Page 1

1

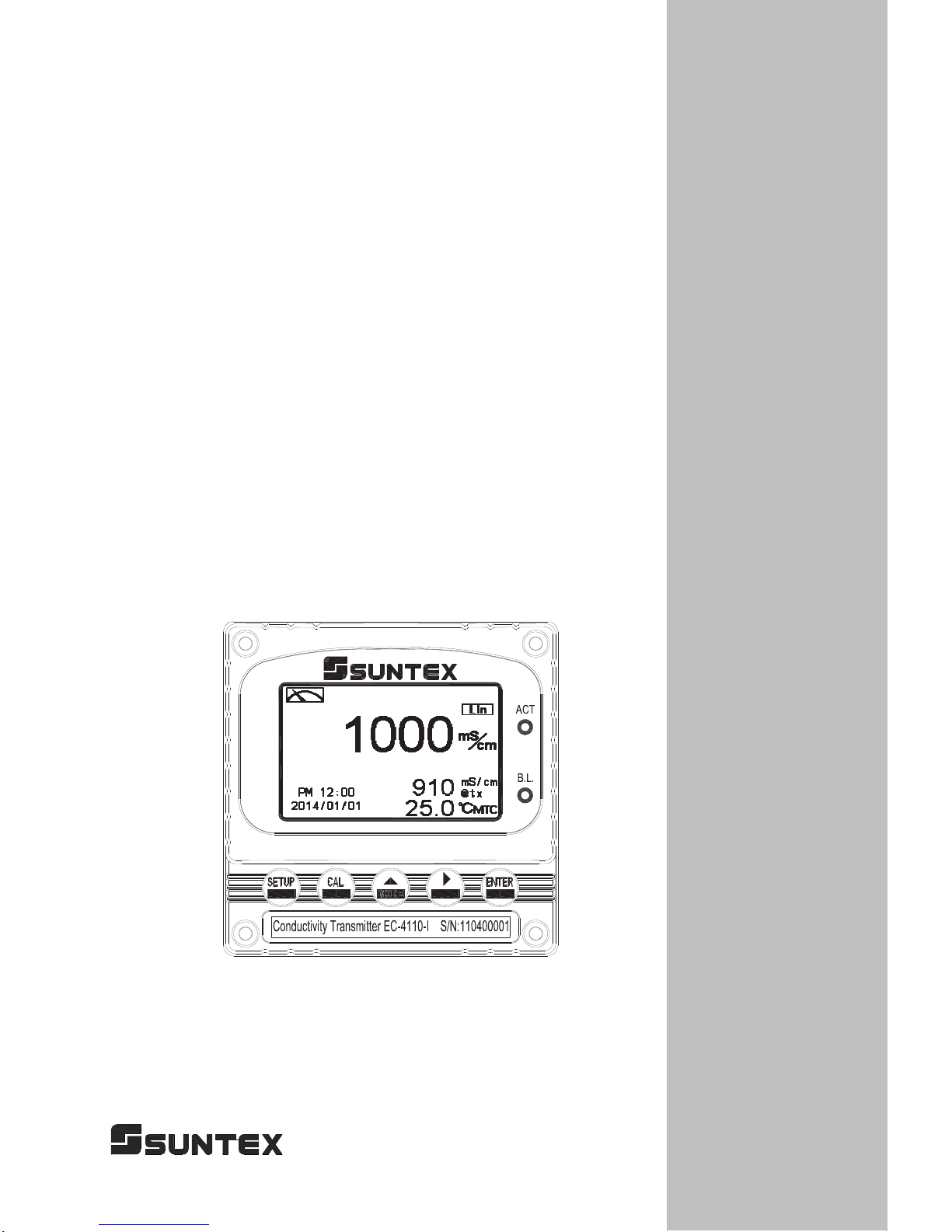

EC-4110-I

EC-4110-ICON

ġ

Intelligent

ġ ġ

Conductivity

Transmitter

Operation

Manual

Page 2

Precautions for installation

Brief Instruction

1

1. Specifications

1.1 Specifications

4

1.2 Product packing 5

1.3 Measurement principle

6

2. Assembly and installation

2.1 Transmitter installation 8

2.2 Illustration of panel mounting 8

2.3 Illustration of wall mounting and pipe mounting

9

3. Overview of Conductivity Transmitter EC-4110-I/EC-4110-ICON

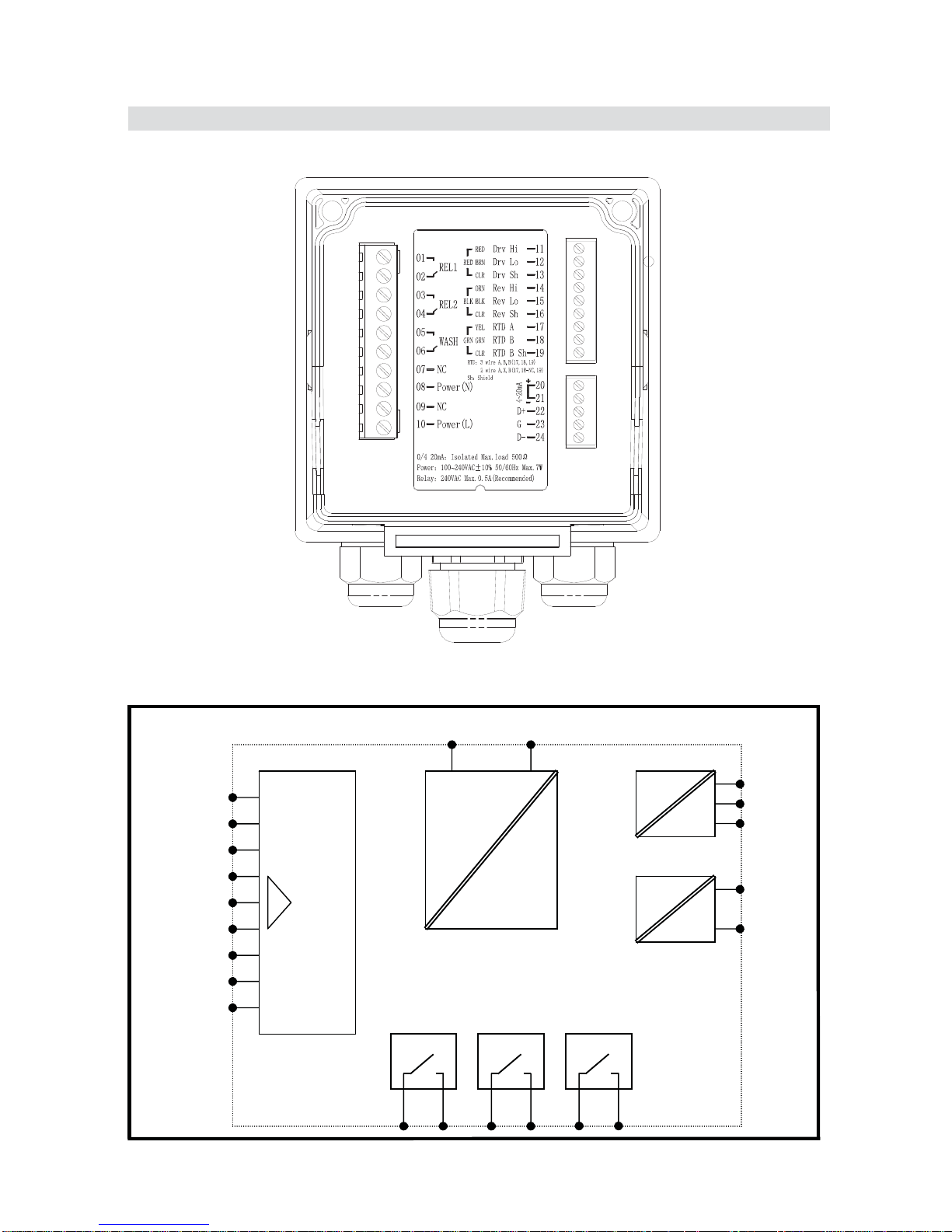

3.1 Illustration of rear panel 10

3.2 Illustration of terminal function

10

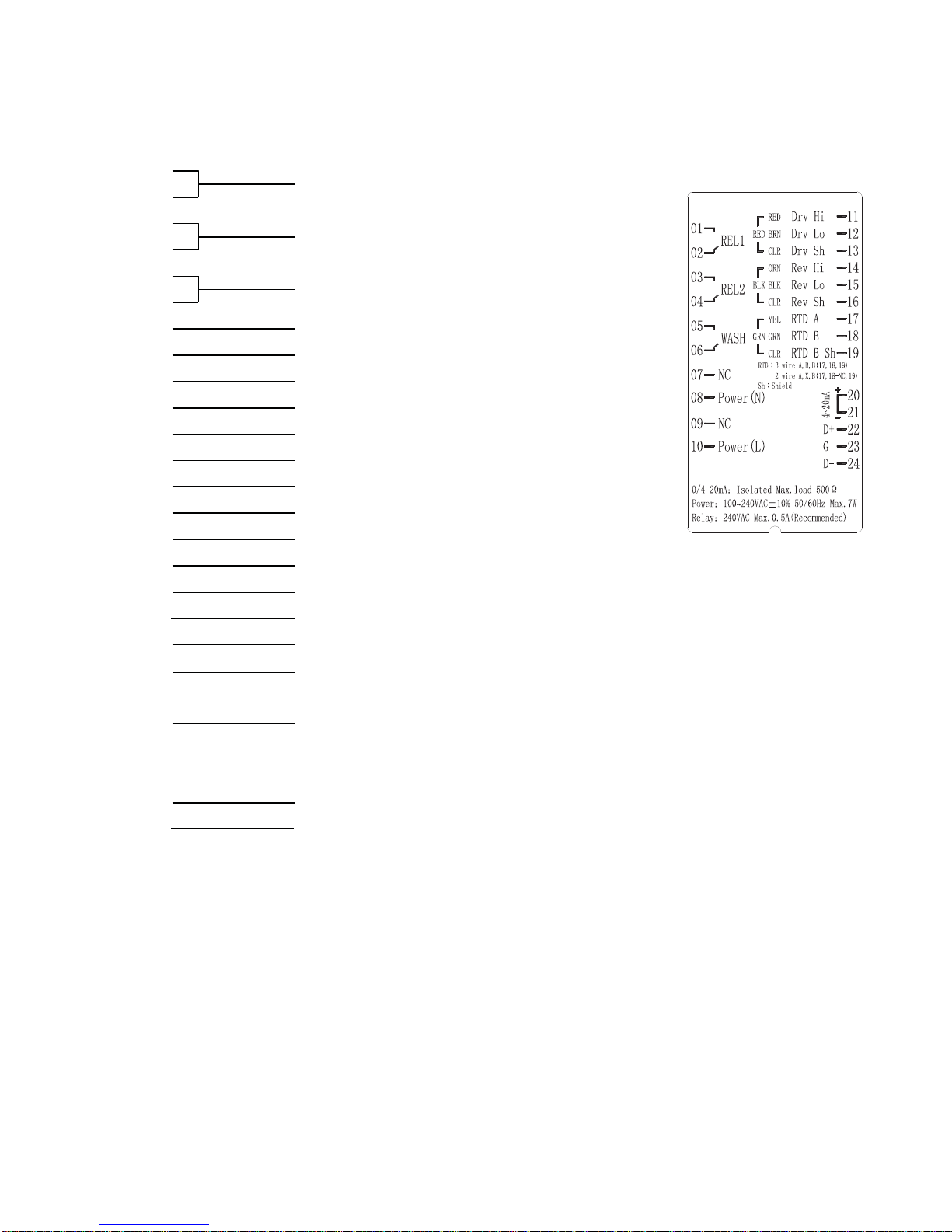

3.3 Description of terminal function 11

3.4 Wiring of cable 12

3.5 Circuit of cable

12

3.6 Illustration of electrical connection 13

3.7 Wiring diagram of extension cable

14

4. Configuration

4.1 Illustration of front panel

15

4.2 Keypad 15

4.3 LED indicators 15

5. Operation

5.1 Measurement mode

16

5.2 Set-up menu 16

5.3 Calibration menu

16

5.4 Shortcuts 16

5.5 Default value

5.5.1 Setting default value 16

5.5.2 Calibration default value

17

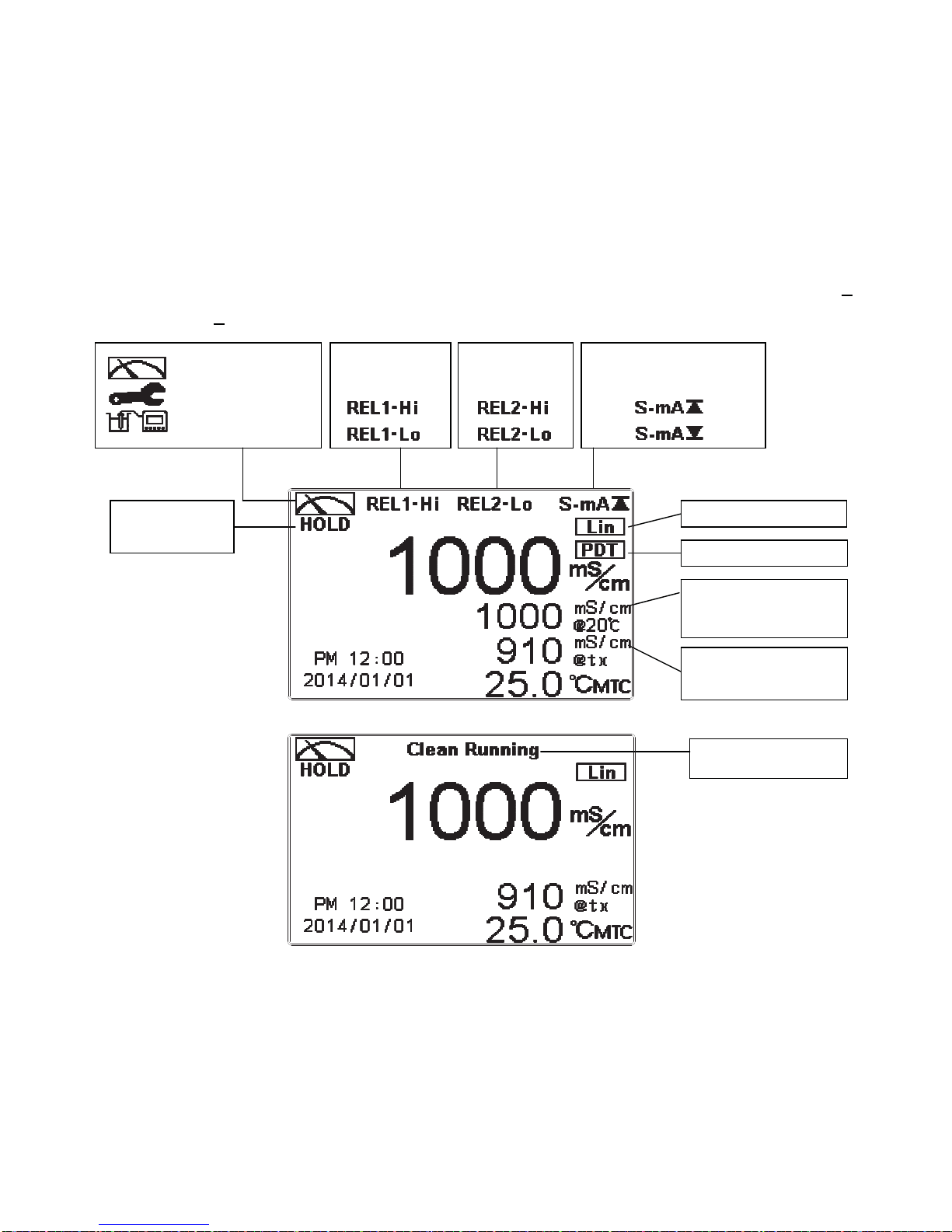

6. Measurement display mode

6.1 T ext mode

18

6.2 Real-time chart mode

19

6.3 Trace mode

20

6.4 Warning symbols and text

21

CONTENTS

Page 3

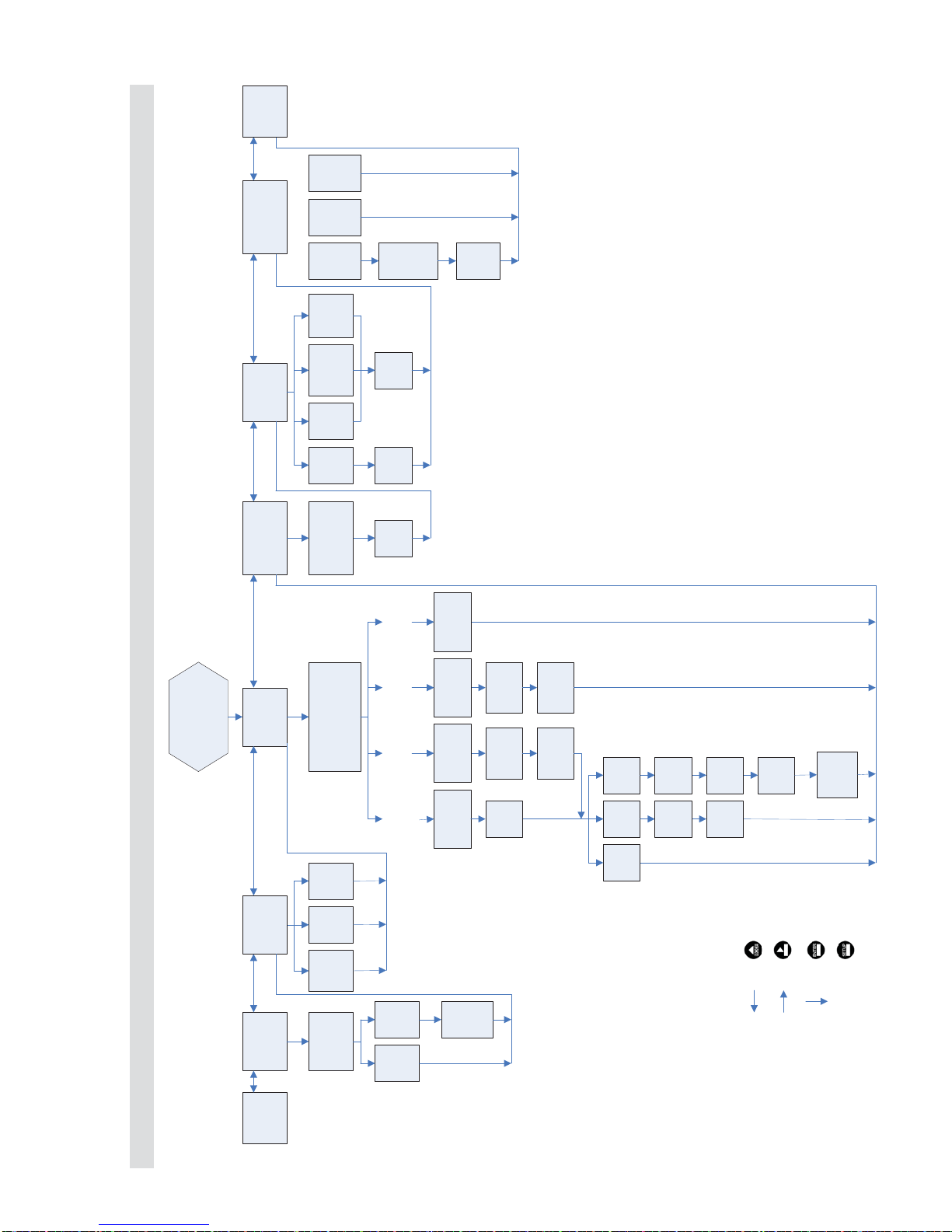

7. Settings

Block diagram of settings

22

7.1 Entry of set-up menu 24

7.2 Security code of settings(Code)

25

7.3 Language 26

7.4 Measurement parameters(Mode) 27

7.4.1 Conductivity with temperature compensation 27

7.4.2 Absolute conductivity

29

7.4.3 Concentration 31

7.4.3.1 Defined concentration table

33

7.4.4 TDS 37

7.4.5 Salinity

38

7.5 Product adjustment 39

7.6 Temperature 40

7.7 Temperature compensation coefficient

41

7.8 Relay 1 43

7.9 Relay 2 44

7.10 Clean

45

7.11 Current output 46

7.12 RS-485 communication 48

7.13 Date/Time (Clock)

49

7.14 Sample average of measurements (Digital filter)

50

7.15 Backlight 51

7.16 Contrast

52

7.17 Logbook 53

7.18 Automatically back to measurement mode(Return) 54

8. Calibration

Block diagram of Calibration

55

8.1 Entry of calibration menu 56

8.2 Security password of calibration

57

8.3 Zero-point calibration

58

8.4 Cell constant calibration

59

8.5 Standard solution calibration(Std. solution)

60

8.5.1 KCl standard solution 60

8.5.1 NaCl standard solution

62

8.6 Automatically back to measurement mode(Return) 64

Page 4

Thank you for purchasing Suntex products. In order to continually improve and enhance the transmitter’s

function, Suntex reserves the right to modify the content and icon display of the product. The actual situation

