suntouch TapeMat D12 series, TapeMat C12 series, TapeMat C15 series Installation Instructions Manual

Installation Manual

TapeMat

®

Please be aware local codes may require this product and/or the thermostatic control to

be installed or connected by an electrician. Please leave this manual with the end user.

Includes Custom TapeMat® and ShowerMat™

Series D12,

C12 & C15

Assembled in the

USA

IOM-WR-TapeMat 1526 2 of 32

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information can result

in death, serious personal injury, property damage, or damage

to the equipment.

Keep this Manual for future reference.

Specifications for TapeMat:

Floor heating mats are a simple way to heat an indoor space. This instruction manual is

provided as a guide to installing TapeMats, including design considerations, installation steps,

limitations, precautions, and floor covering guidelines.

TapeMat is a complete heating mat consisting of a series heating wire and a power lead for

connection to the electric power supply.

The heating wire length cannot be cut to fit.

Controls:

TapeMats must be controlled by a SunStat® floor sensing thermostat. (Listed separately)

Voltage:

120 VAC, 240 VAC, 1-phase (see Table 2)

Watts:

D12 and C12 Series - 12 W/ft2 (41 Btu /h/ft2), C15 Series 15 W/ft2 (51 Btu/h/ft2)

Maximum circuit load:

15 A

Maximum circuit overload protection:

20 A breaker

GFCI:

(Ground Fault Circuit Interrupter) required for each circuit (included in the SunStat control)

Listing:

UL Listed for U.S. and Canada under UL 1693 and CAN/CSA C22.2 No. 130.2-93,

File No. E185866

Application:

Indoor floor heating only (-X on the nameplate label indicates CUL Listing for this

application).

Suitable for installation in a shower area (see Step 3.10 for restrictions). (-W on

the nameplate label indicates CUL Listing for Wet Location in Canada per Canadian Electrical

Code, Part I (CEC).

Embedded in polymer-modified cement based mortar only (see Phase 4).

D12 and C12 Series - May be installed under masonry or non-masonry surfaces as indicated

in this manual.

C15 Series - May only be installed

under masonry surfaces as indicated

in this manual.

Minimum bend radius:

1 inch

Maximum exposure temperature:

(Continuous and storage)

194ºF (90ºC)

Minimum installation

temperature:

50ºF (10ºC)

Installation must be performed by qualified persons, in accordance with local codes, ANSI/

NFPA 70 (NEC Article 424) and CEC Part 1 Section 62 where applicable. Prior to installation,

please consult the local codes in order to understand what is acceptable. To the extent this

information is not consistent with local codes, the local codes should be followed. However,

electrical wiring is required from a circuit breaker or other electrical circuit to the control.

It is recommended that an electrician perform these installation steps. Please be aware

local codes may require this product and/or the control to be installed by an electrician.

