Suntrap ST-250-32, ST-315-48, ST-160-16, ST-160LPG21-16, ST-250NG26-32 Installation Instructions And Owner's Manual

...Page 1

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

Solar Hot Water

Installation Instructions

and Owners Manual

AS 2712 Lic 21687

SAI Global

WMKA Lic 21688

SAI Global

This Manual Covers 10 system models:

Electric Boost Models:

ST-160-16: ST-250-32: ST-315-32: ST-250-48: ST-315-48

December 2010 issue 10.4

Suntrap Pty Ltd

PO Box 3164

Dural

NSW 2158

Tel: 02 9651 2866

Gas Boost Models:

ST-160NG21-16 / ST-160LPG21-16: ST-250NG26-32 / ST-250LPG26-32

ST-315NG26-32 / ST-315LPG26-32: ST-250NG26-48 / ST-250LPG26-48

ST-315NG26-48 / ST-315LPG26-48

Plumbers/Installers – Please read this Manual

before attempting the installation of the Suntrap

Solar Hot Water System

Page 2

1

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

Contents

1 Suntrap Solar Hot Water systems - Renewable Energy Certificates

2 About your Suntrap Solar Hot Water System

3 Suntrap Solar Hot Water Kit – Parts supplied

4 Schematic Diagram of the Suntrap Solar Hot Water System

5 Completed installation views of assembled parts

6 The Suntrap Solar Control Kit

7 Connections to the Suntrap Solar Collectors

8 Connections to the top of the Solar Hot Water Tank

9 Connections to the middle and bottom of the Solar Hot Water Tank

10 The completed Solar Hot Water Tank assembly

11 Check list immediately prior to commissioning System

12 Instructions for assembling and fitting the solar collectors

13 Completing the installation

14 Priming and filling the system

15 Specifications of the Suntrap Evacuated U Tube Solar Collector SLU-1500/16

16 Warranty and Refund Policy

Page 3

2

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

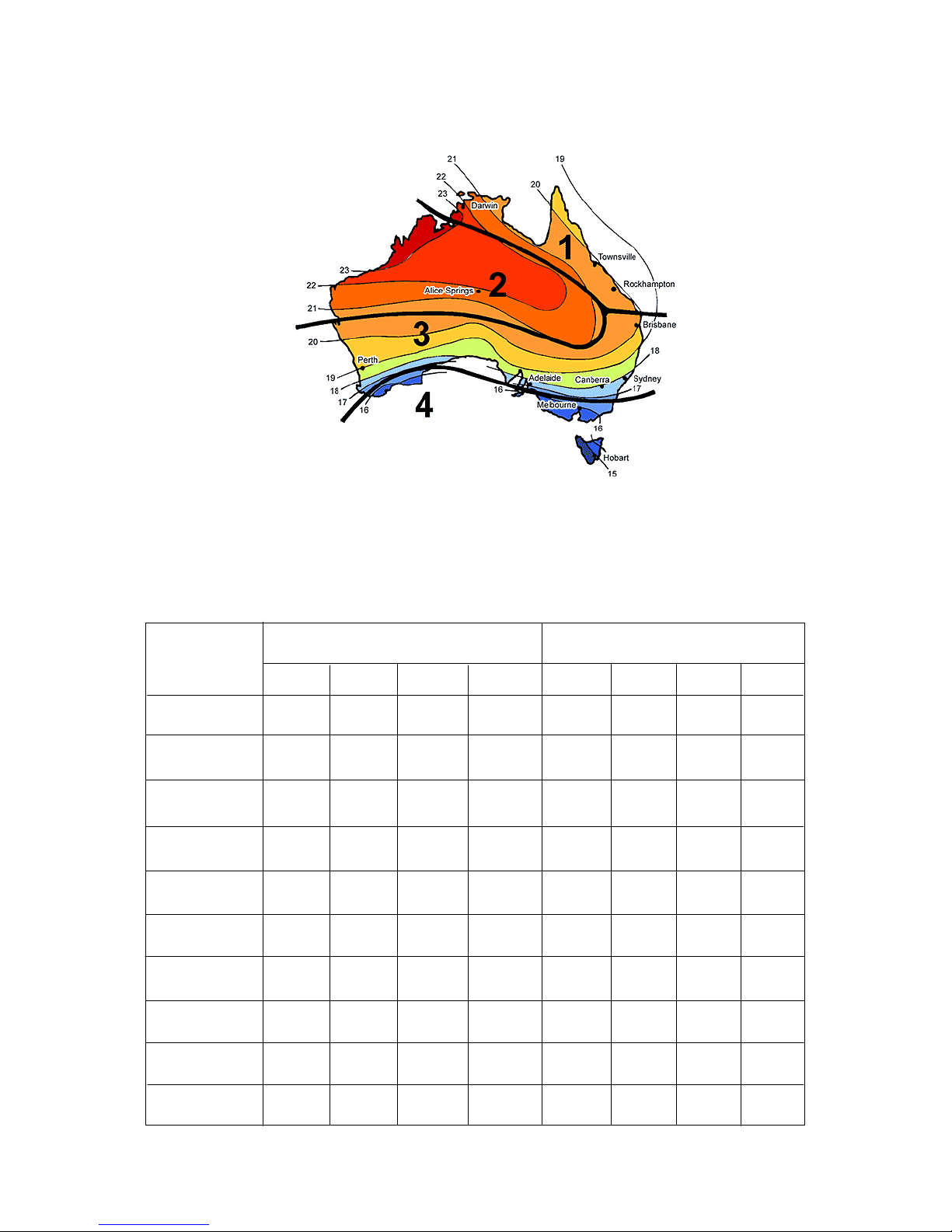

AS/NZS 4234:2007 Climatic Zones

Used in determining the Renewable Energy Certificates across Australia

1. Renewable Energy Certificates

Calculated Renewable Energy for Suntrap Pty Solar Hot water Products

The following table presents the calculated RECS and annual energy saving for the different

Suntrap solar configurations using SLU-1500/16 type evacuated tube collectors

Configuration

Annual Energy Saving (%)

10 Year Renewable Energy

Certificate Allocation

Zone 1

Zone 2

Zone 3

Zone 4

Zone 1

Zone 2

Zone 3

Zone 4

ST-160NG21-16 &

ST-160LPG21-16

ST-250NG26-32 &

ST-250LPG26-32

ST-250NG26-48 &

ST-250LPG26-48

ST-315NG26-32 &

ST-315LPG26-32

ST-315NG26-48 &

ST-315LPG26-48

ST-160-16

ST-250-32

ST-250-48

ST-315-32

ST-315-48

53

61

53

41

22

22

22

18

64

75

78

64

49

37

38

37

30

38

38

45

44

45

63

71

58

30

25

30

30

31

29

30

45

45

45

29

15

16

57

11

29

49

33

78

37

63

37

37

35

35

33

35

24

29

57

71

82

63

77

42

35

69

15

84

83

93

83

83

70

70

93

82

56

74

63

87

73

71

77

88

RENEWABLE ENERGY CERTIFICATES

Page 4

3

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

The water heater boost should remain on unless you plan to be away from home for length of time.

If you need to switch the system off (system close down), switch off the electrical water heater isolating switch

(electric element boost heating), switch off the power to the Solar Control Unit (solar heating), Shut off the cold waterin to the DuoValve (point C) and close the Shut-off ball valve (point E) on the Solar control kit.

To turn on the water heater

Open the DuoValve (point C),- this allows cold water to enter the solar tank, switch on the Solar Control Unit and

open the Shut-off ball valve (point E) on the Solar Control kit, If the solar collectors have been drained then follow the

instructions in section 14 of this document (14. Priming and filling the system).

Heater Boost control

Under ideal conditions, your solar hot water will be kept up to temperature by the solar collectors. However on cloudy

and overcast days and during the winter months, the boost heating element inside the solar water tank (electric boost

systems) may be activated to maintain your water temperature. The heating element (immersion heater), must have

its own dedicated electrical supply and must remain connected to the electrical supply at all times.

