SunStar SPS/E-BS1201H, SPS/E-BS1201M(HP), SPS/E-BS1201M, SPS/E-BR1201M, SPS/E-BS1201L User Manual

...

SSUUNNSSTTAARR MMAACCHHIINNEERRYY CCOO..,, LLTTDD..

MMEEEE--006611111177

R

User’s

Manual

SPS/E-Bartacking Series

SPS/E-

Button Sewing Series

Electronically Controlled

Bartacking Machine

(Electronic Control Part)

Electronically Controlled

Button Sewing Machine

(Electronic Control Part)

1) For proper use of the machine,

thoroughly read this manual before use.

2) Keep this manual in a safe place for

future reference in case the machine

breaks down.

Best Quality

Best Price

Best Service

SSUUNNSSTTAARR MMAACCHHIINNEERRYY CCOO..,, LLTTDD..

R

1.

Thank you for purchasing our product. Based on the rich expertise and

experience accumulated in industrial sewing machine production, SUNSTAR

will manufacture industrial sewing machines, which deliver more diverse

functions, high performance, powerful operation, enhanced durability, and

more sophisticated design to meet a number of user’s needs.

2. Please read this user’s manual thoroughly before using the machine. Make

sure to properly use the machine to enjoy its full performance.

3. The specifications of the machine are subject to change, aimed to enhance

product performance, without prior notice.

4.

This product is designed, manufactured, and sold as an industrial sewing

machine. It should not be used for other than industrial purpose.

Organization of the

BARTACK S/M MODEL

SPS / E - BS1201 - H

1) Electronic Presser Foot Rising Device Attached Type

2) Button Sewing Machine Types

④ Material Type

H : For Heavy weight Materials

M : For Medium Materials

L : For Light Materials

K : For Knitted

M(HP) : For Medium Materials

(Hole-fixing device)

① Sunstar

Pattern

System

② Series Classification

E : Direct Drive Type

(Servo step motor used)

③ Bartack Sewing Machine

③ BR : Full-rotary hook

③ BS : Half-rotary hook

SPS / E - BS1202 - 0 1

④ Button Type

01 : Small-Size Button

(Mechanical Type Wiper)

02 : Large-Size Button

(Mechanical Type Wiper)

03 : Small & Large Size Button

(Solenoid Type Wiper)

① Sunstar

Pattern

System

② Series Classification

E : Direct Drive Type(Servo step motor used)

③ Button S/M Model Name

③ BR : Full-rotary hook

③ BS : Half-rotary hook

4

CONTENTS

1. Machine Safety Regulations

--------------------------------------------------------------------

6

1-1) Machine Transportation ---------------------------------------------------------------------------6

1-2) Machine Installation ------------------------------------------------------------------------------ 6

1-3) Machine Repair ------------------------------------------------------------------------------------ 6

1-4) Machine Operation -------------------------------------------------------------------------------- 7

1-5) Devices for Safety --------------------------------------------------------------------------------- 7

1-6) Caution Mark Position ---------------------------------------------------------------------------- 8

1-7) Contents of Marks --------------------------------------------------------------------------------- 8

2. Electronically Controlled Bartacking SM Specifications

----------------------------

9

3. Preparations before Use

-----------------------------------------------------------------------

10

3-1) Power Connection ------------------------------------------------------------------------------- 10

3-2) Changing Power Voltage ------------------------------------------------------------------------ 11

3-3) Control Box LED Check ------------------------------------------------------------------------ 11

4. SM Operation 1 (Basic)

-------------------------------------------------------------------------

12

4-1) Names and Functions of Keys in the Operation Box --------------------------------------- 12

4-2) Setting Item Data -------------------------------------------------------------------------------- 13

4-3) Checking Pattern Shape ------------------------------------------------------------------------- 16

4-4) Sewing --------------------------------------------------------------------------------------------- 16

4-5) Changing Sewing Pattern ----------------------------------------------------------------------- 17

4-6) Lower Thread Winding ------------------------------------------------------------------------- 17

5. SM Operation 2 (Advanced)

-------------------------------------------------------------------

18

5-1) User Program ------------------------------------------------------------------------------------- 18