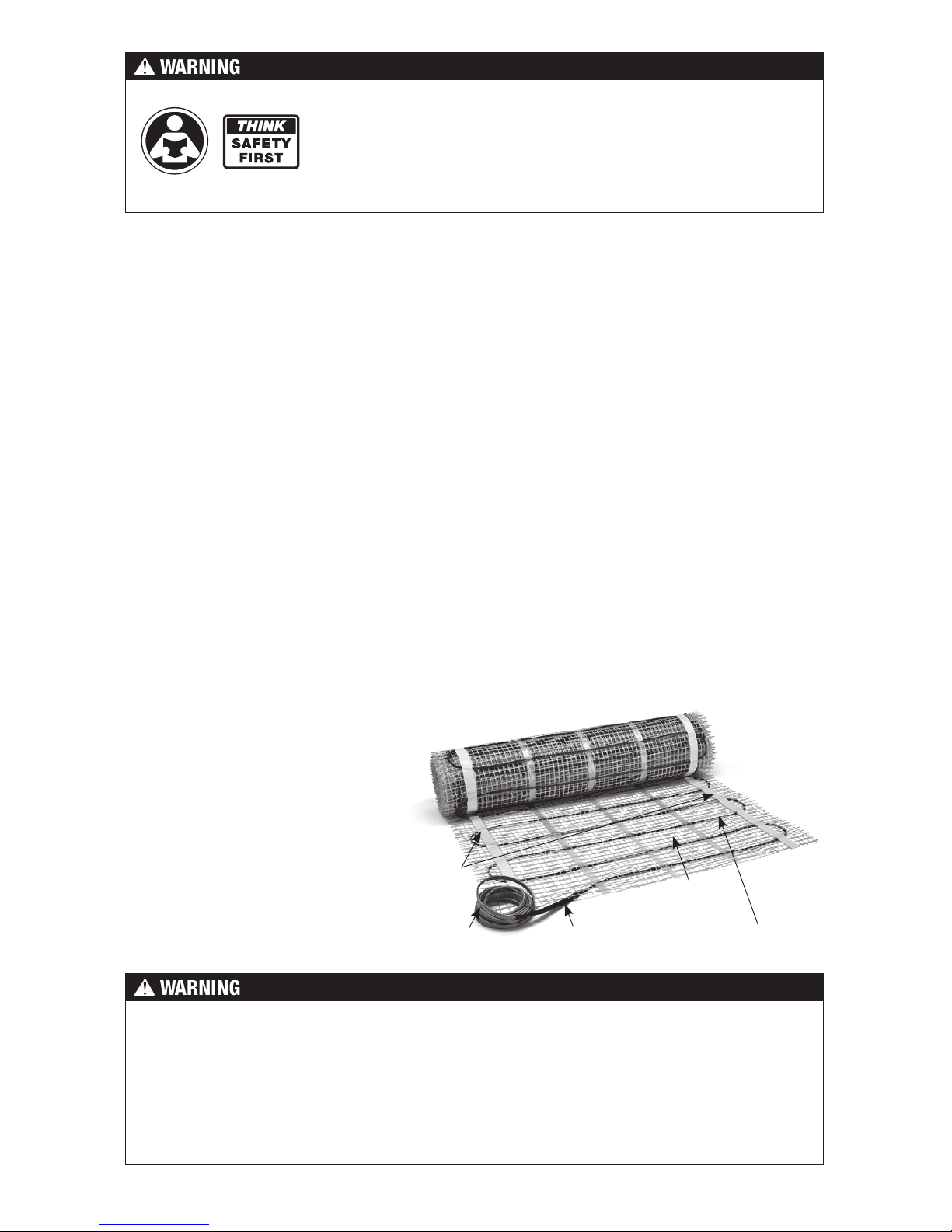

Doublesided Tape

Heating Wire

Factory Splice

Power lead

Mat Mesh

3 of 32 © 2015 Watts Water Technologies

Expected floor temperature

Heating performance is never guaranteed. The floor temperature attainable is dependent on

how well the floor is insulated, the temperature of the floor before start up, and the overall

thermal drain of the floor mass. Insulation is required for best performance. Refer to Phase 4

for important design considerations.

Important Safety Information

This is a safety-alert symbol. The safety alert symbol is shown alone or used with

a signal word (DANGER, WARNING, or CAUTION), a pictorial and/or a safety

message to identify hazards.

When you see this symbol alone or with a signal word on your equipment or in

this Manual, be alert to the potential for death or serious personal injury.

This pictorial alerts you to electricity, electrocution, and shock hazards.

This symbol identifies hazards which, if not avoided, could result in death

or serious injury.

This symbol identifies hazards which, if not avoided, could result in minor

or moderate injury.

This symbol identifies practices, actions, or failure to act which could result

in property damage or damage to the equipment.

Table of Contents

Important Safety Information .....................3

Phase 1 - Preparations ..............................5

Phase 2 - Electrical Rough-in ....................9

Phase 3 - TapeMat Installation ................11

Phase 4 - Floor Coverings ....................... 17

Phase 5 - Control Installation ..................20

Appendices ..............................................22

Troubleshooting .......................................29

Warranty ................................................... 31

These are the three most common installa tions:

1.

Wood framing:

With the mat installed on a well-insulated wood subfloor, and thin-set mortar

and tile on top, most floors can be heated up to 20°F warmer than they would otherwise be.

2. Insulated concrete slab:

With the mat installed on an insulated concrete slab, and thin-set

mortar and tile on top, most floors can be heated up to perhaps 15°F warmer than they

would otherwise be.

3.

Uninsulated concrete slab:

With the mat installed on an uninsulated concrete slab, and

thin-set mortar and tile on top, most floors can be heated up to perhaps 10°–15°F warmer

than they would otherwise be.

Please consult a designer or the factory if questions remain about the surface tempera ture

that can be expected from the cables in any particular construction.

IOM-WR-TapeMat 1526 4 of 32

NEVER install TapeMat under carpet, wood, vinyl, or other non-masonry flooring without

embedding it in thin-set, thick-set, or self-leveling mortar.

NEVER install TapeMat in adhesives or glues intended for vinyl tile or other laminate flooring, or

in pre-mix mortars. It must be embedded in polymer-modified, cement based mortar.

NEVER cut the heating wire. Doing so will cause dangerous overheating and will void the

warranty. The power lead may be cut shorter if necessary, but never remove completely

from the heating wire.

NEVER bang a trowel or other tool on the heating wire. Be careful not to nick, cut, or pinch

the wire causing it to be damaged.

NEVER use nails, staples, or similar to fasten the heating wire to the floor.

NEVER attempt to repair a damaged heating wire, splice, or power lead using unauthorized

parts. Use only factory authorized repair parts and methods.

NEVER attempt to repair a damaged shower mat. It must be replaced.

NEVER splice one mat heating wire to another mat heating wire to make a longer mat. Multiple

mat power leads must be connected in parallel in a junction box or to the thermostat.

NEVER install one mat on top of another or overlap the heating wire on itself. This will cause

dangerous overheating.

NEVER forget to install the floor sensor included with the thermostat.

