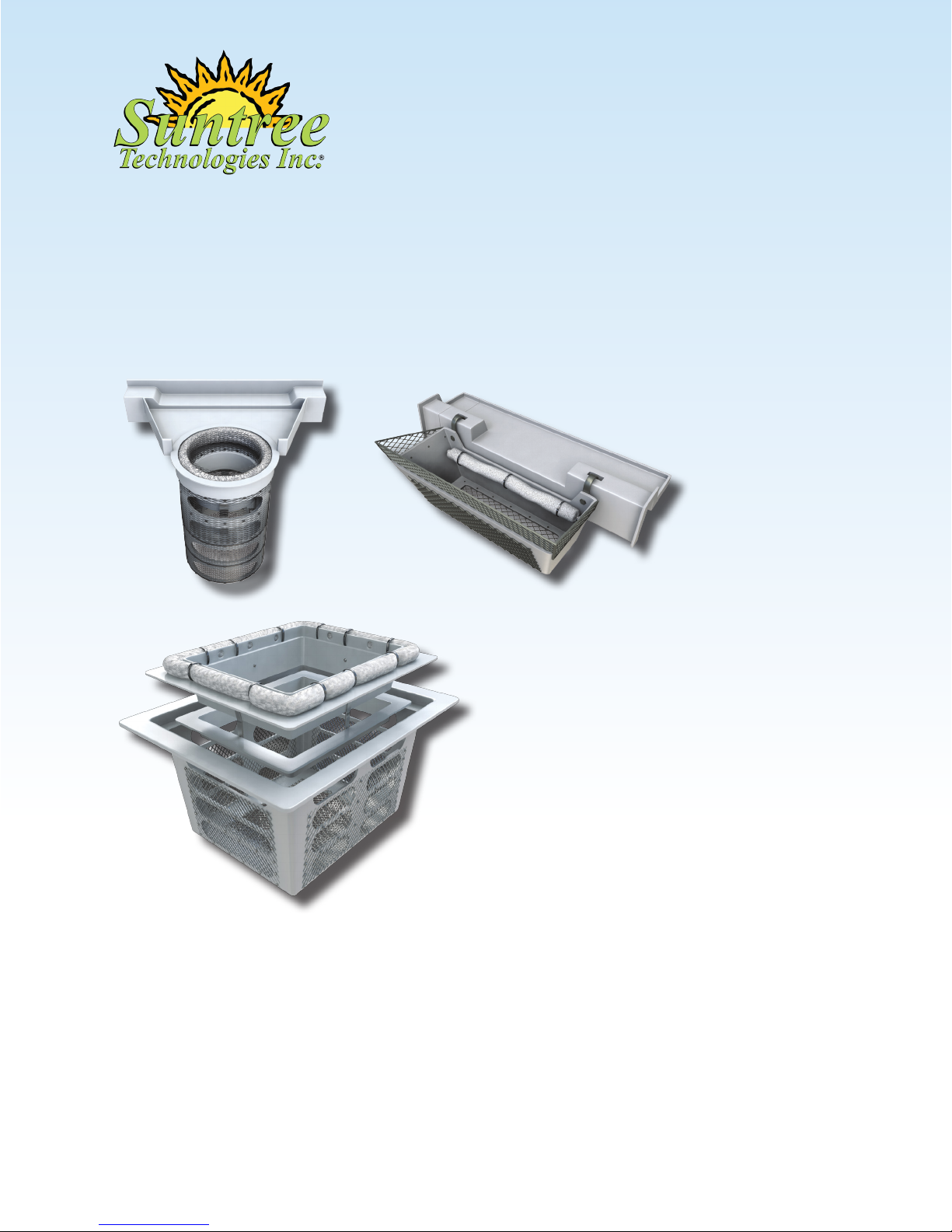

Suntree Technologies Curb Inlet Basket, Grate Inlet Skimmer Box, StormBoom Operation And Maintenance Manual

Inlet Filters | Catch Basin Inserts

Operation and Maintenance Manual

Version 1.0

Suntree Technologies, Inc®

798 Clearlake Road, Suite 2

Cocoa Florida 32922

321.637.7552

www.suntreetech.com

info@suntreetech.com

Table of Contents

Warning pg 03

Curb Inlet Basket™ Information pg 04

Curb Inlet Basket™ Operation pg 05

Curb Inlet Basket™ Maintenance pg 06

Grate Inlet Skimmer Box™ Information pg 07

GISB™ Specifications pg 08

GISB™ Operation pg 09

GISB™ Maintenance pg 10

StormBoom™ Media pg 11

Warranty pg 12

Notes pg 13

Contact Information pg 14

"Innovative Stormwater Management Solutions"

Since 1993

Warning

Read the Following Information, Instructions and

Warnings Before Inspecting, Cleaning or Performing

Maintenance on this Stormwater Treatment Device.

