SunStar SPS/E-BS1202 Series, SPS/E-BR1202 Series User Manual

SSUUNNSSTTAARR MMAACCHHIINNEERRYY CCOO..,, LLTTDD..

User’s

Manual

SPS/E-BS1202 Series

SPS/E-BR1202 Series

Electronically Controlled

Button Sewing Machine

(Mechanical Part)

R

MMMMEE--006600771133

1) FOR AT MOST USE WITH EASINESS,

PLEASE CERTAINLY READ THIS MANUAL

BEFORE STARTING USE.

2) KEEP THIS MANUAL IN SAFE PLACE

FOR REFERENCE WHEN THE MACHINE

BREAKS DOWN.

Best Quality

Best Price

Best Service

SSUUNNSSTTAARR MMAACCHHIINNEERRYY CCOO..,, LLTTDD..

R

1.

Thank you for purchasing our product. Based on the rich expertise and

experience accumulated in industrial sewing machine production, SUNSTAR

will manufacture industrial sewing machines, which deliver more diverse

functions, high performance, powerful operation, enhanced durability, and

more sophisticated design to meet a number of user’s needs.

2. Please read this user’s manual thoroughly before using the machine. Make

sure to properly use the machine to enjoy its full performance.

3. The specifications of the machine are subject to change, aimed to enhance

product performance, without prior notice.

4.

This product is designed, manufactured, and sold as an industrial sewing

machine. It should not be used for other than industrial purpose.

4

Contents

1. Machine Type and Specifications

..............................................................................

6

2. Safety Rules

.........................................................................................................................

7

2.1) Safety Stickers

...................................................................................................................

7

2.2) Machine Delivery

..............................................................................................................

8

2.3) Machine Installation

..........................................................................................................

9

2.4) Machine Operation

............................................................................................................

9

2.5) Repair and Maintenance

..................................................................................................

10

2.6) Devices for safety

............................................................................................................

10

2.7) Location of Safety Labels

................................................................................................

11

3. Assembly

............................................................................................................................

12

3.1) Name of Machine Parts

...................................................................................................

12

4. Machine Installation

.......................................................................................................

13

4.1) Installation Environment

.................................................................................................

13

4.2) Electricity Environment

................................................................................................

13

4.3) Table Installation

.............................................................................................................

13

4.4) Machine Installation

........................................................................................................

14

4.5) Accessory Installation

.....................................................................................................

16

5. Machine Operation

.........................................................................................................

17

5.1) How to supply oil

............................................................................................................

17

5.2) How to grease

..................................................................................................................

17

5.3) Needle

..............................................................................................................................

18

5.4) Thread

..............................................................................................................................

18

5.5) Pedal Operation

...............................................................................................................

20

6. Maintenance

.......................................................................................................................

21

6.1) Adjustment of Needle Bar Height

..................................................................................

21

6.2) Adjustment of Needle and Hook

....................................................................................

21

6.3) Adjustment of Lower Shaft Gear and Oscillating Shaft (BS : Semi-rotary)

.................

22

6.4) Adjustment of Shuttle Upside Spring Position (BS : Semi-rotary)

...............................

23

6.5) How to adjust the ascending range of button clamp

......................................................

23

6.6) How to adjust the button clamp holder tension

..............................................................

24

6.7) Adjusting the parts of thread release

...............................................................................

24

6.8) Adjustment of Wiper-related Parts

.................................................................................

25

6.9) Adjustment of Trimmer-related Parts

.............................................................................

26

6.10) Adjustment of Thread Volume on Bobbin

...................................................................

28

5

6.11) Adjustment of Hand Pulley Device

..............................................................................

29

6.12) Assembly and Adjustment of Direct Drive Motor

.......................................................

29

6.13) Setting up the X-Y Origin

.............................................................................................

29

6.14) How to adjust the feeding plate

...................................................................................

30

6.15) Checking the setting position of button clamp

.............................................................

30

6.16) How to set up the button clamp adjusting plate

...........................................................

31

6.17) How to attach the spacer spring plate

...........................................................................

31

6.18) Oil Supply

......................................................................................................................

31

6.19) Cleaning

.........................................................................................................................

34

6.20) Handling of Waste Oil

...................................................................................................

34

7. Cause of Breakdown and Troubleshooting

........................................................

35

8. Pattern List

.........................................................................................................................

37

9. Drawing of Table

..............................................................................................................

38

10. GAUGE LIST

....................................................................................................................

39

11. OPTION LIST

...................................................................................................................

