Page 1

5

Portable

Conductivity/

Resistivity

Meter

SC-110

Operation

Manual

Page 2

i

Content Table

1. Specifications 1

2. Configuration

2.1 Display 2

2.2 Socket 2

2.3 Keypad 3

3. Operation

3.1 Measurement 4

3.2 Measurement function and file bit shift 4

3.3 Temperature function and compensation 5

3.4 Auto Read 5

4. Settings

Block diagram of settings 6

4.1 Parameter settings 7

4.1.1 Entry of set-up mode 7

4.1.2 Settings of measurement mode 7

4.1.3 Settings of data deletion 7

4.1.4 Settings of baud rate (BAUD) 8

4.1.5 Settings of system time 9

4.2 Deletion of all stored data 10

4.3 System reset 10

Block diagram of calibration and temperature compensation settings 11

4.4 Settings of calibration parameter 12

4.4.1 Electrode coefficient and calibration parameter 12

4.4.2 Standard solution calibration parameter 13

4.4.3 Temperature compensation coefficient 13

Block diagram of operations in measurement mode 14

4.5 Auto/manual data storage 15

4.5.1 Auto storage 15

4.5.2 Manual storage 15

4.5.3 Data full 15

4.6 Data readout and output 16

4.6.1 Auto transmission 16

4.6.2 Manual readout and transmission 16

5. Calibration

Block diagram of Calibration 20

5.1 Standard solution preparation 21

Page 3

ii

5.2 Calibration mode 21

5.3 Entry of calibration mode 21

5.3.1 Electrode coefficient calibration 21

5.3.2 Standard solution single-point calibration 21

5.3.3 Standard solution five-point calibration 22

6. Instruction set for RS232 23

7. Alternative fittings 23

8. Failure recovery 24

9. Maintenance 25

Page 4

1

1. Specifications

Mode SC-110

Function

µS/mS/MΩ/Salinity/TDS/Temp.

Cond.

0.00 uS/cm ~ 200.0 mS/cm in 5 measuring ranges for manual or auto switch

Res.

0.00~100.00 MΩ- cm

Salt

0.0~70.0ppt

TDS

0~2000ppm

Range

TEMP

-10.0~110.0°C

Cond.

0.01µS/cm

Res.

0.01 MΩ-cm

Salt

0.1 ppt

TDS

1 ppm

Resolution

TEMP

0.1°C

Cond.

±0.5%(±1Digit)

Res.

±1%(±1Digit)

Salt.

±0.5%(±1Digit)

TDS

±0.5%(±1Digit)

Accuracy

Temp.

±0.2°C(±1Digit)

PT-1000 or NTC 30K auto recognition

Temperature

Compensation

Auto / Manual selectable

Temperature

Coefficient

Non-linear / 0.00 ~ 10.00 % Linear

Ref. Temperature

T

ref

25℃

Manual calibration

Single point known standard solution or electrode constant calibration

Standard solution

calibration

Single or up to 5-point known standard solution calibration; default five

standard solution 10/84/1413 uS/cm & 12.88/100 mS/cm adjustable

RS232 interface

YES

Output Data logging

450 sets (measuring value, temp., date, time & ID)

Ambient

temperature

0~50°C

Storage

Temperature

-20~70°C

Display

1/2” LCD

Power

4 x AA battery

Battery

Around 350 — 1000 hrs according to measuring range; auto shut-off within10

minutes of no use

Protection Type

IP65

Certified to

CE

Dimension

(L x W x H)

