FA-HC30144

FL10, 13, 15 HOVERCOVER

ASSEMBLY , INSTALLATION & USE MANUAL

© SUNSTREAM CORPORATION 2010—ALL RIGHTS RESERVED

PART NO. 690178 REV: C

READ CAREFULLY

KEEP THESE INSTRUCTIONS

Table of Contents

Disclaimer of Liability

Parts List

Assembly

Height Adjustment

Safety Instructions/Maintenance

Warranty

3

4-5

6-19

20

21

22

Tools Recommended

Socket Wrench, 9/16” & 1/2” sockets

9/16” Wrench

1/2” Wrench

Drill

5/16” & 3/8’ Drill bits

3/8” Nut Driver

Screwdriver

Anti-seize

PART NO. 690178 REV: C 2

Disclaimer of Liability

These assembly and installation instructions have been provided by Sunstream Corporation at the

request of the potential installer and/or assembler. If you are not an authorized Sunstream Dealer

and are not a reasonably skilled mechanic, please contact Sunstream so that we can refer you to a

local dealer who can skillfully and safely perform the assembly and installation of your Sunstream

boat lift.

It is the potential installer and/or assembler’s responsibility to determine whether he or she has the

necessary skills, knowledge, and tools to properly and safely assemble and/or install the Sunstream

Lift described herein. Improper assembly and/or installation may cause the lift to function improperly or not to function. Improper assembly and/or installation may additionally cause a risk to

personal safety or property. If the assembler and/or installer is confused or has questions or concerns about a particular assembly or installation, he or she should contact Sunstream by telephone

at (253)-395-0500, Int’l (001)-(253)-395-0500 before proceeding further. The information contained in these instructions does not constitute a warranty or guarantee of any kind.

An assembler’s and/or installer’s failure to correctly follow these assembly and installation instructions constitutes a waiver of the assembler and/or installer’s rights against Sunstream regarding any subsequent damages to property or personal injury caused by the assembler’s and/or installer’s improper assembly and/or installation.