39

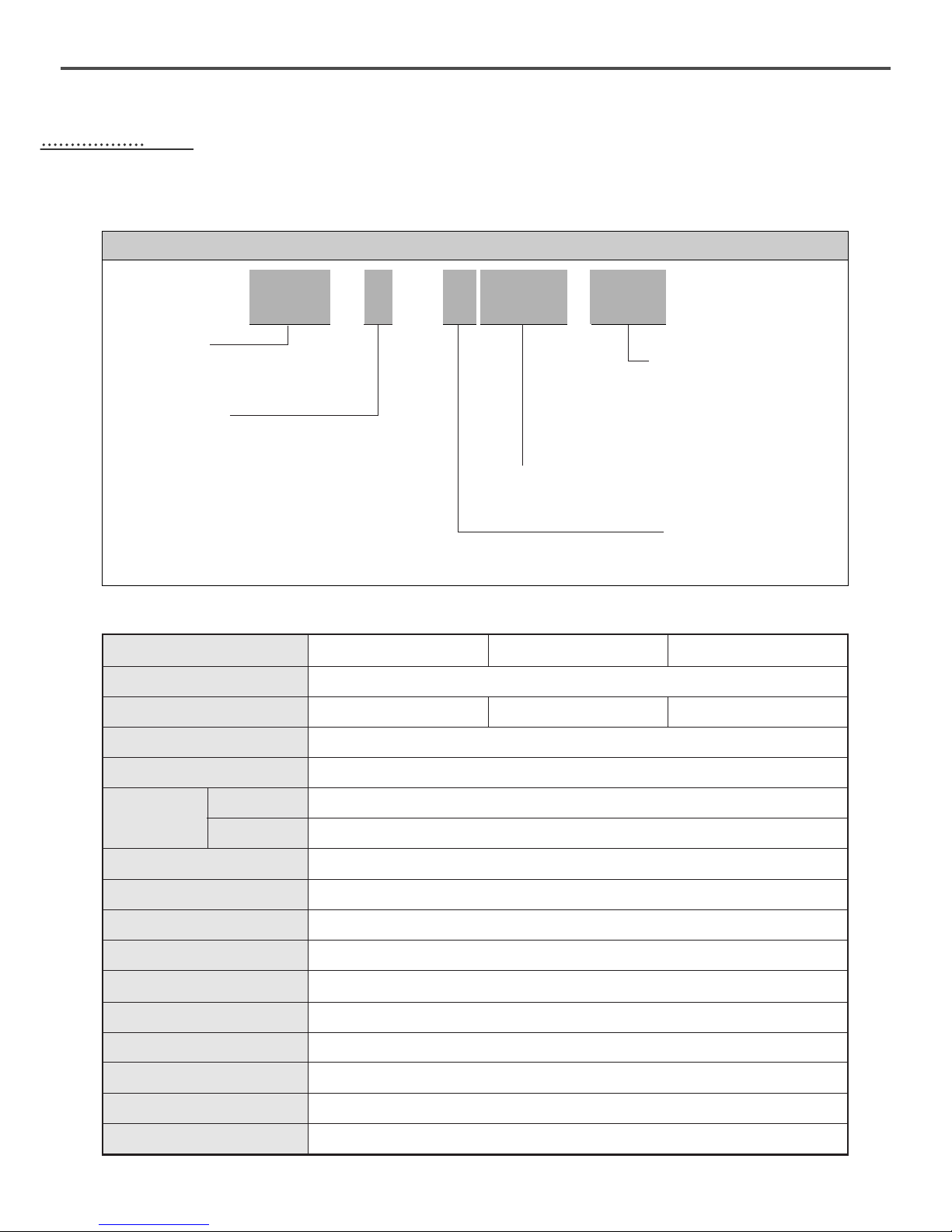

Name of Model

Speed

Button Size

Wiper Specification

Needle

Button Clamp Lift

No. of Patterns

No. of Stitches

Enlargement / Reduction

Memory

Proper Temperatare of machine running

Proper Temperatare of machine running

Main Motor

Power consumption

Power

6

11

Machine Type and Specifications

② Series Type

E:Motor direct drive-type

① SunStar

Pattern

System

⑤ Button Type

01 : Small-Size Button

(Mechanical Type Wiper)

02: Large-Size Button

(Mechanical Type Wiper)

03 : Small & Large Size Button

(Solenoid wiper Type Wiper)

④ Button S/M Model Name

③ Bartack Sewing Machine

Name

S : Shuttle Hook

R : Rotary Hook

SPS / E- B1202

Max. 2,700spm (Standard : 2,500spm)

Mechanical Type Wiper

DP×17 #14

shuttle hook

2× rotary hook

Max. 13mm

Max. 99 Patterns (Standard: 33 Patterns)

