Page 1

1

CT-6300RS

Microprocessor

Residual Chlorine/

Ozone

Transmitter

Setup Cal. Mode Enter

Operation

Manual

Page 2

1. Specifications 1

2. Precautions for installation 2

3. Assembly and installation

3.1 Controller installation 2

3.2 Illustration of panel mounting 2

3.3 Illustration of wall mounting and pipe mounting 3

4. Overview of Residual Chlorine/Ozone Transmitter CT -6300RS

4.1 Illustration of rear panel 4

4.2 Illustration of terminal function 4

4.3 Description of terminal function 5

4.4 Illustration of cable wiring 5

4.5 Illustration of electrical connection 6

5. Configuration

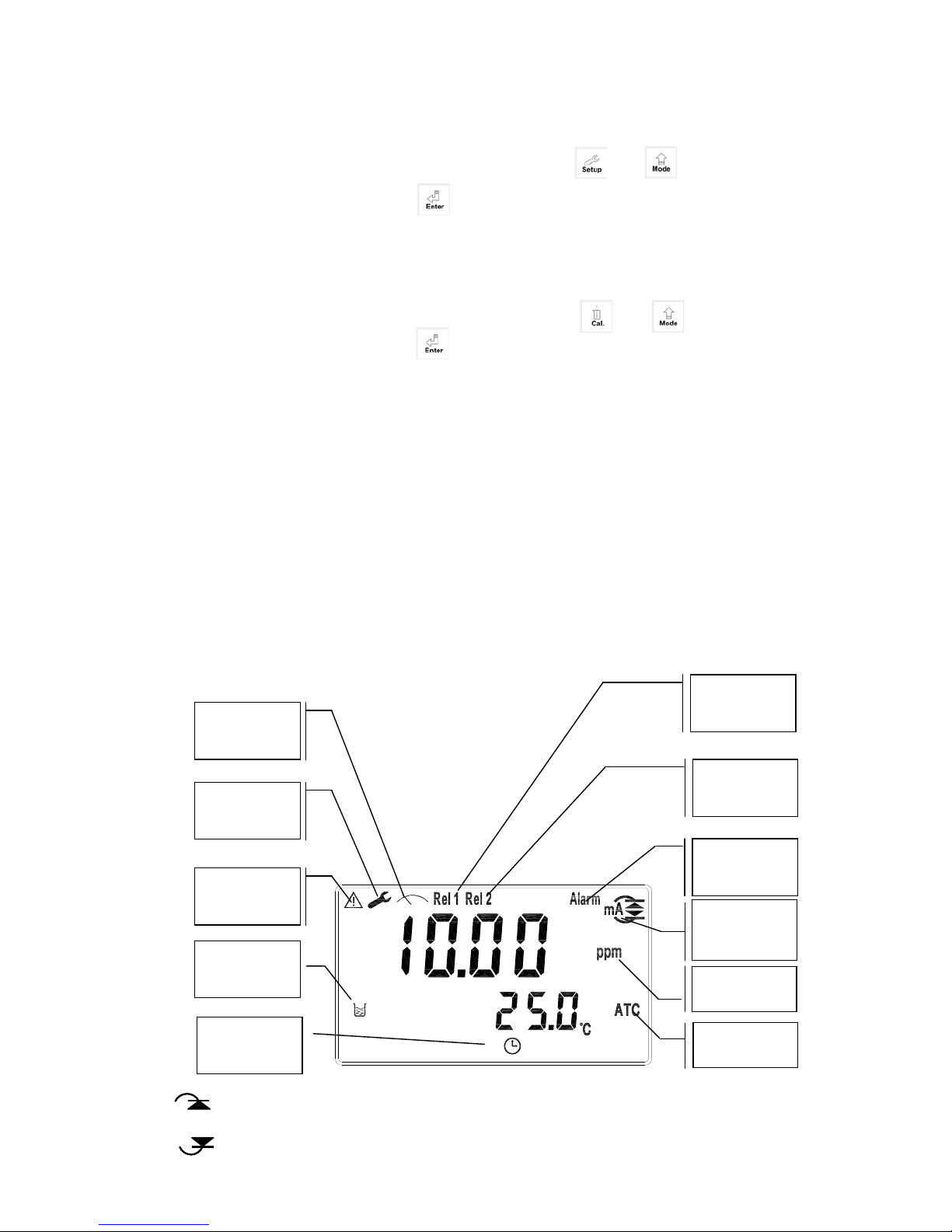

5.1 Illustration of front panel 7

5.2 Keypad 7

5.3 LED indicators 8

5.4 Display 8

6. Operation

6.1 Measurement mode 9

6.2 Set-up mode 9

6.3 Calibration mode 9

6.4 Reset 9

7. Settings

Block diagram of settings 10

7.1 Entry of set-up mode 12

7.2 Security code of settings 12

7.3 Measurement parameter set-up 13

7.4 Temperature set-up 14

7.5 Auto return set-up 14

7.6 Hi point Setting 15

7.7 Lo point Setting 16

7.8 Wash time 17

7.9 Analog output 1 (Residual Chlorine/Ozone) 18

7.10 Date/Time set-up 19

7.11 RS-485 set-up 20

7.12 Averaged signal value set-up 21

CONTENTS

Page 3

7.13 Backlight LCD 22

8. Calibration

Block diagram of Calibration 23

8.1 Security code of calibration 24

8.1.1 Authority of Security Code 24

8.1.2 Security Code Settings 24

8.2 Calibration principle 25

8.3 Current type sensor calibration mode 25

8.4 Voltage type sensor calibration mode 26

8.5 Last calibration data 27

8.6 Attention of sensor usage 28

9. Modbus protocol and instructions for CT-6300RS 29

10. Error messages (Error code) 34

11. Maintenance 35

Page 4

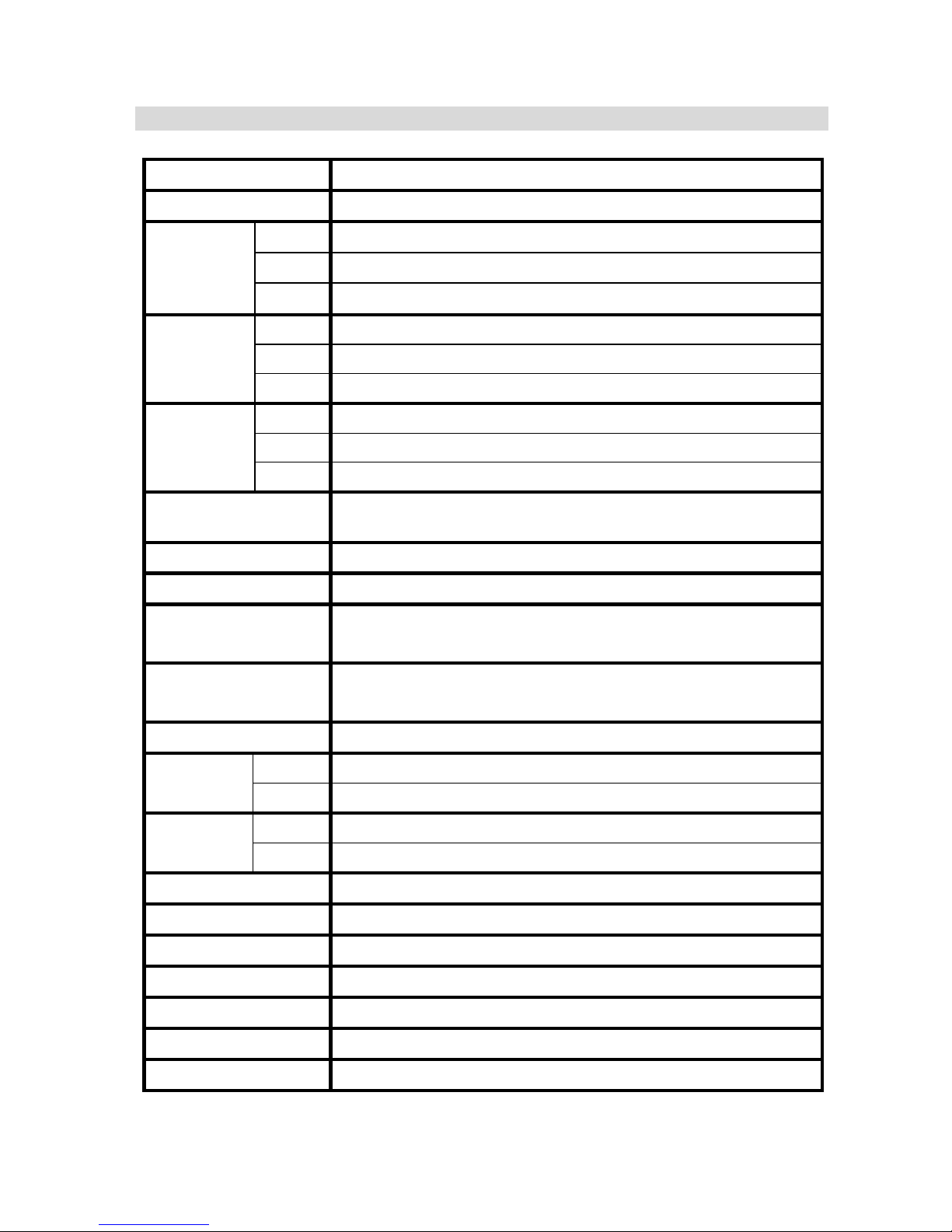

1. Specifications

Model CT-6300RS

Measuring modes Residual(Free) Chlorine / Ozone / Temperature

Cl2 0.00~100.00 ppm(mg/l), depends on sensor

O3 0.00~20.00 ppm(mg/l), depends on sensor

Ranges

TEMP -30.0~130.0°C

Cl2 0.01 ppm(mg/l)

O3 0.01 ppm(mg/l)

Resolutions

TEMP 0.1°C

Cl2 ±0.5%±1Digit

O3 ±0.5%±1Digit

Accuracy

TEMP ±0.2°C±1Digit

Temperature

Compensation

Automatic with PT-1000 / NTC-30K or manual adjustment