is subject to the instrument without notice. The operation manual is only provided for function and

installation description, Suntex Instruments Co., Ltd. is not liable for any person or entity for any direct or

indirect loss or damage due to improper usage of this product. If you have any questions or find omission,

negligence or mistakes of the operation manual, please contact with our staff, thank you.

Precautions for installation

Wrong wiring will lead to breakdown or electrical shock of the instrument, please read this

operation manual clearly before installation.

zMake sure to remove AC power from the transmitter before wiring input, output connections,

and remove it before opening the transmitter’s housing.

zThe installation site of the transmitter should be good in ventilation and avoid direct

sunshine.

zThe material of signal cable should be special coaxial cable. Strongly recommend using our

coaxial cable. Do not use normal wires instead.

zAvoid electrical surge when using power. Especially when using three-phase power, use

ground wire correctly. If the power surges interference occurs, separate the power supply of

transmitter from the control device, such as: dosing machines, mixers, etc. to make individual

power supply for the transmitter; or set surge absorber to reduce the power surges at all

electromagnetic switches and power control device coils.

zThe internal relay contact of the instruments is for alarm or control function. Due to safety,

please must connect to external relays which can stand enough ampere to make sure the

safety operation of the instrument.˄Please refer to chapter 3.6ȾIllustration of electrical

connectionȿ˅

zThere a manufacturer logo usually shows in the display of transmitter, and the illustration of

each function in the manual is no longer expressed.

!

!

!

!

!

!

!

!

!

!

!

Page 5

9. Modbus protocol and instructions 65

9.1 Communication connection

65

9.2 Modbus address table 67

9.3 Modbus example descriptions

71

10. Error messages (Error code)

72

11. Installation of cells

11.1 Appearance of cells

73

11.2 Installation approach

74

11.2.1 Flange installation 74

11.2.2 Tee installation

75

11.2.3 Immersion installation 76

12. Appendix

77

Page 6

Brief Instruction

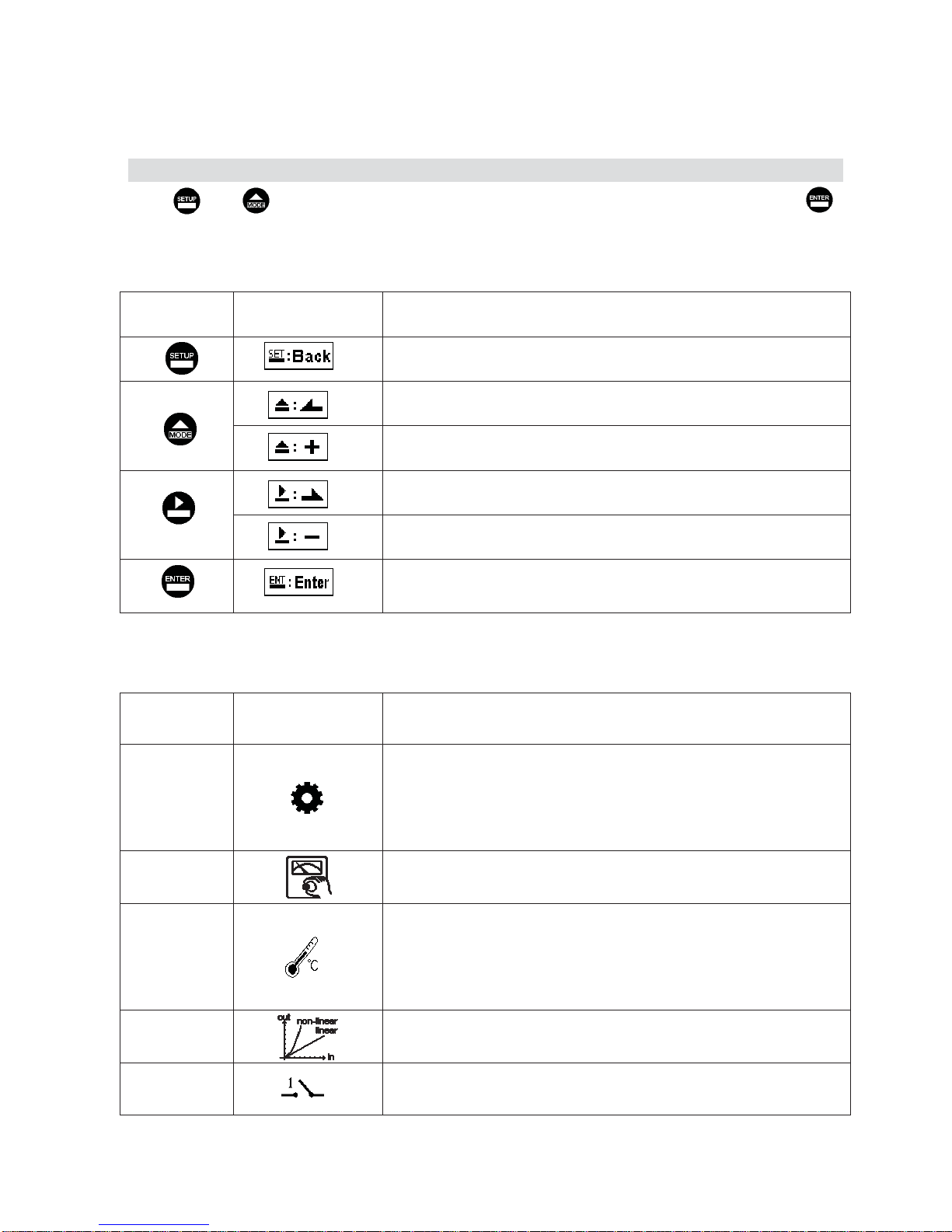

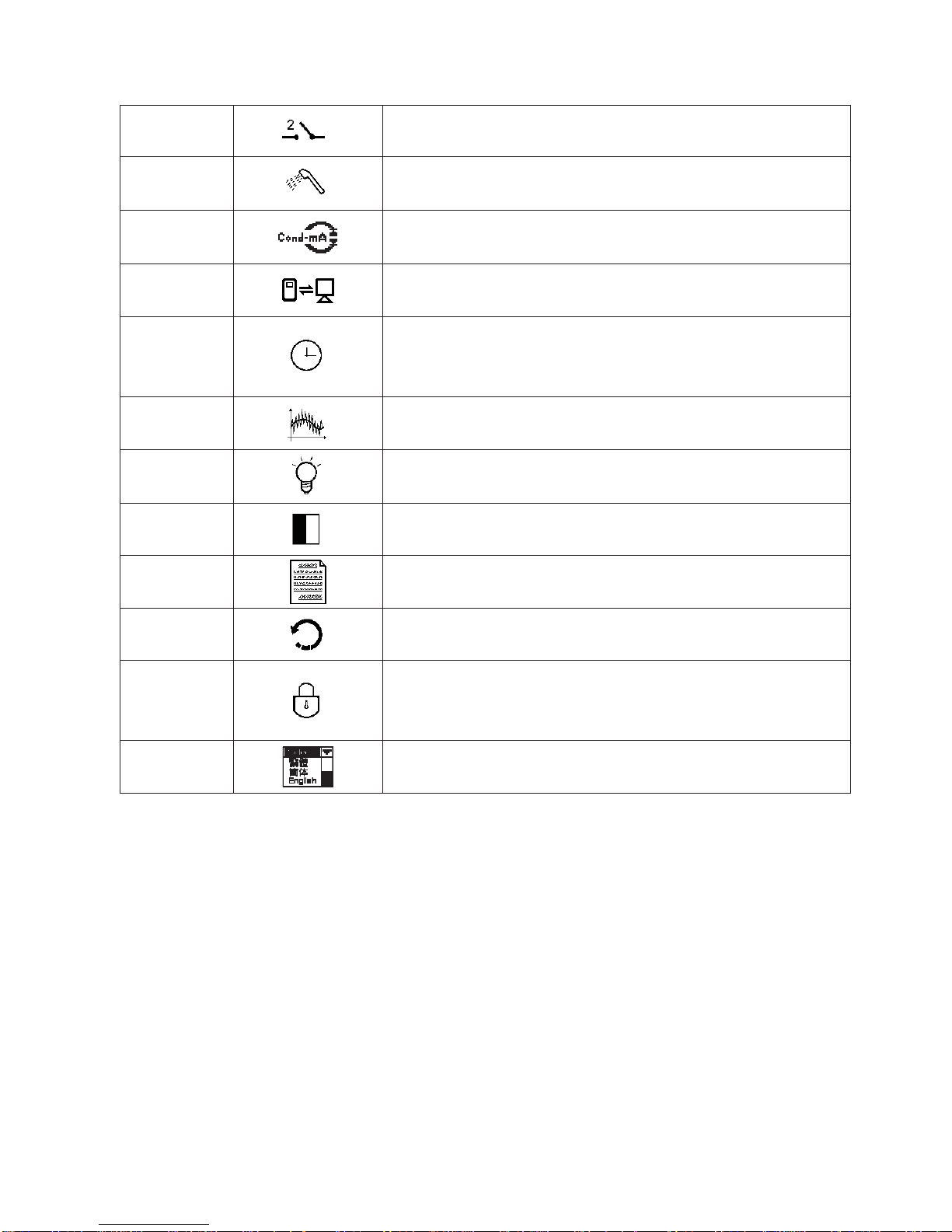

Description of set-up settings (see chapter 7 for details)

Press and simultaneously to see the overview of the set-up settings now. Then press I

if you would like to modify set-up settings. Press keypad according to index of keypad on the screen.