PART NO. 690178 REV: C 3

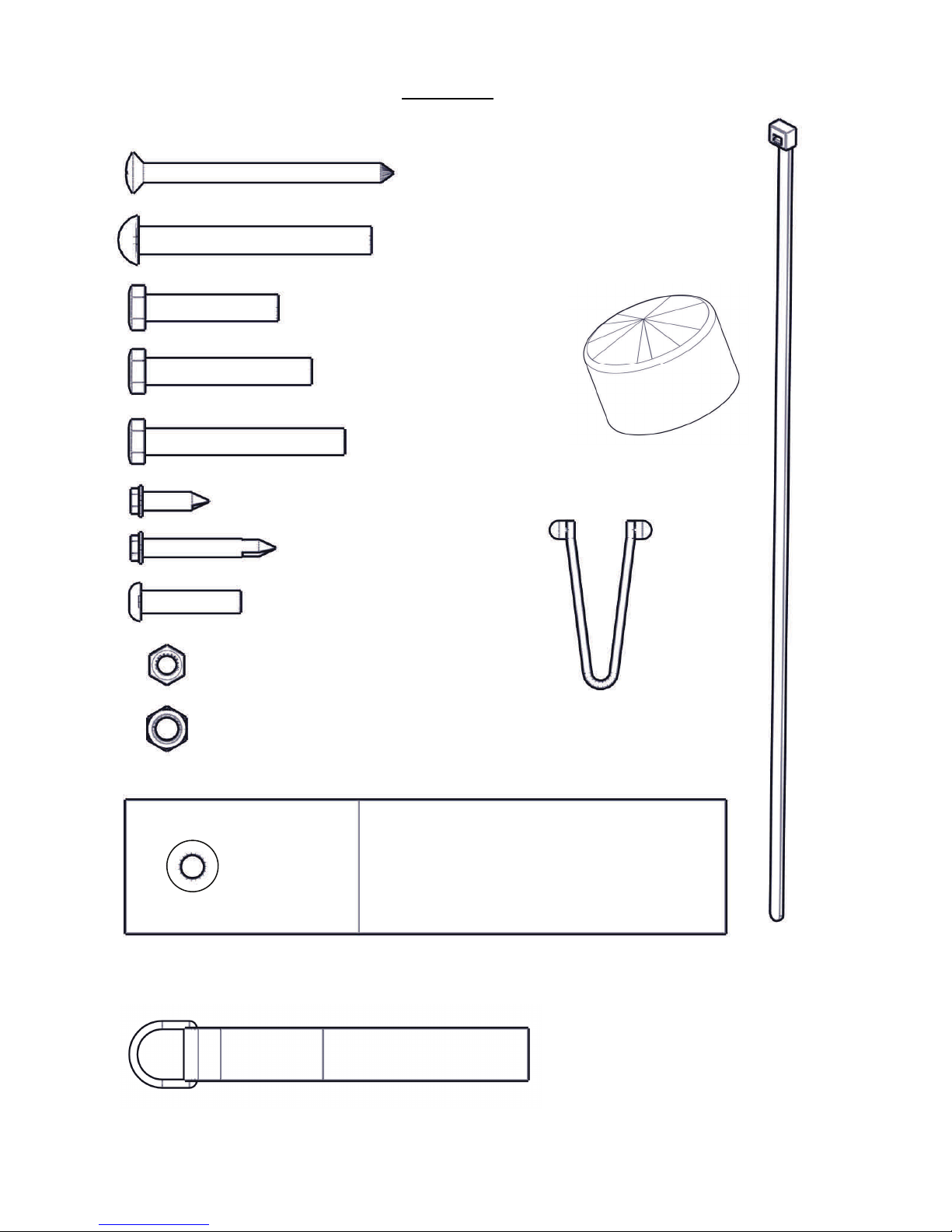

Parts List

16

34

4

4

16

25

8

12

SELF THREADING SCREW #14 X 4.00”

MACHINE SCREW 5/16” X 3.50”

11-051401-90

BOLT, 3/8” X 2.00”

11-060801-32

BOLT, 3/8” X 2.50”

11-061001-92

BOLT, 3/8” X 3.00”

11-061200-16

SELF DRILLING SCREW #14 X 1.00”

11-000401-93

SELF DRILLING SCREW #14 X 2.00”

11-000001-81

BOLT, 5/16” X 1.50”

11-050600-38

11-041602-40

4

CAP

690501

17

WIRE TIE

690255

55

28

10

16

NYLOCK, 5/16”

12-050000-62

NYLOCK, 3/8”