5-2) Sewing using Combination Function --------------------------------------------------------- 19

5-3) Sewing using Lower Thread Counter -------------------------------------------------------- 20

5-4) Precautions ---------------------------------------------------------------------------------------- 21

6. Using Memory Switch

---------------------------------------------------------------------------

22

6-1) Memory Switch Operation --------------------------------------------------------------------- 22

6-2) Example of Memory Switch Set-up ----------------------------------------------------------- 22

6-3) Memory Switch Functions Table -------------------------------------------------------------- 26

7. Maintaining/Repairing

---------------------------------------------------------------------------

30

5

7-1) Cleaning Control box --------------------------------------------------------------------------- 30

7-2) Replacing Fuse ---------------------------------------------------------------------------------- 30

7-3) Testing the Machine ----------------------------------------------------------------------------- 31

7-4) Other Functions ---------------------------------------------------------------------------------- 35

7-5) Installing and Replacing ROM ---------------------------------------------------------------- 36

7-6) Pattern download from PDA (or PC) -------------------------------------------------------- 41

7-7) Pattern download from CF card --------------------------------------------------------------- 42

8. Error List

---------------------------------------------------------------------------------------------

44

9. How Select the Sewing Pattern List and the Sewing Lange

----------------------

47

9-1) BS(R)1201 Series -------------------------------------------------------------------------------- 47

9-2) BS(R)1202 Series -------------------------------------------------------------------------------- 48

10. BASIC MANUAL

---------------------------------------------------------------------------------

49

6

11

Machine Safety Regulations

Safety instruction on this manual are defined as Danger, Warning and Caution.

If you do not keep the instructions, physical injury on the human body and machine damage might be occurred.

: When the machine is improperly handled, user injury or physical damage to the machine is expected to occur.

: When the machine is improperly handled, critical injury or death of a user is expected to occur.

: When the machine is improperly handled, critical injury or death of a user is expected to occur, and the high-level

of emergency situation would like to happen.

Danger

Warning

Caution

1-1) Machine

Transportation

Danger

1-2) Machine

Installation

Caution

1-3) Machine Repair

Danger

Those in charge of transporting the machine should know the safety regulations very well.

The following indications should be followed when the machine is being transported.

ⓐ More than 2 people must transport the machine.

ⓑ To prevent accidents from occurring during transportation, wipe off the oil on the machine

well.

The machine may not work well or breakdown if installed in certain places. Install the

machine where the following qualifications agree.

ⓐ Remove the package and wrappings starting from the top. Take special notice on the nails

on the wooden boxes.

ⓑ Dust and moisture stains and rusts the machine. Install an airconditioner and clean the

machine regularly.

ⓒ Keep the machine out of the sun. If the machine is exposed in direct ray of light for a long

time, transformation of color and shape can be happened.

ⓓ Leave sufficient space of more than 50cm behind, and on the right, left and back side of

the machine for repairing.

ⓔ Do not operate in explosive atmospheres. To avoid explosion, do not operate this machine in

an explosive atmosphere including a place where large quantities of aerosol spray product

are being used or where oxygen is being administered unless it has been specifically

certified for such operation.

ⓕ The machine were not provided with alocal lighting due to the feature of machine.

Therefore the illumination of the working area must be fulfilled by end user.

[Refer] Details for machine installment are described in 4. Machine Installment.

When the machine needs to be repaired, only the assigned troubleshooting engineer educated

at the company should take charge.

ⓐ Before cleaning or repairing the machine, close down the motive power and wait 5

minutes till the machine is completely out of power.

ⓑ Not any of the machine specifications or parts should be changed without consulting the

company. Such changes may make the operation dangerous.

ⓒ Spare parts produced by the company should only be used for replacements.

ⓓ Put all the safety covers back on after the machine has been repaired.

7

Bartack Series is made to sew patterns on fabrics and other similar material for

manufacturing. Follow the following indications when operating the machine.

ⓐ Read through this manual carefully and completely before operating the machine.

ⓑ Wear the proper clothes for work.

ⓒ Keep hands or other parts of the body away from the machine operation parts(needle,

shuttle, thread take-up lever, and pulley etc.) when the machine is being operated.