Water pressure

The water pressure used with this Solar Hot Water system must be a minimum of 200kpa.

Tank Sizes

160 litre 1140mm(h) x 580mm dia. 250 litre 1620mm(h) x 580mm dia. 315 litre 1980mm(h) x 580mm dia.

Solar collector roof space required

1 collector 1.2m(w) x 1.8m(h) 2 collectors 2.4m(w) x 1.8m(h) 3 collectors 3.6m(w) x 1.8m(h)

Note:

All installations must be carried out by authorised plumbers or other authorised persons.

Installer - Please familiarise yourself with all the diagrams and pictures before starting to connect the system

together. Installation instructions begin at section 10.

Some diagrams/pictures are representative only and some pictures are shown before pipe insulation has

been fitted for clarity. To comply with AS2712 certification, the plumbing between the solar hot water tank

and the solar collectors must be installed using 12mm internal pipe diameter with insulation thickness of

40mm on the inlet pipe and 12mm internal pipe diameter with insulation thickness of 40mm on the outlet

pipe, both pipes using insulation material to ISOpipe insulation standards. For Gas Boosted systems the

pipe between the Solar preheat tank and Gas Booster must use Armaflex 32mm thickness insulation.

2. About your Suntrap Solar Hot Water System

Congratulations for choosing a Suntrap Solar Hot Water System. All the systems are designed to have the Solar Collectors

mounted on the roof, and the Solar tank installed at ground level. Three sizes of Everlast Stainless steel solar hot water tanks

are used and have either an electric or gas boost as supplementary heating sources. Tanks have capacities of 160, 250 or

315 litres with either a 3.6 KW heater, or a Bosch 21e/26e gas heater.

The Solar Tanks are suitable for installations either inside or outdoors. If the area in which the system is to be installed is subject to

freezing conditions, then the hot and cold solar copper pipes must be fully insulated with closed cell polymer insulation to offer

protection against freeze damage.

All electrically boosted Suntrap Solar Hot Water systems are certified to be connected to a dedicated Off Peak 1 electrical supply.

Risk of scalding

Be aware that the solar hot water temperature can cause scalding. Check the temperature before use. A temperature limiting

device (Tempering Valve) is provided with all Suntrap Solar Hot Water kits and must be fitted to avoid very hot water from the

hot taps (bathrooms, showers etc.)

Temperature adjustment

On electrically boosted systems, the solar tank thermostat determines the tank temperature during off-peak boosting and may be

adjusted by a licensed tradesperson if required. The Tempering Valve is required to prevent scalding as solar hot water can

be much hotter than just electrically heated water. The Solar Control Unit will control the solar pump to circulate the water

when there is a temperature difference of 9 degrees centigrade or more between the tank temperature and the solar collector

outlet temperature, or when the temperature of the solar collectors are +3 degrees centigrade (to prevent the solar collectors

from freezing).

The Solar Tank thermostat temperature has been factory set and should not require adjustment. The water heater is supplied with

a Pressure and Temperature Relief valve (PTR 850 Valve) which must not be tampered with.

Safety

The tank is supplied with a Pressure and Temperature Relief valve, a Pressure Limiting Valve, and a thermostat. These devices

must be kept in working order at all times. High temperatures can exist in the solar pipes and precautions must be taken to

avoid young children touching them.

If any power cords or plugs are damaged, then these must be replaced by a licensed electrician.

To turn off the hot water

Page 5

4

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

Thermostat setting (Electric Boost) – Higher tank temperatures during boost times may be obtained by the adjustment of the

tank thermostat (by a qualified electrician/tradesperson). Please also note that all hot water will be tempered through the

Tempering Valve to prevent scalding from the solar hot water.

Holidays – When away for a period of time, close the system down. Switch off and unplug the solar controller and move the Shut

off ball-valve at point E to the off position, turn off the ‘mains water in’ at the DuoValve at point C, switch off the ‘off peak’ booster

supply. If freezing conditions are expected while away, leave the solar controller switched on and the Shut off ball-valve (point E)

switched on, so the Solar Hot water system will automatically defrost the Solar collectors as required, otherwise drain the solar

collectors and close the system down as above.

Installation Notes

In the Sydney area the ideal orientation and angle to mount the solar collectors for the winter sun (best for all round

performance) is for the solar collectors to face True North (approx 11 degrees West of Magnetic North) at an angle of 33

degrees. Suntrap U Tube collectors will also work horizontally at an efficiency of 84%, Standard roofs of 26 degrees will provide

an efficiency of approx 97%.

The system is designed to operate with the solar collectors installed on a roof at a height greater than the top of the solar hot

water tank, with the solar hot water tank installed at ground level. Insulated copper pipes to and from the solar collectors must be

direct, and each direction (flow and return) must always run in a continuous rise and fall situation.

The solar collector should be mounted so the Manifold is at the top (higher) level than the bottom of the collector.

The tank must be located onto a firm base and sufficient space must be provided around the solar hot water tank for servicing.

The Solar Hot Water system uses a different number of solar collectors depending on the system model being installed and the

maximum pipe lengths to and from the solar collectors should not exceed 40 meters. Keep the number of 90 degree bends in the

pipe work to the minimum. The system must be installed with all copper piping (with insulation thickness of 40mm all the way to

the solar collectors and back to the solar hot water tank, and for Gas Boosted systems use insulation thickness of 32mm on the

pipe between the Solar Preheat Tank and Gas Booster), brass fittings, W62 and W63 brass fittings, Conetite unions, and/or

brass fittings with copper olives.

Warning - Roof assembly and installation of the solar collectors should be undertaken in cool conditions (early

morning) as the fittings can get too hot to handle and could cause injury if touched.

Warning – When purging the system using the purge valve at point G, extreme caution must be taken as water expelled

at this point can be extremely hot. This is best carried out when the solar collectors are cool.

The installation must comply with the requirements of AS/NZS 3000 and AS/NZS 3500.4.

If the tank is to be installed inside a property, then it must be installed in a ‘safe tray’, so that in the event of a leak, the property

will not be damaged by water (AS/NZS 3500.4). Draining of the ‘safe tray’ must also comply with AS/NZS 3500.4.

Caring for your system

At the top of the Solar hot water tank there is an 850kpa Pressure and Temperature Relief valve, and it is possible from time to time

that a small amount of water will escape from this valve when the water inside the tank expands during heating periods. This is quite

normal. Every 6 months this valve should be manually operated to ensure that it is in working order. If at any time you believe that

your Suntrap Solar Hot Water system is not functioning correctly, then please give us a call.

Regular Care: Pressure and Temperature Relief (PTR) Valve: This valve is next to the top pipe of the solar tank at point J. The valve

should be checked at regular intervals and replaced every 5 years. To check that the valve is working properly, gently lift the lever

until water flows, then gently let the lever return to its original position. (See Loosing water from the Expansion Control Valve below)

Collector Glass: To assure that maximum efficiency is gained from the Hot water solar system, ensure that the solar collector glass

is kept free of dirt. Hose down the collectors with water and use a soft brush from time to time to keep clean.

Water not hot enough:

This may be caused by the following:

Insufficient sunlight – due to cloudy weather, or cool temperatures during winter – check that the booster heater is working in these

circumstances.

Booster heating not working – check that it is switched on at the electrical distribution panel.

Solar water not hot enough when conditions are good – Check that the solar pump indicator is illuminated on the Solar Control Unit:

Check that the pump is plugged into the Solar Control Unit: Check that the Solar Control Unit is plugged into the electrical supply,

and switched on . Also check that the collectors have unrestricted access to the sun. 2 x solar collectors for a 315 litre tank, with a

3.6 KW boost heater (or a gas booster) is an ideal combination and will provide the solar water temperatures required, under normal

working conditions, if the system is working correctly.