Max. 10,000 Stitches

20%~200%

P-ROM

5℃~40℃

20%~80%

500W direct drive AC servo motor×1 / step motor×3

600VA

1ф : 100~240V / 3ф : 200V~440V, 50/60Hz

Bartack Sewing Machine Model

SPS/E(R)1202-01 SPS/E(R)1202-02 SPS/E(R)1202-03

ф8~ф20mm ф8~ф32mm ф8~ф32mm

Hook

BS

BR

7

22

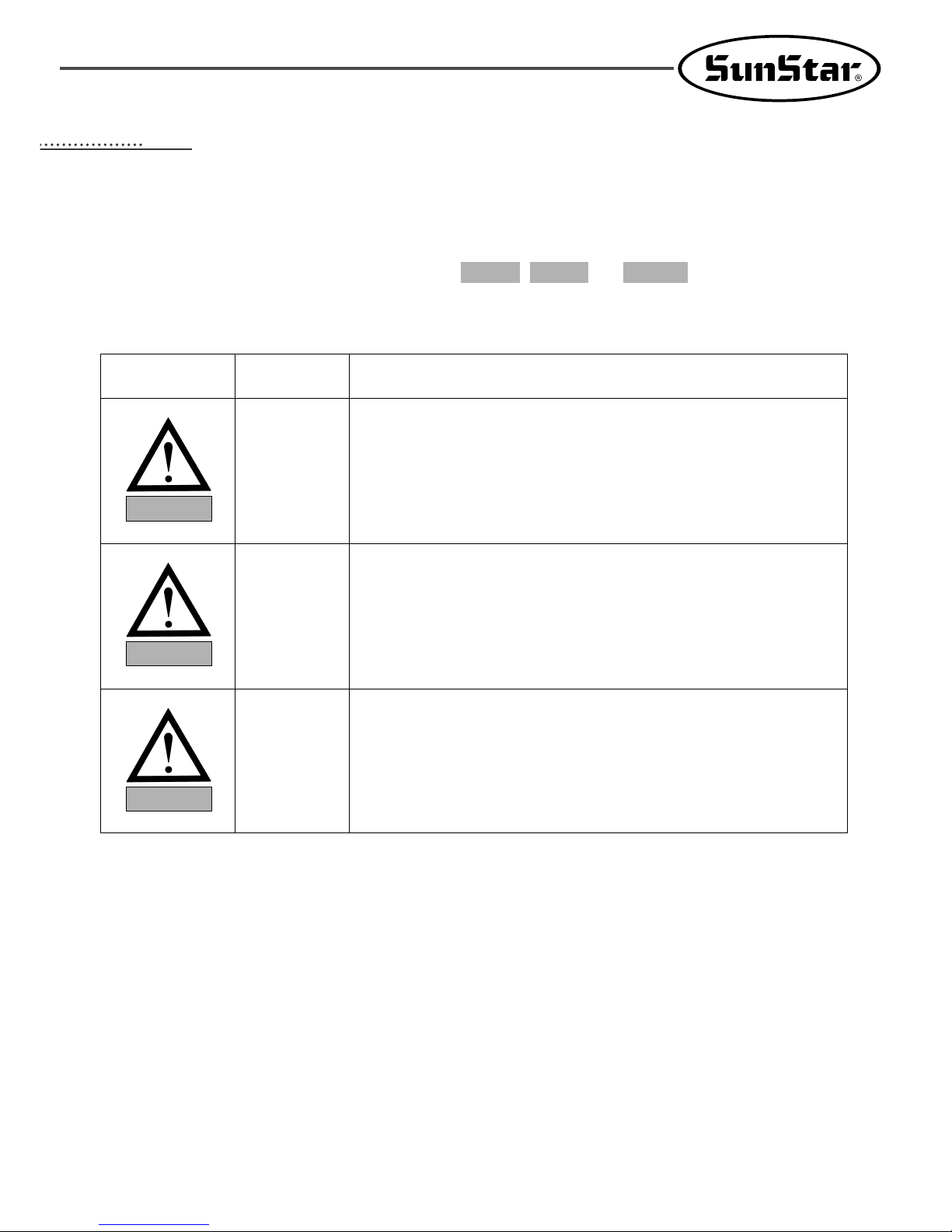

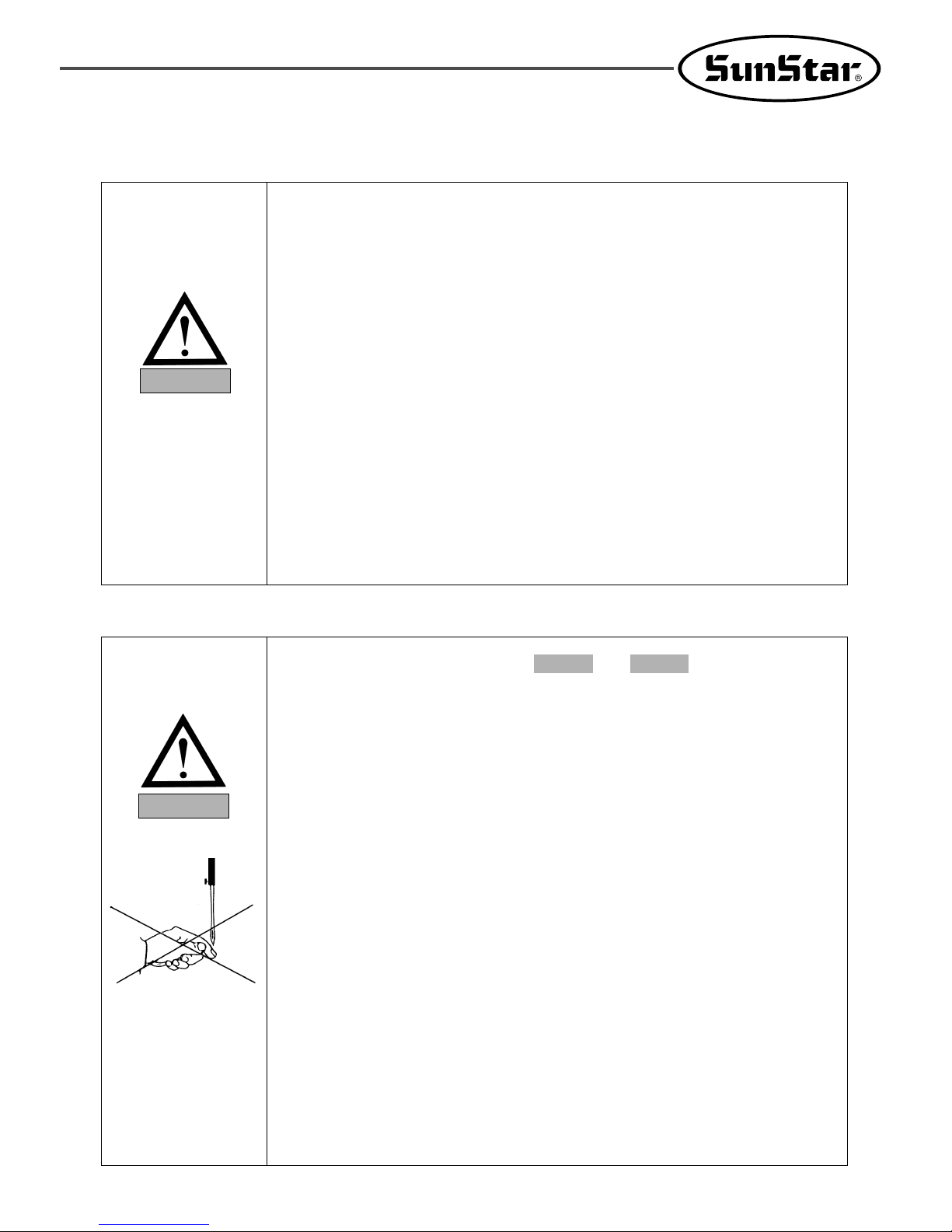

Safety Rules

2.1) Safety Stickers

The safety stickers in this user’s manual are divided into , , and . They indicate that if the

safety rules are not kept, injury or damage to machine might occur as a result.