185 x 98 x 38mm

Weight

0.35Kg

Page 5

2

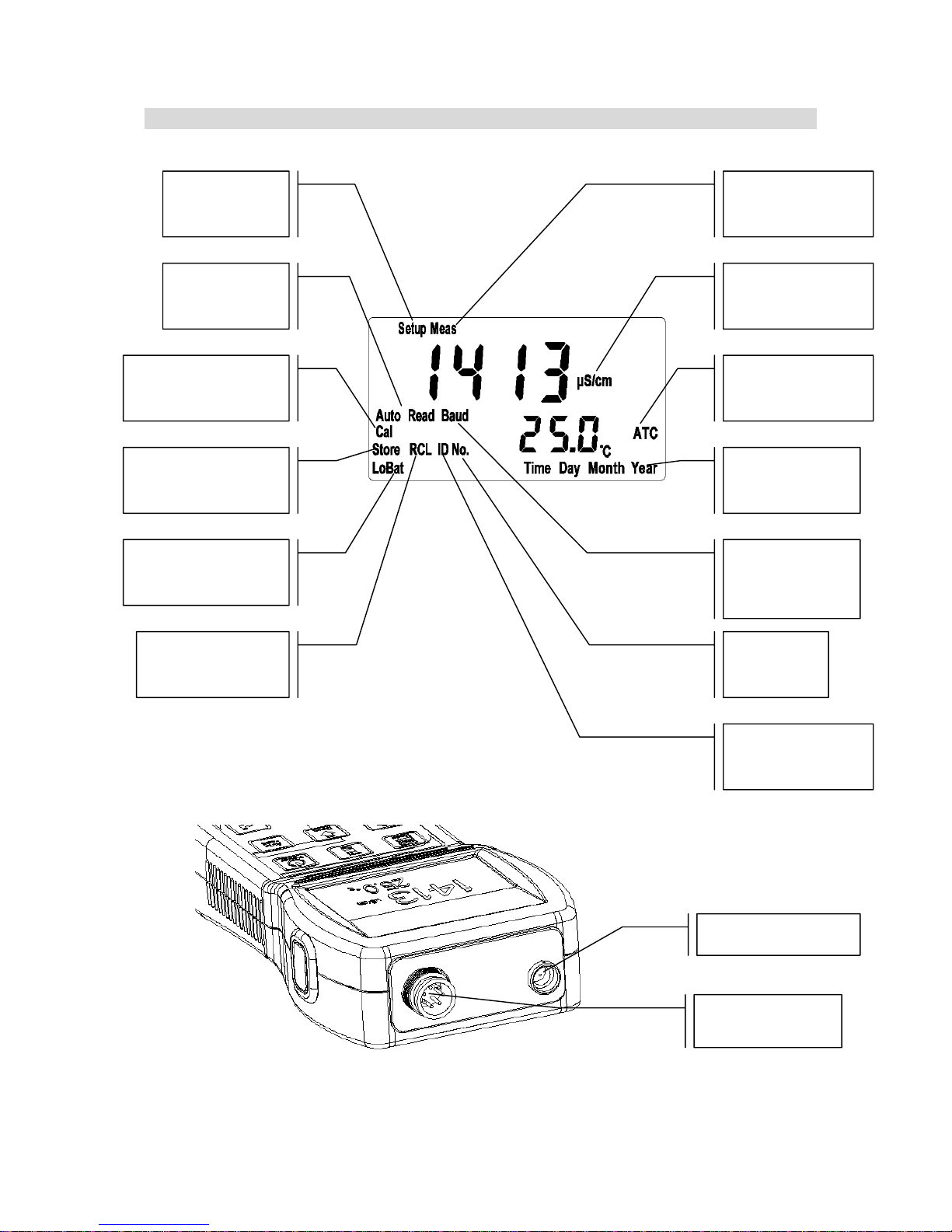

2. Configuration

2.1 Display:

2.2 Socket:

Set-up mode

Measurement mode

Measurement unit

Auto temperature

compensation

Time reminder

Auto read

Calibration mode

Data storage mode

Low battery

reminder

Data read

/Transmission mode

Data Storage ID

number

Storage ID

Transmission

speed

Conductivity

electrode socket

RS232 interface socket

Page 6

3

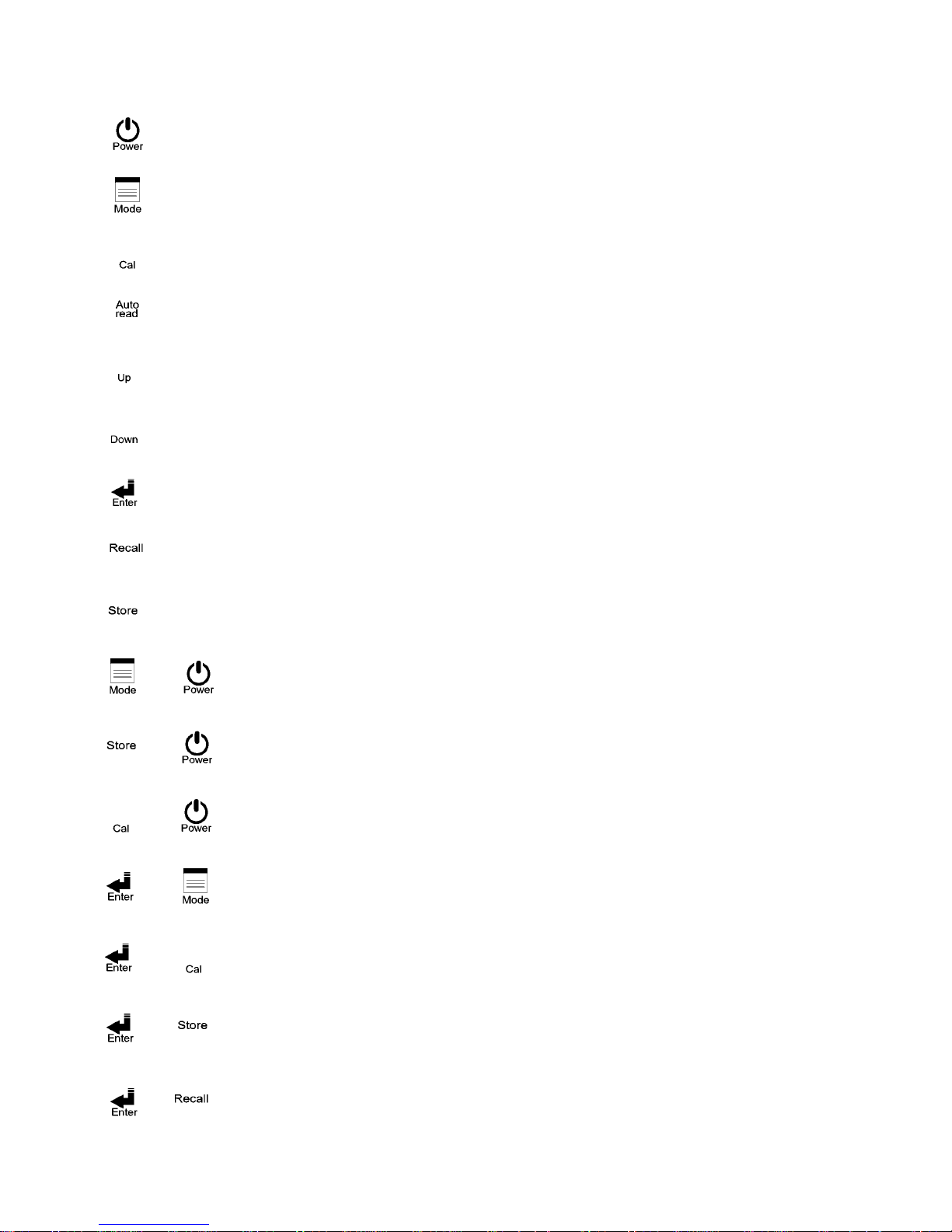

: Power switch. Push it to power on and push it again to power off. Auto shut-off

within10 minutes of no use

: Cond./Res./Salt/TDS measurement shift key; pushing it at any time will allow

backing to the measurement mode.

: Enter calibration mode.

: Key for auto read in measurement mode. Push one time for startup and push again for

cancellation.

: Upward or leftward key. For value adjustment, push it to increase the speed.

: Downward or rightward key. For value adjustment, push it to decrease the speed.

: (ENTER) Input, confirm, execute, and RS-232 manual output

: (Recall) Manual data read startup key and value read selection key.

: (Store) Manual data storage startup key

: Enter system parameter set-up, see 4.1

: Delete all stored data, see 4.2

: System reset, see 4.3

: Shift among the five manual modes and the auto mode. See 3.1

: Enter calibration parameter settings. See 4.4

: Enter auto continual storage settings. See 4.5

: Enter auto continual transmission settings. See 4.6

2.3 Keypad:

+

+

+

+

+

+

+

Page 7

4

3. Operation

3.1 Measurement:

Push key to start up the instrument. It will automatically enter the measurement mode

of final operation and begin to measure.

