Page 1

Dual Channel

2

℃

℃

Conductivity

Controller

EC-4200

Operational

Manual

CH1

18.00 1.000

CH

MΩ uS

ATC 25.0

μP CONDUCTIVITY CONTROLLER EC-4200

MTC 25.0

0

Page 2

1 Specifications

2 Assembly and installation

2.1

2.2

2.3

3

3.1

3.2

3.3

3.4

3.4.1

3.4.2

3.5

4

4.1

4.2

4.3

4.4

4.5

5 Measurement

5.1

5.2

5.3

5.4

5.5

5.6

5.6.1

6 Setup

6.1

6.2

6.3

6.3.1

6.3.2

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.11.1

6.11.2

6.12

6.12.1

6.12.2

7 Calibration

7.1

7.1.1

7.1.2

Precautions for installation

Installation of controller

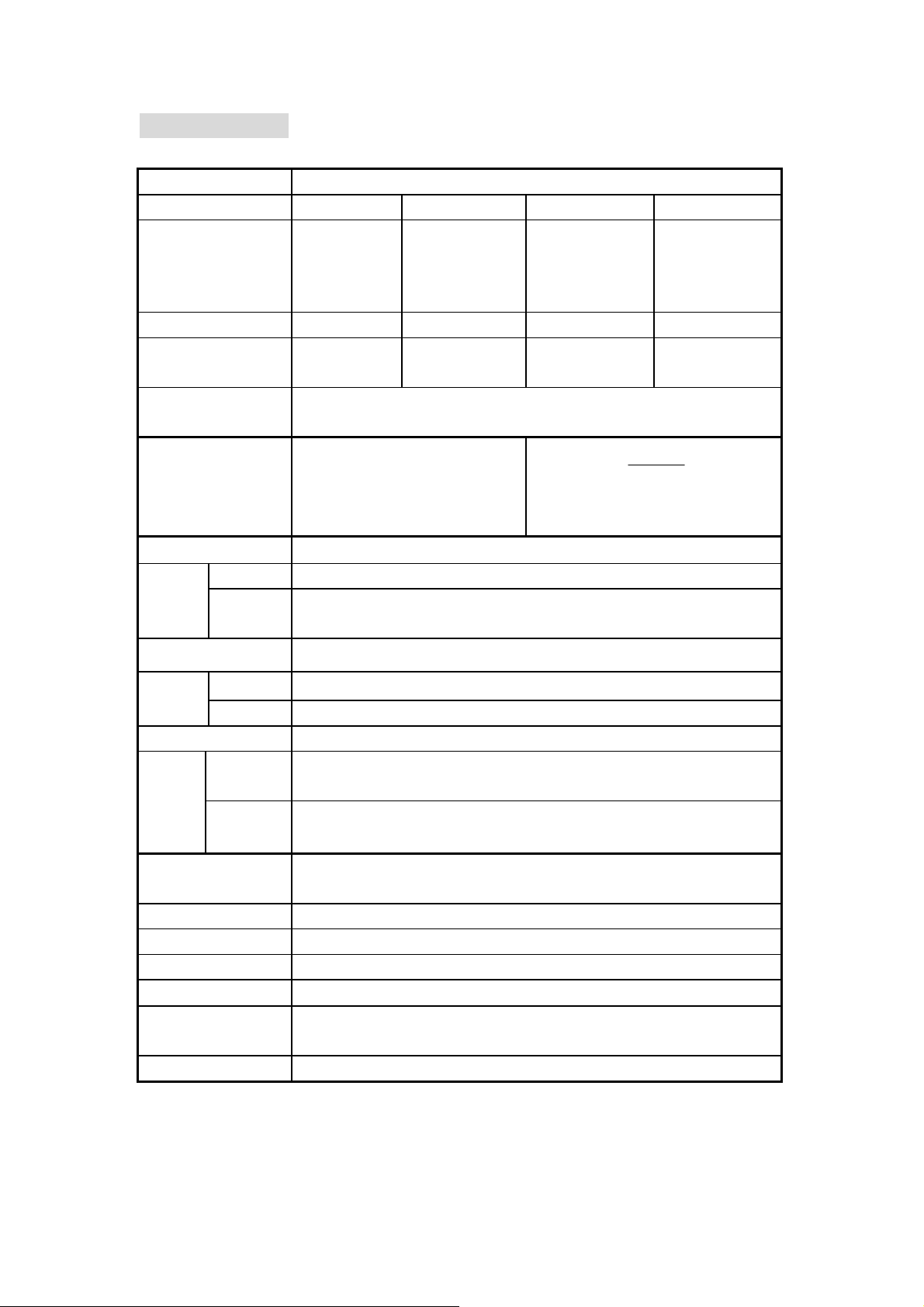

Cut out dimension

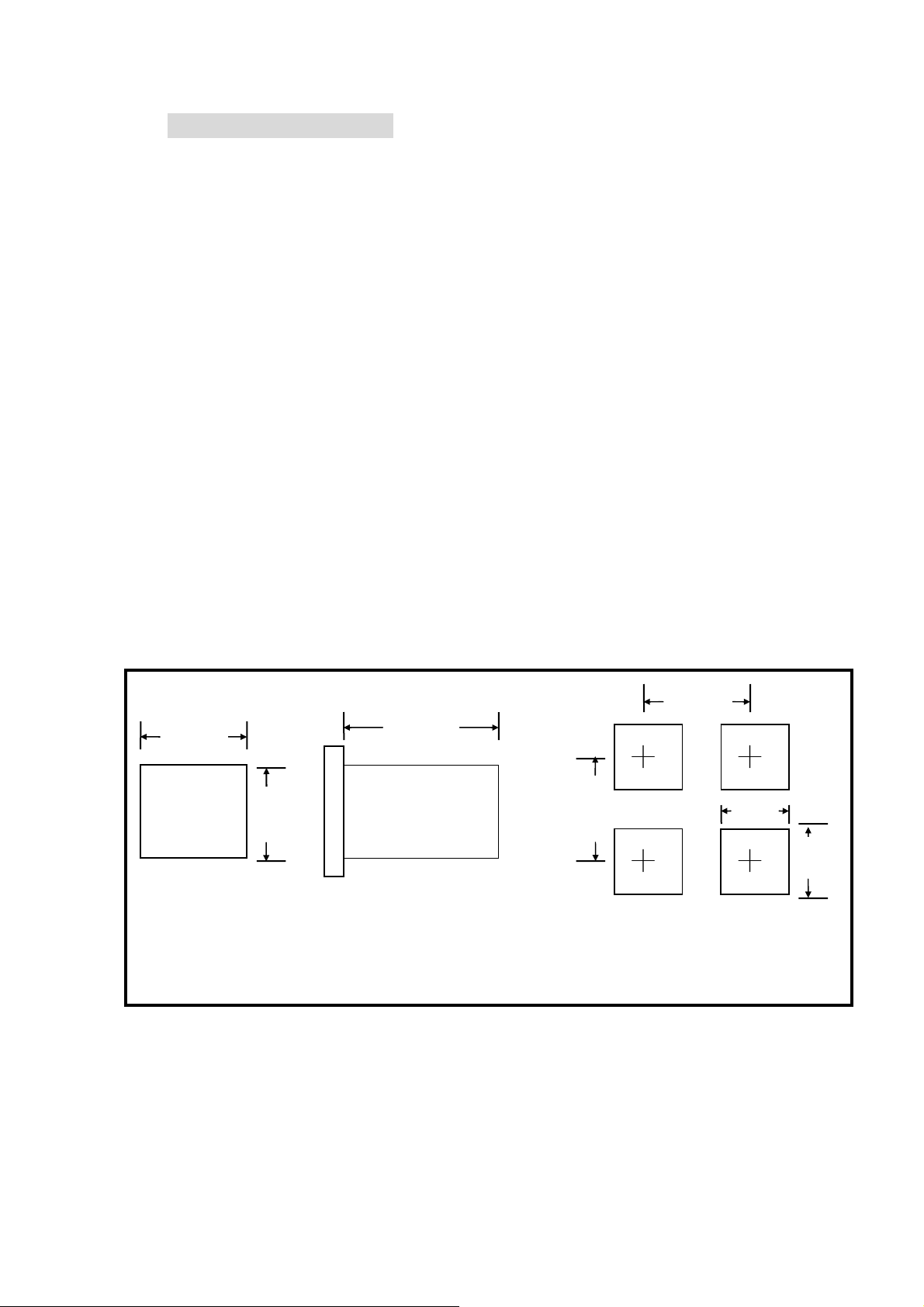

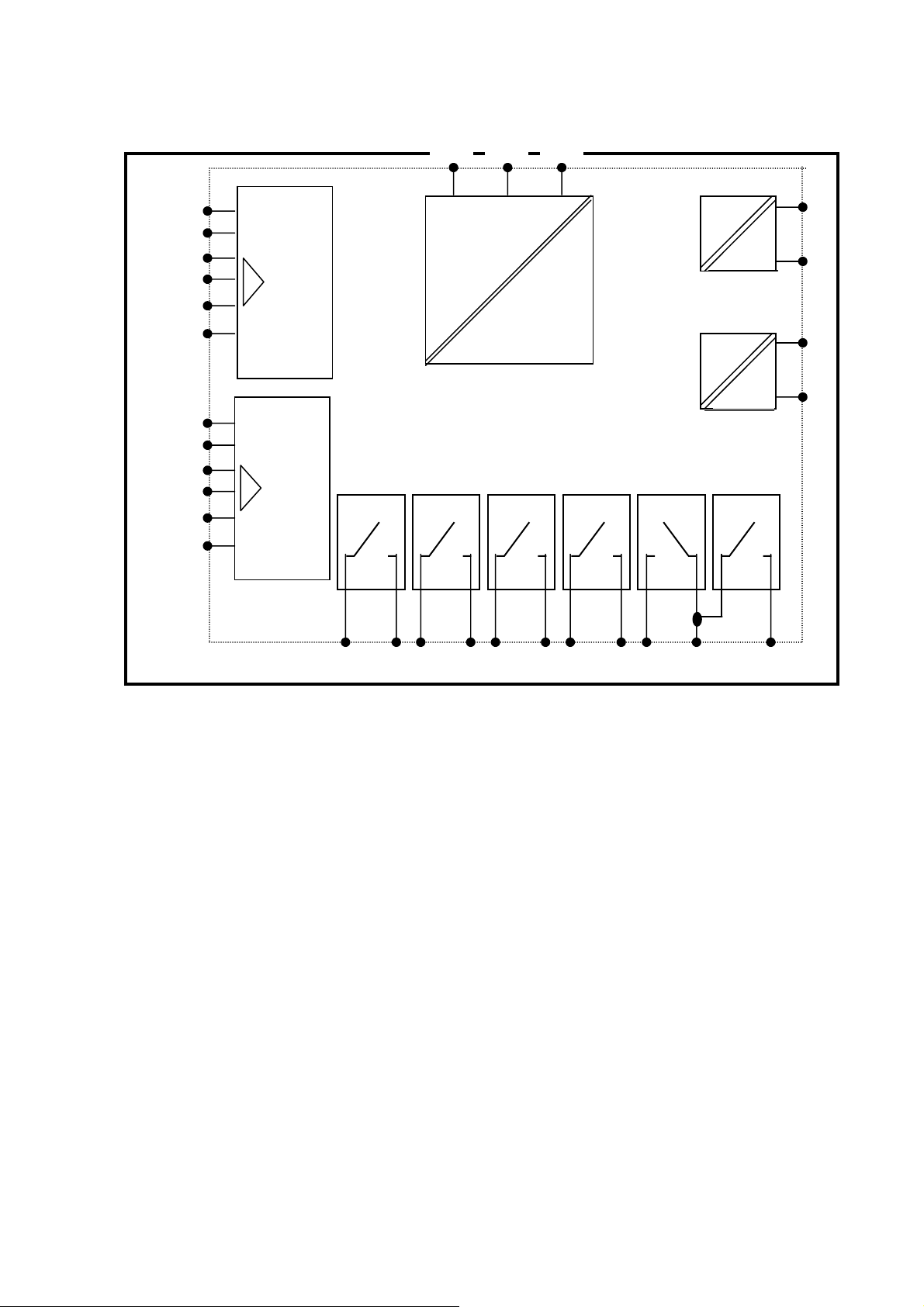

Block diagram and rear panel

Rear panel

Function block diagram

Descriptions of rear panel

Connection diagram of electrode

Wiring of electrode

Circuit of electrode

Electrical connection diagram

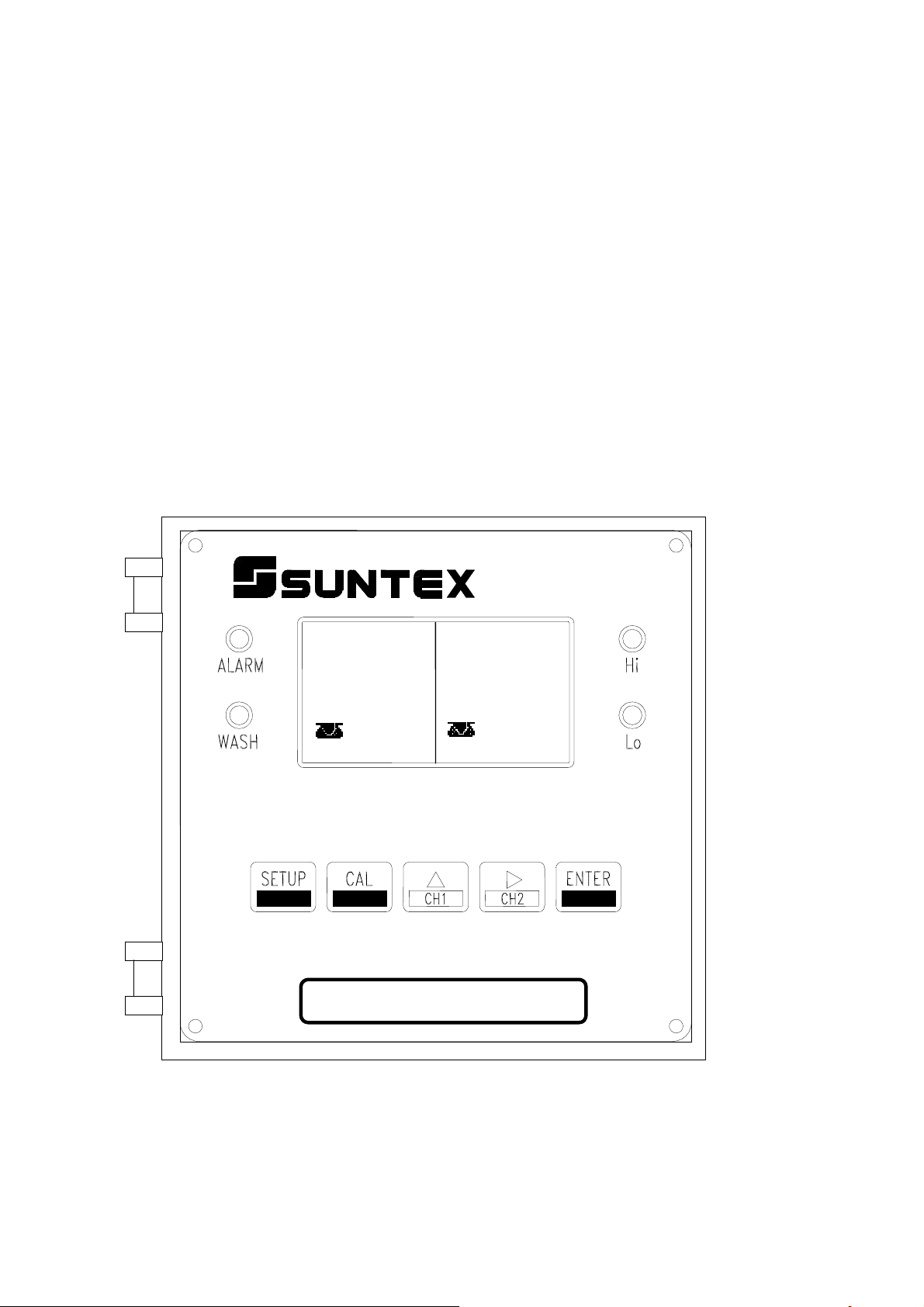

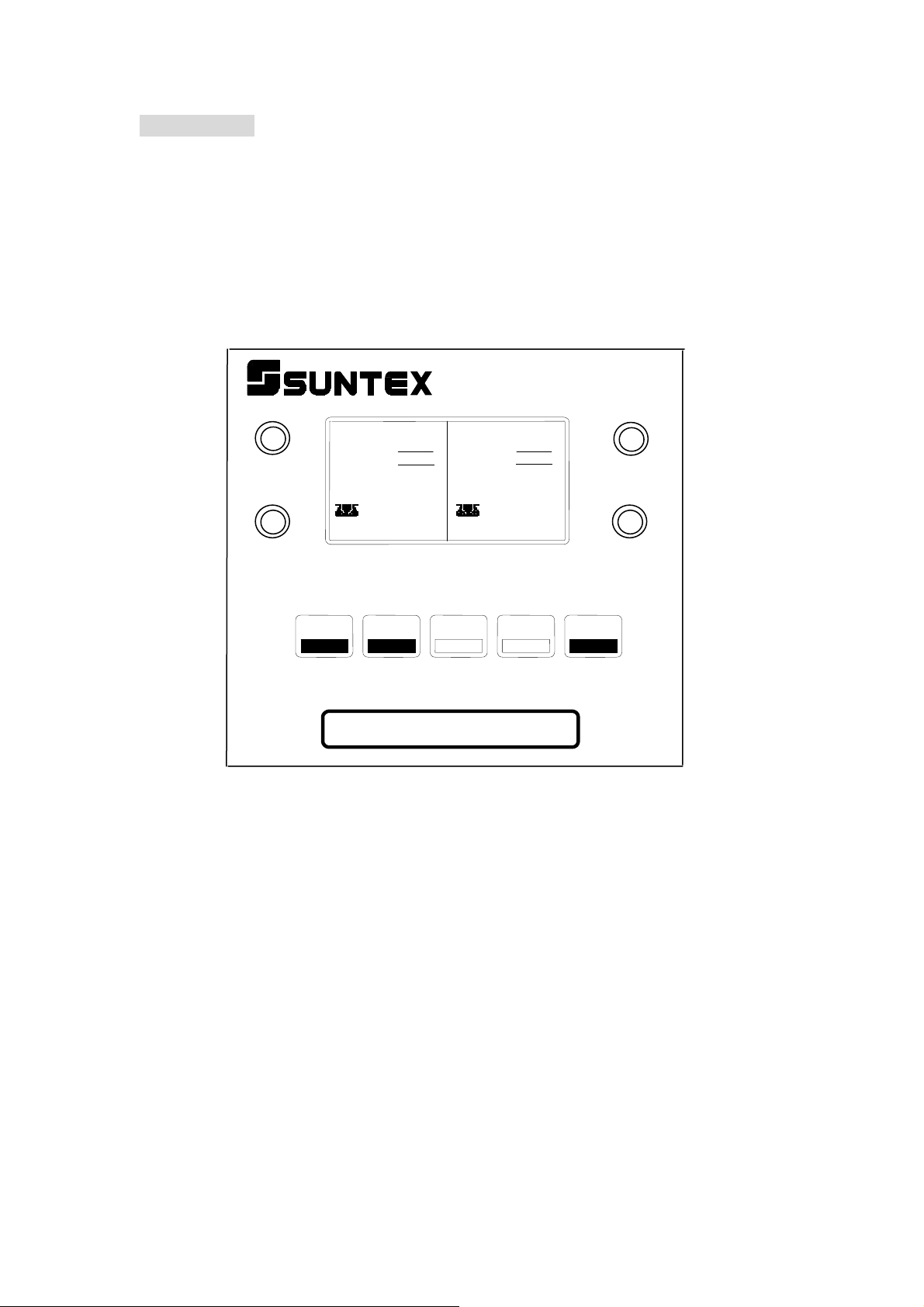

Illustration of function on front panel

Front panel

Descriptions of LCD screen

Functions of LCD screen

Descriptions of buttons

LED indicators

Overview flow chart of measurement mode

Access setup mode

Access calibration mode

Restore default setup parameters

Restore default calibration parameters

Screen switch

Operating mode screen swapping

Overview flow chart of setup mode

Access setup mode

Select measuring mode