ⓓ Keep the covers and safety plates on the machine during operation.

ⓔ Be sure to connect the earthing conductor.

ⓕ Close down the electric motive power and check if the switch is turned “off”before

opening electric boxes such as the control box.

ⓖ Stop the machine before threading the needle or checking after work.

ⓗ Do not step on the pedal when turning the power on.

ⓘ Do not use several motor per a electric outlet.

ⓙ If possible, install the machine away from loud noise such as high frequency welding

machines

ⓚ Be careful when the upper feed plate comes down to press. Otherwise, the finger or hand

height be hurt at smacking.

1-4) Machine

Operation

Caution

Caution

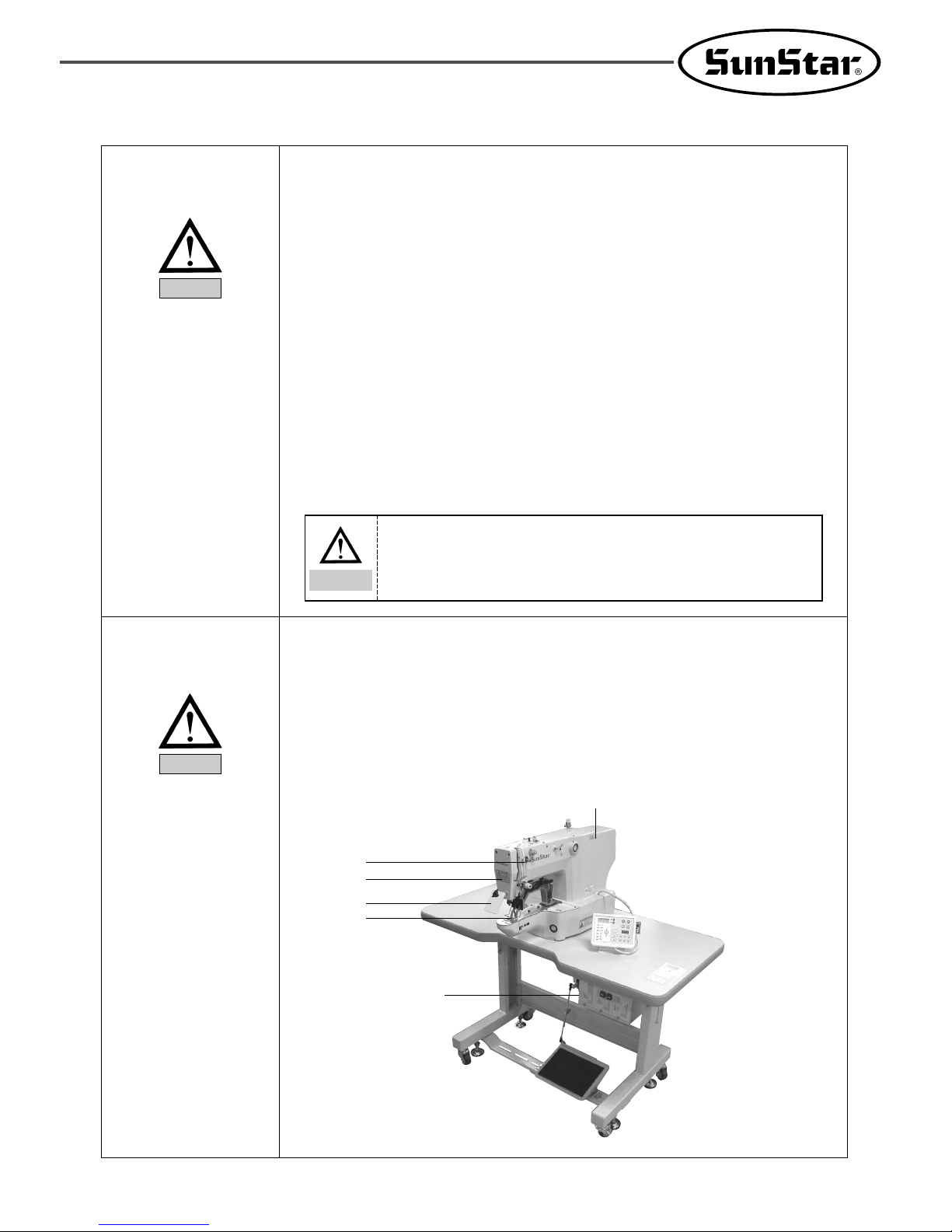

ⓐ Safety label : It describes cautions during operating the sewing machine.