Air in system – Proper circulation of water is not being maintained – Ensure that the air vent is open (point K), then remove (purge)

any air from the system as described in sections 9 and 14. (9. Connections to the middle and bottom of the Solar Tank and (14.

Priming and filling the system)

Excessive use of water – The different Suntrap Solar Hot water System models are designed to cover the requirements of a small to

large number of users, each having their own demand on hot water. A greater demand will cause the water to cool, and longer use of

the booster will be required.

Loosing water from the Expansion Control Valve (Point L) – Arrangements other than Off Peak 1 electrical boosting, especially in

Summer, can result in excessive use of electrical boost heating, leaving the solar heating little to do. This can lead to extremely high

temperatures and water expansion in the solar collectors, resulting in excessive water exit from the Expansion Control

Valve and/or the PTR Valve. Off Peak 1 secondary boosting ensures minimal hours of electrical boosting and maximises the benefits

and efficiency of solar heating obtained from the sun. Suntrap systems are certified to use Off Peak 1 electrical boosting.

Page 6

5

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

Mains water supply:

The system is fitted with a water pressure limiting valve (connected to the DuoValve at point C). This ensures that the tank is never

under excess pressure. The valve is rated at 500 kpa and must never be changed for a higher rating.

Installation of the Solar Hot Water Tank and Solar Collectors:

The Solar Hot water tank and the Solar Collectors are provided as part of the Suntrap Solar Hot water kit, and all components must

be installed, maintained and operated as per instructions otherwise all warranties are null and void.

3. Suntrap Solar Hot Water Kits - Parts Supplied

The Suntrap Solar Hot Water Kits:

All kit components must be used as per supplied. The kit of parts include sub-assemblies which must be fitted complete as supplied.

Suntrap Pty Ltd reserves the right to vary the kit contents and components at its discretion at any time.

There are 10 Suntrap Kits as follows:

(Please note that there are 16 glass evacuated tubes per solar collector.)

Roof space required for Solar collectors:

1 x solar collector 1.2 meters wide x 1.8 meters high

2 x solar collectors 2.4 meters wide x 1.8 meters high

3 x solar collectors 3.6 meters wide x 1.8 meters high

Electric Boost Models:

ST-160-16: 160 litre solar hot water tank with 1 solar collector and electric boost -

1140mm (h) x 580mm (dia)

ST-250-32: 250 litre solar hot water tank with 2 solar collectors and electric boost-

1620mm (h) x 580mm (dia)

ST-315-32: 315 litre solar hot water tank with 2 solar collectors and electric boost-

1980mm (h) x 580mm (dia)

ST-250-48: 250 litre solar hot water tank with 3 solar collectors and electric boost-

1620mm (h) x 580mm (dia)

ST-315-48: 315 litre solar hot water tank with 3 solar collectors and electric boost-

1980mm (h) x 580mm (dia)

Gas Boost Models:

ST-160NG21-16 / ST-160LPG21-16: 160 litre solar hot water tank with 1 solar collector and gas boost -

1140mm (h) x 580mm (dia)

ST-250NG26-32 / ST-250LPG26-32: 250 litre solar hot water tank with 2 solar collectors and gas boost-

1620mm (h) x 580mm (dia)

ST-315NG26-32 / ST-315LPG26-32: 315 litre solar hot water tank with 2 solar collectors and gas boost-

1980mm (h) x 580mm (dia)

ST-250NG26-48 / ST-250LPG26-48: 250 litre solar hot water tank with 3 solar collectors and gas boost-

1620mm (h) x 580mm (dia)

ST-315NG26-48 / ST-315LPG26-48: 315 litre solar hot water tank with 3 solar collectors and gas boost-

1980mm (h) x 580mm (dia)

For 1 x solar collector (ST-160-16: ST-160NG21-16 / ST-160LPG21-16)

Part/n – SET116 1 x complete Suntrap evacuated tube Solar Collector with 16 x evacuated glass tubes

Part/n – SSF001 4 x square sections of stainless steel for Roof Frame (top, bottom and 2 sides)

Part/n – MOU001 4 x brackets and 24 screws for assembling the Roof Frame, 2 x left hand, and 2 x right hand

collector brackets to connect the solar collector to the Roof Frame, 4 x nuts and bolts and

4 x screws for the collector brackets, 4 x stainless steel straps for attaching the Roof Frame

to the roof, 4 x screws for attaching the stainless steel straps to the Roof Frame, 8 x roof screws

for attaching stainless steel straps to the roof rafters.

There are no interconnecting solar collector components required for this system

Page 7

6

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

For 2 x solar collectors (ST-250-32: ST-315-32: ST-250NG26-32 / ST- 250LPG26-32: ST-315NG26-32 / ST-315LPG26-35)

Part/n – SET232 2 x complete Suntrap evacuated tube Solar Collectors, each with 16 x evacuated glass tubes

Part/n – SSF002 4 x square sections of stainless steel for Roof Frame (top, bottom and 2 sides)

Part/n – MOU002 4 x brackets and 24 screws for assembling the Roof Frame, 4 x left hand, and 4 x right hand

collector brackets to connect the solar collectors to the Roof Frame, 8 x nuts and bolts and

8 x screws for the collector brackets, 4 x stainless steel straps for attaching the Roof Frame

to the roof, 4 x screws for attaching the stainless steel straps to the Roof Frame, 8 x roof screws

for attaching stainless steel straps to the roof rafters.

Part/n – FCS002 2 x couplings used to connect the solar collectors together (point N). Includes: 2 x ¾”F x 3/4” CTI

unions, 1 x 82mm x 20mm diameter copper pipe

FCS002 – Coupling components used

to connect 2 x Solar Collectors together

For 3 x solar collectors (ST-250-48: ST-315-48: ST-250NG26-48 / ST-250LPG26-48: ST-315NG26-48 / ST-315LPG26-48)

Part/n – SET348 3 x complete Suntrap evacuated tube Solar Collectors, each with 16 x evacuated glass tubes

Part/n – SSF003 4 x square sections of stainless steel for Roof Frame (top, bottom and 2 sides)

Part/n – MOU003 4 x brackets and 24 screws for assembling the Roof Frame, 6 x left hand, and 6 x right hand

collector brackets to connect the solar collectors to the Roof Frame, 12 x nuts and bolts and

12 x screws for the collector brackets, 4 x stainless steel straps for attaching the Roof Frame to

the roof, 4 x screws for attaching the stainless steel straps to the Roof Frame, 8 x roof screws

for attaching stainless steel straps to the roof rafters.

Part/n – FCS003 4 x couplings used to connect the solar collectors together (points M and N). Includes: 4 x ¾”F x ¾”

CTI Conetite unions, 2 x 82mm x 20mm diameter copper pipes.

