SUNWARD SWL3210, SWL Series Service Manual

Service Manual

Product for the world

SKID-STEER LOADER

HUNAN SUNWARD INTELLIGENT MACHINERY CO., LTD.

SWL3210 Service Manual

1

INDEX

1 INTRODUCTION ....................................................................................................................................... 4

1.1 MODELS AVAILABLE...................................................................................................................... 4

1.2 ABOUT

THIS MANUAL .................................................................................................................... 4

1.3 TREATMENT

OF THIS MANUAL.................................................................................................... 4

1.4 UNITS.................................................................................................................................................. 4

1.5 DEFINITION

OF “LEFT” SIDE AND “RIGHT” SIDE ...................................................................... 4

1.6 PRECONDITION

TO USE THE MACHINE ...................................................................................... 5

1.7 S

IGNALS................................................................................................................................................ 5

2 SECURITY.................................................................................................................................................. 7

2.1 MEANING OF THE SAFETY SIGNS ................................................................................................ 7

2.1.1 GENERAL SIGNS ....................................................................................................................... 7

2.1.2 ACOUSTIC SIGNS.................................................................................................................... 10

2.2 LOCATION

OF THE SAFETY LABELS .........................................................................................11

2.3 GENERAL

PREVENTION ............................................................................................................... 11

2.3.1 GENERAL SAFETY RULES.................................................................................................... 11

2.3.2 CLOTHING AND PERSONAL PROTECTION....................................................................... 12

2.3.3 ENTER AND LEAVE THE MACHINE ................................................................................... 12

2.3.4 PREVENTION OF FIRE TO FUEL AND OIL ......................................................................... 13

2.3.5 PREVENTION OF BURNS....................................................................................................... 14

2.3.6 PREVENTION OF DAMAGE OF WORKING EQUIPMENT ................................................ 14

2.3.7 PREVENTION OF ELECTRIC SHOCK................................................................................... 14

2.3.8 LIMITS OF THE MACHINE .................................................................................................... 15

2.4 MAINTENANCE

PREVENTION..................................................................................................... 15

2.4.1 GENERAL RULES.................................................................................................................... 15

2.4.2 RUNNING THE ENGINE DURING THE MAINTENANCE.................................................. 16

2.4.3 WORKING UNDER THE WORKING EQUIPMENT AND MACHINE ................................ 16

2.4.4 SAFETY RULES FOR HIGH-PRESSURE OIL AND HOSE .................................................. 17

2.4.5 PREVENTION ON THE STARTER AND ALTERNATOR.................................................... 17

2.4.6 PREVENTION OF BATTERY HAZARD ................................................................................ 17

2.4.7 PRECAUTION DURING INFLATING THE TIRES ............................................................... 18

3 GENERAL DESCRIPTION OF THE MACHINE ................................................................................... 19

3.1 DESCRIPTION

OF THE MACHINE ................................................................................................ 19

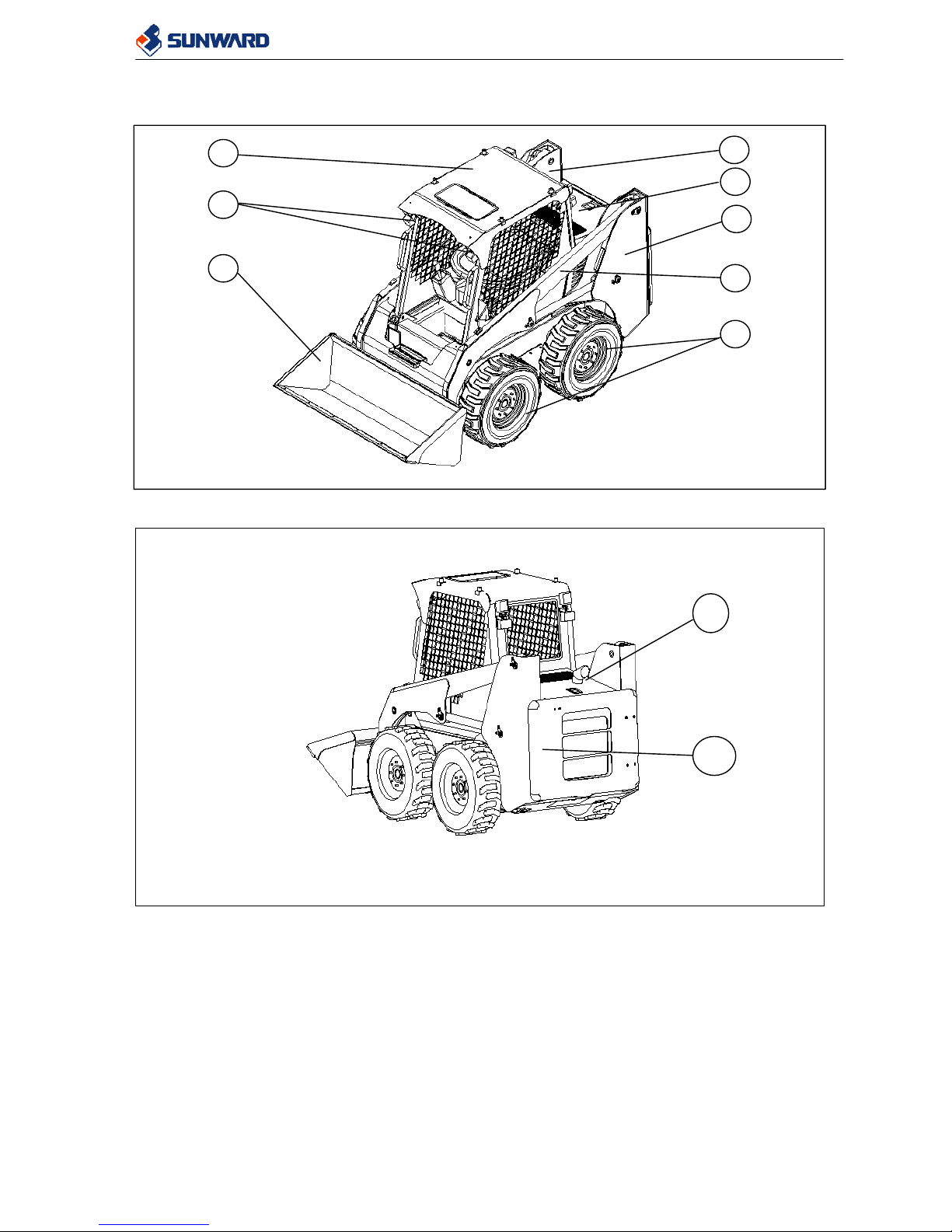

3.1.1 FRONT VIEW............................................................................................................................ 19

3.1.2 REAR VIEW .............................................................................................................................. 19

3.1.3 MACHINE DISTRIBUTION..................................................................................................... 20

3.2 SPECIFICATION ..............................................................................................................................21

3.2.1 GENERAL DATA ..................................................................................................................... 21

3.2.2 OVERALL DIMENSION .......................................................................................................... 21

3.2.3 ENGINE .....................................................................................................................................22

3.2.4 ELECTRIC SYSTEM ................................................................................................................ 22

3.2.5 PNEUMATIC............................................................................................................................. 23

3.2.6 OILS AND COOLANT.............................................................................................................. 23

3.2.7 CAPACITIES ............................................................................................................................. 23

3.2.8 TORQUE FOR SCREWS ..........................................................................................................24

3.2.9 LUBRICATION POINTS .......................................................................................................... 25

4 HYDRAULIC SYSTEM ........................................................................................................................... 26

4.1 MAIN

TRAVEL PUMP..................................................................................................................... 26

4.1.1 ILLUSTRATION OF MAIN TRAVEL PUMP COMPONENTS ............................................. 26

4.1.2 PIPELINE CONNECTION (FOR TESTING) OF MAIN TRAVEL PUMP............................. 30

4.1.3 SET PRESSURE DATA FOR MAIN TRAVEL PUMP ........................................................... 31

4.2 TRAVEL

MOTOR............................................................................................................................. 33

4.2.1 ILLUSTRATION OF TRAVEL MOTOR MAIN COMPONENTS......................................... 33

4.2.2 PICTURE OF BRAKE OIL PIPES’ CONNECTION................................................................ 35

4.2.3 ROTATION DIRECTION OF TRAVEL MOTOR. .................................................................35

4.2.4 PRESSURE FOR ARRESTING GEAR’S START ................................................................... 35

4.3 WORKING

REAR PUMP ................................................................................................................. 36

SWL3210 Service Manual

2

4.3.1 OUTSIDE VIEW OF GEAR PUMP.......................................................................................... 36

4.3.2 BREAKDOWN DRAWING OF GEAR PUMP ........................................................................37

4.3.3 MANIFOLD VALVE................................................................................................................. 37

4.3.4 OUTSIDE VIEW AND ILLUSTRATION OF MANIFOLD VALVE...................................... 37

4.3.5 SET THE DATA ........................................................................................................................ 38

4.4 BUCKET-LIFT

VALVE.................................................................................................................... 39

4.4.1 THE OUTLINE AND ILLUSTRATION OF BUCKET-LIFT VALVE.................................... 39

4.5

LARGE FLOW CONTROL BLOCK (ONLY FOR LARGE FLOW SYSTEM)................................................. 41

4.5.1 OUTSIDE VIEW AND ILLUSTRATION OF LARGE FLOW CONTROL BLOCK.............. 41

4.5.2 SET THE DATA ........................................................................................................................ 42

4.5.3 OPERATING HANDLE ............................................................................................................ 42

4.5.4 OUTSIDE VIEW AND DATA OF HAND LEVER.................................................................. 42

4.6 PEDAL

OPERATION VALVE .........................................................................................................48

4.7 HYDRAULIC

DIAGRAM ................................................................................................................ 49

5 ELECTRICAL SYSTEM ..........................................................................................................................50

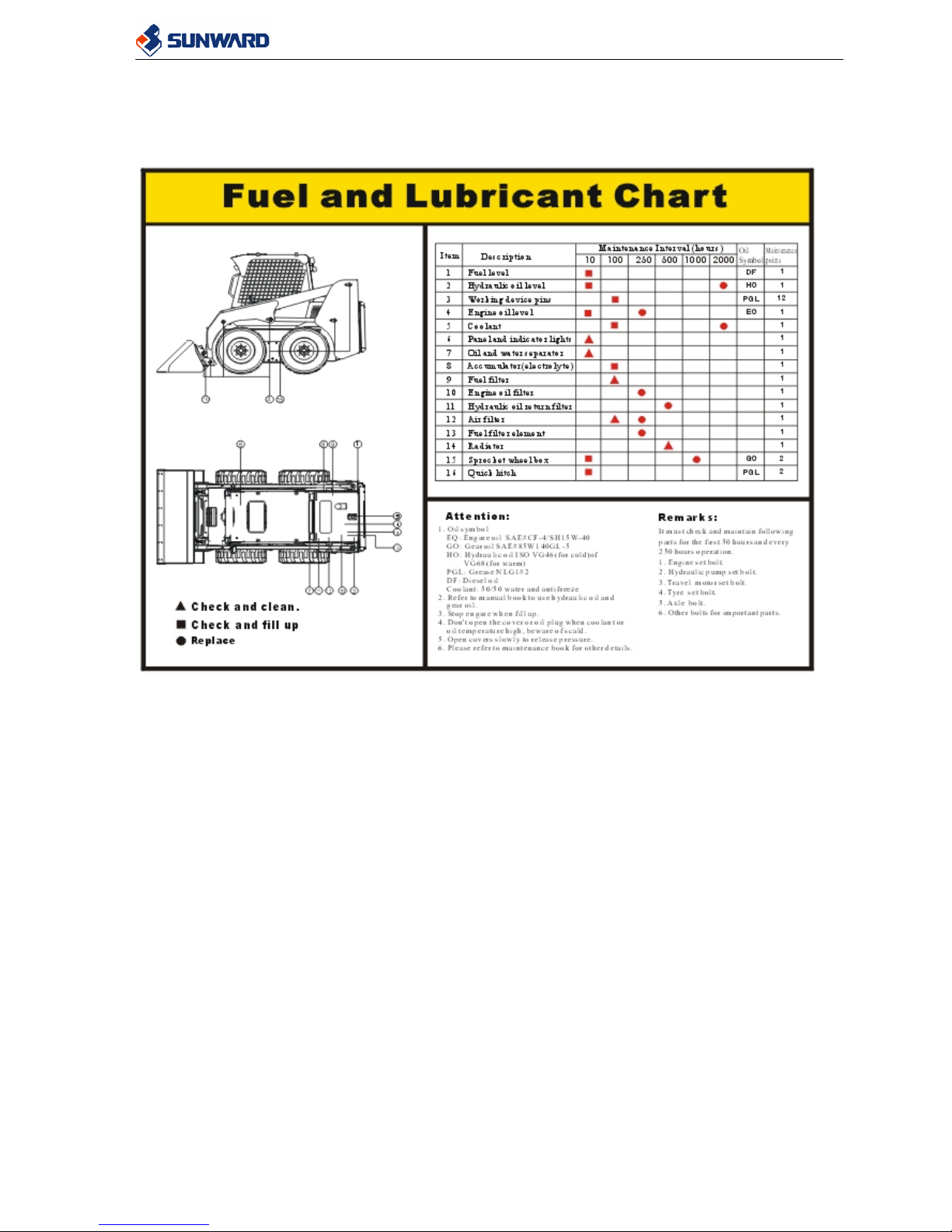

5.1 INSTALLATION SITE 1.......................................................................................................................... 50

5.2

INSTALLATION SITE 2.......................................................................................................................... 51

5.3 D

IAGRAM............................................................................................................................................ 52

5.4 C

IRCUIT DIAGRAM ..............................................................................................................................54

5.4.1 POWER AND ENGINE CIRCUIT............................................................................................ 54

5.4.2 Safety and protection of circuit................................................................................................... 60

5.4.3 MONITOR CIRCUIT................................................................................................................. 63

5.4.4 LAMP AND FLOAT CONTROL CIRCUIT ............................................................................. 65

5.4.5 OPTION CIRCUIT..................................................................................................................... 67

6 TRAVEL SYSTEM................................................................................................................................... 68

6.1 TRAVEL

SYSTEM COMPONENT....................................................................................................... 68

6.1.1 WHEEL SHAFT......................................................................................................................... 69

6.2 P

OWER TRAIN MAINTENANCE .............................................................................................................71

6.2.1 REMOVAL OF THE FRONT WHEEL SHAFT AND REAR WHEEL SHAFT ..................... 71

6.2.2 CLEANING AND INSPECTION .............................................................................................. 75

6.2.3 REPAIR OR REPLACEMENT ................................................................................................. 75

6.2.4 INSTALLATION ....................................................................................................................... 75

7 MAINTENANCE ...................................................................................................................................... 77

7.1 REQUIREMENT

SERVICE.............................................................................................................. 77

7.2 ADVICE

FOR THE MAINTENANCE.............................................................................................. 77

7.3 DESCRIPTION

FOR MACHINE MAINTENANCE ........................................................................ 78

7.3.1 ENGINE DESCRIPTION .......................................................................................................... 78

7.3.2 SAFETY BELT .......................................................................................................................... 78