WarningDangerCaution

No. Name

Description

Caution

Warning

Danger

Caution

If the machine is not properly handled, it may cause injury to

users or physical damage to the machine.

If the machine is not properly handled, it may cause death or

severe injury to users.

If the machine is not properly handled, it may cause death or

severe injury to users, and the urgency of the danger is very

high.

Warning

Danger

8

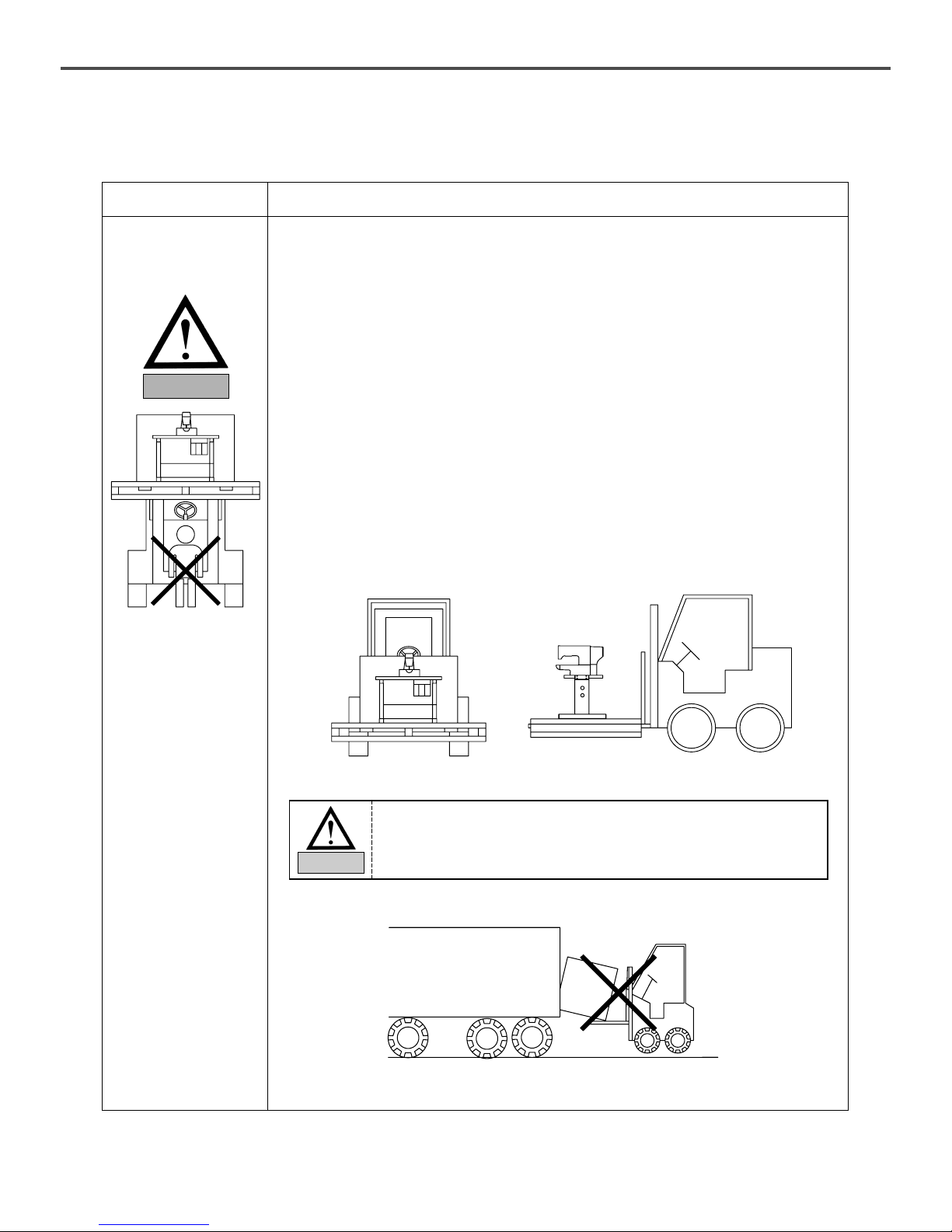

2.2) Machine Delivery

Danger

The machine delivery shall be conducted by the persons who are knowledgeable

about the safety instructions and rules. The following safety rules must be

observed:

2.2.1) Manual delivery

When the machine is delivered by persons, they shall wear special shoes and tightly hold

the machine on the left and right sides.

2.2.2) Forklift delivery

1) A forklift shall be big enough to endure the weight of the sewing machine and carry

the machine.

2) Use the palette when lifting the machine. Set the center of gravity of the machine

(center of the left and right sides) at the fork arm of the forklift and carefully lift the

machine.

Ban people from

standing under the

machine and remove

obstacles near the

machine.