12-060000-22

VELCRO STRAP

69-000001-00

D-RING VELCRO STRAP

690493

6

SNAP BUTTON

15-000001-83

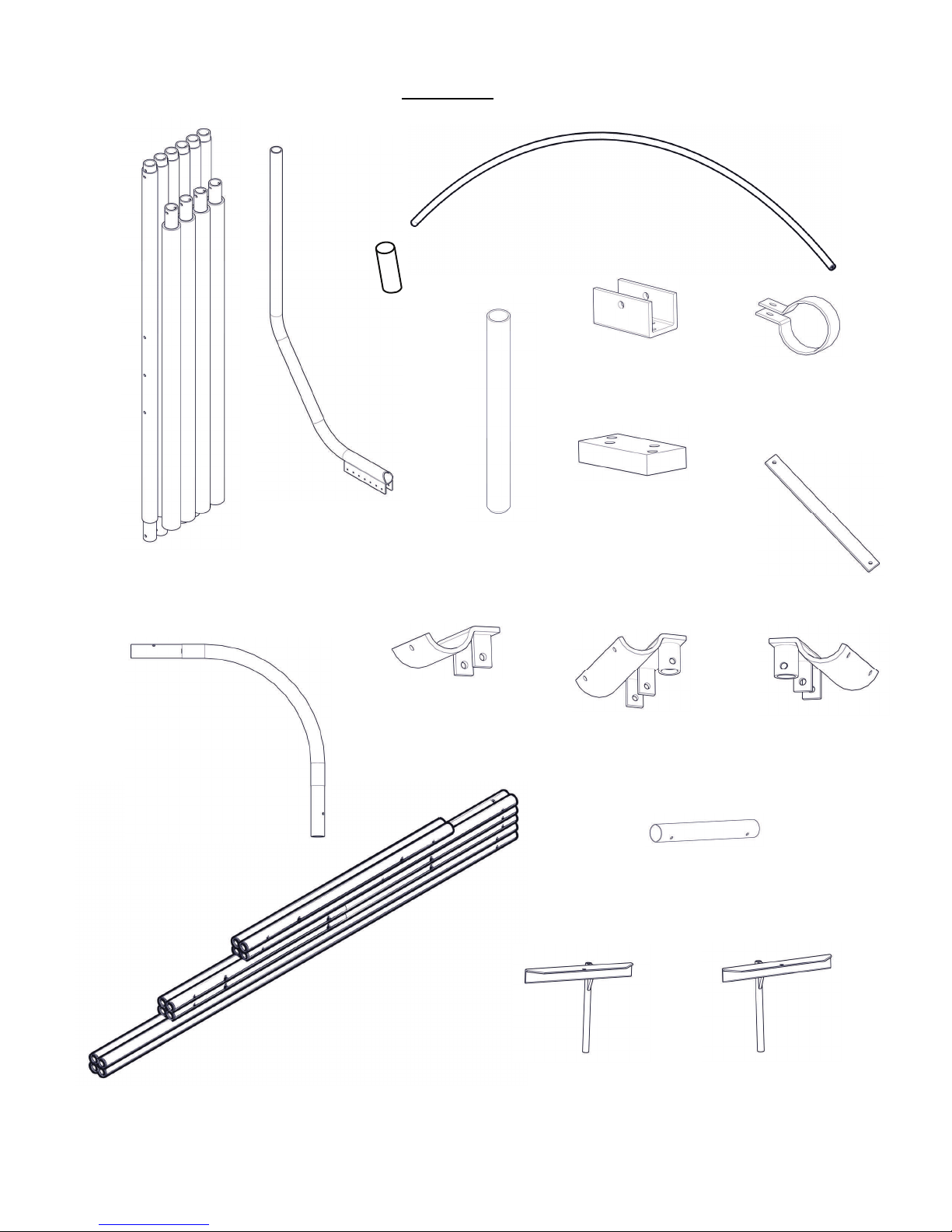

RAFTERS

PART NO. 690178 REV: C 4

Parts List

8

RAFTER

941624

4

1

UPRIGHT AS.

94-000009-30

4

PVC ELBOW

44-000011-69

STOP TUBE

440627

2

GUIDE ON

95-000006-19

GUIDE ON SLEEVE

44-000008-99

2

END BRACKET

95-000008-85

2

6

FLOAT BRACKET

44-000011-56

2

SHIM

42-000012-72

2

FRAME BRACKET L

95-000007-92

12

CLAMP

42-000012-73

6

DIAGONAL BAR

44-000012-66

2

FRAME BRACKET R

95-000007-93

1

FRAME TUBE AS.