NEVER install TapeMat in any walls, or over walls or partitions that extend to the ceiling.

NEVER install mats under cabinets or other built-ins having no floor clearance, or in small

closets. Excessive heat will build up in these confined spaces, and the mat can be

damaged by fasteners (nails, screws, etc.) used to install built-ins.

NEVER remove the nameplate label from the power leads. Make sure it is viewable for

inspection later.

NEVER extend the heating wire beyond the room or area in which it originates.

NEVER allow a power lead or sensor wire to cross over or under a heating cable. Damage

could result.

NEVER put the system into full operation until the tile or flooring installer verifies all cement

materials are fully cured (typically two to four weeks).

Table 1

As with any electrical product, care should be taken to guard against the

potential risk of fire, electric shock, and injury to persons. The following

cautions must be observed:

Local building or electrical codes may require modifications to the information provided.

You are required to consult the local building and electrical codes prior to installation. If

this information is not consistent with local building or electrical codes, the local codes

should be followed.

ALW AYS completely embed the heating wire and factory splices in the floor mortar.

ALW AYS maintain a minimum of 2.5" spacing between heating wires.

5 of 32 © 2015 Watts Water Technologies

Installation must be performed by qualified personnel, in accordance with local codes and

standards. A licensed electrician is recommended.

Phase 1 - Preparations

ALWAYS pay close attention to voltage and amperage requirements of the breaker, the

thermostat, and the TapeMat. For instance, do not supply 240 VAC power to 120

VAC TapeMat as damage will result.

ALW AYS make sure all electrical work is done by qualified persons in accordance with local

building and electrical codes, Section 62 of the Canadian Electrical Code (CEC)

Part I, and the National Electrical Code (NEC), especially Article 424.

ALW AYS use copper only as supply conductors to the thermostat. Do not use aluminum.

ALW AYS seek help if a problem arises. If ever in doubt about the correct installation procedure

to follow, or if the product appears to be damaged, the factory must be called before

proceeding with the installation.

Before installing TapeMat, make sure to fully inspect the products and carefully plan the site.

Items Needed

Materials:

• SunStat thermostat control with floor sensor.

• SunStat Relay control (if required)

•

Control electrical box (UL Listed, extra deep, see control instructions for size and type required)

• Junction electric box (if required, see Step 2.2)

• Wire nuts (Must be UL Listed and proper size)

• Flexible or rigid conduit (if required, see Step 2.4, must be UL Listed and proper size)

• 12-gauge or 14-gauge electrical wiring cable (consult local code)

• Nail plate (see Step 3.8)

Tools:

• Digital multi-meter for ohms testing; must read up to 20,000 ohms to measure sensor

• Drill with 1/2" & 3/4" bits

• Hammer and chisel

• Hot glue gun and hot glue (craft grade)

• Wire strippers

• Phillips screwdriver

• Fish tape

• Hole saw

• Floor covering installation tools

Floor sensor is

included in the

SunStat thermostat

packaging. This must

be installed in the

floor with the mat.

IOM-WR-TapeMat 1526 6 of 32

It is important to select the proper size mat for the given area. Mats cannot be cut shorter

in order to fit a given area. Doing so will damage the heating wire and prevent the system

from working.