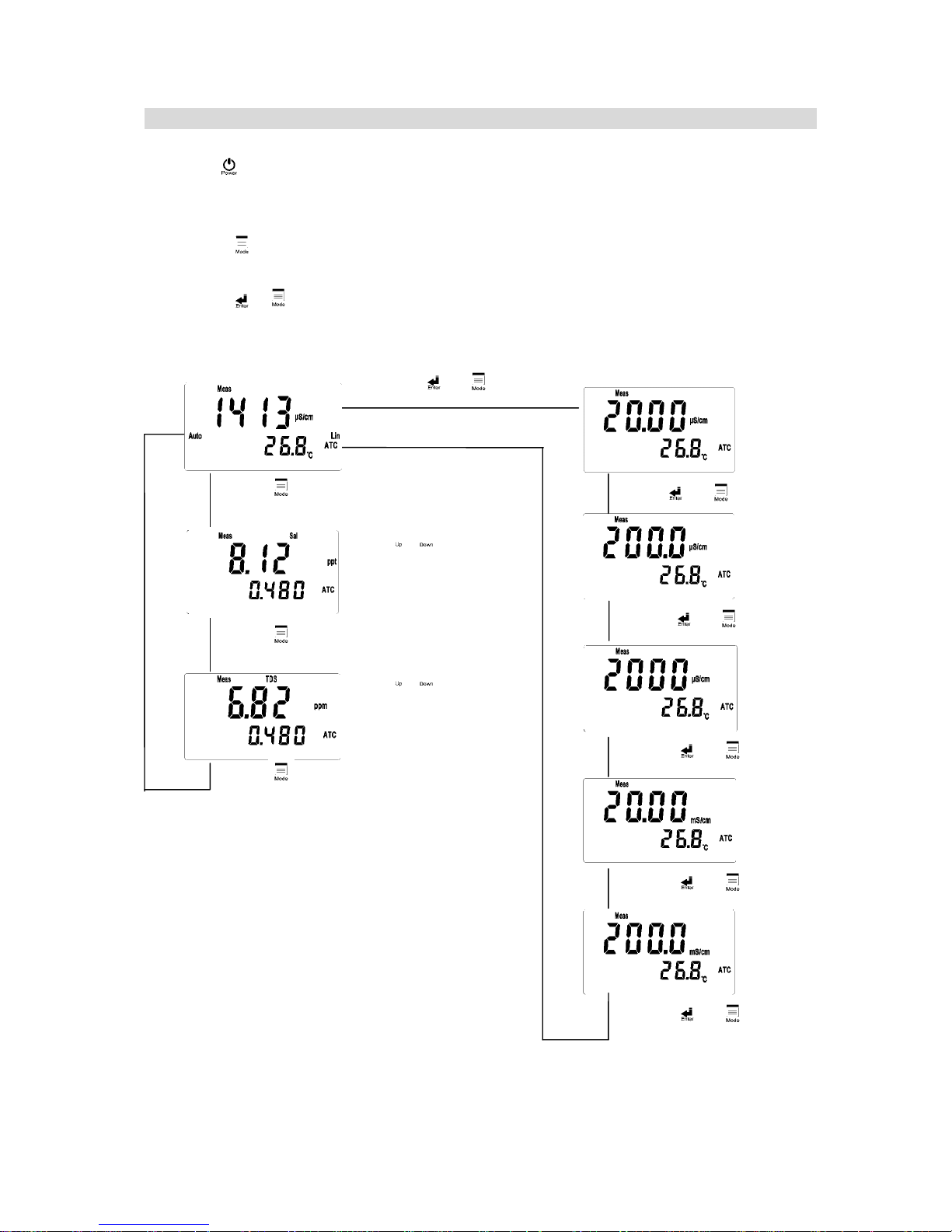

3.2 Measurement function and file bit shift:

1. Push key to shift among Cond., Salt, and TDS in Cond. Mode. This function is

unavailable in Res. mode.

2. Push + keys to shift among the five manual shifts and the auto shift. After

entering auto mode, AUTO characters will disappear after 3 seconds.

Remark: Before measuring salt and TDS, please finish the calibration according to the

conductivity calibration steps, and then set the factor value according to the standard

solution of salt and TDS.

Push to shift

Salt unit

Push to shift

TDS unit

Push to adjust

the salt value. Note:

Factor range is 0.4~1.5

Push to adjust

Total Dissolved

Solids. Note: Factor

range is 0.4~1.5

Push +

Push +

Push

Push +

Push +

Push +

Push +

Page 8

5

3.3 Temperature function and compensation:

1. ATC: Auto judgment of whether there is temperature probe and recognition of NTC30K

or PT1000. Push or to adjust the temperature within in ±5℃. At the same time,

push keys to back to the original value.

2. MTC: Enter MTC 25℃ automatically when there is no temperature probe. Push

or to adjust the temperature. At the same time, push keys to back to the

default value 25.0℃.

3. Temperature compensation: Because the temperature of the to-be-tested solution may not

be 25℃, for standardization, the conductivity value of solution not at the temperature of

25℃ will be calculated to that of solution at the temperature of 25℃. This is temperature

compensation.

4. According to the temperature coefficient required by the measurement, three kinds of

temperature compensation can be applied: Lin, nLin, and non compensation (0.00%). See

the setting method in 4.4.3, and the user can set as needed.

5. Temp. Coefficient (called as TC for short), the conductivity value of the solution will

increase as the temperature rises at a different rate. See the relations as follows:

C25

Conductivity at 25℃

Ct

Conductivity at T℃

Formula 1: Ct = C25 { 1+β( T – 25 ) }

T Temp. of the tested solution

β Temp. Coefficient

Formula 2: β = ( Ct-C

25

) / { C

25

( T-25 )}

6. How to measure the TC of the tested solution: If the user wants to get a more accurate

value, the above formula can be applied to measure the TC of the tested solution and set

an appropriate TC on the machine. Take 0.01N Kcl as an instance, set the TC as non

compensation (0.00%) in the machine. Control the same tested solution respectively at

5℃ and 20℃. The value 1413μS tested at C25 is just the conductivity of the solution at

25℃; and the value 1278μS tested at Ct is just the conductivity of the solution at 20℃.

According to formula 2, β=1.91%.

3.4 Auto Read:

In the measurement mode, push to start up and push to read. Then, push

Enter to make the next measurement. Push or at any time will allow backing to

the measurement mode.

Auto Read symbol twinkles

for about 10 seconds.

Auto Read symbol stop twinkling

and a value will appear after the

measurement is stable.