This manual is intended to explain the specifics of the

Suntree Technologies, Inc® Grate Inlet Skimmer Box™,

High Capacity Curb Inlet Basket™ and Standard Capacity

Curb Inlet Basket™ while reviewing the aspects of existing

regulations and safety procedures. It is the responsibility of

all personnel to familiarize themselves with, understand

and comply with all applicable local, state and federal laws

before attempting to inspect or service this unit.

All precautions and procedures in this manual are current

at the time of printing but are subject to change based

on the development of new processes and procedures.

Suntree Technologies, Inc.® assumes no responsibility

and is not accountable for any injuries, fines, penalties

or losses that occur involving any procedure in this

manual or other unaddressable actions taken.

The Grate Inlet Skimmer Box™, High Capacity Curb

Inlet Basket™ and Standard Capacity Curb Inlet Basket™

performance is based on the procedures being followed in

this manual. Non-Compliance with the outlined measures

will be the responsibility of the owner.

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 03

Curb Inlet Basket™ Information

Standard Capacity Curb Inlet Basket™ and

High Capacity Curb Inlet Basket™ Information

The Standard Capacity Curb Inlet Basket™ (used in

shallow catch basins) and High Capacity Curb Inlet Basket™

(used in deep catch basins) are specialized inlet filters used

specifically for curb inlets where the only access element is

a manhole. Both units are made of UV Coated marine grade

fiberglass and stainless steel to ensure longevity and

durability. Stormwater flow is directed into the filtration

basket via a shelf system that is located directly under the

manhole for easy access. Under high volume flows, the

water can bypass the filtration system by simply flowing

past the filter and into the catch basin.

Benefits

• Will not impede design flow of the inlet.

High Capacity Curb Inlet Basket™

with built in shelf system for ease

of installation and service. For use

in deep catch basins.

• Removes more than 80% of total suspended solids.

• The High Capacity Curb Inlet Basket is able to retain

hundreds of pounds of debris and sediment.

• Screens of different sieve sizes optimize filtration and flow.

• Bypass openings prevent clogging.

• Multi stage filtration captures hydrocarbons, sediment, litter

and foliage.

• No need to enter the confined space of the catch basin.

• Easily serviced by vacuum truck.

Standard Capacity Curb Inlet

Basket™ with built in shelf system

for ease of installation and

service. Typically used regularly

in shallow catch basins.

Curb inlet where servicing can only occur via

access from the manhole.

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 04

Curb Inlet Basket™ Operation

Operation Summary

The Curb Inlet Basket™ (CIB™) and High Capacity Curb

Inlet Basket™ (HCCIB™) are unique for their “Shelf System”

which directs stormwater flow into the filter positioned

directly under the access manhole. The Shelf System

can be manufactured to any size and style of catch basin.

The CIB™ and HCCIB™ are multi stage filtration systems

that can capture a variety of pollutants during a storm:

1 Stormwater carrying debris and pollutants enters the

inlet through the curb.

2 An adjustable throat width funnels water to the weir.

The immediate drop in the throat elevation prevents

head loss through the inlet. This allows sediment to

collect along the incoming side of the weir.

3 The water then flows over the weir and into the removable

filtration basket, filtering out trash, foliage and sediment.

Furthermore, If a StormBoom™ is installed, it will filter out

any hydrocarbons from the stormwater as it flows into the

filtration basket.

4 Filtered water leaves the basket and enters the catch basin

where it flows down stream. The position of the curb inlet

basket high in the catch basin allows for captured debris

to dry between storm events as well as avoid restriction to

any up stream pipes.

High Capacity Curb Inlet Basket™

after storm event containing

dry foliage and debris ready for

collection and disposal.

Standard Capacity Curb Inlet

Basket™ removed from shelf

inside inlet. The filtration basket

holds dried debris ready to be

disposed of and screen cleaned.

Curb Inlet Basket™ operation diagram depicting water flow.

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 05

Curb Inlet Basket™ Maintenance

Maintenance Summary

Heavy equipment is not required and the use of a vacuum

truck is optional when servicing the CIB™. Whether servicing

manually or with a vacuum truck, the 15 minute cleaning

time facilitated by the Shelf System eliminates the need for

confined space entry.

Manual Servicing

• Remove the manhole cover.

• Remove filtration basket either by hand or with

manhole hook tool.

• Cut zip ties, remove StormBoom™ and dispose.