Ambient Temp. 0~50°C

Storage Temp. -10~70°C

Display

LCD display with sensitization sensor for

auto/manual illumination function

Analog output

Isolated DC 0/4~20mA corresponding to

residual chlorine/ ozone measurement, max. load 500Ω

Serial Interface RS-485(MODBUS RTU or ASCII)

Contact 240VAC, 0.5A Max. (recommend)

Settings

Activate Hi/Lo two limited programmable

Contact 240VAC, 0.5A Max. (recommend)

Wash

Time ON: 0∼9999 sec. / OFF: 0.0∼999.9 hours

Voltage output DC±8V , 0.5W Max.

Power Supply 100V~240VAC±10%, 5W Max., 50/60Hz

Installation Wall or Pipe or Panel Mounting

Dimensions 144 mm × 144 mm × 115 mm (H×W×D)

Cut off Dimensions 138 mm × 138 mm (H×W)

Weight 0.82Kg

Protection IP 65 (NEMX 4X)

Note: The specifications and appearance of the instrument are subject to change without notice.

1

Page 5

Wrong wiring will lead to breakdown or electrical shock of the instrument, please read this

operation manual clearly before installation.

z Make sure to remove AC power from the transmitter before wiring input, output connections,

and remove it before opening the transmitter housing.

z The installation site of the transmitter should be good in ventilation and avoid direct

sunshine.

z The material of signal cable should be special coaxial cable. Strongly recommend using our

coaxial cable. Do not use normal wires instead.

z Avoid electrical surge when using power. Especially when using three-phase power, use

ground wire correctly.

z The internal relay contact of the instruments is for alarm or control function. Due to

safety, please must connect to external relay which can stand enough ampere to make

sure the safety operation of the instruments. (Please refer to chapter 4.5“Illustration of

electrical connection”)

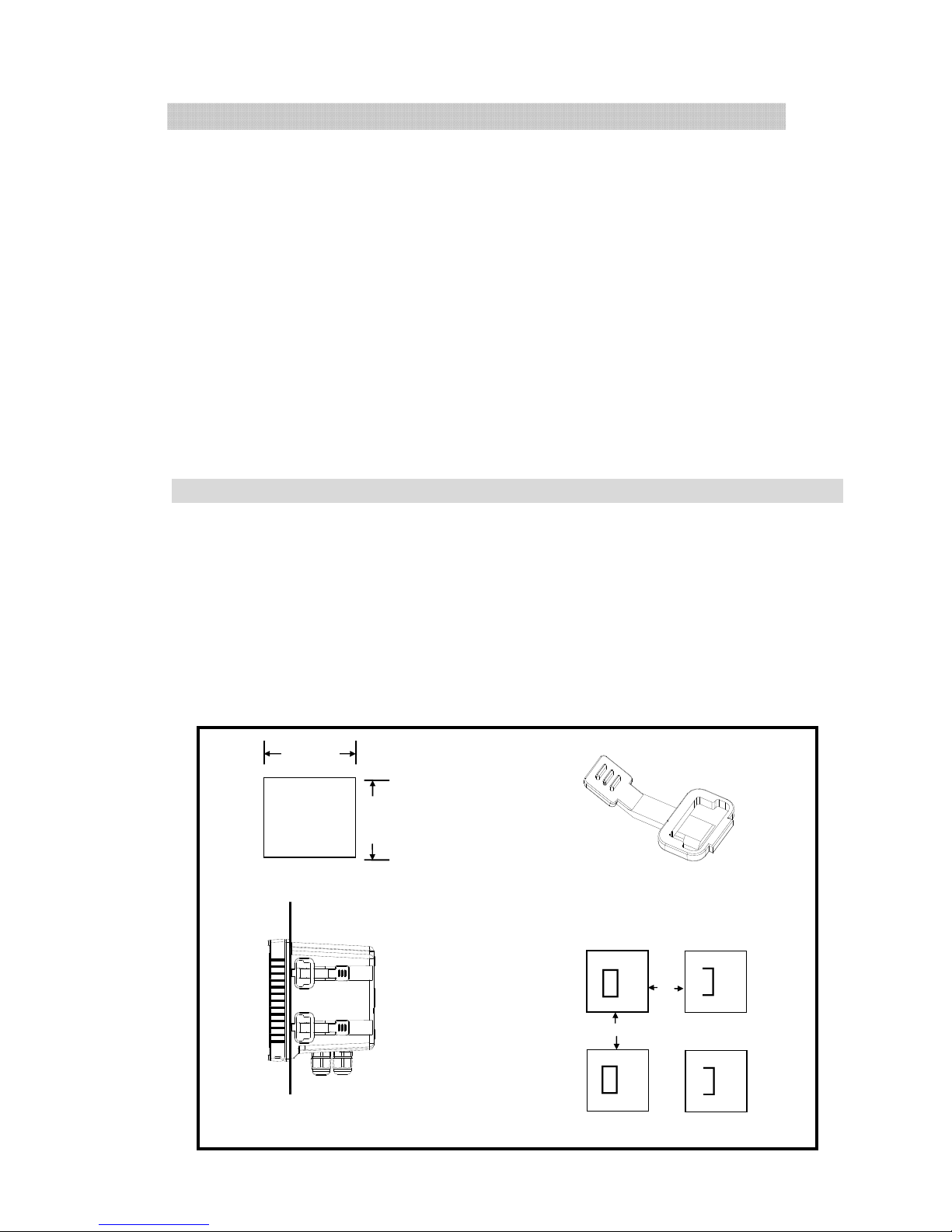

3. Assembly and installation

3.1 T ransmitter installation: This transmitter can be installed through panel mounting,

wall mounting and pipe mounting.

Installation of panel mounting: First, prepare a square hole of 138 x 138mm on the panel box,

and then insert the transmitter directly into the panel box. Insert the accessorial mounting

bracket from the rear, and make it be fixed in to pickup groove.

