LCR METE

R

Model : LCR-9073A

Y

our purchase of this LCR

METER marks a step

forward for you into the

field of precision

measurement. Although

this LCR METER is a

complex and delicate

instrument, its durable

structure will allow many

years of use if proper

operating techniques are

developed. Please read

the following instructions

carefully and always keep

this manual within easy

reach.

OPERATION MANUAL

TABLE OF CONTENTS

1. FEATURES................................................................ 1

2. SPECIFICATIONS...................................................... 1

2-1 General Specifications..........................................1

2-2 Electrical specifications........................................

.

3

3. FRONT PANEL DESCRIPTION....................................

.

6

3-1 Display .............................................................. 6

3-2 LCD backli

g

ht ON/OFF button...............................6

3-3 LC/R select switch .............................................. 6

3-4 Function rotary switch/Power switch..................... 6

3-5 L/C Measuring terminal 1.................................. 6

3-6 L/C Measuring terminal 2 .................................. 6

3-7 Resistance/Diode Measurin

g

terminal ...................6

3-8 RS-232 Output Terminal......................................

.

6

3-9 Stand ................................................................

.

6

3-10 Battery cover Screw ..........................................6

3-11 Battery Compartment/Cover .............................. 6

4. INDUCTANCE (L) MEASUREMENT PROCEDURE ..........7

5. CAPACITANCE (C) MEASUREMENT PROCEDURE ........ 7

6. RESISTANCE (R) MEASUREMENT PROCEDURE ..........

.

9

7. DIODE MEASURING PROCEDURE...............................9

8. MAINTENANCE ........................................................

.

11

9. RS232 COMPUTER INTERFACE..................................

.

11

10. BATTERY REPLACEMENT ........................................ 13

1. FEATURES

* Professional LCR meter, used the LSI-circuit and

exclusive microprocessor circuit, high reliability and

High measuring accuracy.

* Wide ranger measurement for Inductance, Capacitance

and Resistance measurement.

* Test frequency : 100 Hz, 1 KHz.

* Input overload protection

* Rotary switch function selector.

* RS232/USB Computer interface.

*Diode test.

* Large LCD display with backlight.

* Built-in low battery indicator

2. SPECIFICATIONS

2-1 General Specifications

Display 67 mm x 27 mm large LCD display.

17 mm x 9 mm, digit size.

* With LCD backlight ON/OFF control.

Measurement

Inductance ( L ) :

5 ranges : 2 mH to 20 H.

Capacitance ( C ) :

6 ranges : 2 nF to 200 uF.

Resistance ( R ) :

6 ranges : 200 ohm to 20 Mega ohm.

Diode test

Circuit Custom one-chip of microprocessor LSI

circuit

Sampling Time Approx. 0.4 second.

1

Data Output RS 232/USB PC computer interface.

* Connect the optional RS232 cable

UPCB-02 will get the RS232 plug.

* Connect the optional USB cable

USB-01 will get the USB plug.

Over Input Show " 1 " indicator.

Indication

Operating 0 to 50 ( 32 to 122 ).℃℃℉ ℉

Temperature

Operating Less than 80% RH.

Humidity

Power Supply Alkaline or heavy duty type DC 9V

battery, 006P, MN1604 (PP3) or

equivalent.

Power Approx. 12 mA.

Consumption

Weight 314 g/0.69 lb.

Dimension 204 x 90 x 36 mm

( 8.0 x 3.5 x 1.4 inch ).

Accessories Instruction manual............... 1 PC.

Included

T

est alligator clips................ 1 Pair.