ⓑ Thread take-up cover : It prevents from any contact between body and take-up lever.

ⓒ Motor cover : It prevents from accidents during rotation of motor.

ⓓ Label for specification of power : It describes cautions for safety to protect against

electric shock. (Voltage and Hz)

ⓔ Finger guard : It prevent from contacts between a finger and needle.

ⓕ Safety plate : It protects eyes against needle breaks.

1-5) Devices for

Safety

1) Make sure that the cover is in place, while the machine is

operating. Otherwise, the belt might injure or cut a finger.

2) Make sure that the power is turned "OFF" before examining

or adjusting the machine.

Warning

ⓒ

ⓐ

ⓑ

ⓕ

ⓔ

ⓓ

8

1)

2)

1-7) Contents of

Marks

CAUTION

경고

Do not operate without finger guard

and safety devices. Before threading,

changing bobbin and needle, cleaning

etc. switch off main switch.

손가락 보호대와 안전장치 없이 작동하지 마

십시오.

실, 보빈, 바늘교환시나 청소전에는 반드시

주전원의 스위치를 꺼 주십시오.

WARNING

경고

Hazardous voltage will cause injury.

Be sure to wait at least 360 seconds

before opening this cover after turn

off main switch and unplug a power

cord.

고압 전류에 의해 감전될 수 있으므로 커버

를 열 때는 전원을 내리고 전원 플러그를 뽑

고 나서 360초간 기다린 후 여십시오.

Warning

1-6) Caution Mark

Position

CAUTION

경고

Do not operate without finger guard and

safety devices. Before threading, changing

bobbin and needle, cleaning etc. switch off

main switch.

손가락 보호대와 안전장치 없이 작동하지

마십시오.

실, 보빈, 바늘교환시나 청소전에는 반드시 주

전원의 스위치를 꺼 주십시오.

WARNING

경고

Hazardous voltage will cause injury.

Be sure to wait at least 360 seconds before

opening this cover after turn off main switch

and unplug a power cord.

고압 전류에 의해 감전될 수 있으므로 커버를

열 때는 전원을 내리고 전원 플러그를 뽑고 나

서 360초간 기다린 후 여십시오.

Caution mark is attached on the machine for safety.

When you operate the machine, observe the directions on the mark.

Position of Warning Mark

Caution

9

22

Electronically Controlled Bartacking SM Specifications

Type

Application

Sewing Scope (X, Y)

Maximum Speed

Stitch Length

Needle

Hook

Height of Presser foot

Needle Bar Stroke

Trimmer

Wiper

Lower Thread Counter

Max Speed Limit

Feeding System

No. of Stitch Input

No. of Pattern Input

Scale Scope

Memory Device

Motor

Power consumption

Optimal Temperature

Optimal Humidity

Power

X : 40mm, Y : 30mm (Max)

0.05 ~ 12.7mm

Up to 17mm (step motor is used)

41.2mm

Electronic solenoid type

○

○

Up to 100 ~ 3,200 spm with an external switch

R-θmethod (step motor is used)

Up to 10,000 stitches

Up to 99 patterns (default : 32 patterns)

20 ~ 200 % (adjustable by 1%)

P-ROM

550W direct drive AC servo motor (standard power: 600 W)

600VA

5℃~40℃

20% ~ 80%

Single-phase : 100~240V, 3-phase : 200~440V, 50/60Hz

SPS/E-BS1201H SPS/E-BS1201M SPS/E-BS1201L SPS/E-BS1201K

SPS/E-BS1201M

(HP)

SPS/E-BR1201M SPS/E-BR1201L SPS/E-BR1201K

Heavy

materials

General

materials

Light

materials

Knitwear

General

materials (hole

fixing device)

General

materials

Knitwear

Light

materials

3200spm 3200spm 2700spm 2700spm 3200spm 2500spm 2200spm 2200spm

DP×17#19

Standard shuttle hook

2× rotary hook

DP×5#16 DP×5#11 DP×5#11 DP×5#16 DP×5#16 DP×5#11 DP×5#11

33

Preparations before Use

10

3-1) Power Connection

■ Voltage Specification

Voltage information is tagged on the power plug as indicated below.

