Sunstar Machinery DPK-2, DPK-3 User Manual

SSUUNNSSTTAARR MMAACCHHIINNEERRYY CCOO..,, LLTTDD..

SSUUNNSSTTAARR MMAACCHHIINNEERRYY CCOO..,, LLTTDD..

R

HIGH-SPEED,

SINGLE-NEEDLE

LOCKSTITCH ZIGZAG

SEWING MACHINES

USER

MANUAL

DPK-2

DPK-3

1) For proper use of the machine, read this

manual thoroughly before use.

2) Keep this manual in a safe place for future

reference in case the machine breaks

down.

MMMMEE--005500662299

- 2 -

■ LUBRICATION

Lubrication is one of the most critical factors in ensuring proper operation of delicate sewing machines as DPK series. Note that

supplying high-quality lubricants to all driving parts can enhance durability of the machine. Use P-50C, lubricant that comes with the

sewing machine, or S.F. (70W-150) of the pulley brand.

■ NEEDLE

All needles have type and size number, and the size number is carved on the needle body. The needle used for DPK series is straightblade DP×5 (135) (6) coated with chrome. The needle size is determined by the thread size and the thickness or weight of the sewing

materials.

The needle size is set as follows at the factory, unless is specified otherwise.

– Size number 11~16: for DPK-2 models

– Size number 14~16: for DPK-3 models

■ FEATURES

– Improved adjustment of needle zigzags and stitch lengths

– Innovative thread take-up lever

– Protection of internal machine parts from dust with the enclosed mechanism

■ THE DPK SEWING MACHINE SERIES

SunStar’s DPK series are single-needle, zigzag lockstitch sewing machines. This series promises to offer more user convenience,

speedy thread take-up at the start of sewing, and smooth and quite machine operations. Enjoy excellent and consistent stitches at all

speed, even at the maximum speed of 2,800 r.p.m.

■ DRIVING MOTOR, PULLEY AND BELT

We recommend that the motors and belts with the following specifications be used for proper operation of the machines.

Motor: Motor with separate transmission

– 3-phase, 2-pole, 200W output (or 1/4 horsepower)

– Motor speed: Approximately 450 r.p.m at 50Hz, and 1,750 r.p.m at 60Hz

Belt used: M-or V-shaped belt

Select the motor and pulley in reference to the below table

CAUTION: Operate the machine at a recommended speed

Rigorous testing and inspections have been performed on the machines at the factory. However, to ensure safe and proper use of

the machine, the user should carefully observe the following instructions.

During the first two weeks of machine operation, run the machine at 2,200 r.p.m for DPK-2, and at 2,000 r.p.m for DPK-3

machines. Afterwards, operate at a continuous rated 2,500 r.p.m for DPK-2, and at 2,300 r.p.m for DPK-3. Keep in mind that in

actual operation of the machine, the speed must be adjusted in line with the operation method and the user's control over the

machine.