Index of keypad

keypad Accordingly item Description

Back to upper layer

Choose leftward of change to left page

Increase digit

Choose rightward of change to right page

Decrease digit

Confirm settings after modifications and then go through next

step

Selection of set-up items

keypad Accordingly item Description

Mode

Measurement mode, to choose Conductivity with temp.

compensation (Cond.@tref), Concentration, TDS, Salinity or

Absolute Conductivity (Cond.@tx) and measurement mode can

be displayed in Text Mode, Real-time Mode, or Trace Mode.

Product Adj. Sample reading adjustment—for resistivity mode only.

Temperature

Temperature measurement and compensation, including MTC,

PTC1000, PTC100, or NTC (4 types in total). MTC---Manual

Temperature Compensation, PTC1000/PTC100/NTC--- Auto

Temperature Compensation

Compensation

Temperature compensation setting, selection from linear(Lin.),

non-linear(Non-Lin.), no compensation(Lin., 0.0%), 3 types

Relay 1 First relay setting, to choose action off or Hi/Lo alarm

к

Page 7

Relay 2 Second relay setting, to choose action off or Hi/Lo alarm

Clean

Automatic wash time setting, to choose electrode clean

equipment’s ON and OFF duration

Current

Output

Current output according to Cond.@tref, Concentration, TDS,

Salinity, or Cond.@tx setting range

RS-485 RS485 serial interface (Modbus protocol)

Clock

Clock setting (When out of power and reboot it, the

instrument’s time setting can maintain to the real time. If

not, please replace the inner 3V CR2025 battery.)

Digital Filter

Take every serial 1~60 measurements, average them

continuously, and make it as the readings

Back Light

Backlight setting, to set Auto/ON/OFF backlight, brightness,

and sensitivity

Contrast Contrast of screen setting

Logbook Event recorder logbook (50 data)

Return Setting of returning to the measurement mode

Code

Security code of set-up mode. The set-up code is precedential to

calibration code, thus it can pass a different security code of

calibration.

Language Available for English, Traditional Chinese, Simplified Chinese

л

Page 8

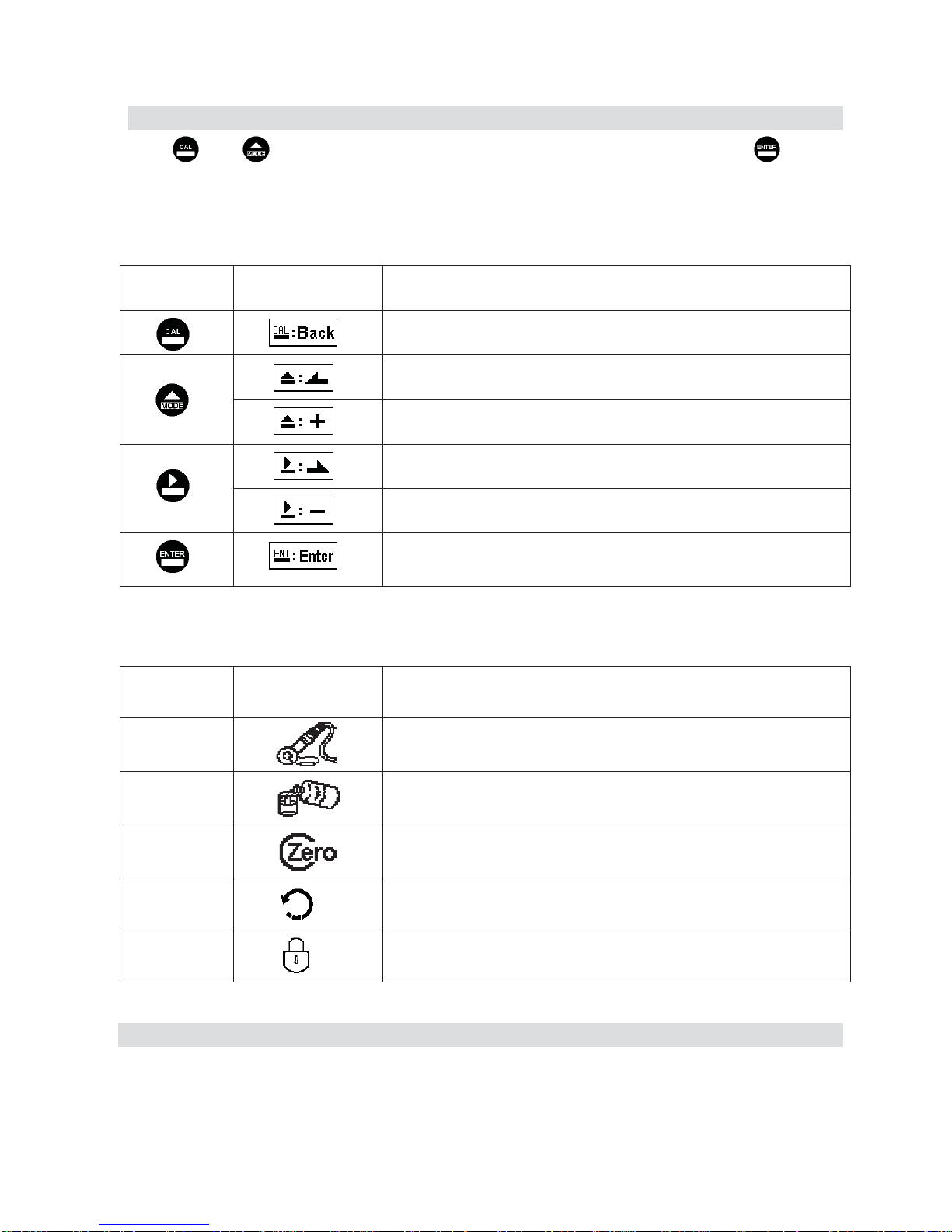

Description of calibration settings (see chapter 8 for details)ġ ġġġġġġġġġġġġġ

Press and simultaneously to see the last calibration information. Then press if you

would like to make a new calibration or modify setting of calibration. Press keypad according to

index of keypad on the screen.

Index of keypad:

keypad Accordingly item Description

Back to upper layer

Choose leftward of change to left page

Increase digit

Choose rightward of change to right page

Decrease digit

Confirm settings after modifications and then go through next

step

Selection of calibration items

keypad Accordingly item Description

Cell Constant

To adjust the instrument cell constant setting until the value

goes the same with the given cell constant of the sensor

Std. Solution Use the appropriate standard solution to calibrate the system

Zero Zero-point calibration

Return Time interval setting of returning to the measurement mode

Code Security code of calibration mode.

Note

ġ

Due to the need for continuous improvement of the transmitter function, we reserve the right to modify the

content and the icon of the function. The actual icons and contents are subject to the instrument without notice.

м

Page 9

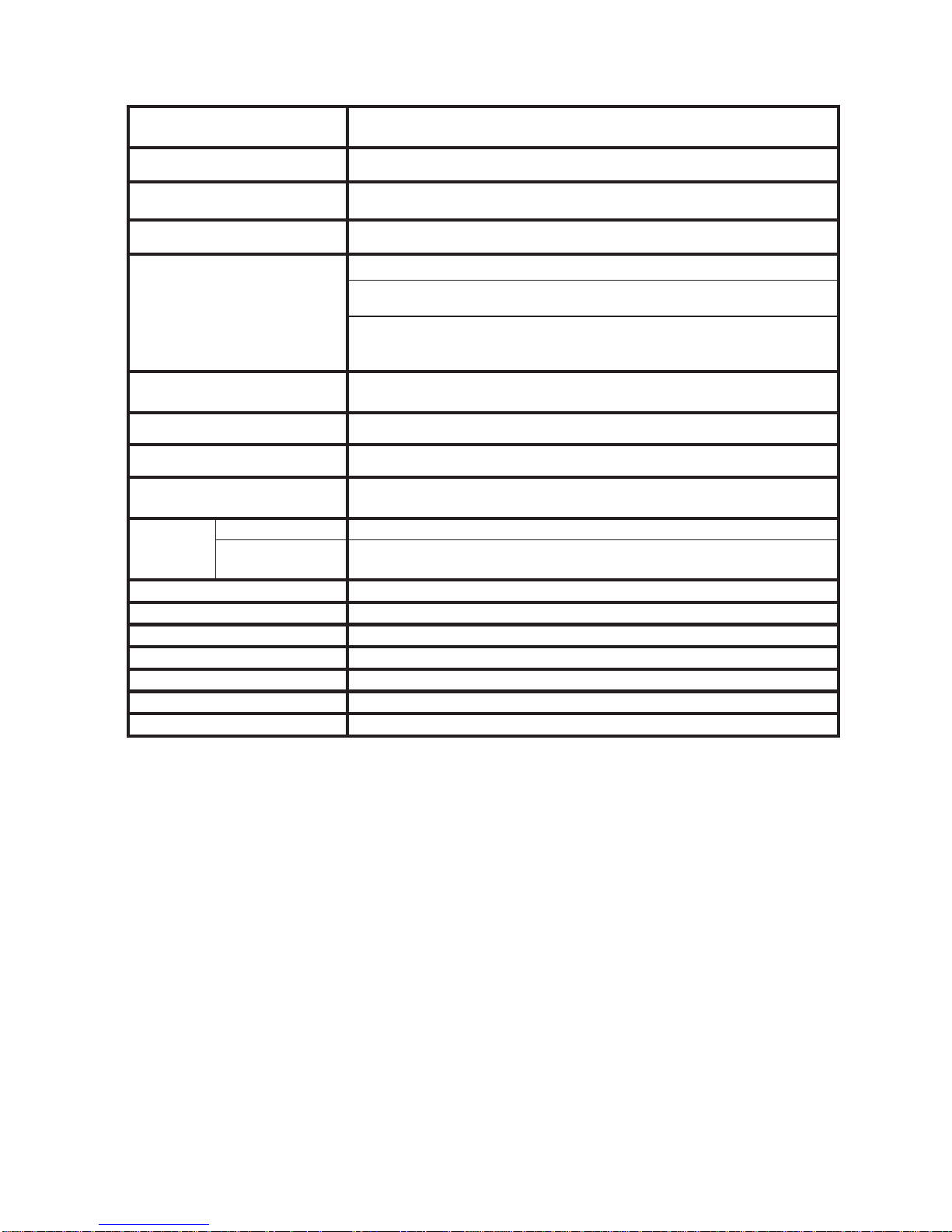

1. Specifications

1.1 Specifications

Model EC-4110-I EC-4110-ICON

Measuring modes Conductivity/TDS/Salinity/Temp./Concentration (EC-4110-ICON only)

Ranges

Conductivity

0.000 ȝS/cm~2000 mS/cm, Auto or Fixed

Salinity

0.0 ppt~70.0ppt

TDS 0ppm~19999ppm; 0.00~199.9ppt

Temp. PTC1000/PTC100: -30.0~200.0ÛC, NTC30K: -30.0~130.0ÛC

Concentration

NaCl_28%烉0-28 %

HCl_18%烉0-18 %

HCl_39%烉22-39 %

HNO3_30%烉0-30 %

HNO3_96%烉35-96 %

NaOH_24%烉0-24 %

NaOH_50%烉15-50 %

H2SO4_37%烉0-37 %

H2SO4_88%烉28-88 %

H2SO4_99%烉89-99 %

H3PO4_35%烉0-35 %

The boundary value of conc.

conversion range of each solution can

vary with changes of temp., if go over

range, there twinkles an alarm on the

display screen.

Self-defined table (up to 9 temp. data,

and there are 9 corresponding points

for cond. v.s. conc. at each temp.)(9 x

9 matrix)

Resolutions

Concentration

0.01 %

Conductivity

0.1 ȝS/cm, 0.01 / 0.1 / 1 mS/cm

Temp. 0.1ÛC

Accuracy

Conductivity

±1% (± 1Digit)

Temp.

±0.2qC (± 1 Digit),

Equipped with temperature error correction function

Temperature

Compensation

Automatic with NTC30K/ PTC1000/PTC100

Manual T emperature Compensation

Calibration mode

(1)Manual cell constant adjustment

(2)Conductivity standard solution calibration

(3)Zero-point calibration

Product Adjustment 0.7000~1.3000

Ambient Temp. 0~50 ÛC

Storage Temp. -20~70 ÛC

Cell Constant freely selectable 0.008~9.9999 cm-1

н

Page 10

Temperature Coefficient

Linear temperature compensation from (0.00%~ 40.00%),

Non-Linear compensation, or No compensation

Compensation Temperature Freely set reference temperature 0~200 ÛC

Display Screen

Large LCM with sensitization sensor for auto/manual illumination

function and contract functio

n

Languages

English / Traditional Chinese / Simplified Chinese

Display

Text mode: Numerical display

Chart mode: 3 mins real-time dynamic graph

(

conc. and cond. only)

Trace mode: Set up from 3 mins to four weeks duration of the

measured value trend graph

(

conc. and cond. only)

Analog output

Isolated DC 0/4~20mA corresponding to main measurement,

max. load 500:

Logbook 50 event records

RS-485 interface Isolated (MODBUS RTU or ASCII)

Modbus communication

Offer measuring value, calibration data, product adjustment,

logbook, control parameter, etc or system setup

Settings

Contact RELAY contact, 240VAC 0.5A Max.(recommended)

Activate

Hi/Lo. Hi/Hi. Lo/Lo selectable two limited programmable,

ON/OFF

Wash RELAY contact ON 0~99min. 59sec. / OFF 0~999hr 59min.

Protection IP65 (NEMA 4X)

Power Supply 100V~240VAC±10%, 7W max., 50/60Hz

Installation Wall or Pipe or Panel Mounting

Dimensions 96m × 96mm × 132mm (HuWuD)

Cut off Dimensions 93 mm u 93 mm (HuW)

Weight 0.5Kg

Note: The specifications are subject to change without notice.

о

Page 11

1.2 Product packing

1.2.1 Standard accessories

1. Transmitter

2. 8-201-PFA-10 sensor assembly(Including temperature sensor with PTC1000 and signal cable

for 10 meter)

1.2.2 Optional accessories

If necessary, please order the spare parts as follows:

1. Installation炷please refer to ch.11: Installation of Sensor Assembly炸

1.1 Flange Mounting

1. 8-201-PFA-10 sensor assembly

2. 5419059 Teflon gasket

3. 5420048 FEP sealing loop

4. 5329003 G3/4" hexagon nut

1.2 Tee installation

1. 5419061 stell tee(2"-3/4")

2. 5329003 G3/4" hexagon nut

1.3 Immersion installation

1. 5419060 immerison nut fitting(1"-3/4")

2. 7202-DO100 DO protection holder 1M

3. Threading type烉8-26 waterproof cap or coiling type烉8-09-6 circle junction box

2. Extension cable max. up to 50M (zero-point calibration, cell constant calibration or product

adjustment are required after installation)

1. 8-09-9 square junction box 9T

2. 5251023 signal cable, please advise specific length as ordered(M)

3. Standard calibration buffers(optional)

Note: Installation can be referred to chap. 11: Installation of Sensor Assembly

1.3 Measurement principle

1. EC-4110-I/EC-4110-ICON utililze conversion of electric field and magnetic field to measure

the conductivity in a sample solution. Sensor assembly is composed of Drive Coil and

Receive Coil, whose induction is not directly contact with sample solution, belonging to

inductive type. It is also composed of chemical-resistant materials, for example: the

8-201-PFA-10 is made up of PFA that can be applied to acidic, alkaline, salt solutions,

effluents, etc. in online monitoring industrial environments.