1. Do NOT use the machine with different voltage specification.

2. Please refer to 『Changing Power Voltage』section before changing the voltage.

■ Single phase connection (100V, 110V, 120V, 200V, 220V, 240V)

■ 3-phase connection (200V, 220V, 240V, 380V)

이 기계의 전기 사양은 공장 출고 시 아래의 표기되로 결선되어 있습니다.

V

단상 (1 Phase) 삼상 (3 Phase)

110V 120V 220V 240V 220V 240V

V

V

The Electric Specification of This Machine is Connected Under Marked.

V

In case of 3-phase 380V, it is necessary to install an additional trans box on the table (check

it out upon making a purchase order).

Caution

11

3-2) Changing Power Voltage

Use SMPS to maintain constant voltage when changing the input voltage.

This machine adopts a free voltage system. Use the voltage connector to set voltage status of the main shaft board at

110V or 220V according to the input voltage.

for input

voltage

110V

for input

voltage

220V

Input voltage setting

110V

CN6

CN7

CN2

CN5

CN4

CN3

CN1

220V

CN6 CN7 JP1

CN6 CN7 JP1

Incorrect setting of the voltage connector may damage the control box.

Caution

3-3) Control Box LED Check

LED displays the power supply status to each board. Therefore when problems occurs, it is easy to identify where the

problems were developed.

1. E-SERIES

LED LEDPower Supply Status Power Supply Status

LED1 LED5Digital Board +5V Input

Main Shaft Board 220V Input

LED2 LED6Digital Board +12V Input

Main Shaft Board +5V Input

LED3 LED7Step Board +5V Input

Main Shaft Board +12V Input

LED4 Step Board +48V Input

12

44

SM Operation 1 (Basic)