FCS003 – Coupling components used to

Connect the 3 x Solar Collectors together

Page 8

7

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

Part/n – EST160 1 x 160 litre Everlast stainless steel solar hot water tank with a single 3.6 KW heating element

or

Part/n – EST250 1 x 250 litre Everlast stainless steel solar hot water tank with a single 3.6 KW heating element

or

Part/n – EST315 1 x 315 litre Everlast stainless steel solar hot water tank with a single 3.6 KW heating element

or

Part/n – GST160 1 x 160 litre Everlast stainless steel solar hot water tank for Bosch 21e gas boost

or

Part/n – GST250 1 x 250 litre Everlast stainless steel solar hot water tank for Bosch 26e gas boost

or

Part/n – GST315 1 x 315 litre Everlast stainless steel solar hot water tank for Bosch 26e gas boost

Part/n – SCU20A Solar Control Kit (assembly), comprising 1 x Solar Control unit, 1 x Solar pump,

1 x ½”F x ½” CTI Conetite union, 4 x screws for attaching to wall

Part/n – SWI00A Solar water Inlet assembly to collectors, 1 x 850 kpa Expansion Control Valve, 1 x 15mm Tee

fitting, 1 x ½”M x ½” CTI Conetight union, 1 x ¾” to 15mm reducer

Part/n – CWI20A 1 x Cold water inlet assembly (point H), comprising 1 x W63 bent brass fitting, 1 x 20mm-

15mm Reducer plus 1 x 15mm copper Tee

Part/n – SWR00A 1 x Solar Collector Outlet assembly (point k), comprising an Air vent, solar collector temperature

receptacle, 1 x 15mm Kinko nut, 1 x 15mm olive, 2 x 15mm Tee fittings, 2 x 15mm nipples,

1 x ½”M x ½” CTI Conetite union, 1 x 15mm-10mm bush, 1 x ¾” to 15mm reducer

Part/n – DUO00A 1 x DuoValve assembly comprising 1 x duo valve, 2 x 15mm nipples, 1 x W62 straight brass fitting

Part/n – PLV00A 1 x Pressure Limiting Valve 500 kpa assembly, 1 x 15mm nipple, 1 x W62 straight brass fitting

Part/n – NRV00A 1 x Solar Return Inlet check valve, 1 x 20mm nipple, 1 x 20mm-15mm nipple, 1 x 15mm brass

Tee, 1 x 15mm brass elbow, 1 x W62 straight brass fitting, 1 x 15mm nipple for W62, 1 x 15mm

purge valve (point G)

Part/n – SOV00A 1 x Shut-off ball valve assembly comprising 1 x ball valve, 1 x ½”M x 1/2” CTI Conetite union

Part/n – END004 4 x plastic end caps for Roof Frame

Part/n – PTR850 1 x 850 kpa Pressure and Temperature Relief valve (point J)

Part/n – BSR00A 1 x ¾ “- ½” reducer, ½ “ nipple, ½” olive, ½ “ Kinko nut, copper sensor receptacle, 1 x Blanking Plug

Part/n – SHW00E 1 x Solar Tank hot water out connection, comprising 1 x 15mm F/F Brass Elbow, 1 x 20mm-

15mm Reducer (point F) - Electric Tank

Part/n – SHW00G 1 x Solar Tank hot water out and Gas Booster connection kit, comprising 1 x ¾” nipple and 1 x ¾” W62

1 x ¾”F to ½” Conetite CTI union, 2 x ¾” No 3, 1 x Water Valve, 1 x Gas Valve, 3 x Teflon washers

Part/n – SEC002 1 x solar tank sensor cable,1 x solar collector sensor cable, 1 x test plug, cable ties

Part/n – SRC00A 1 x Solar recycle outlet connector, comprising 1 x W63 bent brass fitting, 1 x 20mm-

15mm Reducer (point P)

Part/n – TEMP01 1 x Solar Rated Tempering Valve

Part/n – PTFE01 1 x reel of PTFE tape (for 1 or 2 solar collectors)

Part/n – PTFE02 2 x reels of PTFE tape (for 3 solar collectors)

Part/n – BGB21E 1 x Bosch Highflow Gas Boost Heater 21E - (model YE2170RAH - incorporates a Solar Transfer Valve)

Part/n – BGB26E 1 x Bosch Highflow Gas Boost Heater 26E - (model YE2670RAH - incorporates a Solar Transfer Valve)

BGB21E – Bosch Gas Boost Heater 21E

BGB26E – Bosch Gas Boost Heater 26E

For Gas Boost Heater Systems

Page 9

8

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

PTFE001 – Thread Tape

SSF001 - Stainless Steel Frame

SSF002 - Stainless Steel Frame

SSF003 - Stainless Steel Frame

PTFE002 – Thread Tape

SRC00A – Solar recycle outlet

Connector

SOV00A –Shut-off ball valve assembly

PTR850 – Pressure and Temperature

Relief Valve (actual model may vary)

Note: This item is packed behind the electrical

heater accesspanel In the Everlast Electric

boosted Solar Tanks

END004 – Plastic End Caps

for Roof Frame

SET348 - 3 x Solar Collectors

EST315 - Everlast stainless steel

315 litre Solar tank

SET161 - 1 x Solar Collector

SET232 - 2 x Solar Collectors

SHW00E – Electric Boost - Solar Tank Hot Water

out connector (connects to Tempering valve)

SHW00G – Gas Boost - Solar Tank Hot Water

out connector and Gas Booster connection kit

BSR00A – Bottom Sensor Receptacle

and ¾” BSP Blanking Plug

SEC002 – Sensor Cables, Cable Ties

and Test Plug

Page 10

9

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

3. Suntrap Solar Hot Water Kit - Parts supplied (cont)

SCU20A - Solar Control Kit assembly

CWI20A – Cold Water Inlet assembly, and copper Tee

SWR00A- Solar Collector outlet assembly

SWI00A Solar Collector inlet assembly including the

Expansion Control Valve

NRV00A – Solar Return Inlet Non-Return Valve with Purge

Valve assembly (Solar hot water in to Solar Tank

)

DUO00A DuoValve assembly (actual model may vary)

PLV00A – Mains water inlet Pressure Limiting Valve

assembly

TEMP01 – Solar Rated Tempering Valve

(fitted to the Hot water outlet to the bathrooms)

Page 11

4. Schematic Diagram of the Suntrap Solar Hot Water System (Electric Boost)

10

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

Schematic Diagram of the Suntrap Solar Hot Water System (Gas Boost)

Solar

Pump

Solar

Control

Unit

Solar

Collector

Solar

Collector

Hot Water Out

to taps

Tank temperature sensor

Pump

Control

Connection

Solar Hot Water Out

Non Return Valve

and Purge Valve

(G)

F

E

J

U

H

Solar

temperature

sensor cable

850 kpa Pressure and

Temperature Relief Valve

Solar Tank 500 kpa Pressure Limiting Valve

Air Vent

K LM

Cold Water in

Solar

recycle

Electrical

supply for

heating element

O

Solar Collector outlet connection

Solar Collector inlet connection

Solar

Collector

N

Either one, two or three Solar Collectors,

depending on system

Tempering

Valve

D

Domestic electrical supply

Expansion Control Valve

DuoValve (on/off and one way)

Tank temp

receptacle

Shut-off ball valve

S

T

C

Use copper Tee

G

Cold Water in

V

Blanking Plug

Solar Collector temp receptacle

P

Solar Hot

water tank

R

Solar Hot

Water tank

Solar

Pump

Solar

Control

Unit

Solar

Collector

Solar

Collector

Hot Water Out

to taps

Tank temperature sensor

Pump

Control

Connection

Solar Hot

Water Out

Non Return Valve

and Purge Valve

(G)

F

E

J

G

H

Solar

temperature

sensor cable

850 kpa Pressure and

Temperature Relief Valve

Solar Tank 500 kpa Pressure Limiting Valve

Air Vent

K LM

Cold Water in

Electrical

supply

Cold

Water in

Solar

heating

recycle

Solar Collector outlet connection

Solar Collector inlet connection

Solar

Collector

N

Either one, two or three Solar Collectors,

depending on system

Tank temp receptacle

Outlet B

Inlet A

Bosch Gas Booster (21E/26E)

Solar Transfer

Valve (STV)

Tempering Valve

50

50

Bolt Gas Booster to Tank if possible

P

Outlet C

D

Solar recycle

Expansion Control Valve

DuoValve (on/off and one way)

Shut-off ball valve

C

T

Use copper Tee

S

U

V

Blanking

Plug

Solar Collector temp receptacle

R

Gas Booster

Water In

Gas Booster

Hot Water Out

Page 12

11

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

5. The Suntrap Solar Control Kit (Electric)

• The Solar Control Kit contains the following

items:

• 1. The Solar Pump

• 2. Shut-off ball valve (P/n SOV00A)

• 3. The Solar Controller Unit

• Two water pipe connections are made to the

Suntrap Solar Control Kit. Both water pipe

connections are made via 15mm Conetite unions.