Double display without Rejection display

Single display or with one CH as Rejection display

Washing time setup

Calibration Interval

Frequency

Current alarm setting

Current output

Set Lo point

Set Hi point

Temperature Compensation

Non linear temperature compensation

Linear temperature compensation

Temperature measuring

Temperature probe connecting

Manual temperature setup

Ω-CM Calibration mode

Cell constant input

User buffer solution calibration

1

Page 3

7.2

7.2.1

7.2.2

7.2.3

7.2.4

S/CM and rejection calibration mode

Cell constant input

User buffer solution calibration

Calibrate electrode by 0.1KNCL solution

Calibrate electrode by 0.01N KCL solution

8 Error message

8.1

8.2

Calibration error

Measuring error

2

Page 4

1.SPECIFICATIONS

MODEL EC4200

Measuring mode Resistivity Conductivity TEMP. Rejection

Measuring Ranges

0.00 M

Ω.cm~

0.05 uS/cm~

200.0 mS/cm

0.0~100.0 ℃

0.0~100.0 %

20.00 M

Ω.cm

Resolution 0.01 MΩ

Accuracy ±1 %

(±1Digit)

Temp

0.01uS

±1 %

(±1Digit)

0.1 ℃

±0.1 %

(±0.5℃)

Auto with PT1000/NTC30 or manual

0.1 %

±0.01

(±1Digit)

compensation

Temp Coefficient Linear compensation

from0.00 % ~ 5.00 % or

non-linear for natural

water

Amb Temp

0~50°C

screen Graphic LCD display Display

method Dual channel simultaneous display, or CH1/CH2 single

display

Signal Output

Set

Contact 240VAC 2A max.

Isolated current DC 4~20mA, Max. load 500Ω

points

Control Independent Hi/Lo ON/OFF RELAY contact