2. EC-4110-I/EC-4110-ICON apply alternative signals of electric field to activate drive coil to

produce the magnetic field. After that, sample solution(containing ions in different conc.)

turns into a conductive circuit, and then the signal can b e received on receive cell, turned into

magnitude of current to measure the conductivity.

3. The temperature probes have three-wiring type PTC1000 and PTC100 and two-wiring type

NTC30K as reference. Users can select the spec according to sensor assembl y. ȾCond.@txȿ

which presents conductivity is being measured at actual tmeperature Ⱦtxȿ, is regarded as

absolute conductivity. Refer to temperature compensation modes (linear, non-linear, or off)

п

Page 12

and reference temperature, “Cond.@tref” is to present conductivity based on desired ref.

temperature.

4. EC-4110-I/EC-4110-ICON both have measurement of salinity and TDS.

5. EC-4110-ICON has built-in conc. conversion table including NaCl, HCl, HNO

3

, NaOH,

H

2SO4

, H3PO4, etc. Users can select the corresponding solution types and conc. range. When

the conc. range is not applicable, there twinkles error message as an alarm during

measurement. The absolute conductivity “Cond.@tx” can be turned into concentration of th e

sample solution, and with compensation of ref. temperature it also can be treated as

“Cond.@tref.”

6. EC-4110-ICON has self-defined conversion table between cond. and conc., and there are conc.

units %, ppm, or ppt as reference.

7. Self-defined table( max. up to 9 temperature data, and there includes 9 corresponding cond.

and conc. at each temp.) (9 x 9 matrix) can be input corresponding conductivity and

concentration at the same temperature by users. The temp., cond., and conc. can be

individually input in ascendant or descendant order. After that, the unit is going to check the

data and correct somewhere the order goes wr ong. When users only have data of cond. and

conc. at one kind of temp. for conversion, it is necessary to apply linear temperature

compensation to input T.C. value.

8. Due to conductivity attained by electromagnetic induction not by contact type, cell constant is

to perform the geometric structure characteristic of a drive coil and a receive coil, and the

signal cable of the sensor is labeled with cell constant made by lab when out of factory. The

inductive signals can be influenced by the surroundings environments such as installation

pipeline wall effect, metal(conductive) pipeline and plastic(insulation, non-conductive)

pipeline, the distance from sensor assembly and the shell of pipeline. After installed,

zero-point calibration in air and cell constant calibration are required, and there is no need to

change the labeled cell constant since it can use span calibration to make product adjustment

in the field directly.

9. It should restart zero-point calibration in air after each installation or maintenance, and the

surface of sensor assembly needs cleaning without any attachment, making it dry, and using

cell constant or product adjustment for calibration.

10. The default measuring range is 2000mS/cm, and users can select 2000mS, 999.9mS, 99.99mS,

9.99mS, ȝ6, or AUTO, where AUTO means automatic switch unit.

р

Page 13

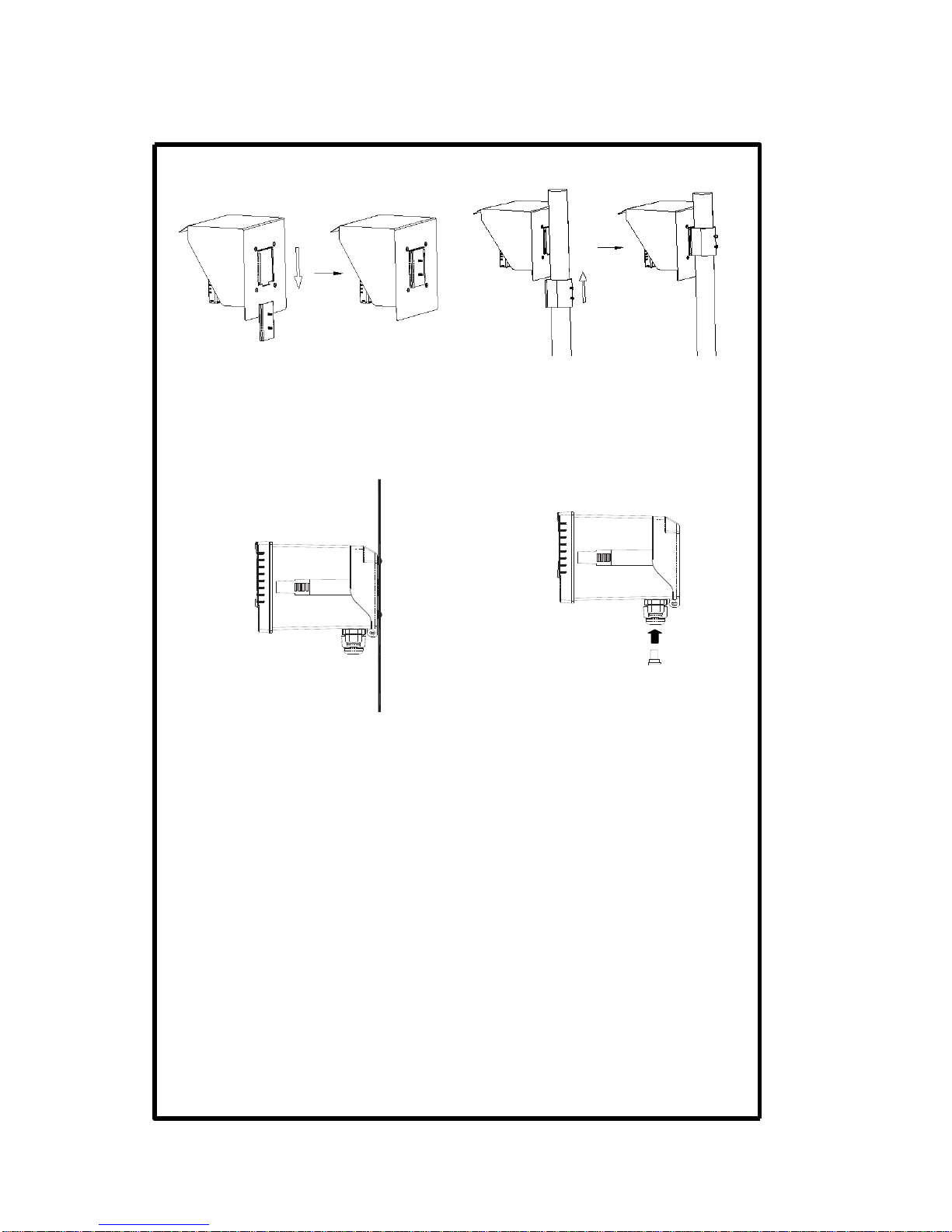

2. Assembly and installation

2.1 T ransmitter installation:

This transmitter can be installed through panel mounting, wall mounting and 2” pipe mounting.

Installation of panel mounting:

Firstĭ prepare a square hole of 93 x 93mm on the panel box, and then insert the controller

directly into the panel box. Insert the accessorial mounting bracket from the rear, and make it be

fixed into pickup groove.

2.2 Illustration of panel mounting

93 mm

93 mm

Hole size

87 mm

為

87 mm

Hole distances on the panel box

Mounting bracket

Illustration of panel mounting,

fixed with mounting bracketġ

為

為

為

112 mm

с

Page 14

2.3 Illustration of wall mounting and pipe mounting

Installation of wall mounting

Fixed with 4 x M4 screws

Sun Shield (Pipe mounting, Optional)

( Order No.: 8-35 + 8-35-1 + 8-35-3)

Sun Shield (Wall mounting, Optional)

(Order No.: 8-35 + 8-35-2 + 8-35-3)

Insert the single hole rubber plug into

the unused cable gland, and tighten up

the cable gland to prevent from the

penetration of water vapor.

т

Page 15

3. Overview of Conductivity transmitter EC-4110-I/EC-4110-ICON

3.1 Illustration of rear panel

3.2 Illustration of terminal function

WASH/ClnREL2REL1

POWER

AC

INPUT

POWER

4/20m

A

為

炼

RS-485

D+(B)

G

D-(A)

Drv Hi

Drv Lo

Drv S

h

Rev Hi

Rev Lo

Rev S

h

RTD A

RTD B

RTD B S

h

кй

Page 16

3.3 Description of terminal function

炿烀

REL1: First alarm control, the contact for an

external rela

y

炿烁

炿烂

REL2: Second alarm control, the contact for an

external rela

y

炿烃

炿烄

WASH: Wash relay contact for an external relay

炿烅

炿烆

NC: None contact

炿烇

Power(NĪĻ100~240VAC Power supply terminal

炿烈

NC: None contact

烀炿

Power(L

ĪġĻ

100~240VAC Power supply terminal

烀烀

烀烁

烀烂

Drv Sh: Shield

烀烃

Drv Hi: Sensor receive coil terminal, High

烀烄

Drv Lo: Sensor receive coil terminal, Low

烀烅

Drv Sh: Shield

烀烆

RTD A: Three-wiring temp. probe terminal A

烀烇

RTD B: Three-wiring temp. probe terminal B

烀烈

RTD B Sh: Three-wiring temp. probe terminal B Shield

烁炿

4~20mA +terminal: Master measure current output terminal +, for an

external recorder or PLC control

烁烀

4~20mA – terminal: Master measure current output terminal -, for an

external recorder or PLC control

烁烁

D+(B): RS-485 output D+(B)

烁烂

G: RS-485 output GND

烁烃

D-(A): RS-485 output D-(A)

Temp. probe is PTC1000/PTC100(three-wiring diagram contacts 17 RTD A, 18 RTD B, and 19

RTD B Sh.)

Temp. probe is NTC30K(two-wiring diagram contacts 17 RTD A and 19 RTD B Sh.)

Temp. probe is PTC1000/PTC100(two-wiring diagram shorts with 18 RTD B and 19 RTD B Sh.)