• Point D is from the cold water inlet to the bottom of

the solar tank.

• Point E is the pumped outlet to the solar collector

• There are 2 electrical plug-in connections

associated with the Suntrap Solar Control Kit:

• The solar pump is plugged into the Pump socket

underneath the Solar Control Unit

• The complete Solar Control Kit is plugged into a

standard 10 amp domestic power socket

• There are 2 temperature sensor cables which need

to be plugged into the underside of the Suntrap

Solar Control Unit: these are the Tank sensor (from

Point H) and the Collector sensor (from Point K)

cables

E

1

2

3

D

The Suntrap Solar Control Kit (Gas)

• The Gas Boost Solar Control Kit contains the

following items:

• 1. The Solar Pump

• 2. The Solar Controller Unit

• 3. The ½”F x ½” Conetite CTI union

• There are two water pipe connections made to the

Suntrap Solar Control Kit and shut-off ball valve. All

water pipe connections are made via 15mm

Conetight unions.

• Cold water enters from the mains water supply

through the DuoValve and Pressure Limiting Valve

(point C)

• Cold water enters the bottom of the solar tank (Point

H)

• Point D is the inlet to the solar pump from the Tank

Solar Re-cycle (Point P)

• Point E is the pumped outlet to the solar collectors

E

D

Bottom connections to Gas Tank

Top connections to Gas Tank

P

P

J

F

F

J

H

H

G

G

To Solar Collectors

(via pump)

Cold Water in

From solar Collectors

850 kpa PTR Valve

connection

Solar Hot Water out

Cold Water in

Solar

Hot

Water

Out to

PTR Valve

C

Solar

Transfer

Valve,

Gas boost

Heater and

Tempering

Valve to

Hot Water

taps

U

Tank temp

receptacle

Tank temp

receptacle

U

Page 13

12

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

6. Completed installation views of assembled parts

Solar Control Kit – solar pump and Solar Control Unit

Also shows shut-off ball valve fitted P/n SOV00A

Cold Water Inlet - and Tank temperature sensor

receptacle (Points H and U)

Solar collector outlet assembly consisting of the Air Vent

assembly, solar collector temperature sensor receptacle and

a ½”M x ½” CTI Conetite union to join to 15 mm pipe (Point K)

Solar collector inlet assembly, including the Expansion

Control Valve and the ½”M x ½” CTI Conetite

union to join to 15 mm pipe (Point L)

Part/n SCU20A and SOV00A

Part/n CWI20A (H) and BSR00A (U)

Part/n SWR00A

L

Part/n SWI00A

K

U

H

L

K

850kpa Pressure and Temperature Relief valve (point J)

Solar return inlet - non-return valve with the purge

valve assembly (point G)

Showing both the Pressure and Temperature Relief valve

(Point J) and solar hot water out connections (points F, S)

(Electric Boost) (Point T is cold water in to Tempering Valve)

Coupling between the solar collectors (Points M and N)

(Note: actual model may vary)

Part/n FCS002, FCS003

Part/n PTR850

Part/n NRV00A

Part/n SHW00E (Point F),TEMP01, PTR850 and Blanking Plug (V)

J

Please note that on Gas Tanks the connections

F and J are swapped over)

M and N

S

J

F

T

V

G

R

Page 14

13

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

Sensor Cables, Cable Ties and Test PlugSolar Control Unit indicator panel

Underside of the Solar Control Unit showing

Plug and Sensor connection points

Underside of Solar Control Unit showing temperature

sensor plug-in positions

6. Completed views of assembled parts (cont)

7. Connections to the Suntrap Solar Collectors

• Using 40mm thickness insulation, a 15mm

copper pipe from the Solar control Kit (point E)

connects to a ½” M x ½” CTI Conetite union

threaded on to a Tee. Connect the other side of

the Tee to the inlet side of the solar connectors

(point L) through the ¾” F to 15mm brass

adapter. (use thread tape)

• Screw the Expansion Control Valve onto the

Tee using the 15 mm nipple supplied (use

thread tape)

• – The solar collectors are connected ‘in series’

using brass connectors

• Using 40mm thickness insulation, a 15mm

copper pipe from the middle pipe connection on

the Solar Tank (point G) is connected to the solar

collector outlet (Point K)

• The Air Vent and Solar temperature ‘collector’

sensor assembly is connected into the solar

collector outlet (Point K)

• The Air Vent is screwed into the brass Tee fitting

using the 15mm -10mm brass bush as shown

(mount vertically)

• The ½”M x ½” CTI Conetite union is used to

connect to the solar water return outlet pipe

• Use thread tape on the solar collector threaded

connection

• The ¾” F to 15mm brass reducer connects the

Air Vent assembly to the collector

L

K

Page 15

14

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

7. Connections to the Suntrap Solar Collectors (cont)

• The top picture shows the Solar Collector

inlet connection (with the Expansion Control

Valve) from the solar pump to the solar

collectors using the connectors supplied

(Point L). Use the ¾”F to 15mm brass

reducer, the 15mm Brass Tee and ½”M x ½”

Conetite CTI union to connect to the Solar

inlet pipe. Use the 15mm nipple to connect

the Expansion Control Valve.

• Use thread tape on the solar collector

threaded connection.

• (Part/n SWI00A)

Part/n SWI00A

Part/n FCS002, FCS003

The lower picture shows the connection between

the solar panels (in ‘series’) using the

supplied connectors (Point M).

• The 2 connectors used are ¾”F x ¾”

Conetite CTI unions fitted onto an 82mm

length x 20mm dia copper pipe.

• Use thread tape on the solar collector

threaded connections

(Note: This part is not supplied with a 1 x

solar collector system.)

M and N

L

8. Connections to the top of the Solar Hot Water Tank

• This picture shows the connection to the top

pipe connection on the solar tank (Point F)

which is the Hot water outlet to the

Tempering Valve

• The Tempering Valve (Point S) – Hot water

out to hot taps

• The cold water input to the Tempering Valve

enters at (Point T). This connection to the

cold water supply to be made after the cold

water has flowed through the DuoValve and

500 kpa pressure limiting valve

• The 850kpa Pressure and Temperature

Relief valve (fitted at Point J) – is supplied

as part of the kit from Suntrap.

• Fit the Blanking Plug to point V (part of

P/N BSR00A) - this port is not used

• The bottom picture shows the Solar Hot

water out connector and the Gas Booster

connection kit

Please note that on Gas Tanks these connections

are swapped over (Electric boost tank shown)

SHW00G – Solar hot water out connector and

Gas Booster connection kit

F

S

T

J

F

V

S

R

Page 16

15

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

9. Connections to the middle and bottom of the Solar Tank

• The middle Solar tank connection (Point G)

Solar hot water in - has a non-return valve fitted.

Connection is made via 15mm W62 brass fitting.

• Please note the purge valve which must be

used to remove all the air from the solar

collectors and the system during the initial fill

with water. Failure to bleed air from this point

will prevent the solar return water from operating

the non return valve. All air must be expelled at

this point and only water be present, otherwise

the solar water will not circulate between the

solar collectors and the tank. WARNING –

water expelled from this point can be

extremely hot and precautions must be

taken.

• The Solar tank temperature receptacle (Point U)

is where the sensor cable from the Solar Control

unit (front ‘TANK’ socket marked blue) is placed.

Push the sensor head in as far as it will go. This

is the point where the tank temperature is

measured .

• The mains cold water in at the bottom of the

Solar tank connection (H) is made by screwing

the complete assembly into the tank.

Connection to the pipe is made via the W63

bent brass fitting.

• The solar recycle connection (solar flow) is

connected from Point P on the tank to the inlet

to the solar pump (Point D).