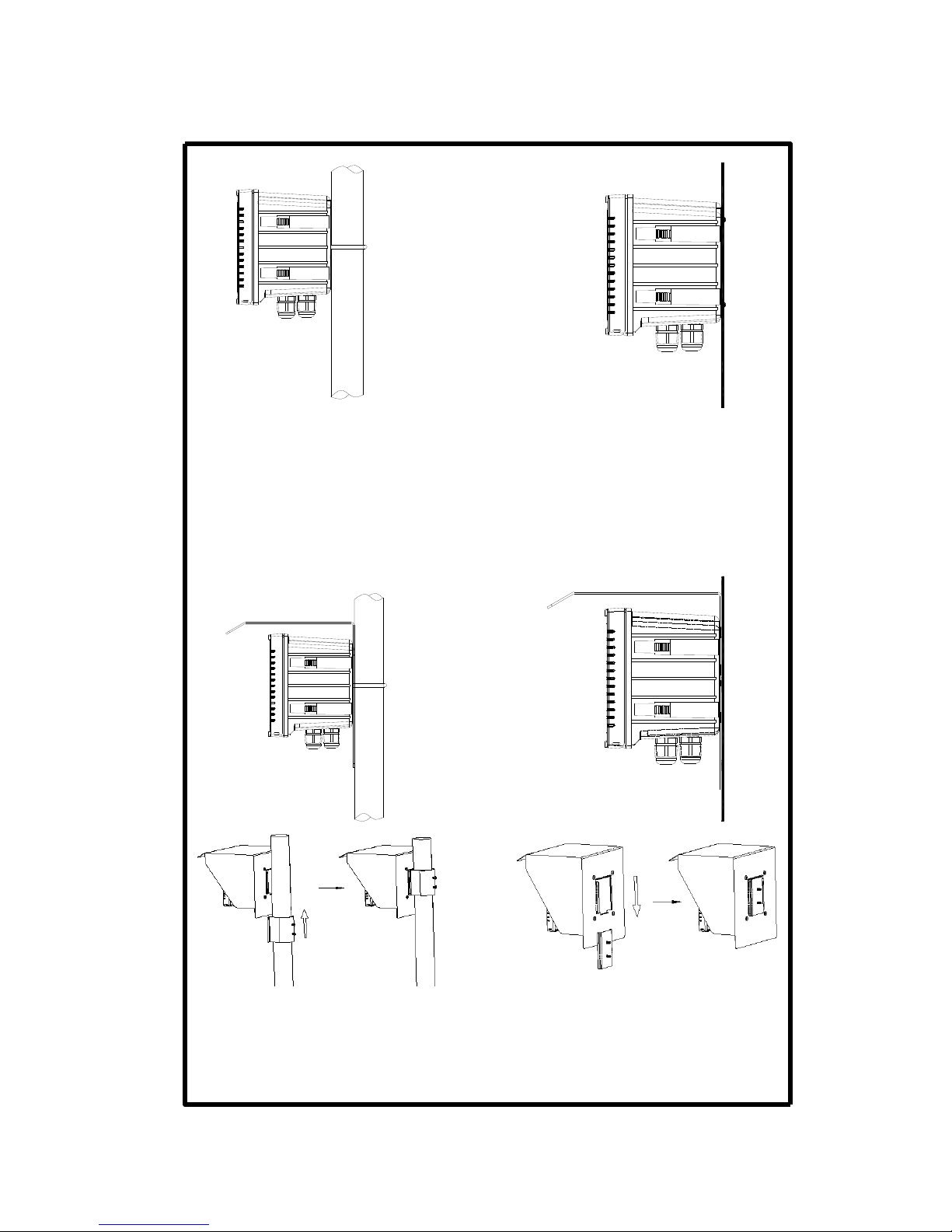

3.2 Illustration of panel mounting:

2. Precautions for installation

138mm

138mm

42mm

+

+

42mm

Hole distances on the panel box

Mounting bracket

Illustration of panel mounting,

fixed with Mounting bracket

+

+

2

Page 6

3.3 Illustration of Wall mounting and pipe mounting

Installation of pipe mounting

Fixed with U-shaped pipe clip

Order No.: 8-34

Installation of wall mounting

Fixed with 4 x M5 screws

Sun Shield (Pipe mounting)

Order No.: 8-35 and 8-35-1

Sun Shield (Wall mounting)

Order No.: 8-35 and 8-35-2

3

Page 7

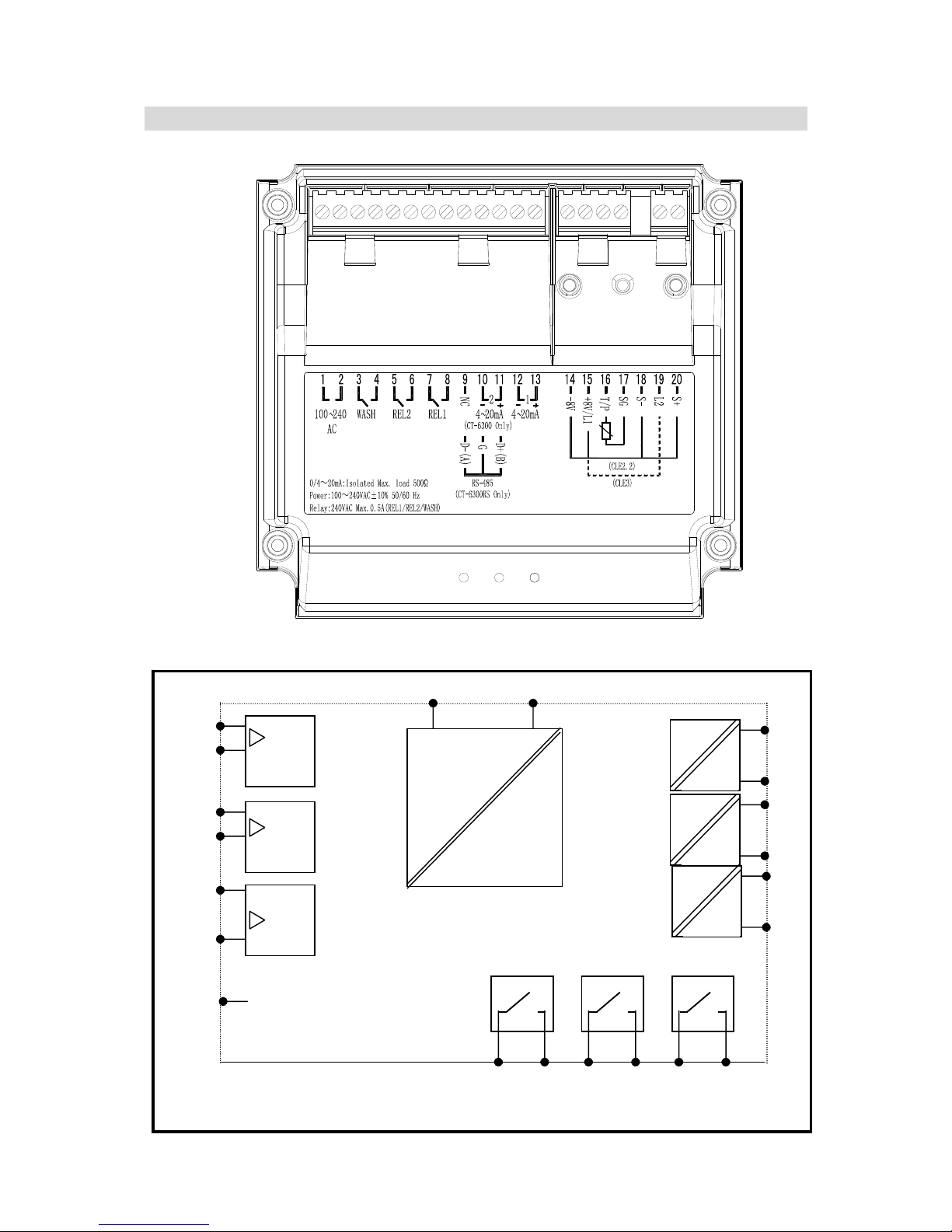

4. Overview of residual chlorine/ozone transmitter CT-6300RS

4.1 Illustration of rear panel

4.2 Illustration of terminal function

+

-

S+

S-

GND

TP

T

HI LO

WASH

POWER

AC

INPUT POWER

+

-

±8V

+

-

GND

Chlorine/O³

4 wire electrode (voltage type)