Alarm Output Single ON/OFF RELAY output, 240VAC 2A max.

Wash

Contact Single ON/OFF RELAY output,240VAC 2A max.(Only with

the mode of% Rejection)

Time ON: 0~9999mins

OFF; 0~9999mins

Calibration

0~999 hours

Interval

Electrode status Yes

Power supply 115V or 230VAC±15%,50/60Hz

Installation Panel Mounting

Dimensions

Cut out

144X144X195mm(H×W×D)

135X135(H×W)

dimensions

Weight 1.9Kg

3

Page 5

2. Assembly and installation

2.1 Precautions for installation

Wrong wiring will lead to breakdown of the instrument or electrical shock,

please read the operating manual clearly before installation.

a. Make sure to remove AC power to the controller before wiring input and output

connections, and before opening the controller housing.

b. The installation site of the controller should be well ventilated and avoid direct

sunlight.

c. Relay contacts are subjected to electrical erosion. Do not connect relay contacts

directly to heavy loads, connect a magnetic switch instead. Especially with

inductive and capacitive loads, the service life of the contacts will be reduced.

d. For suppression of sparks and arcing, components such as RC combinations,

nonlinear resistors, series resistors, diodes and varistors are used.

2.2 Installation of controller

Reserve a 135x 135mm hole on the front panel of the wall mount chassis and

insert the controller from the front of the chassis, fasten the fixed support to fix the

controller.