95-000009-27

BAG 1

1

OWNERS MANUAL 690178

1

PART NO. 690178 REV: C 5

1

END FLOAT BRACKET L

95-000008-87

6

UNION SLEEVE

44-000011-72

1

END FLOAT BRACKET R

95-000008-86

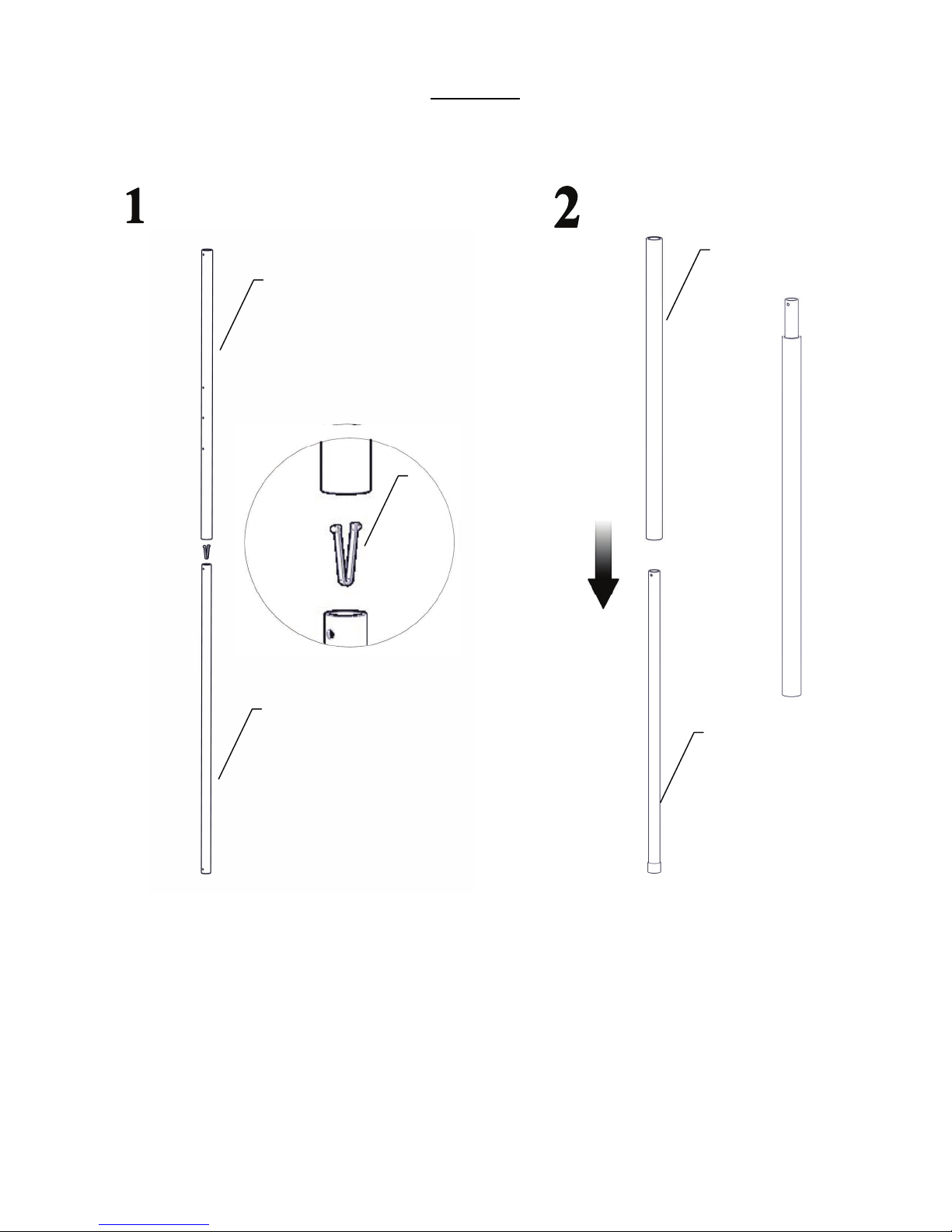

Assembly

Assemble all Telescoping Linkages Assemble all Slide Tubes

Outer PVC Guide

Outer Telescoping Linkage

Snap Button

Inner Telescoping Linkage

Note orientation

Inner Aluminum Guide

PART NO. 690178 REV: C 6

PVC Guide