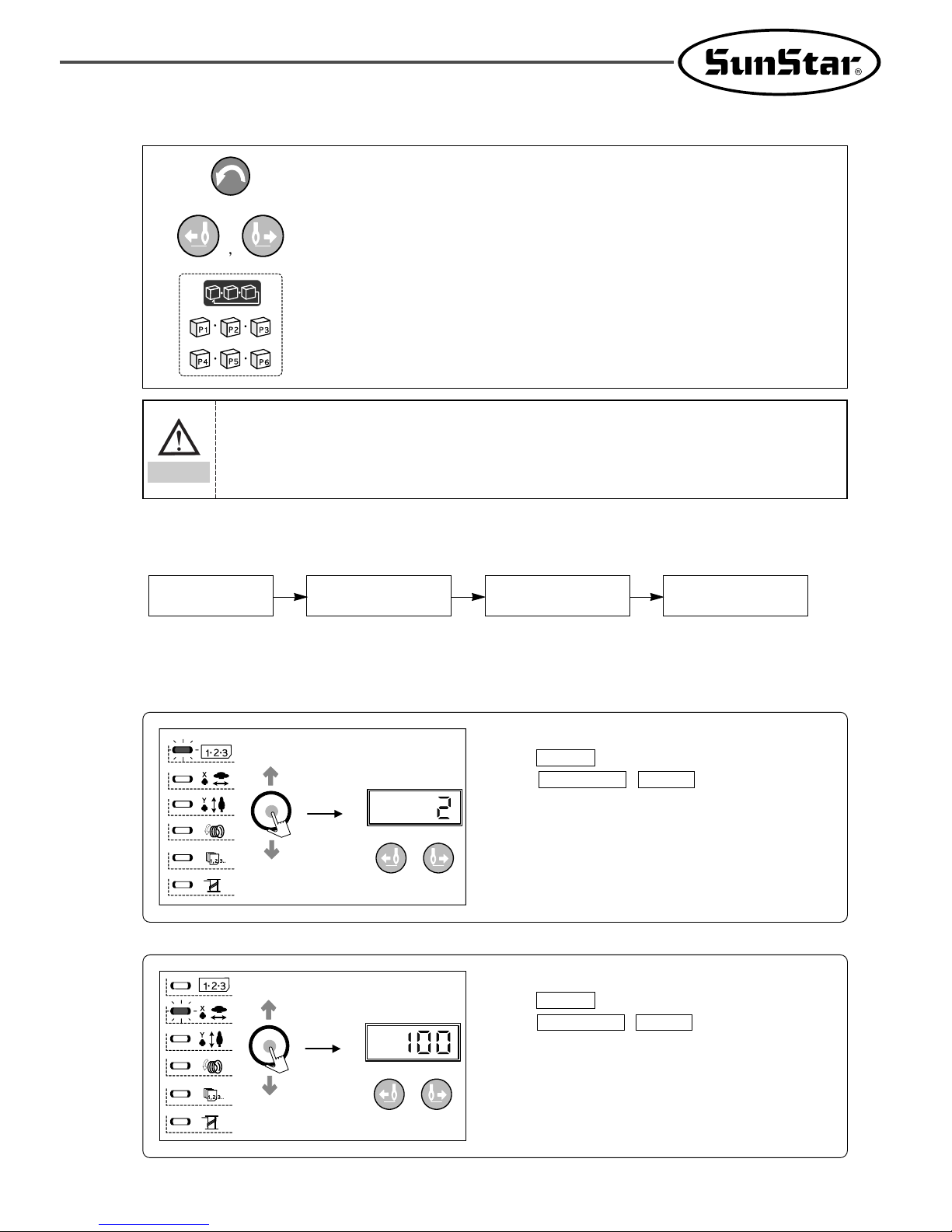

4-1) Names and Functions of Keys in the Operation Box

※ Previous pattern number will appear when you turn on the power.

Refer to the following functions of LED and keys.

Press READY to prepare the machine for sewing. READY light will turn on.

Indicates an error.

Press to select item. At every press item changes as below. Selected item will be lighted.

Pattern

No.

X Scale % Y Scale %

Sewing

Speed

Counter

Thread

winding

Sewing ready lamp Ready key

Reset key

+/Forward

–/Back

Communication

Serial download

(Note 1)

CF card download

(Note 1)

Register

LED display

Error lamp

Set pattern No.

X-scale

Y-scale

Speed

Production counter

Lower thread winding

Select

(Note 1) : To use the

download function, the

‘Communication Ready’

key should be pressed at

the same time.

13

Press to set the machine back to the default value.

Press to increase/decrease the set value or to move the needle bar backward or forward.

One click to call a certain pattern.