Drv HiĻSensor drive coil terminal, High

Drv Lo

Ļ

Sensor drive coil terminal, Low

кк

Page 17

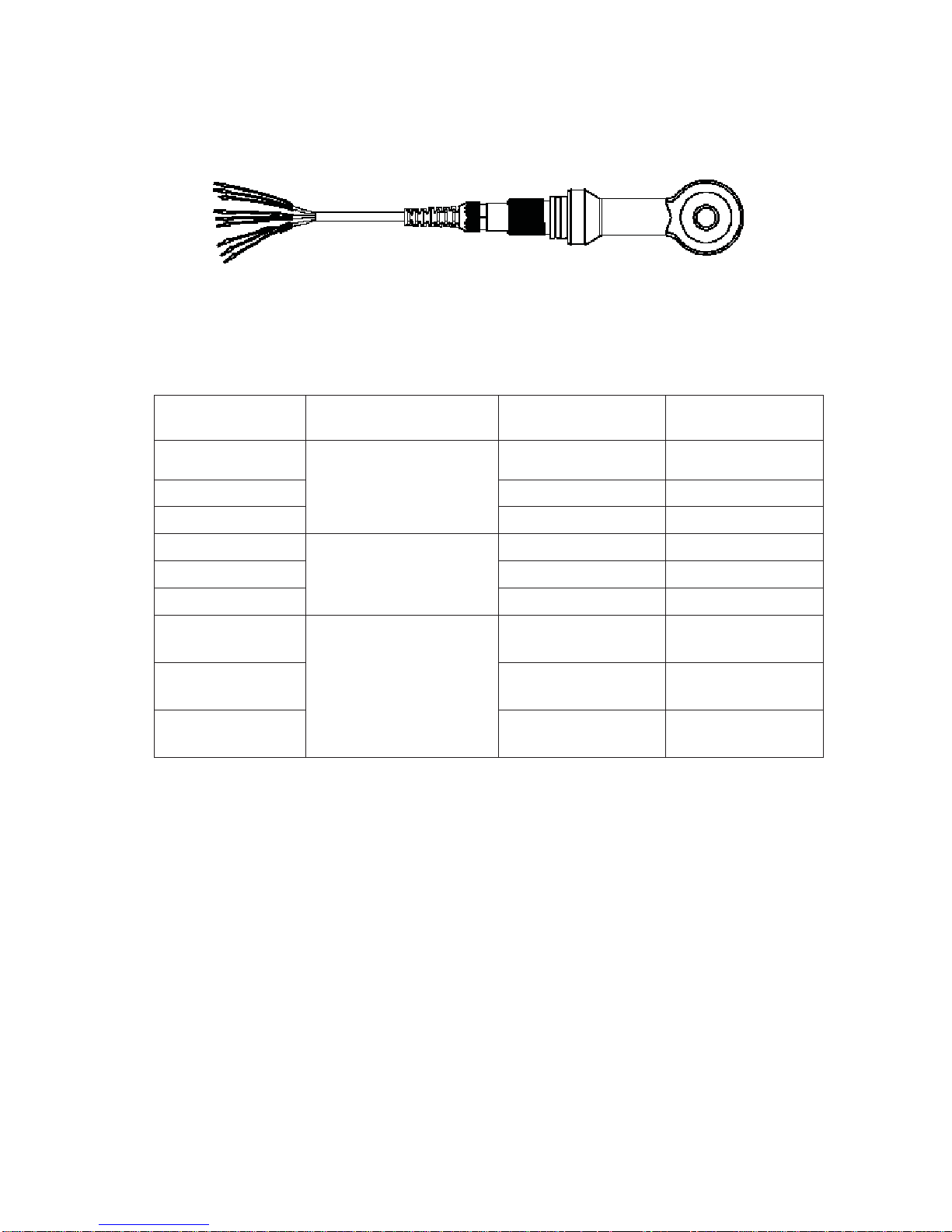

3.4 Wiring of cable

3.5 Circuit of cable

8-201-PFA-10 sensor assembly, 10M

Terminals Color of heat shrink tube Wire color Wire descriptions

Drv Hi

Red

Red Send H

Drv Lo

Brown Send L

Drv Sh

Clear Send SHIELD

Rev Hi

Black

Orange Receive H

Rev Lo

Black Receive L

Rev Sh

Clear Receive SHIELD

RTD A

Green

Yellow

PTC1000

RTD-A

RTD B

Green

PTC1000

RTD-B

RTD B Sh

Clear

PTC1000

RTD-B

кл

Page 18

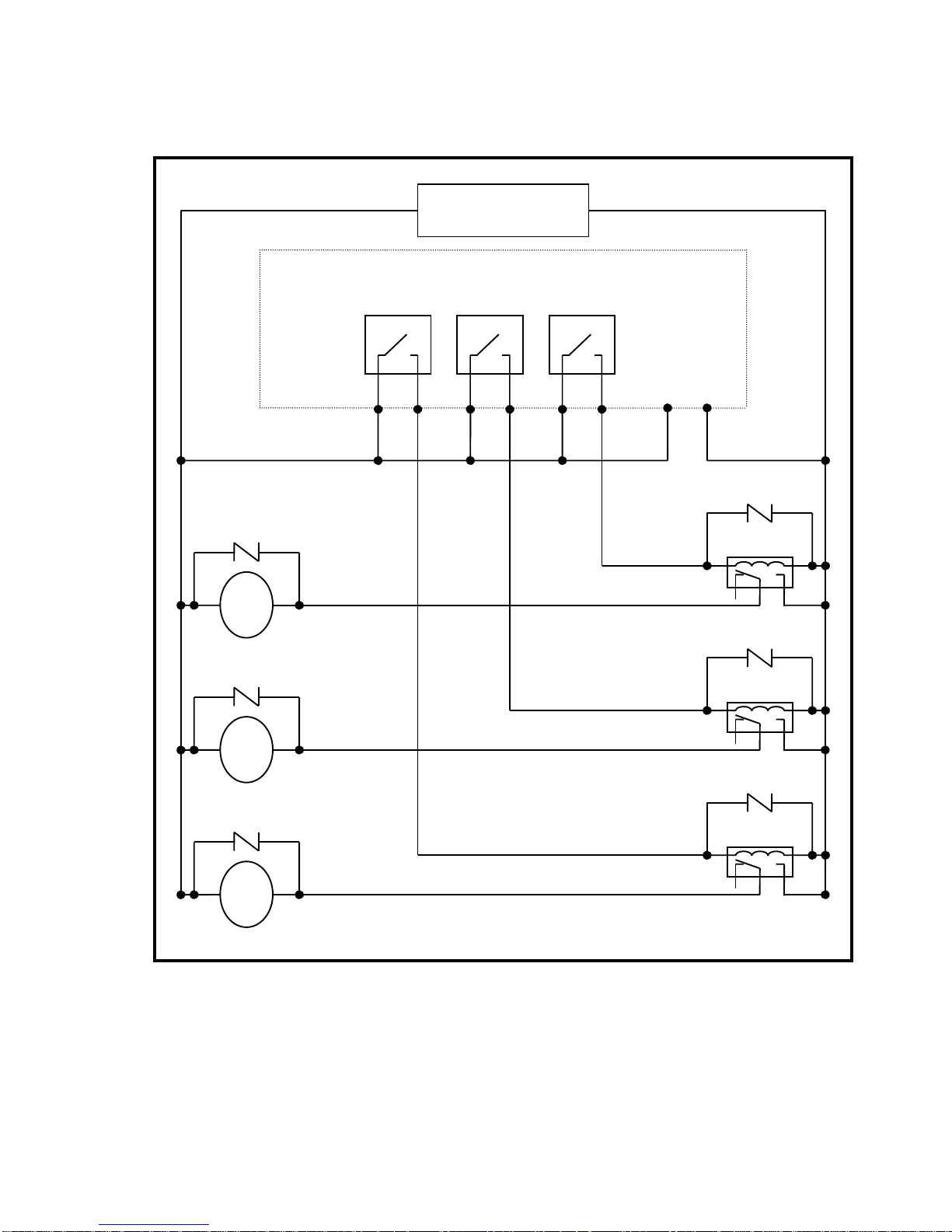

3.6 Illustration of electrical connection

Note: The transmitter built-in miniature relays is necessary to be repaired and replaced by professional technicians.

It is recommended to use an external relay (Power Relay) to activate the external equipments.

100V~240VAC

Relay 2Relay 1 WASH/Cln

100V~240VAC

Transmitter

Surge absorber

External relay

Surge absorber

External relay

Surge absorber

External relay

Cleaning device

Surge absorber

M

Dose feeder

Surge absorber

M

Dose feeder

Surge absorber

M

км

Page 19

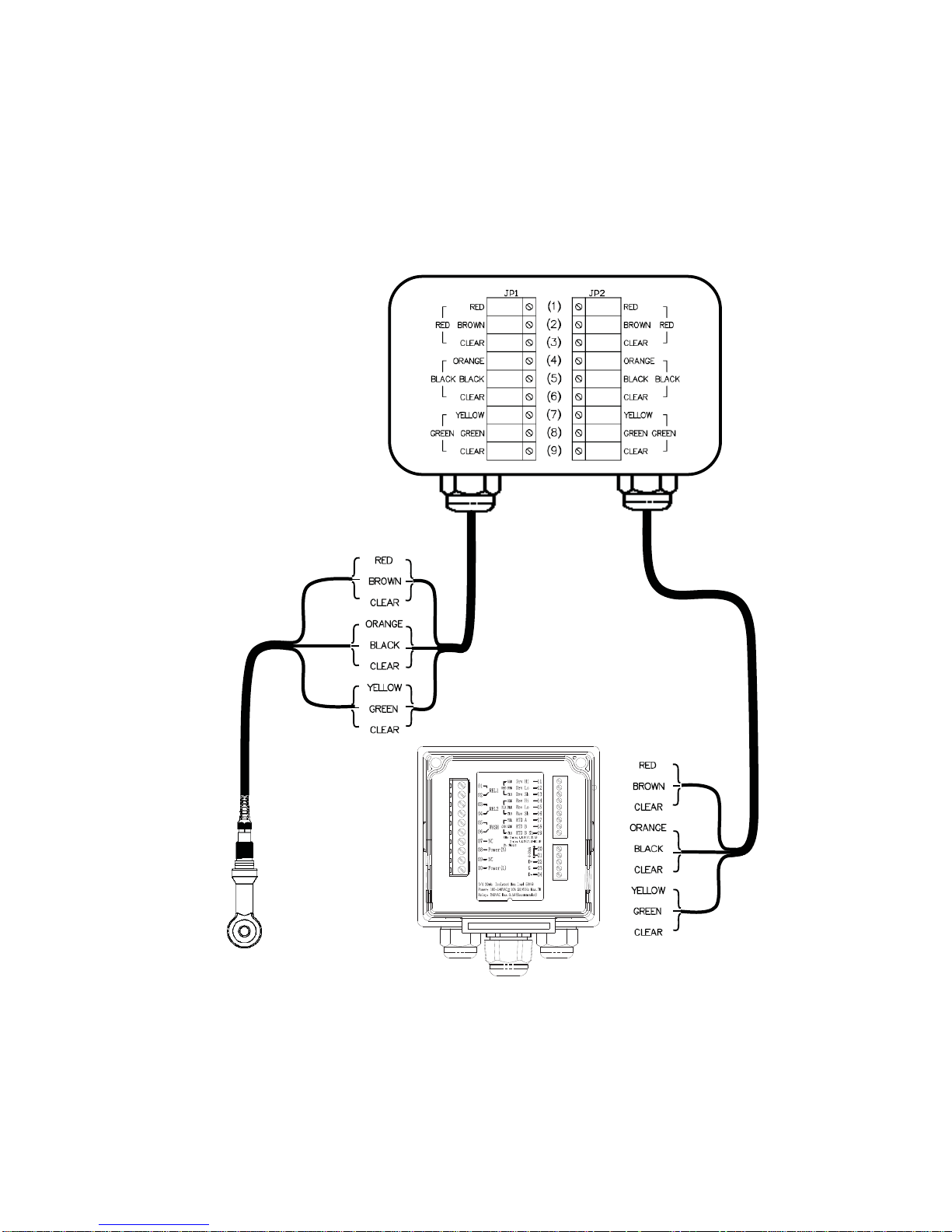

3.7 Wiring diagram of extension cable

When the length of signal cable needs extension(max. up to 50M), 8-09-9 square junction box

9T(there are 4 M4 fixed screws on the rear) and extension signal cable can be used. After

installation, it needs re-calibration of zero-point of the sensor and cell constant, or product

adjustments in field. Wiring diagram is as follows:

RED

BLACK

GREEN

RED

BLACK

GREEN

(8Ͳ201ͲPFAͲ10)10M

(ECͲ4110ͲI/ECͲ4110ͲICON)

11

12

13

14

15

16

17

18

19

8Ͳ09Ͳ9squarejunctionbox9T

Please inform specific

length of extension signal

cable as ordered.

кн

Page 20

4. Configuration

ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ

4.1 Illustration of front panel

4.2 Keypad

In order to prevent inappropriate operation by others, before the parameter setting and

calibration, the operation applies multi-keysĭġand coding protection if necessary. Description of

the key functions is in the following:

烉In the parameter set-up mode, pressing this key allows you exit parameter set-up mode

and back to Measurement mode.

Ļ In the Calibration mode, pressing this key allows you exit Calibration mode and back to

Measurement mode.

烉1. In the parameter set-up mode and Calibration mode, pressing this key to select

leftward or change to another page.

2. When adjusting value, press this key to increase the value.

烉1. In the parameter set-up mode and Calibration mode, pressing this key to select

rightward or change to another page.

2. When adjusting value, press this key to decrease the value.

烉Key for confirmation; pressing this key is essential when modifying data value or

selecting the parameter setting items in the window.

4.3 LED indicators:

ACT

烉

Washing operation relay(Clean) and dosing operation relay (Relay 1, Relay 2) indicator

B.L. : Light sensor; in the automatic display backlit mode, the lamp will light or go out as the

change of environmental brightness.

ко

Page 21

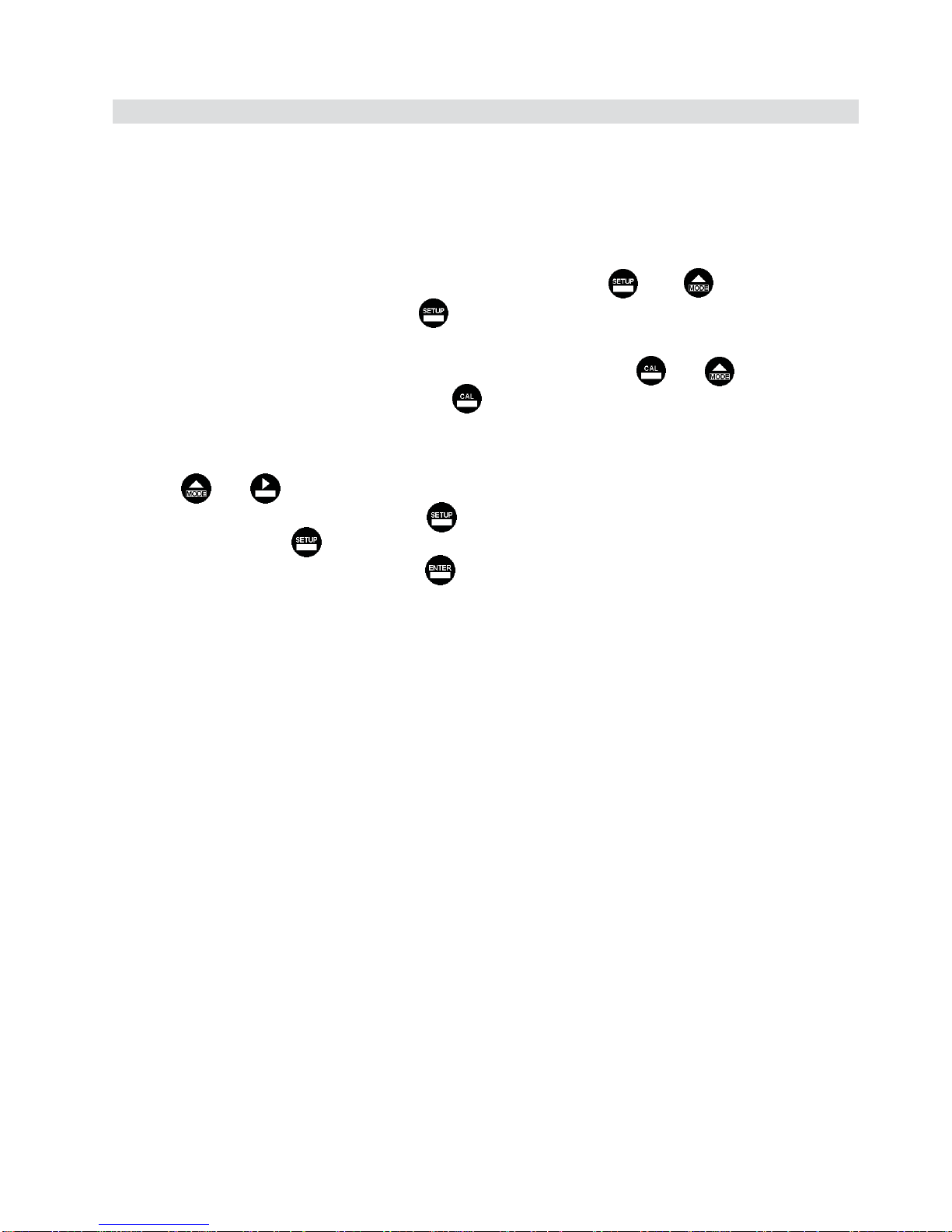

5. Operation

5.1 Measurement mode:

ġġġAfter all electrical connections are finished and tested, connect the instrument to the power

supply and turn it on. The transmitter will automatically entering measurement mode with the

factory default settings or the last settings from user.

5.2 Set-up menu:

ġġġPlease refer to the set-up instructions in Chapter 7. Press and simultaneously to

enter into set-up menu, and press to go press to back to measurement mode.

5.3 Calibration menu:

ġġġPlease refer to the calibration instructions in Chapter 8. Press and simultaneously to

enter into calibration menu, and press to go back to measurement mode.

5.4 Shortcuts:

1. In the measurement mode, if selecting MTC for temperature compensation mode, you may press

and to adjust MTC temperature value.

2. Under measurement mode, press continuously for 2 seconds to see the Logbook function

directly. Press key to back to measurement mode.

3. Under measurement mode, press continuously for 2 seconds to switch the display mode

from text mode, trace mode, and real-time chart display mode.

5.5 Default value:

5.5.1 Setting default value:ġġġġ ġġġġġġġġġġġġġġġġġġġġġġġġġġġ

Measurement mode: Conductivity@tref

Range: 2000mS

Temperature compensation: PTC1000

Temperature Coefficient: Lin, 2.00%

Relay 1: High point alarm: AUTO, SP1= 1000mS, Hys.=10mS

Relay 2: Low point alarm: AUTO, SP2 =100 mS, Hys.= 1.0 mS

Wash time: OFF

Analog current output (Cond/Res): 4~20 mA, 0~1000mS

RS-485: RTU, 19200,EVEN, 1, ID: 1

Date & Time: 2014/1/1 00:00:00

Digital filter: 0

Backlight setting: Off

Contrast: 0

Logbook: None

Auto back: Auto, 3 minutes

Code set-up: Off

5.5.2 Calibration default value:

ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ ġ

кп

Page 22

Cal Type: No Cal

Cal T emperature: None

Cell Constant: 2.700

Zero: 0.0ȝS

Auto back: Auto, 3 minutes

Code set-up: Off

Note: The factory default of calibration presetting is “No Cal”, and the cell constant setting is “2.700”. It means

that the user has not calibrated the sensor with the transmitter yet. When selecting standard solution or

directly adjusting cell constant to finish calibration, the display shows cell constant of the cell. It should

re-start a zero-point calibration in air after installation or maintenance, and the surface of sensor needs

cleaning without attachment with cleaning solutions during calibration.