Optional * Data Acquisition software,

Accessories SW-801-WIN

* USB cable, USB-01

* RS232 cable, UPCB-02

2

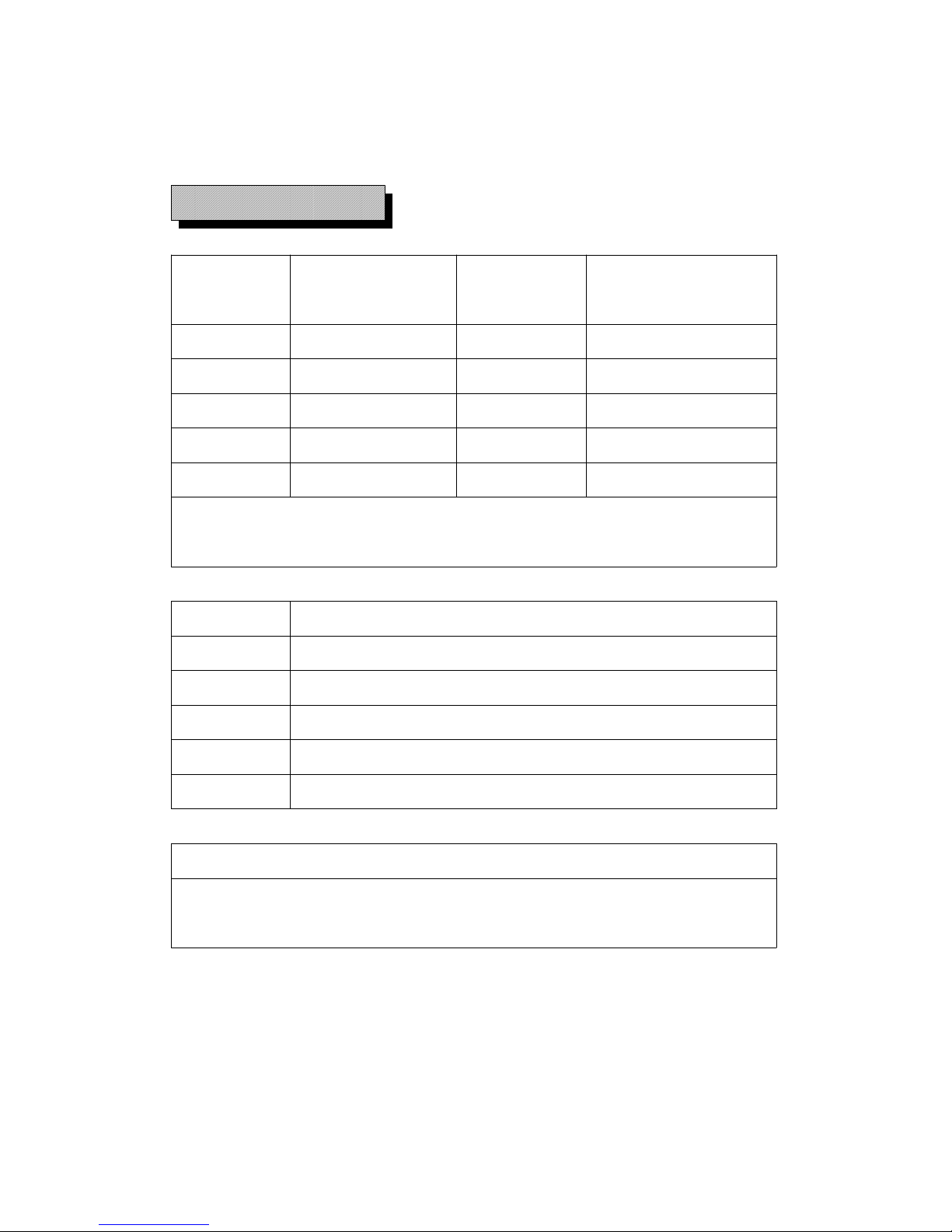

2-2 Electrical specifications ( 23 ± 5 )℃

L ( Inductance )

Range Resolution Test Accuracy

Frequency

2 mH 1 uH 1 kHz ± ( 2 %+2d )

20 mH 10 uH 1 kHz ± ( 2 %+2d )

200 mH 100 uH 1 kHz ± ( 2 %+2d )

2 H 1 mH 1 kHz ± ( 5 %+2d )

20 H 10 mH 100 Hz ± ( 5 %+2d )

uH = micro Henry ( 10^-6 H )

mH = mili Henry ( 10^-3 H )

Range Current through Inductance under test

2 mH 150 u A

20 mH 150 u A

200 mH 150 u A

2 H 150 u A

20 H 15 u A

Overload Rating

AC 10V ( 50 Hz/60 Hz ) max, or DC 10V max.,

less than 30 second.