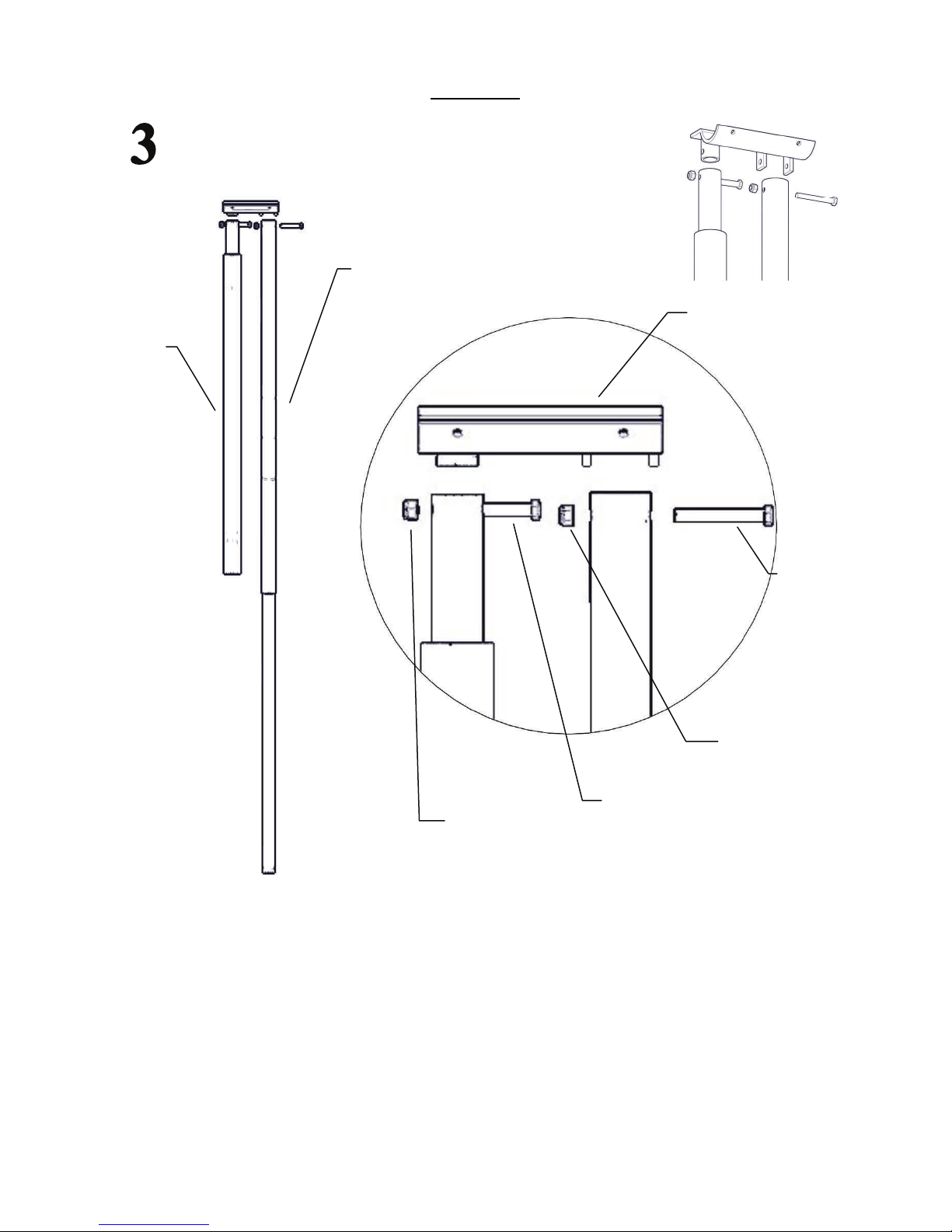

Assemble all Uprights

Assembly

Telescoping

Linkage

Frame Bracket

Bolt, 3/8” x 3.00”

Nylock 3/8”

Bolt, 3/8” x 2.50”

Nylock 3/8”

IMPORTANT:

Do not over tighten bolt. Squeezing the frame bracket prevents Linkage from pivoting.

PART NO. 690178 REV: C 7

Assemble Frame

End Tube

Assembly

End Tube

5/16” X 3.50”

MACHINE SCREW

18X

Side Tube

Ensure all Velcro Strap hooks & loops face to inside of frame.