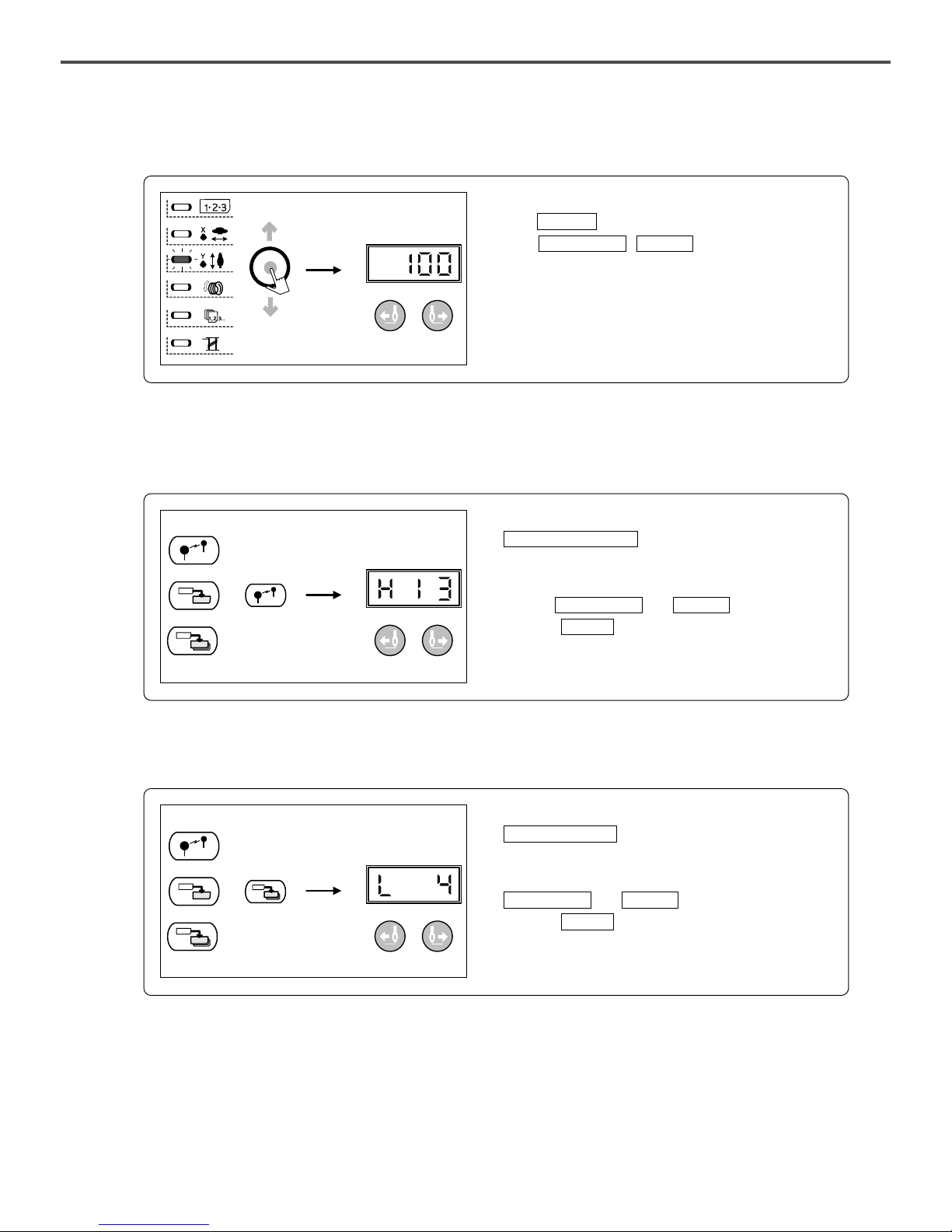

4-2) Setting Item Data

You can set each item in the following order.

A. Turn on the power.

Item “Pattern No.” will lit up and the previous pattern number will appear.

B. Set the pattern number.

C. Set X Scale %.

Pattern No. X Scale % Y Scale % Sewing Speed

1) Press to display NO.

2) Press , to display “2” on the

screen (setting pattern No.2).

※ Refer to the program list.

–/BACK+/FORWARD

SELECT

1) Press to display item “X-Scale”.

2) Press , to set within the range

of 20%~200%.

–/BACK+/FORWARD

SELECT

1) For direct connection type, if the head is laid down on the side while the power is on, ““oPEn

””

will appear. If READY key is on at this time, sewing does not start with your pedaling.

2)

If the head is laid down on the side while sewing, ““oPEn””will not appear until sewing is

completed.

Caution

14

D. Set Y Scale %

1) Press to display item “Y-Scale”.

2) Press , to set within the range

of 20%~200%.