Back to the measurement

Push or

Page 9

6

4. Settings

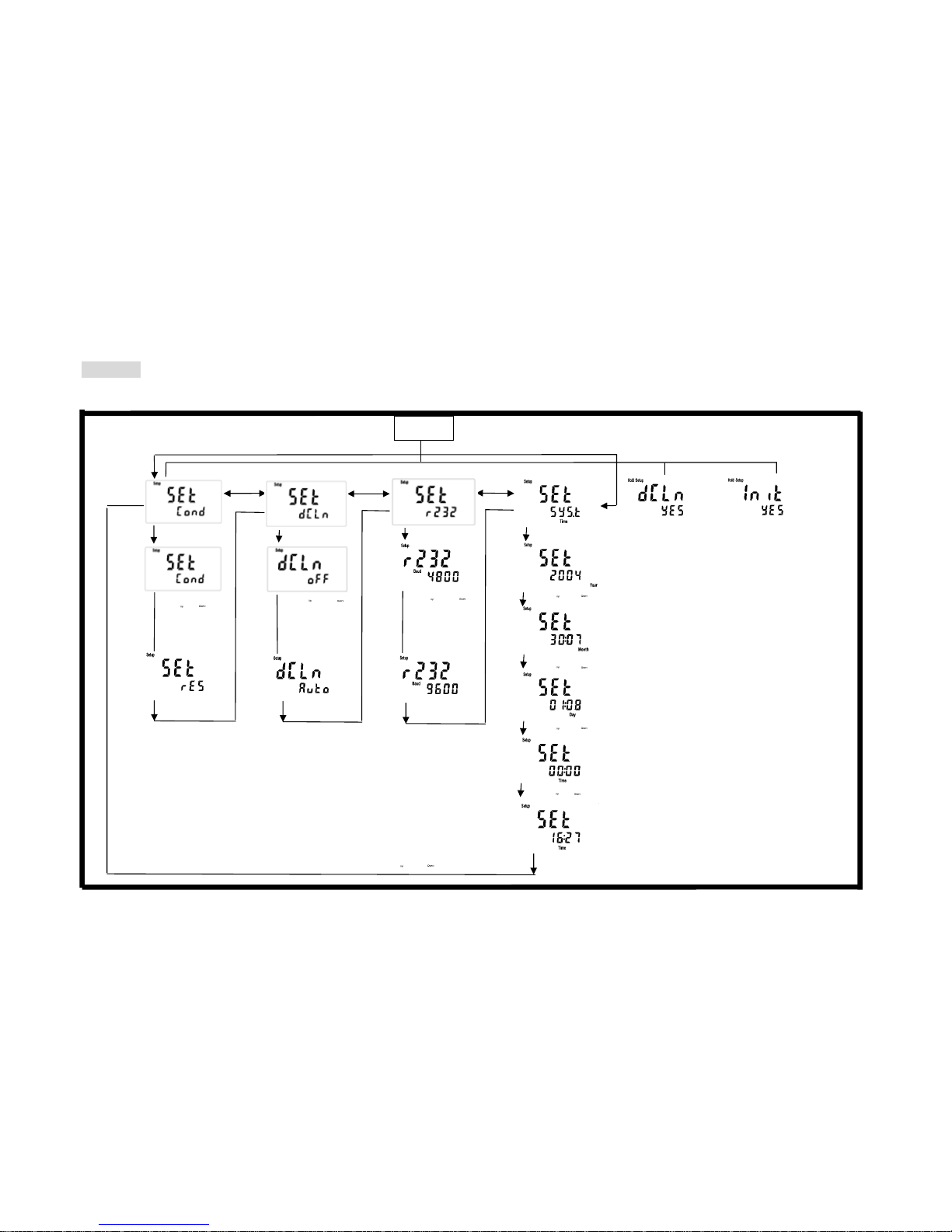

Block diagram of settings

↓: Enter key

→: Downward key for right

←: Upward key for left

Data overcast settings

Baud rate settings

Push or

to select auto

overcast or

cancel overcast

Push or

to select other

transmission

speed: 1200,

2400, 4800 or

9600

Push Store+Powe

r

,

Loose Power+Store

To delete all stored

data

Push CAL+Power,

Loose Power+CAL

System reset

Push Mode+Power

Loose Power+MODE to

enter the measurement

mode

Settings of measurement

Power off

System time settings

Push or to modify the minute

Push or to modify the year

Push or to modify the month

Push or to modify the day

Push or to modify the

Push or

to select

conductivity or

specific resistivity

Page 10

7

4.1 Parameter settings:

4.1.1 Entry of set-up mode:

In the power-off status, push first and then; after that loose first and

then to enter the parameter set-up mode. Use to select.

4.1.2 Settings of measurement mode:

4.1.3 Settings of data deletion:

Enter “Settings of data deletion”

Push or to select

MΩ-cm、uS/cm

Push to enter

Push to confirm

Push to enter

Enter “Settings of baud rate”

Push or to select auto

overcast or cancel auto overcast

Push to confirm

Page 11

8

4.1.4 Settings of baud rate (BAUD):

Enter “Settings of RS-232 baud rate”

Push to enter

Enter “Settings of system time

Push to confirm

Push or

to select

Push or

to select

Push or

to select

Page 12

9

4.1.5 Settings of system time:

Enter “Settings of system time”

Push to enter

Push or to modify the year,

push to confirm

Push or to modify the month,

push to confirm

Push or to modify the day,

push to confirm

Push or to modify the hour,

push to confirm

Push or to modify the minute,

push to confirm

Back to “Setting of measurement mod,

or push to back to measurement mode

Page 13

10

4.2 Deletion of all stored data:

In the power-on status, push first and then; after that loose first and then

to enter the data deletion mode.

4.3 System reset:

In the power-off status, push first and then; after that loose first and

then to enter the system reset page.

Factory defaults:

Data deletion settings: Auto

(BAUD) settings: 4800

Data transmission settings: read the stored data on the display (Sto diSP)

Back to the measurement

Back to the measurement

Push to confirm to delete all stored

data or push to back to the

Push to confirm the system reset;

or push to back to the

Page 14

11

Block diagram of calibration and temperature compensation settings

Settings in specific resistivity mode

Measurement mode

Power on

Calibration and temperature

compensation settings. Push Enter+CAL

Settings in conductivity mode

Measurem

Power on

Push Enter+CAL

Measurement temperature

Electrode coefficient

calibration settings

Standard solution

calibration settings

Measurement temperature

coefficient settings

Page 15

12

4.4 Settings of calibration parameter:

In the power-on status, push first and then to enter set-up mode of calibration

parameter. Use to select.