7.4 MAINTENANCE

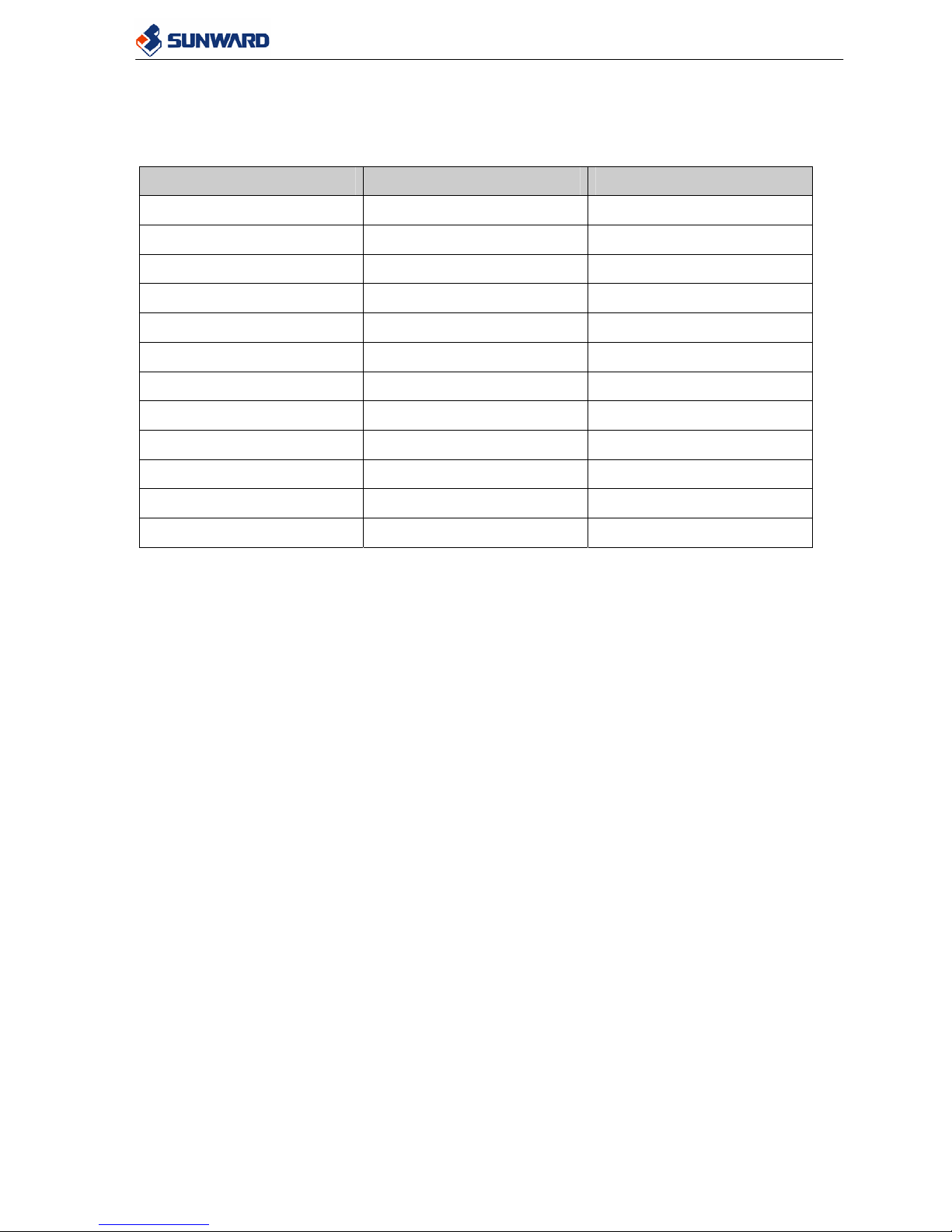

PLAN ...................................................................................................................79

7.4.1 BEFORE STARTING ................................................................................................................ 82

7.4.1.1 CHECKING ENGINE OIL LEVEL............................................................................................................... 82

7.4.1.2 CHECKING ENGINE COOLANT LEVEL...................................................................................................82

7.4.1.3 CHECKING ENGINE FUEL LEVEL..................................................................................................................82

7.4.1.3 CHECKING THE HYDRAULIC OIL LEVEL..............................................................................................82

7.4.1.4 CHECKING THE ELECTRIC CABLES....................................................................................................... 82

7.4.1.5 CHECKING THE TIRES ............................................................................................................................... 83

7.4.1.6 CHECKING THE SAFETY BELT ................................................................................................................83

7.4.1.7 CHECKING THE LEAKING OF OIL ........................................................................................................... 83

7.4.1.8 CHECKING THE QUICK COUPLER...........................................................................................................83

7.4.1.10 ECKING THE WATER AND SEDIMENTS SEPARATOR............................................................................. 83

7.4.2 EVERY 50 HOURS OF OPERATION...................................................................................... 83

7.4.2.1 CHECKING THE COOLER PIPES.....................................................................................................................83

7.4.2.2 CHECKING THE COOLANT LEVEL..........................................................................................................84

7.4.2.3 CHECKING THE TIRE PRESSURE............................................................................................................. 84

7.4.2.4 GREASING THE PINS OF BOOM AND CYLINDERS ..............................................................................84

7.4.2.5 CHECKING THE WHEEL NUT DRIVING TORQUE................................................................................. 84

7.4.3 EVERY 100 HOURS OF OPERATION .......................................................................................... 84

7.4.3.1 CLEANING THE TERMINALS OF THE BATTERY........................................................................................84

7.4.3.2 CLEANING THE OIL TANK’S BREATHER ....................................................................................................84

7.4.3.3 CHECKING THE CYLINDER RODS ................................................................................................................ 84

7.4.3.4 GREASING ALL OF PINS..................................................................................................................................85

SWL3210 Service Manual

3

7.4.4 VERY 250 HOURS OF OPERATION ............................................................................................ 85

7.4.4.1 CHECKING THE GEARING CHAIN TENSION............................................................................................... 85

7.4.4.2 ADJUSTING THE CHAIN IF NECESSARY...................................................................................................... 85

7.4.4.3 CHECKING THE FAN BELT.............................................................................................................................85

7.4.4.4 CLEANING THE RADIATOR............................................................................................................................85

7.4.4.5 CHECKING THE OIL LEVEL IN THE GEAR CHAIN..................................................................................... 85

7.4.4.6 CHANGING THE ENGINE OIL.........................................................................................................................86

7.4.4.7 CHANGING THE ENGINE OIL FILTER........................................................................................................... 86

7.4.4.8 CHANGING THE FUEL FILTER.......................................................................................................................86

7.4.4.9 CHECKING THE NUT TORQUE OF THE HYDARULIC MOTOR AND THE HUB HOLDING TO THE

CHASSIS..........................................................................................................................................................................87

7.4.5 EVERY 500 HOURS OF OPERATION .......................................................................................... 88

7.4.5.1 CLAEN THE FUEL-WATER SEPARATOR......................................................................................................88

7.4.5.2 CHECK THE TIGHTENESS OF PUMP FIXING SCREWS..............................................................................88

7.4.5.3 CHECKING THE FLUID LEVEL OF THE BATTERY.....................................................................................88

7.4.5.4 CHANGING THE HYDRAULIC OIL FILTER .................................................................................................. 89

7.4.6 EVERY 1000 HOURS OF OPERATION.................................................................................. 89

7.4.6.1 CHANGING THE OIL IN THE GEAR CHAIN BOX................................................................................... 89

7.4.6.2 CHANGING THE HYDARULIC OIL AND CLEAN THE SUCTION ........................................................89

7.4.6.3 CHANGING THE AIR FILTER ....................................................................................................................90

7.4.6.4 CHECKING THE PUMP’S PRESSURE AND THE VALVE.......................................................................91

7.4.6.5 CHANGING THE HYDRAULIC OIL TANK BREATHER.........................................................................91

7.4.6.6 CHECKING THE TIGHTNESS OF THE CYLINDER HEAD SCREW.......................................................91

7.4.6.7 CHECKING THE LOOSENESS OF THE VALVE....................................................................................... 91

7.4.7 EVERY 2000 HOURS OF OPERATION.................................................................................. 92

7.4.7.1 CHANGING THE COOLANT....................................................................................................................... 92

7.4.7.2 CHECKING THE STARTER AND ALTERNATOR.................................................................................... 92

7.4.8 WHEN REQUIRED ......................................................................................................................... 92

7.4.8.1 DRAINING THE FUEL TANK........................................................................................................................... 92

7.4.9 TROUBLE SHOOTING................................................................................................................... 93

8 INFORMATION OF MANUFACTURER ................................................................................................... 97

SWL3210 Service Manual

4

1 INTRODUCTION

1.1 MODELS AVAILABLE

This manual is special for the SWL series skid-steer loader. A series of skid-steer loaders

“SWL” are developed by HUNAN SUNWARD INTELLIGENT MACHINERY CO., HUNAN

SUNWARD INTELLIGENT MACHINERY CO., LTD own all intelligence property related to

this machine.

1.2 ABOUT THIS MANUAL

This manual contents all the information about the SWL machine. The safety regulations,

description, service and maintenance instructions are included in this manual. HUNAN

SUNWARD INTELLIGENT MACHINERY CO., LTD supply this manual together with the

spare parts book. He provide the user all information

related to the SWL skid-steer loader and all safety

regulations.

For more information, please contact your SWL dealer.

The dealer knows how to get the best performance of

the machine and how to use the machine correctly in

any case.

1.3 TREATMENT OF THIS MANUAL

This operation and maintenance manual must be

handled with great care and always kept in the machine,

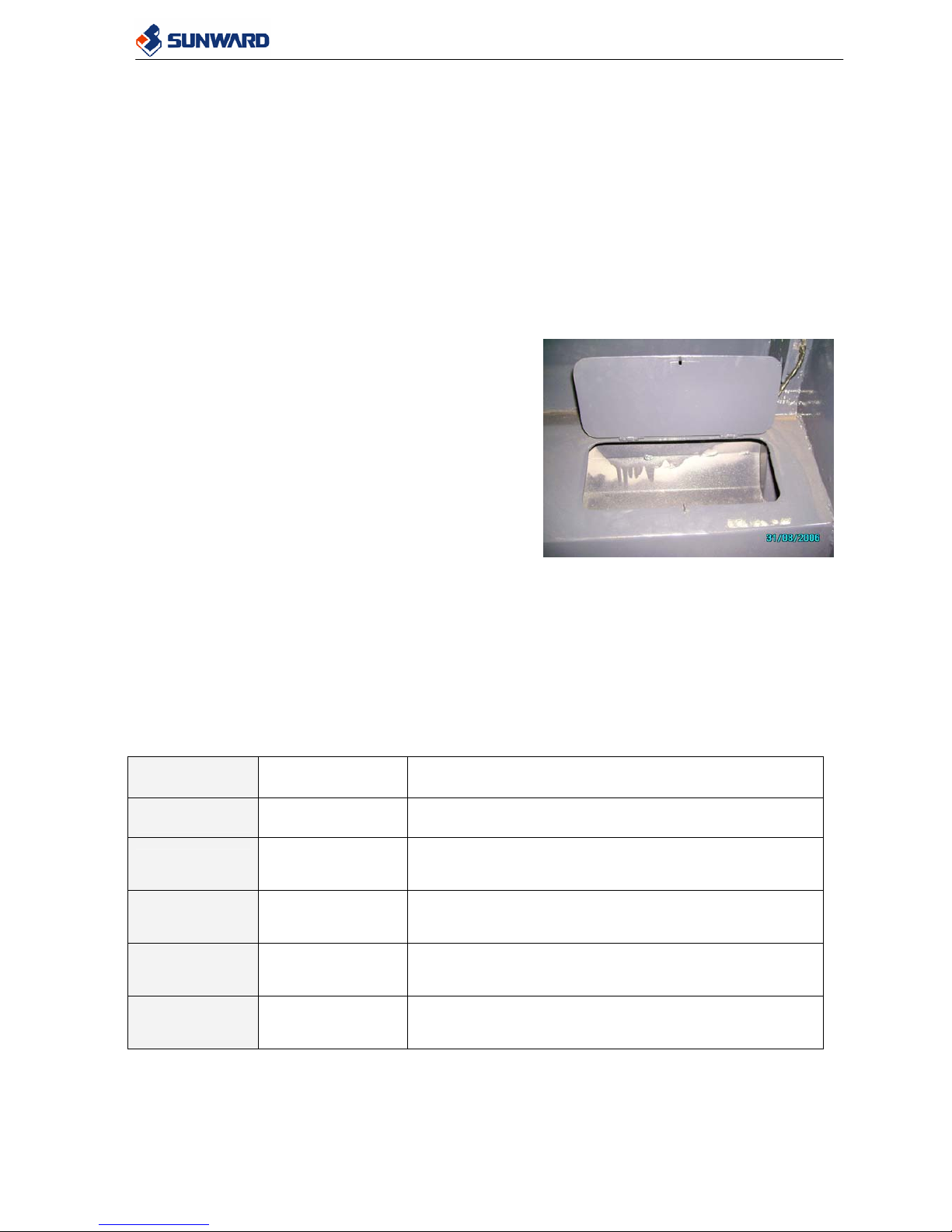

so that the operator can consult it at any moment. There is a compartment special for operation

manual and spare parts inside cabin. It locates on the behind of the seat. See the right picture.

The operation manual must be always kept in this case.

In case of damage or lose this manual, request to HUNAN SUNWARD INTELLIGENT

MACHINERY CO., LTD or the SWL dealers for a new one.

1.4 UNITS

In this manual we have taken the international unit system. We are using millimeter for distance,

liter for volume, degree for angle, etc.