Chlorine/O³

2 wire electrode (current type)

L1

L2

4

Page 8

4.3 Description of terminal function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

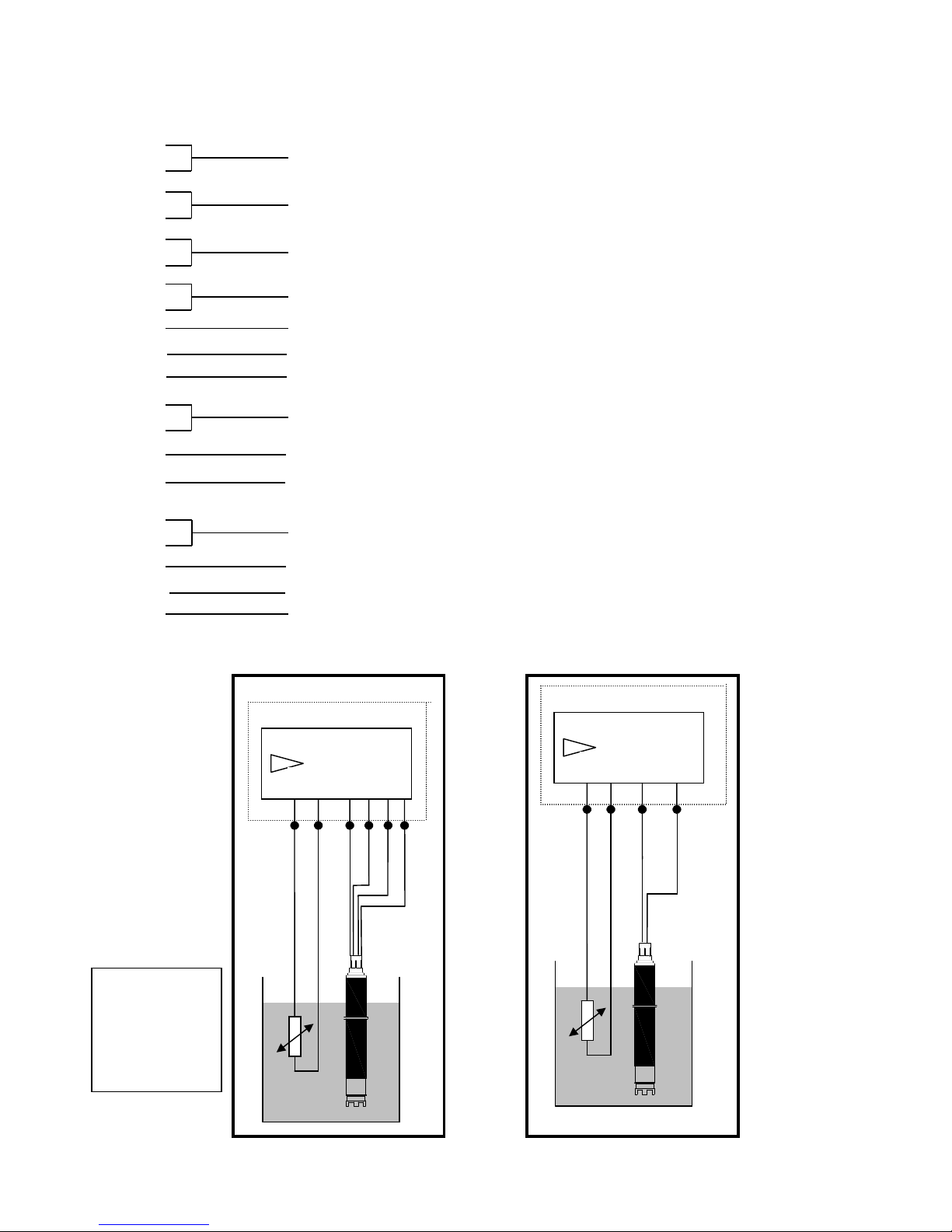

4.4 Illustration of cable wiring

Chlorine / O3

L2

2 wire electrode

(

current type

)

PT1000

N

TC30

K

T/P SG L1

1

2

Chlorine / O3

S+

4 wire electrode

(

voltage type

)

PT1000

N

TC30K

T/P

SG

S-

br

w

g

bl

+8 -8

AC100~240V: Power supply terminal

WASH: External wash relay terminal

REL2: External relay terminal Low Point control

REL1: External relay terminal High Point control

RS-485 output: GND

4~20mA:Master measurement current output terminal, for external

recorder or PLC control

DC-8V:Connect to voltage type electrode (CLE2.2) terminal V-(brown wire)

RS-485 output: D-(A)

T/P: Connect to earth end of temperature probe

DC+8V/ L1:Connect to a voltage type electrode (CLE2.2)terminal V+(green wire),

or connect to a current type electrode(CLE3, or OZE3) terminal 1.

S-: Connect to black signal wire of the voltage type of electrode (CLE2.2)

L2: Connect to terminal 2 of the current type electrode (CLE3, or OZE3)

S+: Connect to white signal wire of the voltage type of electrode (CLE2.2)

g: green wire

br: brown wire

bl: black wire

w: white wire

Wiring of 4 wire electrode

(voltage type)

Wiring of 2 wire electrode (current type),

leverage transmitter’s DC ±8V

14

15

RS-485 output: D+(B)