4.4.1 Electrode coefficient and calibration parameter:

(Only suitable when the measurement unit is conductivity)

Push to confirm

Back to measurement mode

Push to enter the settings

of calibration temperature

Push to confirm

Push or

to select

Push or to set the temperature

Push or

to select

Push to confirm

Page 16

13

4.4.2 Standard solution calibration parameter:

(Only suitable when the measurement unit is conductivity)

4.4.3 Temperature compensation coefficient:

Push or

to select

Push to confirm

Back to measurement mode

Push to confirm

Push to confirm

Back to measurement

Push to confirm

Push or

to select

Push or to set the temperature

Push or

to select

Push to confirm

Page 17

14

Block diagram of operations in measurement mode

Appear recently stored

Push or to close

Read the ID, and push or

to in

q

uire other data through ID

Back to the

measurement

mode

Read the stored yea

r

Read the stored date

Read the stored time

If the Auto and Store

icons shine, it means

that the data is stored

In case of data full

unable to store,

Store will twinkle

Back to the

measurement

Appear the

ori

g

inal ID

Push or to

set the ID number

Push or

to set the minute

If the Auto and Store

icons shine, it means

that the data is stored

Continual

measurement and data

Cancel continual

storage

Data store full

Transmissi

Power on

Storage

Auto store

Push Enter+Store

Appear the original ID

Back to the

measurement

Manual

store push

After

transmission,

back to the

measurement

mode

automatically

Auto transmission

Push Enter+Recall

Continual

The stored data

is transmitted

The stored data is

transmitted through RS232

The calibrated data is

transmitted to the dis

play

The stored data is

transmitted to the display

Manual read and transmission

Push Recall to shift circularl

y

among 4 modes

CEL

L

direct

Std simple point

calibration

Std five point

calibration

Back to

the

measurem

ent mode

Back to

the

measurem

ent mode

Back to

the

measurem

ent mode

After

transmission,

back to the

measurement

mode

automatically

Push or to

set the second

Push or to

set the ID number

Push or to

set the minute

Push or to

set the second

Push or to

modify the

Page 18

15

4.5 Auto/manual data storage:

4.5.1 Auto storage:

In the measurement mode, push first

and then to enter the auto continual

storage set-up mode.

4.5.2 Manual storage:

In the measurement mode, push to

enter manual store page.

4.5.3 Data full:

When the data is full to store, the

display will shine as a reminder, and

five seconds later, it will back to the

original measurement mode.

According to step 4.2, delete all the data.

In case of auto overcast, there will no

reminder of data full.

Back to the measurement

Push to confirm

Push or to set ID number;

Push to confirm the storage

Back to measurement mode

Push to confirm

Push or to set ID

number; Push to confirm

and enter settings of automatic

Push or to set the minute,

and push for confirmation and

settings of second

Push + or push to

cancel the auto store mode

If the Auto and Store

icons shine, it means

that the data is stored

Push or to set the seconds,

and push for confirmation. (The

minimum value is 5 seconds)

Page 19

16

4.6 Data readout and output:

4.6.1 Auto transmission:

In the measurement mode, push first

and then to enter auto transmission.

4.6.2 Manual readout and transmission:

In the measurement mode, push to shift

among 4 modes circularly, and push to

enter.

A. Read the stored data on the display

Push or to set the minute,

and push for confirmation and

enter the second setting.

Back to measurement mode

Push or to set the seconds,

and push for confirmation.

(The minimum value is 5 seconds)

If the Auto and Store icons

shine, it means that the data

is stored automatically

Push to enter, and the recently

stored data will appear

Push or to modify the

inquiry site. Push to confirm.

Read the ID and push and to inquire

other data according to the Id. Push to

read the data value and year.

Push to read the stored date

Push to read the stored time

Push + or push

to cancel the auto store mode

Back to measurement mode

Push

Push to read the store temperature

Page 20

17

B. Transmit the stored data through RS-232

Transmit all stored data through RS-232

C. Read the calibrated data on the display

C.1 Read the CELL calibrated data (when

the calibration parameter is set as

CELL calibration)

After the transmission, back

to measurement mode

Back to measurement mode

Push to enter, and the standard solution

value and electrode coefficient appear

Push to enter, the calibrated

temperature compensation coefficient

Push , and the calibration

record year appears

Push and the calibration record

date appears

Push

Push to transmit

Push and the calibration

record time appears

Page 21

18

C.2 Read simple-point calibration data of

standard solution (when the

calibration parameter is set as Std 1P

calibration).

Back to measurement mode

Push to enter, and the data and

electrode coefficient of standard

Push and the calibration record

Push and the calibration

record date appears

Push and the calibration record

time appears

Push

Page 22

19

C.3 Read five-point calibration data of

standard solution (when the

calibration parameter is set as Std 5P

calibration).