ITEM UNIT SYMBOL

Distance

Millimeter mm

Volume

Liter L

Angle

Degree

°

Temperature

Celsius degree

°C

Sound

Decibel dB

1.5 DEFINITION OF “LEFT” SIDE AND “RIGHT” SIDE

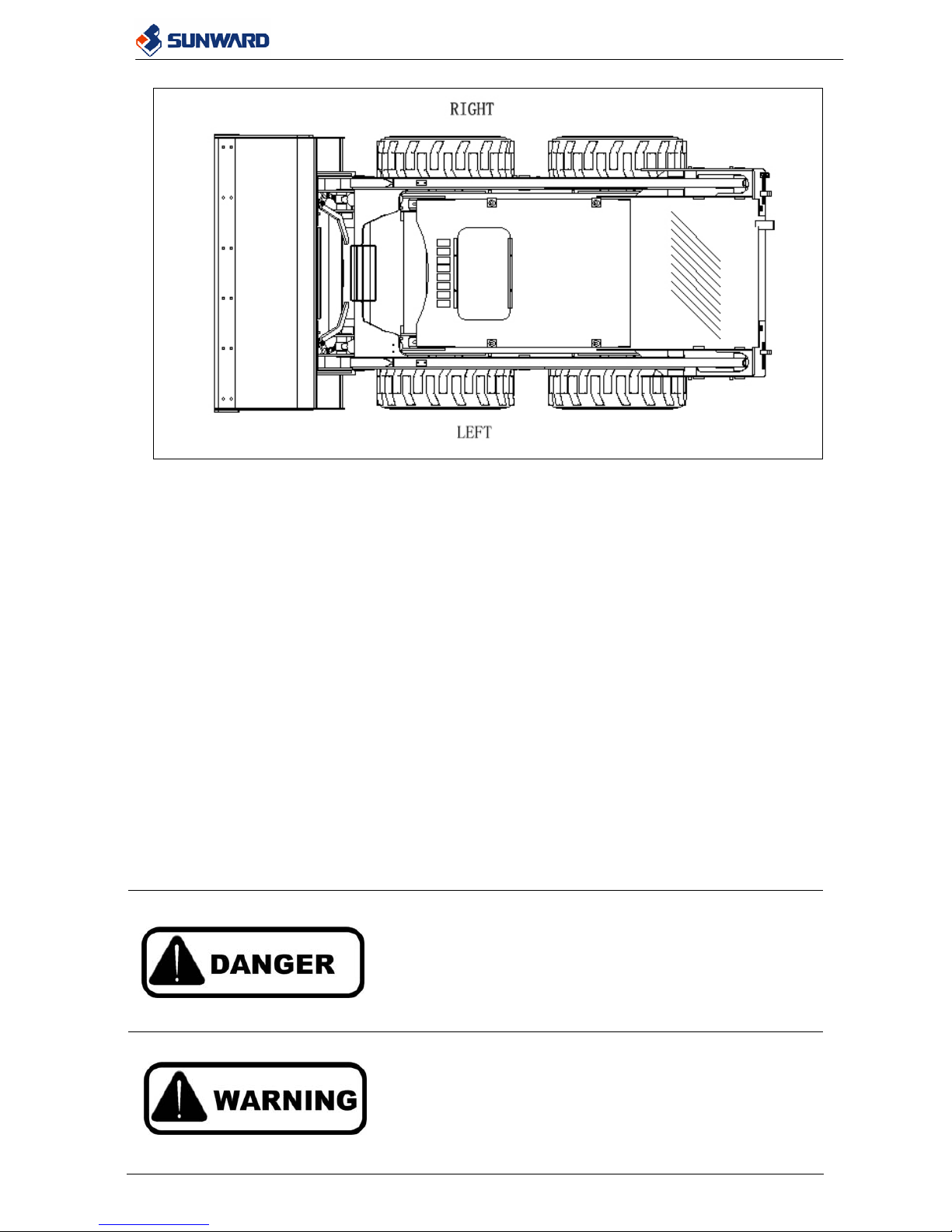

In this manual, “left” and “right” imply your left hand side and right hand side when you are

seated properly in the machine. It is also showed in the picture below.

SWL3210 Service Manual

5

1.6 PRECONDITION TO USE THE MACHINE

z To maintain this skid-steer loader properly and safely, operator must know well about this

machine and have basic experience on using this kind of machine.

z The operator must take special attention on the security recommendation in order to

preserve his security and the security of persons around him.

z Do not work with the machine until you are sure that you can control it properly. Do not

begin a work until you are sure there is no danger for you and for people around you.

z If you have any doubt regarding the safety regulations, please contact your SWL dealer.

1.7 SIGNALS

To help you to maintain machine safely, we have described many safety precautions in this

manual. Also many precaution labels are put on the machine. Many different signal words are

used in the manual and on the labels.

The following signal words are used to inform you that there is a potential hazardous situation

that may lead to personal injury and damage. In this manual and on the precaution labels on the

machine, the following signal words are used to express the level of the potential hazardous.

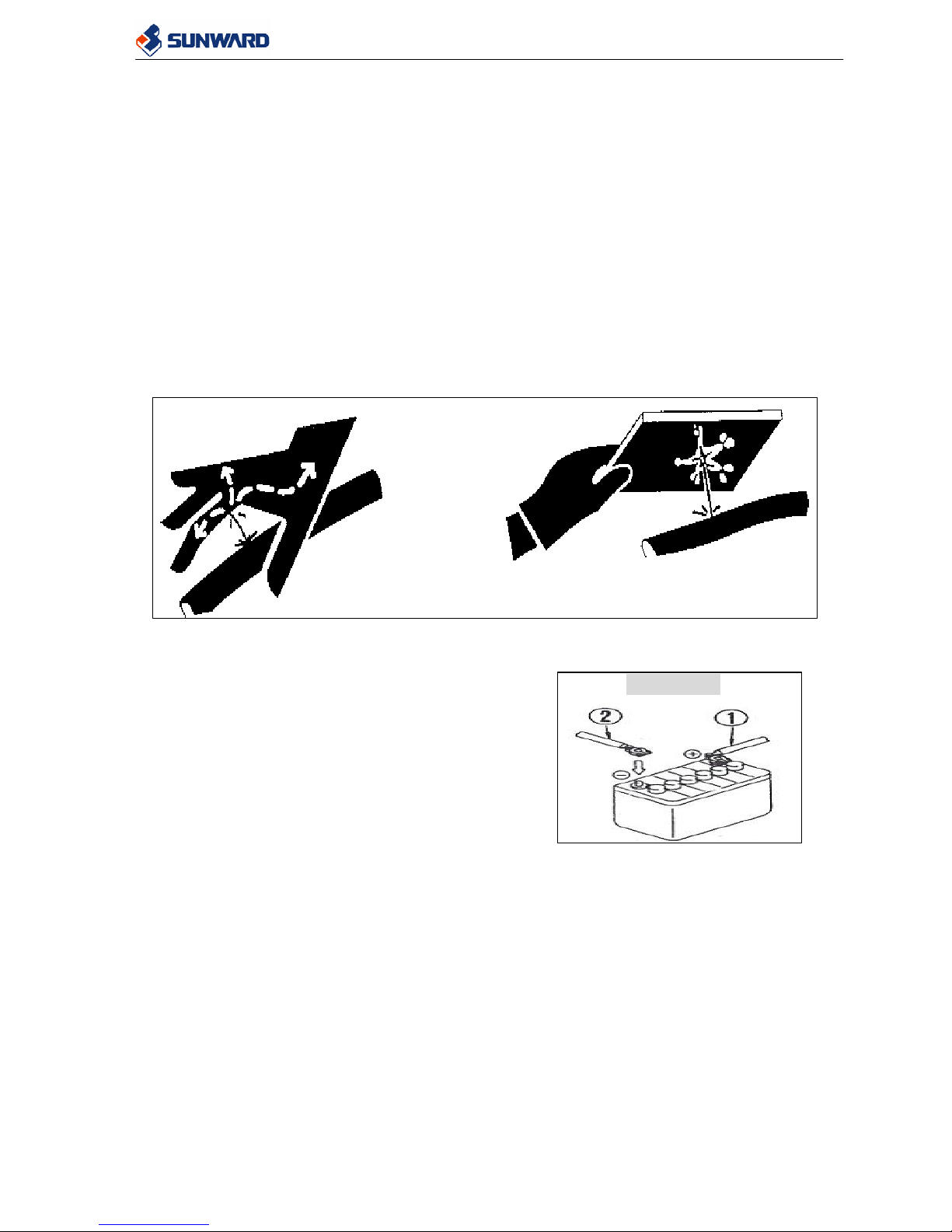

If not avoided, it has great possibility to lead to serious

injuries or death to the operator (or other persons). It is used

to express the most extreme dangerous situation.

If not avoided, this situation could cause serious injuries

even death.

SWL3210 Service Manual

6

If not avoided, this situation may cause minor or moderate

injury to operator (or other persons) or damage to the

machine.

There are other signal words showed under to indicate precautions that are useful for operator.

It is used for precautions that must be taken to avoid actions

what could shorten the life of the machine.

It is used for information that is extremely useful to know.

The safety message may not include all the possible safety precautions. It is impossible to

describe all the potential hazard may appear during the operation or maintenance. For any

question regarding the safety regulation please contact your dealer.

SWL3210 Service Manual

7

2 SECURITY

This section describes the possible hazards that may appear during the operation and

maintenance of the machine. Authorized additional equipments have their manual given

together with the equipments.

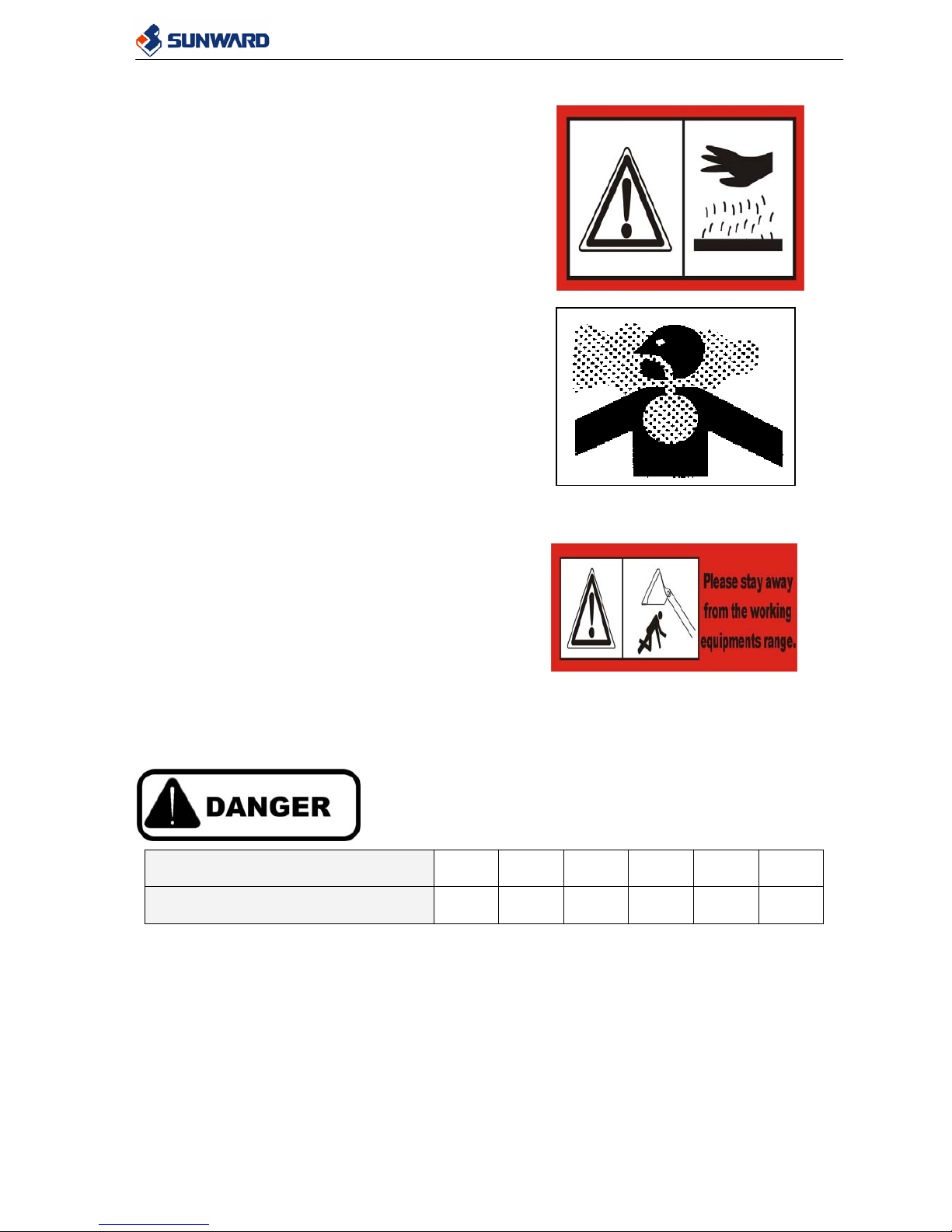

2.1 MEANING OF THE SAFETY SIGNS

Safety precaution labels are fixed to the machine to warn about possible hazards that may cause

personal injuries or even death. They are placed where the possible danger is. Before using the

machine make sure you understand all the security labels. Keep all the labels clean and readable.

Change all the damaged labels.