5

Page 9

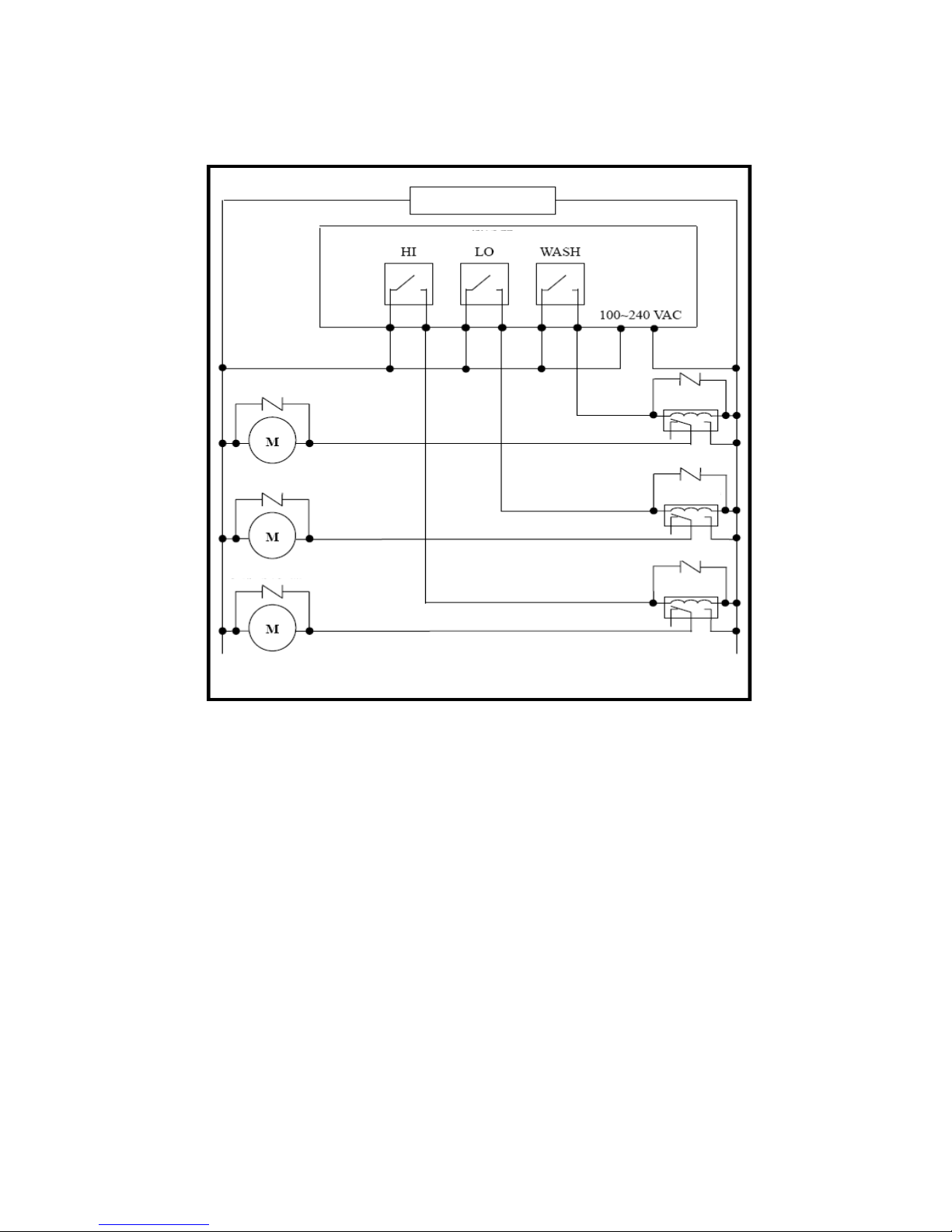

4.5 Illustration of electrical connection:

Surge absorber

Surge absorber

Surge absorber

Surge absorber

Transmitter

Cleaning device

Dose feeder

Dose feeder

100 ~ 240VAC

Surge absorber

Surge absorber

External relay

External relay

External relay

6

Page 10

5. Configuration:

5.1 Illustration of front panel:

5.2 Keypad:

In order to prevent inappropriate operation by others, before the parameter setting and

calibration, the operation applies multi-keys, and coding protection if necessary.

Description of the key functions is in the following:

In the parameter set-up mode, pressing this key allows you exit parameter set-up

mode and back to Measurement mode.

In the Calibration mode, pressing this key allows you exit Calibration mode and

back to Measurement mode.

In the parameter set-up mode and Calibration mode, pressing this key to

increase the value or to scroll to other function.

In the parameter set-up mode and Calibration mode, pressing this key to

decrease the value or to scroll to other function.

: Key for confirmation; pressing this key is essential when modifying data value

or selecting the parameter setting items in the window.

: In the Measurement mode, pressing these two keys simultaneously

allows you enter Calibration mode.

: In the Measurement mode, pressing these two keys simultaneously

allows you enter parameter set-up mode.

+

+

Setup Cal. Mode Enter

7

Page 11

In the Measurement mode, press the two keys simultaneously for

five seconds, and then press until you see a clock signal appearing on the display;

then loose all keys to restore factory default settings.

In the Measurement mode, press the two keys simultaneously for

five seconds, and then press until you see a clock signal appearing on the display;

then loose all keys to restore factory default calibrations.

5.3 LED indicators:

WASH: Washing device operation indicator lamp; when the washing device is started up,

the Alarm indicator will light.

HI : Controlling operation indicator lamp; when the high setting point is reached, the

REL1 indicator will light.

LO : Controlling operation indicator lamp; when the low setting point is started up, the

REL2 indicator will light.

B.L. : Light sensor; in the automatic display backlit mode, the lamp will light or go out

as the change of environmental brightness.

5.4 Display:

(Master Reset)Restore factory default parameter’s settings

+

+

(Calibration Reset)Restore factory default calibration’s settings

Calibration

mode

Controlling

function

locked

Set-up

mode

Measurement

mode

Relay 1

alarm

activated

Relay 2

alarm

ac

t

ivated

Clean device

activated

Output

current

Over ran

g

e

Measurement

uni

t

Recovery

indicator

mA

mA

: Measurement is over-range than the setting which is corresponding to output 20mA

: Measurement is over-range than the setting which is corresponding to output 0/4mA

Auto temp.

co

m

p

ensation

8

Page 12

6. Operation

6.1 Measurement mode:

After all electrical connections are finished and tested, connect the instrument to the

power supply and turn it on. The transmitter will automatically entering measurement

mode with the factory default settings or the last settings from user.

6.2 Set-up mode:

Please refer to the set-up instructions in Chapter 7, and press to back to

measurement mode.

6.3 Calibration mode:

Please refer to the calibration instruction in chapter 8, and press to back to

measurement mode.

6.4 Reset:

Factory default value:

Measurement mode: CLE2, 20.00 ppm

Temperature compensation: MTC

Auto return: AUTO

Relay 1(High point alarm):AUTO,SP1= 10.00 ppm,db1= 0.10 ppm

Relay 2(Low point alarm):AUTO,SP2= 1.00 ppm,db2= 0.10 ppm

Wash time: OFF(ON.S=0S,OFF.H=O.OH,DB.S=10S)

Analog output4~20 mA,0.0~20.00 ppm

Date & Time: 2010/1/1, 00:00:00

RS-485: RTU,Even,19200,ID:01

Code: OFF

9

Page 13

7. Settings

Block diagram of settings 1:

Parameter

Setting

Conf.

Setting)

Code

Setting

℃

Setting

(Temp.)

Relay 1

Setting

Cln

(Clean)

Setting

Cl/O3

Setting

(Analog)

Default

(密碼設定)

OFF

CodeONCode

Pass

code

change

Select

CL

(Chlorine)

OFF

(MTC

)

Input

Temp.

Temp.

Correct

(±5℃)

Imput

REL1

SP

Input

REL1

DB

REL1

Active or

Inactive

Relay1

Test

Cln

Off-time

Input

Cln

DB

Input

Cln

Test

Cln

On-time

Input

b.L.

Setting

(Backlight)

Pass code

Input

Active

Pass code

:Right forward key

:Up forward key

:ENTER key

Select

CLE2

Select

CLE3

PTC

REL1ONREL1

OFF

Relay2

Setting

Input

REL2

SP

Input

REL2

DB

REL2

Active or

Inactive

Relay2

Test

REL2ONREL2

OFF

Select

O3

(Ozone)

Select

O3E3

Std.b

(Auto

return)

OnAuto

Select

O3E2

ppm

or

mg/l

ppm

or

mg/l

ppm

or

mg/l

ppm

or

mg/l

Cln

Active or

Inactive

Cln ONCln

OFF

Range

2.00

Range

100.0

Range

20.00

Temo.

Correct

(±5℃)

NTC

Continued on next page Continued on next page

10

Page 14

Cl/O3

Setting

(An alog)

SEC

Settin g

(D ig ital

filter)

Re la tiv e

valu e to

20mA

0/4 and

20mA

Output Test

0/2 0mA o r

4/20mA

Output

Signal

average

: Right fo r ward k e y

: U p fo rw ard ke y

:EN TER key

Re la tiv e

valu e to

0 or 4mA

b.L.

Setting

(Backlight)

Select

Auto

mode

Select

ON

mode

OFF

Bright

-ness

setting

Bright

-ness

setting

Sensi-

tivity

setting

RTC

Settin g

(Tim e)

SERL

Set

(RS-485)

Input year

Select

comm unica

-tion mode

Input date

Select Odd

or Even

parity

Input time

Select

Baud rate

Set

ID

Cln

Settin g

(Clean)

Code

Setting

Connected with previous page Connected with previous page

Block diagram of settings 2:

11

Page 15

7.1 Entry of set-up mode

In the measurement mode, pressing the two keys simultaneously allows

you enter the parameter set-up mode. You can back to the measurement mode at any

time by pressing the key . The original code is 1111.

7.2 Security code of settings

In the set-up mode, you can set up the code by pressing the key , and confirm by

pressing the key .

+

Enter parameter selection set-up

Press for confirmation

Press for confirmation

Press or

Press for confirmation

When the first “0” of the digits 0000

sparkles, press upward key or rightward

key to input the code, and press ENTER

for confirmation. Then, continue

inputting the second digit, and by

analogy.