2.3 Cut out dimension

135mm

Front view Side view

135mm 194mm 135mm

180mm

180mm

+

+

Distances among

+

+

135mm

4

Page 6

3. Block diagram and rear panel

CH2

SHIELD S HIELD

CH1

CELL1

CELL2

CELL3

CELL4

TP

CELL1

CELL2

CELL3

CELL4

TP

5

Page 7

3.2 Function block diagram

CH1

SHIELD

CELL1

CELL2

CELL3

CELL4

TP

CH1

SHIELD

I1

V1

V2

I2

T

230V 115V 0V

AC

INPUT POWER

CH1

4/20mA

+

-

+

CH2

SHIELD

CELL1

CELL2

CELL3

CELL4

TP

CH2

SHIELD

I1

V1

V2

I2

T

CH2

4/20mA

H1 L1 H2 L2 ALARM WAS H

-

6

Page 8

3.3 Descriptions of rear panel

CH1

SHIELD

CH1 CELL 1 :

CH1 CELL 2 :

CH1 CELL 3 :

CH1 CELL 4 :

CH1 TP :

Connecting to the net wire of CH1 CELL

:

Apply an ion plate between CH1 CELL 1 and CH1 CELL2,

connected to the transparent wire of the CH1 CELL

Apply an ion plate between CH1 CELL 3 and CH1 CELL4,

connected to the green wire of the conductivity. Or connecting to

the white wire of the resistivity.

Connected to the red wire of the conductivity CELL. Or

connecting to the yellow wire of the resistivity CELL.

CH1 4-20mA : CH1 current output for recorder or PLC connection.

CH2

SHIELD

CH2 CELL 1 :

CH2 CELL 2 :

CH2 CELL 3 :

CH2 CELL 4 :

CH2 TP :

CH2 4-20mA :

: Connecting to the central net wire of CH2 CELL

Apply an ion plate to short circuit CH2 CELL 1 and CH2 CELL 2,

connected to the transparent wire of the CH2 CELL.

Apply an ion plate to short circuit CH2 CELL 3 and CH2 CELL 4,

connect to the green wire of conductivity; Or connecting to white

wire of the resistivity.

connect to the red wire of conductivity CELL; Or connecting to

yellow wire of the resistivity CELL.

CH2 current output for recorder or PLC connection.

H1: NO&COM :

CH1 High relay contact. It will be closed when contact is ON,

open when OFF.

L1: NO&COM :

H2: NO&COM :

CH1 Low relay contact. It will be closed when contact is ON,

open when OFF.

CH2 High relay contact. It will be closed when contact is ON,

open when OFF.

L2: NO&COM :

CH2 Low relay contacts. It will be closed when contact is ON,

open when OFF.

ALARM NO : ALARM relay contact. This terminal will be open with

ALARM/WASH COM when controller AC power is removed or

ALARM is OFF; closed when Alarm is ON.

WASH NO : Wash relay contact. This terminal will be open with

ALARM/WASH COM when controller AC power is removed or WASH

is OFF; closed when WASH is ON.

ALARM/WASH COM :

Apply with ALARM NO or WASH NO.

230V : AC power of the controller(AC115V or 230V)

115V

0V

7

Page 9

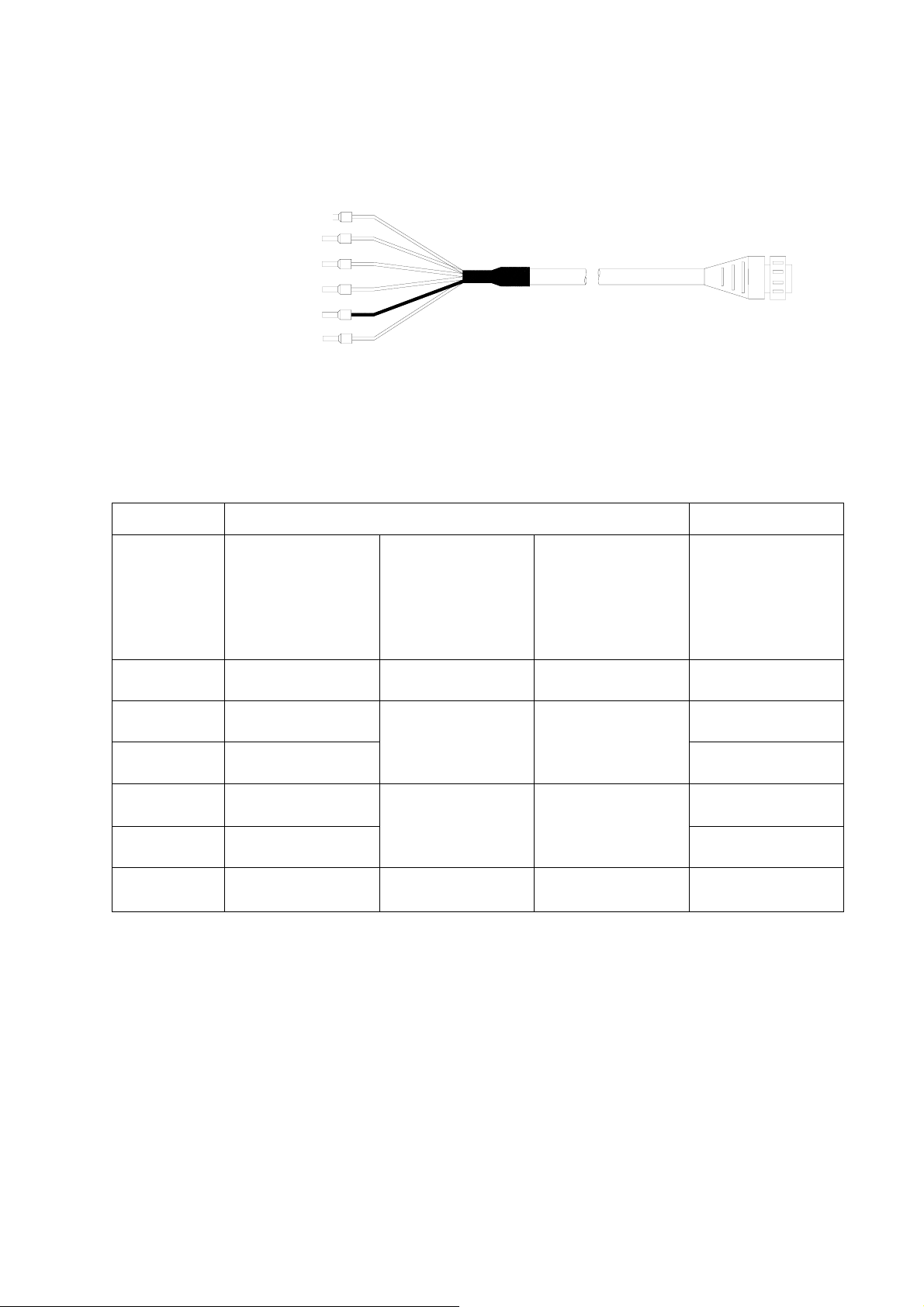

3.4 Connection diagram of electrode

3.4.1 Wiring of electrode

SHIELD (transparent)

CELL1 (brown)

CELL2 (red)

CELL3 (orange)

CELL4 (black)

T/P (yellow)

3.4.2 Circuit of electrode

Suntex electrode Others

Controller

rear panel

SHIELD

CELL 1

CELL 2

CELL 3

CELL 4

T / P

2E electrode

8-221

∕8-222

4E electrode 8-241

8-11-3

wiring

8-12-6

wiring

Please read the

description of

electrode

wiring

Transparent line Net line Net line SHIELD

Brown line CELL1

Short with ion

plate, connected to

Red line

Orange line CELL3

the transparent line

Short with ion

plate, connected to

Black line

the white line

Yellow line Yellow line Red line

Short with ion

plate, connected to

the transparent line

Short with ion

plate, connected to

the green line

connect to CELL4)