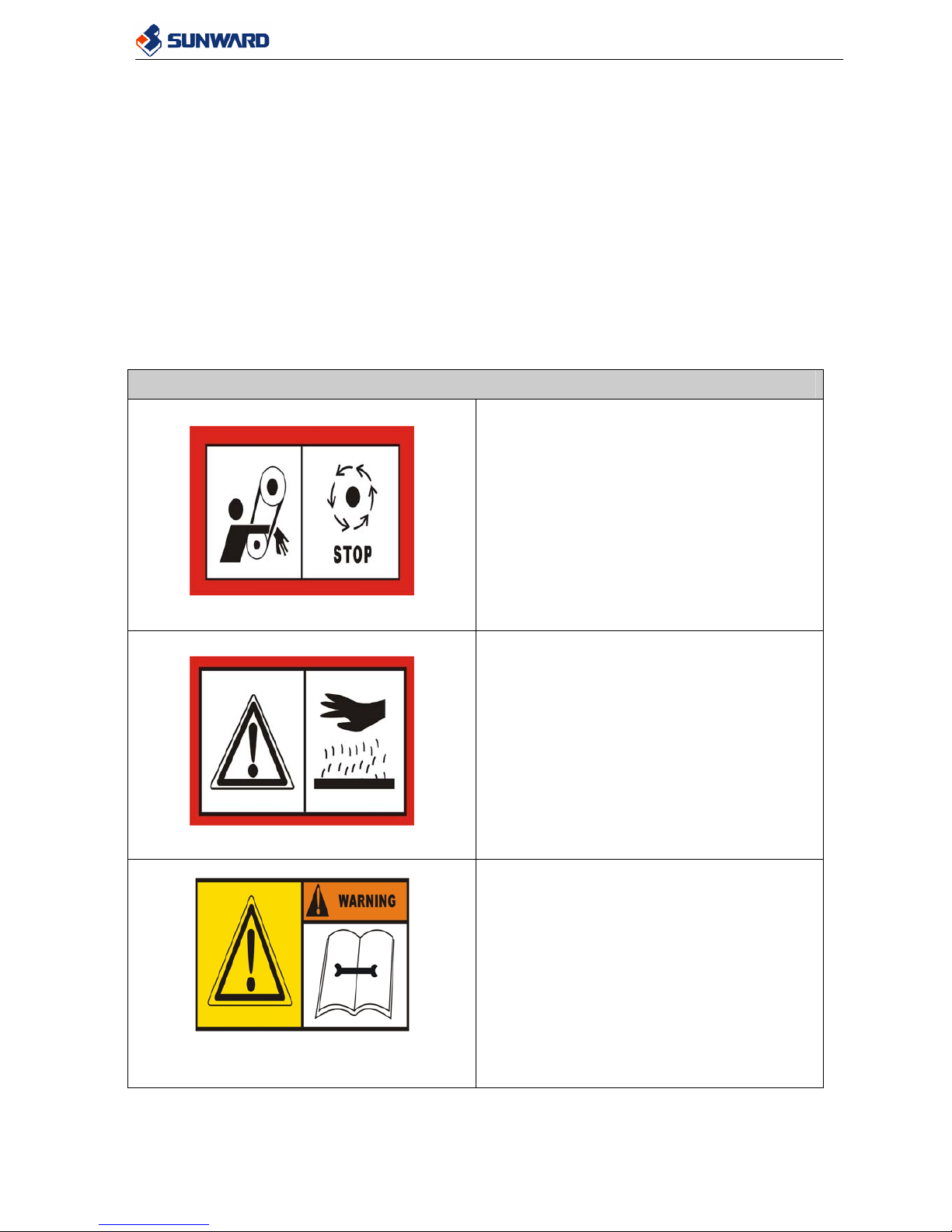

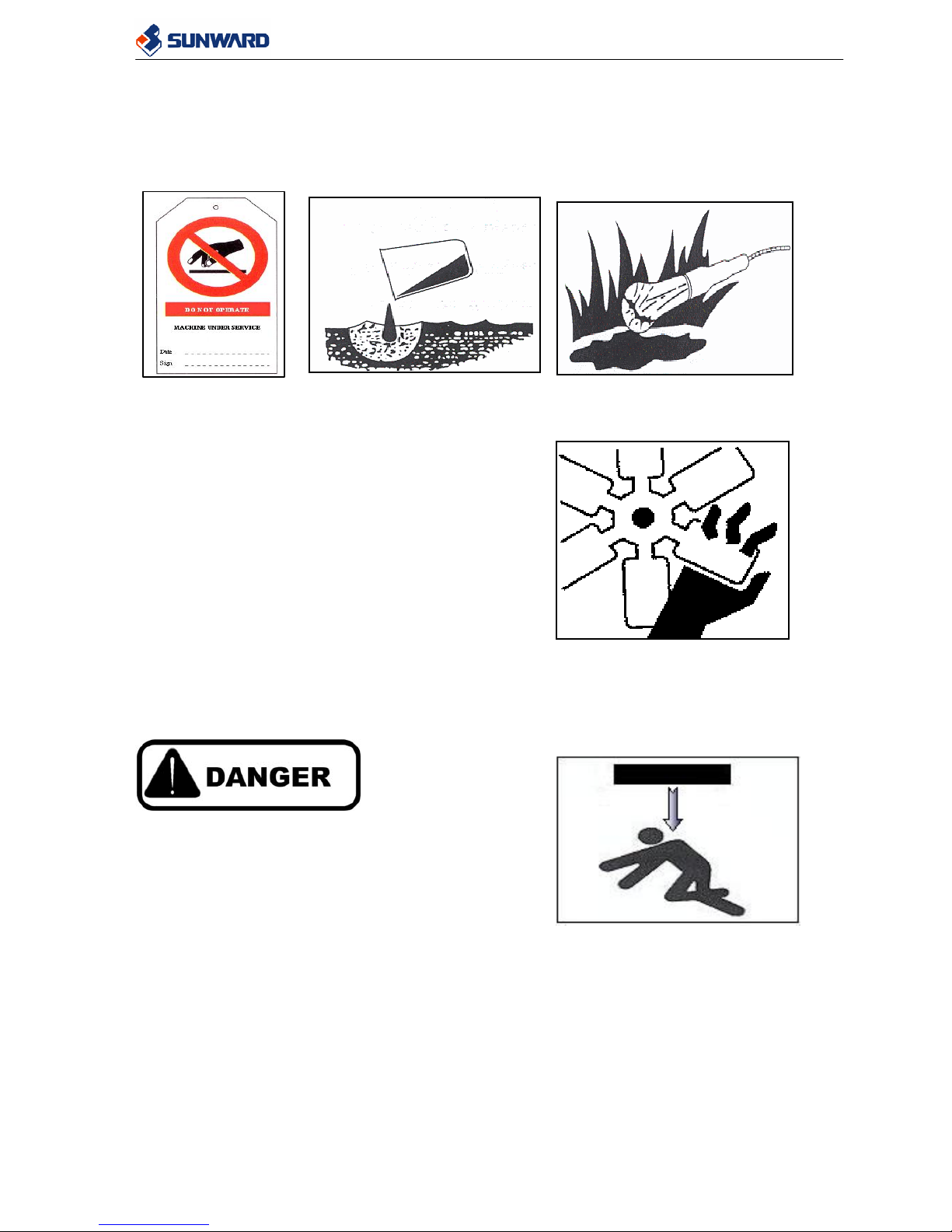

2.1.1 GENERAL SIGNS

The following table shows the different labels fixed on the machine and the respective meanings.