3

C ( Capacitance )

Range Resolution Test Accuracy

Frequency

2 nF 1 pF 1 kHz ± ( 2 %+2d )

20 nF 10 pF 1 kHz ± ( 2 %+2d )

200 nF 100 pF 1 kHz ± ( 2 %+2d )

2 uF 0.001 uF 1 kHz ± ( 2 %+2d )

20 uF 0.01 uF 100 Hz ± ( 2 %+2d )

200 uF 0.1 uF 100 Hz ± ( 2 %+2d )

pF = pico Farad ( 10^-12 F )

nF= nano Farad (10^-9 F )

uF= micro Farad ( 10^-6 F )

Range Voltage across Capacitance under test

2n F 150 mV

20 nF 150 mV

200 nF 150 mV

2 uF 150 mV

20 uF 150 mV

200 uF 15 mV

Overload Rating

Charged capacitor 100 uF/ 50 V Max.

4

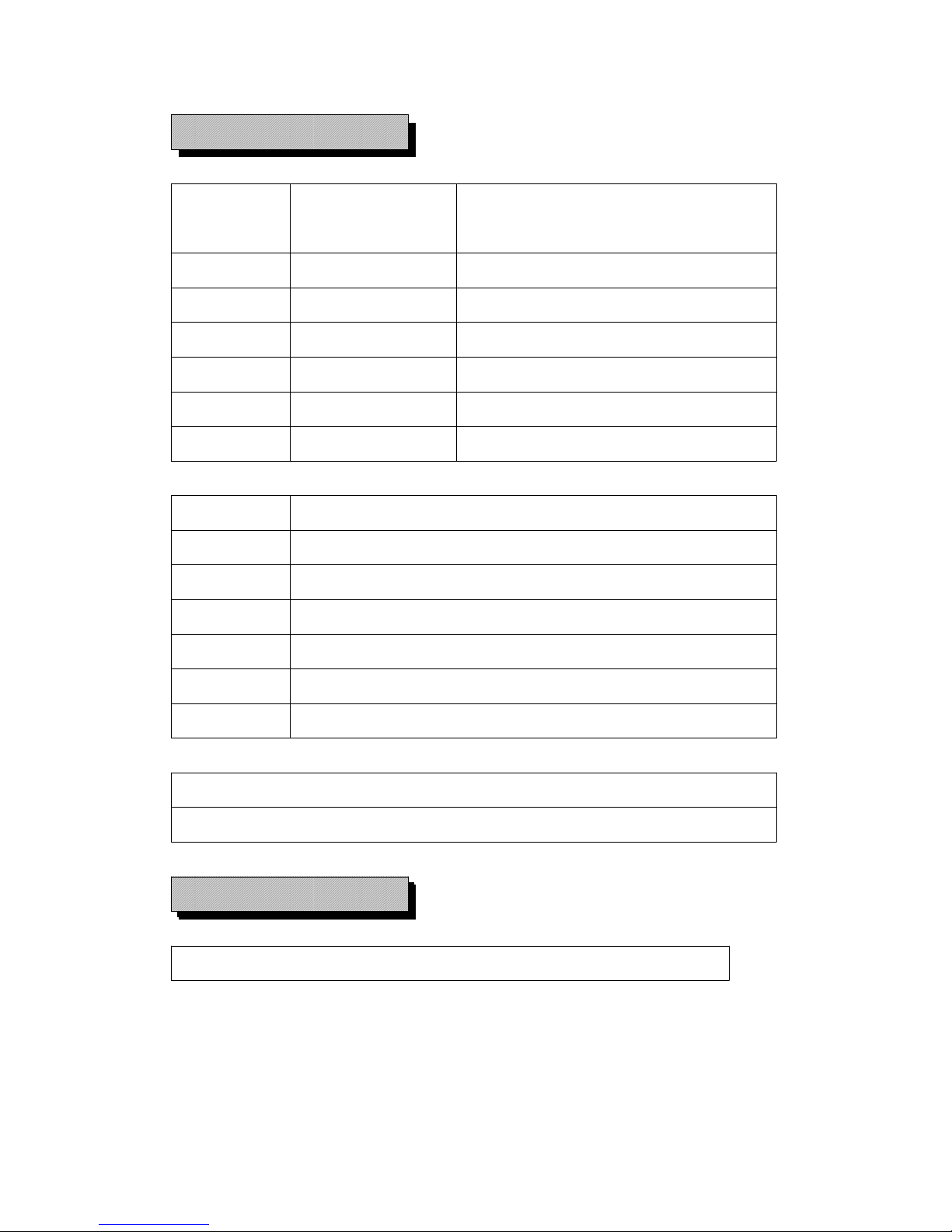

R ( Resistance )

Range Resolution Accuracy

200 Ω 0.1Ω ± ( 1 % + 2d )

2 kΩ 1 Ω ± ( 1 % + 2d )

20 kΩ 10 Ω ± ( 1 % + 2d )

200 kΩ 100 Ω ± ( 1 % + 2d )

2 MΩ 1 kΩ ± ( 1 % + 2d )

20 MΩ 10 kΩ ± ( 2 % + 2d )

Range Open circuit Voltage

200 Ω 2.4 V

2 kΩ 2.4 V

20 kΩ Approx. DC 250 m V

200 kΩ Approx. DC 250 m V

2 MΩ Approx. DC 250 m V

20 MΩ Approx. DC 250 m V

Overload Rating

AC / DC 500V at 20 seconds Max.