CELL2

CELL4

T / P(other wire

8

Page 10

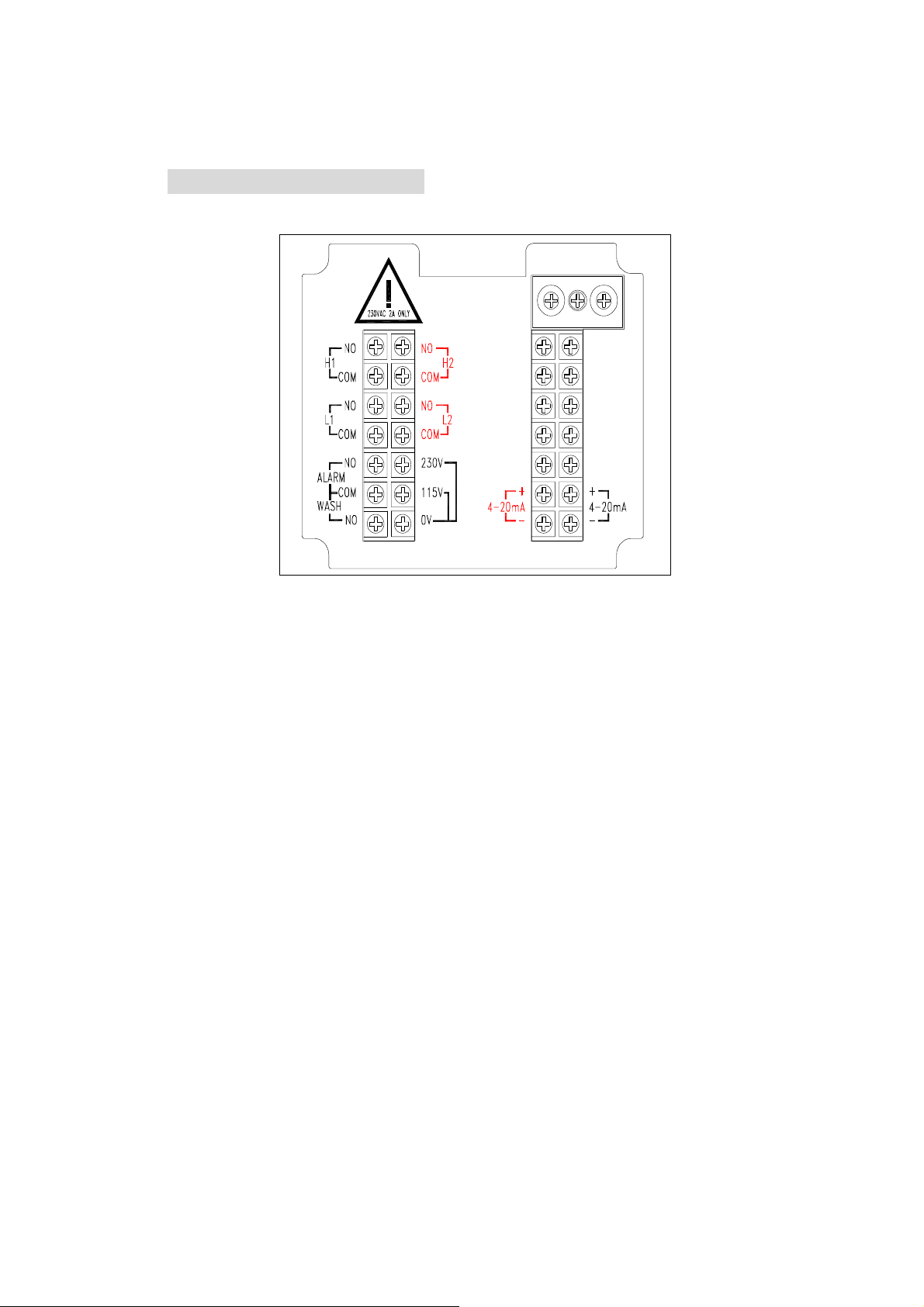

3.5 Electrical connection diagram

y

y

y

y

y

y

Va r is t or

M

Va r is t or

M

115V or 230VAC

H1 L1 H2 L2 ALARM WA S H

Va r is t or

rela

Cleaning device

rela

Dosage adding machine

Va r is t or

M

Va r is t or

M

Va r is t or

M

Va r is t or

rela

Dosage adding machine

rela

Dosage adding machine

rela

Dosage adding machine

rela

alarm

9

Page 11

4.Introduction

℃

WAS

o

4.1 Front panel

ALARM

H

CH1

H1 L1 ▼MA

18.00 1.000

MΩ

ATC 25.0

℃

CH2

H2 L2

▲MA

mS

MTC 25.0

Hi

L

SETUP

CAL

▲

CH1 CH2

►

ENTER

μP CONDUCTIVITY CONTROLLER EC-4200

10

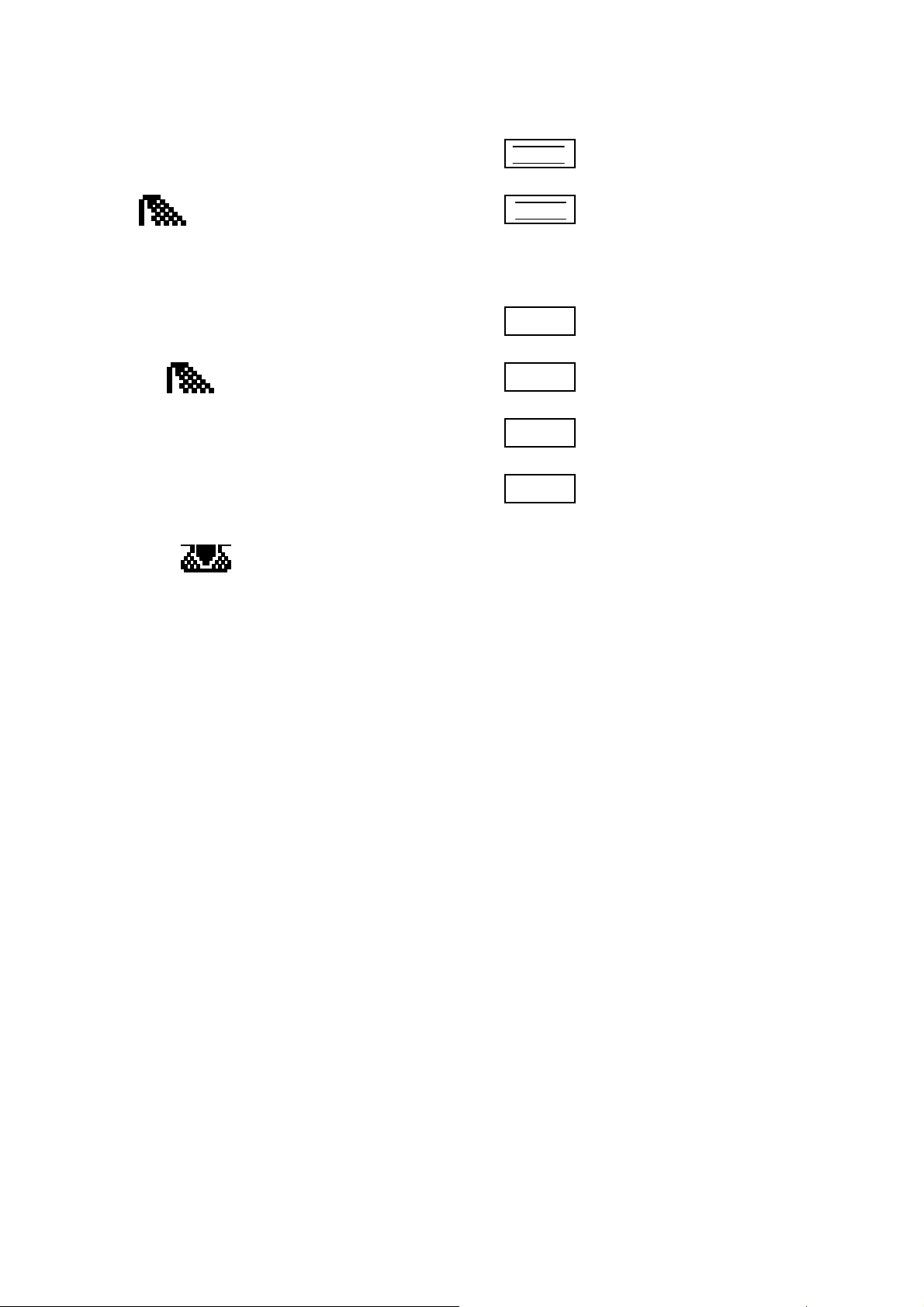

Page 12

4.2Descriptions of LCD screen:

O

3.

Current output status:

1. Wash relay indicator

ON Activates wash relay,

when wash on time is up.

FF

Activates wash relay, when

wash on time is off.

2.

Calibration prompter

Reminding user that it is

time to calibrate electrode. It will

▲MA

▼MA

4.

High and low point relay indicators

H1

L1

H2

L2

output current over than

20MA

output current lower than

4MA

CH1 high point relay on.

CH1 low point relay on.

CH2 high point relay on.