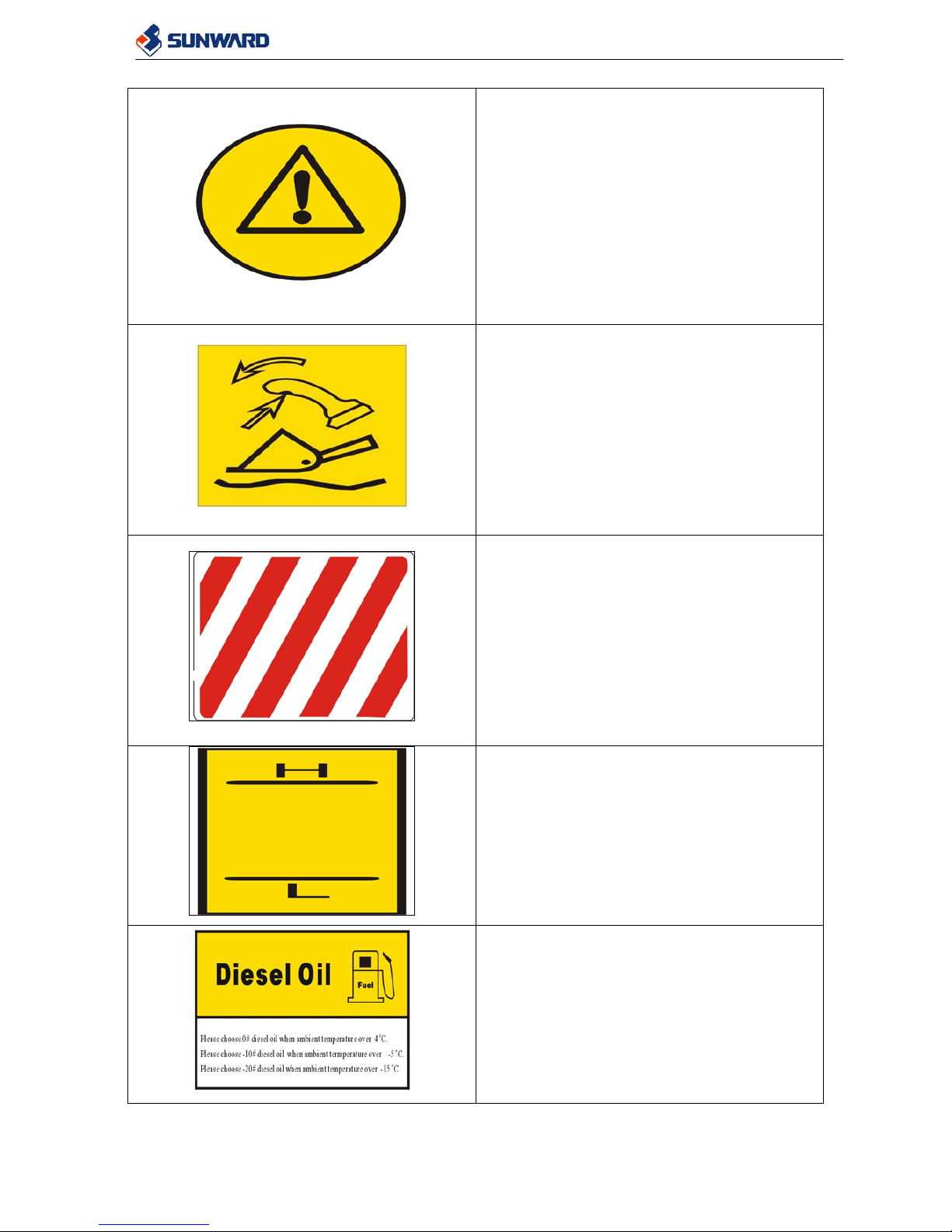

GENERAL LABELS

Moving crawlers, when Entanglements in can

cause serious injury

High temperature

See manual book

SWL3210 Service Manual

8

Note

Float

Tail warning

Oil level

Diesel Oil

SWL3210 Service Manual

9

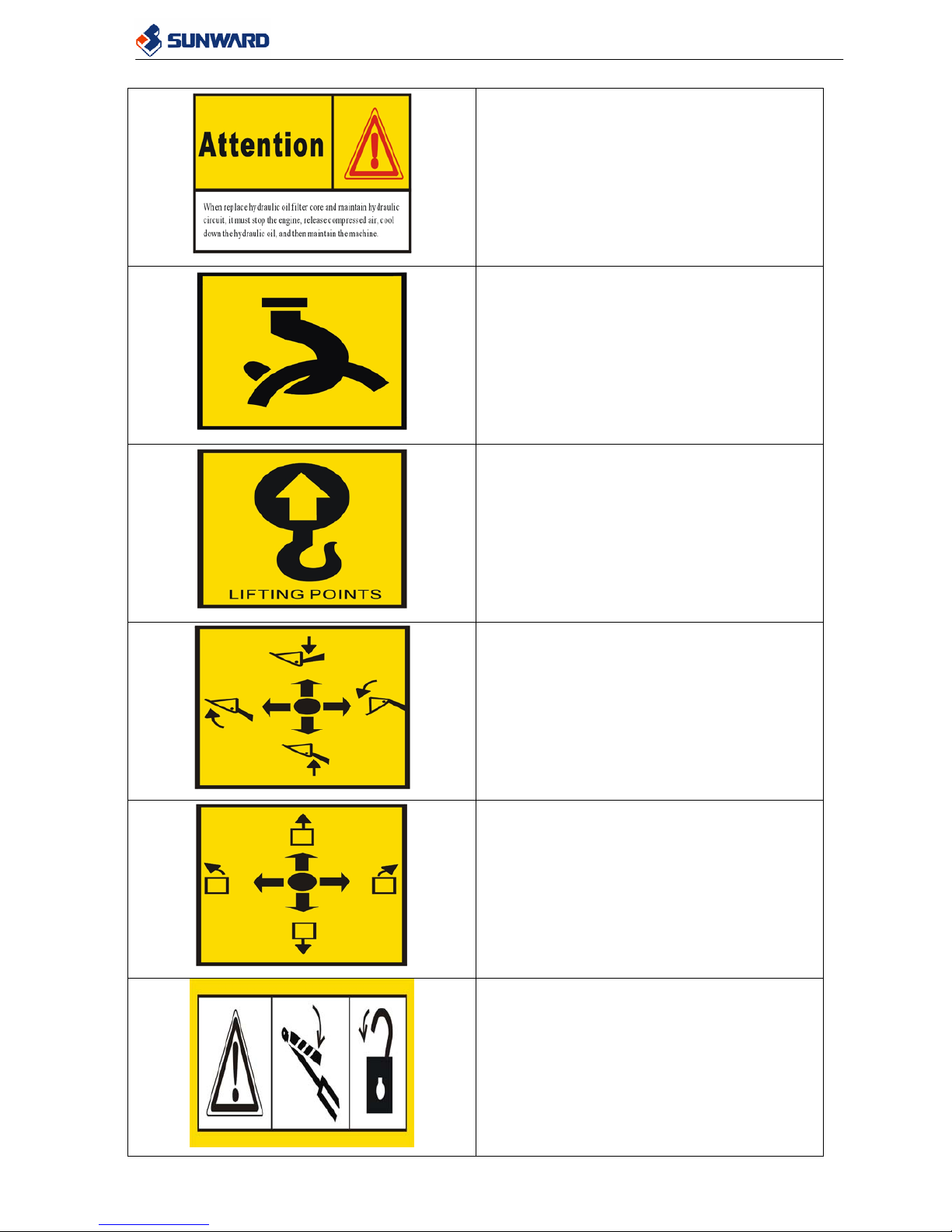

Oil filter

Drag position

Lifting points

Operation direction

Operation direction

Safety pin for boom

SWL3210 Service Manual

10

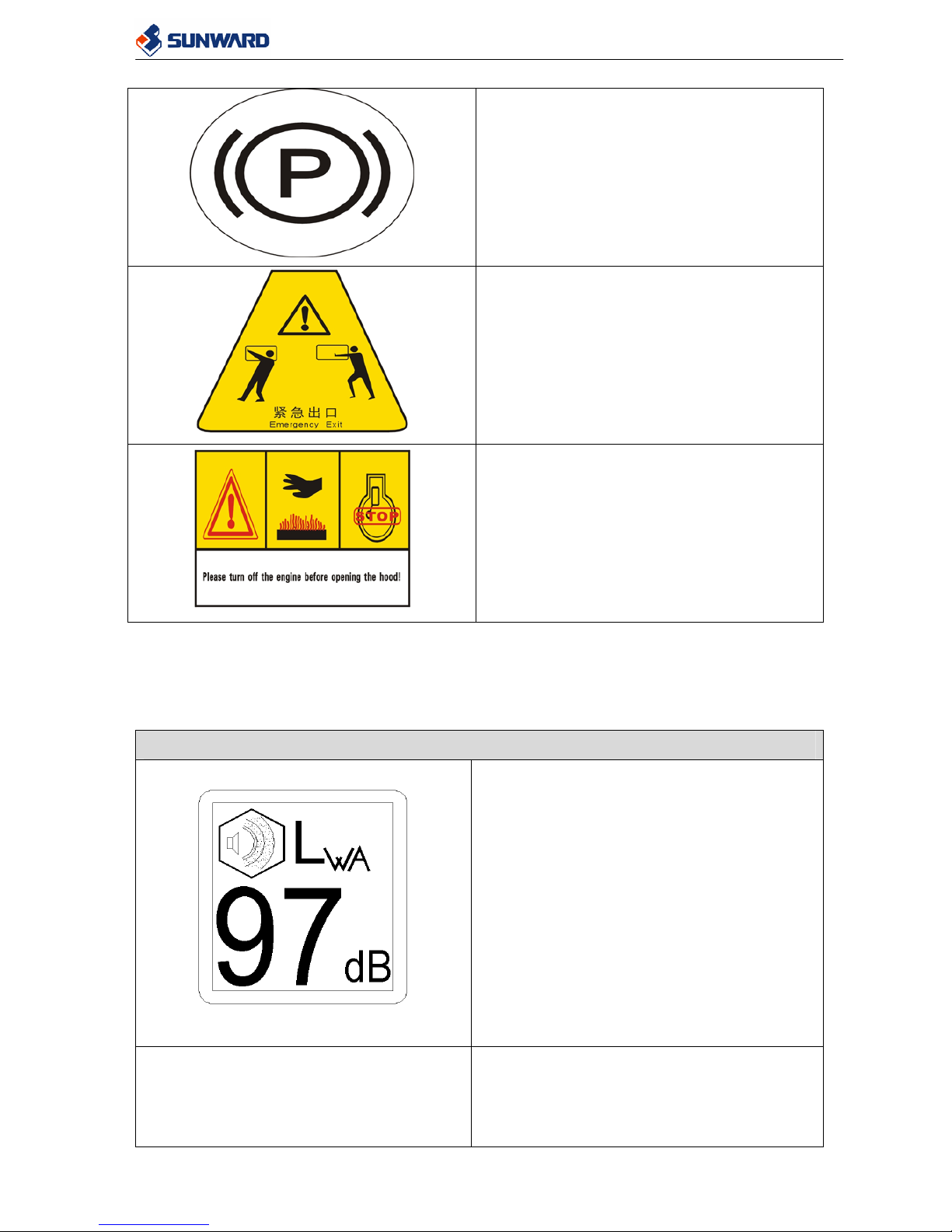

Security button

Emergency exit

Engine hood

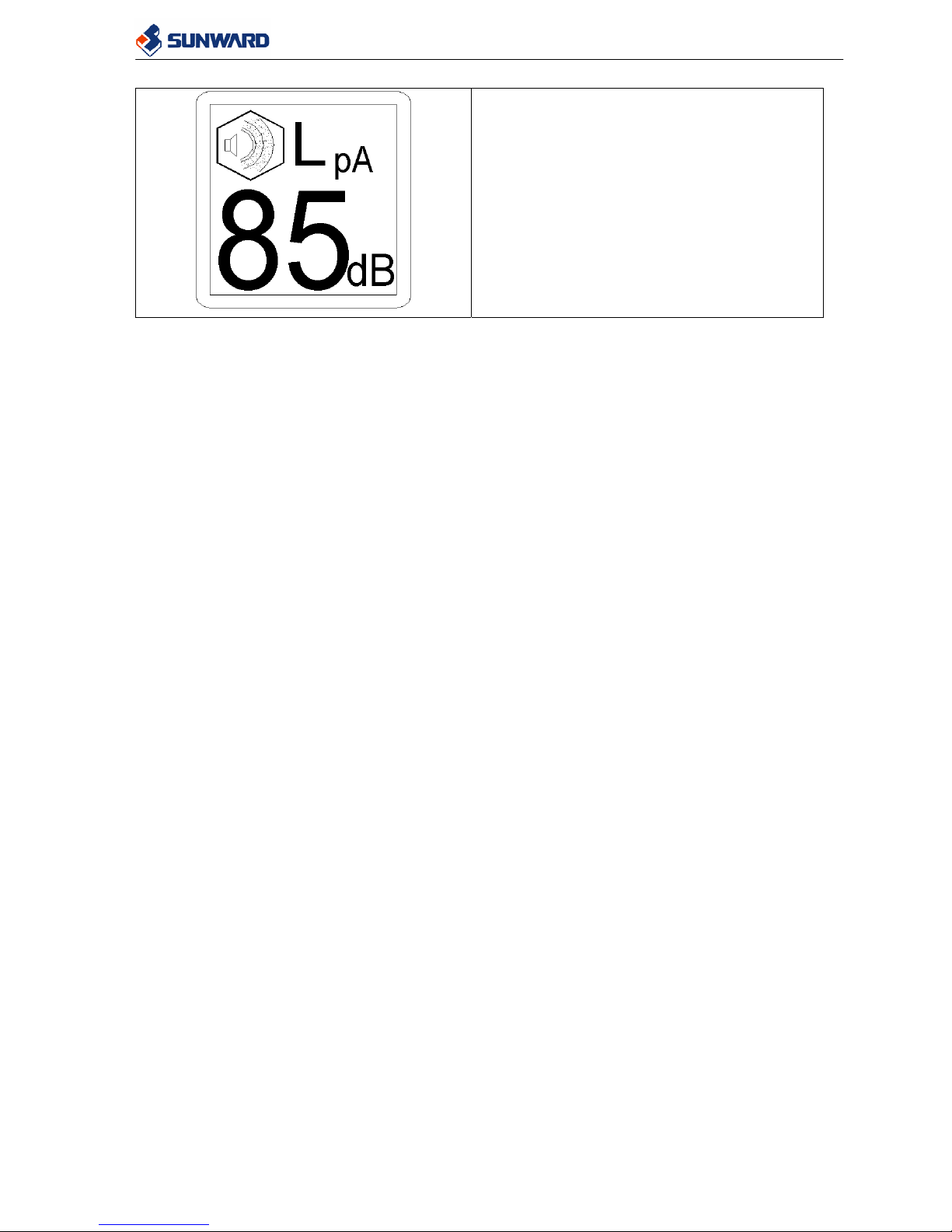

2.1.2 ACOUSTIC SIGNS

The following table shows the different acoustic labels fixed on the machine and the respective

meaning.

ACOUSTIC LABELS

The max noisy level out of cabin.

The max noisy level in cabin.

SWL3210 Service Manual

11

2.2 LOCATION OF THE SAFETY LABELS

The safety labels were located in striking position.

2.3 GENERAL PREVENTION

2.3.1 GENERAL SAFETY RULES

The following items are extremely important. Operators must read with great care and follow

them while operating and performing maintenance.

z Only authorized and experienced personnel can use or maintain the machine.

z The using and maintenance must be taken follow with the safety rules describe in this

manual.

z Use the machine only when the machine is in good operating condition.

z Don’t use the machine for the tasks exceed its capacity.

z Operate the machine only when the operator is seated correctly in the driving position.

z Before do any maintenance, position the machine on a firm and level surface, lower

working equipments to the ground, engage the safety lock of working equipment, stop the

engine.

z It is forbidden to modify the connections and safety settings of the hydraulic system. Before

do any modification, please consult your dealer. Any unauthorized modification may lead to

serious injury to operator or damage to the machine. HUNAN SUNWARD

INTELLIGENT MACHINERY CO., LTD will not take the responsibility to the result

caused by this kind of unauthorized modification.

z Install only authorized auxiliary equipments. Any additional equipment more than the

authorized auxiliary equipments list in this manual may not perform well even cause

damage to the machine and injury to persons. See the list of authorized auxiliary

equipments.

z Before travel on the road, make sure the lights, signaling and safety device are in good

condition and engage relative safety devices.

z Do not use the machine before read and understand this manual. Any inappropriate use of

this machine could be very dangerous for the operator and the person around the machine.

Many of the accident are caused by insufficient knowledge of the safety regulations

described in this manual.

z It is extremely dangerous operate the machine under the effect of alcohol or drugs. Do not

take alcohol, medicine what makes you sleepy or drugs before or during use the machine.

SWL3210 Service Manual

12

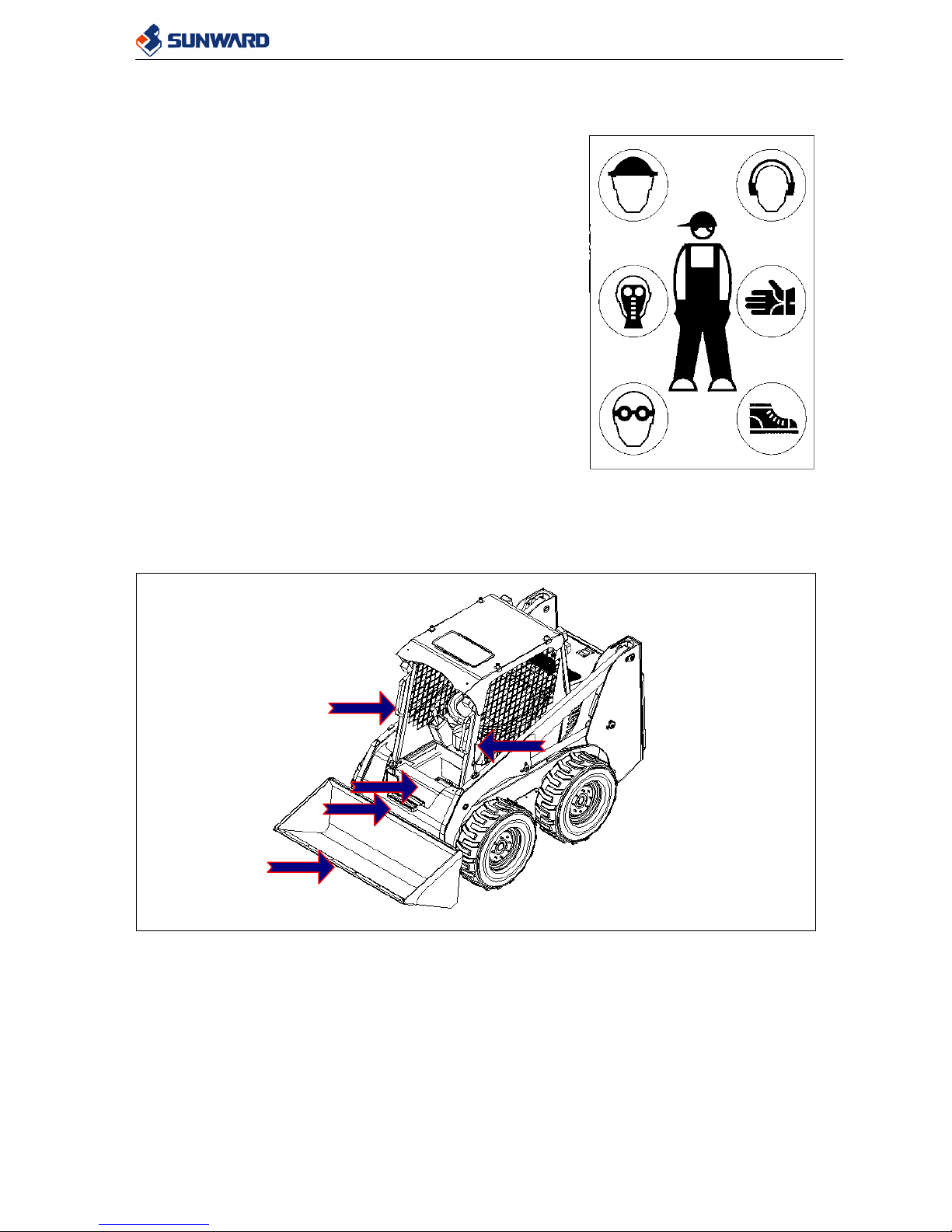

2.3.2 CLOTHING AND PERSONAL PROTECTION

z Inappropriate clothing may lead to injury to the

operator. Please wear in the protective clothing while

operating or performing maintenance such as hardhat,

goggles glasses, mask gloves, safety shoes and

headphones.

z If you have long hair, tie up them before approach the

machine since they can get entangled in the moving

part of the machine and cause serious injuries and

damage.

z When working for 8 hours with a noise exceeding 90

dB, it is necessary to use headphones.

z When working in a special dangerous area, additional

protections could be required according to the

conditions.

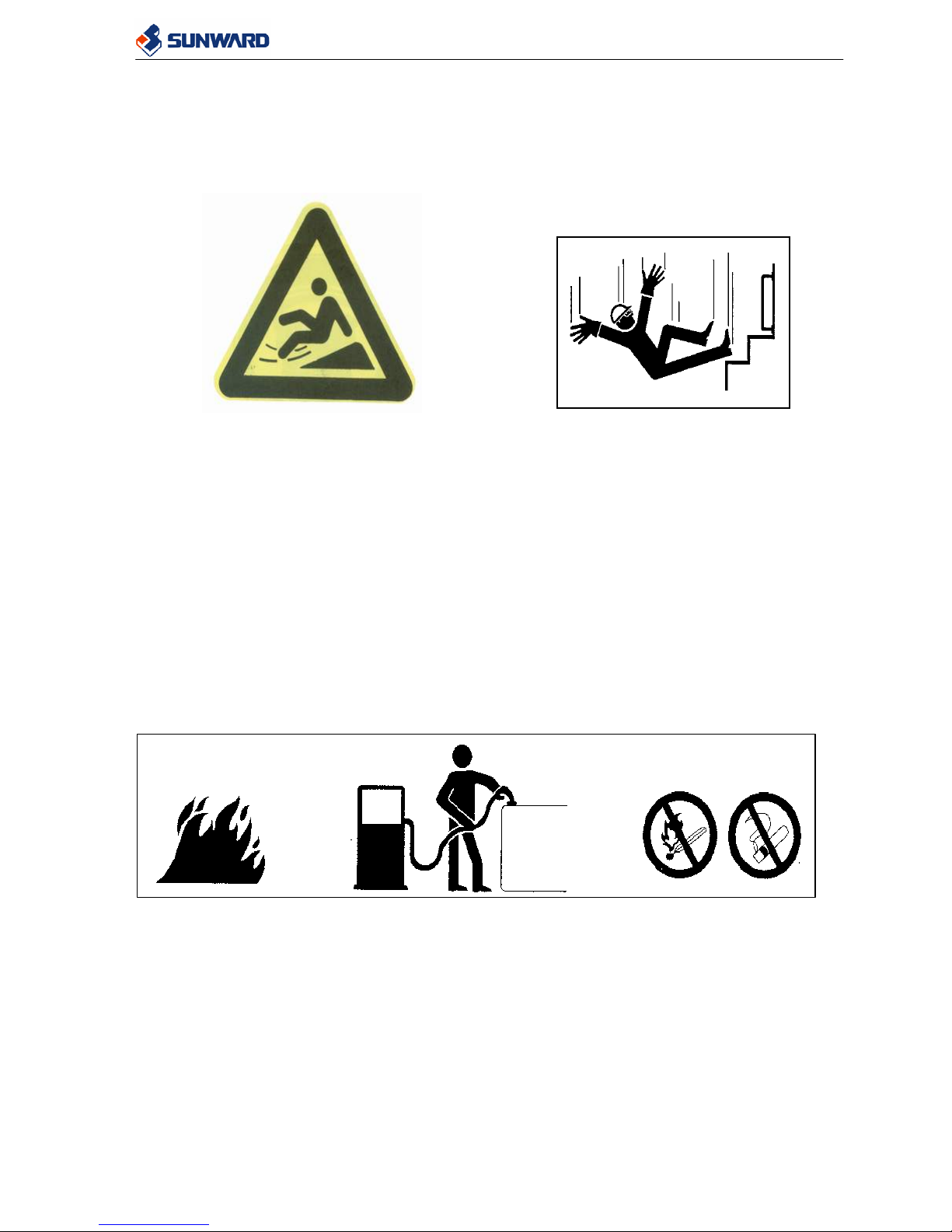

2.3.3 ENTER AND LEAVE THE MACHINE

Use the appropriate footplates and handles showed in the following picture while entering and

leaving the machine.。

z Enter and leave the machine only when the machine is not moving unless it is in

emergency.

z Never hold on the joysticks.

z Use always the appropriate handles while entering and leaving the machine.

z Always be carefully while entering and leaving the machine. Keep your body balance

during the whole processes of entering and leaving the machine.

SWL3210 Service Manual

13

z Before enter and leave the machine, make sure the footplate and handles are not covered

with oil, grease, ice or other slippery matter. In case it happens, clean the slippery matter

carefully immediately.

z Take great care in case the machine is wet. It could be very slippery.

Before leave machine, carry out the following procedures in the sequence.

1) Park the machine in a safe position.

2) Lower the working equipment to the ground.

3) Engage the parking brake.

4) Engage the auxiliary equipment control pedal retainer.

5) Raise the restrain bar to upward.

6) Stop the engine.

2.3.4 PREVENTION OF FIRE TO FUEL AND OIL

z Fuel and oil are easily to cause fire if they meet flame.

z Keep always flame away from the fuel and oil.

z Stop the engine and never smoke during refueling.

z Only do the refilling fuel and oil in the well ventilated areas.

z Close well the safety cap after charge or fuel.

z Do not fill the tanks in order to leave room for the fuel expansion.

z If some fuel or oil is spilled wipe it up immediately.