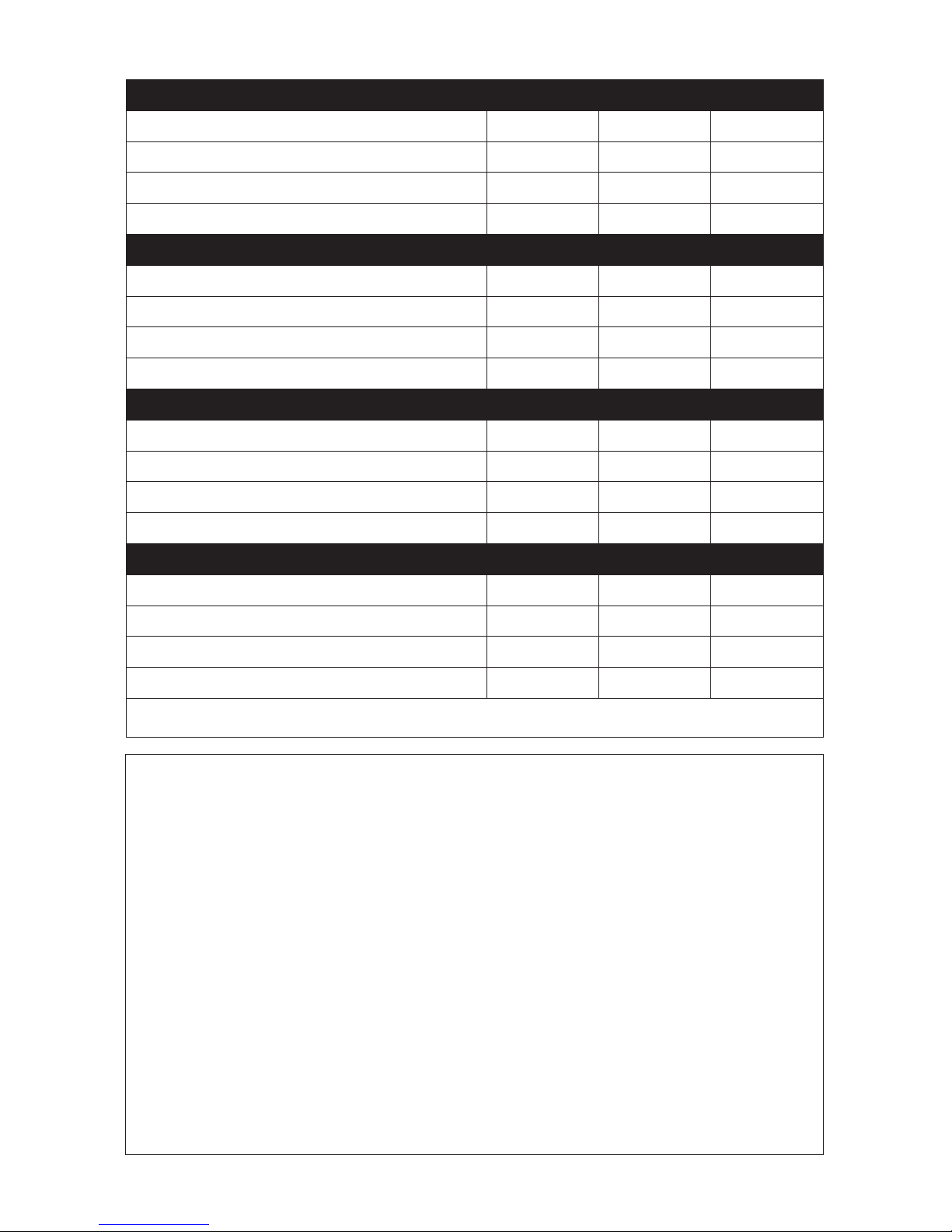

Please check the product label for exact ratings. This table is for reference only.