Mark

Description

Make sure to maintain the balance of the machine when unloading the

machine by using a forklift or crane to prevent the deformation of the

machine or to prevent people from being exposed to danger.

Warning

9

Warning

2.3) Machine Installation

Caution

Depending on the installation environment, function errors, breakdown, or

other physical damage might result. Make sure to meet the following

conditions for machine installation:

1) The workbench or table where the machine is installed should be durable enough to

endure the weight of the machine (see the name plate).

2) Dust and humidity are the cause of machine pollution and erosion. Please install an air

conditioner and conduct regular maintenance of the machine.

3) Install the machine at the place where it is not exposed to direct sunlight (if the machine is

exposed to direct sunlight for a long time, it may cause discoloration or deformation).

4) Secure the space around the machine. Place the machine at least 50cm away from the

left, right, and rear walls to secure sufficient space for maintenance activities.

5) Explosion risk : To prevent possible explosion, immediately stop the machine

operation if there are inflammable materials in the air.

6) Lighting : The machine does not offer lighting devices. When necessary, install needed

lighting.

7) Overturn risk : Do not install the machine on the unstable stand or table. If the machine

drops, it may cause injury or severe impact on the machine. If the machine is suddenly

stopped or the external impact is imposed, the machine might be capsized.

2.4) Machine Operation

The machine body is attached with and stickers at each

dangerous part to emphasize safety instructions. With the full understanding

of the safety instructions, make sure to observe the following during machine

operation:

1) Before turning on the power, read this manual thoroughly and have a full

understanding of machine operation.

2) Get properly dressed. Long hair, necklace, bracelet, or wide sleeve might be fed into the

machine during operation. Wear slip-free shoes to prevent slipping on the floor.

3) Check the moving scope of machine before its operation to find out whether the scope

is proper.

4) Keep hands and head away from the machine parts where accidents might occur

(needle, hook, thread take-up lever, pulley, etc.) during operation.

5) Do not remove the safety cover which protects pulley and shaft during machine

operation for user’s safety.

6) Cut the power supply before disassembling the electric box such as the control box,

and double-check that the power switch is “Off.”

7) Make sure that the power switch is “Off”when the upper shaft is manually rotated.

8) Stop the machine when the needle is replaced or when inspecting the machine after

sewing work is done.

9) Make sure to follow the cautions below. Otherwise, physical damage to the machine

such as malfunction and breakdown might result:

- Do not put articles on the S/M table.

- Avoid using a crooked needle or the needle with damaged tip.

- Use the presser foot appropriate to working conditions.

WarningCaution

10

2.5) Repair and Maintenance

When machine repair is needed, it shall be conducted by SunStar A/S

engineers only who have finished the due training course.

1) For cleaning and repair, cut the main power supply. Wait for 4 minutes before starting

maintenance to make the machine completely discharged.

2) Do not modify the machine specifications or parts without substantial consultations

with SunStar. Otherwise, it may threaten safety during machine operation.

3) Use the parts manufactured by SunStar to repair or replace the machine parts during

A/S service.

4) When repairing is completed, re-install all the removed safety covers.