6 ft Center Tube

7”

NYLOCK, 3/8”

VELCRO STRAP

18X

10X

5”

PVC Elbow

PART NO. 690178 REV: C 8

Union Sleeve

Note rafter hole orientation

IMPORTANT:

Ensure Side Tube dimensions are as follows:

Holes 5” from end connect to PVC Elbow.

Holes 7” from end connect to Union Sleeve.

Secure rafters.

Assembly

#14 x 4.00”

Self Threading Screw

16X

D-Ring Velcro Strap

16X

Ensure all Velcro Strap hooks & loops face to inside of frame.

PART NO. 690178 REV: C 9

Assembly

Remove Guide-on caps from existing guide-ons.

Install additional guide-ons and drop stop tubes down guide-ons.

Guide-on Sleeve

2X

Stop tubes

Bolt 3/8” X 3.00”

Nylock 3/8”

6X

Set guide-ons to desired boat beam width.

Install End Float Brackets

4X

PART NO. 690178 REV: C 10

End Float

Bracket L

FWD

End Float

Bracket R

End Float Bracket L

2X

Assembly

Align Telescoping Linkages with Guide-ons.

Position Float Bracket an attach with Self Drilling Screws. If a 3/8” Nut Driver is not available,

drill a 3/16” hole and install with 3/8” socket wrench. Dimension reflects approximate location.

PART NO. 690178 REV: C 11

Self Drilling Screw

#14 X 1.00”

Float Bracket

9”

16X

Attach telescoping Linkages.

Assembly

Self Drilling

8X

Screw

Float Bracket

Shim

8.5”

Position Float Bracket and attach Self Drilling Screws through shim and secure into end float

brackets. Shim can be pre-drilled prior to securing. Dimension reflects approximate location.

PART NO. 690178 REV: C 12

Assembly

Align Telescoping Linkages with Guide-ons.

4X

Nylock 3/8”

Bolt, 3/8” X 3.00”

2X

Nylock 3/8”

Bolt, 3/8” X 3.00”

IMPORTANT:

Do not over tighten bolt. Squeezing the float bracket prevents Linkage from pivoting.

PART NO. 690178 REV: C 13

Assembly

Assemble and set Frame Attachment Tubes.

4X

Insert caps on end of tubes.

IMPORTANT:

Set Adjustable Frame Attachment Tubes on Frame Brackets and position to desired location.

PART NO. 690178 REV: C 14

Nylock, 5/16”

Bolt, 5/16” X 3.50”

Continued

Assembly

Adjustable Frame Attachment Tube.

1

NOTE: Use wire ties to temporarily hold frame

while assembling.

”

5

2

.

7

PART NO. 690178 REV: C 15

Secure Frame.

Assembly

Frame Assembly

Clamp

Adjustable Frame

Attachment Tube.

Nylock, 5/16”

Bolt, 5/16” X 1½”

IMPORTANT:

Set Hovercover Frame Assembly on Adjustable Frame Attachment Tubes and adjust Frame

Assembly to desired location over craft. Attach Frame using Clamps and fasteners.

PART NO. 690178 REV: C 17

10X

Assembly

Nylock, 5/16”

Frame Bracket

Drill using Frame Brackets as a template and attach fasteners.

Repeat for all brackets including forward brackets.

Bolt, 5/16” X 3.50”

PART NO. 690178 REV: C 18

Secure Cover, tighten Velcro

Assembly

1. Lay fabric over Frame.

2. Pull the corner pockets over the Frame Elbows & leave the split corner for later.

3. Pull split corner over Elbows. Pull long side of fabric over frame and then pull the

split corner over Elbow last.

4. IMPORTANT - Pull Velcro straps through drawstring but do not secure Velcro yet.

5. Tighten drawstring TIGHTLY and tie rings together.

CAUTION:

Tighten drawstring prior to securing Velcro. Water may pool in corners if cover is

improperly secured.

PART NO. 690178 REV: C 19

Height Adjustment

FL10 Hovercover clearances with lift up and down.

Height of the Hovercover is adjusted with the Telescoping Linkages.