Table 2 - Mat Sizes

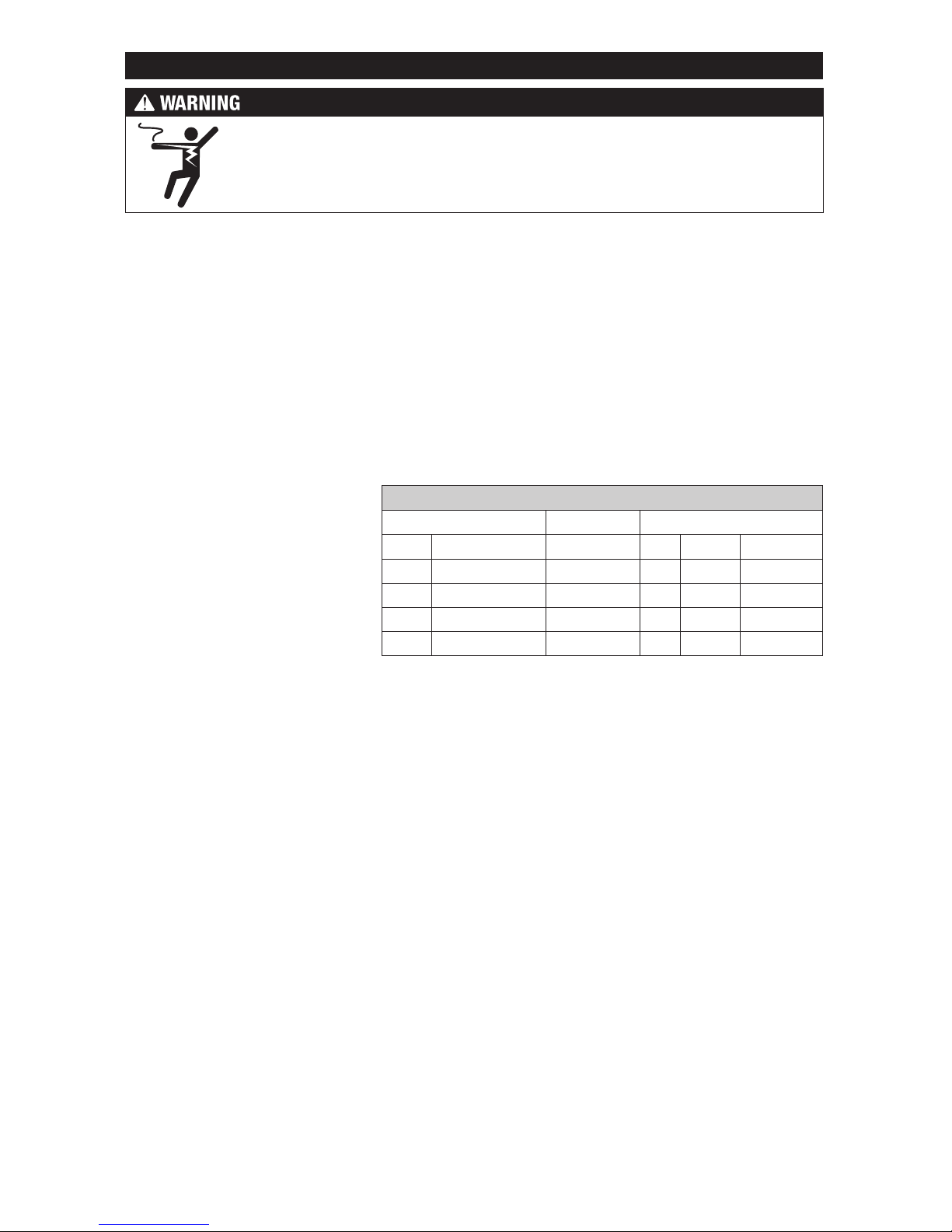

Inspect mat, control, and sensor

To prevent the risk of personal injury and/or death, make sure power is not

applied to the product until it is fully installed and ready for final testing. All

work must be done with power turned off to the circuit being worked on.

STEP 1.1

Remove the TapeMat, SunStat Control, and sensor from their packages. Inspect them for any

visible damage and verify everything is the correct size and type according to the plan and

the order. Do not attempt to install a damaged product.

120 VAC TapeMat

2 ft Wide

Mat

Ft

2

Mat Size

(W x L)

Model

Number

Amp

Draw

Ohms

10 2' x 5' 12000524 1.0

109 - 134

15 2' x 7'-6" 12000724

1.5 76 - 94

20 2' x 10' 12001024

2.0 57 - 71

25 2' x 12'-6" 12001224

2.5 43 - 54

30 2' x 15' 12001524

3.0 34 - 42

35 2' x 17'-6" 12001724

3.5 29 - 36

40 2' x 20' 12002024

4.0 25 - 32

45 2' x 22'-6" 12002224

4.5 22 - 28

50 2' x 25' 12002524

5.0 20 - 26

60 2' x 30' 12003024

6.0 17 - 21

70 2' x 35' 12003524

7.0 14 - 18

80 2' x 40' 12004024

8.0 12 - 16

90 2' x 45' 12004524

9.0 11-14

100 2' x 50' 12005024

10.0 10-13

3 ft Wide

15 3' x 5'

12000536 1.5 76 - 95

20 3' x 6'-8"

12000636 2.0 58 - 72

25 3' x 8'-4"

12000836 2.5 44 - 55

30 3' x 10'

12001036 3.0 34 - 42

45 3' x 15'

12001536 4.5 22 - 28

60 3' x 20'

12002036 6.0 17 - 22

240 VAC TapeMat

2 ft Wide

Mat

Ft

2

Mat Size

(W x L)

Model

Number

Amp

Draw

Ohms

20 2' x 10'

24001024 1.0 221 - 271

30 2' x 15'

24001524 1.5 153 - 188

40 2' x 20'

24002024 2.0 115 - 142

50 2' x 25'

24002524 2.5 87 - 108

60 2' x 30'

24003024 3.0 68 - 84

70 2' x 35'

24003524 3.5 58 - 72

80 2' x 40'

24004024 4.0 51 - 63

90 2' x 45'

24004524 4.5 45 - 56

100 2' x 50'

24005024 5.0 40 - 51

120 2' x 60'

24006024 6.0 34 - 42

140 2' x 70'

24007024 7.0 29 - 36

160 2' x 80'

24008024 8.0 25 - 32

180 2' x 90'

24009024 9.0 22-28

200

24010024 10.0 20-26

3 ft Wide

30

3' x 10' 24001036 1.5 154 - 190

40

3' x 13'-4" 24001336 2.0 116 - 143

50

3' x 16'-8" 24001636 2.5 88 - 109

60

3' x 20' 24002036 3.0 68 - 84

90

3' x 30' 24003036 4.5 45 - 56

120

3' x 40' 24004036 6.0 34 - 43

120 VAC ShowerMat

Mat

Ft

2

Mat Size

(W x L)

Order

Number

Model

Number

Amp

Draw

Ohms

10 36" x 60" 81017075 C12120010ST-S3660 1.0 109 - 137

10 48" x 48" 81017076 C12120010ST-S4848 1.0 109 - 137

7 of 32 © 2015 Watts Water Technologies

Do not remove this nameplate label. The

electrical inspector will need to see this.

STEP 1.2

Record the product information in Ta ble 4.

Give this information to the homeowner to

keep in a safe place.

The Mat model number, serial number, voltage,

and resistance range are shown on a nameplate

label attached to the power leads.