–/BACK+/FORWARD

SELECT

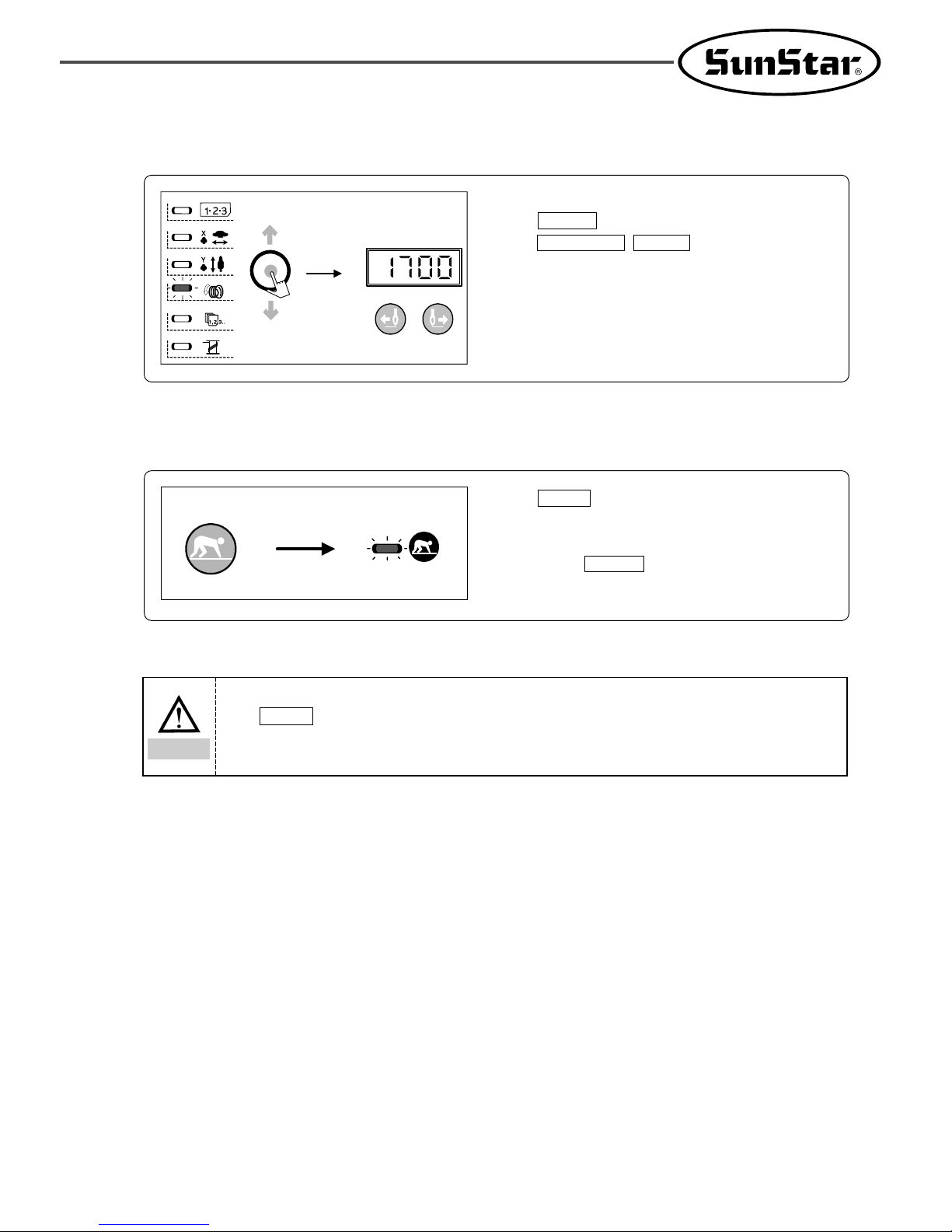

E. Adjustment of Presser Plate Height

a. Adjustment of ascending height

1) Press the key to display the

height of the presser foot when it is lifted.

2) Set the height within the scope of H 10 ~ H 17 by

pressing and .

3) Press the key to save the changed values and

make the machine return to the ready mode.

READY

–/BACK+/FORWARD

Communication ready

b. Adjustment of descending height

1) Press the key to display the height

of the presser foot when it descends.

2) Set the height within the scope of L 1 ~ L 17 by pressing

and .

3) Press the key to save the changed values and

make the machine return to the ready mode.

READY

–/BACK+/FORWARD

CF card download

15

F. Set Sewing Speed

G. Setting Done

1) Press to display item “Speed”.

2) Press , to set the speed at 1700.

–/BACK+/FORWARD

SELECT

1) Press .

2) Presser plate will move/lift and READY light will be on.

The machine will be on standby

※ You can press to confirm the setting.

SELECT

READY

Check the pattern number before starting the machine.

1) If is pressed with the pattern number “0” (default status), the machine will move

back to original point. Use it to check the machine original point.

2) If you select a pattern that contains no data, error “Er01” will appear. Select other pattern.

READY

Caution

Loading...

Loading...