G

U

H

P

U

10. The completed Solar Hot Water Tank assembly

• The Tank and Solar control kit must be

positioned close together

• The Solar tank must sit on firm and level ground

• If the solar tank is to be installed inside a

building, then solar tank must sit within a ‘safe

tray’ which meets the drainage requirements of

AS/NZS 3500.4

Electric Boost:

Solar hot water is piped directly to the domestic

hot water taps (via a Tempering valve). An

electrical connection must be made from the

Solar Hot Water tank to a dedicated electrical

heater supply to provide a ‘boost’ at times when

necessary. (connected to a dedicated electrical

supply for this purpose - (point O)

Electrical cable entry is via an entry provided

to the side of the access cover

Gas Boost:

A separate Gas Boost heater must be installed

on the hot water outlet from the solar tank. For

maximum operational efficiency the Gas Boost

heater (incorporating the Solar Transfer Valve

(STV) should be mounted as close as possible to

the solar tank to minimise the effect of ‘dead leg’

water (water that goes cold in the pipes between

the Tank and Gas Boost heater) from

unnecessarily activating the Gas boost heater.

A Tempering valve is also required to be fitted,

prior to the hot water going to the domestic hot

water taps.

Electrical connection for Boost (Point O)

Cable

Entry

point

Part/n EST315

Safe

Tray

Page 17

16

12. Instructions for assembling and fitting the Solar collectors

• Your solar collectors will arrive with the evacuated glass tubes installed. These evacuated glass tubes must be

handled very carefully – Please note that these glass tubes never come into contact with the solar hot water, so if

they ever got broken during the operational life of the solar hot water system, no solar hot water will ever get lost.

They are easy to replace in-situ and do not require the system to be drained. This is because the Suntrap Solar

Hot water system uses U-Tube solar collector technology which fully contains all the solar water within high

pressure copper pipes which run inside the evacuated glass tubes.

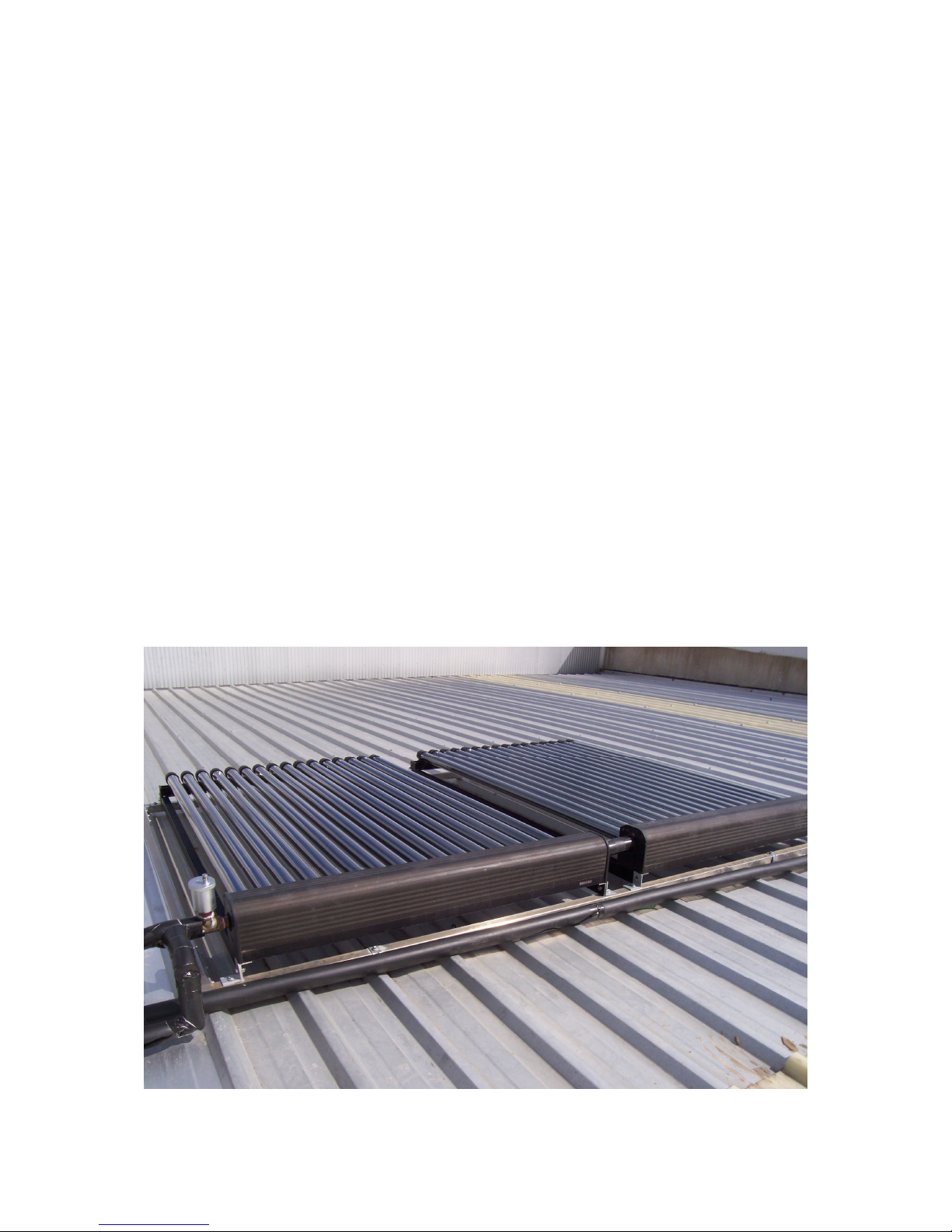

As can be seen from the following pictures, the evacuated glass tubes slide into the

collector manifold and are retained by plastic shrouds at the opposite end.

16 U-tubes make up 1 x Solar Collector

2 x Solar collectors are shown below

Part/n SET232

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

11. Check list immediately prior to commissioning System

Pre-check list before starting to commission system:

Do not attempt Solar collector installation on a hot day – the Solar collectors and

fittings will be too hot to touch

• Turn off mains water supply valve

• Make sure all connections are tightened

• Make sure all fittings are securely tightened

• Ensure Air vent valve has been opened at least 1 turn (and leave open)

• Understand the importance of correctly purging the system – use of the purge valve at

point G (and the Test plug) – if air is left in the system, this valve will not open and

recirculation will not take place: the Solar collectors and pipe work will pressurise, the

pump will be put under strain and damage could result. WARNING – the water

expelled from point G can be extremely hot and precautions must be taken.

• Ensure that the temperature sensors are correctly placed and secure – again, if these

are not sensing the correct temperatures, the Solar controller will not operate correctly,

which could result in the PTR valve on the tank operating prematurely, and wasting

water. (incorrect temperature detected and solar tank water gets too warm)

• Turn on mains water supply valve, Turn on Duo Valve

• Turn on ball valve at point C (handle in-line with pipe)

• Check diagram below – connections and components to be installed in the order

shown

• OK to start commissioning system

Cold water in

DuoValve

500kpa Pressure Limiting Valve

To Tempering valve (point T)

Tank cold water in

(point H)

Mains water supply valve

Use copper Tee

Page 18

17

Removing the evacuated glass tubes from the Collector frame

Note the groove on the

front face which is

located into the frame

Push the rear of the evacuated glass

tube retainer upwards

Gently pull the retainer

off the evacuated glass tube

Place the evacuated glass tube retainer to one side

and gently pull the evacuated glass tube out of the

Manifold and over the copper U-Tube.

The evacuated glass tube will slide out of the manifold with the rubber

grommet, When sliding the evacuated glass tube from the manifold

and over the copper U-tube, ensure it is kept in-line with the aluminium

U-Tube copper pipe retainers, so nothing is damaged.

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

12. Instructions for assembling and fitting the Solar Collectors (cont)

• The solar collector frames are mounted on a Roof Frame which must be assembled using the 4 x lengths of

square section stainless steel, brackets and screws supplied. Tap in the 4 x plastic end caps into the cut-off ends

of the frame square sections

• 4 x ‘L’ shaped brackets attach each collector frame to the Roof Frame

• With all the evacuated glass tubes removed (see below) from the collector frames, take the collector frame(s)

to the roof

• The Roof Frame is then taken to the roof and placed in its final position.