Black

Lead

White or

Blue Lead

Ground

Lead

Black

Lead

White or

Blue Lead

Ground

Lead

Black

Lead

White or

Blue Lead

Ground

Lead

200 ohm

setting

Black wire

to COM

Red wire

to

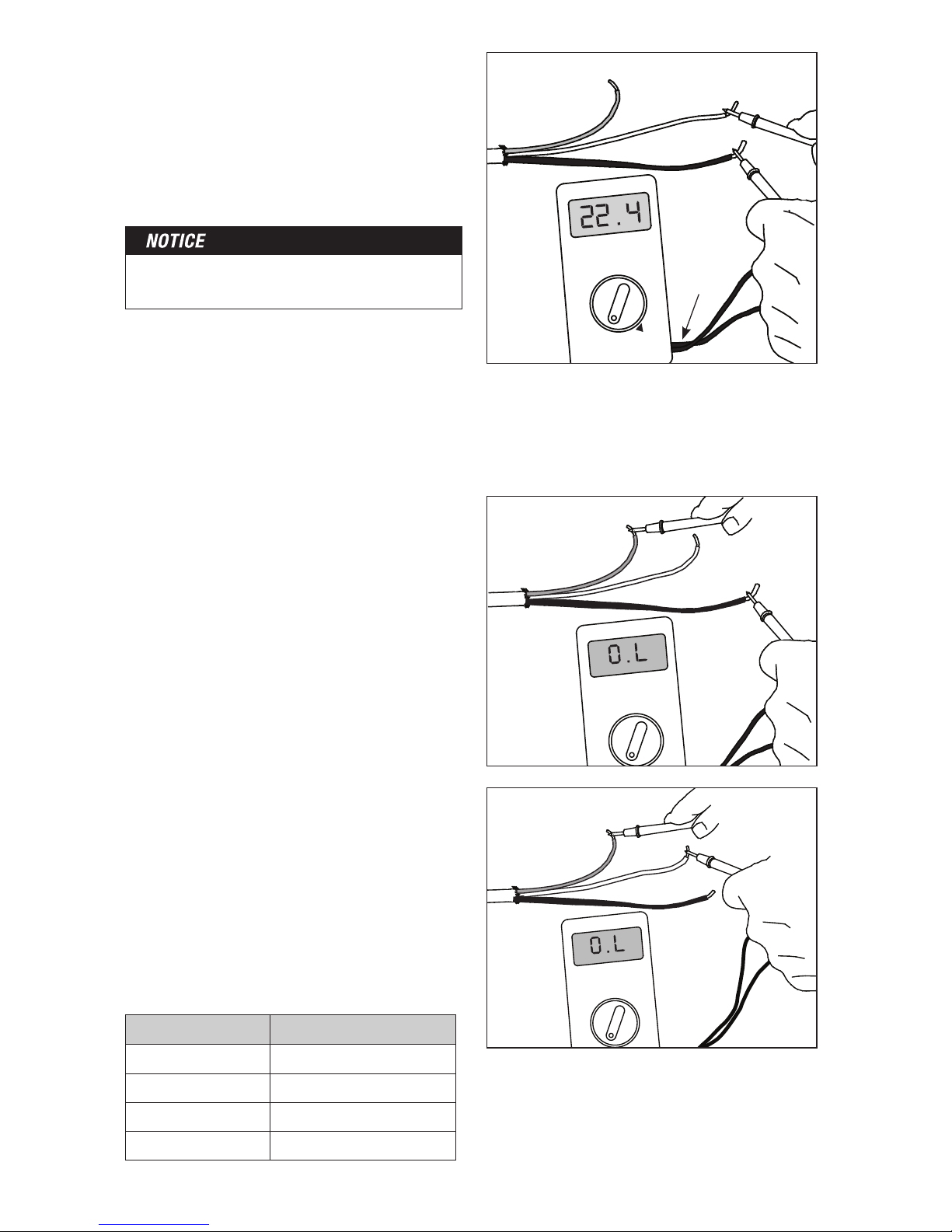

Readings between the Black and Ground and

the White (or Blue for 240 VAC) and Ground

power lead wires should measure “open”, or

“O.L”, or the same as displayed when the test

leads are not touching anything.

Press the test lead tips to the Black and White

(or Blue for 240 VAC) power lead wires. This

reading should correspond to the factory

resistance range on the nameplate label

attached to the Power lead.