D. Transmit the stored data through RS-232

Transmit all stored data through RS-232

Back to measurement mode

Push , show the Buffer1. If

there’s no Buffer1, show NULL

Push , show the Buffer2. If

there’s no Buffer1, show NULL

Push , show the Buffer3. If

there’s no Buffer1, show NULL

Push , show the Buffer4. If there’s

no Buffer1, show NULL

Push , show the Buffer5. If

there’s no Buffer1, show NULL

Push and the calibration

record year appears

Push and the calibration

record date

Push and the calibration

Push

After the transmission, back

to measurement mode

Push to transmit

Page 23

20

5. Calibration

Block diagram of Calibration

Use ↑↓keys to

select

known

standard

solution value

Back to

measurem

ent mode

Push【MODE】

Use ↑↓keys to

select

known

standard

solution value

Back to

measurem

ent mode

按【MODE】

The

instrument is

reading

coefficient

The

instrument is

reading

coefficient

The

instrument is

reading

coefficient

Use ↑↓keys to

select

known

standard

solution value

The

instrument

is reading

coefficient

The instrument

is reading

coefficien

t

Use ↑↓keys to select

standard solution

value, including:

10.00uS/cm,

84.0uS/cm,

1413uS/cm,

12.88mS/cm,

100.0 mS/cm

five default values

Back to

measurement

mode

Use ↑↓keys to

select suitable

coefficient

C=.0100

C=0.100

C=0.475

C=10.00

Coefficient

valve shines,

use ↑↓ keys to

adjust

coefficient

value

Back to

measurement

mode

Push CALke

y

Power

Conductivity mode

Specific resistivity mode

Use ↑↓keys to

select

known

standard

solution value

The

instrument is

reading

coefficient

Backto

measu

r

Push【MODE】

Back to

measurem

Push【MODE】

Use ↑↓keys to select

known standard

solution value

Back to

measurem

ent mode

Push

Use ↑↓keys to

select suitable

coefficient

C=.0100

Coefficient valve

shines,use ↑↓

keys to adjust

coefficient value

to the known

standard solution

value

Back to

measurement

mode

Page 24

21

5.1 Standard solution preparation:

Put the agent potassium chloride in an oven of 150℃~180℃ for 5 hours, and then put it in a dry container

until it cools to the room temperature. Dissolve 0.7456 g potassium chloride into 1kilolitre pure water to be

0.01N potassium chloride standard solution (1413uS/cm).

5.2 Calibration mode:

Measured

functions

Calibration method Preset temperature compensation method

Set CELL CONSTANT

(Lin) 2.00% adjustable

Std 1P Prepare 5 selectable kinds of Buffer According to standard solution default

Conductivity

Std 5P Prepare 5 selectable kinds of Buffer According to standard solution default

Special resistivity Set CELL CONSTANT (nLin)

5.3 Entry of calibration mode: Temperature coefficient produces a great influence on measurement of

conductivity, so it is suggested to control the temperature of standard solution within 25±3℃ during the

calibration.

5.3.1 Electrode coefficient calibration:

1. When the calibration parameter is set as electrode coefficient set-up

mode (see 4.4), push to enter the electrode coefficient set-up page,

and then push to enter the next page.

2. Push or to select electrode coefficient default 10.00, 0.475,

0.100 or .0100 (special resistivity only includes 0.100 and .0100), in

order to select a suitable electrode coefficient value. After selecting the

suitable default, push to enter the next page.

3. Then, the electrode coefficient value begins to twinkle. Push or

to adjust the electrode coefficient value until equal to the buffer’s

standard. Then, push to back to the measurement mode.

5.3.2 Standard solution single-point calibration:

1. When the calibration parameter is set as single-point calibration

(see 4.4), push to enter Standard solution single-point calibration,

and then push to enter the calibration solution selection page.

2. Show the first known buffer’s standard and temperature. Push

or to adjust the known buffer’s standard, including five default

values 10.00uS, 84.0uS, 1413uS, 12.88mS and 100.0mS. After selecting

the suitable default, push to enter the next page.

3. The symbol Auto Read begins to twinkle, indicating that the

instrument begins auto calibration. After the calibration, the display

shows the calibrated electrode coefficient automatically.

Page 25

22

4. After the calibration, the display shows the calibrated electrode

coefficient automatically. Push to back to the measurement mode.

5.3.3 Standard solution five-point calibration:

1. When the calibration parameter is set as five-point calibration (see

4.4), push to enter Standard solution five-point calibration, and

then push to enter the first CAL1 page. Pushing at any time will

allow you intermit the calibration and back to the measurement mode.

2 Push or to select calibration point CAL1~5. Their default

values are respectively 10.00uS, 84.0uS, 1413uS, 12.88mS and

100.0mS. You can select any calibration point to make single-point,

two-point, three-point, four-point, and five-point calibration. After that,

clean and dry electrode before, and then put it into the buffer solution.

Push to enter the calibration page.

3. The symbol Auto Read begins to twinkle, indicating that the

instrument begins auto calibration. After the calibration, the display

shows the calibrated electrode coefficient automatically.

4. After the calibration, the display shows the calibrated electrode

coefficient automatically.

5. Push to enter the second calibration (CAL2) and finish the first

point calibration. Push to store the calibration data and the system will

exit calibration mode and back to measurement mode.

6. Other CAL2~CAL5 calibration applies the same steps as CAL1.

Characteristics: The design of this instrument has no limit of the calibration sequence, so after finishing

any point calibration, you can push to enter the next point calibration, and push to store the

calibration data. Then, exit the calibration mode and back to the measurement mode to finish the

calibration of any one or a few points.