(If security code is

cancelled, you can enter

the set-up mode directly

without inputting the

password any more. You

can reset the security code

by pressing “Mode” key

by double pressing.)

Modify the code =>

If you input the wrong

code, the CODE will

sparkle 4 times, and

then the display will

back for another input.

12

Page 16

7.3 Measurement parameter set-up

Please select” CL” for residual chlorine measurement. Then, please select “CLE2” for

4-wire (voltage type) electrode; select “CLE3” for 2-wire(current type) electrode. Then,

according to sensor model, select measuring limit “2.00ppm, “20.00ppm”, or “100.0ppm.”

Please select” O3 ” for ozone measurement. Then, please select “O3E2” for 4-wire

(voltage type) electrode; or select “O3E3” for 2-wire(current type) electrode.

to select O3orCL

Enter “temperature” set-up

When select CLE3

When select O3E3, O3E2, CLE2

Press for confirmation

Press for confirmation

Press or

Press for confirmation

Press for confirmation

Press for confirmation

to select mg/l or ppm

Press or

to select 2.00, 20.00, or 100.0ppm

Press or

13

Page 17

7.4 Temperature parameter

7.5 Auto return set-up

Enter setup of auto return mode (Return) to set the function that the instrument

automatically exit the setup menu after a period of time without pressing any key.

Enter “Auto return” set-up

Enter “High point alarm” set-up

If select auto, the display

automatically exit the setting or

calibration mode and back to

measurement mode after a period

of time without pressing any key.

Same as left procedure

Use standard thermometer to test

the actual temperature of the

solution, and press or

to input the correct temperature

value.

If necessary, compare with the

actual temperature value tested by

standard thermometer. Press

or to input the modified

value.

Press for confirmation

press

or

for selection

press

or

for

selection

Press for confirmation

Press for confirmation

to select

Press or

If select on, it needs to exit

setting or calibration mode

manually

Press for confirmation

14

Page 18

7.6 Hi point

Set the TH (THRESHOLD) and DB (DEADBAND) of Hi (REL1). The range for TH is

0.00~20.00ppm(mg/l); while the range for DB is 0.00~3.00ppm(mg/l).

Enter “Low point alarm” set-up

Press or to

decide to activate REL1

or not.

Press or

to make REL1

terminal or lamp test

Choose “on”,

lamp “HI” will be

lighted up on for a

while

Press or to set an

appropriate hysteresis value

Press for confirmation

Press for confirmation

Press for confirmation

Press for confirmation

Press for

confirmation

Press for confirmation

Press or to set the

required alarm point

15

Page 19

7.7 Lo point

Set the TH (THRESHOLD) and DB (DEADBAND) of Lo (REL2). The range for TH is

0.00~20.00ppm(mg/l); while the range for DB is 0.00~3.00ppm(mg/l).

Enter “Auto clean time” set-up

Press or to

decide to activate REL2

or not.

Press or

to make REL2

terminal or lamp test

Choose “on”,

lamp “Lo” will be

lighted up on for a

while

Press or to set an

appropriate hysteresis value

Press for confirmation

Press for confirmation

Press for

confirmation

Press for confirmation

Press or to set the

required alarm point

Press for confirmation

Press for confirmation

16

Page 20

Press or

to make RELAY tes

t

Press or to set the current output

and relay hysteresis value ( unit: second)

7.8 Wash time

Set the automatic starting time and turn-off time of the washing function. If any value

is set to be 0, the instrument will automatically stop this function.

Enter “Analog output 1 (Chlorine /O3 )” set-up

Press or to set the turnoff

time of the washing function (unit: hour)

Choose “on”, lamp “WASH” will

be lighted up for a while

Press or to set the starting

of the washing function (unit: second)

Press for confirmation

Press for confirmation

Press for confirmation

Press for confirmation

Press for confirmation

Press or to

activate the auto clean

function or not

17

Page 21

7.9 Analog output 1(Chlorine /O3 )

The user can adjust the relative relationship between the Chlorine /O3 measurement

range and the output current according to actual situation, in order to improve the

recognition of current output.

.

Enter “Date/Time” set-up

Press for confirmation

Press or

to make stimulation

test for a current

output of 0, 4 and

20mA

Press or to set the relative upper limit of

measurement value of 20mA

Press or to

select current output

mode 0-20 or 4-20 mA

Press for confirmation

Press for confirmation

Press or to set the

relative lower limit of

measurement value of 0.0mA

Press or

to set the relative

lower limit of

measurement value

of 4.0mA

Press for confirmation

Press for confirmation

18

Page 22

7.10 Date/time set-up

Enter setup of Date/Time(real time clock). Set the “Year”, “Month”, “Date”, “Hour”,

and “Minute” time. The transmitter may keep the clock in operation even when

encountering power failure. Only when the inner battery is out of power, the clock

may stop operation. Then, please replace the 3V CR2025 Li battery inside the

transmitter.

Enter “RS-485” Set-up

Press for confirmation

Press for confirmation

Press or to set the year

Press for confirmation

Press to set month and day.

Press key for moving to next digit’s setting.

Press for confirmation

Use to set the time.

The key is for digital displacement.

19

Page 23

7.11 RS-485 set-up

Uses may according to your need to freely set the ID and transmissioin speed of

the serial output.

Enter “Average signal value” Set-up

Press to confirm it

Press to confirm it

Press to confirm it

Press to confirm it

Press to confirm it

Press or to

set the ID of this instrument

Press or to

set the transmission speed

(Even parity)

(None parity)

(Odd parity)

Press or to

select parity

or no parity

Press or to

select parity

or no parity

Press or to

select RTU or ASCII

transmission mode

20

Page 24

7.12 Average signal value set-up

You may set which number of measurement value to make an averaged value to increase

the stability of display value.

Enter “Backlight display” set-up

Press or to set the number of

measuring value for an averaged value

Press for confirmation

Press for confirmation

Press for confirmation

21

Page 25

7.13 Backlight settings

Use or to

select -2, -1, 0, 1, 2 five

backlit brightness levels

Back to security code of setting mode

Use or to

select -2, -1, 0, 1, 2 five

backlit brightness levels

Use or to select -2,

-1,0,1,2 five levels of sensitivity

of linear optical sensor

Press for confirmation

Press for confirmation

Press for confirmation

Press for confirmation

Press for confirmation

Press for confirmation

Press for confirmation

Use or to select automatic, manual or off.

22

Page 26

8. Calibration

Calibration

mode

Code

Set

SLP

Redy

Pass code

input

OFF

CodeONCode

Pass

code

change

OS

Redy

SLP

setting

Pass code

input

Active

pass code

OS

setting

:toward right key

:toward up key

:enter key

Block diagram of calibration

23

Page 27

8.1 Security code of calibration

8.1.1 Code authorization: There is a two level password protection design. The

authorization of settings password is prior to the authorization of calibration password.

Therefore, you can unlock the calibration code with your “settings password” (security

code of settings), or directly input with your calibration password (security code of

calibration).

8.1.2 Code set: In the measurement mode, press simultaneously to

access calibration mode. The default security code of calibration is “1100”.

Back to Calibration Mode

+

Modify your own

code by

Press for confirmation

Press for confirmation

When the first “0” of the digits 0000

sparkles, press upward key or

rightward key to input the code, and

press ENTER for confirmation.

Then, continue inputting the second

digit, and by analogy.

(If security code is

cancelled, you can enter

the set-up mode directly

without inputting the

password any longer.

You can re-enter into the

calibration code setting

display by pressing

“Mode” key twice)

If you input the

wrong code, the

CODE will sparkle

4 times and then

the display will

back for another

input.

Press for confirmation

Press for confirmation

24

Page 28

8.2 Calibration principle: You may decide if you need to make a zero-point(offset: “oS” in

the display) calibration. If not, you may directly make a slope calibration (“SLP “in the

display.