кр

Page 23

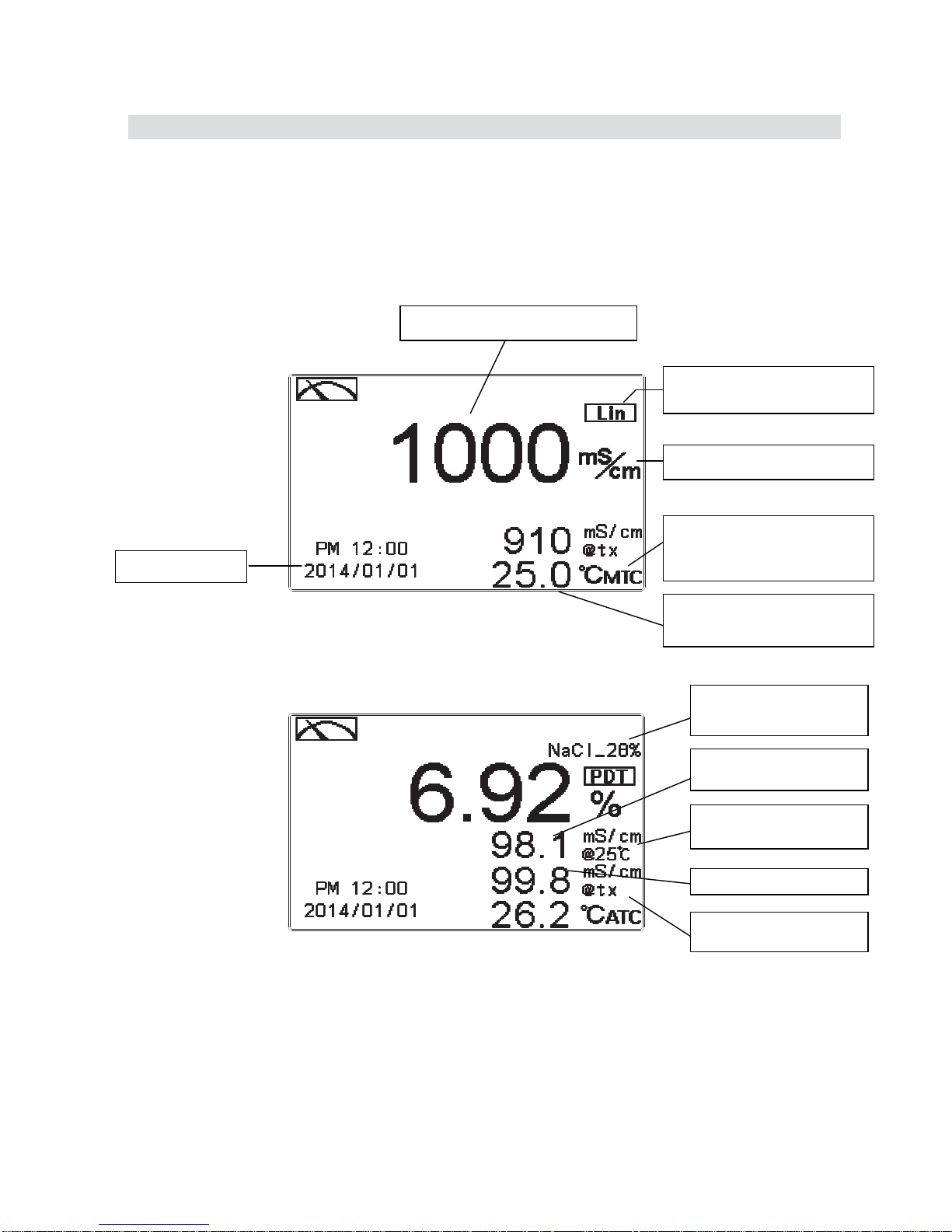

6. Measurement display mode

6.1 Text mode

The normal mode is for digit display, the content is as the following illustration. It mainly

includes main measurement value and unit, temperature measurement value and unit,

temperature compensation mode, and clock display.

The first line is main measurement to correspond to desired parameter, and the second

and the third line are auxiliary one to show related values but not necessary parameters.

The fourth line is to show temperature basically.

Main measurement unit

Temperature

compensation Mode

(

MTC/ATC

)

Temperature

measurement & unit

Main measurement

Clock display

Temperature

Compensation mode

Third measuring value

Second measuring

value

Second measuring

value unit

Third measuring value

unit

Conc. type and range

кс

Page 24

6.2 Real-Time Chart mode

Real-time chart mode is for dynamic display of real-time graphics. The duration is about three

minutes of the recent changes in measured values of the curve. Users can set the mode to its

corresponding Cond./Conc. measuring range (see section 7.4). The smaller the range is set, the

higher resolution of the display is. When entering setup or calibration mode and returning to

measurement mode, the real-time graphic will be re-updated. When the measured value exceeds a

set range of the upper and lower limit, the graphics will be presented in the upper and lower limits

dotted line. Real-time chart mode display is shown as below. There are also real-time measurement

value, & unit, and temperature value & unit which are displayed in the bottom of the screen. The

timeline in real-time graphic is divided into 12 depict, which is describe the range of

representatives of each of 1 / 4 minutes (15 seconds).

3 minutes of main measurement

record curve

Main measurement

value & unit

Temperature value

& unit

The current

instantaneous value

Upper limit

Lower limit

кт

Page 25

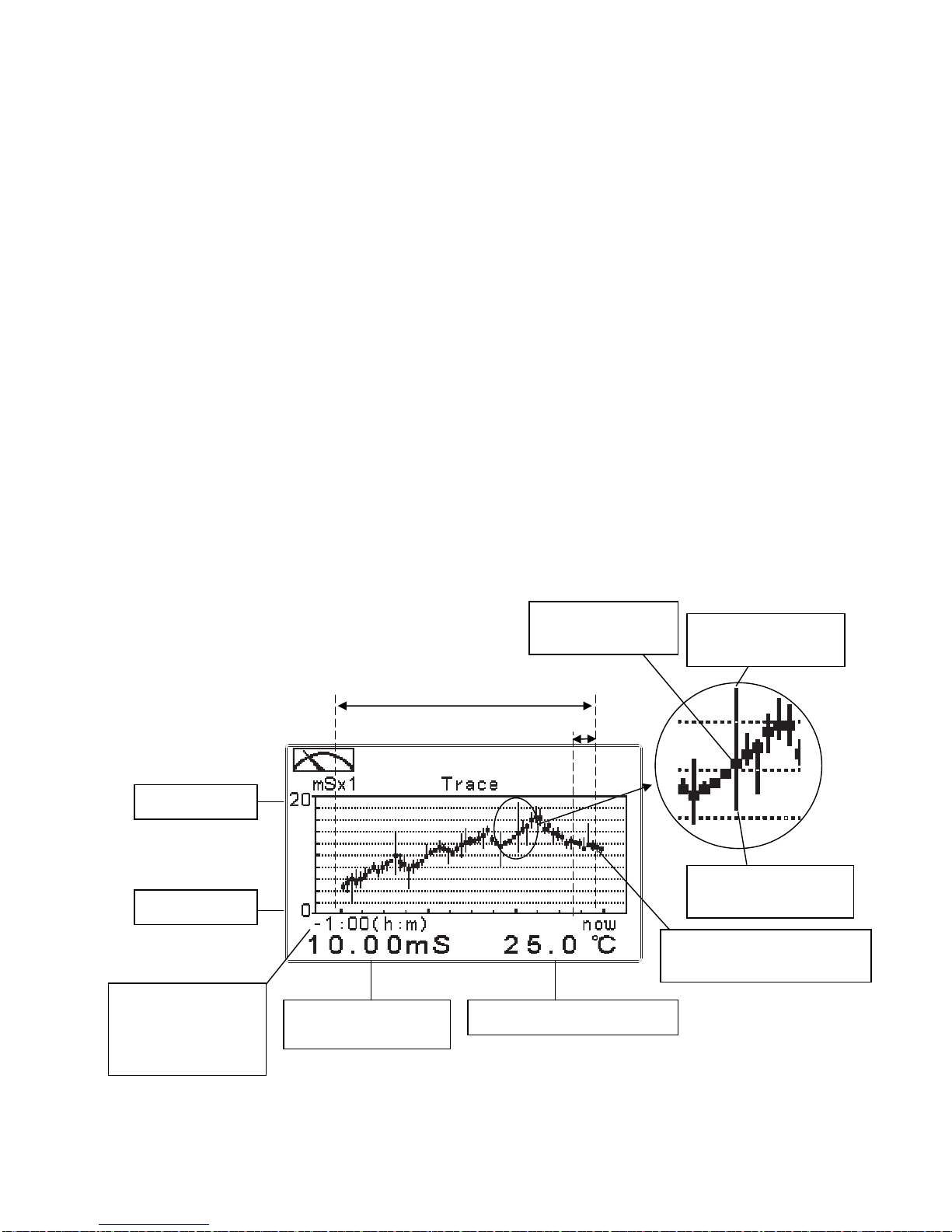

6.3 Trace mode

The feature of the trace mode is the record duration which can be set by the user (range from

three minutes, up to four weeks). The trend graphic records the measurements in the past T time.

The trend is recorded by the 60 group structure. Hence, each group of units is recorded in T/60

time interval. The trend line is constructed by all value data which is calculated to the average

(Mean Value), maximum (Max Value) and minimum (Min Value) form. When the latest T/60

record shows in the rightmost of the trend graphic, all the previous record will be moved to the left

side of the graphic. For example, T is set to 60 hours, then each set of records will be calculated to

the average, the maximum, the minimum values after one hour(T/60 = 1), each time interval.

Timeline of trends which is divided into 12 depictions showed on the horizontal axis of the display

is on behalf of each characterization interval T/12. So, every depiction has 5 (T/60) sets of records.

Users can set the corresponding Cond./Conc. measuring range in its set-up menu(see section 7.4).

The smaller the range is set, the higher resolution of the display is. The trace mode is shown as

below. There are also real-time measurement value, & unit, and temperature value & unit which

are displayed in the bottom of the screen.

Attention: When the time interval has been reset, the trend in the data will not be retained, it will

start a new trace record.

Note: The time display format (XX: XX) (hr: min), for example, appear as four weeks (672:00).

T/12

Trend recording interval

Whole Time(60 data record sets)

Main measurement

value & unit

Temperature value & unit

Upper limit

Lower limit

The max. value of

the T/60 interval

The min. value of

the T/60 interval

The mean value

of the T/60

The latest set of record

shown on the right sector

Record

duration(T), the

negative sign is to

mean the record

лй

Page 26

6.4 Warning symbols and text

1. When the clean function is activated, the display shows and twinkles the description, “Clean Running”.

At the same time, the ACT indicator LED lights up, and the transmitter automatically turns off Relay 1

and Relay 2 function. After finishing cleaning, the Relay 1 and Relay 2 will automatically back to

normal status.

2. When Relay 1/Relay 2 which is set in high setting point is in action, the display shows and twinkles the

description, “REL 1-HI/REL 2-HI”, and ACT indicator LED lights up. When Relay 1/Relay 2 which is

set in low setting point is in action, the display shows and twinkles the description, “REL 1-Lo/ REL

2-Lo”, and ACT indicator LED lights up.

3. When the Analog 1 current output exceeds the upper/lower limitation, the display twinkles ”

S-mA /

S-mA ” as an alarm.

Note: The “HOLD” warning text appears when clean function is activated, or when entering setup menu, or

when entering calibration menu. Under HOLD status, the corresponding display and output are as

follows:

1. Both Relay 1 and Relay 2 cease from action. If enter setting menu or calibration menu under clean status,

the instrument will stop clean status automatically.

2. The current output which is corresponding to measurement value remains at the last output value before

HOLD status.

3. The last signal output value of RS-485 interface is kept at the last output value before HOLD status.

ˑ

Control function

on hold

Product adjust ON

Compensation unit

mS/cm炯tref

conductivity with

temperature comp.

mS/cm炯tx

absolute conductivity

: measurement mode

: set-up mode

: calibration mode

Relay 1 high or

low point alarm

Relay 2 high or

low point alarm

Analog 1 output current

over range alarm

W

ash device in action

condition

лк

Page 27

7. Settings

Block diagram of setting part 1

EC-4110-I

EC-4110-ICON

Overview

Mode Code Temperature

Input

Code

OFF ON

New

Code

MTC NTC PTC1000

Set

Temp.

Correct

Temp.

English

Traditi

onal

chinese

Simplif

ied

chinese

Return

Continue on next page

Language

烉

烉

烉

烉

Back to the previous

level / action

Product Adj.

Correct

SPAN

ON

Compensation

Linear

Comp.

Non-

Linear

Comp.

Input

linear

Comp.

Select

Product Adj.

ON or OFF

Set time

duration

Delete

all

YES

Select

Cond.@tref/Conc./TDS/

Salinity/Cond.@tx

Modes

Digital

Mode

Chart

Mode

Trace

Mode

Continue on next page

Relay 1

Cond.@tref

Cond.@tx

Mode

Conc.

Mode

TDS

Mode

Salinity

Mode

Select

Range

Set

Max

value

Set

Min.

value

Set

Max.

value

Set

Min.

Value

Input TC

Select

Solution

Select

Range

婧㔜

FACTOR

PTC100

No

Comp.

Input

TC

Value

Sub-display

ON or OFF

Sub-display

ON or OFF

Sub-display

ON or OFF

Sub-display

ON or OFF

лл

Page 28

Block diagram of setting part 2

Relay 1

Input

Relay1

SP value

Input

Relay1 Hys.

Value

Relay1

ON / OFF

Relay1

Test

Relay1

Hi / Lo

point

AUTO

Relay 2

Input

Relay2 Hys.

Value

Relay2

ON / OFF

Relay2

Test

Input

Relay2 SP

Value

Relay2

Hi / Lo

point

AUTO

Continue with previous page

Compensation Clean Current Output

Input

Clean

Close timing

Input Clean

Hys. Time

Interval

Clean

Test

Input

Clean

Timing

Input

Corresponding

Value to

0 or 4mA

Input

Corresponding

Value to 20mA

0/20 or 4/20mA

analog output

current

Clean

ON / OFF

AUTO

RS-485

RTU or

ASCII

Baud Rate

Parity

ID

Stop Bits

Clock

Set Month

Set Date

Set Time

Clock

ON or

OFF

ON

Digit Filter

Input

Back Light

Auto ON OFF

Input

Lightn

ess

Input

Sensitive

ness

Input

Lightness

Contrast

Input

Contrast

Logbook

Read

Historical

Data

Return

Input

Return

Time

Auto

Exit

Manual

Exit

Continue with previous page

Code

лм

Page 29

7.1 Entry of set-up menu

In the measurement mode, pressing the two keys and simultaneously allows

you enter the overview of current setting, and press to enter the set-up mode to modify

the setting if necessary.