Diode test

Short/non conductance, good/defect test

5

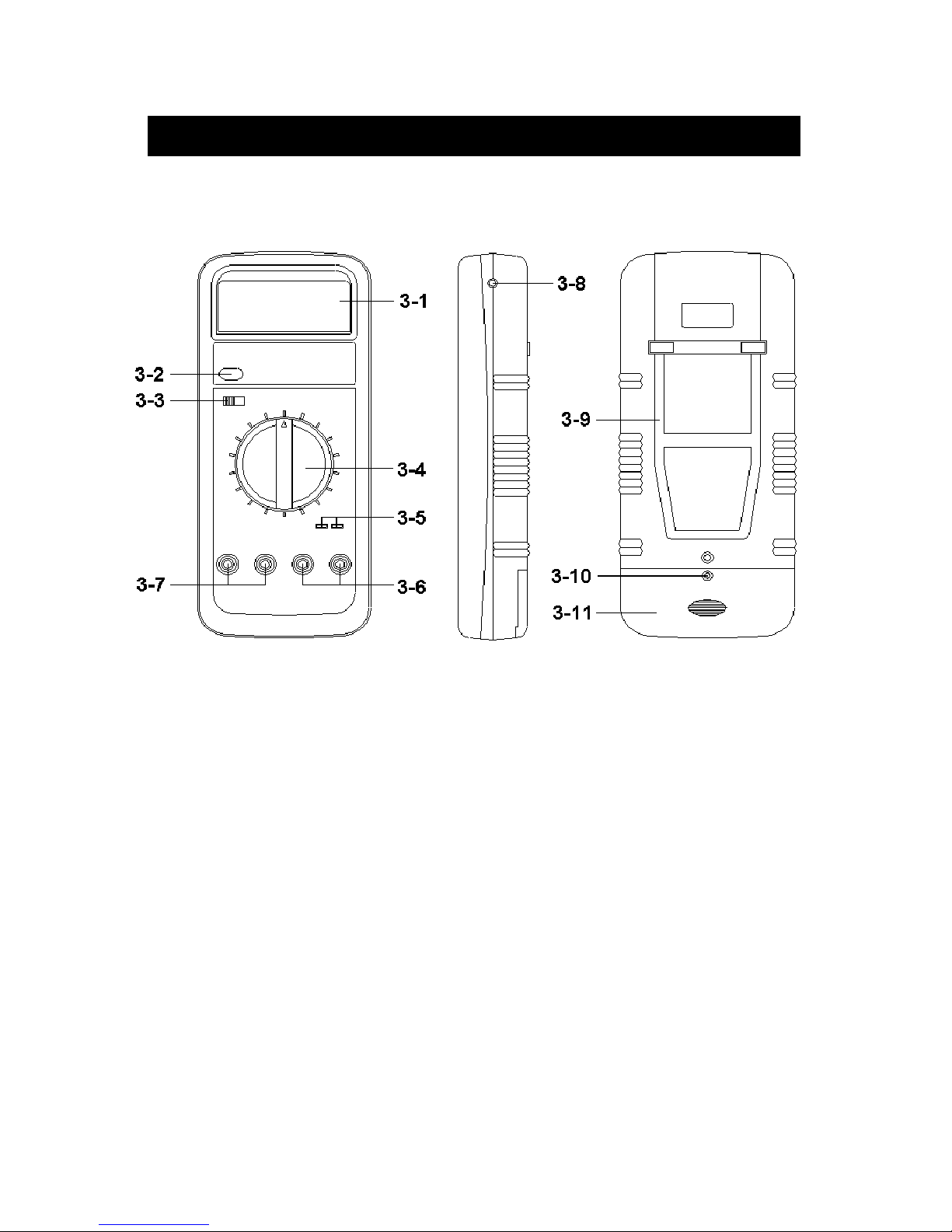

3. FRONT PANEL DESCRIPTION

Fig. 1

3-1 Display

3-2 LCD backlight ON/OFF button

3-3 LC/R select switch

3-4 Function rotary switch/Power switch

3-5 L/C Measuring terminal 1

3-6 L/C Measuring terminal 2

3-7 Resistance/Diode Measuring terminal

3-8 RS-232 Output Terminal

3-9 Stand

3-10 Battery cover Screw

3-11 Battery Compartment/Cove

6

4. INDUCTANCE (L) MEASUREMENT

PROCEDURE

1)Slide the " LC/R select switch " ( 3-3, Fig. 1 ) to the " LC "

position.

2)Rotate the function switch for the maximum expected

inductance range.

3) Fully discharge any charged inductors.

4)Insert the tested inductor into socket " L/C Measuring

input terminal 1 " ( 3-5, Fig. 1 ). Alternatively, connect

the inductor to " L/C Measuring input terminal 2 " ( 3-6,

Fig. 1 ). via using the measuring alligators supplied .

Note :

a. If the inductance value is unmarked start with the

highest range and keep decreasing until a suitable

reading is obtained.

b. Measurement of very low inductance should be

performed using extremely short leads in order to

avoid introducing any stray inductance.

c. This instruments is not intended for determining the

" Q " factor for the inductor. Misleading readings may

be obtained if the measurement of the inductance of

a resistor is attempted.

5. CAPACITANCE (C) MEASUREMENT

PROCEDURE

1)Slide the " LC/R select switch " ( 3-3, Fig. 1 ) to the " LC "