The Hovercover has four preset positions incrementing every six inches. The height clearances for the Hovercover are:

1. With the lift in the up position, the distance between the bottom of the boat and the

bottom of the Hovercover frame.

2. With the lift in the down position, the distance between the surface of the water to

the bottom of the Hovercover frame.

The Hovercover can be set to the following range of heights .

Minimum

Height

Maximum

Height

NOTE:

Maximum and Minimum Heights are calculated from boat models with a 21° deadrise hull.

Maximum Boat Height assumes curved windshield. Actual height will be determined

by shape of boat.

Lift

Up

72”

84”

Lift

Down

97”

109”

Maximum

Boat Height

-

103”

Lift

Up

PART NO. 690178 REV: C 20

Lift

Down

Safety Instructions

If you have any questions, please call your dealer, or Sunstream at (253-395-0500).

Save These Instructions

Your safety and the safety of others is very important. Proper use of the information in this manual will help avoid

potential hazards that could cause damage to property and/or personal injury. It is not possible, however, to identify

and warn users of all hazards associated with the assembly, installation, operation, and maintenance of the Float Lift.

You must use your own good judgment.

Failure to comply with the following rules may result in severe injury and/or death and damage to

property.

1. Refer to your FloatLift™ owner’s manual to review safety specifications for your FloatLift.

2. The Hovercover moves from a raised position to a lowered position relative to your boat. In the low-

3. Be sure the Hovercover's height range is properly adjusted for your watercraft to avoid damage to

4. Avoid putting your hands or other body parts on the Hovercover's moving parts while the Hovercover

5. Be aware of environmental forces while using the Hovercover. Strong winds may cause the cover to

6. The Hovercover is a lightweight structure that is NOT designed to hold body weight. DO NOT hang

ered position, the Hovercover is meant to provide a close fit to your watercraft. Be aware of people in

the boat and the risk of the Hovercover contacting them.

boat windshields or other high reaching fixtures.

operates. Do not let children or others contact the Hovercover's moving parts while it operates.

become unstable. Excessive wave action may cause the cause the cover to become unstable. Remove

the fabric cover in the case of predicted extreme weather.

from the Hovercover.

Maintenance

1. Sunstream recommends an annual inspection by your Sunstream dealer.

2. Refer to your FloatLift™ owner’s manual to review maintenance requirements for your FloatLift.

3. Check telescoping PVC guides for binding and add light lubrication as needed. If binding continues, wrap duct tape around base of outer PVC Guide.

4. Check Velcro connections from time to time to ensure a continued tight fit.

5. Report evidence of excessive wear and tear to your Sunstream dealer or to Sunstream.

6. Remove canopy cover before snowfall.

7. Remove canopy cover if winds exceed 30 mph for a prolonged period of time.

Do not allow water to collect on the canopy fabric. Re-tighten tightening cords and/or adjust rafters

8.

to avoid such water collection.

Remove your canopy top for off-season storage or if boat is not on lift for an extended period of

9.

time.

Tighten nuts and bolts as needed.

10.

PART NO. 690178 REV: C 21

Standard Warranty

WARRANTY: Sunstream Corporation (“Company”) warrants its Products for non-commercial and/or non-governmental use for

a period of three (3)* years, in both fresh and salt water, to the original Purchaser (“Purchaser”) against manufacturing defects in all

Product materials and workmanship beginning from date of purchase of the Product from Company** under the following terms and

conditions:

NOTICE REQUIREMENTS AND REMEDIES

: If the Purchaser discovers a defect, the Company, or its authorized Company

dealer or agent, will, at the Company’s option: (1) repair the Product, (2) replace the defective part, or (3) refund the purchase price of

the Product upon confirmation by Company that the Product is defective, provided that the Company receives notice

of the defect from

the Purchaser or Company dealer before the warranty period lapses. Product changes caused by age or environment (such as marine

growth or heat) shall not constitute a defect. Confirmation of the defect shall require that reasonable proof of the defect be provided by

Purchaser to Company or Company dealer, and may include that the Product or part be returned to Company for inspection at

Purchaser’s initial expense. This warranty shall not apply if Company receives notification after the before-stated deadline, regardless

of when the defect occurred or was discovered, and regardless of the reason for the delay in notification. “Notification” shall be deemed

to have occurred when the Purchaser or Company dealer sends written notice to Company by fax or by e-mail and when receipt is

confirmed by Company’s response.