Temperature Typical Values

55°F (13°C) 17,000 ohms

65°F (18°C) 13,000 ohms

75°F (24°C) 10,000 ohms

85°F (29°C) 8,000 ohms

Table 3 - Floor Sensor Resistance Values

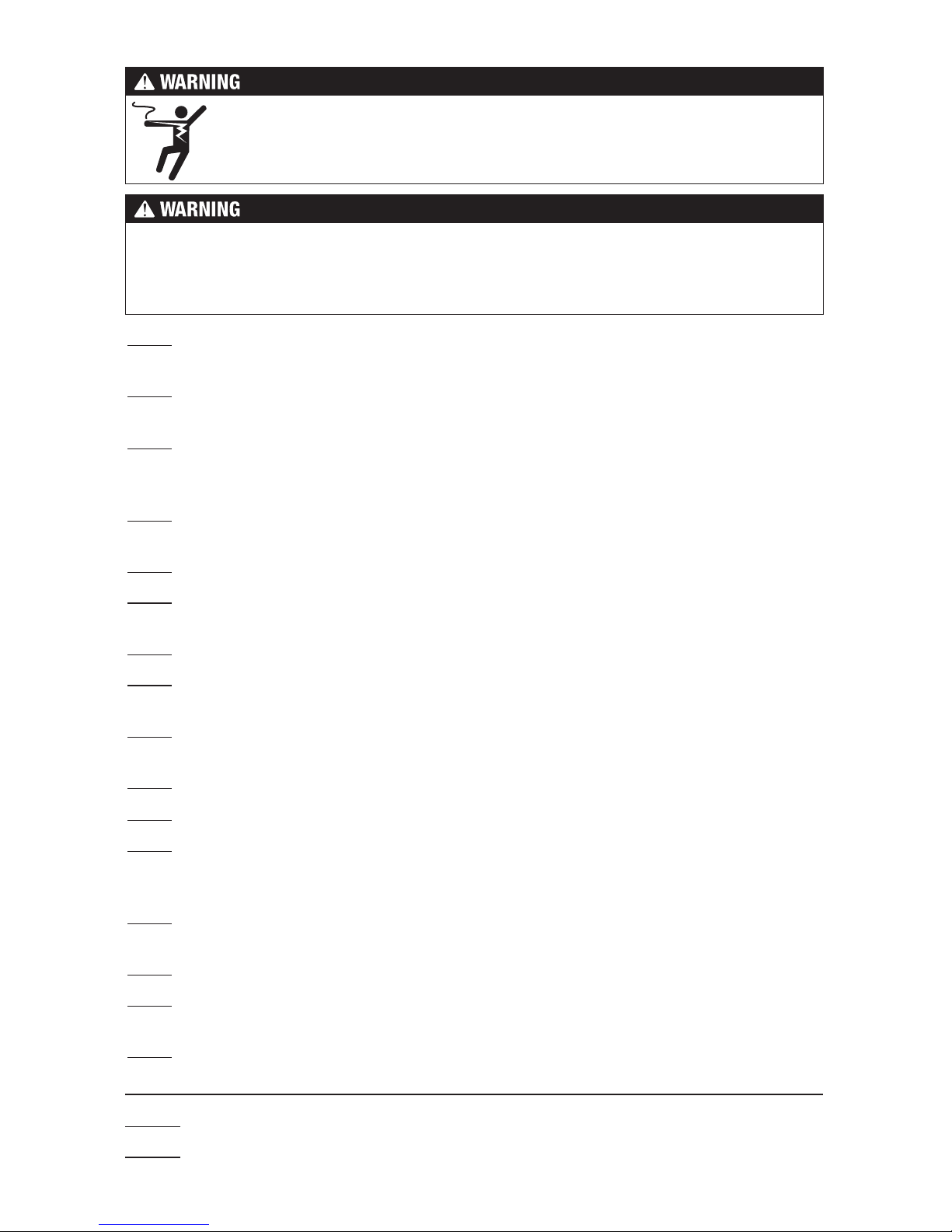

STEP 1.3

Use a digital multi-meter set to the 200Ω or

2000Ω (2kΩ) range to measure the resistance

between the conductors of the mat power

leads. Record these resistances in Table 4

under “Out of the box before installation”.

The resistance should measure within the

resistance range on the nameplate label.

If it is a little low, it may be due to low air

temperatures or meter calibration. Consult

the factory if in doubt.

Measure the resistance between either of

the white or black leads and ground lead.

This measurement should be “open”, usually

indicated by an “OL” or a “I”. This is the same

as displayed when the test leads are not

touching anything.

If there is any change in the reading, record

this information and contact the factory before

continuing. This could indicate damage, test

lead problems, or a number of other issues.

Try “pinning” the test leads to the cable lead

wires against a hard non-metal surface if the

readings continue to fluctuate.

Change the meter to the 20,000 ohms (20 kΩ)

range. Measure between the lead wires of the

control sensor. This resistance varies according

to the temperature sensed. Tab le 3 provides

approximate resistance-to-temperature values

for reference.

IOM-WR-TapeMat 1526 8 of 32

Mat 1 Mat 2 Mat 3

Mat serial number

Mat model

Mat voltage

Factory mat resistance range

OUT OF THE BOX BEFORE INSTALLATION (OHMS)

Mat black to white (black to blue for 240VAC)

Mat black to ground

Mat white to ground (blue to ground for 240VAC)

Sensor wire

AFTER MAT AND SENSOR ARE FASTENED TO FLOOR (OHMS)

Mat black to white (black to blue for 240VAC)

Mat black to ground

Mat white to ground (blue to ground for 240VAC)

Sensor wire

AFTER FLOOR COVERINGS ARE INSTALLED (OHMS)

Mat black to white (black to blue for 240VAC)

Mat black to ground

Mat white to ground (blue to ground for 240VAC)

Sensor wire

Retain this log to retain the warranty! Do not discard!