• Attach new StormBoom™ with zip ties.

• Brush filtration basket screens clean if necessary.

• Replace filtration basket and replace manhole cover.

Vacuum Servicing

• Remove the manhole cover.

• Cut zip ties, remove StormBoom™ and dispose.

• Reach into filtration basket with vacuum truck hose and

suction out debris.

• Attach new StormBoom™ to skimmer tray with zip ties.

• Replace filtration basket and replace manhole cover.

Standard Capacity Curb Inlet

Basket™ installed under the

manhole cover, full of trash and

debris and ready for servicing.

High Capacity Curb Inlet Basket™

full of debris and needs to be

cleaned. The StormBoom™ is

discolored indicating the need

for necessary replacement.

The shelf system allows for easy access to each

Curb Inlet Basket™ for manual servicing.

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 06

Grate Inlet Skimmer Box™ (GISB™)

General Information

The Grate Inlet Skimmer Box™ (GISB™) is a specialized inlet

filter used specifically for grated catch basins. The unit is

made of marine grade fiberglass and stainless steel to

ensure longevity and durability. During a storm event, all

incoming stormwater passes through the internal skimmer

tray and into contact with a hydrocarbon absorption boom.

Stormwater and solid material then fall into the lower

section of the skimmer box where small sieve sized filters

capture and retain all solids. Turbulence deflectors within

the filtration box act to calm the water and allow for a

greater removal efficiency. Purified stormwater is thus

able to pass into the catch basin system allowing the

filters to dry after each storm event.

Benefits

Grate removed and prepared

for installation of the Grate Inlet

Skimmer Box™.

• Will not impede design flow of the inlet.

• Captures hundreds of pounds of debris and sediment.

• Screens of different sieve sizes optimize filtration and flow.

• Bypass openings prevent clogging.

• Interior components are easily removed to allow access to

the lower chamber.

• Removes more than 80% of total suspended solids

• No need to enter the confined space of the catch basin.

• Easily serviced by vacuum truck.

Grate Inlet Skimmer Box™

filtration basket installed into

the grate inlet.

Grate Inlet Skimmer Box™

skimmer tray installed into the

filtration basket and ready for use.

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 07

GISB™ Specifications

Common Size GISB™ Flow Rate Specifications

The maximum flow rate of the Grate Inlet Skimmer Box™

is determined by the amount of flow that can pass through

the throat, the exception is found only in very large units.

For instance, if the potential flow through the throat is less

than the potential flow through the bypass, then the throat

determines the maximum flow. However, if the potential

water flow through the bypass is more than the throat,

then the bypass determines the maximum flow. Filtered

flow represents the potential flow rate through all screens

and does not include the potential flow through the bypass.

Water flow through the bypass happens only when the

flow rate through the grate exceeds the flow rate through

all the screens or the filtration basket is full.

GISB

Model #

12-12-12 12 12 12 0.5 2.1 1.0

15-30-25 15 30 25 0.54 18.5 6.6

I-24-24-25 24 24 25 4.4 4.0 4.0

A-24-37-25 24 37 25 10.2 21.1 8.7

C-28-37-25 28 37 25 12.2 19.4 7.4

36-36-25 36 36 25 18.8 23.4 13.4

E-36-54-18 36 54 18 37.6 27.8 15.0

S-46-39-18 46 39 18 38.2 28.1 14.8

F-48-30-18 48 30 18 22.5 22.6 10.4

Width

(Inches)

Length

(Inches)

Depth

(Inches)

Throat Filtered

Flow

(cfs)

Bypass

Flow

(cfs)

G-52-58-18 52 58 18 89.3 40.1 25

H-78-36-18 78 36 18 67.1 50.6 25.1

*GISB™ flow rates are based on common size units,

however, custom size units are available.

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 08

GISB™ Operation

Operation Summary

1 Stormwater enters the inlet through the grate and passes

through the StormBoom™ installed around the basket top.

2 Throughout the storm event, water continues to come in

contact with the StormBoom™ and then flows into the

lower filtration chamber.

3 As the storm intensity increases, the water level in the

GISB™ rises to an adjacent level with the medium size

sieve screens and turbulence deflector.

4 If the storm intensity becomes a high flow event, the water

level in the GISB™ rises to a level adjacent to the coarse

sieve size screens above the turbulence deflector.

5 If the stormwater flow rate is extreme or the GISB™ is full

where it exceeds flow through all the screens, the water

will bypass the screens by passing through skimmer

protected openings at the top of the GISB™.

6 After the storm event has subsided, the stormwater

will drain from the GISB™, leaving all collected debris

suspended in the basket to dry until removal during

routine maintenance.