CH2 low point relay on.

start blinking when time ticks to

80% of CAL INTERVAL TIME,

steadily appears when CAL

INTERVAL TIME is up.

11

Page 13

4.3 Functions of LCD screen

y

Output

current lower

than 4MA

CH1

Low rela

CH1

High alarm

CH1

Va l ue

CH1

measure unit

Automatic

Temperatur

CH2

HIGH

ALARM

CH2

% REJECT

H1 L1 H2 L2

▼MA ▲MA

PERMEATE

99.0 1000

%

ON

ATC 25.0℃ MTC 25.0℃

mS

LOW ALARM

Output current

over 20MA

CH2

Va l ue

CH2

measure unit

Temperature

Reading

Wash

Relay On

Temperature

Reading

Time to

Calibrate

Manual

Temp

Compensation

12

Page 14

4.4 Descriptions of buttons

The unit provides multi-key to prevent

people from unauthorized access, as the

following:

SETUP

:Setup access key.

In measurement mode:

To coordinate CH1 or CH2

,it allows

you to access CH1or CH2 parameter

setup mode.

In parameter setup mode:

Press

SETUP to exit setup mode and

return to measurement mode.

CAL

:Calibration access key .

CH1

: In measurement mode.

z To coordinate SETUP or

CAL allows you to access

setup mode or calibration

mode of channel 1.

z To coordinate ENTER

allows you switch to

CH1 screen.

: Right/Down or CH2

CH2

key.

Right key:

● Shift cursor to next right.

● Left or right selection on the

menu.

Down key

:

In measurement mode:

To coordinate CH1 or CH2

, it

allows you to access CH1or CH2

calibration mode.

In setup mode:

Press

CAL to exit calibration mode

and return to measurement mode.

:Up or CH1 key.

CH1

Up key:

● Allows you to Increase numeric

values.

● Move cursor up within menu.

● Toggle parameters.

Allows you todecrease numerical

values or move menu cursor

down.

。

CH2

1

:○

In measurement mode, to

coordinated SETUP or CAL

allows you to access CH2

parameter setup mode or

calibration mode CH2.

2

○

coordinated ENTER allows

you to switch to CH2 screen.

ENTER

:Enter key.

In parameter setup or calibration mode:

● Select items within menu.

● Store input data in the setup mode.

In measuring mode:

coordinated CH1 or CH2 to switch

screen.

13

Page 15

Review of multi-key:

Access channel CH1 setup mode.

+

Access channel CH2 setup mode.

+

Access channel CH1 calibration

mode.

+

Access channel CH2 calibration

mode.

+

SETUP

SETUP

CAL

CAL

CH1

4

CH2

CH1

4

4

CH2

CH2

Switch channel CH1 to full screen.

+

Switch channel CH2 to full screen.

+

Split screen into dual channel.

CH1 CH2

CH1

CH1

CH1

4

4

CH2

CH2

+

4

4

CH2

ENTER

ENTER

ENTER

14

Page 16

4.5 LED indicators

Lo LED indicates L1/2 relay activated

The unit has 4 kinds of LED indicators

they are ALARM, WASH, Hi and Lo.

Both ALARM and WASH indicators are

red LEDs, Hi and Lo indicators are

triple colored

(red, green and orange)

LEDs.

ALARM LED

The following conditions will lead to an

alarm warning.

1.

Resistivity over range.

2.

Current output exceeds 4~

20mA

3.

Temperature over range.

WASH LED indicates wash relay

activated or not. (Only for rejection

or not.

Colors of Lo LED:

Red ● CH1 activated.

Green ● CH2 activated.

Orange ● Both CH1 and CH2

activated.

Condition of activating L1 relay

Measuring value ≦Threshold (TH)

Condition of activating L1 relay

Measuring value ≧ [Threshold +

Dead Band (DB)]

function)

Hi LED indicates H1/2 relay activated

or not.

Colors of Hi LED:

● CH1 activated.

Red

Green ● CH2 activated.

Orange ● Both CH1 and CH2

activated.

Condition of activating H1 relay

Measuring value ≧ Threshold(TH)

Condition of de-activating H1 relay

Measuring value ≦ [Threshold –

Dead Band(DB)]

15

Page 17

5 Measurement mode

5.1 Overview flow chart of measurement mode

Power on

Enter

Measurement

CAL+CH1

or

CAL

+CH2

ENTER

CAL.

MODE

PRESS

CAL

KEY

BACK

SETUP+CH1

or

SETUP

+CH2

ENTER

SETUP

MODE

PRESS

SETUP

KEY

BACK TO

CAL+CH1+ENTER

or

CAL

+CH2 +ENTER

RESTORE

DEFAULT

CALIBRATION

PARAMETERS

SETUP+CH1+ENTER

or

SETUP

+CH2 +ENTER

RESTORE

DEFAULT

SETUP

PARAMETERS

CH1+ENTERor

CH2+ENTERor

CH1+CH2+ENTER

SCREEN

SWAPPING

OPERATION

TO

MEAS.

MODE

MEAS.

MODE

16

Page 18

5.2 Access setup mode

Ω

Ω

g

Q

g

Q

Operating flow chart

Access CH1setup mode

CH1

CH1

18.00

18.00

MΩ

MΩ

ATC 25.0℃ MTC 25.0℃

ATC 25.0℃ MTC 25.0℃

SETUP + CH1

CH1

MEAS MODE

TIME

TIME

FRE

ATC 25.0℃ MTC 25.0℃

UENCY

CH2

CH2

1.413

1.413

mS

mS

CH2

1.413

mS

Access CH2 setup mode

CH1

18.00

M

ATC 25.0℃ MTC 25.0℃

SETUP+ CH2

CH1

18.00

M

ATC 25.0℃ MTC 25.0℃

CH2

1.413

mS

CH2

MEAS MODE

TIME

TIME

FRE

UENCY

Move cursor up or down by using 5、4 to where cursor stays, then press

ENTER to select item. Please read chapter 6 for detailed r eference.

17

Page 19

5.3 Access calibration mode

Ω

Ω

K

Operating flow chart

Access CH1 calibration

mode

CH1

18.00

M

ATC 25.0℃ MTC 25.0℃

CAL+CH1 CAL + CH2

CH1

CAL MODE

CELL K

STD SOL.

ATC 25.0℃ MTC 25.0℃

CH2

1.413

CH2

1.413

mS

mS

Access CH2 calibration

mode

CH1

18.00

M

ATC 25.0℃ MTC 25.0℃

CH1

CH2

1.413

mS

CH2

CAL MODE

CELL

18.00

STD SOL.

MΩ

ATC 25.0℃ MTC 25.0℃

Please read page 7 for detailed reference.

18

Page 20

5.4 Restoring default setup parameters

Ω

g

Q

g

Q

Ω

Ω

Ω

g

Q

g

Q

p

Operating flow chart

CH1 restoring default setup

arameters

CH1

CH1

18.00

18.00

MΩ

M

ATC 25.0℃ MTC 25.0℃

ATC 25.0℃ MTC 25.0℃

SETUP + CH1

CH1

MEAS MODE

TIME

TIME

FRE

ATC 25.0℃ MTC 25.0℃

UENCY

CH2

CH2

1.413

1.413

CH2

1.413

mS

mS

mS

CH1 restoring default setup

parameters

CH1

18.00

M

ATC 25.0℃ MTC 25.0℃

SETUP + CH2

CH1

18.00

M

ATC 25.0℃ MTC 25.0℃

CH2

1.413

mS

CH2

MEAS MODE

TIME

TIME

FRE

UENCY

Keep the above keys pressed, 5

seconds later, press ENTER

simultaneously till a clock indicator

appears, thenreleaseall keys.

CH1

MEAS MODE

TIME

TIME

FRE

ATC 25.0℃ MTC 25.0℃

UENCY

Press SETUP to meas. mode. Press SETUP to meas. mode.

CH2

1.413

mS

Keep the above keys pressed, 5

seconds later, press ENTER

simultaneously till a clock indicator

appears, thenreleaseall keys.