position.

7

2)Rotate the function switch for the maximum expected

capacitance range.

3) Fully discharge any charged capacitors.

4)Observe polarity when connecting polarized capacitors.

5)Insert the tested capacitor into socket " L/C Measuring

input terminal 1 " ( 3-5, Fig. 1 ). Alternatively, connect

the capacitor to " L/C Measuring input terminal 2 " ( 3-6,

Fig. 1 ) via using the measuring alligators supplied .

6)The Display value indicated corresponds to the range

selected. If the Display shows " 1 ", it indicates an out

of range selected measurement, then select to the next

higher range.

Note :

a. If the capacitance value is unmarked start with the

highest range and keep decreasing until a suitable

reading is obtained.

b. A capacitor with low voltage leakage will read over

range, or a much higher value than normal. An

open circuit capacitor will read zero on all ranges

possibly a few pF on 2 nF range due to stray

capacitance of the instrument.

c. Measurement of very low capacitance should be

performed using extremely short leads in order to

avoid introducing any stray capacitance.

d. When using the test leads, remember that the leads

may introduce a measurable capacitance to the

measurement.

e. Capacitors, especially electrolytic type, often have

wide tolerances.

8

6. RESISTANCE (R) MEASUREMENT

PROCEDURE

1)Slide the " LC/R select switch " ( 3-3, Fig. 1 ) to the " R "

position.