GISB™ after storm event, full of debris and discolored StormBoom™

indicating the need for service and replacement.

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 09

GISB™ Maintenance

Maintenance Summary

The Grate Inlet Skimmer Box™ is recommended to be

inspected and serviced quarterly. However, site conditions

can affect the service interval to be either longer or shorter

than the quarterly recommendation. The maximum flow

capacity of the Grate Inlet Skimmer Box™ will be restored

after each servicing. The flow rate through the unit will be

the same as a new one no matter the times serviced due

to the durable stainless steel construction of the GISB™

The unit can easily be serviced manually or with the

assistance of a vacuum truck.

Manual Servicing

• Remove the grate.

• Remove the skimmer tray.

• Cut zip ties, remove StormBoom™ and dispose.

• Remove and dispose of debris in skimmer tray.

• Attach new StormBoom™ to skimmer tray with zip ties.

• Remove filtration box, dispose of debris and brush screens.

• Replace filtration box into inlet, replace skimmer tray into

filtration box and replace grate.

Vacuum Servicing

• Remove the grate.

• Remove the skimmer tray.

• Cut zip ties, remove StormBoom™ and dispose.

• Remove and dispose of debris in skimmer tray.

• Attach new StormBoom™ to skimmer tray with zip ties.

• Reach into filtration box with vacuum and suction out debris

and clean screens with spray wand or brush.

• Replace filtration box into inlet, replace skimmer tray into

filtration box and replace grate.

Grate Inlet Skimmer Box™

filtration basket removed by hand

for manual disposal of debris and

basket cleaning.

Grate Inlet Skimmer Box™

filtration basket being cleaned via

vacuum truck hose and screens

washed with spray wand.

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 10

StormBoom™ Media

Hydrocarbon Absorption Booms

Suntree Technologies Inc.® manufactures various

media based StormBooms™ designed to filter a

variety of pollutants. There are four types of media

that StormBooms™ can be made of including:

• Type 1: Hydrophobic Treated Cellulose is a wide

spectrum absorbent with a large sieve covering

capable of absorbing chemicals other than oils

and hydrocarbons. This media is a cellulose filler

made from reclaimed paper mill by-products.

Liquids are drawn into the cellulose fibers through

capillaries and are encapsulated in the boom. It is

recommended that this type of boom should be

replaced every 3 to 4 months.

• Type 2: Melt Blown Polypropylene with a large size

sieve covering which is limited to hydrocarbon

absorption but will not biodegrade. This type of

boom is recommended to be replaced every 3 to

4 months or when it starts to look darkened.

• Type 3: 50 – 50 blend of Hydrophobic Treated

Cellulose and Melt Blown Polypropylene with a

large sieve sized covering. This boom offers wide

spectrum absorption with an extra emphasis on

hydrocarbons. This boom is vastly effective in high

pollutant areas such as repair facilities and gas

stations. It is recommended that this type of boom

be replaced every 3 to 4 months.

• Type 4: Polymer Crumb Filler with a fine sieve size

covering. This media will not absorb water and

can float indefinitely as well as not biodegrade.

This media is limited to hydrocarbon absorption

which occurs on contact by chemically bonding

with hydrocarbon molecules. This type of boom

should be replaced every 3 to 4 months or as

needed, when it starts to darken in color.

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 11

Warranty

Warranty Information

Suntree Technologies, Inc® products are engineered and

manufactured with the intent of being a permanent part of

the infrastructure. Suntree Technologies, Inc® warranties

its products to be free from manufacturing defects for a

period of five (5) years from the date of purchase.

In the event a warranty claim is made and determined

to be valid, Suntree Technologies will replace or repair

the product at their own discretion. Warranty claims

must be submitted, evaluated and approved by

Suntree Technologies for the claim to be determined

valid. All warranty work must be authorized by Suntree

Technologies prior to work beginning not covered by

this warranty. There are no warranties expressed or

implied other than what is specified herein.

Abusive treatment, neglect or improper use of the

Curb Inlet Basket™, High Capacity Curb Inlet Basket™

or Grate Inlet Skimmer Box™ will not be covered.

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 12

Notes

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 13

Contact

General Inquires

For additional information concerning general usage,

maintenance products, warranties or replacement parts

please contact:

Suntree Technologies Inc.®

798 Clearlake Road, Suite 2

Cocoa, Florida 32922

Phone: 321.637.7552

Fax: 321.637.7554

Web: www.suntreetech.com

Email: info@suntreetech.com

Visit our website for in depth information

on all of our products!

Inlet Filters | Catch Basin Inserts Operation and Maintenance Manual 14

Loading...

Loading...