CH1

18.00

M

ATC 25.0℃ MTC 25.0℃

CH2

MEAS MODE

TIME

TIME

FRE

UENCY

19

Page 21

5.5 Restoring default calibration parameters

Ω

Ω

Ω

Ω

Operating flow chart

CH1 Restoring default calibration

parameters

CH1

CH1

18.00

18.00

MΩ

M

ATC 25.0℃ MTC 25.0℃

ATC 25.0℃ MTC 25.0℃

CAL + CH1

CH1

CAL MODE

CELL K

STD SOL.

ATC 25.0℃ MTC 25.0℃

CH2

CH2

1.413

1.413

CH2

1.413

mS

mS

mS

CH2 Restoring default calibration

parameters

CH1

18.00

M

ATC 25.0℃ MTC 25.0℃

CAL + CH2

CH1

18.00

M

ATC 25.0℃ MTC 25.0℃

CH2

1.413

mS

CH2

CAL MODE

CELL K

STD SOL.

Keep the above keys pressed, 5 seconds

later, press ENTER simultaneously

till a clock indicator appears,

thenreleaseall keys.

CH1

CAL MODE

CELL K

STD SOL.

ATC 25.0℃ MTC 25.0℃

Press SETUP to meas. mode. Press SETUP to meas. mode.

CH2

1.413

mS

Keep the above keys pressed, 5

seconds later, press ENTER

simultaneously till a clock

indicator appears, thenreleaseall

keys.

CH1

CH2

CAL MODE

18.00

CELL K

STD SOL.

M

ATC 25.0℃ MTC 25.0℃

20

Page 22

5.6 Screen switch

Ω

Operating flow chart

Y

CH2

CH2+

ENTER

1.4 13

X

CH1

CH1

18.00

18.00

MΩ

M

ATC 25.0℃ MTC 25.0℃

ATC 25.0℃ MTC 25.0℃

CH1+

CH2+

ENTER

CH2

CH2

1.413

1.413

mS

mS

mS

CH1+

ENTER

CH1+

ENTER

MTC 25.0℃

CH2+

ENTER

CH1+

CH2+

Z

CH1

ENTER

18. 00

ATC 25.0℃

MΩ

21

Page 23

5.6.1 Operating mode screen swapping

In measurement mode, EC4200 allows you to monitor two different or the same types

of Resistivity/Conductivity. If you just measure one channel only, you can enlarge the

screen for the best view. Details as the following:

1.

Spilt screen -> enlarged CH1 only np (like the picture above)

CH1 + ENTER

2.

Spilt screen -> enlarged CH2 only no (like the picture above)

CH2 + ENTER

3.

Enlarged CH1 only -> spilt screen pn (like the picture above)

CH1 + CH2 + ENTER

4.

Enlarged CH2 only -> spilt screen on(like the picture above)

CH1 + CH2 + ENTER

5. Enlarged CH1 only -> Enlarged CH2 only po(like the picture above)

CH2 + ENTER

6. Enlarged CH2 only-> Enlarged CH1 only op (like the picture above)

CH1 + ENTER

22

Page 24

6 Setup

y

A

6.1 Overview flow chart of setup

mode

Setup mode

Entr

MEAS

MODE

ENTER ENTER ENTER ENTER ENTERENTERENTER ENTER ENTER ENTER ENTER

select

Ω-CM

S/CM

rejection

mode

Select

conductivity

and unit

TIME

Select

rejection

Input

comparing

point

Set

Wash relay

On time

Set

Wash relay

Off time

TIME

Key

calibration

interval

FREQUENCY MA

ALARM

select

50/60Hz

Power

frequency

select

ON/OFF

MA

HOLD

select

LAST/FIX

Current

holding

Select fix:

input

Fix current

Val ue

RANGE

Input

4 MA

Correspondi

measuring

value

Measuring

Mapping

MA

ng

Input

20 MA

LO SET HI SET

Input

low point

setting value

Input

Low point

Dead band

Input

high point

setting value

Input

High point

Dead band

TEMP

COMP

linear/non-li

near temp

compensatio

Select linear

input temp.

coefficient

Select

ATC/MTC

Select

auto/Manual

Tem p

compensation

NTC30K or

Manual :

Temperature

value

temp. value

uto :

Select

PT1000

Set

select:

input

solution

23

Page 25

6.2 Access parameter setup mode

6.3 Select measuring mode

Access channel CH1 setup mode.

Press

SETUP + CH1

Access channel CH2 setup mode.

Press

SETUP + CH2

Select Ω–CM or S⁄CM or REJECTION

display.

6.3.1 double display without %

rejection

▓ MEAS MODE

□ TIME

□ TIME

□ FREQUENCY

Press ENTER

MEAS MODE

Ω–CM

S∕CM

REJECTION

Presst

Select Ω–CM or

S⁄CM or

REJECTION

Press ENTER

confirm it.

S/CM RANGE

▓ AUTO

□ 20.00uS

□ 200.0uS

Press t 4 select

AUTO,20.00uS

200.0uS,2.000mS

20.00mS,200.0mS

Press ENTER

confirm it.

When select

S∕CM

24

Page 26

6.3.2 Single display or with one CH

6.4 Wa shing time setup

as rejection display

▓ MEAS MODE

□ TIME

□ TIME

□ FREQUENCY

MEAS MODE

Ω–CM

S∕CM

Presst select

Ω–CM or

S

∕CM press

ENTER

confirm it

S/CM RANGE

▓ AUTO

□ 20.00uS

□ 200.0uS

Press ENTER

When

selecting

S

∕CM

Can only be accessed when CH is

rejection display.

□MEAS MODE

▓ TIME

□ TIME

□ FREQUENCY

Press ENTER

WASH TIME

TH = 90.0%

ON = 0030M

OFF = 0030M

Press t 4set TH value

Press ENTER confirm it.

WASH TIME

TH = 90.0%

ON = 003

0M

OFF = 0030M

Presst 4 set ON value

press ENTER confirm it.

Press t 4 select

AUTO,20.00uS

200.0uS,2.000mS

20.00mS,200.0mS

Press ENTER

confirm it.

WASH TIME

TH = 90.0%

ON = 0030M

OFF = 003

0M

Press t 4 set OFF

value. Press ENTER

confirm it.

25

Page 27

6.5 Calibration interval

If the value is zero, then stop this

function.

□MEAS MODE

□ TIME

▓ TIME

□FREQUENCY

Press ENTER

CAL

INTERVAL

ON= 168H

presst 4 set interval

press ENTER confirm it.

6.6 Frequency

Set 50Hz or 60Hz power frequency.

□MEAS MODE

□ TIME

□ TIME

▓FREQUENCY

Press ENTER

PWR FREQ

60HZ

50HZ

Press t select

60Hz or 50Hz

Press ENTER

confirm it.

26

Page 28

6.7 Current alarm setting

6.8 Current output

when the current is exceeded 4-20mA,

select on or off.

▓ MA ALARM

□ MA HOLD

□ MA RANGE

□ LO SET

Press ENTER

4/20 MA

ALARM OUT

ON OFF

Press 4 select ON/OFF

Press ENTER confirm

it.

Set current output corresponding to

measuring range.

■ MA RANGE

□ LO SET

□ HI SET

□ TEMP COMP

Press ENTER enter

selections

4⁄20MA IN

SET POINT

4=00.00MΩ

20=20.00MΩ

Press t 4 set minimum

value

Press ENTER confirm it.

4⁄20MA IN

SET POINT

4=00.00MΩ

20=020.0MΩ

Press t 4 set maximum press

ENTER confirm it.

27

Page 29

6.9 Set low point

6.10 Set high point

Set low threshold and dead band. The

range of threshold is 0.00M

Ω~20.00 M

Ω、0.00uS~200. 0 MS、0.0%~100.0%

□ MA RANGE

■ LO SET

□ HI SET

□ TEMP COMP

press ENTER

enter selections

SETUP

LO POINT

TH=00.10 MΩ

Set high threshold and dead band. The

range of threshold is 0.00M

Ω~20.00 M

Ω、0.00uS~200. 0 mS、0.0%~100.0%

□ MA RANGE

□ LO SET

■ HI SET

□ TEMP COMP

Press ENTER enter

selections

SETUP

HI POINT

TH=00.10 MΩ

DB=00.10 MΩ

Press t 4set

TH value

Press ENTER

confirm it.