5.3.4 Error messages: In case of any error messages when the calibration

fails, please refer to chapter 8 Failure Recovery to remove the errors and

restart the calibration.

Page 26

23

6. Instruction set for RS232

The communication between the base unit and the Windows Hyper Terminal is set as follows:

1. Click 【start】on the lower left, and select 【program set】→【Accessorial applications】→

【Communication】→【Hyper Terminal 】, and the display will show a window of “Hyper Term inal” .

2. Set icon and online name for Hyper Terminal before entering the “ONLINE” window.

3. Select communication terminal (for example, select 「connect COM1」) in 「Use online (N):」in

“ONLINE” window, and then enter the window “COM1 content”.

4. In 「transmission bit per second (B):」in “COM1 content”, select baud rate=9600 (It should be consistent

with controller settings), data bit (D)=8, parity check(P)=none, stop bit (S)= 1, flow control (E) =none.

5. Click 【intermit online】

6. Click 【file】→【content】, and enter the window “XXX content”.

7. Click 【setting value】→【ASCII setting】to enter “ASCII setting” window.

8. In “ASCII setting” window, select 「newline at the end of each line (S)」,「Respond to the input characters

(E)」,「Add LF at the end of each input line (A)」 and 「newline if exceeding the width of terminal (W)」,

and then leave “ASCII setting” window by pushing 【confirm】.

9. Push 【confirm】to leave “XXX content” window.

10. Push 【call】to link the communication.

7. Alternative fittings

Name Order number

Conductivity electrode C≒0.475

8-243

Special resistivity electrode C≒0.01

8-221-01

Special resistivity electrode C≒0.05

8-222-01

Flow cell 8-TF-02

10 µS KCl Calibration Solution in 16-oz(about 473ml) glass bottle

00652-24

84 µS KCl Calibration Solution in 500-ml leak-proof bottle

00653-16

1,413 µS KCl Calibration Solution in 500-ml leak-proof bottle

00653-18

12,880µS KCl Calibration Solution in 500-ml leak-proof bottle

00606-10

100,000S KCl Calibration Solution in 16-oz(about 473ml) glass bottle

00652-34

Page 27

24

8. Failure recovery

Failure phenomenon Possible causes Disposition

ERR1 The electrode coefficient bears a

large deviation when use the

standard solution in calibration.

Replace new standard solution for another

calibration. For others, please refer to the

disposition of measurement deviation in

the following.

ERR2 The measurement is unstable when

use the standard solution in

calibration.

Please refer to the disposition of unstable

measurement in the following.

The electrode is polluted. Clean and wash the electrode

The electrode coefficient (C) is

wrongly set.

Modify the electrode coefficient

The temperature coefficient (TC) is

wrongly set.

Modify the temperature compensation

coefficient.

The electrode is damaged or

broken-down.

Readjust the coefficient

There are air bubbles on the

electrode.

Churn up to remove the bubbles.

The battery is low. Replace with new battery.

Measurement deviation

Instrument fault Send to the original factory for repair.

The electrode is disturbed by the

bubbles.

Churn up to remove the bubbles.

The electrode is polluted. Clean and wash the electrode.

Electrode fault Replace the electrode.

The battery is low. Replace with new battery.

Unstable measurement

Instrument fault Send to the original factory for repair.

The electrode plugs is not inserted

into the required place.

Check the electrode plugs and reinsert it

into the required place.

The conductivity value is

zero or the special

resistivity value is out of

the range.

The electrode is broken. Replace the electrode.

Not soak deeply enough. Deepen the soaked length to ensure the

accuracy of temperature.

Deviation of standard comparison Use standard thermometer comparison to

correct the difference in temperature

The temperature sensor is broken Replace the electrode.

The battery is low. Replace with new battery.

Temperature deviation

Instrument fault Send to the original factory for repair.

The electrode plugs is not inserted

into the required place.

Check the electrode plugs and reinsert it

into the required place.

The temperature sensor is broken Replace the electrode.

Temperature is wrongly

displayed.

Instrument fault Send to the original factory for repair.

Page 28

25

9. Maintenance

9.1 Maintenance of base unit: Please keep it in dry and ventilated environment. Use wrung soft wet cloth to

wipe the generally polluted surface. For pollution by grease, please remove the stain with waxed soft wet

cloth. Solvent is strictly prohibited.

9.2 Battery replacement:

a. When the display shows Lo Bat during the instrument works, please replace with alkali dry cells.

b. First power off the instrument, and then use cross head screwdriver to dismantle the four screws on the

back of the instrument.

c. Open the back cover and remove the battery protection cover.

d. Take out the old battery and put in 4 new AA batteries in correct directions.

e. Reinstall the battery cover and back cover, and lock the 4 screws to finish the battery replacement.

f. Caution! The battery replacement should be finished within 20 seconds; otherwise the date data will

disappear and should be reset.

9.3 Maintenance of electrode: The substances on the measuring side of electrode will influence the

measurement value and cause deviation. Please clean and maintain it regularly. Use soft brush or cotton stick

to clean the graphite surface of electrode.

Pollution types Cleaning methods

Pollution by grease Use mild degreasing agent to clean the electrode.

Pollution by dirt Soak in 2~5% Hcl for about 5 minutes.

Loading...

Loading...