• The collector frame(s) must then be mounted to the frame using collector mounting brackets and nuts and washers and

screws. Note there are left-hand and right-hand brackets supplied.

• The thinnest edge of each mounting bracket (from slot to edge) must be positioned to the outside of the frame

• Finally (see the next pages) , the stainless steel straps must be positioned along the frame (two at the top and two at

the bottom to line up with the roof rafters under the roof tiles on which to screw the frame (assuming a tiled roof)

on each stainless steel strap, screw one screw into the frame and the other 2 x screws into a roof rafter. Repeat

for each stainless steel strap

• Take the evacuated glass tubes to the roof and insert all evacuated glass tubes into the solar collector frames

Thin

edge

Page 19

18

12. Instructions for assembling and fitting the Solar Collectors (cont).

Refitting the Evacuated Glass Tubes.

Slide the evacuated glass tubes over the U-Tube copper pipes and aluminium retainers and into the manifold.

Gently ease the grommet into position for a flush seal.

The stainless steel Roof Frame and the stainless steel straps are taken to the roof with no bends in them. When the position of

the Roof Frame has been established, slide a tile up and locate a rafter. Using 2 x of the long roof screws, screw the strap into

position on the rafter so that there will be a sufficient length exposed beyond the normal position of the tile to attach to the roof

frame. Slide the tile back into its normal position. Re-position the Roof Frame, then bend the strap around the Roof Frame to

secure. Repeat this for the other 3 x stainless steel straps.

When all the stainless steel straps have been bent around the Roof Frame and the Roof Frame is in its final position, drill through

both the straps and frame with a 3 mm drill, and screw together.

To refit the evacuated glass tubes into the

Collectors - Reverse the instructions for

removing the evacuated glass tubes from

the collector frame (see previous page).

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

13. Completing the Installation

• Please refer to Schematic Diagram (Section 4) for all reference points:

• Please note that the blue and red dots on each end on the collector have no significance – flow and return can be in

either direction.

• For the Solar Tank Installation - Please refer to the Everlast Owners Manual and Installation Guide.

• Pipe insulation - Use 40mm thickness ISOpipe insulation material on the solar inlet and solar outlet pipes all the way from the

solar hot water tank to the solar collectors and back to the solar hot water tank. For Gas Boosted systems, use Armaflex

material 32mm thickness insulation between the Solar Preheat Tank and the Gas Booster.

• Position the Solar Hot Water tank on firm and level ground near an electrical supply.

• Screw the Shut-off valve to the outlet of the solar pump (Point E). Fit the ½”M x ½” Contite CTI union to the Shut-off valve.

• Position the Solar Control Kit on a wall adjacent to the Solar Hot Water Tank approx 120cm from the ground and within the

‘Tank’ sensor cable length.

• Remove all evacuated glass tubes from the collector frame(s) and put to one side (see section 12).

• Identify the final position of the solar collectors on the roof.

• Assemble the Roof Frame and take it to the roof (see section 12).

• Attach the assembled Roof Frame to the roof using the 4 x stainless steel straps (see section 12)

If installing the Roof Frame on colorbond (Metal) material, use rubber insulating strip between the Roof Frame and the Roof

• Take the collector frames(s) to the roof (support the U tubes and aluminium fins

• when moving the bare collector frames. Keep all the U tubes in-line and at

90 degrees to the manifold at all times) see picture – use a piece of wood

and some tape as shown - and attach these collector frames to the Roof Frame

using the brackets and nuts and bolts and screws supplied (see section 12).

• Take the evacuated glass tubes to the roof.

• Re-fit all the glass evacuated glass tubes to the collector frame(s) – (see section 12).

• Fit the Air Vent assembly to the solar collector outlet connection on the Solar Collector using thread tape (Point K). Use two

spanners to prevent twisting the manifold. Ensure that the air bleed valve is unscrewed - open (see section 7).

• Screw the Air Vent into the Air Vent Assembly using thread tape.

• Fit the 850 kpa Pressure and Temperature Relief valve assembly on the Solar Hot Water tank, using thread tape (Point J)

(see section 8).

• Fit the 500 kpa Pressure limiting valve assembly on the Solar Hot Water tank, using thread tape

• (Point H)(see section 9).

• Fit the non-return valve assembly and the purge valve on the solar input on the Solar Hot Water Tank, using thread tape

(Point G) (see section 9).

Page 20

19

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

• Ensure that the DuoValve is closed (on the mains water-in pipe)

• Turn on the main water supply.

• Check for water leaks along this mains ‘cold water in’ pipe.

• Turn on a hot water tap fed from the Solar tank (this assists with the removal of air from the system

during initial fill.

• Open the DuoValve on the Mains water-in pipe to allow water to enter the Solar tank.

• Open the purge valve on the Solar Return Inlet connection to the tank (point G) (very important to

prevent an air lock on initial fill). Warning – the water expelled from point G can be very hot and

precautions must be taken. This is best carried out when the Solar Collectors are cool.

• While filling the Solar Tank with water - hold open the 850kpa Pressure and Temperature valve

(Point J) – this also assists with the removal of air during initial fill.

• Also while filling the Solar Tank with water - watch for water to be expelled at the purge valve on the Solar

Return Inlet connection to the Tank point (point G) (water will have now partially filled the on-roof solar

collectors and pipes) –air will ‘hiss’ until water is expelled). When only water flows, close the purge valve.

• When water is expelled from the P and T Relief valve (Point J), let the valve close.

• Allow water to continue to enter the Solar Tank. Water will begin to come out of the hot water tap

previously left open. When there is a steady flow of water, turn off all hot taps. Check for any water leaks.

• Plug the solar pump into the ‘Pump’ socket on the underside of the Solar Control Unit.

• Plug the Solar Control Unit into a suitable electricity supply, and switch on the Solar Control Unit. The power

light should illuminate. Unplug the Collector Sensor cable (marked with a Red label) from the Solar Controller.

Plug the ‘Test Plug’ (supplied with the Solar Controller) into the Collector sensor input (marked with a Red label)

on the underside of the Solar controller and the pump should start. Open the purge valve and run the pump

for 10 minutes to ensure all the air is excluded from the solar collectors. Close the purge valve. Remove the

key to a safe place. Remove the ‘Test Plug’ to a safe place. Replug the collector sensor lead into the Controller.

• Ensure that Silicone seal is around the tank sensor cable, only at the entry point to the temperature receptacle

(for easy sensor removal if necessary).

• When the Solar Collector temperature sensor detects a temperature greater than 9 degrees above the tank

water temperature, or 1 degree centigrade, the solar pump will run and the ‘pump’ indicator will illuminate.

• Check for any leaks and take corrective action.

• Look forward to a very efficient and cost effective hot water delivery system, powered by the sun.

14. Priming and filling the system

• Fit the Solar hot water outlet connector to the Solar Tank, using thread tape (Point H).

• Connect the DuoValve (P/N DUO00A) and the water Pressure Limiting Valve (P/N PLV00A) together,

ensuring that the arrows on the valves are towards tank (point C), using thread tape. Run a length of

15mm pipe from the Pressure Limiting Valve to the tank. (Use the copper 15mm Tee to connect to

Tempering valve (Point T), Connect the Solar recycle (point P) on the tank to the solar pump inlet (Point D).

Run a length of 15mm pipe from the Duo Valve and connect back to the ‘mains cold water in’ connection

Point C).

• Connect the Solar Collectors together using the connectors supplied. Use thread tape on the solar

collector threaded connections (Points M and or N). Use two spanners to prevent twisting the manifold.

• Run a length of 15mm pipe and connect from the Shut-off ball valve (Solar Pump outlet connection – point E)

to the ½”M x ½” CTI Conetite union on the 15mm Brass Tee on the Solar Collector inlet connector.