SETUP

LO POINT

TH=00.10 MΩ

DB=00.10 MΩ

Press t 4 set

DB value

Press ENTER

confirm it.

DB=00.10 MΩ

Press t 4 set TH value

Press ENTER confirm it.

SETUP

HI POINT

TH=00.10 MΩ

DB=00.10 MΩ

Press t 4 set DB value

Press ENTER confirm it.

28

Page 30

6.11 Temp. compensation

6.11.1 Non-linear compensation

□ LO SET

□ HI SET

■ TEMP COMP

□ ATC / MTC

Press ENTER enter

selections

TEMP

COMPENSATE

NO-LINEAR

LINEAR

6.11.2 Linear compensation

RANGE:0.00%~5.00%

□ LO SET

□ HI SET

■ TEMP COMP

□ ATC / MTC

Press ENTER enter

selections

TEMP

COMPENSATE

NO-LINEAR

LINEAR

Pres t selection

compensation method

Press ENTER

to confirm it.

Press t select

compensation method.

Press ENTER to confirm

it.

TEMP

LINEAR

COMPENSATE

2.00%

Press t 4linear temp

compensation ratio.

Press ENTER to confirm it.

29

Page 31

6.12 Temp. measuring

6.12.1 Temp. probe connecting

Choose either NTC30K OR PT1000TEMP

PROBE

□ LO SET

□ HI SET

□ TEMP COMP

■ ATC / MTC

Press ENTER then enter

selections

ATC/MTC

SELECTION

AUTO

MANUAL

Press t select AUTO

Press ENTER to

confirm it

ATC PROBE

PT1000

NTC30K

Presstselect NTC30K

probe. Press ENTER

ATC PROBE

PT1000

NTC30K

Presstselect PT1000

probe press ENTER

confirm it.

CAL. TEMP

025.0℃

Press t 4 set

solution temp.

confirm it.

Press ENTER to

confirm.

30

Page 32

6.12.2 Manual temperature setup

RANGE:0.0℃ ~ 100.0℃

□ LO SET

□ HI SET

□ TEMP COMP

■ ATC / MTC

Press ENTER then

enter selections

ATC/MTC

SELECTION

AUTO

MANUAL

Press t select manual

Press ENTER to confirm

it.

MTC

SET TEMP.

025.0℃

Press t 4 manual input

temp. value.

Press ENTER to confirm it.

31

Page 33

7calibration

7.1 Ω-CM calibration mode

7.1.1 Cell constant input

CAL MODE

CELL K

STD SOL.

Exit-press CAL

continue-press

ENTER

CAL. CELL

K=00.0500

Exit-press

ACCESS CH1 CALIBRATION

MODE.

PRESS CAL+CH1

ACCESS CH1 CALIBRATION

MODE

PRESS CAL+CH2

Ω-CM Calibration mode is divided

into cell constant input(see 7.1.1) and

user buffer solution calibration(see

7.1.2).

Cell constant input:the range is 0.0100

CELL

CONSTANT

01.0000

Exit-press CAL

Press 5 4 input

coefficient value.

Press ENTER confirm it

CAL. CELL

K=01.0000

CAL

continue-press

ENTER

~ 50.0000.

User buffer solution calibration:let

User input the value of buffer solution,

use this value (must use non-linear

temp compensation) to calculate the

coefficient of electrode.

Exit-press CAL

continue-press

ENTER

32

Page 34

7.1.2 User buffer solution calibration

CAL MODE

CELL K

STD SOL.

Exit-press CAL

continue-press

ENTER

CAL. CELL

S=18.18MΩ

K=01.0000

Exit-press CAL

continue-press

ENTER

CAL. CELL

INPUT 25℃

STD SOL.

18.18MΩ

Exit-pressCAL

PRESS5 4 input solution

value

press ENTER confirm it

01.43

MΩ

01.43

MΩ

Exit-pressCAL

To calculate-press ENTER

wait for stability-do not press

any key.

CAL. CELL

S=18.18MΩ

K=00.0500

Exit-press CAL

continue-press

ENTER

33

Page 35

7.2 s/cm and rejection calibration

mode

7.2.1 cell constant input

CAL MODE

CELL K

STD SOL.

Exit-pressCAL

Continue-press

ENTER

CAL. CELL

K=00.0500

Exit-press CAL

continue-press

ENTER

CELL

CONSTANT

01.0000

ACCESS CH1 CALIBRATION MODE.

PRESS CAL+CH1

ACCESS CH2 CALIBRATION MODE

PRESS CAL+CH2

S/CM Calibration mode is divided into

cell constant input(see 7.1.1) and user

buffer solution calibration(see 7.1.2).

Use 0.1n kcl solution to calibrate

coefficient of electrode.

(see 7.2.3). Use

0.01n kcl solution to calibrate

coefficient of electrode.

(see 7.2.4) All

four types.

Cell constant input:the range is 0.0100

~ 50.0000.

User buffer solution calibration:let

User input the value of buffer solution,

use this value to calculate the

coefficient of electrode.

Use 0.1n kcl and 0.1n kcl solution to

Exit-press CAL

Press 5 4 input

coefficient value

calibrate coefficient of electrode.

:The

program will find corresponding value

to calibrate the coefficient of electrode.

CAL. CELL

K=01.0000

Exit-press CAL

continue-press

ENTER

34

Page 36

7.2.2 User buffer solution calibration

CAL MODE

CELL K

STD SOL.

Exit-press CAL

continue-press

ENTER

CAL MODE

STD SOL.

0.1N KCL.

0.01N KCL

Exit-pressCAL

press 5 4 select solution type

press ENTER confirm it

CAL. CELL

S=1.400mS

K=01.0000

Exit-press CAL

continue-press

ENTER

CAL. CELL

INPUT 25℃

STD SOL.

1.400mS

1.400

mS

1.400

mS

Exit-pressCAL

To calculate-press ENTER

wait for stablity-do not press

CAL. CELL

S=1.400 mS

K=01.0000

Exit-pressCAL

PRESS5 4 key in solution

value

press ENTER confirm it

35

Exit-press CAL

continue-press

ENTER

Page 37

7.2.3 Calibration electrode by 0.01 k

ncl solution

CAL MODE

CELL K

STD SOL.

Exit-press CAL

continue-press

ENTER

CAL MODE

STD SOL.

0.1N KCL.

0.01N KCL

Exit-pressCAL

PRESS5 SELECT SOLUTION TYPE

Continue-presseENTER

CAL. CELL

S=12.88mS

K=01.0000

Exit-press CAL

continue-press

ENTER

12.88

mS

12.88

mS

Exit-pressCAL

To calculate-press ENTER

wait for stablity-do not prees

any key.

CAL. CELL

S=12.88 mS

K=01.0000

Exit-press CAL

continue-press

ENTER

36

Page 38

7.2.4 Calibrate electrode by 0.01N

KCL solution

CAL MODE

離開-按

CELL K

STD SOL.

Exit-press CAL

continue-press

ENTER

CAL MODE

STD SOL.

0.1N KCL.

0.01N KCL

Exit-pressCAL

PRESS5selection solution type.

Continue-press ENTER

CAL. CELL

S=1.413mS

K=01.0000

Exit-press CAL

continue-press

ENTER

1.413

mS

1.413

mS

Exit-pressCAL

To calculate-press ENTER

wait for stablity-do not press any

key.

CAL. CELL

S=1.413 mS

K=01.0000

Exit-press CAL

continue-press

ENTER

37

Page 39

8. ERROR MESSAGE

8.1 CALIBRATION ERROR

In measuring mode: If the value is over

value

(range 0-200ms)

1. During calibrating, ,if the coefficient is over

00.0100~50.0000,it shows the following

sign.。But k= value will not change.

During calibration: If the electrode

value is not stable the k=value will not

change.

CELL CONST

OVER RANGE

ERROR

UNSTABLE

2.

Measuring temp. is over range.

H1

ATC 25.0℃

CH1

100.0

AT C ℃

▲mA

mS

mS

8.2 Measuring error

1 . In resistivity mode: If the value is

over rang, it following sign will be

shown

(range is 0-20MΩ)

H2

▲mA

MΩ

ATC 25.0℃

38

Loading...

Loading...