2)Rotate the function switch for the maximum expected

resistance range.

3)Connect the tested resistor into socket " Resistance

Measuring input terminal " ( 3-6, Fig. 1 ) via using

the measuring alligators supplied .

4)The Display value indicate corresponds to the range

selected. If the Display shows " 1 ", it indicates an out

of range selected measurement, then select the next

higher range.

Note :

In order to make precision measurement at lower

range, to deduct the stray resistance of measuring leads

from the readings. The stray resistance can be

measured by shorting the leads.

7. DIODE MEASUREMENT

PROCEDURE

1)Slide the " LC/R select switch " ( 3-3, Fig. 1 ) to the " R "

position.

2)Rotate the function switch to the " Diode " range.

3)Connect Red alligator to " + " socket of " Diode

Measuring terminal " ( 3-7, Fig. 1 ).

4)Connect Black alligator to " - " socket of " Diode

Measuring terminal " ( 3-7, Fig. 1 ).

9

5)a. When connected with polarity as shown in Fig. 2, a

forward current flow is established and the approx.

Diode Forward Voltage (VF) values in volt will display

on the display reading. If the diode under test is

defective, ".000" or near ".000" value (short circuit) or

" 1 " (open circuit) will be displayed.

Fig. 2

b. When connected as shown in Fig. 3, a reverse check on

the diode is made. If the diode under test is good,

" 1 " will be displayed. If the diode under test is

defective, ".000" or other numbers will be displayed.

Proper diode testing should include both steps a. and

b. above.

Fig. 3

10

8. MAINTENANCE

1)This LCR METER is intended for measuring the

capacitance value of a capacitor, the inductance value

of an inductor. It is not intended for determining the " Q "

factor for above reactive components. Misleading

readings may be obtained if the measurement of the

inductance or capacitance of resistor is attempted

2)When measuring components within a circuit ensure the

circuit the is switched off and de-energized before

connecting the test leads.

3)Instruments used in dusty environments should be

stripped and cleaned periodically.

4)Do not leave the instrument exposed to direct heat from

the sun for long periods.

5)Before removing the battery compartment cover,

ensure that the instrument is disconnected from any

circuit and the power switch is in the off position.

6)For all measurements, connect the Black alligator into

" - " terminal and Red alligator into " + " terminal .

9. RS232 COMPUTER INTERFACE

The instrument has RS232 PC serial interface via a 3.5

mm terminal ( 3-8, Fig. 1 ).

The data output is a 16 digit stream which can be

utilized for user's specific application.

11

A RS232 lead with the following connection will be

required to link the instrument with the PC serial port.

Meter PC

(9W 'D" Connector)

Center Pin........................Pin 4

(3.5 mm jack plug)

Ground/shield.....................Pin 2

2.2 K

resister

Pin 5

The 16 digits data stream will be displayed in the

following format :

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Each digit indicates the following status :

D15 Start Word

D14 4

D13 1

D12, D11 Annunciator for Display

M ohm = 40 mH = 41 nF = 43

K ohm = 39 H = 42 uF = 44

ohm = 38

D10 Polarity

0 = Positive 1 = Negative

12

D9 Decimal Point(DP), position from right to the

left

0 = No DP, 1= 1 DP, 2 = 2 DP, 3 = 3 DP

D8 to D1 Display reading, D1 = LSD, D8 = MSD

For example :

If the display reading is 1234, then D8 to

D1 is : 00001234

D0 End Word

RS232 FORMAT : 9600, N, 8, 1

Baud rate 9600

Parity No parity

Data bit no. 8 Data bits

Stop bit 1 Stop bit

10. BATTERY REPLACEMENT

1)When the Display will show " BAT " indicator, it

should to replace the battery although accurate

measurement may still be kept within certain period.

2)To replace the battery, loss the " battery cover screw "

( 3-10, Fig. 1 ) slide the battery cover ( 3-11, Fig 1 )

always from the meter and remove the battery

3)Install a new 9v (pp3 type) battery and replace the cover.

13

0905-LCR9073A

Loading...

Loading...