OZONE (O3) Residual chlorine(Cl))

Zero-point

calibration

1. Not necessary (zero point accuracy of

the sensor< ±0.05ppm)

2. If in need, use distilled water or pure

water which contains no ozone to

clean it, and then drain out the water,

make zero point calibration with the

sensor in air.

1. Not necessary (zero point accuracy of

the sensor< ±0.05ppm)

2. If in need, use distilled water or pure

water which contains no chlorine to

clean it, and then drain out the water,

make zero point calibration with the

sensor in air.

Slope

calibration

Use spectrophotometer with ozone

reagent to make a measurement value

bench mark, and compare it with the

online measurement.

Use residual chlorine reagent (DPD-1)

to make a measurement value bench

mark, and compare it with the online

measurement.

8.3 Current type sensor calibration mode (ex: Ozone sensor)

1. Press to enter into calibration mode. According to 同時按

鍵,即可進入校正程式,利用按 或 鍵可視需要

選擇零點 “OFFSET 校正(顯示 oS)"後按 鍵進行步驟 3 或選擇斜率“Slope

校正(顯示 SLP)" 後按 鍵進行步驟 4。

2. 在校正時可隨時按 鍵離開校正程式,回到測量狀態。

3. 按 或 鍵輸入使顯示值與水樣臭氧值相同

(如右圖1.00ppm),接著

按 鍵,斜率校正

完畢,並

自動跳出校正程式,回

到測量狀態。

2. Press at any time under calibration mode to go back to

measurement mode.

1. Press to enter into calibration mode. According to

your need, press or to select zero-point (offset)

(displayed as “ oS ”), press to proceed step 3, or select

“slope calibration”(displayed as “SLP”), and then press to

proceed step 4.

+

3. When selecting zero-point (offset) calibration, please make

zero-point calibration in air after cleaning the sensor with

distilled or pure water which do not contain with chlorine. Wait

for display value becoming stable, press or to

adjust the value until it becomes 0.00. Then, press .

After zero-point calibration, the procedure will automatically

lead to slope calibration (displayed as “SLP”). If you do not

need to make a slope calibration, press to leave the

calibration mode and back to measurement mode.

4. When selecting slope calibration, put sensor into flow-through

chamber, and make the sample go into the chamber at least 15

minutes until the display value becomes stable. Leverage

spectrophotometer measurement as a bench mark value to

compare and adjust with the online value.

25

Page 29

8.4 Voltage type sensor calibration mode (ex: residual

chlorine sensor)

5. Press or to make the display value as same as the

bench mark value (ex: right illustration: 1.00ppm). Then, press

to finish the slope calibration and automatically leave

calibration mode and return to the measurement mode.

2. Press at any time under calibration mode to go back to

measurement mode.

1. Press to enter into calibration mode. According to

your need, press or to select zero-point (offset)

(displayed as “ oS ”), press to proceed step 3, or select

“slope calibration”(displayed as “SLP”), and then press to

proceed step 4.

+

3. When selecting zero-point (offset) calibration, please make

zero-point calibration in air after cleaning the sensor with

distilled or pure water which do not contain with chlorine. Wait

for display value becoming stable, press or to

adjust the value until it becomes 0.00. Then, press .

After zero-point calibration, the procedure will automatically

lead to slope calibration (displayed as “SLP”). If you do not

need to make a slope calibration, press to leave the

calibration mode and back to measurement mode.

4. When selecting slope calibration, put sensor into flow-through

chamber, and make the sample go into the chamber at least 15

minutes until the display value becomes stable. Use residual

chlorine reagent (DPD-1) to make a measurement value bench

mark, and compare with the online measurement.

26

Page 30

8.5 Last Calibration Data

Back to“Calibration code"set-up

Press , if show

none, it represents no

calibration data.

Press to show year

of calibration data

Press to show date

of calibration data

Press to show time

of calibration data

Press to show

temperature record of

calibration data

Press to show OS(zero-point) value of

calibration data. If there was only SLOPE

calibration, there is no OS data.

Press to show SLP(SLOPE) value of

calibration data. If there was only OS

calibration, there is no SLP data.

Press to confirm it.

27

Page 31

8.6 Attention of sensor usage

1. The transmitter is suitable both for 4-wire (voltage type) sensor and 2-wire

(current type) sensor. (Note: “C” means residual chlorine sensor, “O”

represents ozone sensor.)

2. Ambient temperature: -5~50˚C (Auto temperature compensation, maximum

temperature changes: less than 0.3˚C/mins.)

3. Maximum pressure— 1bar.

4. Applied flow: less than 30 L/hr. If the flow is under 15% of recommended

speed, the measurement reaction can speed twice up.

5. Initialization time: the initialization time is about 1~3 hours. Reserved and

re-initialization for measurement needs about 0.5~2 hours. After changing

membrane or electrolyte, it needs about 0.5 hour for re-initialization. After

clean electrode, it needs about 1~3 hours for re-initialization. Immerse the

sensor into a stirred sample solution at least 15 minutes before each

measurement.

6. Ambient pH: the sample solution must be controlled within pH 5.5 ~

8.0(especially for residual chlorine sensor) , and it must be under a stable

pH condition.

7. Calibration cycle: the sensor is not necessary for zero-point calibration. Use

DPD-1 residual chlorine agent for slope calibration. If you need high accuracy

measurement, it is recommended for making slope calibration method

everyday.

8. Life of membrane: about one year, depends on sample solution.

9. Life of electrolyte: about 6~8 weeks, depends on sample solution.

10. Material-membrane cover: transparent PVC, electrode body: black PVC

Attention: The front white part of the sensor is membrane. Do not tear down

the membrane, or it may not measure any more.

28

Page 32

9. MODBUS protocol and instructions for CT-6300RS

9.1 Communication connection

The RS-485 communication port of the transmitter features with electronic

isolation protection, lightning protection, and to provide internal independent ground

solution. It is allowed to use normal twisted-pair (segregation double-stranded twisted

pair cable) cable connections. All devices are in contact with a double-stranded, and

then all together, and another line will be connected with all the negative contacts, and

the isolated shield wire must be connected to GND. When we talk about

communication in the laboratory, the stand-alone master-slave communication is

relatively simple. Hence, it is allowed to consider using the normal cable instead.

However, there should be strictly in accordance with the requirements of industrial

engineering construction. Wiring diagram is as follows:

Note:

1. The RS-485 interface of CT-6300RS transmitter has a protective earth terminal.

When communicate with the RS-485, there should use with solution ground to

eliminate risk of safety.

2. It is allowed to use a 120 ohm impedance matching resistors at terminal

equipment in the transmission lines (D +, D-) ends across to effectively reduce or

eliminate signal reflection.

3. Without repeaters, the RS-485 network can not exceed a maximum of 32 nodes.

The maximum communication transmission distance of RS-485 is up to 1200

meters.

4. When communication, all the equipments of the network should be maintained in

the same transfer mode, baud rate, parity consistent. And each of the device

address can not be the same, so as not to conflict resulted in the normal network

communications.

5. The Modbus command of the transmitter can only access 50 registers. If it

exceeds the length, then it returns abnormal message.

D+

GND Master

D-

R

CT-6300RS

ID: 01

CT-6300RS

ID: 02

Other

Modbus

equipment

.....