Danger

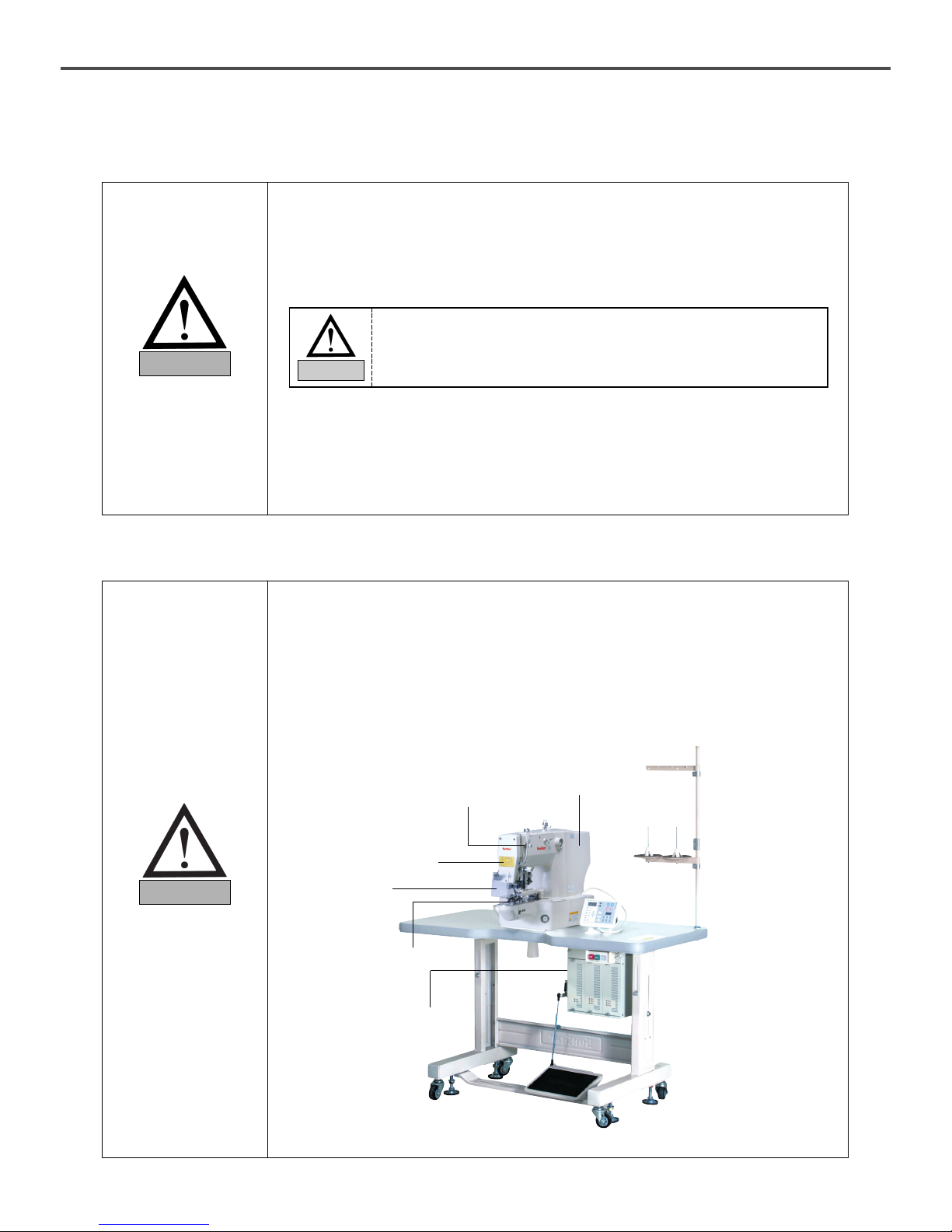

2.6) Devices for safety

ⓐ Safety label : It describes cautions during operating the machine.

ⓑ Thread take-up cover : It prevents from any contact between body and take-up lever.

ⓒ Motor Cover : It prevents from insertion of hands, feet or clothes by Motor.

ⓓ Label for specification of power : It describes cautions for safety to protect against

electric shock during rotating the motors. (Voltage input / use Hz)

ⓔ Finger guard : It prevent from contacts between a finger and needle.

ⓕ Safety plate : It protects eyes against needle breaks.

Caution

ⓐ

ⓕ

ⓔ

ⓓ

ⓑ

ⓒ

For main shaft motor and X,Y drive box, it takes 10 minutes before they

are completely discharged after the main power is cut.

Caution

11

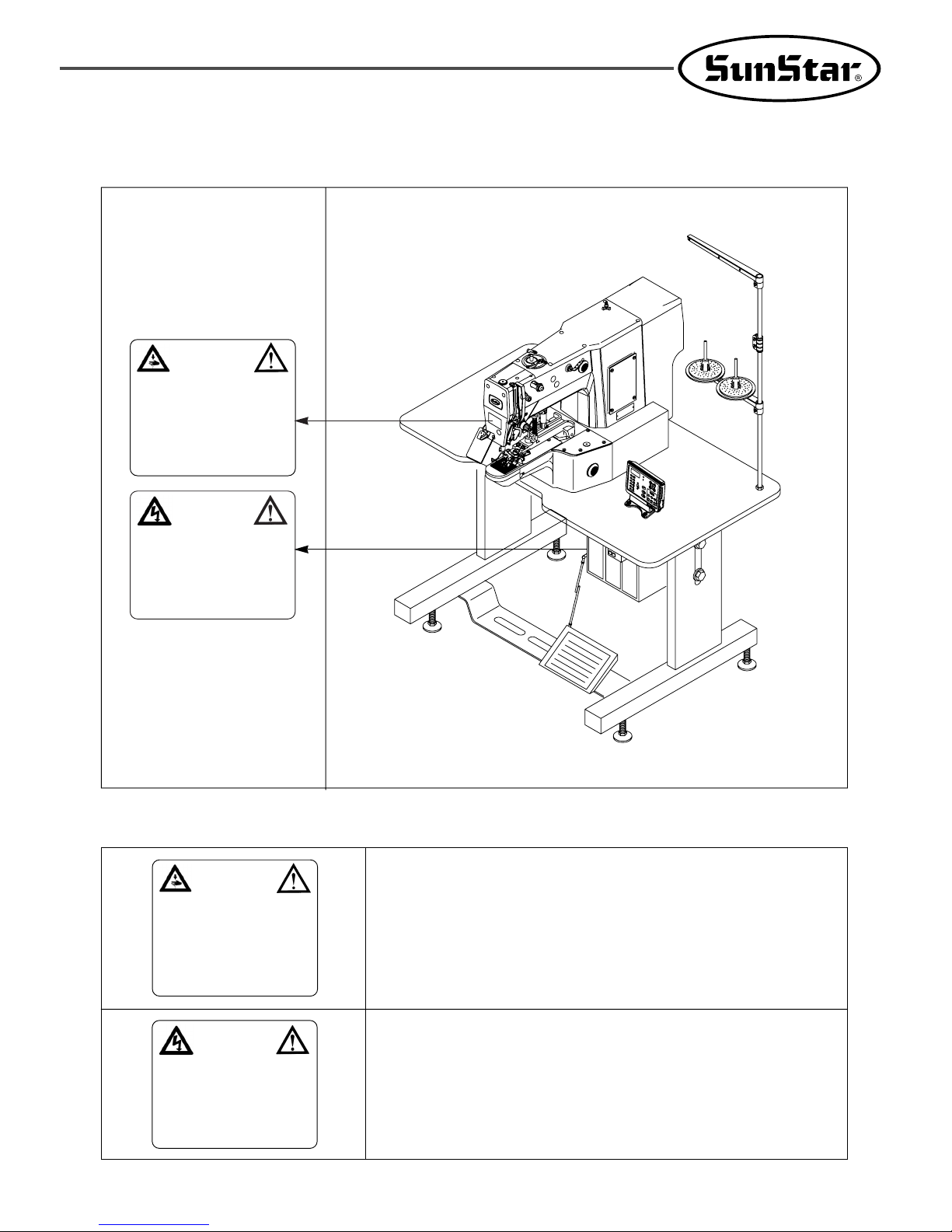

2.7) Location of Safety Labels

CAUTION

경고

Do not operate without finger guard and

safety devices. Before threading, changing

bobbin and needle, cleaning etc. switch off

main switch.