EXCLUSIONS

: This warranty does not apply to damages caused by or due to: (1) accident (including, without limitation,

collision, fire, flood, wind, ice or any other natural disaster or acts of God), abuse, misuse, overloading, out of level or improper boat

loading (i.e.: not fully on, too far on, or crooked on lift), or (2) faulty assembly or installation if such assembly or installation was not

performed by a Company employee or Company dealer. Company is not responsible for determining the weight or dimensions of

Purchaser’s boat, and Purchaser is advised that published boat specifications are often inaccurate. This warranty is void if the Product

has been modified without the permission of the Company or if any Company serial number has been removed or defaced. Normal

maintenance requires an annual inspection of the Product by a Company employee or Company dealer, including bolts, pins, hydraulics,

pump, electronics, and welds and failure to undertake such maintenance may constitute “abuse.” Lift components’ fluid level and

condition, including battery water and acid, SunFluid and strainer cleaning are maintenance items and are not covered by this warranty.

Zincs, ropes, batteries, cosmetic concerns and custom coatings are not covered by this warranty. Batteries supplied by Company that are

maintained in top operating condition by Purchaser are warranted for a period of one (1) year. Underwater light systems and the

DockJock are not warranted for use in brackish or salt water. This warranty does not void or alter any rights the Purchaser may have

against dealers or suppliers of component parts.

SALT WATER REQUIREMENTS AND EXCLUSIONS

maintenance requires that the Purchaser shall attach to the product, maintain and regularly check sacrificial anodes, also known as

prevent electrolysis from damaging the lift metals, and that failure to attach and maintain the zincs constitutes “abuse.” *** Underwater light systems

and the Dock Jock™ personal watercraft lifts are not warranted for brackish or salt water use regardless of zinc use.*

IN

TERNATIONAL WARRANTY

Canada, replacement parts shall be shipped with the dealer’s next containe

product if possible to expedite response. Purchaser has the option to pay for expedited freight if desired.

LIM

ITATIONS

furnished under this Agreement. Seller disclaims any implied warranty of merchantability or fitness for a particular purpose. Th

liability of any kind shall be limited to the remedies provided in

consequential damages or loss of use, revenue or profit. State law may override the above exceptions or limitations.

: Except as expressly stated herein, there are no warranties, expressed or implied, by operation of law or otherwise, of the Product

: The Purchaser agrees that if the Product leaves the borders of the United States of America, Puerto Rico or

: If any Company Product is used in brackish or salt water, the Purchaser agrees that proper

“zincs,” in order to

r order. International dealers have the option of using parts from stocked

e sole remedy for

this warranty and shall in no event include any incidental, indirect, special or

*Fresh water applications for underwater light systems and the Dock Jock™ winch and strap are warranted for one (1) year; salt water

applications are not warranted for these Products.

**If the Product is purchased from a Company dealer, the warranty term begins upon the date the Product is sold to the end Purchaser

or three (3) months from the date the Product is shipped from Company, whichever occurs first.

***Under normal conditions, zincs should last at least one (1) year. If Purchaser observes that the zincs are deteriorating in a shorter

time period, an external current could be entering the system and the Purchaser must find the source of this current and stop

it, or change zincs more frequently.

Sunstream Corporation

22149 68th Avenue South

Kent, WA 98032

USA

Web Site: www.sunstreamcorp.com

Phone: 1-253-395-0500 Fax. 1-253-395-0501

001-253-395-0500 (Int’l) 001-253-395-0501 (Int’l)

E-mail: warranty@sunstreamcorp.com

PART NO. 690178 REV: C 22

Loading...

Loading...