29

Page 33

9.2 MODBUS name and address table

Function Code:03H, 06, 10H Modbus response (setup parameter)

Logic

address

Item

Number

of Byte

Informati

on type

Description of

data transmission

Default value Note

0001H Equipment’s ID 2 USHORT 1-247 1

0002H

Transmitter

model

6 USHORT ASCII Code CT-6300RS

0: RTU

0005H

Communication

protocol

2 USHORT

1: ASCII

0

0: 2400

1: 4800

2: 9600

0006H

Serial

transmission

speed (Baud rate)

2 USHORT

3: 19200

3

0: None

1: Even

0007H Parity 2 USHORT

2: Odd

1

0008H USHORT Second

0009H USHORT Minute

000AH USHORT Hour

000BH USHORT Day

000CH USHORT Month

000DH

Real-time clock* 12

USHORT Year

2011-01-01,

00:00:00

000EH Code setting* 2 USHORT Code setting 1111

0: MTC

1: PTC

000FH

Temperature

mode*

2 USHORT

2: NTC

0

USHORT 0: OFF

0010H 2

USHORT 1: AUTO

0

0011H 2 USHORT ON.S: 0-9999 0 Second

0012H 4 USHORT OFF.H: 0-999.9 0 Hour

0014H

WASH relay*

2 USHORT DB.S: 0-9999 0 Second

0: OFF

0015H 2 USHORT

1: AUTO

1

0017H 4 FLOAT SP1 10.00ppm

0019H

Relay 1 *

4 FLOAT DB1 0.10ppm

Data

affected by

sign byte

30

Page 34

0: OFF

001BH 2 USHORT

1: AUTO

1

001DH 4 FLOAT SP2 1.00ppm

001FH

Relay 2 *

4 FLOAT DB2 0.10ppm

Data

affected by

sign byte

0: AUTO

1: ON

0021H 2 USHORT

2: OFF

2

SHORT 2: Highest bright

SHORT 1: high bright

SHORT 0: Standard

SHORT -1: Low bright

0022H

Backlight

Brightness *

2

SHORT -2: Lowest bright

0

SHORT

2: Highest

Sensitivity

SHORT

1: High

Sensitivity

SHORT 0: Standard

SHORT

-1: Low

Sensitivity

0023H

Backlight

Sensitivity*

2

SHORT

-2: Lowest

Sensitivity

0

0024H

Sample average

of measurements

(Digital Filter) *

2 USHORT 1-60 5

0025H-

0030H

Factory reserved

Note : The actions without * sign only support for function code 03H. The actions with * sign support

function code 03H, 06H, 10H. USHORT data range from 0 to 65535, SHORT data range from

-32768 to 32767. FLOAT is a 4 data bits IEEE 754 format float. The data range follows is the same.

31

Page 35

Function code: 03H Modbus response (measurement parameter)

Logic

address

Item

Number

of Byte

Informati

on type

Description of

data transmission

Default value Note

0031H

Number of

measurement

channels

2 USHORT

CT-6300RS only

has one channel

1

pH

ORP(mV)

uS/cm

mS/cm

MΩ-cm

ppt

ppm

mg/l

%

mA

˚C

NTU

FNU

0032H

Sign byte

6 CHAR

FTU

ASCII

code

0035H

Residual chlorine

/Ozone

measurement

4 FLOAT

Residual chlorine

/Ozone

measurement

Data

affected by

sign byte

0037H

Temperature

measurement

4 FLOAT

Temperature

measurement

0039H-

0050H

Factory reserved

Important: Usage address please refer to 03H Modbus response (measurement parameter)

Function code: 01H Modbus response (dispersion parameter)

Logic

address

Item BIT Description Default value Note

0070H LO Alarm 1 Contact on 0 (Contact off)

0071H Hi Alarm 1 Contact on 0 (Contact off)

0072H mA too high 1

Contact on 0 (Contact off)

0073H mA too low 1

Contact on 0 (Contact off)

0074H Exceed temp. range 1

Contact on 0 (Contact off)

0075H

Exceed Residual

chlorine /Ozone range

1

Contact on 0 (Contact off)

0076H RLY1 Action * 1 Contact on 0 (Contact off)

0077H RLY2 Action* 1 Contact on 0 (Contact off)

0078H WASH Action* 1 Contact on 0 (Contact off)

0079H Measurement status 1 Contact on 1 (Contact on)

0: Hold

1: Measurement

007AH-0

090H

Factory reserved

32

Page 36

9.3 Modbus example description(ex: function code 03H)

The following description takes the temperature reading(0037H) as an example. Set the

temperature at the transmitter at MTC 25.1oC, and confirm that host and sub-machine

communication format settings are correct. The host according to the following left table

to send commands, and then to get the response from sub-machine according to

following right table. This example shows the message transmission function code 03H

data format. If under other function code, the logic mode is the same.

ASCII Mode:

Request Response

Message Framing Hex Message Framing Hex

ID, Address 01 ID, Address 01

Function code 03 Function code 03

Starting Address Hi 00 Byte Count 04

Starting Address Lo 37 Register value Hi CC

No. of Registers Hi 00 Register value Lo CD

No. of Registers Lo 02 Register value Hi 41

LRC C3 Register value Lo C8

LRC 56

RTU Mode:

Request Response

Message Framing Hex Message Framing Hex

ID, Address 01 ID, Address 01

Function code 03 Function code 03

Starting Address Hi 00 Byte Count 04

Starting Address Lo 37 Register value Hi CC

No. of Registers Hi 00 Register value Lo CD

No. of Registers Lo 02 Register value Hi 41

CRC Check Lo 75 Register value Lo C8

CRC Check Hi C5 CRC Check Lo 65

CRC Check Hi 5A

Note: FLOAT is a 32-bit IEEE 754 format. The above table, for an example, is divided

into two 16-bit register data transmission. The back 16-bit register(CC CD) will be

transferred first, and then the first 16-bit register (41 C8) will be transferred later.

Every 16-bit format is high-bit in the front and low-bit in the post. For example, the

temperature now is 25.1oC. The 16-bit of FLOAT data(Hexadecimal) will show

41 C8 CC CD. The transmission order is CC CD 41 C8.

33

Page 37

10. Error messages (Error code)

Messages Reason Dispositions

Serious error that

does not permit any

further measuring

Please call service

engineer.

SLOPE value

exceeds the upper or

lower limit

Maintain the

electrode or change a

new electrode, and

make another

calibration.

OFFSET(zero-point

electric potential)

value exceeds the

upper or lower limit

Maintain the

electrode or replace

the electrode, and

make another

calibration.

34

Page 38

11. Maintenance

Generally speaking, under normal operation, the controller produced by our

company need no maintenance except regular cleaning and calibration of the

electrode to ensure accurate and stable measurement and system operation. When

the sensor cannot be calibrated or has too much error, please follow the instruction

below to maintain the sensor .

1. Please pull out the sensor from the flow-through chamber. Clean the sensor’s

membrane with tap water (low flow) to remove the contamination above the

sensor head.

2. Lightly rotate and remove the sensor’s membrane cover. Check whether the

upper and lower filter membranes of the sensor are broken or not. If yes, please

replace with a new membrane kit. If not, remove the coating material (ex: rust)

by immersing the sensor membrane into 5% HCL (for over a night).

3. Clean negative (silver) pole and positive (golden) pole:

Gently clean the negative pole and positive pole with clean water. If you

still find some contamination, take action by following instruction.

(1)Negative (silver) pole: You can gently rub the negative(silver) pole with

fingers. Do not use other tool to clean to prevent scraping.

(2)Positive (golden) pole: You can gently rub the positive (golden) pole with

fingers. However, if there is water stain on the golden pole, or if the

oxidation is difficult to clean, you may use micro-particle sandpaper to

gently rub the surface of positive (golden) pole.

4. After cleaning it, please make dry it by sun-shine, drain out the water inside by

fill in electrolyte.

5. Fill in the electrolyte into membrane cap until it is 80% full( do not contain any

bubble). Then, gently tight the cap up to the sensor. After tight up, reverse the

sensor to see if there is any bubble in side the membrane cap. (If yes, please

open the cap, and re-fill in the electrolyte. After the clean procedure, please

follow this operation manual to finish installation and calibration procedures.

35

Page 39

Page 40

SUNTEX INSTRUMENTS CO., LTD.

13F, No. 31, Lane 169, Kangning St.,

Xizhi Dist., New Taipei City, Taiwan (R. O.C.)

Tel: 886-2-2695-9688

Fax: 886-2-2695-9693

e-mail: suntex@ms1.hinet.net

www.suntex.com.tw/en

5040C CT-6300RS/Technical data subject to alternations/ Quality Systems ISO 9001/201206

Loading...

Loading...