손가락 보호대와 안전장치 없이 작동하지

마십시오.

실, 보빈, 바늘교환시나 청소전에는 반드시

주전원의 스위치를 꺼 주십시오.

WARNING

경고

Hazardous voltage will cause injury.

Be sure to wait at least 360 seconds

before opening this cover after turn off

main switch and unplug a power cord.

고압 전류에 의해 감전될 수 있으므로 커버를

열 때는 전원을 내리고 전원 플러그를 뽑고 나

서 360초간 기다린 후 여십시오.

2.8) Type of Safety Labels

Do not operate without finger guard and safety devices. Before threading,

changing bobbin and needle, and cleaning, turn off the main switch.

Hazardous voltage will cause injury.

Be sure to wait at least 360 seconds before opening this cover after turn

off main switch and unplug a power cord.

CAUTION

경고

Do not operate without finger guard and

safety devices. Before threading, changing

bobbin and needle, cleaning etc. switch

off main switch.

손가락 보호대와 안전장치 없이 작동하지

마십시오.

실, 보빈, 바늘교환시나 청소전에는 반드시

주전원의 스위치를 꺼 주십시오.

WARNING

경고

Hazardous voltage will cause injury.

Be sure to wait at least 360 seconds

before opening this cover after turn off

main switch and unplug a power cord.

고압 전류에 의해 감전될 수 있으므로 커버를

열 때는 전원을 내리고 전원 플러그를 뽑고 나

서 360초간 기다린 후 여십시오.

12

33

Assembly

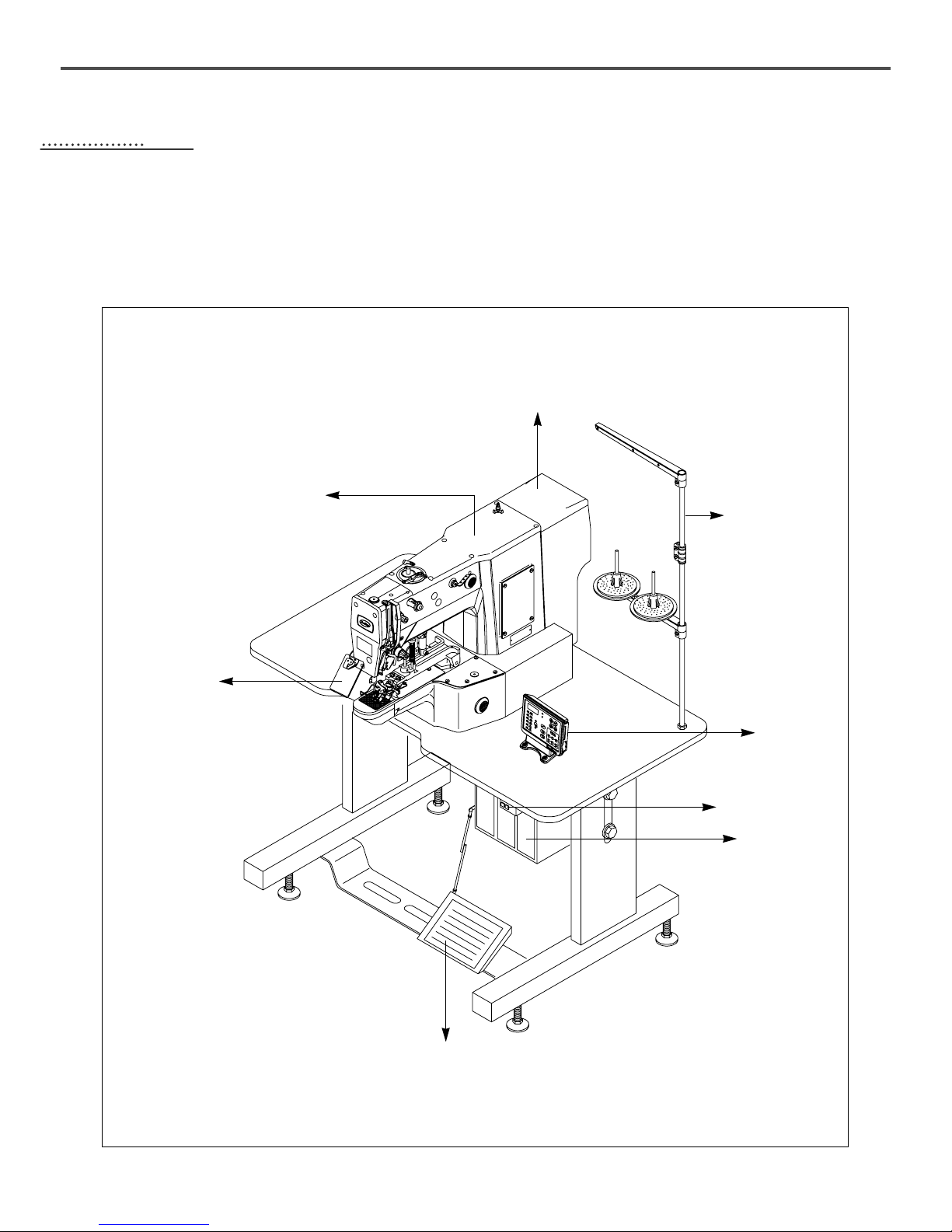

3.1) Name of Machine Parts

3.1.1) Name of Machine Parts

Power Switch

Thread Stand

Arm

Safety Plate

Motor Cover

OP Box

Control Box

Pedal

13

44

Machine Installation

4.1) Installation Environment

1) To prevent accidents stemming from mal-operation, do not use the machine if the voltage is 10% above the rated voltage.