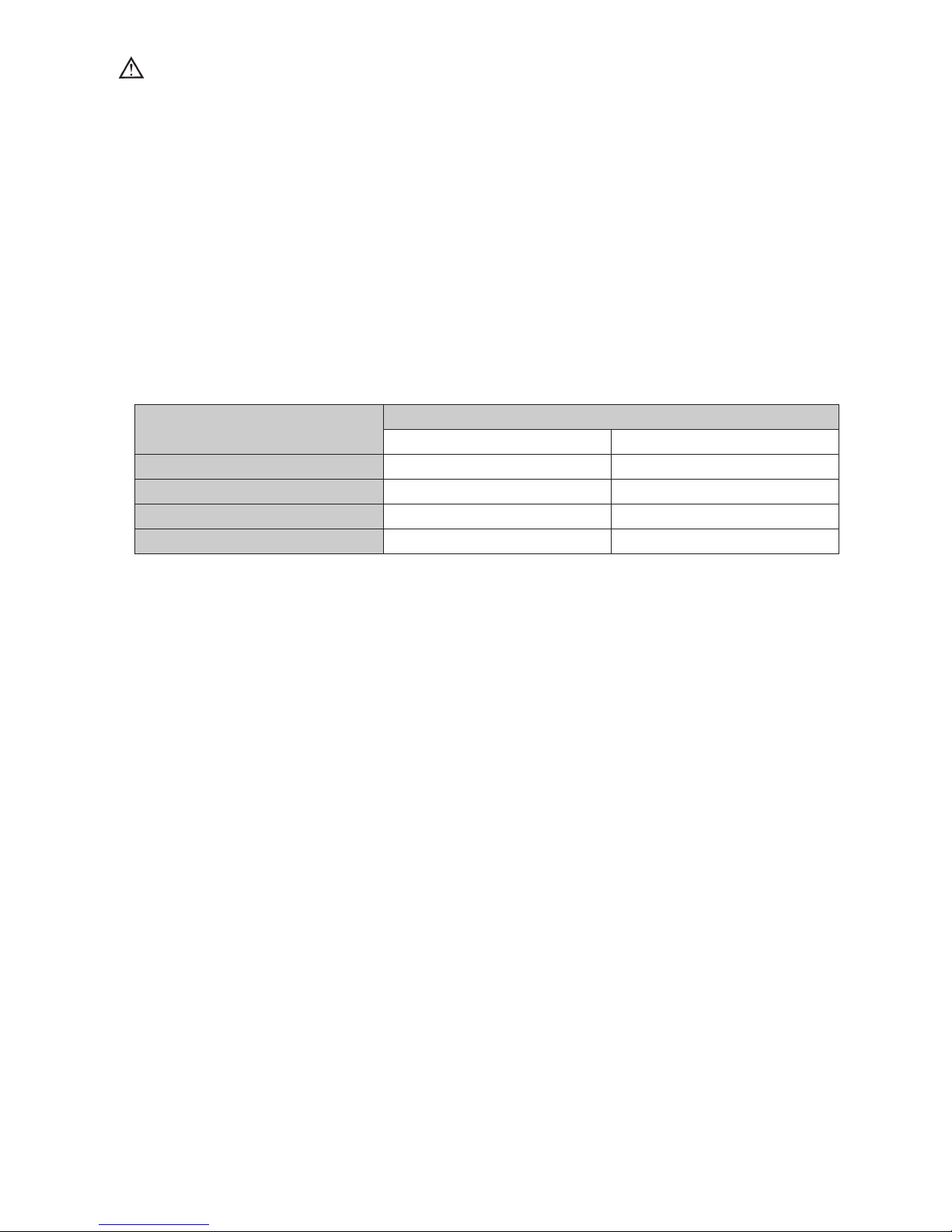

Speed of the machines

(r.p.m.)

Outer diameter of the motor pulley

60Hz 50Hz

70mm 85mm

60mm 75mm

55mm 65mm

50mm 60mm

2,800

2,500

2,200

2,000

- 3 -

■ SPECIFICTION OF DPK SERIES

■ APPLICATION

SunStar’s DPK-2 models are high-speed, single-needle, two-thread zigzag lockstitch sewing machines for industrial use. Specially

designed for hemming, seaming, padding and attaching on knitted underwear, lingerie, dresses, trousers and other articles of light to

medium heavy materials made of cotton, wool, silks, rayon, nylon and similar synthetics. In addition, this sewing machine creates a

hand-made effect by: enabling the user to attach pre-made waistband linings to upper garments or men’s trousers; joining two pieces

of cloth or lightweight leather, and preparing coat linings or finishing up coat collars. DPK-3 features up to 10mm (13/32˝)-sized

large needles for zigzagging. Specially made for all types of sewing works on medium to heavy materials. Good for basting and

tacking coat lining, hemming and stitching the edges of heavyweight leather, tents, sails and other fabrics, and sewing the shoe uppers

and seaming the edges of inlay soles.