Enter set-up menu

“Measurement (Mode)”

Pressġġġġ

Pressġġand simultaneously

Pressġġ

Pressġġor

Pressġġto confirm it

лн

Page 30

7.2 Security code of settings

After entering set-up mode, select “code” item, press to enter into code

procedure. The code pre-setting is 1111.

Note: The code of setting mode is prior to the code for calibration. That means that

the code of setting mode can be used for the code of calibration mode.

Enter “Language” Setup

Press or

Press to confirm it.

When a wrong password is

keyed in, the display shows

“Error Code”, press to

re-key in it, or press to

exit.

The first ‘0” of digits ‘0000” start

to twinkle. Press or to

adjust the value, and then press

to confirm it and continually key

in the next digit, and so on.

(Select to turn on or turn off

code protection function. If

you select turn on, please

key in a new code. There

will be a code requirement

showing in display when you

re-enter to the setup mode.

Key in the correct password

to enter into setup mode.)

Key in new password

Press to confirm it.

Press to confirm it.

Press to confirm it.

ло

Page 31

7.3 Language

Enter Language setup menu, select the system language from English, Traditional

Chinese and Simplified Chinese.

Enter “Measurement Mode” Setup

Press to confirm it.

Pressġ or ġġ

to select

language type

Press to confirm it.

Pressġ or ġġ

to select

language type

Press to confirm it.

Press to confirm it. Press to confirm it.

лп

Page 32

7.4 Mode

The default setting of measuring range is 2000mS/cm, and users can select the desired range

according to requirements from 2000mS, 999.9mS, 99.99mS, 9.99mS, ȝ6 or AUTO range

selection.

7.4.1 Conductivity with Temperature Compensation (Cond.@tref)

Conductivity with temperature compensation means that conductivity can be obtained by

linear or non-linear temperature compensation setting. (“temperature compensation

coefficient” and “temperature compensation reference temperature”, please refer to ch7.7

“Temperature Compensation Coefficient”.)

Enter setup of Mode, select “Cond.@tref” and measuring range from 2000mS, 999.9mS,

99.99mS, 9.99mS, 999.9ȝ6 or AUTO range selection, and then select display mode.

Select Trace Mode Select Chart Mode

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press or to select

Cond.@tref

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press or to input

upper limit

Press or to select

to turn the auxiliary subtitle

on or offġ

Press or to select

measuring range or auto range

selectionġ

Press to confirm it.

Press or to input

lower limit

Press to confirm it.

лр

Page 33

Enter ȾProduct Adjustment.ȿSetup

Select Digital Mode

Digital Mode

Chart Mode Trace Mode

Press or to select

display modeġ

Press to confirm it.

Press to confirm it.

Select YES & Press

to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Select NO to preserve the

setting and previous data

Press to confirm it.

To set record duration T,

press or

to adjust the hour value ,

press to confirm

and move to minute

adjustment part.

лс

Page 34

7.4.2 Absolute Conductivity(Cond.@tx)

Absolute conductivity is to present the actual conductivity without temperature compensation of

a measured solution.

Enter setup of Mode and select absolute conductivity ” Cond.@tx”. Then select the measuring

range from 2000mS, 999.9mS, 99.99mS, 9.99mS, ȝ6 or AUTO range selection and display

mode.

Select Trace Mode

Select Digital Mode

Select Chart Mode

Press to confirm it.

Press to confirm it. Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press or to input

upper limit

Press or to input

lower limit

Press or to select

Cond.@txġ

Press or to select

to turn the auxiliary subtitle

on or offġ

Press or to select

measuring range or auto range

selectionġ

Press or to select

display modeġ

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

лт

Page 35

Press to confirm it.

EnterȾProduct AdjustmentȿSetup

Digital Mode Chart Mode Trace Mode

To set record duration T,

press or

to adjust the hour value ,

press to confirm

and move to minute

adjustment part.

Select YES & Press

to confirm it.

Select NO to preserve the

setting and previous data

Press to confirm it.

Press to confirm it.

мй

Page 36

7.4.3 Concentration (EC-4110-ICON Only)

Enter setup of Mode and select “Conc.” measuring mode, optimum measuring solution,

varieties and concentration.

Built-in measuring ranges are listed below: NaCl_28%(0-28%), HCl_18%(0-18%),

HCl_39%(22-39%), HNO3_30%(0-30%), HNO3_96%(35-96%), NaOH_24%(0-24%),

NaOH_50%(15-50%), H

2SO4

_37%(0-37%), H2SO4_88%(28-88%), H2SO4_99%(89-99%),

H3PO4_35%(0-35%) or Defined, and then select display mode.

As conductivity or concentration exceeds boundary limits of its measuring range, the

measured value twinkling will represent an error warning, however, please note that “Defined”

is without measuring range limitation and an error warning.

Concentration conversion boundary values of each solution vary with the changes of

temperature.

Press to confirm it.

Select Trace Mode

Select Digital Mode

Select Chart Mode

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press or to select

Conc.

Press or to turn the

auxiliary subtitle on or off

Press to confirm it.

Press to confirm it.

Press or to input

upper limit

Press or to input

T.C. value

Press or to select the solution

Press or to select display mode

Press to confirm it.

Press to confirm it.

мк

Page 37

Press to confirm it.

Press to confirm it.

EnterȾProduct AdjustmentȿSetup

Digital Mode Chart Mode Trace Mode

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press or to input

lower limit

Select NO to preserve the

setting and previous data

Select YES & Press to

confirm it.

Press to confirm it.

To set record duration T,

press or

to adjust the hour value ,

press to confirm

and move to minute

adjustment part.

мл

Page 38

7.4.3.1 Defined concentration table

If the measured sample information is not listed in built-in table of the transmitter, users can

input their defined table. Defined table can be input data with temperature of measured

solution, sort ascending or sort descending, from 1~9 temperature table. At least two or up

to nine conductivity and concentration conversion data are included at each temperature

(more data, more approximate the solution concentration, higher conversion resolution), and

each data include one concentration and its corresponding conductivity.

Conductivity or concentration needs to be input in ascending or descending order. If users’

measured solution only has one data (one concentration and its corresponding conductivity),

they need to set linear temperature compensation coefficient for that in order to make the

temperature compensation.

Defined table default setting which includes 9 data is for Hydrofluoric Acid at 25ɗ. Users

can revise the data, in addition, they need to input linear temperature compensation

coefficient (refer to HF table); for users only with one data, after inputting corresponding

value of conductivity and concentration, it also requires T.C. coefficient.

If the data are attained by two or more temperature points, there is no need to input T.C.

coefficient because the unit can calculate the corresponding concentration value and

conductivity with reference temperature based on conversion data in different temperature.

Once default conversion table for HF is being changed, it needs re-input again.

If the temperature, conductivity and concentration of test solution are approximate to

measured solution, higher & more accurate conversion relation can be required.

Press to confirm it.

Press or to input T.C. coefficient

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press or to select

Conc.

Press or to turn the

auxiliary subtitle on or off

мм

Page 39

Press or to set the

number of Conc. points

one temp. point two or more temp. points

Press or to select

Defined.

Press to confirm it.

Press to confirm it.

Press or to set the

unit of Conc.

Press or to set desired number

of tables

Press or to set the

unit of conc.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press or to set the

T.C. coefficient

Press or to set the

number of Conc. points

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

мн

Page 40

If the temperature is not input in ascending or descending order, there shows Temp. Error on the

display screen.

If the conductivity is not input in ascending or descending order, there shows Cond. Error on the

display screen.

If the concentration is not input in ascending or descending order, there shows Conc. Error on the

display screen.

Current T able

T ota l Tables

Temp. of the Table

Points

Input Conc.

Save & Exit

Input Corresponding

Cond. to Conc.

Save & Next Page

one temp. point two or more temp. points

Press to confirm it.

мо

Page 41

Concentration %

Hydrofluoric Acid

HF Solution mS/cm at 25ɗ

ɗ

0.0001 0.01

0.0003

0.03

0.001

0.099

0.003

0.290

0.01

0.630

0.03.

1.49

0.1

2.42

0.3

5.1

1.0

11.7

3.0

34.7

5.0

62.0

10.0

118.0

20.0

232.3

30.0

390.0

*Please refer to the concentration and conductivity conversion table of Hydrofluoric Acid (HF)

(for reference only, users need to revise it on their own)

*T.C. coefficient for common solution is within 1.8~2%, but it is 0.7% for Hydrofluoric acid (HF).

Besides, according to the changes of concentration, T.C. coefficient changes and thus users need to

adjust it depending on the requirements. For example, T.C. coefficient for 0.5%, 1.0%, 3.0% HF is

about 0.70%, 0.73%, 0.74%. Users can attain the T.C. coefficient depending on actual situation of

measured solution.

*T.C. coefficient for Hydrofluoric Acid (HF)

(for reference only, users need to revise it on their own)

ġ

ġ

мп

Page 42

7.4.4 TDS

Enter the setup of Mode, select TDS measuring mode and units from ppm or ppt and set the

TDS constant. The default TDS constant is SSPȝ6.

Press to confirm it.

Press to confirm it.

EnterȾProduct AdjustmentȿSetup

Press or to select TDS

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press or to turn the

auxiliary subtitle on or off

Press to confirm it.

Press to confirm it.

Press or to select

the unit

мр

Page 43

7.4.5 Salinity

Enter setup of Mode and select Salinity measuring mode.

Press to confirm it.

Press or to turn the

auxiliary subtitle on or off

Press to confirm it.

Press to confirm it.

EnterȾProduct AdjustmentȿSetup

Press to confirm it.

Press to confirm it.

Press or to select TDS

мс

Page 44

7.5 Product Adjustment

Enter setup of Product Adjustment to make the fine adjustment of the measurement reading.

There is no need for users to take out the sensor from the field and calibrate it. Via this function

the measuring values from the field can be compared to the result that came from the sampling

and directly adjusted to the same value. If turning on this function, there shows the symbol

“PDT” on the display screen.(please refer to ch6.4 “Warning symbols and text”).

The inductive sensor applies electromagnetic effects to measure the conductivity of a sample

solution which can be affected by length of signal cable and the distance between a sensor and

the shell of pipe, making an influence on the cell factor and measuring value. At the moment,

Product Adjustment can be used to calibrate the measuring value without changing the cell

factor.

Users may compare the reading with the

actual measured value. Press or

to adjust the Cell Factor( a cell constant’s

multiplier) in the main display in order to

modify the reading of measurement

which shows in the bottom part of

display.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it. Press to confirm it.

Press to confirm it.

Press to confirm it.

EnterȾTemperatureȿSetup

Press or

to switch on or

switch off.

мт

Page 45

7.6 Temperature

Enter setup of “Temperature” to select temperature probe types. Select from 37&.ȍ (PT-1000),

37&ȍ (PT-100), or NTC(NT30K) for Auto Temperature Compensation or MTC(Manual

Adjustment).ġ

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it. Press to confirm it.

Press to confirm it.

Press to confirm it.

EnterȾTemperature Compensation CoefficientȿSetup

Press to confirm it.

Use standard thermometer to test

the actual temperature of the

solution, and press or

to input the correct temperature

value.

If necessary, compare with

the actual temperature

value tested by standard

thermometer.

Press or to

input the modified value.

Press to confirm it.

нй

Page 46

7.7 Temperature Compensation Coefficient

The default setup of temperature compensation reference temperature is 25 䉝, and temperature

compensation coefficient is 2.00%.

Enter setup of Temperature Compensation Coefficient mode and select T.C. coefficient from

Linear, Non-Linear or No according to measurement requirements. Normally, select linear

compensation for Conductivity measurement (Cond.).

Temperature coefficient (hereinafter referred to as TC): Conductivity of solution increases with

rising temperature. The relationship is as follows:(reference temperature ”t

ref

” is 25䉝, users can

change depending no requirements)

How to get TC of solution:

C

tref

Conductivity at reference temperature

Ct = C

tref

^Į7炼t

ref

) }

C

t1

&RQGXFWLYLW\DW7Û&

T

1

Measured solution temperature

Į &

t2炼Ct1

) / Ct1 ( T2炼t

ref

)炼Ct1 ( T1炼t

ref

)

C

t2

&RQGXFWLYLW\DW7Û&

T

2

Measured solution temperature

Į Temperature compensation

coefficient

Take an example for 0.01M KCl. Set the TC of the instrument to non-compensated炷Lin, 0.00炴炸,

and control the temperature at C

t1

Û&DQGDWCt2Û&ġC

t1

means the measurement value at 20Û&6XFK

as

C

20

= 1278ȝ6&t2 means the measurement value at 30Û&6XFKDVC

30

= 155ȝ6%DVHGRQWKH

IRUPXODVDERYHĮ烌1.94%.

Linear compensation range: 0.00炴焍40.00炴

Temperature compensation range(C

tref

): PT1000/PT100/MTC 0 䉝焍200 䉝

NTC30K 0 䉝焍130 䉝

Press to confirm it.

Press to confirm it.

1278(30炼25) 炼1552(20炼25)

1552炼1278

ǘ100 = 1.94

Ƞ烌

Press to confirm it.

Press to confirm it. Press to confirm it.

Pressġ or ġġ

to select

Pressġ or ġġ

to select

нк

Page 47

Linear Mode Non-Linear Mode No Mode

ņůŵŦųȾRelay 1ȿŔŦŵŶűġ

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Pressġ or ġġ

to set compensation

coefficient.

MAX: 40.00%

Pressġ or ġġ

to set compensation

temperature

нл

Page 48

7.8 Relay 1

Enter setup of Relay 1. Select the item to turn on or turn of the relay 1 function. If you select to

turn on the relay 1, then select for using relay 1 as “High set-point” alarm or “Low set-point”

alarm. Set the value of set-point (SP) and Hysteresis (Hys.). The relationship between parameters

can refer to an explanatory diagram of the box (as a high point alarm).

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

High Point Alarm Control

off off

on

on

SP

Hys.

%/mS/ȫS/ppm/ppt

t (sec)

ņůŵŦųȾRelay 2ȿŔŦŵŶűġ

SelectġAUTO.ġ

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press ġ or

to select Hi point

or Lo point alarm.

Press or

to adjust Hysteresis

(Hys.) value

Press or to adjust

set-point (SP) value.

If the measuring range of

conductivity is set as AUTO,

then it needs to be set unit

ȝ6FPRUP6FPYDOue, and

decimal point by orders.

Press ġ or to

select to activate a test on

REL1. If “ON”, the relay

1 is in action, and the

“ACT” indication light

will light up.

нм

Page 49

7.9 Relay 2

Enter setup of Relay 2. Select the item to turn on or turn of the relay 2 function. If you select to

turn on the relay 2, then select for using relay 2 as “High set-point” alarm or “Low set-point”

alarm. Set the value of set-point (SP) and Hysteresis (Hys.). The relationship between parameters

can refer to an explanatory diagram of the box (as a high point alarm).

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Low Point Alarm Control

off

SP

Hys.