2) To prevent accidents stemming from mal-operation, make sure to check if the air pressure is proper before using any air

pressure devices such as air cylinder.

3) Proper temperature during machine operation : 5°~ 40°C

4) Proper temperature during machine storage : -10°~ 60°C

5) Humidity : Relative humidity – within 20 ~ 80%

4.2) Electricity Environment

1) Power voltage

- The power voltage shall be within 10% of the rated voltage.

- It is recommended to use the power frequency within +/- 1% of the rated frequency (50/60Hz).

2) Noise of electromagnetic wave

- Do not share the power with the products which have either strong magnetic field or use high frequency. Make the

machine stay away from the products mentioned above.

3) Take care not to spill water and coffee on the machine.

4) Do not drop Control Box and the motor to the floor.

4.3) Table Installation

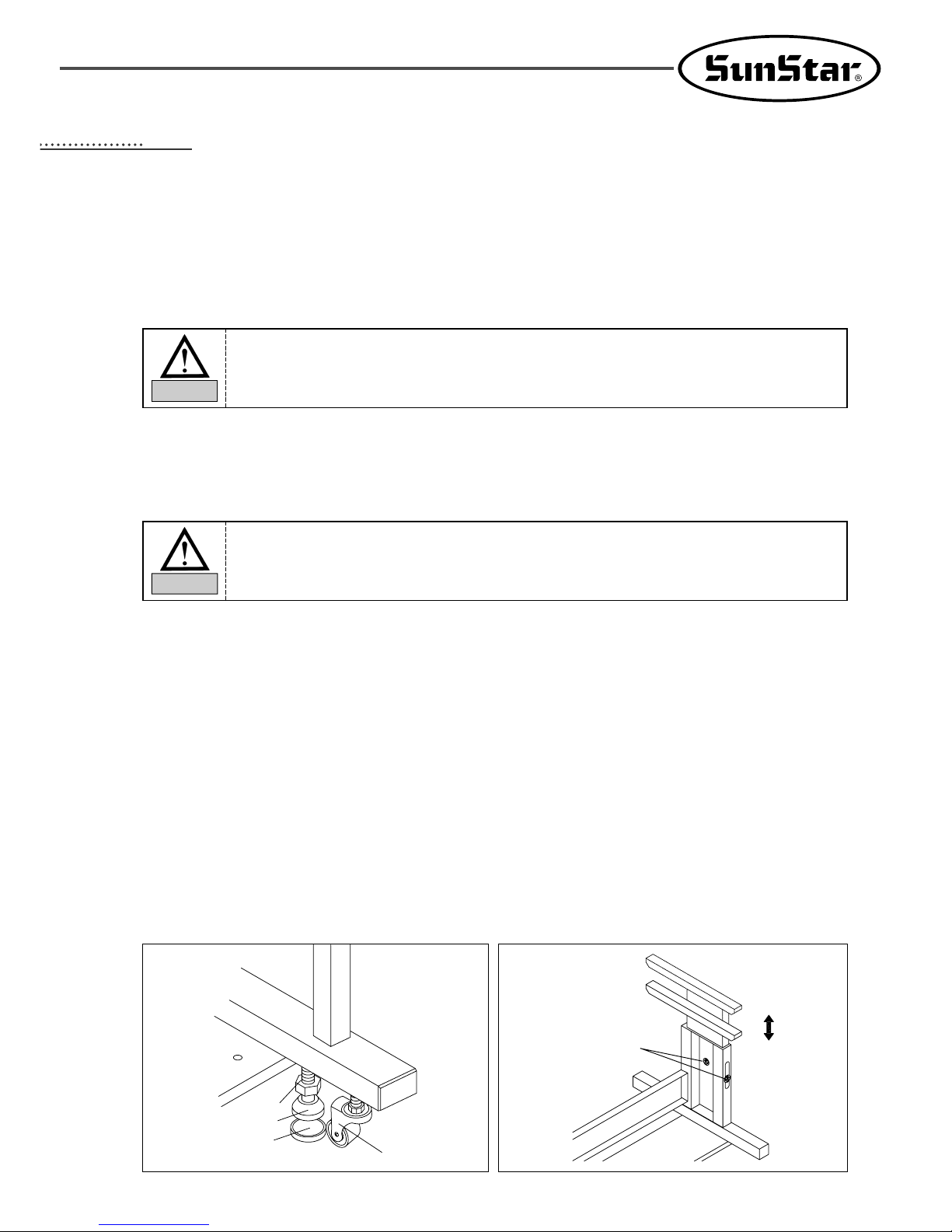

1) Table fixing

- Insert the shock absorbing rubber into the level adjuster and raise it until the caster freely moves.

- After the table is installed, tighten the nut to fix the level adjuster.

2) Table height adjustment

- Use the bolts attached to the table to adjust the height of the table to make sure that the users can smoothly and

conveniently work.

Nut

Level Adjuster

Shock Absorbing

Rubber

Caster

Bolt

To guarantee smooth operation of the product, the installation environment shall be prepared as

described in User’s Manual. Otherwise, unexpected damage might occur to the product.

Caution

The voltage shall be within 10% of the rated voltage.

Warning

Loading...

Loading...