SWL3210 Service Manual

14

2.3.5 PREVENTION OF BURNS

z After operating for a period, the engine, coolant,

hydraulic oil, engine oil, radiator and pumps are

hot. Do not touch them until they cool down.

z In case of entailing working with hot oil, hot

coolant or hot hydraulic oil, wear gloves, heavy

clothing and safety goggles before do any check

or maintenance.

z Loosen the coolant safety cap slowly when the

coolant is hot to release the residual pressure

inside the tank before open it. If it is hot it may

spurt out and cause serious burns.

z Before checking the coolant level, the hydraulic

oil level and the engine oil level, stop the engine

and wait till they cool down.

2.3.6 PREVENTION OF DAMAGE OF WORKING

EQUIPMENT

z Do not stand in the area that the working

equipment can reach when the machine is operating. It may cause serious injury or even

death.

z Before perform working equipments, the

operator must make sure that nobody is in the

dangerous area that working equipment can

reach.

z Try to lower the working equipment to the

ground every time when you park the machine.

z During maintenance, make sure the equipment is locked correctly before go into the

area under lifted working equipment.

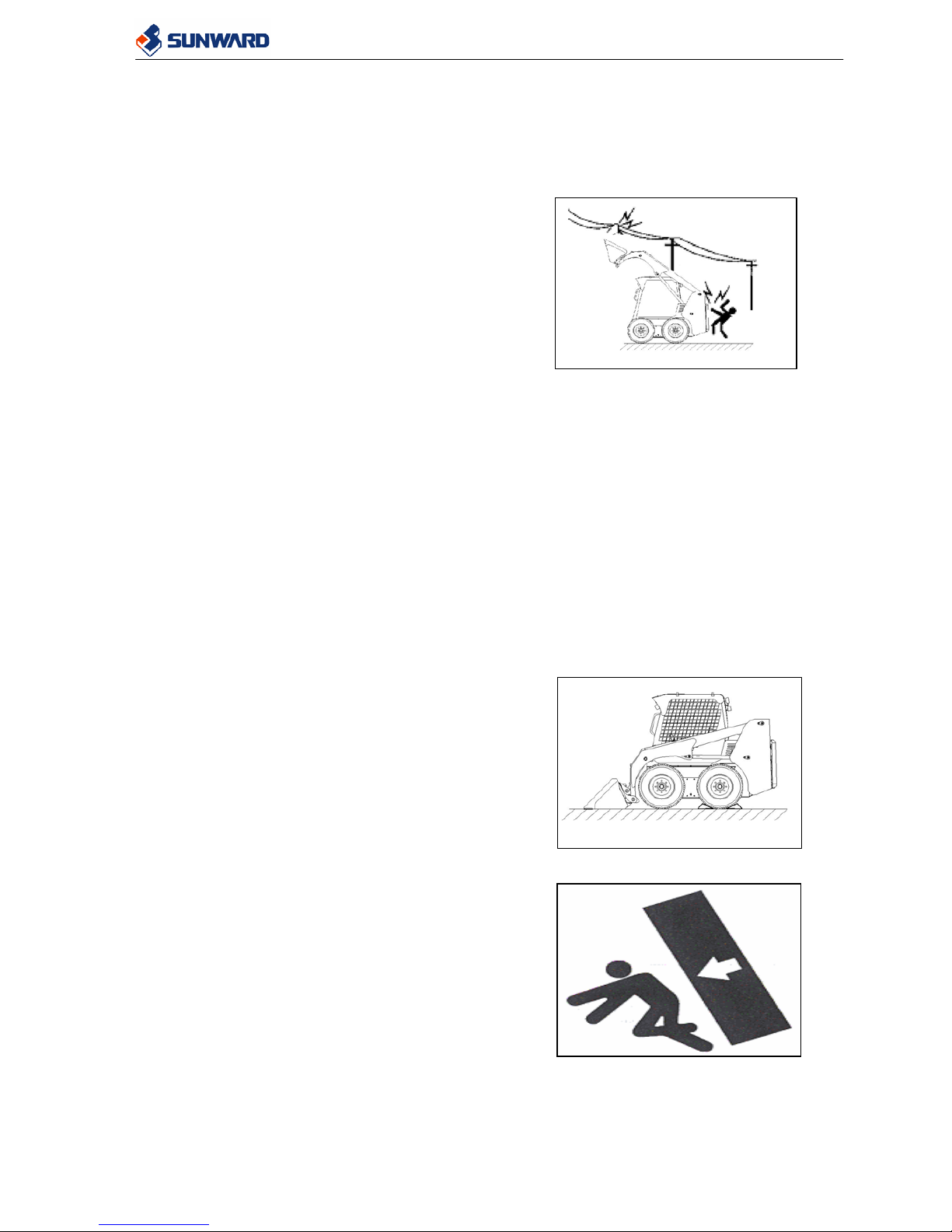

2.3.7 PREVENTION OF ELECTRIC SHOCK

Voltage of Cables (kV)

1.0 6.6 33 66 154 275

Distance must be kept (m)

5.0 5.2 5.5 6.0 8.0 10.0

SWL3210 Service Manual

15

z Do not travel or operate the machine near the electrical cables. On the working sites

where the machine may go close to electrical cables, follow the procedures below.

Otherwise it is possible to get an electric shock, which may cause serious injury even

death.

z Before starting working near the electrical cables,

consult the power company what is the voltage

with the cables and inform the power company

of your coming work. If necessary, ask them to

take actions.

z To prepare for any possible emergencies, wear

rubber shoes and gloves. Prepare all things you

need to call the power company immediately in

case of accident.

z Even going close to the high-voltage cables can cause electric shock. Always maintain a

safe distance (see the table up) from the cables.

z Use a signalman to give warning if the machine approached too close to the electrical

cables.

z If the machine come too close to or entangled with the electrical cables, do not leave the

cabin and let any person approach the machine until the electricity has been shut off.

2.3.8 LIMITS OF THE MACHINE

z This machine has been designed for one operator. More than one passenger on the

machine can be extremely dangerous. Never transport more than one passenger with this

machine.

z Overload could cause serious injuries or even death. Never overload the machine. For

the detail capacity of machine, please refer the section of specification in this manual.

Do not try to get a better efficiency of the

machine by doing any unauthorized change.

2.4 MAINTENANCE PREVENTION

2.4.1 GENERAL RULES

z To do any maintenance position the machine on a

firm and flat surface, rest the equipments on the

ground, engage the security locks, apply the

parking brake and stop the engine. If necessary,

put wedges under wheels to fix the machine.

Before doing the maintenance, place the warning tag

“DO NOT OPERATE” to the joysticks and ignition

switch. Make sure nobody other who is not doing

maintenance together with you operate the machine while

you doing maintenance.

z Only authorized and duly trained personnel can

do the service and repair. Only do the

maintenance that you are certain. If you have any

question, please consult the dealers.

SWL3210 Service Manual

16

z Keep the machine and the ambient clean. Keep the parts and tools in proper place.

z To prevent pollution, never deposit the fuel, oil and grease directly onto the ground. Use

containers to keep the fuel, oil and grease and drain them according to the local

regulations.

2.4.2 RUNNING THE ENGINE DURING THE MAINTENANCE

z If the maintenance must be carried out with

engine running, two workers are necessary. One

worker must always seat in the operator’s seat

and be ready to stop the engine at any time.

z Keep the safety lock in function during the

maintenance operations.

z When the engine is running, don’t touch the

rotating parts. The rotating parts like fan and fan

belt are extremely dangerous because they can

make you get caught. Be careful not to come

close to them.

2.4.3 WORKING UNDER THE WORKING EQUIPMENT AND MACHINE

z If it is necessary to carry out service and

maintenance under the working equipment or the

machine, support the equipment and machine

with block and stands strong enough to support

the weight of the working equipment and

machine.

z Lower the working equipment to the ground or the lowest position before working

under the machine.

WRONG

SWL3210 Service Manual

17

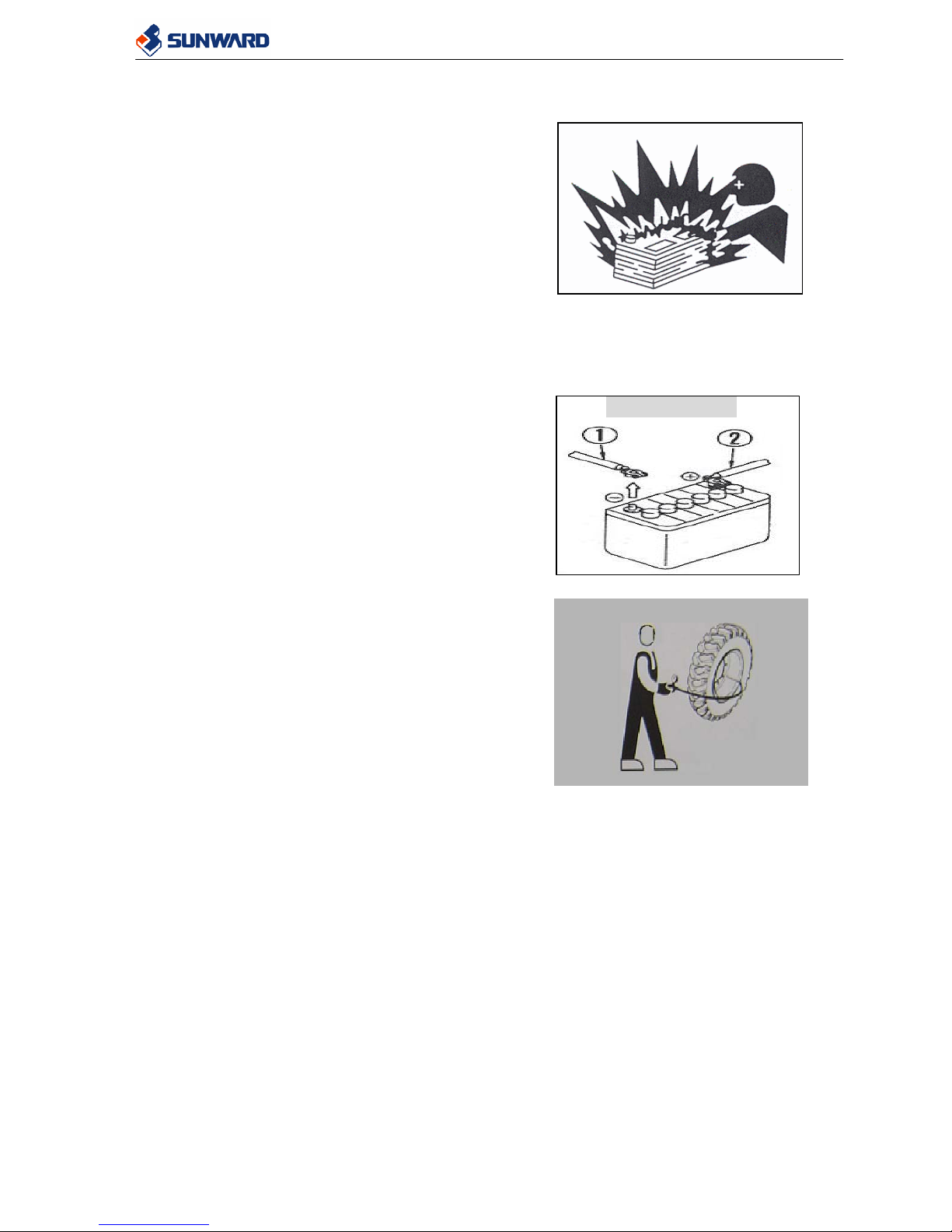

2.4.4 SAFETY RULES FOR HIGH-PRESSURE OIL AND HOSE

z The hydraulic system is always under internal pressure. Before do any inspecting or

replacing hoses, always lower the working equipment and make sure that the pressure in

the hydraulic circuit has been released.

z The high-pressure oil leakage from small holes can penetrate your skin or injury your

eyes. Extreme care must be taken when you are inspecting high-pressure oil leakage.

Wear goggles and thick gloves. Use a piece of cardboard to check oil leakage instead of

your hands.

z Damaged hoses could be extremely dangerous and could cause serious injuries. Change

the damaged hoses and connections as soon as possible.

z If you are hit by a jet of high-pressure oil and suffer injury to your skin and eyes, wash

your skin and eyes with clean water and consult a doctor immediately.

2.4.5 PREVENTION ON THE STARTER AND

ALTERNATOR

z Before doing any check on the electric circuit,

disconnect the battery in order to cut off the

current.

z If some electrical welding has to be done on the

machine, it is necessary to disconnect the battery

and also the alternator.

z Never try to start the engine by manipulating the

connexions of the starter. It will cause sudden machine move. It is very dangerous for

the operators.

2.4.6 PREVENTION OF BATTERY HAZARD

Battery electrolyte contains sulphuric acid and generates flammable hydrogen gas. The

sulphuric acid is extremely harmful to your body.

Solutions for the accidents:

1) If the electrolyte contact your eyes flush them immediately with plenty water and

contact a doctor immediately. Acid could cause blindness.

2) If some electrolyte contact with your skin, wash immediately with plenty water.

3) If accidentally you ingest some acid, drink a large quantity of milk, eaten eggs or

vegetable oil and call immediately a doctor.

Please always follow with the following precautions:

WRONG

RIGHT

CONNECT

SWL3210 Service Manual

18

z Always wear goggles and gloves when you are working with the battery.

z Stop the engine and remove the key before

working on the battery.

z Never smoke and use any flame near the battery.

z Always tighten the terminals and caps securely.

Loosen terminals or caps may cause fire and

explosion.

z Do not let tools other metal objects make any

contact between battery terminal.

z Disconnect first the negative earth cable (-) and then the other positive cable (+).When

connecting, connect fist the positive cable (+) and then the negative earth cable (-).

z If there is a welding operating on the machine, please disconnect the battery cables

before it.

2.4.7 PRECAUTION DURING INFLATING THE

TIRES

• Take into consideration that tires can burst while

being inflating. Inflate the tires bit by bit.

• For inflating the tires use an air-compressing gun

with extension and a gauge for control the

pressure in the tire.

• Do the maintenance of the tires like described in

the relating item of this manual.

• Do not stand very close to the tire during inflating

the tire and make sure that nobody stands close.

• Follow the recommendation for the pressure

given in the related item of this manual. Make

sure that the tire pressure is the same on both

sides of the machine.