Table 4 - Mat and Sensor Resistance Log

INSTALLATION NOTES

9 of 32 © 2015 Watts Water Technologies

Phase 2 - Electrical Rough-in

To prevent the risk of personal injury and/or death, make sure power is not

applied to the product until it is fully installed and ready for final testing. All

work must be done with power turned off to the circuit being worked on.

STEP 2.1:

Circuit Breaker (Overcurrent Protection)

TapeMat(s) must be protected against overload by a circuit breaker. GFCI type (ground fault

circuit interrupter) or AFCI type (arc-fault circuit interrupter) breakers may be used if desired,

but are not necessary when using SunStat controls with integral GFCI

The rating of the breaker (see Table 5) is determined by the amp draw of the heating mats.

Add the amp ratings of all mats to be connected to the SunStat control (see Table 2 or the

Nameplate Label on the mat). If the total is less than 12 amps, use a 15 or 20 A breaker

(preference is 15 A). If the total is between 12 and 15 amps, use a 20 A breaker. If the total

is over 15 A, another circuit will be required with its own breaker and SunStat control.

Circuit Breakers and Supply Wire

Mat(s) Supply Wire Breaker

VAC total amps (AWG)* qty type** rating

120 up to 12 amps 14 1 SP 15 or 20 A

120 up to 15 amps 12 1 SP 20 A

240 up to 12 amps 14 1 DP 15 or 20 A

240 up to 15 amps 12 1 DP 20 A

* Recommended only. Follow local codes for wire gauge size.

** SP= single-pole, DP=double-pole

Table 5

STEP 2.2:

Install Electrical Boxes

SunStat Thermostat:

Install an extra-deep electrical box for the SunStat thermostat. Follow the instructions included

with the SunStat for complete information on location and wiring. The thermostat must be

located at least 4 feet (1.2 meters) away from shower openings to avoid being exposed to

water or touched by a person while in the shower area.

SunStat Relay:

Install an extra-deep electrical box for any SunStat Relay(s). The SunStat Relay is used when

more than 15 amps must be controlled by one SunStat Thermostat. Follow the instructions

included with the SunStat Relay for complete information on location and wiring.

Junction Boxes:

If a mat is to be located so its Power lead is not long enough to reach the SunStat Control or

SunStat Relay directly, a junction box must be installed. Do not attempt to make a connection

to other wiring without a junction box. Use a standard junction box with a cover, mounting

it below the subfloor, in the attic, in the wall, or in another location easily accessible after all

coverings are complete. If the SunStat sensor wire is not long enough to reach the SunStat

Control directly, it may be extended. A junction box may be required by local code to make this

connection. Follow the installation instructions included with the SunStat Control for details.

For construction with an existing wall or where the wall is covered, cut the necessary openings

to mount the electrical boxes listed above. Wait to install the boxes until all wiring is fed into

these locations to make it easier to pull the wire.

It may be possible to tap into

an existing circuit as long as

there is adequate capacity for

the mat(s) and any additional appliance, such as a hair dryer or

vacuum cleaner. Avoid circuits

which have lighting, motors,

exhaust fans, or hot tub pumps

due to possible interference.

IOM-WR-TapeMat 1526 10 of 32

STEP 2.3:

Bottom Plate Work

Drill or chisel holes at the bottom plate as indicated. One hole is for routing the power lead

conduit and the other is for the thermostat sensor. These holes should be directly below the

electrical box(es).

Power lead

conduit

Wire

Clip

Power

lead

Sensor wire

Sensor wire

If going in to an existing wall, cut out

dry wall and chisel out bottom plate

to route wires to control.

STEP 2.4:

Install Power Lead Conduit and Thermostat Sensor

Power Lead Conduit:

The shielded power lead can be installed with or without electrical conduit (recommended

for added protection against nails or screws) depending on code requirements. Remove one

of the knock-outs in the electrical box to route the power lead. If electrical conduit is not

required by code, install a wire collar to secure the power leads where they enter the box. If

conduit is required by code, install 1/2" (minimum) conduit from the bottom plate up to the

electrical box. For multiple power leads (multiple mats) install 3/4" conduit.

Thermostat Sensor:

The SunStat Control sensor can be installed with or without electrical conduit depending on

code requirements. Conduit is recommended for added protection against nails or screws. Do

not place the sensor in the same conduit as the power leads to avoid possible interference.

Open a separate knock-out in the bottom of the thermostat box. Feed the sensor (and conduit,

if used) through the knock-out, down through the cut-out in the bottom plate, and out into the

floor where the heating mat will be installed. If the sensor wire needs to be secured to the wall

stud, wait until after the mat and sensor are completely installed on the floor.

STEP 2.5:

Rough-in Wiring:

Install appropriate 12 or 14 AWG electrical wire from the circuit breaker or branch circuit

source to the SunStat Control electrical box (and SunStat Relay box(es) if needed) following

all codes, see Ta ble 5.

If SunStat Relay(s) are used, feed appropriate wire between the SunStat Relay(s) and the

SunStat Control. See SunStat Relay instructions for details of wire size and type.

Loading...

Loading...