%/mS/ȫS/ppm/ppt

t (sec)

off

on

on

ņůŵŦųȾCleanȿŔŦŵŶűġ

Select AUTO.

Press to confirm it.

Press to confirm it.

Press ġ or

to select Hi point

or Lo point alarm.

Press ġ or

to activate Relay 2

Press or

to adjust Hysteresis

(Hys.) value

Press ġ or to

select to activate a test on

REL2. If “ON”, the relay

2 is in action, and the

“ACT” indication light

will light up.

нн

Page 50

7.10 Clean

Enter setup of “Clean” function. Select the icon to turn on or turn off the clean function. If you

select “Auto” turning on, then set the timer of the clean function including automatically turning

on time and turning off time, and set the Hysteresis value (Hys.).

Note: When the clean function is turned on, if any value is set to be 0, the instrument will automatically

turn off this function. When the clean function is activated under measurement mode, there is a “Clean

Running” message showing on top of the display. The measurement value will be remained at the last

measured value before cleaning. If enter setting menu or calibration menu under clean status, the

instrument will stop clean status automatically.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

on off on off on

off off

on on

off

T

on Thys

T

off

Ton T

hys Toff

T

off

Clean Timer Control

Relay

Contact

Timer

Settin

g

s

Measure

Action

Enter “Current Output” Setup

Press ġ or

to select to activate

Clean or not.

Press ġ or to

adjust the auto turning

on time.

Press to confirm

the minute part, and

move to adjust the

second part.

Press ġ or to

adjust the auto turning

off time.

Press to confirm

the minute part, and

move to adjust the

second part.

Press to confirm it.

Press or to

adjust duration time for

Hysteresis (Hys.)

Press to confirm the

minute part, and move to

adjust the second part.

Press ġ or to

select to activate a test of

Clean or not. If “ON”, the

Clean function is in

action, and the “ACT”

indication light will light

up.

но

Page 51

7.11 Current Output

Enter setup of Current Output. Select 0~20mA or 4~20mA current output. Set the related value

to the range of Cond. measurement. If the range of the Cond. measu rement is to be set smaller,

the resolution of current output is higher. When the measured value exceeds the higher range

limit, the current will remain approximately 22mA output. When the measured value exceeds

the lower range limit, under 0~20mA mode the current output will remain 0mA output; while

under 4~20mA mode the current output will remain approximately 2mA output. The

exceptional output value can be used as a basis for failure determination. Under

HOLD(measurement) status, the current output maintain the last output value before HOLD

status. However, in order for convenience of insuring the current setting of an external recorder

or of a PLC controller, the current output will be 0/4mA or 20mA under the analog output setup

menu.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press ġ or

to select to current

output range,

0-20mA or 4-20mA.

Press or to set

the lower limit of Cond.

value relative to 4.0mA

output signal. If the

measuring range of

conductivit y measurement

is set as AUTO, then it

needs to EHVHWXQLWȝ6FP

or mS/cm), value, and

decimal point by orders.

Press or to set

the lower limit of Cond.

value relative to 0.0mA

output signal. If the

measuring range of

conductivity measurement

is set as AUTO, then it

QHHGVWREHVHW XQLWȝ6/cm

or mS/cm), value, and

decimal point by orders.

нп

Page 52

Press to confirm it.

Press to confirm it.

4-20mA

0-20mA

EnterȾRS-485 CommunicationȿSetup

Press to confirm it.

Press or to

set the upper limit of

Cond. value relative to

20.0mA output signal.

нр

Page 53

7.12 RS-485 Communication

Enter setup of RS-485 communication. According to the Modbus protocol, set the Transmitting

Mode, Baud Rate, Parity, Stop Bit, and ID number. About the detail of Modbus protocol, please

refer to Ch9 Modbus Protocol. If under HOLD status, the measurement signal output maintains

the last output value before HOLD status.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

EnterȾClockȿSetup

Press to confirm it.

Press to confirm it.

Press or to select

2400, 4800, 9600, or

19200 for Baud Rate.

t

t

Press or to select

RTU or ASCII mode

Press or to select

Even, Odd, or None for

Parity

t

Press or to

select 1 Bit or 2 Bit for

Stop Bit.

Press or to set

the ID number of the

transmitter. The valid

value is from 001 to 247.

нс

Page 54

7.13 Clock

Enter setup of Date/Time(Clock). Set the “Year”, “Month”, “Date”, “Hour”, and “Minute” time.

Note: If you select to turn off the clock function, there will not display clock under measurement

mode. The calibration time of calibration record will also show ”OFF” under calibration

overview display.

Note: With the EC-4110-ICON model, the transmitter may keep the clock in operation even

when encountering power failure. Only when the inner batter y is out of power, the clock may

stop operation. Then, please replace the 3V CR2025 Li batter inside the transmitter.

Press to confirm it.

Press to confirm it.

EnterȾDigital FilterȿSetup

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press or to

set the year.

Select ON & Press to confirm it.

Press or to

set the month part, and

press to move to

adjust the date part.

Press or to

set the hour part, and

press to move to

adjust the minute part.

Press or to

activate the function or

not

нт

Page 55

7.14 Digital Filter

Enter the setup of Digital filter. You may select the number of sample to be averaged each time

to become a reading which is gradually counted in order to increase the stability of

measurement.

Note: “0” represents auto setting according to the conductivity measurement.

Press to confirm it.

Press to confirm it.

Press to confirm it.

EnterȾBack LightȿSetup

Press to confirm it.

Press or to

set the number of

sample to be averaged.

ой

Page 56

7.15 Back Light

Enter setup of backlight display. According to users’ requirements, the brightness of display

(-2~2, dark~bright) and sensitivity of the sensitization sensor(-2~2, insensitive~sensitive) can be

set. On OFF or AUTO backlight mode, if there is a keystroke, then it activates the touch-on state,

activating the backlight. If there is no keystroke for 5 seconds, the display will be back to the

original backlight setting status.

Pressġ or ġġ

to select -2, -1, 0,

1, 2, five backlight

brightness levels

Pressġ or ġġ

to select -2, -1, 0,

1, 2, five backlight

brightness levels

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it. Press to confirm it.

Press to confirm it.

Press to confirm it.

EnterȾContrastȿSetup

ON setting:

The backlight is always on

OFF setting: The backlight is off. When there is a keystroke, it enters to

the touch-on status.

AUTO setting:

According to the ambient light, activate or deactivate the

backlight. When there is a keystroke, it enters to the

touch-on status.

Press or

to select

backlight mode.

Press or

to select

backlight mode.

Pressġ or ġġ

to select -2, -1, 0, 1, 2,

five Backlit sensitization

levels.

ок

Page 57

7.16 Contrast

Enter setup of Contrast. You can set the contrast of display according to your need. (-2, -1, 0, 1,

2, light to dark).

Press to confirm it.

EnterȾLogbookȿSetup

Press to confirm it.

Press to confirm it.

Press to confirm it.

Pressġ or ġġ

to select display

contrast level.

ол

Page 58

7.17 Logbook

Enter setup of Logbook. Users may look up the relative 50 records of the transmitter showed on

the display screen or read by Modbus. The event descriptions are as follows. If users would like

to use Modbus to read the event records, they need to type the serial number 0028 first, and then

they can attain the corresponding event records from 0029H~002FH. Serial number 1 means the

latest event, serial number 2 means the former event, and so on.

Event Description Modbus code

Mea mode Measurement mode 00

Set mode Setting mode 01

Cal mode calibration mode 02

Power On The unit is powered up 03

Power Off The unit is out of power 04

Cond_mA Over Current is over range 05

Error 1 Unstable readings as calibration 06

Error 2

1. Cell factor exceeds the upper/lower limit

2. Temperature is over range

07

Error 3 Wrong password 08

Conc_mA Over Current is over range 09

Error 9 The unit is broken 10

Modbus Write Modbus read-in action 13

EnterȾReturnȿSetup

Press to confirm it.

Press to confirm it.

Pressġ or ġġ

to select different

page

ом

Page 59

7.18 Return

Enter setup of auto return mode (Return) to set the function that the instrument automatically

exit the setup menu after a period of time without pressing any key. The “Manual Exit” means

that it needs to exit setup menu manually, while “Auto” means that the display automatically

exit the setup menu and back to measurement mode after a period of time without pressing any

key.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

EnterȾCodeȿSetup

Press to confirm it.

Press to confirm it.

Pressġ or

to select Auto return

or manual exit.

Pressġ or

to adjust “minute”

part, and press

to confirm it and move

to” second” part.

он

Page 60

8. Calibration

Block diagram of Calibration

EC-4110-I

EC-4110-ICON

Information

Cell

Constant

Std.

Solution

MTC Mode

Cell

Constant

Adjustment

Return

Return

Time

Input

Auto

Manual

Exit

Code

Input

OFF ON

New

Code

Back to previous

level of action

烉

烉

烉

烉

Set

Temperature

ATC Mode

MTC Mode

Ser

Temperature

Select

Std.

Solution

ATC Mode

Calibration

Show

Cell

Constant

Std.

Solution

Adjustment

Std.

Solution

Adjustment

Zero

Zero-point

Calibration

1

оо

Page 61

8.1 Enter calibration setup menu

In the measurement mode, pressing the two keys and simultaneously allows you to

enter theġCalibration Information. If you do not need to re-calibrate the measurement system, press

to go back to measurement mode. If you need to re-calibrate the system, press to enter to

the calibration setup menu. (If the calibration time shows “OFF”, it represents that the clock function

has been turned off.)

Measurement mode

Enter Calibration setup menu

Press and simultaneously

Press to confirm it.

Press to go back to

measurement mode

2

оп

Page 62

8.2 Security password of calibration (Code)

Select the Code (password) icon after entering calibration setup mode. Select to activate code

function or not. The default Calibration setting code is “1100”.

Press or to

select

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Enter “Cell Constant Calibration”

Press to confirm it.

The first ‘0” of digits ‘0000” start

to twinkle. Press or to

adjust the value, and then press

to confirm i t and contin ually key

in the next digit, and so on.

If you input a wrong code, then

the display shows a “Error

Code” message. Press

to restart inputting another

code, or press to exit

the calibration menu.

(Select to turn on or turn off code

protection function. If you select

turn on, please key in a new code.

There will be a code requirement

showing in display when you

re-enter to the setup mode. Key in

the correct password to enter into

calibration setup menu.)

Input the new code.

The steps are as above.

3

ор

Page 63

8.3 Zero-Point Calibration

The inductive sensor connected with the transmitter needs to make a zero point calibration in the

air. Before calibration, it is necessary to make sure that the surface of the inductive sensor is dry

and clean and also in the air. After selecting Zero point calibration and then pressing Enter, the

transmitter will directly calibrate zero point and then display the value.

Press to confirm it.

As the main value is stable and auxiliary value is 0, which

means the calibration has been finished well, and then press

to confirm it and see the calibration information.

4

ос

Page 64

8.4 Cell Constant Calibration

The inductive sensor is immersive to a tested solution, and then input the cell constant which is

qualified in lab and marked on the sensor signal cable.

Due to the fact that the inductive sensor applies electromagnetic induction principle which

belongs to non-contact technology to detect the conductivity of a sample solution. Thus, the

signals may get affected by surroundings such as wall effects, metal(conductor) pipeline or

plastic(insulation) pipeline, distance between the inductive sensor and shell of pipe, etc. the actual

measurement value from the field may be dissimilar to that from the lab. At the moment, by

adjusting the cell constant, Cell Constant Calibration can be made on the field.

Press and to input the cell constant

labeled on the sensor.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Under MTC temperature mode, press or

to adjust temperature value; under ATC temperature

mode(PTC or NTC), it reads the temp. directly.

5

от

Page 65

8.5 Standard solution calibration (Std. Solution)

KCl and NaCl standard solutions can be selected.

1. In the lab, place the inductive sensor into the calibration solution for

30 minutes above. Keeping it at least 3 cm distance from the wall of a

container is to avoid wall effects to cell constant. Then, Cell Constant

by the lab can be attained.

2. Via pipeline installation from the field the standard solution is flown

to the inductive sensor, wall effects can be calibrated and thus Cell

Constant from the field can be attained.

3. It is recommended to use labeled cell constant to calibrate the sensor

on the field and cooperate with product adjustment function. please

refer to ch7.8 Product Adjustment.

4. It is necessary to make sure that the temperature between the

inductive sensor and standard solution should be the same in order to

avoid temperature effects.

Note: it is necessary to make a zero-point calibration first before standard solution

calibration when the inductive sensor runs for the first time.

8.5.1 KCl Standard Solution

Total 3 standard solutions including 111.8mS(1 mol/L), 12.88mS(0.1 mol/L) and 1.413mS(0.01

mol/L can be selected.

Please refer to “Appendix Calibration Solution: Conductivity and Temperature Table” for your

reference.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

3cm 3cm

Press or to

calibrate the KCl solution

6

пй

Page 66

Under MTC temperature

mode, press or

to adjust temperature

value.

Display shows calculated

cell constant value.

ATC Mode MTC Mode

Press to confirm it.

Press or to select

standard solutions from 111.8mS,

12.88mS or 1.413mS.

Press to confirm it and start calibration.

Press or to adjust

the standard solution value.

Press to confirm it.

Press or to adjust

the standard solution value.

Press to confirm it.

The system measures the

standard solution. Press

to show the reading, or wait

for the reading which shows

automatically.

The system measures the

standard solution. Press

to show the reading, or wait

for the reading which shows

automatically.

Press to confirm it and display the calibration result.

7

пк

Page 67

8.5.2 NaCl Standard Solution

total 2 standard solutions including 10.683mS(0.1 mol/L) and 251.3mS(saturated) can be

selected.

Please refer to “Appendix Calibration Solution: Conductivity and Temperature Table” for your

reference.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

ATC Mode MTC Mode

Press or to select

standard solutions from 10.683mS or

251.3mS

Press or to

calibrate the NaCl solution

Press to confirm it and start calibration.

Press or to adjust

the standard solution value.

Press to confirm it.

Under MTC temperature

mode, press or

to adjust temperature

value.

8

пл

Page 68

ATC Mode MTC Mode

Press or to adjust

the standard solution value.

Press to confirm it.

The system measures the

standard solution. Press

to show the reading, or wait

for the reading which shows

automatically.

The system measures the

standard solution. Press

to show the reading, or wait

for the reading which shows

automatically.

Display shows calculated

cell constant value.

Press to confirm it and display the calibration result.

9

пм

Page 69

8.6 Return

Enter setup of auto return mode (Return) to set the function that the instrument automatically

exits the setup menu after a period of time without pressing any key. The “Manual Exit” means that

it needs to exit calibration setup menu manually, while “Auto” means that the display automatically

exits the calibration setup menu and goes back to measurement mode after a period of time without

pressing any key.

Note: The return functions of setup menu and calibration setup menu are independent settings.

Pressġ or ġ to adjust

“minute” part, and press to

confirm it and move to” second” part.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

Press to confirm it.

EnterȾCodeȿSetup

Press to confirm it.

Pressġ or

to select Auto return

or manual exit.

10

пн

Page 70

9. Modbus Protocol and Instructions

9.1 Communication connection