DISCONNECT

SWL3210 Service Manual

19

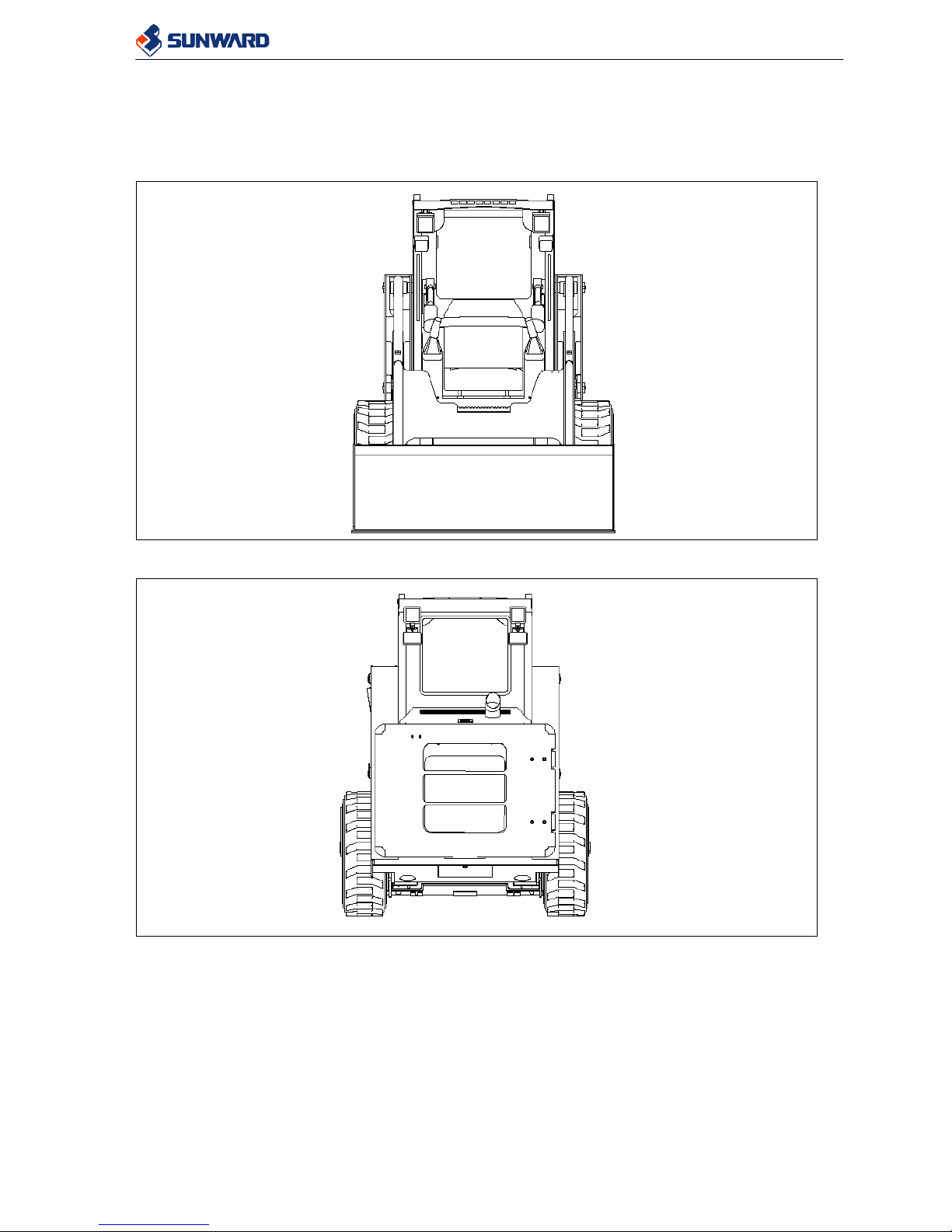

3 GENERAL DESCRIPTION OF THE MACHINE

3.1 DESCRIPTION OF THE MACHINE

3.1.1 FRONT VIEW

3.1.2 REAR VIEW

SWL3210 Service Manual

20

3.1.3 MACHINE DISTRIBUTION

1. Bucket 2.Working lamp

3. Cabin 4.Hydraulic oil tank

5. Engine hood 6. Fuel tank

7. Arm 8. Wheel

9. Exhaust pipe 10. Rear cover

9

10

1

7

2

3

4

5

6

8

SWL3210 Service Manual

21

3.2 SPECIFICATION

3.2.1 GENERAL DATA

ITEM SWL 3210

Operating weight 3250kg

Nominal load 950kg

Tipping Load 1900kg

Bucket volume 0.53m3

Breakout force (lifting cylinder) 2420Kgf

Breakout force (tilting cylinder) 2470Kgf

Max traveling speed 12.6Km/h

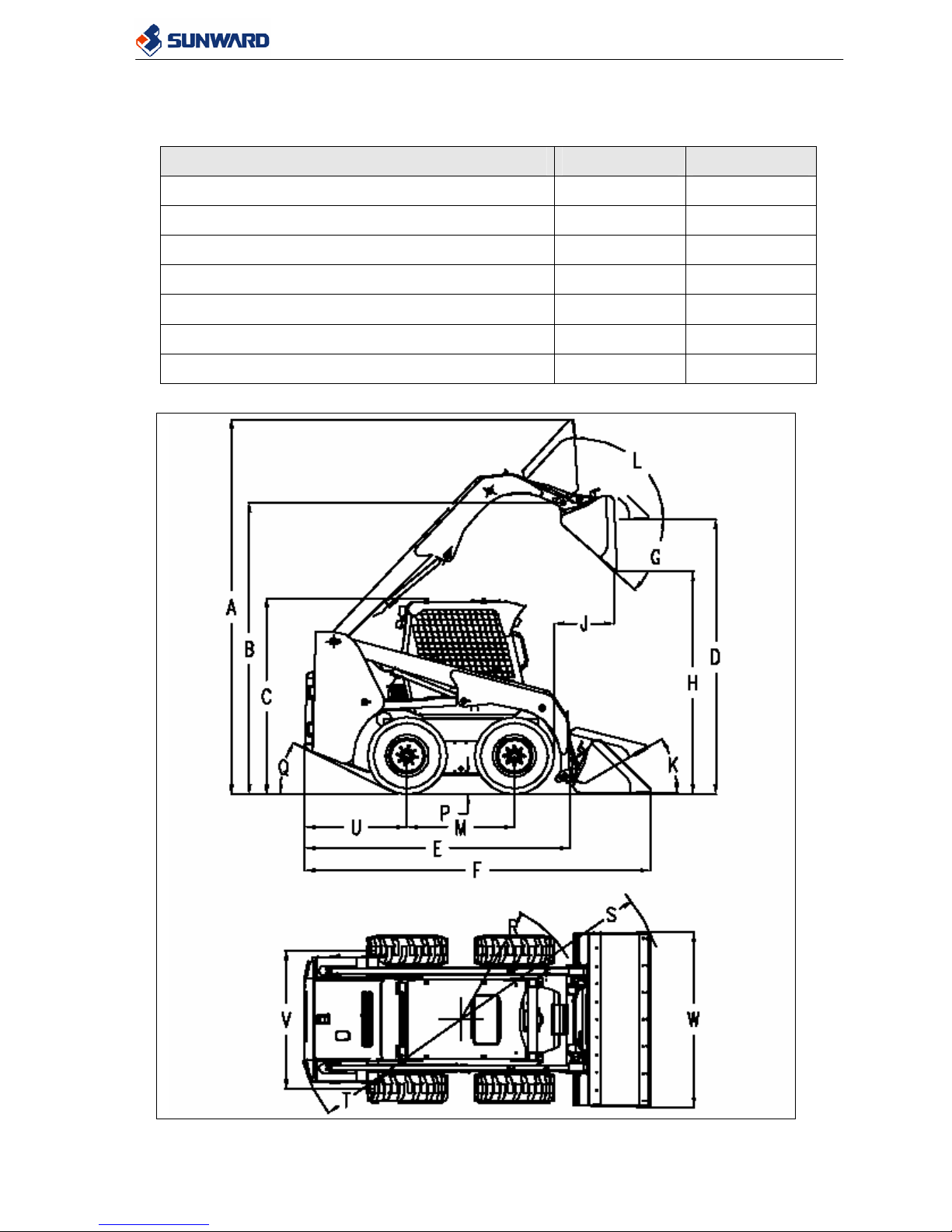

3.2.2 OVERALL DIMENSION

SWL3210 Service Manual

22

Item Specification SWL3210

A Overall operating height

4020 ㎜

B Height to bucket hinge pin

3123 ㎜

C Height to top of cab

2100 ㎜

D Height to bottom of level bucket

2950 ㎜

E Overall length without attachment

2750 ㎜

F Overall length with standard bucket

3590 ㎜

G Dump angle at maximum height 43°

H Dump height

2395 ㎜

J Reach at maximum height

625 ㎜

K Rollback of bucket on ground 30°

L Rollback of bucket at full height 93°

M Wheelbase

1116 ㎜

P Bottom of belly pan

205 ㎜

Q Angle of departure 27°

R Clearance circle front without bucket

1300 ㎜

S Clearance circle front

2180 ㎜

T Clearance circle rear

1700 ㎜

U Rear axle to bumper

1062 ㎜

V Tread width, centerline to centerline

1475 ㎜

W Width with excavating bucket

1880 ㎜

3.2.3 ENGINE

ITEM KUBOTA V3300DI

POWER OUTPUT 54.9Kw

MAX TORQUE 244N-m

ROTATION 2600rpm

3.2.4 ELECTRIC SYSTEM

ITEM SWL 3210

Battery 80Ah or 100Ah

Alternator 12V-45A

Starter motor 12V-3.0A

SWL3210 Service Manual

23

System voltage 12V

Current total 25A

3.2.5 PNEUMATIC

ITEM Pressure

10X16.5 PR10 CHAOYANG 60PSI

12X16.5 PR10 CHAOYANG 60PSI

10X16.5 PR10 MECHILIN 65PSI

12X16.5 PR10 MECHILIN 65PSI

10X16.5 PR10 SOLIDEAL 65PSI

12X16.5 PR10 SOLIDEAL 65PSI

3.2.6 OILS AND COOLANT

z Use only oil and coolant recommended in this manual.

z Use different oils could reduce the efficiency of the machine or even damage the

machine.

OILS, COOLANT AND FUELS SPECIFICATION

Hydraulic Oil

TOTAL AZOLLA ZS46,

MOBIL AW46

Engine Oil

MOBIL DELVAC1330,

ESSO LUBE D-3 10W 30

Engine Coolant

TOTAL MULTIS EP2,

ESSO BEACON EP2

Travelling Mechanism Oil

TOTAL AZOLLA ZS46,

MOBIL AW46

Fuel Diesel Fuel 0#

z Do not mix different kind of oils. If you have oil different from the current oil,

remove all the oil inside the machine.

3.2.7 CAPACITIES

ITEMS CAPACITY (Litre)

Model SWL3210

Hydraulic oil tank 65

Hydraulic system

(Pipes+Tank+Cylinders)

100

Engine coolant 3.5

Engine oil 13.2

Fuel tank 85

Travelling Mechanism 2X15

SWL3210 Service Manual

24

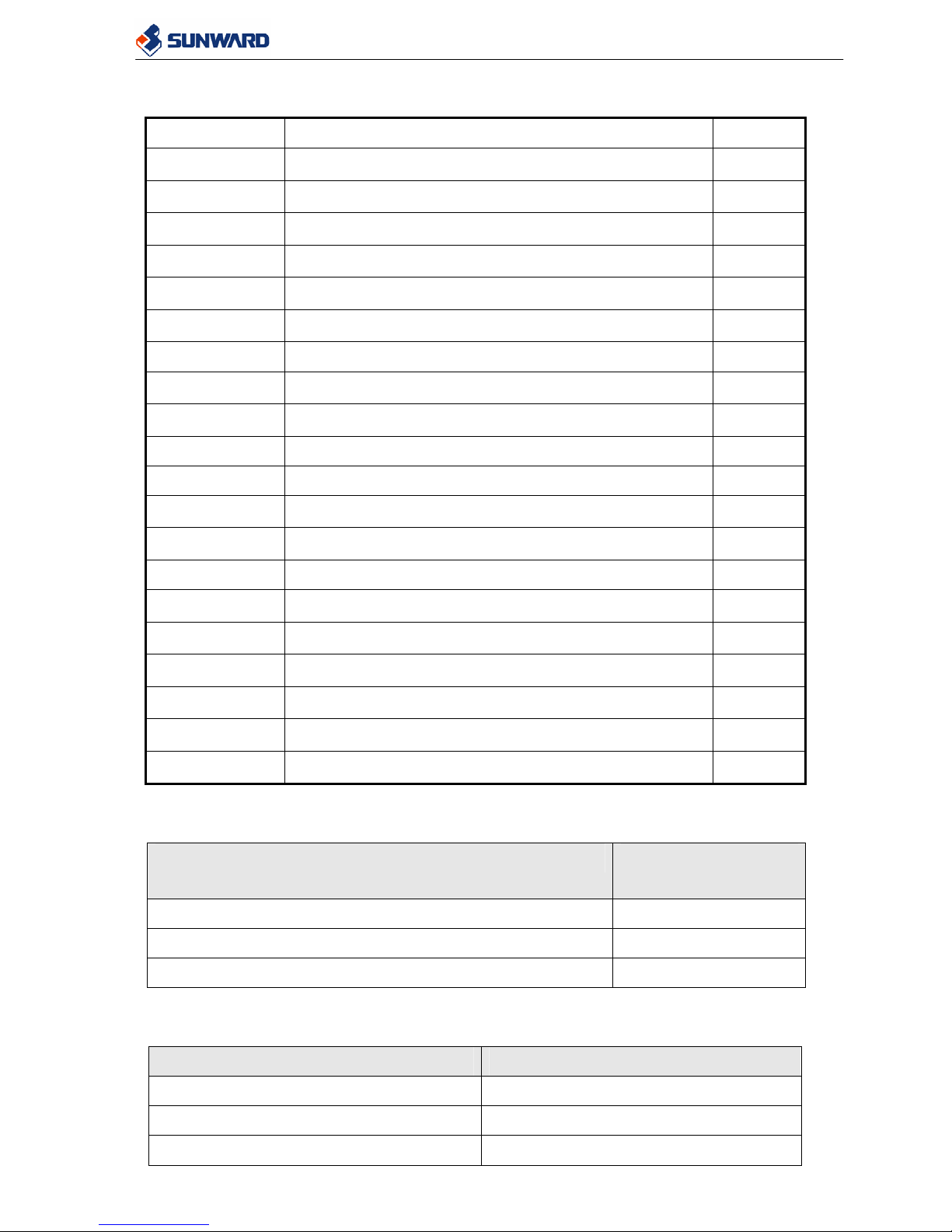

3.2.8 TORQUE FOR SCREWS

Unless other specification, tighten the nuts and bolts according to the torques shown in the

below table. Tighten the goods by the wrenches with gauge.

Thread Diameter (mm) Quality 8.8 Torque (Nm) Quality 10.9 Torque (Nm)

M 6 9~12 13~16

M 8 22~30 30~36

M 10 45~59 65~78

M 12 78~104 110~130

M 14 124~165 180~210

M 16 193~257 280~330

M 18 264~354 380~450

M 20 376~502 540~650

M 22 512~683 740~880

M 24 651~868 940~1120

M 27 952~1269 1400~1650

M 30 1293~1723 1700~2000

When tighten parts of the machine made by steel be careful to not tighten it too strong,

since you could damage this parts.