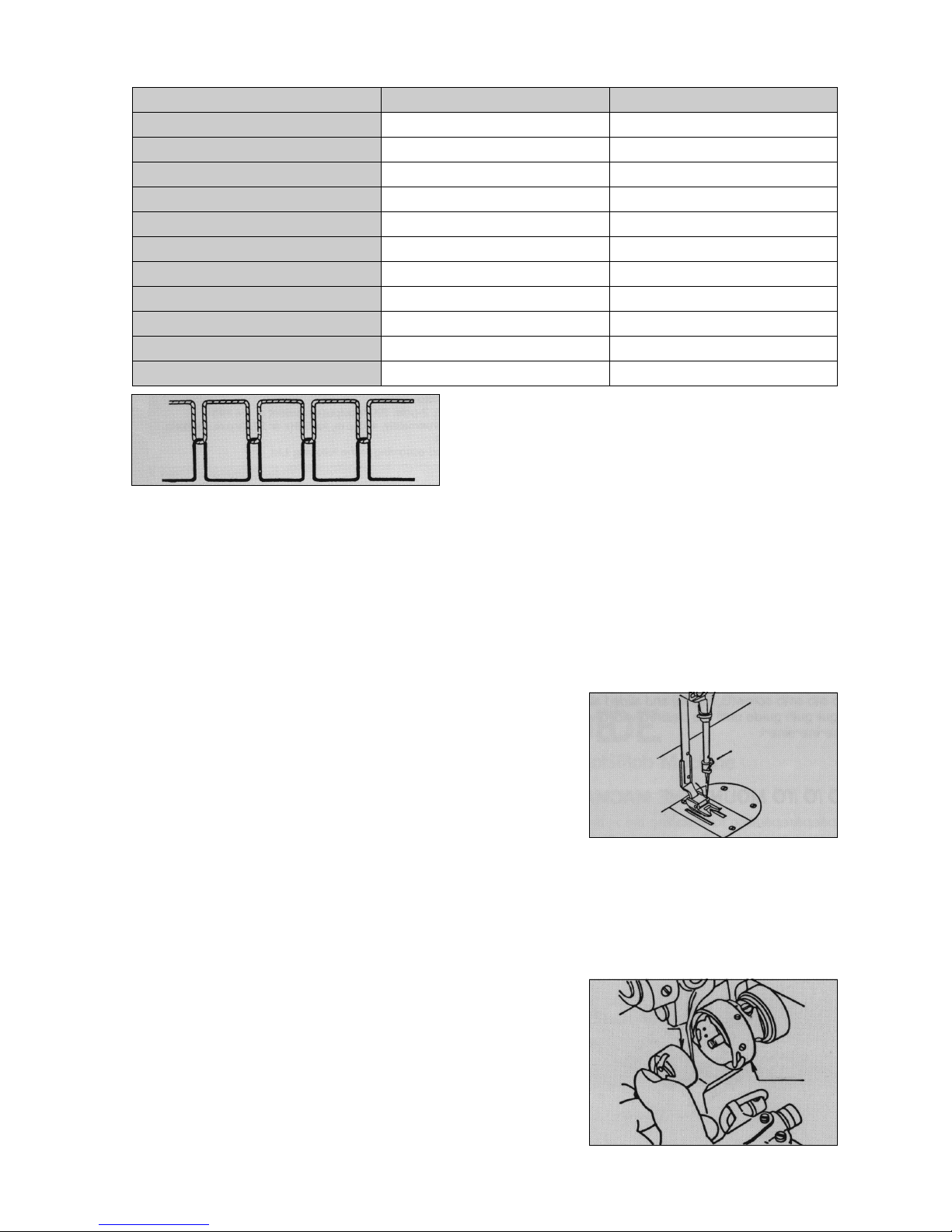

■ HOW TO CHANGE NEEDLES

Turn the handle to bring the needle bar to its highest position. Loosen the needle

clamp screw (A in Figure 2) to take out the used needle. Insert the new needle,

with its groove facing front, into the needle hole as far as it would go. Then firmly

tighten the screw while holding the needle in the right position.

Model DPK-2 DPK-3

2,800 r.p.m.

2,500 r.p.m.

0mm~5mm

6SPI~14SPI (4.2mm~1.8mm)

Descent

Hinge type

Max. 6.0mm

Manual

DP

×

5 #11

Cotton 80/3

General flat seaming

2,500 r.p.m.

2,300 r.p.m.

0mm~10mm

6SPI~14SPI (4.2mm~1.8mm)

Descent

Hinge type

Max. 8.0mm

Manual

DP

×

5 #14

Cotton 80/3

Tacking and basting of upper garments support

Maximum speed

Continuous rated

Needle zigzag

Stitch length

Input

Presser foot

Lifting of presser foot

Lubrication

Needle type and size

Standard thread

Application

[ Fig. 1 ]

[ Fig. 2 ]

■ THREAD

The threads used for sewing should be able to move freely in the needle hole. Roughly or inconsistently woven threads normally

break during sewing, and/or cannot give you the number of stitches you desire to get. The recommended thread for DPK-2 and DPK3 is cotton 80/3. For all DPK sewing machines, you must use threads that are wound from right to left.

■ HOW TO REMOVE THE BOBBIN CASE

Turn the pulley in a counterclockwise direction to move the thread take-up lever to

its highest position. With your left index and the second finger, push up the latch

lever of the bobbin case frame to remove the frame with the bobbin case. Then

push down the latch lever to remove the bobbin case.

[ Fig. 3 ]

A

Bobbin case

Hook

Loading...

Loading...