Connect the 20mm – 15mm adapter to the collector and screw to the brass Tee fitting. Fit the Expansion

Control Valve. Use thread tape on all threaded connections (Points E to L). (use two spanners

to prevent twisting the manifold when tightening the 20mm-15mm adapter to the collector).

• Run a length of 15mm pipe and connect from the Solar Collector outlet assembly – from the ½”M x ½” Conetite

CTI union to the W62 straight brass fitting on the Solar input on the Solar Hot Water, tank (Points K to G).

• Electric Boost - Connect the Brass Elbow fitting to the ‘Solar Hot water out’ (Point F) and then to the Tempering Valve.

• Gas Boost – Fit the W62 and nipple to the tank (Point F), run a 20mm pipe to the Water Inlet connection on the Gas

Booster, then connect from the Hot Water outlet on the Gas Booster with 15mm pipe to the Tempering Valve (Point R)

• Fit the tank temperature sensor receptacle (P/N BSR00A) into point U.

• Screw the 3/4”BSP Blanking Plug into (Point V) on the tank

• Connect a cold water feed (from the Tee in the cold water-in pipe) to the Tempering Valve (Point T)

• From the ‘outlet’ connection of the Tempering Valve (Point S) run a 15mm copper pipe to the Hot

water out (Point S to hot water taps)

• Place the 2 sensor probes into their respective ‘blind’ receptacles – ‘cold water

in’- ‘Tank’ temperature (Point U) and the ‘Solar collector outlet’ – ‘Collector’ temperature (Point K).

• Silicone seal around the sensor cables, only at the entry point to the temperature receptacles.

Plug the other ends of the sensor cables into their respective marked positions on the underside of

the Solar Control Unit.

• Secure any loose cables with cable ties.

• For all Gas Boosted Heater system installations – Please see diagram in Section 4, and notes in Section 10

Gas connection must be carried by a qualified tradesperson – refer to the Gas Boost heater manufacturers instructions.

• Check all fittings and tighten as necessary.

13. Completing the Installation (cont)

Page 21

20

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

The selective coating on the outside of the inner

glass tubes ensures high energy absorption and low

heat loss, which converts solar energy into heat and

transfers this heat to the copper U tubes by the

aluminium fins.

220 0CStagnation temp. (with reflector)

¾”Inlet/outlet conne ctions

1000 KPAMax. Pressure

45 KGNet weight

1.357w(m

2 K)

Heat loss

0.695Intercept efficiency

1.33 m

2

Aperture area

1 mmThickness

8 mmDiameter

CopperMaterial

U Tube

16Tube (pi ece)

SL-I-1500Collector tubes

U-1500/16MODEL Suntrap Evacuated U Tube Solar Collector

220 0CStagnation temp. (with reflector)

¾”Inlet/outlet conne ctions

1000 KPAMax. Pressure

45 KGNet weight

1.357w(m

2 K)

Heat loss

0.695Intercept efficiency

1.33 m

2

Aperture area

1 mmThickness

8 mmDiameter

CopperMaterial

U Tube

16Tube (pi ece)

SL-I-1500Collector tubes

U-1500/16MODEL Suntrap Evacuated U Tube Solar Collector

Features

Simple structure and stable operation;

Utilization all year round even in cold climates;

Can operate with water pressure up to 600Kpa;

Can still operate in the event of occasional tube

breakages;

Modular system means easy handling, installation

and can be extended to cover larger areas;

Easy to install on roofs, balconies or facades;

Can be combined with existing energy source;

Quasi-tracking all day.

15. Specifications of the Suntrap Evacuated Tube Solar Collector SLU-1500/16

19

Suntrap Evacuated U Tube Solar Collector SLU 1500/16

Sunshine in Australia (Zone 3) is rated at 1 Kilowatt per

square meter.

To calculate peak watts per Suntrap U Tube Solar collector,

Multiply the Aperture area x the Intercept efficiency (as above):

1.33 x .695 = 0.924 Kilowatts per hour.

1 x Suntrap U Tube Solar Collector = 924 peak watts per hour

2 x Suntrap U Tube Solar Collectors = 1.84 peak Kilowatts per hour

3 x Suntrap U Tube Solar Collectors = 2.77 peak Kilowatts per hour

Page 22

21

Copyright © 2009 Suntrap Pty Ltd All rights reserved ABN 87 117 052 856

Refund Policy

1. Suntrap products (such as solar collectors, water tanks, pumps, valves etc.) –

In any situation where a product fails to perform as specified, you are entitled to an

exchange or refund upon return of the product(s) to Suntrap within 30 days of purchase.

2. Labour charges and shipping charges will not be refunded.

3. If you change your mind, Suntrap will not refund any monies after the system has been installed.

due to faulty materials.

Scope of Warranty

10. This warranty does not apply to any defects or damage not due to faulty factory parts, including but

not limited to defects or damage caused by or resulting from:-

a) Accidental damage, abuse, misuse, maltreatment, abnormal stress or strain, harsh or adverse

water conditions, contamination or corrosion from particles in the water supply.

b) Alteration or repair of the Suntrap solar hot water system other than by an approved Suntrap

licensed installer, the installer with written authorisation from Suntrap, or a Technician from a Gas

or Electricity utility with approval from Suntrap.

11. This warranty does not cover the effects of the connection of the Suntrap Solar Hot water system to

bore waters and highly mineralised waters where the water used exceeds the following levels:

Total dissolved solids 600 mg/litre or p.p.m: Electrical conductivity 850 uS/cm: Total hardness

200 mg/litre or p.p.m: Chloride 250 mg/litre or p.p.m: Magnesium 10 mg/litre or p.p.m: Sodium

150 mg/litre or p.p.m: pH Min 6.5 and Max 8.5.

12. This warranty does not cover the effects of sludge/sediment as a result of connection to a water

supply from unfiltered or mineral content sources i.e. spring, dam, bore, river or other

.

13. Where a Suntrap solar hot water system or a component is replaced by Suntrap, the balance of any

original warranty will remain effective. The replacement part does not carry any additional

warranty.

14. Suntrap's obligations under this warranty are limited to repairing or replacing the Suntrap solar hot

water system or components. To the extent permitted by law, Suntrap will not be liable for any loss

or damage to roof, furniture, carpets, walls, foundations or any other consequential loss of any kind

caused by a defect in the Suntrap solar hot water system or any component.

Revised 22ndJune 2010

Terms and Conditions of Warranty and Refund Policy

THE SUNTRAP SOLAR HOT WATER PRODUCTS THAT YOU HAVE PURCHASED COME WITH A

COMPREHENSIVE WARRANTY.

THE TERMS AND CONDITIONS OF THE WARRANTY ARE SET OUT BELOW.

1. Solar Collectors

All U tube series solar collectors are covered by a 10 year warranty.

2. Stainless Steel Water Tanks

Stainless steel water tanks are covered by a 10 year manufacturer’s warranty.

3. Solar Booster Pumps

All solar booster pumps are covered by a 5 year warranty.

4. Solar Controllers

All solar controllers are covered by a 5 year warranty.

5. Gas Boost Heaters

All Bosch gas boost heaters are covered by a 5 year manufacturer’s warranty.

6. Valves

All valves are covered by a 5 year warranty.

7. Workmanship

Workmanship is covered by the installers warranty.

8. This warranty is for normal use of the solar hot water system installed in accordance with the Suntrap

Solar Hot Water Installation Instructions and Owners Manual, and covers the repair and/or

replacement of any failed component in the system or where necessary. Under this warranty

Suntrap will repair or replace the component free of charge. The decision to repair or replace the

component will be entirely at the discretion of Suntrap.

9. This warranty only applies to defects in the Suntrap solar hot water systems which have arisen solely

Suntrap Pty Ltd

ABN: 87 117 052 856

PO Box 3164

Dural NSW 2158

Tel: 02 9651 2866

Loading...

Loading...