SWL3210 Service Manual

25

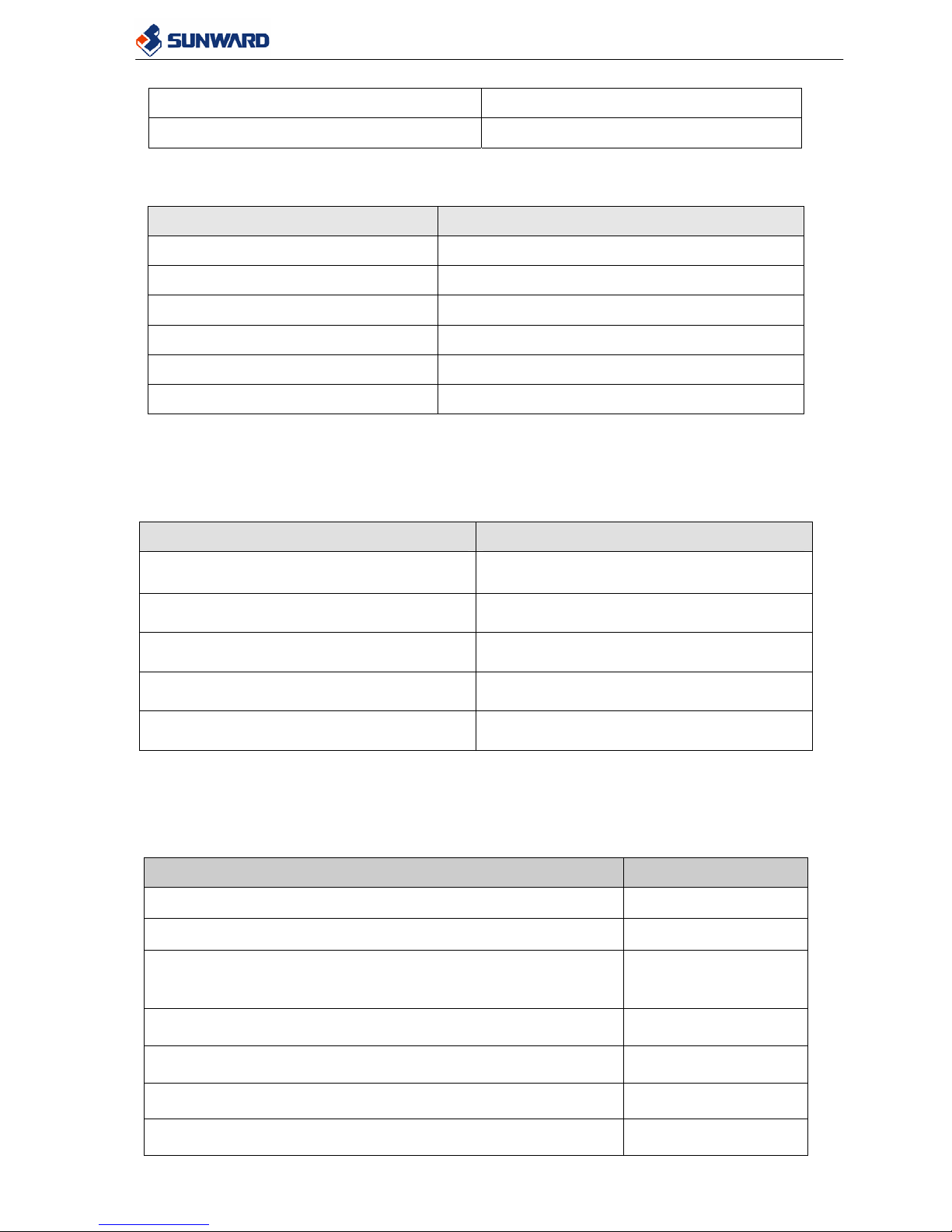

3.2.9 LUBRICATION POINTS

The following drawing shows the main lubrication points.

SWL3210 Service Manual

26

4 HYDRAULIC SYSTEM

4.1 MAIN TRAVEL PUMP

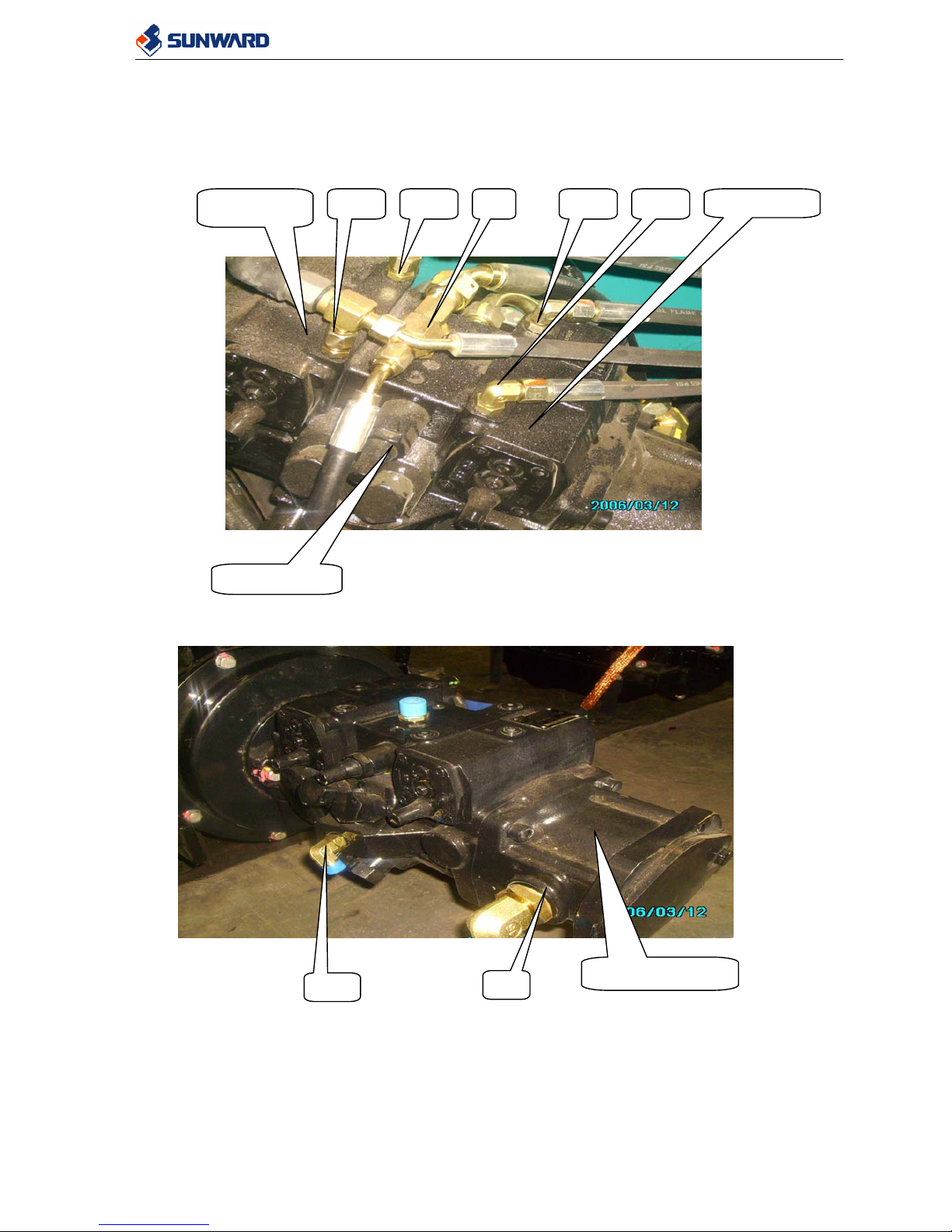

4.1.1 ILLUSTRATION OF MAIN TRAVEL PUMP COMPONENTS

Front pump

Rear pum

p

S

G1

Charge pump

SWL3210 Service Manual

27

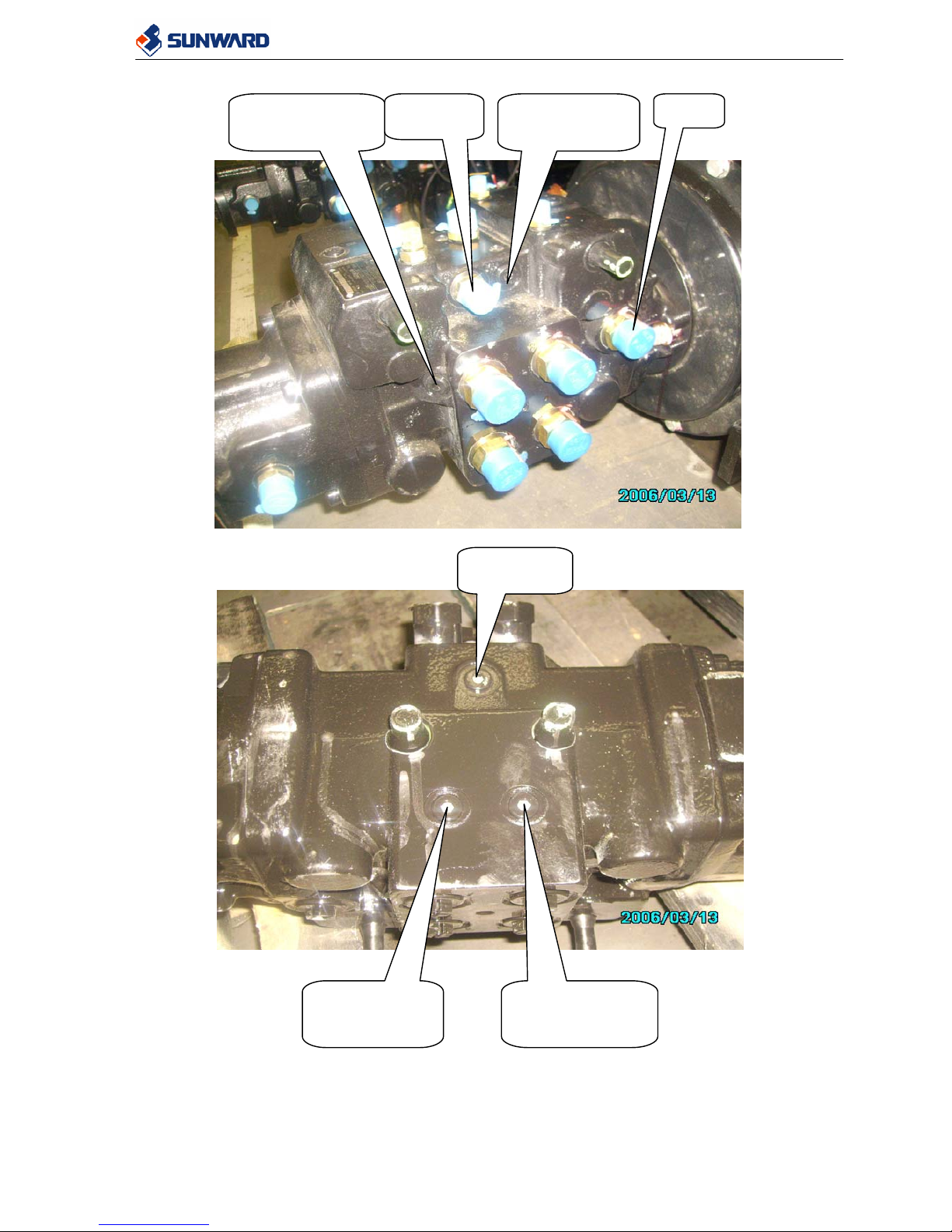

Port A of

rear pump

Port A of front

pump

Port B of front

pump

Port B of

rear pump

Port G2 of

charge pump

Relief valve of

rear pump port B

Relief valve of

front pump port

B

Relief valve of

front pump

p

ort A

Relief valve of

rear pump port A

Relief valve of

charge pump

SWL3210 Service Manual

28

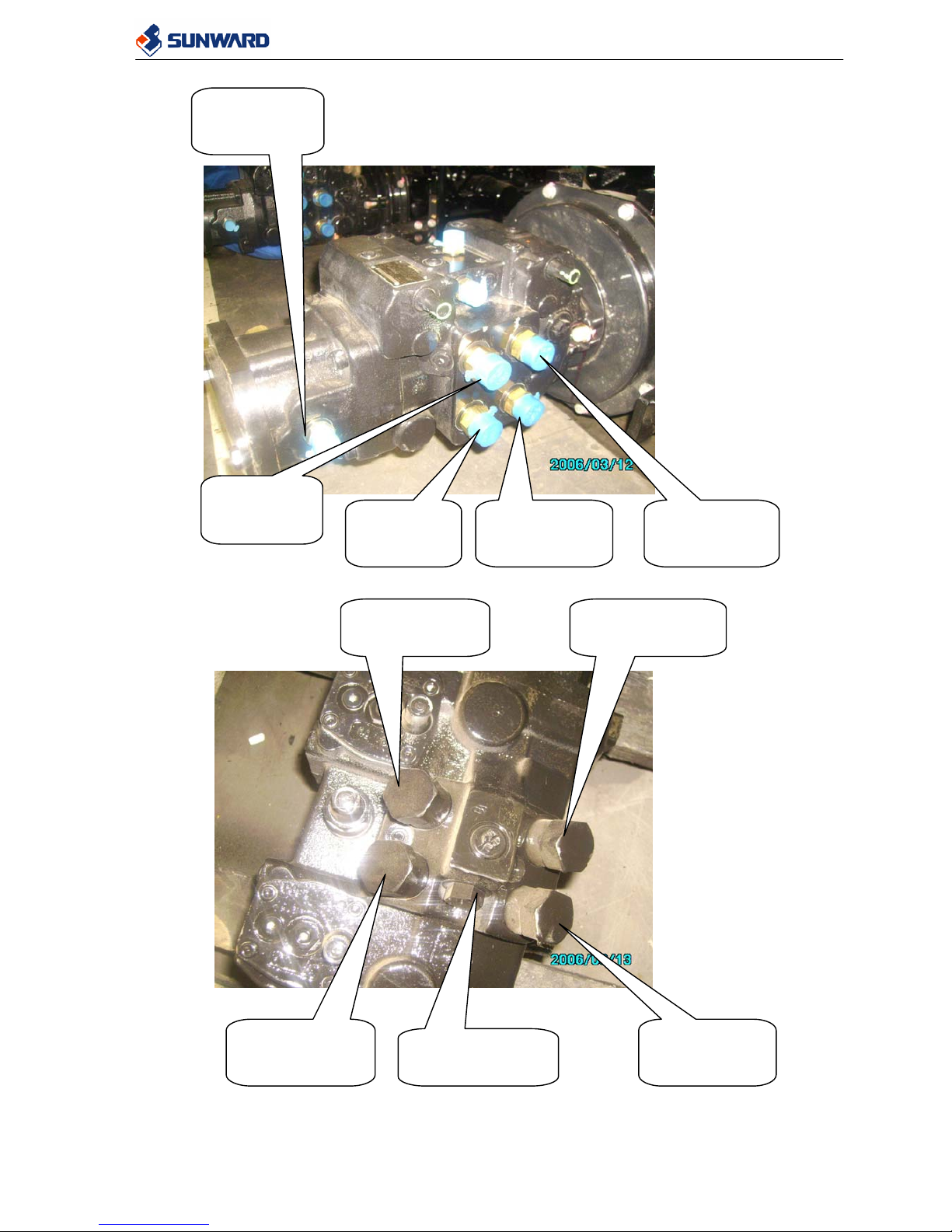

Test port MB of

rear pump B

Test port MB of

front pump B

Port T

Port G

T

est port G

Test port MA

of front pump

A

Test port MA of

rear pump A

SWL3210 Service Manual

29

Bolt of max

displacement of

front pump, A

output

Zero displacement

point adjustment

of front pump

Bolt of max

displacement

of rear pump,

A port output

Zero displacement

point adjustment

of rear pump

Bolt of max

displacement of

rear pump, B port

output

Bolt of max

displacement of

front pump, B port

output

Loading...

Loading...