response time varies with the

Emission

frequency

1

2

3

Response

time

0.5ms or less

0.65ms or less

0.75ms or less

emission frequency as given below.

11

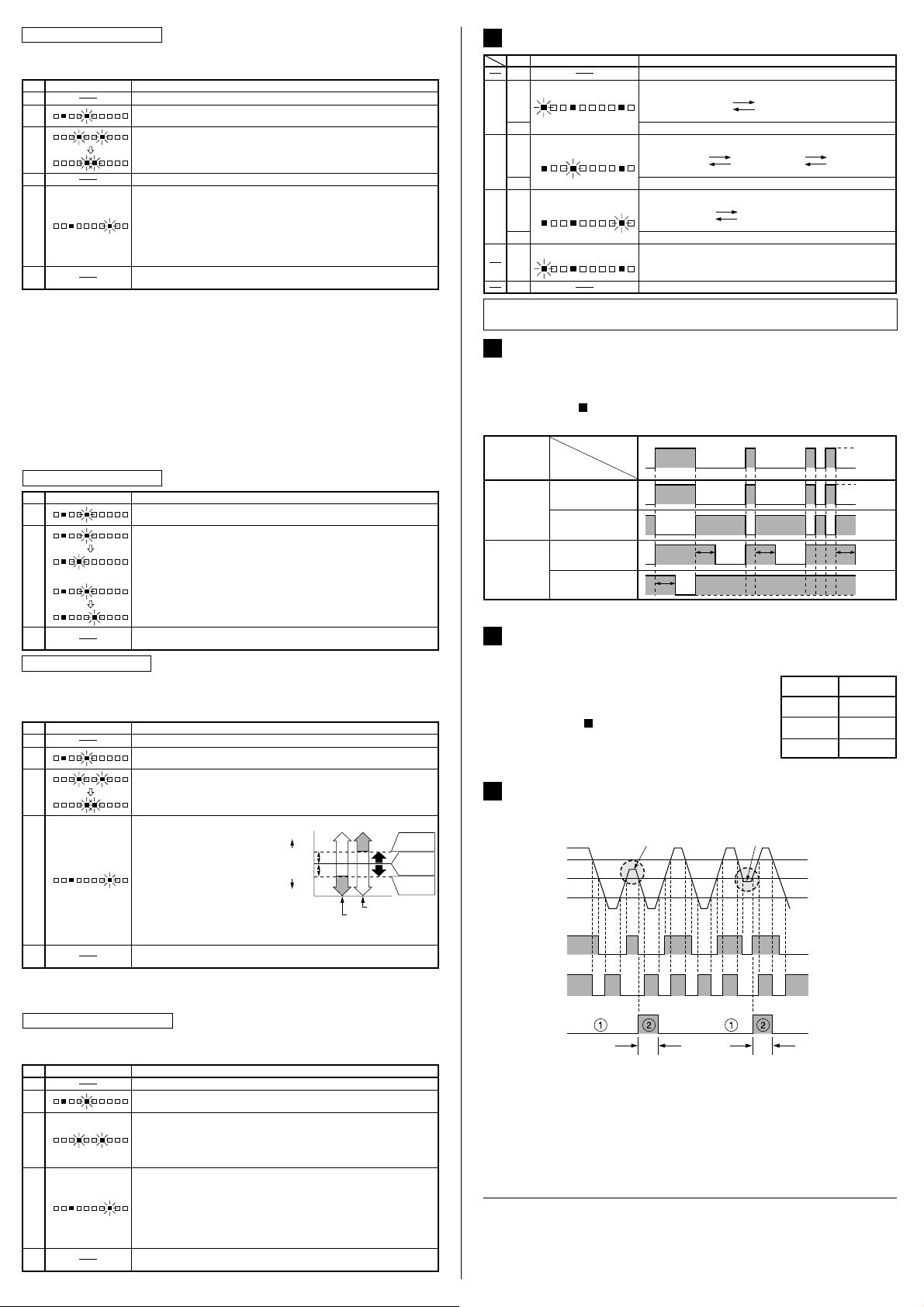

SELF-DIAGNOSIS FUNCTION

٨ This is a function which diagnoses a decrease in the incident light intensity due

to dirt or dust, or optical misalignment, and gives an output.

Insufficient beam intensity Insufficient beam interruption

Stable Light level

Sensing condition

Sensing output

threshold level

Stable Dark level

Sensing output

(Operation indicator)

(in the Light-ON mode)

Stability indicator

Self-diagnosis output

40ms approx. 40ms approx.

The self-diagnosis output transistor stays in the 'OFF' state during stable sensing.

Ԙ

When the sensing output changes, if the incident light intensity does not reach

ԙ

ON (Lights up)

OFF (Lights off)

Lights up

Lights off

ON

OFF

the stable light level or the stable dark level, the self-diagnosis output becomes

'ON'. It automatically turns 'OFF' after 40ms approx. (Emission frequency 2:

50ms approx., Emission frequency 3: 60ms approx.)

Further, the self-diagnosis output is generated at the time when the sensing

output changes from 'ON' to 'OFF' or from 'OFF' to 'ON'.

(The operation of the sensing output is not affected.)

SUNX Limited

http://www.sunx.co.jp/

Head Office

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7211 FAX: +81-(0)568-33-2631

Overseas Sales Dept.

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

PRINTED IN JAPAN

Loading...

Loading...